Morphology Development and Flow Characteristics during High Moisture Extrusion of a Plant-Based Meat Analogue

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Extrusion Trials

2.3. Cryo-Imaging

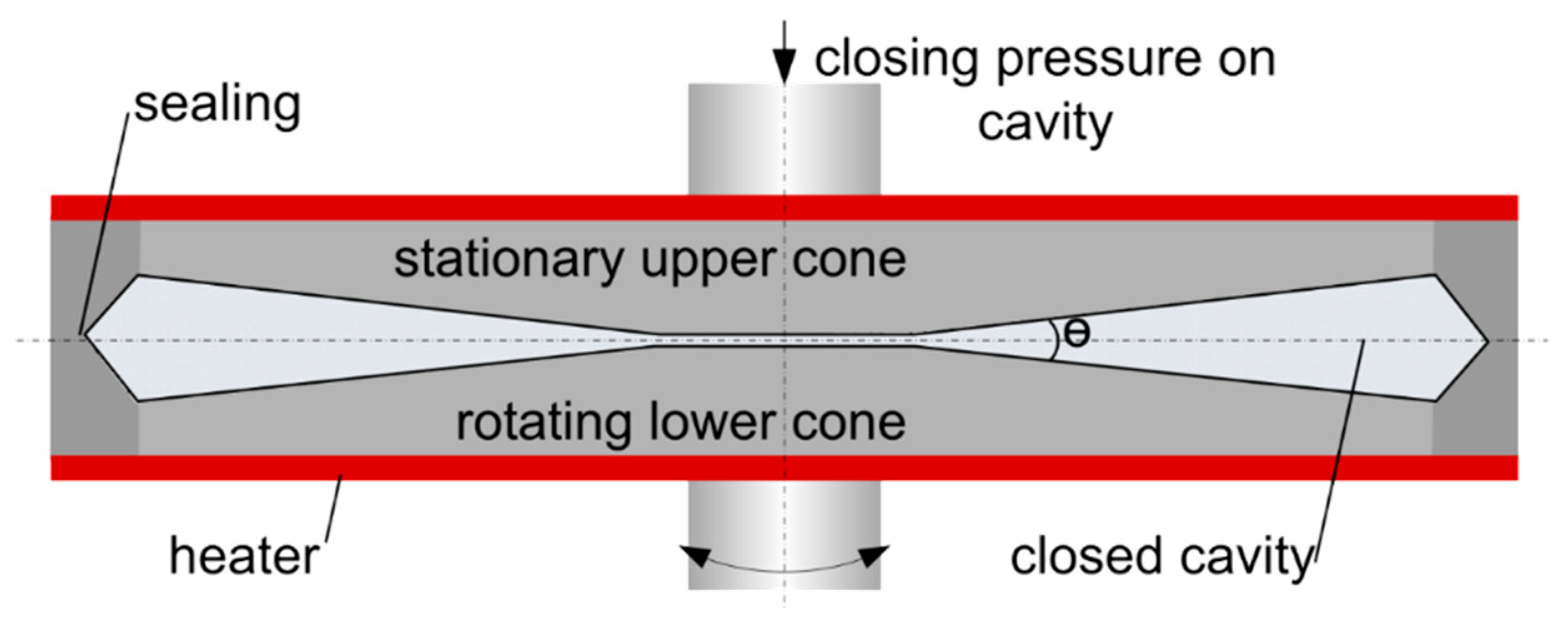

2.4. Rheological Measurements and Fitting

2.5. Material Properties for Simulation

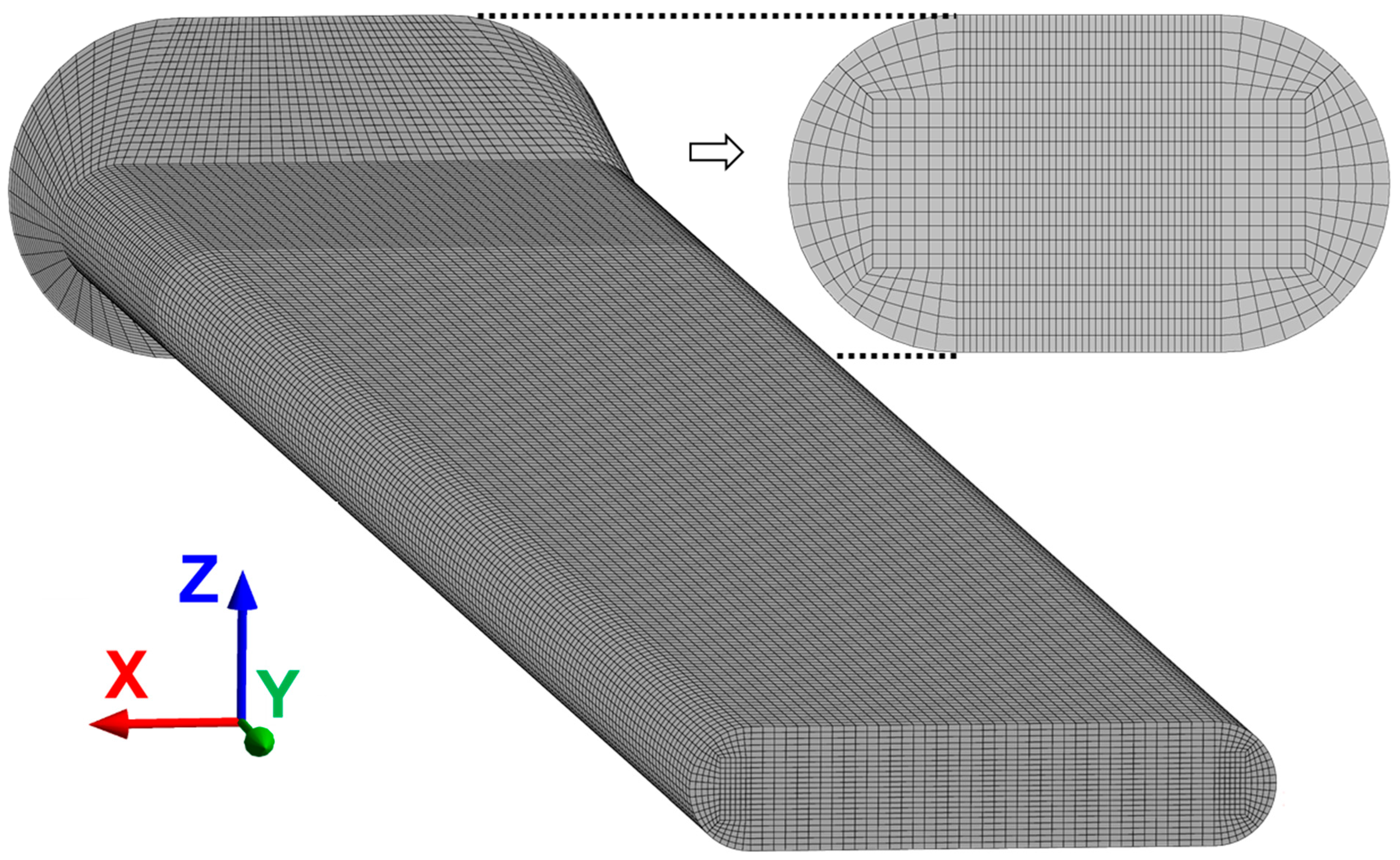

2.6. Numerical Simulation

3. Results

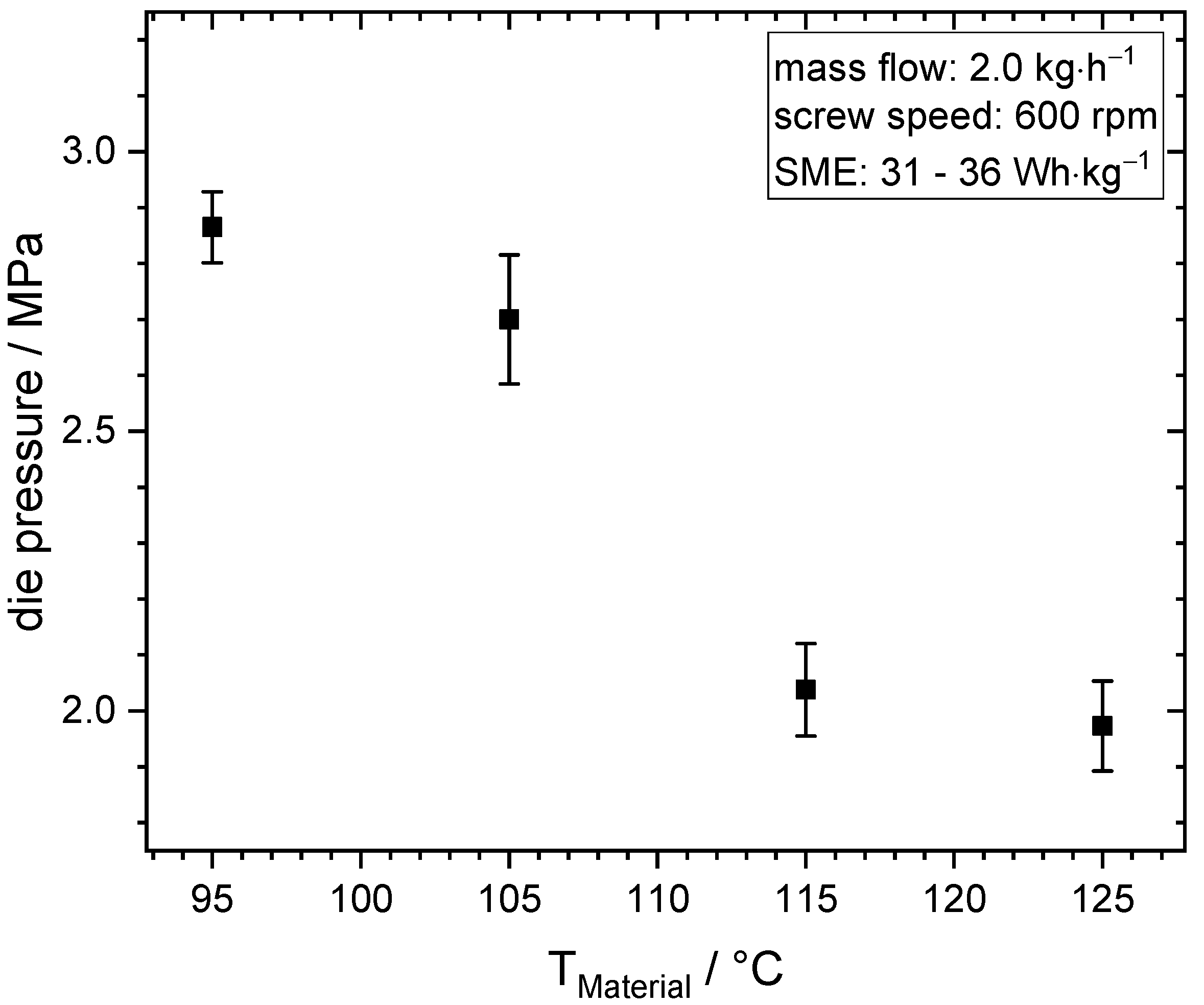

3.1. Influence of Material Temperature on Die Pressure, Product Structure, and Morphology

3.2. Rheological Data

3.3. Morphology Development in the Die Section and Influence of Material Temperature

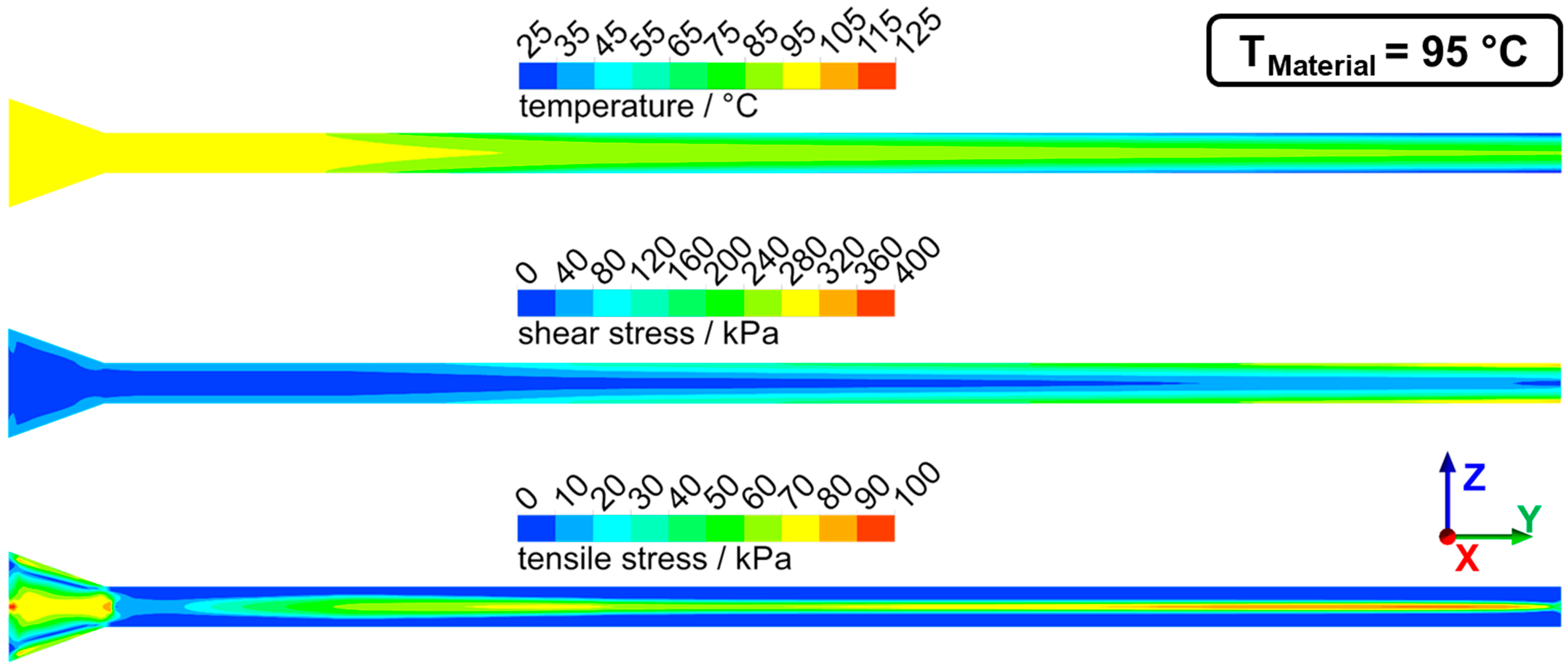

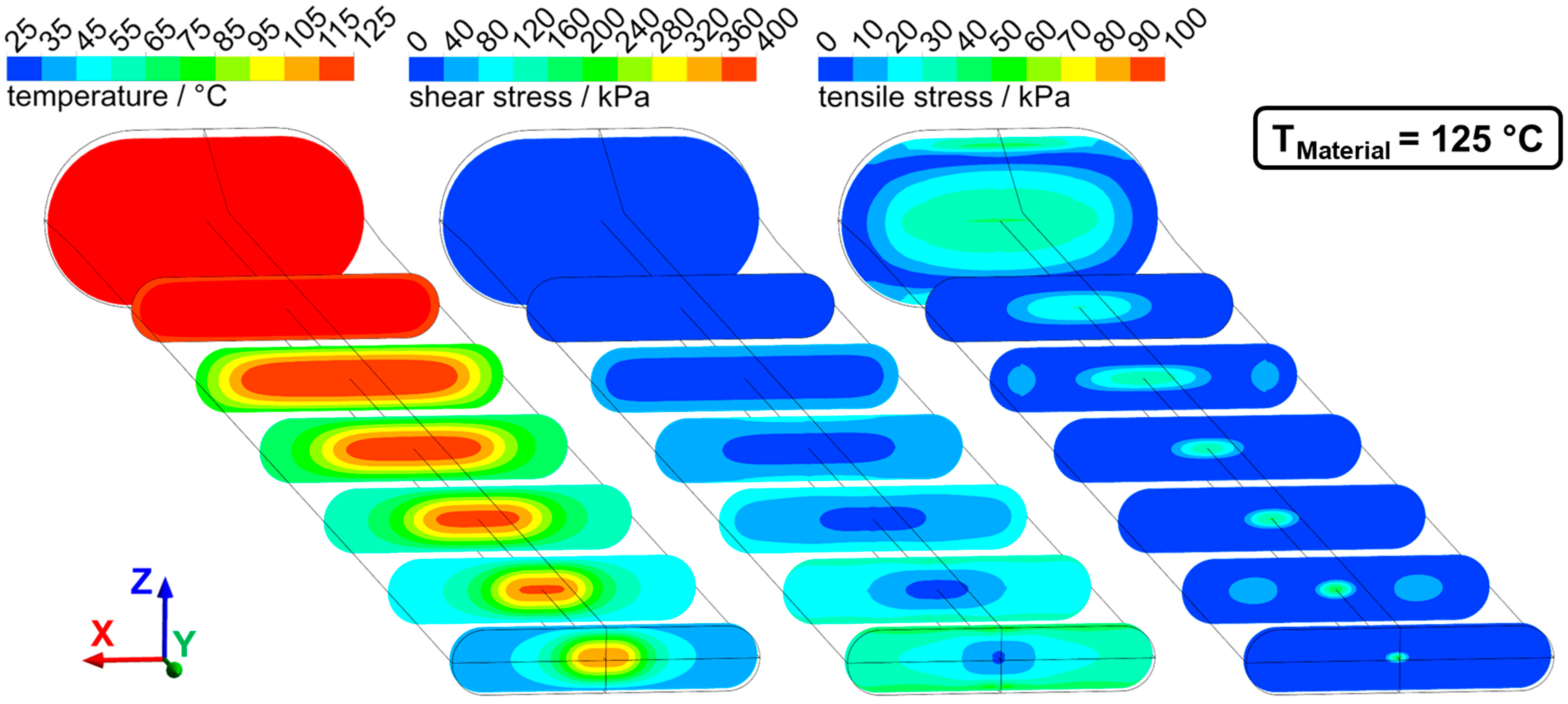

