Effect of Drying Methods on Properties of Potato Flour and Noodles Made with Potato Flour

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Potato Flours

2.3. Moisture and Total Starch Content of Potato Flour

2.4. Scanning Electron Microscopy

2.5. X-ray Diffraction (XRD)

2.6. Laser Confocal Micro-Raman (LCM-Raman) Spectroscopy

2.7. Differential Scanning Calorimetry (DSC)

2.8. Pasting Viscosity and Gel Textural Analysis

2.9. Swelling Power and Starch Solubility

2.10. Preparation of the Noodles Made with Potato Flour

2.11. Color Analysis of Noodles

2.12. Textural Analysis (TPA) of Fresh Noodles

2.13. Statistical Analysis

3. Results

3.1. Moisture and Total Starch Content of Potato Flour

3.2. Granule Morphology

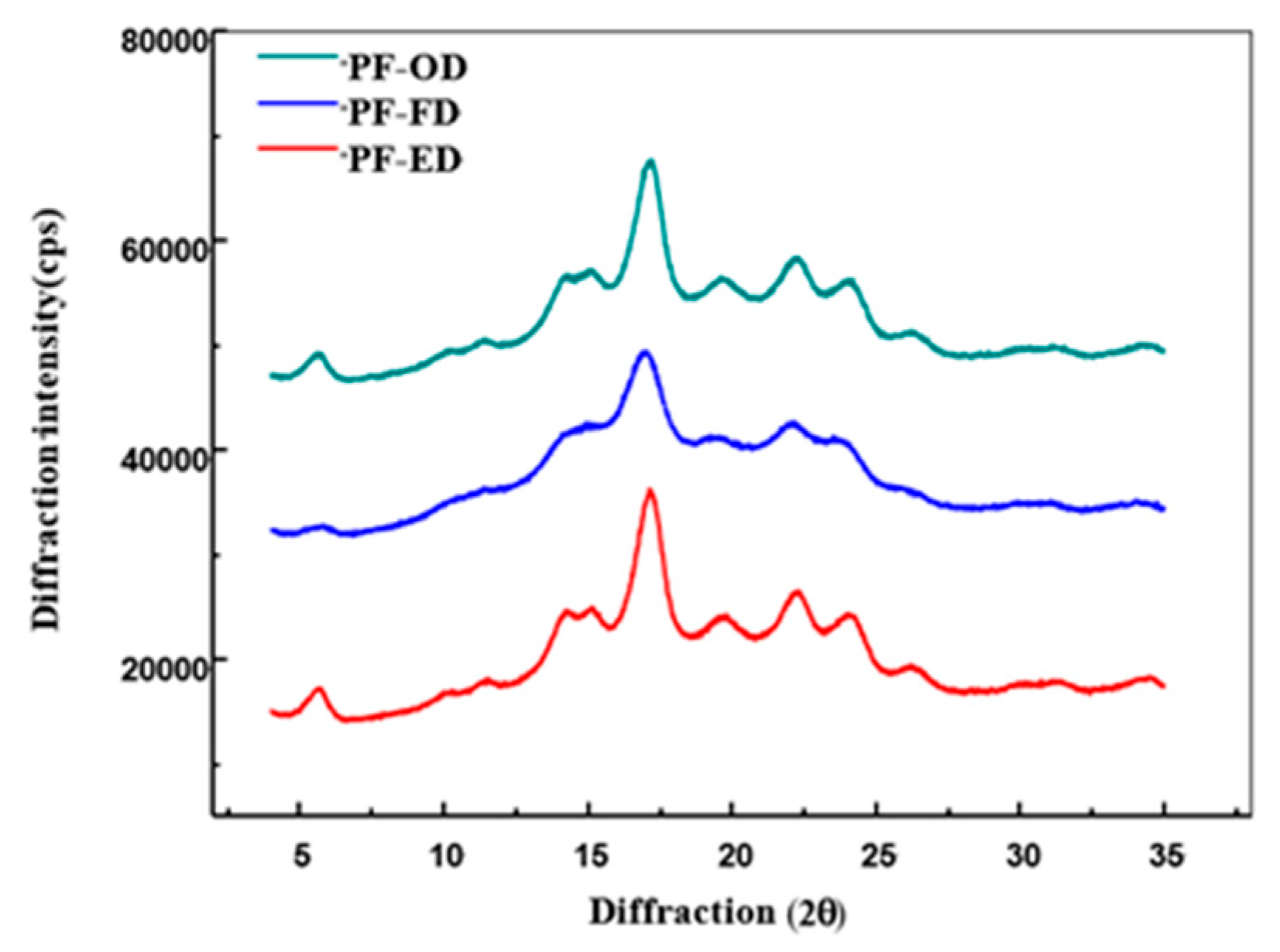

3.3. X-ray Diffraction (XRD)

3.4. LCM-Raman Spectroscopy

3.5. Thermal Properties

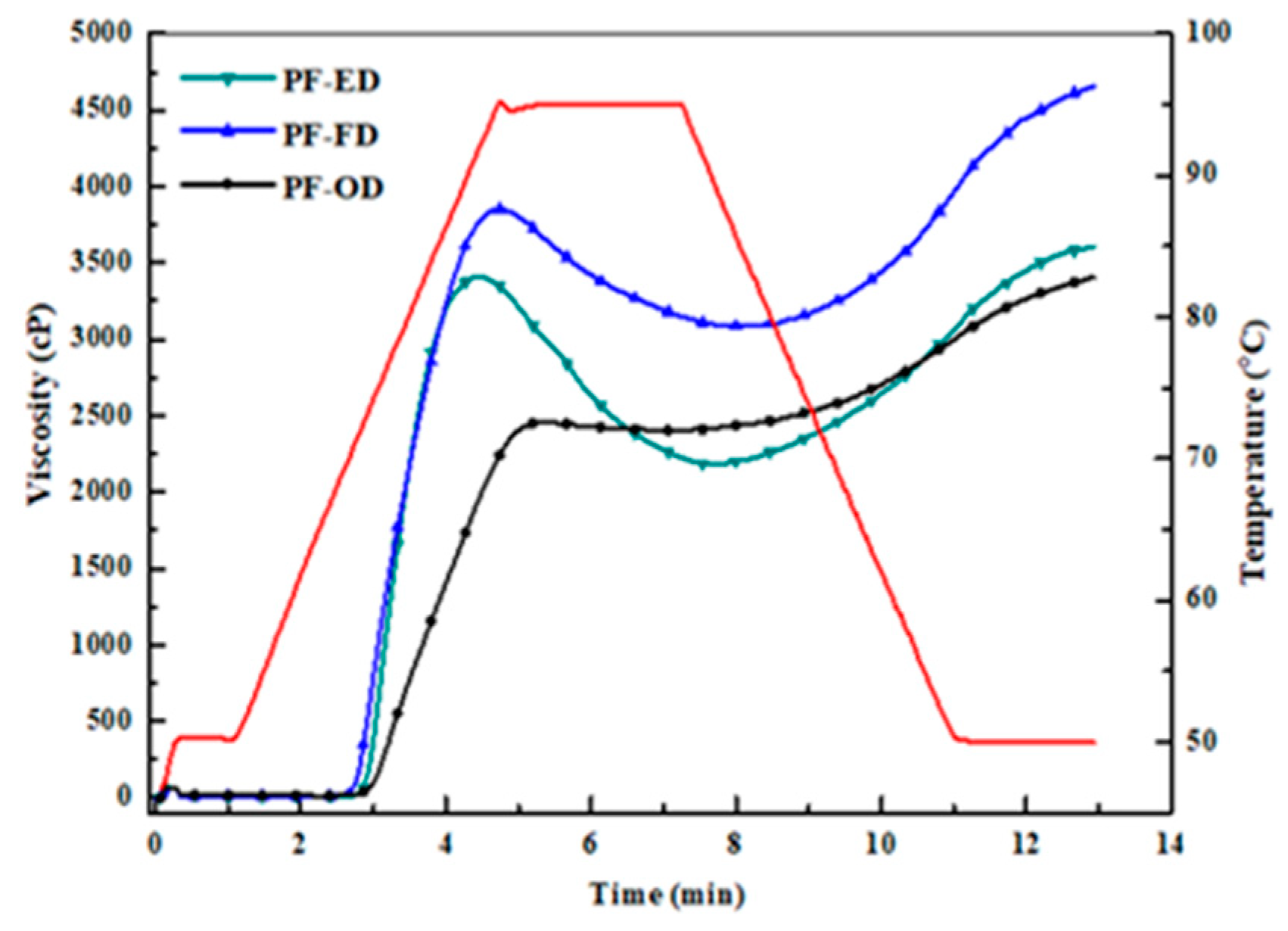

3.6. Pasting Properties

3.7. Gel Textural Analysis

3.8. Swelling Power and Starch Solubility

3.9. Preparation of the Fresh Potato Noodles

