Total and Partial Fat Replacement by Gelled Emulsion (Hemp Oil and Buckwheat Flour) and Its Impact on the Chemical, Technological and Sensory Properties of Frankfurters

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Oil-in-Water Gelled Emulsions

2.3. Preparation of Frankfurters

2.4. Emulsion Stability

2.5. Frankfurters’ Characterization

2.5.1. Proximate Composition

2.5.2. Fatty Acid Profile

2.5.3. Physico-Chemical Properties

pH

Water Activity

Texture

Color

2.5.4. Lipid Oxidation

2.6. Sensory Assessment

2.7. Statistical Analysis

3. Results & Discussion

3.1. Properties of Gelled Emulsion

3.2. Emulsion Stability of Meat Batters

3.3. Properties of Frankfurters Prepared with GE

3.3.1. Proximate Composition

3.3.2. Lipid Profile and Nutritional Parameters

3.3.3. pH and Water Activity

3.3.4. Color

3.3.5. Texture

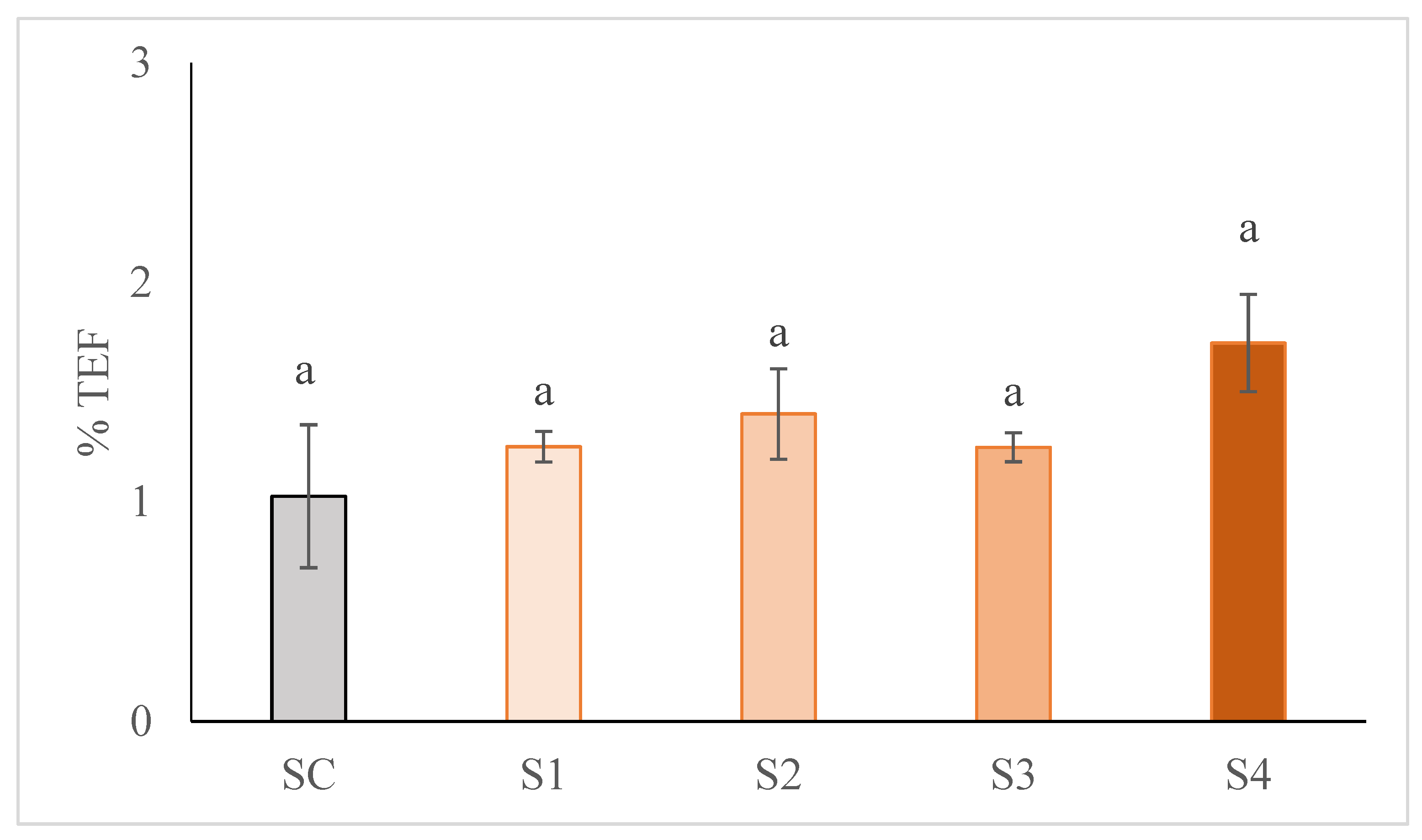

3.3.6. Lipid Oxidation

3.4. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiménez-Colmenero, F.; Herrero, A.; Pintado, T.; Solas, M.T.; Ruiz-Capillas, C. Influence of emulsified olive oil stabilizing system used for pork backfat replacement in frankfurters. Food Res. Int. 2010, 43, 2068–2076. [Google Scholar] [CrossRef]

- Fernández-López, J.; Lucas-González, R.; Viuda-Martos, M.; Sayas-Barberá, E.; Navarro, C.; Haros, C.M.; Pérez-Álvarez, J.A. Chia (Salvia hispanica L.) products as ingredients for reformulating frankfurters: Effects on quality properties and shelf-life. Meat Sci. 2019, 156, 139–145. [Google Scholar] [CrossRef] [PubMed]

- Jandásek, J. Seasoning in the production of frankfurters and sausages. Maso Inter. J. Food Sci. Technol. 2014, 1, 53–62. [Google Scholar]

