Influence of Underutilized Unripe Banana (Cavendish) Flour in the Formulation of Healthier Chorizo

Abstract

:1. Introduction

2. Materials and Methods

2.1. Elaboration of Banana Flour

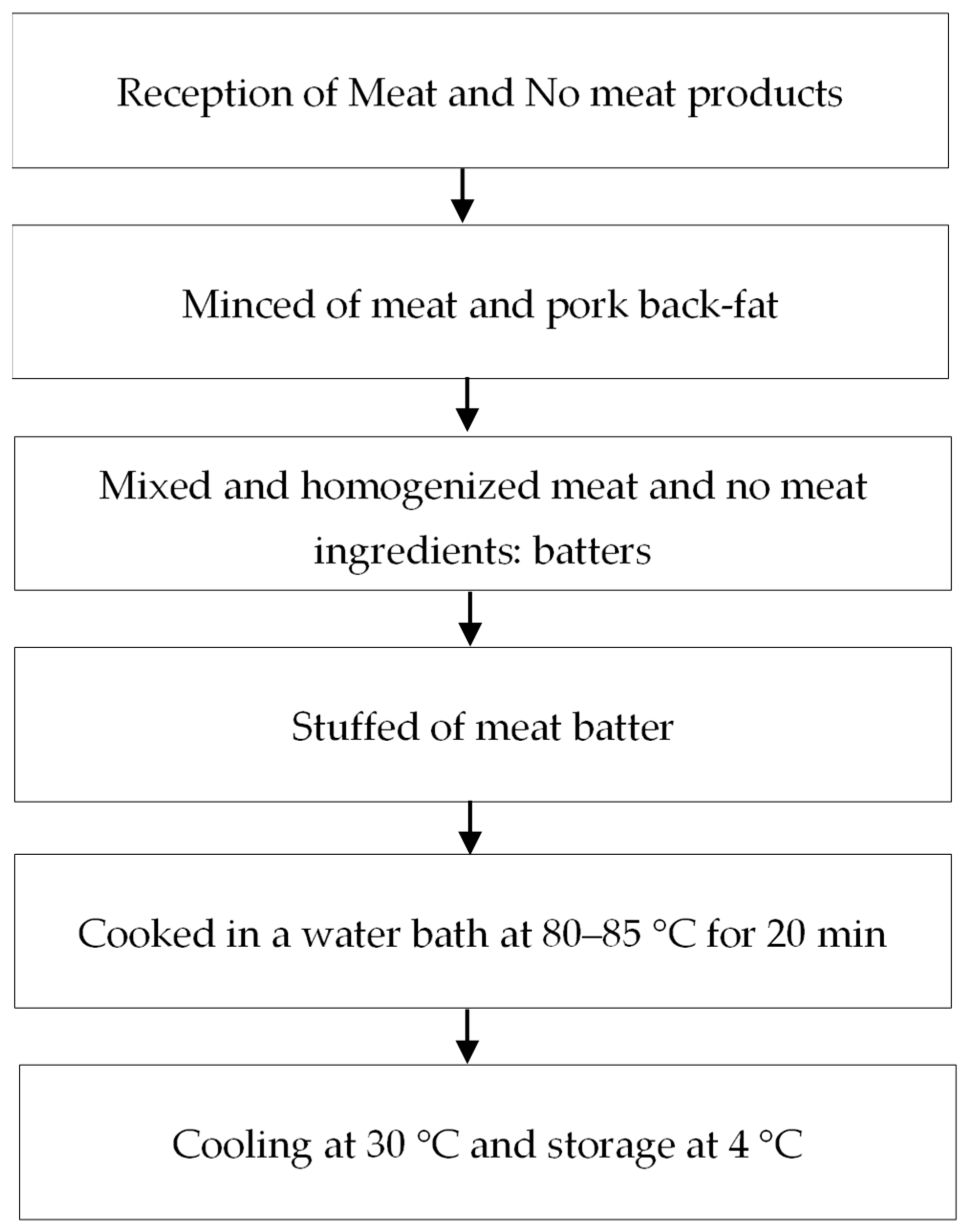

2.2. Preparation of Chorizos

2.3. Cooking Loss

