Optimization and Development of Ready to Eat Chocolate Coated Roasted Flaked Rice as Instant Breakfast Food

Abstract

:1. Introduction

2. Materials and Methods

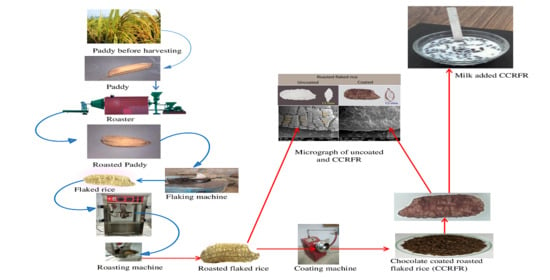

2.1. Preparation of Chocolate—Coated Roasted Flaked Rice (CCRFR)

2.2. Physicochemical Characteristics

2.3. Textural Characteristics

2.4. Functional Characteristics

2.5. Optical Characteristics

2.6. Fourier Transform Infra-Red Spectroscopy (FTIR)

2.7. Pasting Properties

2.8. Morphological Characteristics

2.9. Sensory Characteristics

2.10. Experimental Design and Optimization

2.11. Statistical Evaluation

3. Results and Discussion

3.1. Preparation of CCRFR

3.2. Physicochemical Characteristics

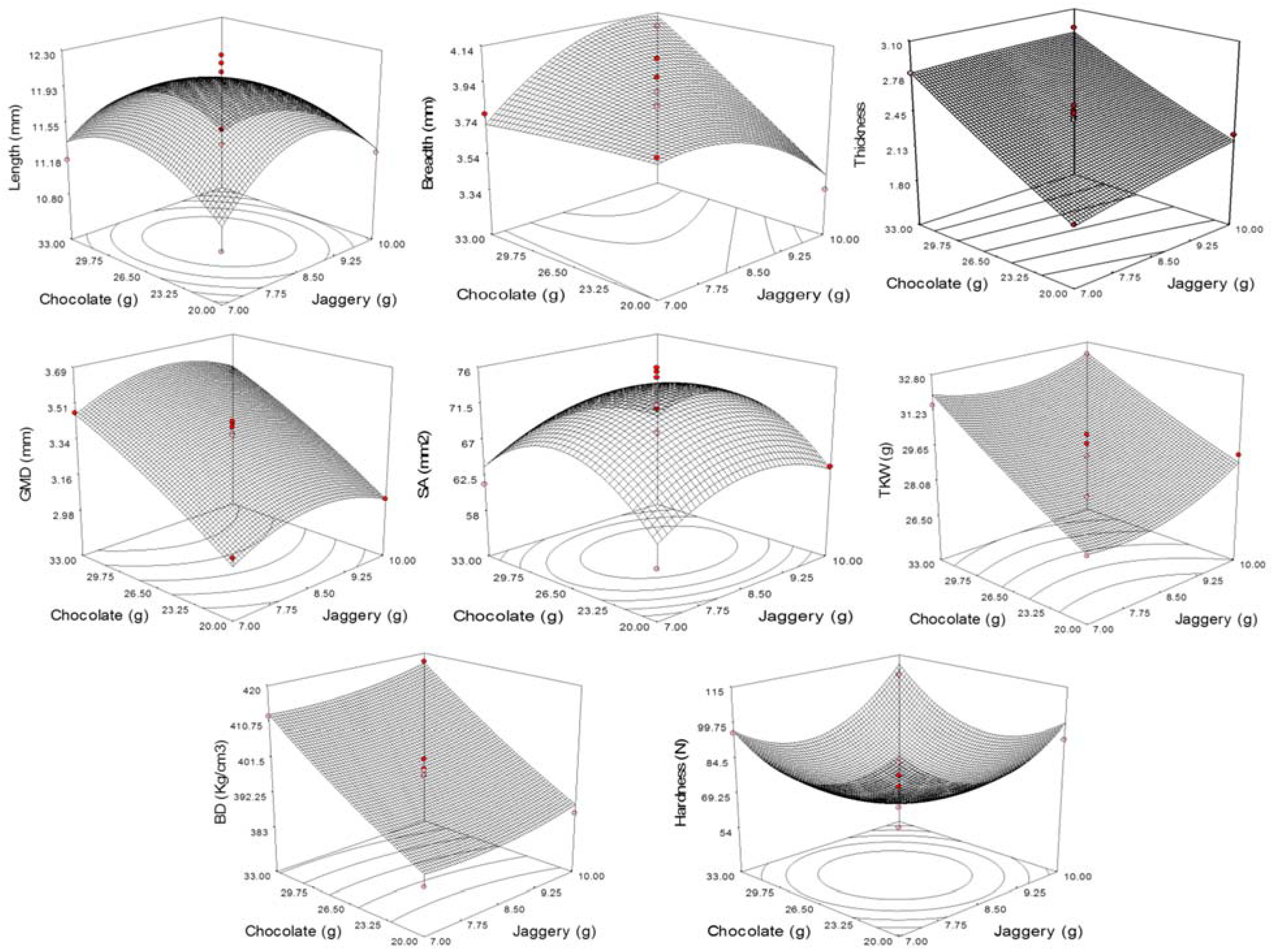

3.2.1. Geometric Mean Diameter (GMD) and Surface Area (SA)

3.2.2. Thousand Kernel Weight (TKW)

3.2.3. Bulk Density (BD)

3.3. Textural Characteristics

3.4. Functional Characteristics

3.5. Optical Characteristics

3.6. Sensory Characteristics

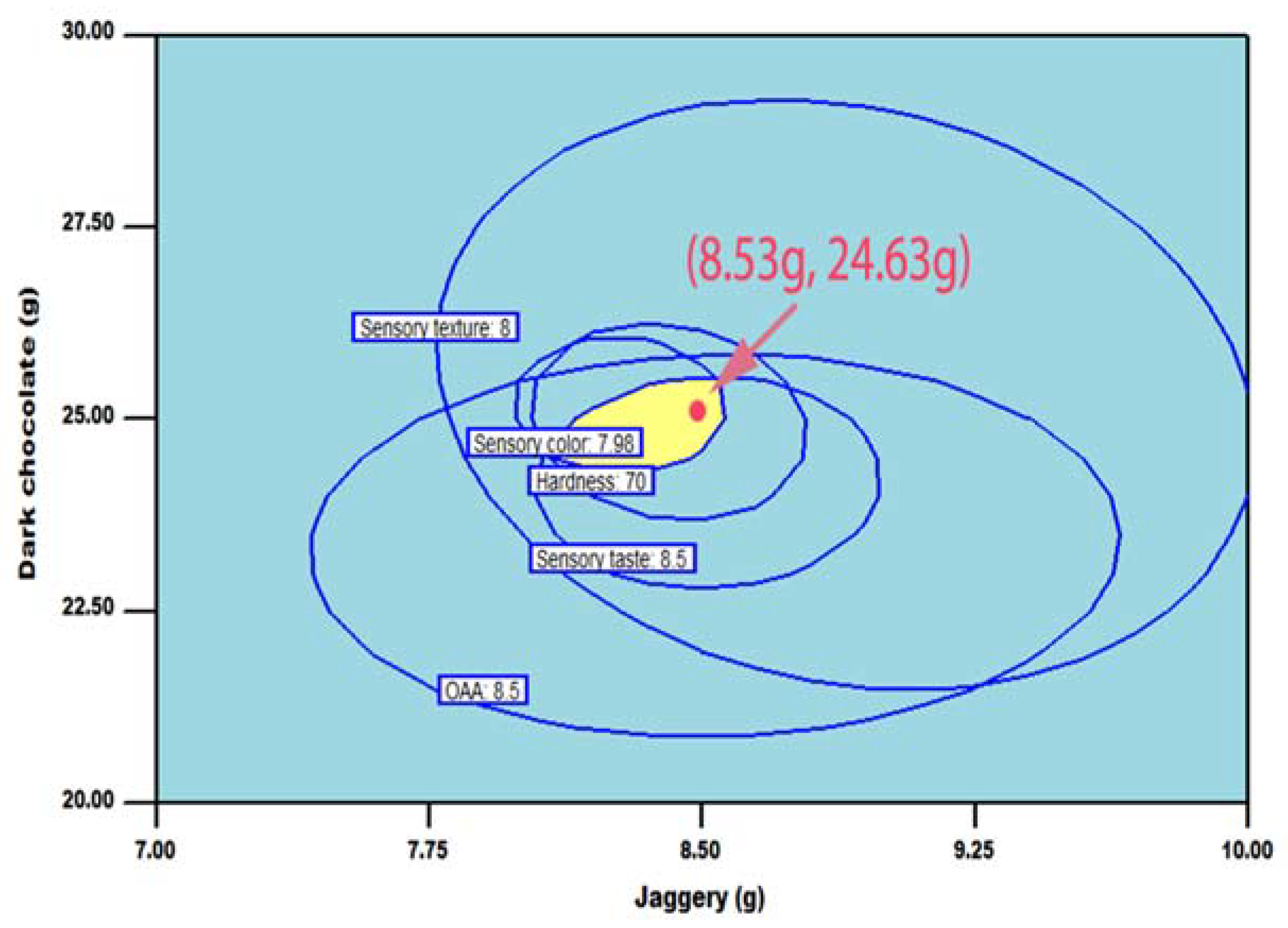

3.7. Optimization of CCRFR

3.8. Comparison of Optimized CCRFR to RFR