- Ospina-E, J.C.; Cruz-S, A.; Pérez-Álvarez, J.A. Development of combinations of chemically modified vegetable oils as pork backfat substitutes in sausages formulation. Meat Sci. 2010, 84, 491–497. [Google Scholar] [CrossRef]

- Ospina-E, J.C.; Sierra-C, A.; Ochoa, O.; Pérez-Álvarez, J.A.; Fernández-López, J. Substitution of saturated fat in processed meat products: A review. Crit. Rev. Food Sci. Nutr. 2021, 52, 113–122. [Google Scholar] [CrossRef]

- Chen, Y.; Jia, X.; Sun, F.; Jiang, S.; Liu, H.; Liu, Q.; Kong, B. Using a stable pre-emulsified canola oil system that includes porcine plasma protein hydrolysates and oxidized tannic acid to partially replace pork fat in frankfurters. Meat Sci. 2020, 160, 10768. [Google Scholar] [CrossRef] [PubMed]

- Pintado, T.; Herrero, A.M.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Strategies for incorporation of chia (Salvia hispanica L.) in frankfurters as a health-promoting ingredient. Meat Sci. 2016, 114, 75–84. [Google Scholar] [CrossRef] [PubMed]

- Peña-Saldarriaga, L.M.; Pérez-Álvarez, J.A.; Fernández-López, J. Quality properties of chicken emulsion-type sausages formulated with chicken fatty byproducts. Foods 2020, 9, 507. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fernández-López, J.; Viuda-Martos, M.; Pérez-Álvarez, J.A. Quinoa and chia products as ingredients for healthier processed meat products: Technological strategies for their application and effects on the final product. Curr. Opin. Food Sci. 2021, 40, 26–32. [Google Scholar] [CrossRef]

- Herrero, A.M.; Ruiz-Capillas, C.; Pintado, T.; Carmona, P.; Jiménez-Colmenero, F. Infrared spectroscopy used to determine effects of chia and olive oil incorporation strategies on lipid structure of reduced-fat frankfurters. Food Chem. 2017, 221, 1333–1339. [Google Scholar] [CrossRef]