2.4. Proximal Analysis

2.5. Energy Value

2.6. Acidity and pH

2.7. Microbiological Analysis

2.8. Texture

2.9. Color

2.10. Sensory Analysis

2.11. Experimental Analysis

3. Results and Discussion

3.1. Compositional Analysis

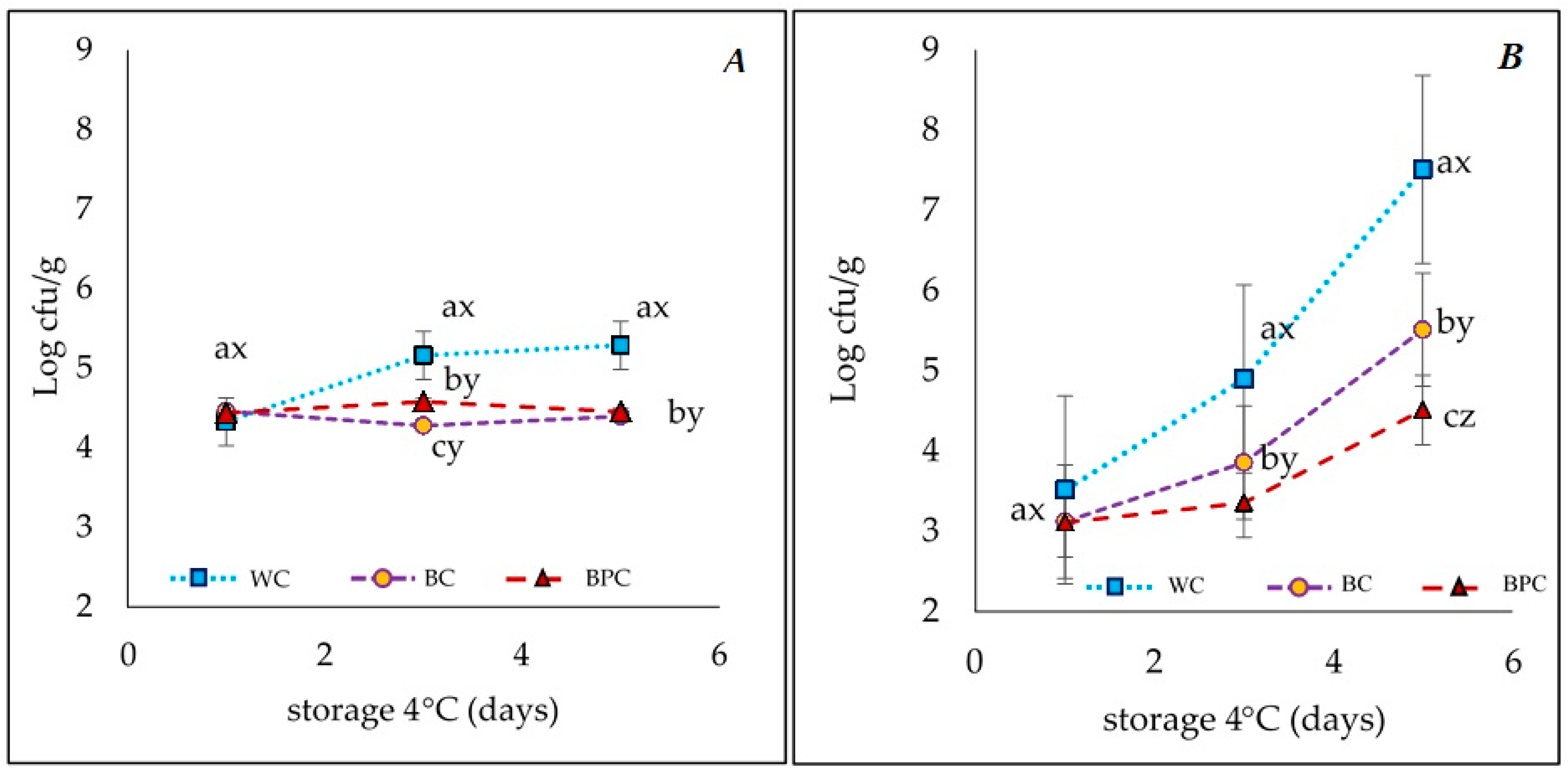