3.10. Color of Potato Noodles

3.11. Textural Profile Analysis (TPA)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmed, S.; Zhou, X.; Pang, Y.; Xu, Y.; Tong, C.; Bao, J. Genetic diversity of potato genotypes estimated by starch physicochemical properties and microsatellite markers. Food Chem. 2018, 257, 368–375. [Google Scholar] [CrossRef]

- Ahmed, S.; Zhou, X.; Pang, Y.; Jin, L.; Bao, J. Improving Starch-Related Traits in Potato Crops: Achievements and Future Challenges. Starch Stärke 2018, 70, 1700113. [Google Scholar] [CrossRef]

- Larder, C.E.; Abergel, M.; Kubow, S.; Donnelly, D.J. Freeze-drying affects the starch digestibility of cooked potato tubers. Food Res. Int. 2018, 103, 208–214. [Google Scholar] [CrossRef]

- Bach, S.; Yada, R.Y.; Bizimungu, B.; Fan, M.; Sullivan, J.A. Genotype by Environment Interaction Effects on Starch Content and Digestibility in Potato (Solanum tu-berosum L.). J. Agric. Food Chem. 2013, 61, 3941–3948. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, K.; Hasjim, J.; Li, E.; Flanagan, B.M.; Gidley, M.J.; Dhital, S. Freeze-Drying Changes the Structure and Digestibility of B-Polymorphic Starches. J. Agric. Food Chem. 2014, 62, 1482–1491. [Google Scholar] [CrossRef]

- Malumba, P.; Massaux, C.; Deroanne, C.; Masimango, T.; Béra, F. Influence of drying temperature on functional properties of wet-milled starch granules. Carbohydr. Polym. 2009, 75, 299–306. [Google Scholar] [CrossRef]

- Setiawan, S.; Widjaja, H.; Rakphongphairoj, V.; Jane, J.-L. Effects of Drying Conditions of Corn Kernels and Storage at an Elevated Humidity on Starch Structures and Properties. J. Agric. Food Chem. 2010, 58, 12260–12267. [Google Scholar] [CrossRef]

- Wang, S.; Liu, C.; Wang, S. Drying methods used in starch isolation change properties of C-type chestnut (Castanea mollissima) starches. LWT 2016, 73, 663–669. [Google Scholar] [CrossRef]

- Ahmed, J.; Al-Attar, H. Effect of drying method on rheological, thermal, and structural properties of chestnut flour doughs. Food Hydrocoll. 2015, 51, 76–87. [Google Scholar] [CrossRef]