- Lucas-González, R.; Roldán-Verdú, A.; Sayas-Barberá, E.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Assessment of emulsion gels formulated with chestnut (Castanea sativa M.) flour and chia (Salvia hispanica L.) oil as partial fat replacers in pork burger formulation. J. Sci. Food Agric. 2020, 100, 1265–1273. [Google Scholar] [CrossRef]

- Pintado, T.; Herrero, A.M.; Jiménez-Colmenero, F.; Pasqualin Calvalheiro, C.; Ruiz-Capillas, C. Chian and oat emulsión gels as new animal fat replacers and healthy bioactive sources in fresh sausages formulation. Meat Sci. 2018, 135, 6–13. [Google Scholar] [CrossRef]

- de Souza Paglarini, C.; de Figueiredo Furtado, G.; Honório, A.R.; Mokarzel, L.; da Silva Vidal, V.A.; Ribeiro, A.P.B.; Pollonio, M.A.R. Functional emulsion gels as pork back fat replacers in Bologna sausage. Food Struct. 2019, 20, 100–105. [Google Scholar] [CrossRef]

- Pintado, T.; Ruiz-Capillas, C.; Herrero, A.M. New lipid materials based on chia emulsion gels: Application in meat products. J. Biomed. Sci. 2019, 18, 13215–13218. [Google Scholar] [CrossRef]

- Botella-Martínez, C.; Pérez-Álvarez, J.A.; Sayas-Barberá, E.; Fernández-López, J.; Viuda-Martos, M. Assessment of chemical, physico-chemical and lipid stability properties of gelled emulsions elaborated with different oils Chia (Salvia hispanica L.) or Hemp (Cannabis sativa L.) and pseudocereals. Foods 2021, 10, 1463. [Google Scholar] [CrossRef] [PubMed]

- Pintado, T.; Ruiz-Capillas, C.; Jiménez-Colmenero, F.; Carmona, P.; Herrero, A.M. Oil-in-water emulsion gels stabilized with chia (Salvia hispanica L.) and cold gelling agents: Technological and infrared spectroscopic characterization. Food Chem. 2015, 185, 470–478. [Google Scholar] [CrossRef] [PubMed]

- Goemaere, O.; Glorieux, S.; Govaert, M.; Steen, L.; Fraeye, I. Phosphate elimination in emulsified meat products: Impact of protein-based ingredients on quality characteristics. Foods 2021, 10, 882. [Google Scholar] [CrossRef] [PubMed]

- Nacak, B.; Öztürk-Kerimoglu, B.; Yildiz, D.; Çagindi, Ö.; Serdaroglu, M. Peanut and linseed oil emulsion gels as potential fat replacer in emulsified sausages. Meat Sci. 2021, 176, 108464. [Google Scholar] [CrossRef] [PubMed]

- da Silva, S.L.; Amaral, J.T.; Ribeiro, M.; Sebasião, E.E.; Vargas, C.; de Lima Franzen, F.; Scheneider, G.; Lorenzo, J.M.; Fries, L.L.M.; Cichoski, A.J.; et al. Fat replacement by oleogel rich in oleic acid and its impact on the technological, nutritional, oxidative, and sensory properties of Bologna-type sausages. Meat Sci. 2019, 149, 141–148. [Google Scholar] [CrossRef]

- Jimenez-Colmenero, F.; Salcedo-Sandoval, L.; Bou, R.; Cofrades, S.; Herrero, A.M.; Ruiz-Capillas, C. Novel applications of oil-structuring methods as a strategy to improve the fat content of meat products. Trends Food Sci. Technol. 2015, 177–188. [Google Scholar] [CrossRef] [Green Version]

- dos Santos, M.; Munekata, P.E.S.; Pateiro, M.; Magalhães, G.C.; Barretto, A.C.S.; Lorenzo, J.M.; Pollonio, M.A.R. Pork skin-based emulsion gels as animal fat replacers in hot-dog style sausages. LWT 2020, 132, 109845. [Google Scholar] [CrossRef]