3.2. Microbiological Analysis

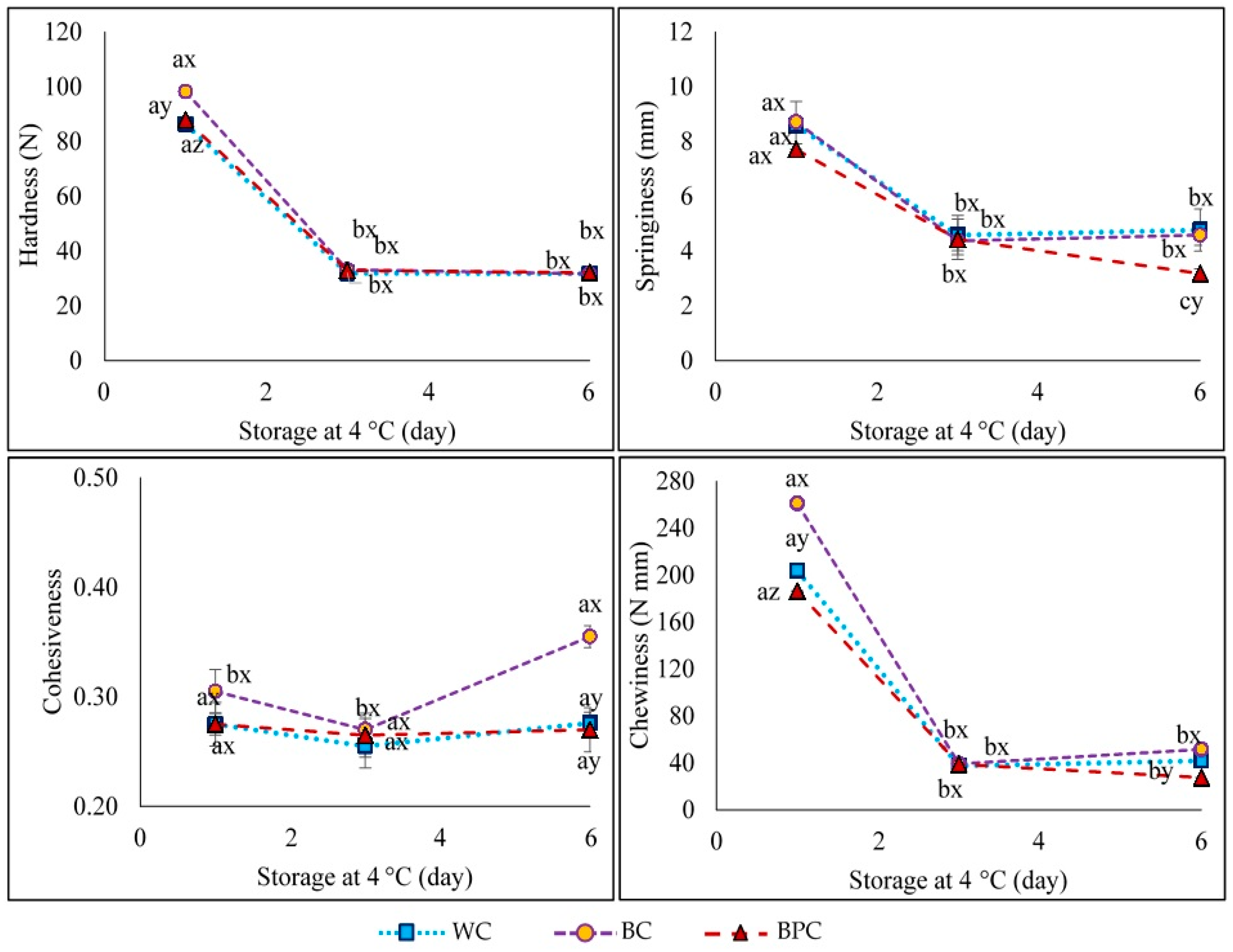

3.3. Textural Measurements

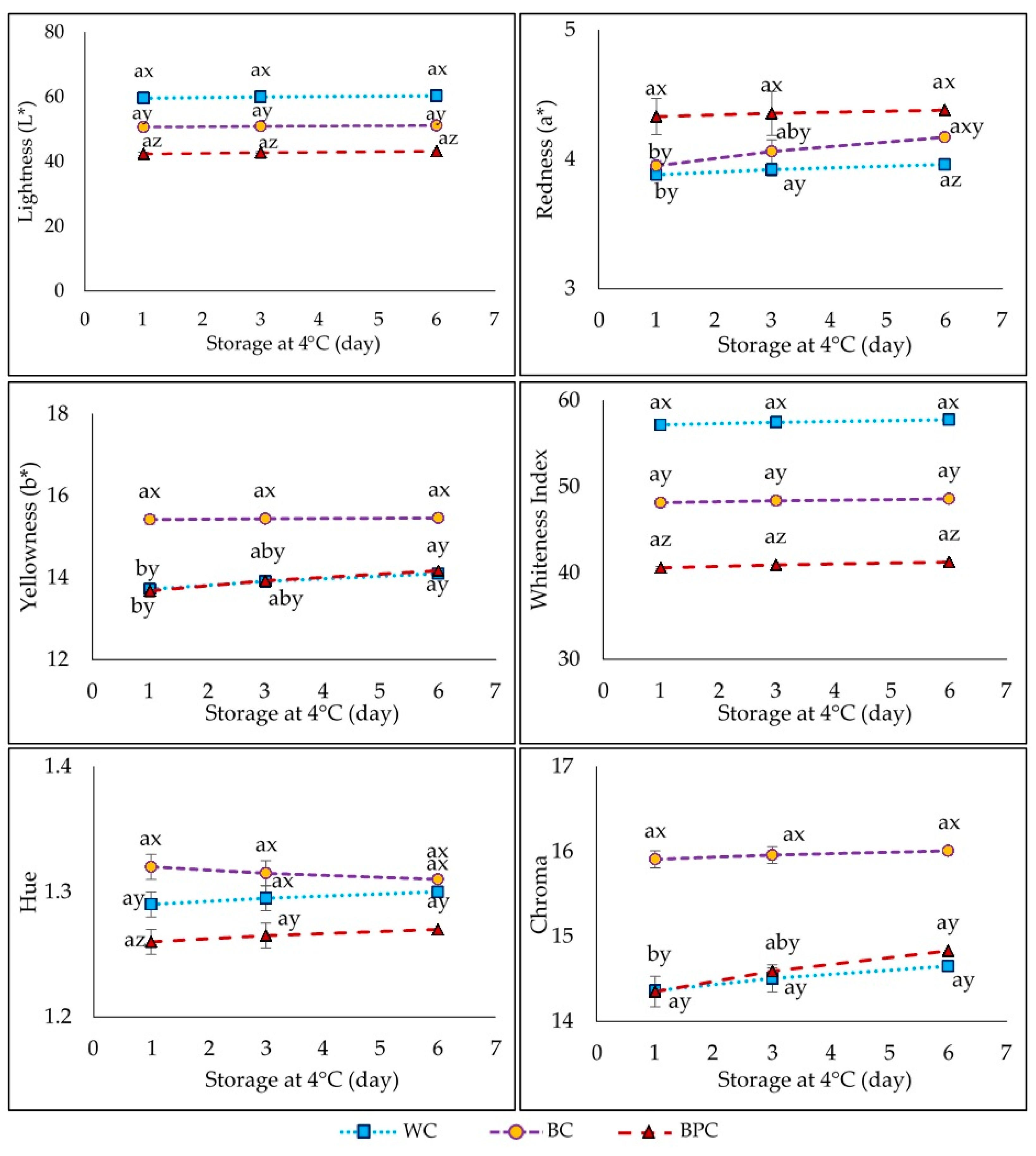

3.4. Color

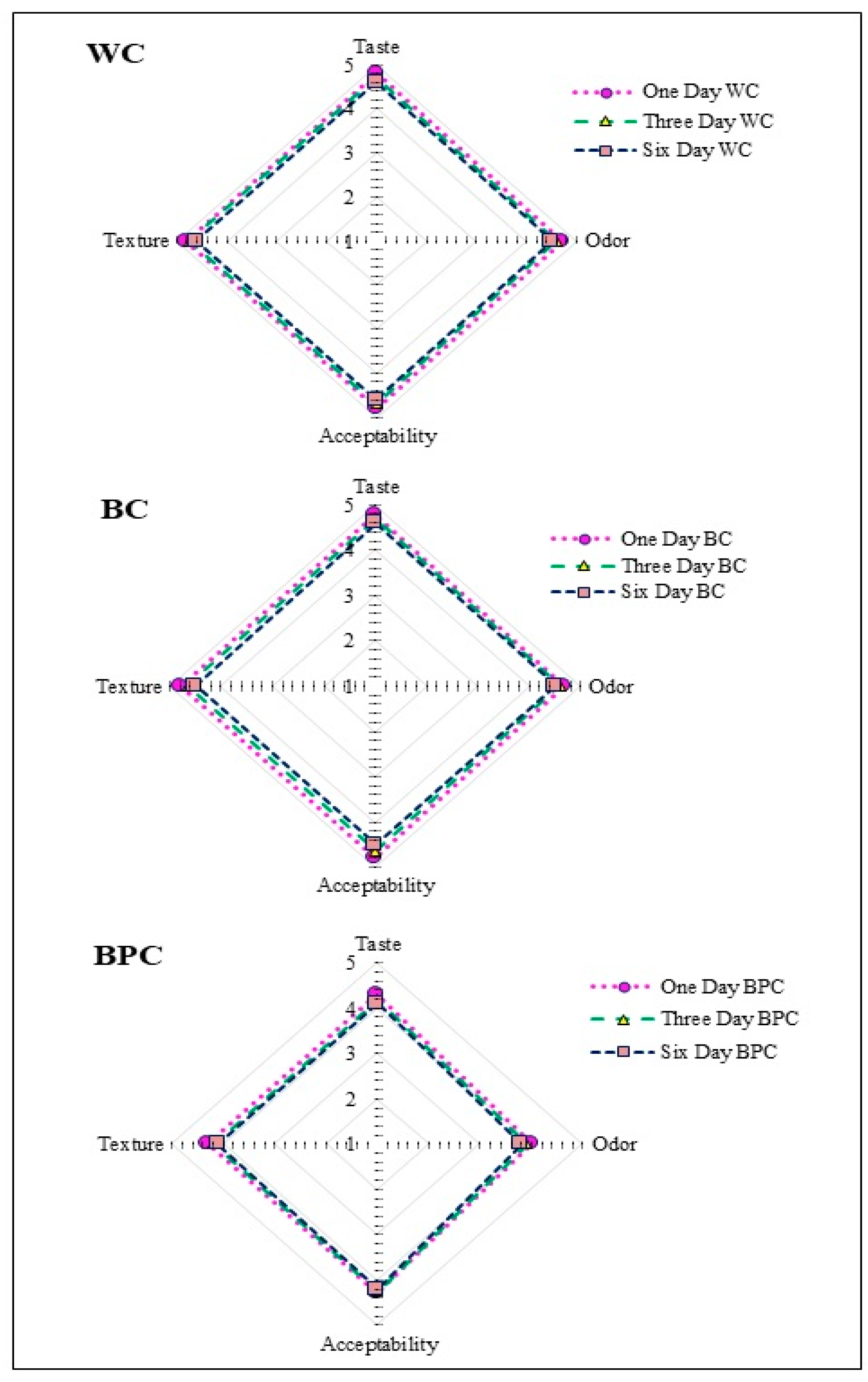

3.5. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Salazar, D.S.L.; Perez, L.; Valencia, A.; Acurio, L.; Gallegos, L.; Alvarez, F.; Amancha, P.; Galarza, C.; Valencia, M.; Rodriguez, C.; et al. Effect of Starter Cultures and Stuffing Time in the Quality of “Chorizo Ambateno”. J. Appl. Eng. Sci. 2017, 12, 5079–5083. [Google Scholar]