- Cruz, B.R.; Abraão, A.S.; Lemos, A.M.; Nunes, F.M. Chemical composition and functional properties of native chestnut starch (Castanea sativa Mill). Carbohydr. Polym. 2013, 94, 594–602. [Google Scholar] [CrossRef]

- Liu, X.-L.; Mu, T.-H.; Sun, H.-N.; Zhang, M.; Chen, J.-W. Influence of potato flour on dough rheological properties and quality of steamed bread. J. Integr. Agric. 2016, 15, 2666–2676. [Google Scholar] [CrossRef]

- Wang, S.; Copeland, L. Phase transitions of pea starch over a wide range of water content. J. Agric. Food Chem. 2012, 60, 6439. [Google Scholar] [CrossRef]

- Wang, S.; Copeland, L. New insights into loss of swelling power and pasting profiles of acid hydrolyzed starch granules. Starch Stärke 2012, 64, 538–544. [Google Scholar] [CrossRef]

- Li, M.; Luo, L.-J.; Zhu, K.-X.; Guo, X.-N.; Peng, W.; Zhou, H.-M. Effect of vacuum mixing on the quality characteristics of fresh noodles. J. Food Eng. 2012, 110, 525–531. [Google Scholar] [CrossRef]

- Wang, S.; Wang, J.; Wang, S.; Wang, S. Annealing improves paste viscosity and stability of starch. Food Hydrocoll. 2017, 62, 203–211. [Google Scholar] [CrossRef]

- Hormdok, R.; Noomhorm, A. Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT 2007, 40, 1723–1731. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Kaur, M.; Mukesh. Studies on noodle quality of potato and rice starches and their blends in relation to their physicochemical, pasting and gel textural properties. LWT 2010, 43, 1289–1293. [Google Scholar] [CrossRef]

- Pu, H.; Wei, J.; Wang, L.; Huang, J.; Chen, X.; Luo, C.; Liu, S.; Zhang, H. Effects of potato/wheat flours ratio on mixing properties of dough and quality of noodles. J. Cereal Sci. 2017, 76, 236–242. [Google Scholar] [CrossRef]

- Chen, Z.; Schols, H.; Voragen, A. Physicochemical Properties of Starches Obtained from Three Varieties of Chinese Sweet Potatoes. J. Food Sci. 2003, 68, 431–437. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, F.; Guo, P.; Dong, S.; Li, H. Effect of wheat flour substitution with potato pulp on dough rheology, the quality of steamed bread and in vitro starch digestibility. LWT 2019, 111, 527–533. [Google Scholar] [CrossRef]

- Singh, J.; Singh, N.; Sharma, T.; Saxena, S. Physicochemical, rheological and cookie making properties of corn and potato flours. Food Chem. 2003, 83, 387–393. [Google Scholar] [CrossRef]

- Linlaud, N.E.; Puppo, M.C.; Ferrero, C. Effect of Hydrocolloids on Water Absorption of Wheat Flour and Farinograph and Textural Characteristics of Dough. Cereal Chem. J. 2009, 86, 376–382. [Google Scholar] [CrossRef]

- Yadav, B.S.; Yadav, R.B.; Kumari, M.; Khatkar, B.S. Studies on suitability of wheat flour blends with sweet potato, colocasia and water chestnut flours for noodle making. LWT 2014, 57, 352–358. [Google Scholar] [CrossRef]

- Zaidul, I.; Norulaini, N.N.; Omar, A.M.; Yamauchi, H.; Noda, T. RVA analysis of mixtures of wheat flour and potato, sweet potato, yam, and cassava starches. Carbohydr. Polym. 2007, 69, 784–791. [Google Scholar] [CrossRef]