- Alejandre, M.; Ansorena, D.; Calvo, M.I.; Cavero, R.Y.; Astiasaran, I. Influence of a gel emulsion containing microalgal oil and a blackthorn (Prunus spinosa L.) branch extract on the antioxidant capacity and acceptability of reduced-fat beef patties. Meat Sci. 2019, 148, 219–222. [Google Scholar] [CrossRef] [PubMed]

- Kavusan, H.S.; Serdaroglu, M.; Nacak, B.; Ipek, G. An approach to manufacture of fresh chicken sausages incorporated with black cumin and flaxseed oil in water gelled emulsion. Food Sci. Anim. Resour. 2020, 40, 426–443. [Google Scholar] [CrossRef]

- Botella-Martínez, C.; Viuda-Martos, M.; Fernández-López, J.; Pérez-Álvarez, J.A. Oleogels, Ingredients to Develop Healthier Meat Products. Tecnifood 2021, 10, 1463. Available online: https://techpress.es/oleogeles-ingredientes-para-desarrollar-productos-carnicos-mas-sanos/# (accessed on 14 April 2021).

- Ellison, C.; Moreno, T.; Catchpole, O.; Fenton, T.; Lagutin, K.; MacKenzie, A.; Mitchell, K.; Scott, D. Extraction of hemp seed using near-critical CO2, propane and dimethyl ether. J. Supercrit. Fluids 2021, 173, 105218. [Google Scholar] [CrossRef]

- Kirala, M.; Gül, V.; Metin Kara, S. Fatty acid composition of hemp seed oils from different locations in Turkey. Span. J. Agric. Res. 2010, 8, 385–390. [Google Scholar] [CrossRef]

- Wojcicki, J.; Samochowiec, L.; Gonet, B.; Juzwiak, S.; Dabrowska-Zamojcin, E.; Katdonska, M.; Tustanowski, S. Effect of buckwheat extracts on free radical generation in rabbits administered high-fat diet. Phytother. Res. 1995, 9, 323–326. [Google Scholar] [CrossRef]

- Quettier-Deleu, C.; Gressier, B.; Vasseur, J.; Dine, T.; Brunet, C.; Luyckx, M.; Cazin, M.; Cazin, J.-C.; Bailleul, F.; Trotin, F. Phenolic compounds and antioxidant activities of buckwheat (Fagopyrum esculentum Moench) hulls and flour. J. Ethnopharmacol. 2000, 72, 35–42. [Google Scholar] [CrossRef]

- Patil, S.L.; Rao, N.B.; Somashekarappa, H.M.; Rajashekhar, K.P. Antigenotoxic potential of rutin and quercetin in Swiss mice exposed to gamma radiation. Biomed. J. 2014, 37, 305–313. [Google Scholar] [CrossRef]

- Yang, J.; Lee, J.; Sung, J. Influence of acid treatment on flavonoid content and biological activity in tartary buckwheat grains and its application for noodles. LWT 2021, 145, 111488. [Google Scholar] [CrossRef]

- Bonafaccia, M.; Marocchinia, M.; Kreft, I. Composition and technological properties of the flour and bran from common and tartary buckwheat. Food Chem. 2003, 80, 9–15. [Google Scholar] [CrossRef]

- Janssen, F.; Pauly, A.; Rombouts, I.; Jansens, K.J.A.; Deleu, L.J.; Delcou, J.A. Proteins of amaranth (Amaranthus spp.), buckwheat (Fagopyrum spp.), and quinoa (Chenopodium spp.): A food science and technology perspective. Comp. Rev. Food Sci. Food Safety 2007, 16, 39–58. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Official Methods of Analysis of AOAC International, 18th ed.; Association of Official Analytical Chemistry: Rockville, MD, USA, 2010. [Google Scholar]

- Folch, J.; Less, M.; Sloane, G.H. A simple method for the isolation and purification of total lipids from animal tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef]

- Ulbricht, T.; Southgate, D. Coronary heart disease: Seven dietary factors. Lancet 1991, 338, 985–992. [Google Scholar] [CrossRef]