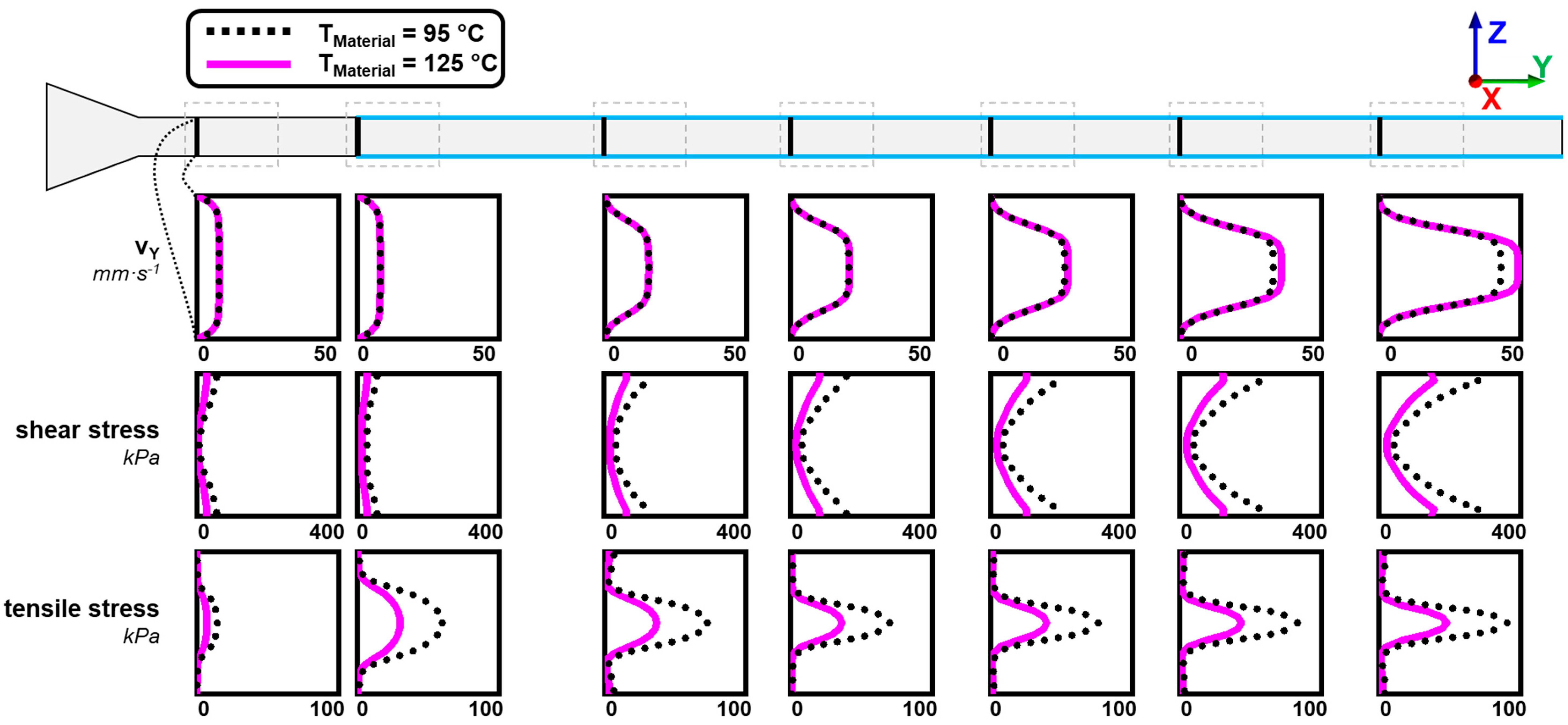

3.4. Flow Characteristics in the Die Section and Influence of Material Temperature

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Hoek, A.C.; Luning, P.A.; Weijzen, P.; Engels, W.; Kok, F.J.; de Graaf, C. Replacement of meat by meat substitutes. A survey on person- and product-related factors in consumer acceptance. Appetite 2011, 56, 662–673. [Google Scholar] [CrossRef]

- Akdogan, H. High moisture food extrusion. Int. J. Food Sci. Nutr. 1999, 34, 195–207. [Google Scholar] [CrossRef]

- Cheftel, J.C.; Kitagawa, M.; Quéguiner, C. New protein texturization processes by extrusion cooking at high moisture levels. Food Rev. Int. 1992, 8, 235–275. [Google Scholar] [CrossRef]