- Salazar, P.; García, M.L.; Selgas, M.D. Short-chain fructooligosaccharides as potential functional ingredient in dry fermented sausages with different fat levels. Int. J. Food Sci. 2009, 44, 1100–1107. [Google Scholar] [CrossRef]

- Muguerza, E.; Gimeno, O.; Ansorena, D.; Astiasarán, I. New formulations for healthier dry fermented sausages: A review. Trends Food Sci Technol. 2004, 15, 452–457. [Google Scholar] [CrossRef]

- Cierach, M.; Modzelewska-Kapituła, M.; Szaciło, K. The influence of carrageenan on the properties of low-fat frankfurters. Meat Sci. 2009, 82, 295–299. [Google Scholar] [CrossRef] [PubMed]

- Gómez, M.; Fonseca, S.; Cachaldora, A.; Carballo, J.; Franco, I. Effect of chestnuts intake by Celta pigs on lipolytic, oxidative and fatty acid profile changes during ripening and vacuum-packed storage of Galician “chorizo”. J. Food Compos. Anal. 2017, 56, 73–83. [Google Scholar] [CrossRef]

- Nowak, B.; Von Mueffling, T.; Grotheer, J.; Klein, G.; Watkinson, B.M. Energy Content, Sensory Properties, and Microbiological Shelf Life of German Bologna-Type Sausages Produced with Citrate or Phosphate and with Inulin as Fat Replacer. J. Food Sci. 2007, 72, S629–S638. [Google Scholar] [CrossRef]

- Jin, S.-K.; Kim, S.-H.; Choi, J.-S.; Yim, D.-G. Effect of diverse binder materials and their addition levels on physico-chemical characteristics of sausages. J. Food Meas. Charact. 2019, 13, 1558–1565. [Google Scholar] [CrossRef]

- Nacak, B.; Kavusan, H.S.; Sarı, B.; Can, H.; Serdaroglu, M. Collaborative effect of fat reduction and α-tocopherol incorporation on oxidative stability in beef sausages. IOP Conf. Ser. Earth Environ. Sci. 2019, 333, 012084. [Google Scholar] [CrossRef] [Green Version]

- Biswas, A.K. Reformulating Meat Products for Improving Nutrition and Health. In Reformulation as a Strategy for Developing Healthier Food Products: Challenges, Recent Developments and Future Prospects; Raikos, V., Ranawana, V., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 291–309. [Google Scholar]

- Ran, M.; Chen, C.; Li, C.; He, L.; Zeng, X. Effects of replacing fat with Perilla seed on the characteristics of meatballs. Meat Sci. 2020, 161, 107995. [Google Scholar] [CrossRef]

- Atashkar, M.; Hojjatoleslamy, M.; Sedaghat Boroujeni, L. The influence of fat substitution with κ-carrageenan, konjac, and tragacanth on the textural properties of low-fat sausage. Food Sci. Nutr. 2018, 6, 1015–1022. [Google Scholar] [CrossRef]

- Choi, Y.-S.; Choi, J.-H.; Han, D.-J.; Kim, H.-Y.; Lee, M.-A.; Jeong, J.-Y.; Chung, H.-J.; Kim, C.-J. Effects of replacing pork back fat with vegetable oils and rice bran fiber on the quality of reduced-fat frankfurters. Meat Sci. 2010, 84, 557–563. [Google Scholar] [CrossRef] [PubMed]

- Ninan, G.; Aswathy, K.; Joshy, C. Development of dietary fiber-incorporated fish sausage. ICAR-Cent. Inst. Fish. Tech. 2018, 4, 16. [Google Scholar]

- dos Santos, M.; Munekata, P.E.; Pateiro, M.; Magalhães, G.C.; Barretto, A.C.S.; Lorenzo, J.M.; Pollonio, M.A.R. Pork skin-based emulsion gels as animal fat replacers in hot-dog style sausages. LWT 2020, 132, 109845. [Google Scholar] [CrossRef]

- Muguerza, E.; Gimeno, O.; Ansorena, D.; Bloukas, J.; Astiasarán, I. Effect of replacing pork backfat with pre-emulsified olive oil on lipid fraction and sensory quality of Chorizo de Pamplona—A traditional Spanish fermented sausage. Meat Sci. 2001, 59, 251–258. [Google Scholar] [CrossRef]

- Scott, G.J. A review of root, tuber and banana crops in developing countries: Past, present and future. Int. J. Food Sci. 2021, 56, 1093–1114. [Google Scholar] [CrossRef] [PubMed]

- Choe, J.; Kim, H.-Y. Quality characteristics of reduced fat emulsion-type chicken sausages using chicken skin and wheat fiber mixture as fat replacer. Poult. Sci. 2019, 98, 2662–2669. [Google Scholar] [CrossRef]