3.8.1. Physical Characteristics

3.8.2. Chemical Characteristics

3.8.3. Fourier Transform Infrared Spectroscopy (FTIR)

3.8.4. Pasting Properties

3.8.5. Functional and Textural Characteristics

3.8.6. Morphological Characteristics (SEM)

3.8.7. Sensory Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- FAOSTAT. 2020. Available online: http://faostat.fao.org (accessed on 30 March 2020).

- Hosseini, S.M.; Soltanizadeh, N.; Mirmoghtadaee, P.; Banavand, P.; Mirmoghtadaie, L.; Shojaee-Aliabadi, S. Gluten-free products in celiac disease: Nutritional and technological challenges and solutions. J. Res. Med. Sci. 2018, 23, 109. [Google Scholar]

- Igoumenidis, P.E.; Lekka, E.G.; Karathanos, V.T. Fortification of white milled rice with phytochemicals during cooking in aqueous extract of Menthaspicata leaves. An adsorption study. LWT Food Sci. Technol. 2015, 65, 589–596. [Google Scholar] [CrossRef]

- Chitra, M.; Singh, V.; Ali, S.Z. Effect of processing paddy on digestibility of rice starch by in vitro studies. J. Food Sci. Technol. 2010, 47, 414–419. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharya, K.R. Rice Quality: A Guide to Rice Properties and Analysis; Woodhead Publishing Ltd.: Cambridge, UK, 2011. [Google Scholar]

- Berger, A.; Rein, D.; Schafer, A.; Monnard, I.; Gremaud, G.; Lambelet, P.; Bertoli, C. Similar cholesterol lowering properties of rice bran oil, with varied oryzanol, in mildly hypercholesterolemic men. Eur. J. Nutr. 2005, 44, 163–173. [Google Scholar] [CrossRef] [PubMed]

- Li, S.C.; Chou, T.C.; Shih, C.K. Effects of brown rice, rice bran, and polished rice on colon carcinogenesis in rats. Food Res. Int. 2011, 44, 209–216. [Google Scholar] [CrossRef]

- Kumar, S.; Prasad, K. Optimization of flaked rice dry roasting in common salt and studies on associated changes in chemical, nutritional, optical, physical, rheological and textural attributes. Asian J. Chem. 2017, 29, 1380–1392. [Google Scholar] [CrossRef]

- Arribas, C.; Cabellos, B.; Guillamón, E.; Pedrosa, M.M. Cooking and sensorial quality, nutritional composition and functional properties of cold-extruded rice/white bean gluten-free fettuccine fortified with whole carob fruit flour. Food Funct. 2020, 11, 7913–7924. [Google Scholar] [CrossRef] [PubMed]