- Noguchi, A. Extrusion cooking of high-moisture protein food. In Extrusion Cooking; Mercier, C., Linko, P., Harper, J.M., Eds.; American Association of Cereal Chemists: Eagan, MN, USA, 1989; pp. 343–370. [Google Scholar]

- Kitabatake, N.; Mégard, D.; Cheftel, J.C. Continuous gel formation by HTST extrusion-cooking: Soy proteins. J. Food Sci. 1985, 50, 1260–1265. [Google Scholar] [CrossRef]

- Bouvier, J.-M.; Campanella, O. Extrusion Processing Technology: Food and Non-Food Biomaterials; John Wiley & Sons Inc.: Chichester, UK, 2014; ISBN 978-1-4443-3811-9. [Google Scholar]

- Zhang, J.; Liu, L.; Jiang, Y.; Faisal, S.; Wei, L.; Cao, C.; Yan, W.; Wang, Q. Converting peanut protein biomass waste into “double green” meat substitutes using a high-moisture extrusion process: A multiscale method to explore a process for forming a meat-like fibrous structure. J. Agric. Food Chem. 2019, 67, 10713–10725. [Google Scholar] [CrossRef]

- Yao, G.; Liu, K.S.; Hsieh, F. A new method for characterizing fiber formation in meat analogs during high-moisture extrusion. J. Food Sci. 2004, 69, 303–307. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, J.; Zhang, Y.; Meng, S.; Wang, Q. Rheological properties of pea protein isolate-amylose/amylopectin mixtures and the application in the high-moisture extruded meat substitutes. Food Hydrocoll. 2021, 106732. [Google Scholar] [CrossRef]

- Kendler, C.; Duchardt, A.; Karbstein, H.P.; Emin, M.A. Effect of oil content and oil addition point on the extrusion processing of wheat gluten-based meat analogues. Foods 2021, 10, 697. [Google Scholar] [CrossRef]

- Wittek, P.; Zeiler, N.; Karbstein, H.P.; Emin, M.A. High moisture extrusion of soy protein: Investigations on the formation of anisotropic product structure. Foods 2021, 10, 102. [Google Scholar] [CrossRef]

- Caporgno, M.P.; Böcker, L.; Müssner, C.; Stirnemann, E.; Haberkorn, I.; Adelmann, H.; Handschin, S.; Windhab, E.J.; Mathys, A. Extruded meat analogues based on yellow, heterotrophically cultivated Auxenochlorella protothecoides microalgae. Innov. Food Sci. Emerg. Technol. 2020, 59, 102275. [Google Scholar] [CrossRef]