- Barretto, A.C.d.S.; Pacheco, M.T.B.; Pollonio, M.A.R. Effect of the addition of wheat fiber and partial pork back fat on the chemical composition, texture and sensory property of low-fat bologna sausage containing inulin and oat fiber. Food Sci. Technol. 2015, 35, 100–107. [Google Scholar] [CrossRef] [Green Version]

- Ranucci, D.; Roila, R.; Andoni, E.; Braconi, P.; Branciari, R. Punica granatum and Citrus spp. extract mix affects spoilage microorganisms growth rate in vacuum-packaged cooked sausages made from pork meat, emmer wheat (Triticum dicoccum Schübler), almond (Prunus dulcis Mill.) and hazelnut (Corylus avellana L.). Foods 2019, 8, 664. [Google Scholar] [CrossRef] [Green Version]

- Salazar, D.; Arancibia, M.; Calderón, L.; López-Caballero, M.E.; Montero, M.P. Underutilized Green Banana (Musa acuminata AAA) Flours to Develop Fiber Enriched Frankfurter-Type Sausages. Foods 2021, 10, 1142. [Google Scholar] [CrossRef]

- Vásquez-Castillo, W.; Racines-Oliva, M.; Moncayo, P.; Viera, W.; Seraquive, M. Calidad del fruto y pérdidas poscosecha de banano orgánico Musa acuminata en el Ecuador. Enfoque UTE 2019, 10, 57–66. [Google Scholar] [CrossRef]

- MAGAP. Agricultural Products; Ministry of Agriculture, Livestock, Aquaculture and Fisheries: Quito, Ecuador, 2020. [Google Scholar]

- Alkarkhi, A.F.; bin Ramli, S.; Yong, Y.S.; Easa, A.M. Comparing physicochemical properties of banana pulp and peel flours prepared from green and ripe fruits. Food Chem. 2011, 129, 312–318. [Google Scholar] [CrossRef] [PubMed]

- Almeida, M.C.B.d.M.; Costa, S.d.S.; Cavalcanti, M.T.; Almeida, E.L. Characterization of Prata Banana (Musa AAB-Prata) Starch: Native and Modified by Annealing. Starch-Stärke 2020, 72, 1900137. [Google Scholar] [CrossRef]

- Gomes, S.; Vieira, B.; Barbosa, C.; Pinheiro, R. Evaluation of mature banana peel flour on physical, chemical, and texture properties of a gluten-free Rissol. J. Food Process. Preserv. 2020, e14441. [Google Scholar] [CrossRef]

- Martins, A.N.A.; Pasquali, M.A.d.B.; Schnorr, C.E.; Martins, J.J.A.; de Araújo, G.T.; Rocha, A.P.T. Development and characterization of blends formulated with banana peel and banana pulp for the production of blends powders rich in antioxidant properties. J. Food Sci. Technol. 2020, 56, 5289–5297. [Google Scholar] [CrossRef] [PubMed]

- Khoozani, A.; Kebede, B.; Birch, J.; Bekhit, A.E.-D.A. The effect of bread fortification with whole green banana flour on its physicochemical, nutritional and in vitro digestibility. Foods 2020, 9, 152. [Google Scholar] [CrossRef] [Green Version]

- Alves, d.S.; Lorenzo, J.M.; Gonçalves, C.A.; Santos, B.A.d.; Heck, R.T.; Cichoski, A.J.; Campagnol, P.C.B. Production of healthier bologna type sausages using pork skin and green banana flour as a fat replacers. Meat Sci. 2016, 121, 73–78. [Google Scholar] [CrossRef]

- Potter, M.D.; Jones, M.P.; Walker, M.M.; Koloski, N.A.; Keely, S.; Holtmann, G.; Talley, A.C.N.J. Incidence and prevalence of self-reported non-coeliac wheat sensitivity and gluten avoidance in Australia. Med. J. Aust. 2020, 212, 126–131. [Google Scholar] [CrossRef] [Green Version]

- AOAC. Official Methods of Analysis, 17th ed.; The Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Francis, F.J.; Clydesdale, F.M. Food Colorimetry: Theory and Applications; AVI Publishing Co. Inc.: Westport, CT, USA, 1975. [Google Scholar]

- Gooch, J. Whiteness index. In Encyclopedic Dictionary of Polymers; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Varga-Visi, É.; Toxanbayeva, B. Application of fat replacers and their effect on quality of comminuted meat products with low lipid content: A review. Acta Aliment. 2017, 46, 181–186. [Google Scholar] [CrossRef]

- Fuentes-Zaragoza, E.; Riquelme-Navarrete, M.J.; Sánchez-Zapata, E.; Pérez-Álvarez, J.A. Resistant starch as functional ingredient: A review. Food Res. Int. 2010, 43, 931–942. [Google Scholar] [CrossRef]

- Li, H.; Gidley, M.J.; Dhital, S. High-amylose starches to bridge the “Fiber Gap”: Development, structure, and nutritional functionality. Compr. Rev. Food Sci. Food Saf. 2019, 18, 362–379. [Google Scholar] [CrossRef] [Green Version]