- Homayouni, A.; Amini, A.; Keshtiban, A.K.; Mortazavian, A.M.; Esazadeh, K.; Pourmoradian, S. Resistant starch in food industry: A changing outlook for consumer and producer. Starch Stärke 2014, 66, 102–114. [Google Scholar] [CrossRef]

- Raigond, P.; Ezekiel, R.; Raigond, B. Resistant starch in food: A review: Resistant starch in food. J. Sci. Food Agric. 2015, 95, 1968–1978. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Kumar, M. Upgradation of jaggery production and preservation technologies. Renew. Sustain. Energy Rev. 2018, 96, 167–180. [Google Scholar] [CrossRef]

- Ottaviani, J.I.; Heiss, C.; Spencer, J.P.E.; Kelm, M.; Schroeter, H. Recommending flavanols and procyanidins for cardiovascular health: Revisited. Mol. Asp. Med. 2018, 61, 63–75. [Google Scholar] [CrossRef]

- Kumar, S.; Haq, R.; Prasad, K. Studies on physico-chemical, functional, pasting and morphological characteristics of developed extra thin flaked rice. J. Saudi Soc. Agric. Sci. 2018, 17, 259–267. [Google Scholar] [CrossRef] [Green Version]

- Zhu, F.; Liu, P. Starch gelatinization, retrogradation, and enzyme susceptibility of retrograded starch: Effect of amylopectin internal molecular structure. Food Chem. 2020, 316, 126036. [Google Scholar] [CrossRef]

- Mudgil, D. Partially Hydrolyzed Guar Gum: Preparation and Properties. In Polymers for Food Applications; Gutiérrez, T.J., Ed.; Springer: Cham, Switzerland, 2018; pp. 529–549. [Google Scholar] [CrossRef]

- Mridula, D.; Pooja, J. Preparation of iron-fortified rice using edible coating materials. Int. J. Food Sci. Technol. 2013, 49, 246–252. [Google Scholar] [CrossRef]

- Shrestha, A.K.; Arcot, J.; Paterson, J.L. Edible coating materials—Their properties and use in the fortification of rice with folic acid. Food Res. Int. 2003, 36, 921–928. [Google Scholar] [CrossRef]

- Kruszelnicka, W.; Marczuk, A.; Kasner, R.; Bałdowska-Witos, P.; Piotrowska, K.; Flizikowski, J.; Tomporowski, A. Mechanical and Processing Properties of Rice Grains. Sustainability 2020, 12, 552. [Google Scholar] [CrossRef] [Green Version]

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials: Vol. 1: Physical Characteristics and Mechanical Properties, 1st ed.; Taylor & Francis Group (CRC-Press): Boca Raton, FL, USA, 1970. [Google Scholar]

- Prasad, K. Application of RSM and MR Optimization in the Development of Ready-to-serve (RTS) Beverage. Int. J. Appl. Agric. Res. 2009, 4, 87–96. [Google Scholar]

- Association of Official Analytical Chemists. AOAC Official Methods of Analysis; Association of Official Analytical Chemists: Washington, DC, USA, 2002. [Google Scholar]

- Ranganna, S. Handbook of Analysis of Quality Control of Fruit and Vegetable Products; Tata McGraw-Hill: New Delhi, India, 2000. [Google Scholar]

- Stojceska, V.; Ainsworth, P.; Plunkett, A.; Ibanoglu, E.; Ibanoglu, S. Cauliflower by-products as a new source of dietary fibre, antioxidants and proteins in cereal based ready-to-eat expanded snacks. J. Food Eng. 2008, 87, 554–563. [Google Scholar] [CrossRef]

- Ainsworth, E.A.; Gillespie, K.M. Estimation of total phenolic content and other oxidation substrates in plant tissues using Folin–Ciocalteu reagent. Nat. Protoc. 2007, 2, 875–877. [Google Scholar] [CrossRef]

- Kumar, S.; Prasad, K. Effect of parboiling and puffing processes on the physicochemical, functional, optical, pasting, thermal, textural and structural properties of selected Indica rice. J. Food Meas. Charact. 2018, 12, 1707–1722. [Google Scholar] [CrossRef]