- Palanisamy, M.; Töpfl, S.; Aganovic, K.; Berger, R.G. Influence of iota carrageenan addition on the properties of soya protein meat analogues. LWT 2018, 87, 546–552. [Google Scholar] [CrossRef]

- Osen, R.; Toelstede, S.; Wild, F.; Eisner, P.; Schweiggert-Weisz, U. High moisture extrusion cooking of pea protein isolates: Raw material characteristics, extruder responses, and texture properties. J. Food Eng. 2014, 127, 67–74. [Google Scholar] [CrossRef]

- Wittek, P.; Karbstein, H.P.; Emin, M.A. Blending proteins in high moisture extrusion to design meat analogues: Rheological properties, morphology development and product properties. Foods 2021, 10, 1509. [Google Scholar] [CrossRef]

- Tolstoguzov, V.B. Thermoplastic extrusion-the mechanism of the formation of extrudate structure and properties. J. Am. Oil Chem. Soc. 1993, 70, 417–424. [Google Scholar] [CrossRef]

- Tolstoguzov, V.B. Some physico-chemical aspects of protein processing into foodstuffs. Food Hydrocoll. 1988, 2, 339–370. [Google Scholar] [CrossRef]

- Schreuders, F.K.G.; Dekkers, B.L.; Bodnár, I.; Erni, P.; Boom, R.M.; van der Goot, A.J. Comparing structuring potential of pea and soy protein with gluten for meat analogue preparation. J. Food Eng. 2019, 261, 32–39. [Google Scholar] [CrossRef]

- Dekkers, B.L.; Hamoen, R.; Boom, R.M.; van der Goot, A.J. Understanding fiber formation in a concentrated soy protein isolate—Pectin blend. J. Food Eng. 2018, 222, 84–92. [Google Scholar] [CrossRef]

- Dekkers, B.L.; Nikiforidis, C.V.; van der Goot, A.J. Shear-induced fibrous structure formation from a pectin/SPI blend. Innov. Food Sci. Emerg. Technol. 2016, 36, 193–200. [Google Scholar] [CrossRef]

- Dekkers, B.L.; De Kort, D.W.; Grabowska, K.J.; Tian, B.; van As, H.; van der Goot, A.J. A combined rheology and time domain NMR approach for determining water distributions in protein blends. Food Hydrocoll. 2016, 60, 525–532. [Google Scholar] [CrossRef]

- Krintiras, G.A.; Göbel, J.; Bouwman, W.G.; van der Goot, A.J.; Stefanidis, G.D. On characterization of anisotropic plant protein structures. Food Funct. 2014, 5, 3233–3240. [Google Scholar] [CrossRef]

- Grabowska, K.J.; Tekidou, S.; Boom, R.M.; van der Goot, A.-J. Shear structuring as a new method to make anisotropic structures from soy-gluten blends. Food Res. Int. 2014, 64, 743–751. [Google Scholar] [CrossRef] [PubMed]

- Pietsch, V.L.; Werner, R.; Karbstein, H.P.; Emin, M.A. High moisture extrusion of wheat gluten: Relationship between process parameters, protein polymerization, and final product characteristics. J. Food Eng. 2019, 259, 3–11. [Google Scholar] [CrossRef]

- Grabowska, K.J.; Zhu, S.; Dekkers, B.L.; de Ruijter, N.C.; Gieteling, J.; van der Goot, A.J. Shear-induced structuring as a tool to make anisotropic materials using soy protein concentrate. J. Food Eng. 2016, 188, 77–86. [Google Scholar] [CrossRef]

- Utracki, L.A.; Shi, Z.H. Development of polymer blend morphology during compounding in a twin-screw extruder. Part I: Droplet dispersion and coalescence—A review. Polym. Eng. Sci. 1992, 32, 1824–1833. [Google Scholar] [CrossRef]

- Vanoene, H. Modes of dispersion of viscoelastic fluids in flow. J. Colloid Interface Sci. 1972, 40, 448–467. [Google Scholar] [CrossRef]

- Wu, S. Formation of dispersed phase in incompatible polymer blends: Interfacial and rheological effects. Polym. Eng. Sci. 1987, 27, 335–343. [Google Scholar] [CrossRef]

- Mighri, F.; Carreau, P.J.; Ajji, A. Influence of elastic properties on drop deformation and breakup in shear flow. J. Rheol. 1998, 42, 1477–1490. [Google Scholar] [CrossRef]

- Mighri, F.; Ajji, A.; Carreau, P.J. Influence of elastic properties on drop deformation in elongational flow. J. Rheol. 1997, 41, 1183–1201. [Google Scholar] [CrossRef]

- Min, K.; White, J.L.; Fellers, J.F. Development of phase morphology in incompatible polymer blends during mixing and its variation in extrusion. Polym. Eng. Sci. 1984, 24, 1327–1336. [Google Scholar] [CrossRef]