- Fernández, M.; Ordoñez, J.A.; Cambero, I.; Santos, C.; Pin, C.; Hoz, L. Fatty acids compositions of selected varieties of Spanish dry ham related to their nutritional implications. Food Chem. 2007, 101, 107–112. [Google Scholar] [CrossRef]

- Bourne, M.C. Texture profile analysis. Food Technol. 1978, 32, 62–65. [Google Scholar]

- Rosmini, M.; Perlo, F.; Pérez-Alvarez, J.; Pagán-Moreno, M.; Gago-Gago, M.; López-Santoveña, F.; Aranda-Catalá, V. TBA test by an extractive method applied to pate. Meat Sci. 1996, 42, 103–110. [Google Scholar] [CrossRef]

- Öztürk-Kerimoğlu, B.; Urgu-Öztürk, M.; Serdaroglu, M. A new inverse olive oil emulsion plus carrot powder to replace animal fat in model meat batters. LWT 2021, 135, 110044. [Google Scholar] [CrossRef]

- European Parliement. Regulation 1924/2006 of the European Parliament and of the council of 20 December 2006 on nutrition and health claims made on foods. Off. J. Eur. Union 2006, OJ, L12, 3–8. [Google Scholar]

- Wood, J.D.; Richardson, R.I.; Nute, G.R.; Fisher, A.V.; Campo, M.M.; Kasapidou, E.; Sheard, P.R.; Enser, M. Effect of fatty acids on meat quality: A review. Meat Sci. 2004, 66, 21–32. [Google Scholar] [CrossRef]

- Fernández-Ginés, J.M.; Fernández-López, J.; Sayas-Barberá, M.E.; Pérez-Alvarez, J.A. Meat products as functional foods: A review. J. Food Sci. 2005, 70, 37–44. [Google Scholar] [CrossRef]

- Aladic, K.; Jarni, K.; Barbir, T.; Vidovik, S.; Vladic, J.; Bilic, M.; Jokic, S. Supercritical CO2 extraction of hemp (Cannabis sativa L.) seed oil. Ind. Crops Prod. 2015, 76, 472–478. [Google Scholar] [CrossRef]

- Martínez, J.A.; Melgosa, M.; Pérez, M.; Hita, E.; Negueruela, A.I. Visual and instrumental color evaluation in red wines. Food Sci. Technol. Int. 2001, 7, 439–444. [Google Scholar] [CrossRef]

- Jiménez-Colmenero, F.; Barreto, G.; Fernández, P.; Carballo, J. Frozen storage of bologna sausages as a function of fat content and of levels of added starch and egg white. Meat Sci. 1996, 42, 325–332. [Google Scholar] [CrossRef] [Green Version]

- Verma, S.P.; Sahoo, J. Improvement in the quality of ground chevon during refrigerated storage by tocopherol acetate preblending. Meat Sci. 2000, 56, 403–413. [Google Scholar] [CrossRef]

- Barros, J.C.; Sichetti-Munekata, P.E.; Alves-Pires, M.; Rodrigues, I.; Andaloussi, O.S.; da Costa-Rodrigues, C.E.; Trindale, M.A. Omega-3- and fibre-enriched chicken nuggests by replacement of chicken skin with chia (Salvia hispánica L.) flour. LWT 2018, 90, 283–289. [Google Scholar] [CrossRef]

| Sample | Moisture | Ash | Fat | Protein |

|---|---|---|---|---|

| SC | 59.66 ± 0.03 d | 2.34 ± 0.15 a | 20.75 ± 0.28 a | 14.59 ± 0.25 a |

| S1 | 61.65 ± 0.56 c | 2.15 ± 0.07 a | 17.20 ± 0.32 b | 14.17 ± 0.19 a,b |

| S2 | 64.94 ± 0.03 a,b | 2.14 ± 0.14 a | 17.02 ± 0.63 b | 12.61 ± 0.10 d |

| S3 | 64.87 ± 0.10 b | 3.11 ± 1.47 a | 14.78 ± 0.09 c | 13.48 ± 0.22 bc |

| S4 | 65.81 ± 0.02 a | 2.39 ± 0.04 a | 12.69 ± 0.10 d | 13.41 ± 0.15 c |

| Fatty Acids (%) | SC | S1 | S2 | S3 | S4 |

|---|---|---|---|---|---|

| C6:0 | 0.01 ± 0.00 aL | 0.01 ± 0.00 aM | 0.02 ± 0.00 aM | 0.02 ± 0.00 aN | 0.02 ± 0.00 aN |