- Watts, B.M.; Ylimaki, G.L.; Jeffery, L.E.; Elias, L.G. Basic Sensory Methods for Food Evaluation; IDRC: Ottawa, ON, Canada, 1989. [Google Scholar]

- Baniwal, P.; Hathan, B.S. Process Parameter Optimization for the Development of Ready-to-Eat Instant Sand Pear Candy Using Response Surface Methodology: Development of RTE Instant Sand Pear Candy. J. Food Proc. Preserv. 2015, 39, 3098–3109. [Google Scholar] [CrossRef]

- Singh, Y.; Prasad, K. Physical characteristics of some of the paddy varieties as affected by shelling and milling operations. ORYZA Int. J. Rice 2013, 50, 174–180. [Google Scholar]

- Sumonsiri, N.; Barringer, S.A. Effect of sodium chloride and food target properties on nonelectrostatic and electrostatic coating. J. Electrostat. 2011, 69, 578–586. [Google Scholar] [CrossRef]

- Beckett, S.T. Industrial Chocolate Manufacture and Use; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Okafor, G.; Usman, G. Physical and functional properties of breakfast cereals from maize, African yam bean and coconut cake. Agro-Sci. J. Trop. Agric. Food Environ. Ext. 2015, 13, 7–16. [Google Scholar] [CrossRef] [Green Version]

- Torres-Martinez, J.L.; Mujica-Paz, H.; Valdez-Fragoso, A.; Ortega-Rivas, E. Coating of Puffed Wheat by a Tumbling Method a Fluidized Bed Technique. Part. Sci. Technol. 2007, 25, 549–554. [Google Scholar] [CrossRef]

- Chassagne-Berces, S.; Leitner, M.; Melado, A.; Barreiro, P.; Correa, E.C.; Blank, I.; Gumy, J.-C.; Chanvrier, H. Effect of fibers and whole grain content on quality attributes of extruded cereals. Procedia Food Sci. 2011, 1, 17–23. [Google Scholar] [CrossRef] [Green Version]

- Kosutic, M.; Filipovic, J.; Pezo, L.; Plavsic, D.; Ivkov, M. Physical and sensory properties of corn flakes with added dry residue of wild oregano distillation. J. Serb. Chem. Soc. 2016, 81, 1013–1024. [Google Scholar] [CrossRef]

- Pardhi, S.D.; Singh, B.; Nayik, G.A.; Dar, B.N. Evaluation of functional properties of extruded snacks developed from brown rice grits by using response surface methodology. J. Saudi Soc. Agric. Sci. 2019, 18, 7–16. [Google Scholar] [CrossRef]

- Badwaik, L.S.; Prasad, K.; Deka, S.C. Optimization of extraction conditions by response surface methodology for preparing partially defatted peanut. Int. Food Res. J. 2012, 19, 341–346. [Google Scholar]

- Vemireddy, L.R.; Satyavathi, V.V.; Siddiq, E.A.; Nagaraju, J. Review of methods for the detection and quantification of adulteration of rice: Basmati as a case study. J. Food Sci. Technol. 2014, 52, 3187–3202. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dutta, H.; Mahanta, C.L. Effect of hydrothermal treatment varying in time and pressure on the properties of parboiled rices with different amylose content. Food Res. Int. 2012, 49, 655–663. [Google Scholar] [CrossRef]

- Kose, S. Effect of sugar type and concentration on pasting and textural properties of corn starch in water and skim milk. Cereal Chem. 2020, 97, 921–929. [Google Scholar] [CrossRef]

- Sharma, R.; Oberoi, D.P.S.; Sogi, D.S.; Gill, B.S. Effect of sugar and gums on the pasting properties of cassava starch. J. Food Process. Preserv. 2009, 33, 401–414. [Google Scholar] [CrossRef]