- Guido, S. Shear-induced droplet deformation: Effects of confined geometry and viscoelasticity. Curr. Opin. Colloid Interface Sci. 2011, 16, 61–70. [Google Scholar] [CrossRef]

- Sandoval Murillo, J.L.; Osen, R.; Hiermaier, S.; Ganzenmüller, G. Towards understanding the mechanism of fibrous texture formation during high-moisture extrusion of meat substitutes. J. Food Eng. 2019, 242, 8–20. [Google Scholar] [CrossRef]

- Emin, M.A.; Wittek, P.; Schwegler, Y. Numerical analysis of thermal and mechanical stress profile during the extrusion processing of plasticized starch by non-isothermal flow simulation. J. Food Eng. 2021, 294, 110407. [Google Scholar] [CrossRef]

- Emin, M.A.; Schuchmann, H.P. Analysis of the dispersive mixing efficiency in a twin-screw extrusion processing of starch based matrix. J. Food Eng. 2013, 115, 132–143. [Google Scholar] [CrossRef]

- Alsteens, B.; Legat, V.; Avalosse, T. Parametric study of the mixing efficiency in a kneading block section of a twin-screw extruder. Int. Polym. Process. 2004, 19, 207–217. [Google Scholar] [CrossRef]

- Avalosse, T. Numerical simulation of distributive mixing in 3-D flows. Macromol. Symp. 1996, 112, 91–98. [Google Scholar] [CrossRef]

- Wittek, P.; Emin, M.A. Three-dimensional modeling of food extrusion processes. Ref. Modul. Food Sci. 2017. [Google Scholar] [CrossRef]

- Emin, M.A. Modeling extrusion processes. In Modeling Food Processing Operations; Elsevier: Amsterdam, The Netherlands, 2015; pp. 235–253. ISBN 9781782422846. [Google Scholar]

- Wittek, P.; Zeiler, N.; Karbstein, H.P.; Emin, M.A. Analysis of the complex rheological properties of highly concentrated proteins with a closed cavity rheometer. Appl. Rheol. 2020, 30, 64–76. [Google Scholar] [CrossRef]

- Emin, M.A.; Quevedo, M.; Wilhelm, M.; Karbstein, H.P. Analysis of the reaction behavior of highly concentrated plant proteins in extrusion-like conditions. Innov. Food Sci. Emerg. Technol. 2017, 44, 15–20. [Google Scholar] [CrossRef]

- Pommet, M.; Morel, M.-H.; Redl, A.; Guilbert, S. Aggregation and degradation of plasticized wheat gluten during thermo-mechanical treatments, as monitored by rheological and biochemical changes. Polymer 2004, 45, 6853–6860. [Google Scholar] [CrossRef]

- Wittek, P.; Walther, G.; Karbstein, H.P.; Emin, M.A. Comparison of the Rheological Properties of Plant Proteins from Various Sources for Extrusion Applications. Foods 2021, 10, 1700. [Google Scholar] [CrossRef]

- Emin, M.A.; Schuchmann, H.P. A mechanistic approach to analyze extrusion processing of biopolymers by numerical, rheological, and optical methods. Trends Food Sci. Technol. 2017, 60, 88–95. [Google Scholar] [CrossRef]

- Cox, W.P.; Merz, E.H. Correlation of dynamic and steady flow viscosities. J. Polym. Sci. 1958, 28, 619–622. [Google Scholar] [CrossRef]

- Bird, R.B.; Carreau, P.J. A nonlinear viscoelastic model for polymer solutions and melts—I. Chem. Eng. Sci. 1968, 23, 427–434. [Google Scholar] [CrossRef]

- Dus, S.J.; Kokini, J.L. Prediction of the nonlinear viscoelastic properties of a hard wheat flour dough using the Bird-Carreau constitutive model. J. Rheol. 1990, 34, 1069–1084. [Google Scholar] [CrossRef]

- Singh, R.P.; Heldman, D.R. Introduction to Food Engineering, 4th ed.; Academic Press Elsevier: Amsterdam, The Netherlands, 2009; ISBN 978-0-12-370900-4. [Google Scholar]

- Sweat, V.E. Experimental values of thermal conductivity of selected fruits and vegetables. J. Food Sci. 1974, 39, 1080–1083. [Google Scholar] [CrossRef]

- Wittek, P.; Pereira, G.G.; Emin, M.A.; Lemiale, V.; Cleary, P.W. Accuracy analysis of SPH for flow in a model extruder with a kneading element. Chem. Eng. Sci. 2018, 187, 256–268. [Google Scholar] [CrossRef]

- Beinert, S.; Gothsch, T.; Kwade, A. Numerical evaluation of flow fields and stresses acting on agglomerates dispersed in high-pressure microsystems. Chem. Eng. Technol. 2012, 35, 1922–1930. [Google Scholar] [CrossRef]

- Trouton, F.T. On the coefficient of viscous traction and its relation to that of viscosity. Proc. R. Soc. Lond. A 1906, 77, 426–440. [Google Scholar] [CrossRef]