| C8:0 | 0.02 ± 0.00 aL | 0.03 ± 0.00 aM | 0.03 ± 0.00 aM | 0.04 ± 0.00 aN | 0.03 ± 0.00 aN |

| C10:0 | 0.06 ± 0.01 aK | 0.06 ± 0.01 aL | 0.05 ± 0.00 bL | 0.04 ± 0.00 cN | 0.02 ± 0.00 dN |

| C12:0 | 0.08 ± 0.00 aK | 0.07 ± 0.00 aL | 0.06 ± 0.00 bL | 0.05 ± 0.00 cN | 0.02 ± 0.00 dN |

| C13:0 | ND | ND | ND | ND | 0.02 ± 0.00 N |

| C14:0 | 1.27 ± 0.02 aE | 1.13 ± 0.02 bG | 0.95 ± 0.02 cG | 0.67 ± 0.01 dJ | 0.37 ± 0.00 eJ |

| C15:0 | 0.07 ± 0.00 aK | 0.06 ± 0.01 aL | 0.05 ± 0.01 bL | 0.05 ± 0.00 bN | 0.03 ± 0.00 cN |

| C16:0 | 22.92 ± 0.03 aB | 21.10 ± 0.05 bB | 18.26 ± 0.21 cC | 14.39 ± 0.09 dC | 9.96 ± 0.13 eC |

| C16:1trans | 0.42 ± 0.00 aG | 0.35 ± 0.01 bJ | 0.26 ± 0.01 cJ | 0.22 ± 0.00 dL | 0.14 ± 0.00 eL |

| C16:1cis | 2.21 ± 0.01 aD | 1.96 ± 0.05 bF | 1.53 ± 0.01 cF | 1.04 ± 0.00 dH | 0.54 ± 0.01 eI |

| C17:0 | 0.38 ± 0.01 aG | 0.36 ± 0.01 bJ | 0.31 ± 0.00 cJ | 0.25 ± 0.00 dL | 0.17 ± 0.00 eL |

| C17:1 | 0.34 ± 0.00 aH | 0.31 ± 0.00 aJ | 0.25 ± 0.02 abJ | 0.19 ± 0.00 bM | 0.07 ± 0.04 cM |

| C18:0 | 10.94 ± 0.04 aC | 10.36 ± 0.03 bD | 9.47 ± 0.02 cD | 7.07 ± 0.02 dE | 4.44 ± 0.07 eD |

| C18:1 cis | 46.71 ± 0.10 aA | 40.45 ± 0.55 bA | 32.38 ± 0.08 cA | 23.53 ± 0.10 dB | 15.56 ± 0.44 eB |

| C18:1 trans | 0.10 ± 0.00 bJ | 0.09 ± 0.00 bL | 0.07 ± 0.00 bL | 1.34 ± 0.00 aG | 0.92 ± 0.16 aG |

| C18:2 (n-6) | 11.56 ± 0.01 eC | 17.51 ± 0.38 dC | 25.54 ± 0.13 cB | 35.09 ± 0.01 bA | 45.62 ± 0.06 aA |

| C18:2(n-3) | 0.09 ± 0.01 eJ | 0.65 ± 0.04 dH | 1.45 ± 0.02 cF | 2.31 ± 0.00 bF | 3.30 ± 0.00 aE |

| C18:3 (n-3) | 0.68 ± 0.01 eF | 3.29 ± 0.18 dE | 6.79 ± 0.17 cE | 10.81 ± 0.00 bD | 15.38 ± 0.00 aB |