- Zhou, Z.; Robards, K.; Helliwell, S.; Blanchard, C. Effect of the addition of fatty acids on rice starch properties. Food Res. Int. 2007, 40, 209–214. [Google Scholar] [CrossRef]

| Independent Variable | Code | Levels in Coded Form | ||||

|---|---|---|---|---|---|---|

| −1.414 | −1.000 | 0.000 | +1.000 | +1.414 | ||

| Jaggery, g | X1 | 6.38 | 7.00 | 8.50 | 10.00 | 10.62 |

| Chocolate, g | X2 | 17.93 | 20.00 | 25.00 | 30.00 | 32.07 |

| Exp. No. | Independent Variables | Dependent Variables * | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Physical, Textural, Functional and Optical Characteristics | Sensory Characteristics | |||||||||||||||

| Jaggery | Dark Chocolate | L (mm) | B (mm) | T (mm) | GMD (mm) | SA (mm2) | TKW (g) | BD (kg/cm3) | HD (N) | MAC (g/g) | ΔE | Colour | Texture | Taste | OAA | |

| X1 | X2 | Y1 | Y2 | Y3 | Y4 | Y5 | Y6 | Y7 | Y8 | Y9 | Y10 | Y11 | Y12 | Y13 | Y14 | |

| 1 | −1 | −1 | 10.83 | 3.81 | 1.93 | 3.04 | 58.30 | 27.30 | 383.00 | 102.87 | 1.47 | 40.76 | 7.46 | 6.85 | 7.85 | 8.00 |

| 2 | 1 | −1 | 11.25 | 3.34 | 2.24 | 3.04 | 63.71 | 29.28 | 386.88 | 93.13 | 1.63 | 44.46 | 7.38 | 7.62 | 8.00 | 8.09 |

| 3 | −1 | 1 | 11.17 | 3.77 | 2.81 | 3.47 | 61.44 | 31.47 | 412.27 | 95.85 | 1.74 | 46.26 | 7.46 | 7.31 | 7.15 | 7.36 |

| 4 | 1 | 1 | 11.00 | 4.06 | 2.91 | 3.49 | 65.80 | 32.22 | 417.57 | 105.46 | 1.91 | 48.48 | 7.31 | 7.54 | 7.46 | 7.55 |

| 5 | −1.414 | 0 | 11.33 | 3.54 | 2.31 | 3.11 | 67.86 | 30.37 | 401.31 | 102.25 | 1.36 | 45.94 | 7.69 | 7.08 | 7.85 | 8.27 |

| 6 | 1.414 | 0 | 10.92 | 3.74 | 2.47 | 3.23 | 65.58 | 31.13 | 405.47 | 114.35 | 1.79 | 48.31 | 7.46 | 7.69 | 7.62 | 8.18 |

| 7 | 0 | −1.414 | 11.50 | 3.70 | 1.89 | 2.98 | 60.82 | 26.58 | 384.83 | 107.03 | 1.29 | 37.40 | 7.38 | 7.31 | 7.54 | 8.18 |

| 8 | 0 | 1.414 | 11.42 | 4.11 | 3.02 | 3.69 | 62.66 | 32.72 | 419.72 | 105.91 | 1.86 | 46.54 | 7.54 | 7.54 | 7.46 | 7.18 |

| 9 | 0 | 0 | 11.33 | 3.82 | 2.46 | 3.37 | 67.94 | 29.23 | 401.33 | 77.42 | 1.71 | 45.23 | 7.92 | 7.85 | 8.23 | 8.55 |

| 10 | 0 | 0 | 12.17 | 3.97 | 2.51 | 3.42 | 74.73 | 30.19 | 398.86 | 54.07 | 1.65 | 46.27 | 8.00 | 8.23 | 8.62 | 8.45 |

| 11 | 0 | 0 | 12.08 | 3.89 | 2.40 | 3.36 | 75.41 | 30.18 | 396.92 | 63.14 | 1.79 | 45.38 | 8.00 | 8.23 | 8.62 | 8.55 |

| 12 | 0 | 0 | 12.25 | 4.07 | 2.38 | 3.43 | 75.91 | 29.77 | 397.22 | 72.55 | 1.88 | 45.39 | 7.92 | 8.15 | 8.62 | 8.75 |