- Petrie, C.J. Extensional viscosity: A critical discussion. J. NonNewton. Fluid Mech. 2006, 137, 15–23. [Google Scholar] [CrossRef]

- Wang, J.; Porter, R.S. On the viscosity-temperature behavior of polymer melts. Rheol. Acta 1995, 34, 496–503. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Texture and chemical characteristics of soy protein meat analog extruded at high moisture. J. Food Sci. 2000, 65, 264–269. [Google Scholar] [CrossRef]

- Chen, F.L.; Wei, Y.M.; Zhang, B.; Ojokoh, A.O. System parameters and product properties response of soybean protein extruded at wide moisture range. J. Food Eng. 2010, 96, 208–213. [Google Scholar] [CrossRef]

- Dekkers, B.L.; Emin, M.A.; Boom, R.M.; van der Goot, A.J. The phase properties of soy protein and wheat gluten in a blend for fibrous structure formation. Food Hydrocoll. 2018, 79, 273–281. [Google Scholar] [CrossRef]

- Klüver, E.; Meyer, M. Thermoplastic processing, rheology, and extrudate properties of wheat, soy, and pea proteins. Polym. Eng. Sci. 2015, 55, 1912–1919. [Google Scholar] [CrossRef]

- Hayashi, N. Molten flow behavior of soy protein isolate with low and intermediate moisture levels. J. Jpn. Soc. Food Sci. 1997, 44, 177–185. [Google Scholar] [CrossRef][Green Version]

- Hayashi, N.; Hayakawa, I.; Fujio, Y. Entrance effect correction on the flow of moisturized soy protein isolate melt in an extrusion viscometer. Int. J. Food Sci. Nutr. 1991, 26, 567–574. [Google Scholar] [CrossRef]

- Fujio, Y.; Hayashi, N.; Hayakawa, I. Effect of moisture content on flow behaviour of molten soy-protein isolate under an elevated temperature. Int. J. Food Sci. Nutr. 1991, 26, 45–51. [Google Scholar] [CrossRef]

- Baird, D.G. Dynamic viscoelastic properties of soy isolate doughs. J. Texture Stud. 1981, 12, 1–16. [Google Scholar] [CrossRef]

- Lerdwijitjarud, W.; Sirivat, A.; Larson, R.G. Influence of elasticity on dispersed-phase droplet size in immiscible polymer blends in simple shearing flow. Polym. Eng. Sci. 2002, 42, 798–809. [Google Scholar] [CrossRef]

- Horvat, M.; Emin, M.A.; Hochstein, B.; Willenbacher, N.; Schuchmann, H.P. A multiple-step slit die rheometer for rheological characterization of extruded starch melts. J. Food Eng. 2013, 116, 398–403. [Google Scholar] [CrossRef]

- Cornet, S.H.V.; Snel, S.J.E.; Schreuders, F.K.G.; van der Sman, R.G.M.; Beyrer, M.; van der Goot, A.J. Thermo-mechanical processing of plant proteins using shear cell and high-moisture extrusion cooking. Crit. Rev. Food Sci. Nutr. 2021, 1–18. [Google Scholar] [CrossRef] [PubMed]

| TMaterial/°C | 95 | 105 | 115 | 125 |

| TBarrel,2/°C | 25 | 25 | 25 | 25 |

| TBarrel,3/°C | 50 | 50 | 50 | 50 |

| TBarrel,4/°C | 90 | 90 | 90 | 90 |

| TBarrel,5/°C | 98 | 109 | 110 | 110 |

| TBarrel,6/°C | 98 | 109 | 124 | 138 |

| TBarrel,7/°C | 98 | 109 | 124 | 138 |

| TBarrel,8/°C | 98 | 109 | 124 | 138 |

| TDie/°C | 98 | 109 | 124 | 138 |

| η0/Pa·s | λ/s | n/- | α/K | Tα/K |

|---|---|---|---|---|

| 4,952,779 | 100 | 0.13606 | 3313.3 | 333.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wittek, P.; Ellwanger, F.; Karbstein, H.P.; Emin, M.A. Morphology Development and Flow Characteristics during High Moisture Extrusion of a Plant-Based Meat Analogue. Foods 2021, 10, 1753. https://doi.org/10.3390/foods10081753

Wittek P, Ellwanger F, Karbstein HP, Emin MA. Morphology Development and Flow Characteristics during High Moisture Extrusion of a Plant-Based Meat Analogue. Foods. 2021; 10(8):1753. https://doi.org/10.3390/foods10081753

Chicago/Turabian StyleWittek, Patrick, Felix Ellwanger, Heike P. Karbstein, and M. Azad Emin. 2021. "Morphology Development and Flow Characteristics during High Moisture Extrusion of a Plant-Based Meat Analogue" Foods 10, no. 8: 1753. https://doi.org/10.3390/foods10081753

APA StyleWittek, P., Ellwanger, F., Karbstein, H. P., & Emin, M. A. (2021). Morphology Development and Flow Characteristics during High Moisture Extrusion of a Plant-Based Meat Analogue. Foods, 10(8), 1753. https://doi.org/10.3390/foods10081753