| C18:3 (n-6) | ND | 0.22 ± 0.02 dK | 0.50 ± 0.03 cH | 0.84 ± 0.00 bI | 1.22 ± 0.01 aF |

| C20:0 | 0.20 ± 0.00 eI | 0.31 ± 0.00 dJ | 0.46 ± 0.01 cH | 0.61 ± 0.00 bJ | 0.75 ± 0.02 aH |

| C20:1 | 1.10 ± 0.03 aE | 0.95 ± 0.01 bG | 0.84 ± 0.01 cG | 0.67 ± 0.00 dJ | 0.55 ± 0.00 eI |

| C20:2 | 0.54 ± 0.01 aF | 0.47 ± 0.00 bI | 0.40 ± 0.01 cI | 0.32 ± 0.00 dK | 0.24 ± 0.01 eK |

| C20:3 | 0.31 ± 0.01 aH | 0.30 ± 0.00 abJ | 0.27 ± 0.00 abJ | 0.25 ± 0.01 bcL | 0.20 ± 0.01 cK |

| C20:5 | ND | ND | 0.15 ± 0.00 cK | 0.24 ± 0.00 bL | 0.32 ± 0.01 aJ |

| C24:0 | ND | ND | ND | ND | 0.20 ± 0.03 K |

| Σ n-3 | 0.98 ± 0.02 eG | 3.59 ± 0.03 dG | 7.21 ± 0.07 cD | 11.30 ± 0.17 bE | 15.90 ± 0.07 aD |

| Σ n-6 | 12.19 ± 0.05 dE | 18.85 ± 0.08 dE | 27.89 ± 0.11 cC | 38.56 ± 0.01 bC | 50.39 ± 0.05 aC |

| n-6/n-3 ratio | 12.39 ± 0.01 aE | 5.25 ± 0.02 bF | 3.87 ± 0.01 cE | 3.41 ± 0.03 dG | 3.17 ± 0.05 eF |

| Σ SFA | 35.96 ± 0.04 aC | 33.49 ± 0.06 bC | 29.66 ± 0.01 cC | 23.17 ± 0.00 dD | 16.03 ± 0.01 eD |

| Σ UFA | 64.05 ± 0.03 eA | 66.55 ± 0.21 dA | 70.42 ± 0.24 cA | 76.85 ± 0.07 bA | 84.06 ± 0.22 aA |

| Σ MUFA | 50.88 ± 0.02 aB | 44.10 ± 0.04 bB | 35.33 ± 0.09 cB | 26.98 ± 0.04 dD | 17.78 ± 0.18 eD |

| Σ PUFA | 13.17 ± 0.01 eD | 22.44 ± 0.02 dD | 35.10 ± 0.06 cB | 49.87 ± 0.02 bB | 66.28 ± 0.13 aB |

| Σ PUFA/ Σ SFA | 0.37 ± 0.01 eH | 0.67 ± 0.03 dI | 1.18 ± 0.02 cF | 2.15 ± 0.07 bG | 4.13 ± 0.02 aF |

| AI * | 0.44 ± 0.01 aH | 0.39 ± 0.00 bJ | 0.31 ± 0.01 cG | 0.22 ± 0.00 dH | 0.14 ± 0.00 eG |

| TI * | 1.02 ± 0.04 aG | 0.77 ± 0.01 bI | 0.54 ± 0.01 cG | 0.33 ± 0.00 dH | 0.18 ± 0.00 eG |

| h/H * | 2.48 ± 0.03 eF | 2.83 ± 0.04 dH | 3.52 ± 0.04 cE | 4.96 ± 0.02 bF | 8.01 ± 0.07 aE |

| Sample | pH | Aw |

|---|---|---|

| SC | 5.88 ± 0.01 c | 0.947 ± 0.003 c |

| S1 | 5.94 ± 0.01 b | 0.953 ± 0.001 bc |

| S2 | 6.09 ± 0.01 a | 0.956 ± 0.002 bc |

| S3 | 5.91 ± 0.01 bc | 0.960 ± 0.003 b |

| S4 | 5.90 ± 0.01 c | 0.969 ± 0.001 a |

| Sample | L * | a * | b * | C * | h | ΔE * |

|---|---|---|---|---|---|---|

| SC | 72.7 ± 0.63 a | 3.42 ± 0.35 a | 9.15 ± 0.24 e | 9.77 ± 0.30 e | 69.53 ± 1.71 e | - |