- Choi, Y.-S.; Choi, J.-H.; Han, D.-J.; Kim, H.-Y.; Lee, M.-A.; Lee, E.-S.; Jeong, J.-Y.; Paik, H.-D.; Kim, C.-J. Effects of rice bran fiber on quality of low-fat tteokgalbi. Food Sci. Biotechnol. 2008, 17, 959–964. [Google Scholar]

- Pietrasik, Z.; Janz, J. Utilization of pea flour, starch-rich and fiber-rich fractions in low fat bologna. Food Res. Int. 2010, 43, 602–608. [Google Scholar] [CrossRef]

- Choi, Y.-S.; Kim, H.-W.; Hwang, K.-E.; Song, D.-H.; Choi, J.-H.; Lee, M.-A.; Chung, H.-J.; Kim, C.-J. Physicochemical properties and sensory characteristics of reduced-fat frankfurters with pork back fat replaced by dietary fiber extracted from makgeolli lees. Meat Sci. 2014, 96, 892–900. [Google Scholar] [CrossRef] [PubMed]

- Henning, S.S.C.; Tshalibe, P.; Hoffman, L.C. Physico-chemical properties of reduced-fat beef species sausage with pork back fat replaced by pineapple dietary fibres and water. LWT 2016, 74, 92–98. [Google Scholar] [CrossRef]

- Emaga, T.H.; Andrianaivo, R.H.; Wathelet, B.; Tchango, J.T.; Paquot, M. Effects of the stage of maturation and varieties on the chemical composition of banana and plantain peels. Food Chem. 2007, 103, 590–600. [Google Scholar] [CrossRef]

- Kayisu, K.; Hood, L.F.; Vansoest, P.J. Characterization of starch and fiber of banana fruit. J. Food Sci. 1981, 46, 1885–1890. [Google Scholar] [CrossRef]

- Mohapatra, D.; Mishra, S.; Sutar, N. Banana and Its By-Product Utilisation: An Overview; National Institute of Science Communication and Information Resources: New Delhi, India, 2010. [Google Scholar]

- Fernández-Ginés, J.; Fernández-López, J.; Sayas-Barberá, E.; Sendra, E.; Pérez-Alvarez, J. Effect of storage conditions on quality characteristics of bologna sausages made with citrus fiber. J. Food Sci. 2003, 68, 710–714. [Google Scholar] [CrossRef]

- EC. Regulation (Ec) No 1924/2006 of of 20 December 2006 on Nutrition and Health Claims Made on Foods; EC: Publications Office of the European Union: Luxembourg, 2007. [Google Scholar]

- Decker, E.A.; Park, Y. Healthier meat products as functional foods. Meat Sci. 2010, 86, 49–55. [Google Scholar] [CrossRef]

- Huang, S.; Tsai, Y.; Chen, C. Effects of wheat fiber, oat fiber, and inulin on sensory and physico-chemical properties of Chinese-style sausages. Asian-Australas. J. Anim. Sci. 2011, 24, 875–880. [Google Scholar] [CrossRef]

- Salcedo-Sandoval, L.; Cofrades, S.; Pérez, C.R.-C.; Solas, M.T.; Jiménez-Colmenero, F. Healthier oils stabilized in konjac matrix as fat replacers in n−3 PUFA enriched frankfurters. Meat Sci. 2013, 93, 757–766. [Google Scholar] [CrossRef]

- WHO. Diet, Nutrition and the Prevention of Chronic Diseases; Technical Report Series 916; World Health Organization: Geneva, Switzerland, 2003. [Google Scholar]

- Jiménez-Colmenero, F.; Carballo, J.; Cofrades, S. Healthier meat and meat products: Their role as functional foods. Meat Sci. 2001, 59, 5–13. [Google Scholar] [CrossRef]

- Fernández-Ginés, J.; Fernández-López, J.; Sayas-Barberá, E.; Sendra, E.; Pérez-Álvarez, J. Lemon albedo as a new source of dietary fiber: Application to bologna sausages. Meat Sci. 2004, 67, 7–13. [Google Scholar] [CrossRef] [PubMed]

- Mehta, N.; Ahlawat, S.; Sharma, D.; Dabur, R. Novel trends in development of dietary fiber rich meat products—A critical review. J. Food Sci. Technol. 2015, 52, 633–647. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gokoglu, N.; Yerlikaya, P.; Uran, H.; Topuz, O.K. The effect of modified atmosphere packaging on the quality and shelf life of frankfurter type-sausages. J. Food Qual. 2010, 33, 367–380. [Google Scholar] [CrossRef]

- Andrés, S.C.; Garcıa, M.; Zaritzky, N.E.; Califano, A.N. Storage stability of low-fat chicken sausages. J. Food Eng. 2006, 72, 311–319. [Google Scholar] [CrossRef]

- Hayes, J.; Canonico, I.; Allen, P. Effects of organic tomato pulp powder and nitrite level on the physicochemical, textural and sensory properties of pork luncheon roll. Meat Sci. 2013, 95, 755–762. [Google Scholar] [CrossRef]