| 13 | 0 | 0 | 12.17 | 3.81 | 2.44 | 3.40 | 71.37 | 27.37 | 398.33 | 77.53 | 1.85 | 45.57 | 8.08 | 8.54 | 8.54 | 8.55 |

| Physical, Textural, Functional and Optical Characteristics | Sensory Characteristics | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Parameters | L (mm) | B (mm) | T (mm) | GMD (mm) | SA (mm2) | TKW (g) | BD (kg/cm3) | HD (N) | MAC (g/g) | ΔE | Colour | Texture | Taste | OAA |

| Constant | 12.00 | 3.911 | 2.439 | 3.394 | 73.071 | 29.347 | 398.533 | 68.943 | 1.776 | 45.567 | 7.985 | 8.200 | 8.523 | 8.569 |

| X1 | −0.042 ns | 0.013 ns | 0.079 * | 0.023 ns | 0.820 ns | 0.476 ns | 1.883 * | 2.124 ns | 0.116 ** | 1.159 *** | −0.070 * | 0.234 ** | 0.017 ns | 0.018 ns |

| X2 | 0.045 ns | 0.156 * | 0.393 * | 0.235 *** | 0.978 ns | 1.972 *** | 13.662 *** | 0.466 ns | 0.170 *** | 2.804 *** | 0.018 ns | 0.089 ns | −0.167 * | −0.325 *** |

| X1.X2 | −0.15 *** | 0.189 * | −0.052 * | 0.002 ns | −0.264 ns | −0.309 ns | 0.355 ns | 4.837 ns | 0.001 ns | −0.370 ns | −0.019 ns | −0.135 ns | 0.038 ns | 0.023 ns |

| X12 | −0.49** | −0.143 * | −0.013 ns | −0.109 *** | −3.654 ** | 0.667 ns | 1.704 ns | 17.664 *** | −0.073 ns | 0.889 ** | −0.233 *** | −0.427 *** | −0.396 *** | −0.222 *** |

| X22 | −0.33 ns | −0.011 ns | 0.021 ns | −0.028 * | −6.145 *** | 0.118 ns | 1.147 ns | 16.749 *** | −0.072 ns | −1.688 *** | −0.290 *** | −0.408 *** | −0.512 *** | −0.495 *** |

| R2 | 0.749 | 0.861 | 0.986 | 0.984 | 0.817 | 0.854 | 0.972 | 0.866 | 0.832 | 0.968 | 0.942 | 0.913 | 0.891 | 0.945 |

| Chi square | 0.065 | 0.020 | 0.008 | 0.003 | 1.087 | 0.210 | 0.114 | 7.653 | 0.052 | 0.076 | 0.007 | 0.031 | 0.044 | 0.019 |