| S1 | 70.42 ± 0.87 bc | 2.88 ± 0.19 b | 11.32 ± 0.42 d | 11.68 ± 0.44 d | 75.70 ± 0.58 d | 3.30 ± 0.47 d |

| S2 | 69.53 ± 1.29 c | 2.80 ± 0.25 b | 13.06 ± 1.72 c | 13.36 ± 1.71 c | 77.72 ± 1.46 c | 5.36 ± 1.27 c |

| S3 | 70.99 ± 0.90 b | 1.21 ± 0.47 c | 15.23 ± 0.31 b | 15.29 ± 0.30 b | 85.45 ± 1.79 b | 6.77 ± 0.24 b |

| S4 | 72.18 ± 0.27 a | 0.38 ± 0.16 d | 17.01 ± 0.33 a | 17.01 ± 0.33 a | 88.73 ± 0.54 a | 8.45 ± 0.33 a |

| Sample | Hardness (N) | Adhesiveness (N s) | Springiness (mm) | Cohesiveness | Chewiness (N mm) |

|---|---|---|---|---|---|

| SC | 87.11 ± 8.86 ab | −0.67 ± 0.34 a | 0.26 ± 0.02 b | 0.78 ± 0.04 a | 17.36 ± 2.12 a |

| S1 | 93.51 ± 9.73 a | −0.72 ± 0.36 a | 0.29 ± 0.04 ab | 0.75 ± 0.03 a | 20.83 ± 4.45 a |

| S2 | 83.91 ± 11.22 ab | −0.52 ± 0.32 a | 0.34 ± 0.02 a | 0.75 ± 0.02 a | 21.37 ± 3.71 a |

| S3 | 89.86 ± 20.73 ab | −0.49 ± 0.32 a | 0.33 ± 0.05 ab | 0.76 ± 0.03 a | 22.82 ± 7.66 a |

| S4 | 63.22 ± 9.72 b | −0.91 ± 0.34 a | 0.25 ± 0.04 b | 0.81 ± 0.02 a | 12.92 ± 3.27 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Botella-Martínez, C.; Viuda-Martos, M.; Pérez-Álvarez, J.A.; Fernández-López, J. Total and Partial Fat Replacement by Gelled Emulsion (Hemp Oil and Buckwheat Flour) and Its Impact on the Chemical, Technological and Sensory Properties of Frankfurters. Foods 2021, 10, 1681. https://doi.org/10.3390/foods10081681

Botella-Martínez C, Viuda-Martos M, Pérez-Álvarez JA, Fernández-López J. Total and Partial Fat Replacement by Gelled Emulsion (Hemp Oil and Buckwheat Flour) and Its Impact on the Chemical, Technological and Sensory Properties of Frankfurters. Foods. 2021; 10(8):1681. https://doi.org/10.3390/foods10081681

Chicago/Turabian StyleBotella-Martínez, Carmen, Manuel Viuda-Martos, José Angel Pérez-Álvarez, and Juana Fernández-López. 2021. "Total and Partial Fat Replacement by Gelled Emulsion (Hemp Oil and Buckwheat Flour) and Its Impact on the Chemical, Technological and Sensory Properties of Frankfurters" Foods 10, no. 8: 1681. https://doi.org/10.3390/foods10081681

APA StyleBotella-Martínez, C., Viuda-Martos, M., Pérez-Álvarez, J. A., & Fernández-López, J. (2021). Total and Partial Fat Replacement by Gelled Emulsion (Hemp Oil and Buckwheat Flour) and Its Impact on the Chemical, Technological and Sensory Properties of Frankfurters. Foods, 10(8), 1681. https://doi.org/10.3390/foods10081681