- Sharma, H.; Mendiratta, S.; Agarwal, R.K.; Kumar, S.; Soni, A. Evaluation of anti-oxidant and anti-microbial activity of various essential oils in fresh chicken sausages. J. Food Sci. Technol. 2017, 54, 279–292. [Google Scholar] [CrossRef]

- Sachindra, N.; Sakhare, P.; Yashoda, K.; Rao, D.N. Microbial profile of buffalo sausage during processing and storage. Food Control 2005, 16, 31–35. [Google Scholar] [CrossRef]

- Wolter, H.; Laing, E.; Viljoen, B.C. Isolation and identification of yeasts associated with intermediate moisture meats. Food Technol. Biotechnol. 2000, 38, 69–76. [Google Scholar]

- Villarroel, P.; Gómez, C.; Vera, C.; Torres, J. Almidón resistente: Características tecnológicas e intereses fisiológicos. Rev. Chil. Nutr. 2018, 45, 271–278. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.-S.; Choi, S.-G.; Jeon, J.-T.; Park, G.-B.; Joo, S.-T. Textural and sensory properties of low fat pork sausages with added hydrated oatmeal and tofu as texture-modifying agents. Meat Sci. 2007, 75, 283–289. [Google Scholar] [CrossRef] [PubMed]

- Yadav, S. Development of dietary fibre enriched chicken sausages by incorporating corn bran, dried apple pomace and dried tomato pomace. Nutr. Food Sci. 2016, 46, 16–29. [Google Scholar] [CrossRef]

| Ingredients | Treatments | ||

|---|---|---|---|

| WC (g/100 g) | BC (g/100 g) | BPC (g/100 g) | |

| Beef | 31 | 31 | 31 |

| Pork | 27 | 27 | 27 |

| Frosty ice | 9 | 9 | 9 |

| Seasonings * | 4.4 | 4.4 | 4.4 |

| Sodium chloride | 1.6 | 1.6 | 1.6 |

| Pork back-fat | 15 | 3 | 3 |

| Wheat flour | 12 | - | - |

| Whole banana flour | - | 24 | - |

| Banana peel flour | - | - | 24 |

| Properties | WC | BC | BPC |

|---|---|---|---|

| Moisture (%) | 62.8 ± 0.84 a | 62.3 ± 0.58 a | 67.7 ± 0.86 b |

| Ash (%) | 3.20 ± 0.05 a | 2.96 ± 0.05 b | 2.96 ± 0.05 b |

| Protein (%) | 12.05 ± 0.27 a | 11.06 ± 0.65 b | 10.16 ± 0.01 c |

| Fat (%) | 13.44 ± 0.57 a | 7.88 ± 0.65 b | 8.71 ± 0.46 c |

| Total Carbohydrates (%) | 8.51 ± 0.75 a | 15.8 ± 0.50 b | 10.09 ± 0.23 c |

| Fiber (%) | 4.32 ± 0.28 a | 5.08 ± 0.46 a | 7.49 ± 0.13 b |

| Calories (Kcal/100 g) | 194.54 ± 0.73 a | 168.37 ± 2.36 b | 144.24 ± 1.57 c |

| Fat Calories (Kcal/100 g) | 62.19 ± 0.49 a | 42.14 ± 0.63 c | 54.26 ± 0.85 b |

| CH and F Calories (Kcal/100 g) | 13.02 ± 0.59 c | 31.55 ± 0.34 a | 15.57 ± 0.29 b |

| Protein Calories (Kcal/100 g) | 24.80 ± 0.69 a | 26.31 ± 0.23 a | 28.17 ± 1.02 a |

| pH | 6.93 ± 0.05 a | 6.84 ± 0.04 b | 6.88 ± 0.03 a,b |

| Acidity (%) | 0.09 ± 0.05 a | 0.08 ± 0.01 a | 0.07 ± 0.01 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salazar, D.; Arancibia, M.; Raza, K.; López-Caballero, M.E.; Montero, M.P. Influence of Underutilized Unripe Banana (Cavendish) Flour in the Formulation of Healthier Chorizo. Foods 2021, 10, 1486. https://doi.org/10.3390/foods10071486

Salazar D, Arancibia M, Raza K, López-Caballero ME, Montero MP. Influence of Underutilized Unripe Banana (Cavendish) Flour in the Formulation of Healthier Chorizo. Foods. 2021; 10(7):1486. https://doi.org/10.3390/foods10071486

Chicago/Turabian StyleSalazar, Diego, Mirari Arancibia, Karen Raza, María Elvira López-Caballero, and Maria Pilar Montero. 2021. "Influence of Underutilized Unripe Banana (Cavendish) Flour in the Formulation of Healthier Chorizo" Foods 10, no. 7: 1486. https://doi.org/10.3390/foods10071486

APA StyleSalazar, D., Arancibia, M., Raza, K., López-Caballero, M. E., & Montero, M. P. (2021). Influence of Underutilized Unripe Banana (Cavendish) Flour in the Formulation of Healthier Chorizo. Foods, 10(7), 1486. https://doi.org/10.3390/foods10071486