| % E | 0.044 | 0.044 | 0.026 | 0.006 | 0.124 | 0.058 | 0.002 | 0.870 | 0.258 | 0.017 | 0.007 | 0.030 | 0.043 | 0.018 |

| RMSE | 0.243 | 0.077 | 0.038 | 0.026 | 2.399 | 0.690 | 1.852 | 6.716 | 0.079 | 0.507 | 0.065 | 0.140 | 0.163 | 0.110 |

| Parameters | RFR | CCRFR | |

|---|---|---|---|

| Estimated Value | Actual Value | ||

| L (mm) | 12.43 ± 0.06 a | 12.00 | 12.52 ± 0.29 a |

| B (mm) | 4.09 ± 0.08 b | 3.90 | 4.24 ± 0.33 a |

| T (mm) | 2.30 ± 0.09 a | 2.41 | 2.39 ± 0.01 a |

| GMD (mm) | 4.95 ± 0.08 b | 3.38 | 4.97 ± 0.05 a |

| SA (mm2) | 77.02 ± 2.61 a | 72.98 | 77.52 ± 1.43 a |

| TKW (g) | 23.13 ± 0.16 b | 29.21 | 29.44 ± 0.41 a |

| BD (kg/m3) | 364.15 ± 6.24 | 397.56 | 392.72 ± 4.02 |

| HD (N) | 62.48 ± 5.01 b | 69.05 | 75.02 ± 3.66 a |

| MAC (g/g) | 3.63 ± 0.35 a | 1.77 | 1.59 ± 0.43 b |

| ΔE | 2.39 ± 0.03 b | 45.37 | 45.85 ± 0.41 a |

| Color | 7.33 ± 0.02 b | 7.98 | 8.08 ± 0.09 a |

| Texture | 7.67 ± 0.03 b | 8.20 | 8.12 ± 0.12 a |

| Taste | 8.33 ± 0.04 a | 8.54 | 8.55 ± 0.13 a |

| OAA | 8.61 ± 0.06 a | 8.59 | 8.62 ± 0.10 a |

| Parameters | RFR | CCRFR |

|---|---|---|

| Moisture (%) | 4.61 ± 0.09 | 6.72 ± 0.64 |

| Crude fat (%) | 2.81 ± 0.15 | 10.16 ± 0.03 |

| Crude fiber (%) | 1.84 ± 0.13 | 2.61 ± 0.12 |

| Protein (%) | 6.10 ± 0.05 | 8.12 ± 0.08 |

| Total ash (%) | 1.58 ± 0.05 | 2.05 ± 0.13 |

| Carbohydrate (%) | 82.28 ± 0.21 | 71.11 ± 0.78 |

| Energy (kcal/100 g) | 387.09 ± 1.63 | 417.17 ± 1.43 |

| Iron (mg/100 g) | 1.64 ± 0.19 | 26.73 ± 0.12 |

| Calcium (mg/100 g) | 19.29 ± 0.62 | 51.59 ± 0.09 |

| Sodium (mg/100 g) | 5.40 ± 0.36 | 17.81 ± 0.51 |

| Potassium (mg/100 g) | 119.00 ± 1.73 | 349.35 ± 2.25 |

| Total polyphenol (mg GAE/100 g) | 1.31 ± 0.04 | 91.20 ± 1.29 |

| Free fatty acid (%) | 0.15 ± 0.03 | 0.17 ± 0.06% |

| Pasting Properties | ||

| Peak viscosity (cP) | 1086.00 | 737.00 |

| Trough viscosity (cP) | 1195.00 | 632.00 |

| Break down viscosity (cP) | 109.00 | 105.00 |

| Final viscosity (cP) | 1639.00 | 1197.00 |

| Set back Viscosity (cP) | 444.00 | 565.00 |

| Peak time (min) | 7.00 | 7.00 |

| Pasting Temperature (°C) | 88.80 | 95.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, S.; Baniwal, P.; Nayik, G.A.; Prasad, K.; Khan, K.A.; Ghramh, H.A.; Kumar, H.; Karabagias, I.K. Optimization and Development of Ready to Eat Chocolate Coated Roasted Flaked Rice as Instant Breakfast Food. Foods 2021, 10, 1658. https://doi.org/10.3390/foods10071658

Kumar S, Baniwal P, Nayik GA, Prasad K, Khan KA, Ghramh HA, Kumar H, Karabagias IK. Optimization and Development of Ready to Eat Chocolate Coated Roasted Flaked Rice as Instant Breakfast Food. Foods. 2021; 10(7):1658. https://doi.org/10.3390/foods10071658

Chicago/Turabian StyleKumar, Shiv, Poonam Baniwal, Gulzar Ahmad Nayik, Kamlesh Prasad, Khalid Ali Khan, Hamed A. Ghramh, Harish Kumar, and Ioannis Konstantinos Karabagias. 2021. "Optimization and Development of Ready to Eat Chocolate Coated Roasted Flaked Rice as Instant Breakfast Food" Foods 10, no. 7: 1658. https://doi.org/10.3390/foods10071658

APA StyleKumar, S., Baniwal, P., Nayik, G. A., Prasad, K., Khan, K. A., Ghramh, H. A., Kumar, H., & Karabagias, I. K. (2021). Optimization and Development of Ready to Eat Chocolate Coated Roasted Flaked Rice as Instant Breakfast Food. Foods, 10(7), 1658. https://doi.org/10.3390/foods10071658