- Guo, X.-N.; Wei, X.-M.; Zhu, K.-X. The impact of protein cross-linking induced by alkali on the quality of buckwheat noodles. Food Chem. 2017, 221, 1178–1185. [Google Scholar] [CrossRef]

| Samples | Moisture (%) | Total Starch Content (%) | XRD Crystallinity (%) | FWHM at 480 cm−1 | Swelling Power (g/g) | Starch Solubility (%) |

|---|---|---|---|---|---|---|

| PF-ED | 10.5 ± 0.2 c | 70.5 ± 0.9 a | 34.2 | 13.8 ± 0.3 a | 15.2 ± 0.2 b | 7.1 ± 0.6 b |

| PF-FD | 5.8 ± 0.1 a | 75.4 ± 0.5 c | 31.3 | 16.8 ± 0.4 c | 12.8 ± 0.0 a | 4.6 ± 0.2 a |

| PF-OD | 8.7 ± 0.3 b | 73.5 ± 0.2 b | 33.5 | 14.9 ± 0.5 b | 15.1 ± 0.2 b | 7.3 ± 0.8 b |

| Samples | To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) |

|---|---|---|---|---|

| PF-ED | 64.6 ± 0.1 b | 68.4 ± 0.1 b | 73.6 ± 0.1 b | 14.5 ± 0.0 b |

| PF-FD | 61.5 ± 0.1 a | 66.8 ± 0.1 a | 72.5 ± 0.2 a | 13.4 ± 0.3 a |

| PF-OD | 65.0 ± 0.1 c | 68.8 ± 0.2 c | 73.7 ± 0.1 b | 14.4 ± 0.3 b |

| Samples | PV (cP) | TV (cP) | BD (cP) | FV (cP) | SB (cP) | PT (°C) |

|---|---|---|---|---|---|---|

| PF-ED | 3431.7 ± 22.5 b | 2181.7 ± 2.5 a | 1250.0 ± 25.0 c | 3556.0 ± 49.0 a | 1406.0 ± 15.0 b | 72.6 ± 0.1 b |

| PF-FD | 3821.0 ± 31.0 c | 3055.0 ± 31.0 c | 766.3 ± 0.6 b | 4608.7 ± 49.5 b | 1553.7 ± 18.5 c | 70.2 ± 0.1 a |

| PF-OD | 2516.7 ± 58.5 a | 2472.0 ± 67.0 b | 44.7 ± 8.5 a | 3548.7 ± 143.5 a | 1076.7 ± 76.5 a | 73.7 ± 0.3 c |

| Samples | Hardness (N) | Springiness | Cohesiveness | Gumminess | Chewiness | Resilience |

|---|---|---|---|---|---|---|

| PF-ED | 525.3 ± 5.2 b | 0.86 ± 0.00 a | 0.82 ± 0.03 c | 430.1 ± 19.1 c | 371.2 ± 17.8 b | 0.61 ± 0.04 c |

| PF-FD | 373.0 ± 23.5 a | 0.95 ± 0.02 b | 0.78 ± 0.00 b | 290.9 ± 20.1 a | 276.4 ± 23.5 a | 0.56 ± 0.01 b |

| PF-OD | 495.9 ± 40.6 b | 0.85 ± 0.04 a | 0.69 ± 0.01 a | 343.1 ± 33.4 b | 293.2 ± 43.5 a | 0.45 ± 0.01 a |

| Samples | L* | a* | b* |

|---|---|---|---|

| WFN | 94.54 | 0.01 | 7.52 |

| PFN-ED10% | 91.87 | 0.27 | 7.27 |

| PFN-ED20% | 90.76 | 0.45 | 7.17 |

| PFN-ED30% | 89.07 | 0.63 | 7.62 |

| PFN-ED40% | 87.40 | 0.80 | 8.02 |

| PFN-ED50% | 86.22 | 0.94 | 8.51 |

| PFN-FD10% | 92.64 | 0.11 | 7.06 |

| PFN-FD20% | 91.23 | 0.21 | 7.04 |

| PFN-FD30% | 89.98 | 0.32 | 7.39 |

| PFN-FD40% | 89.11 | 0.43 | 7.46 |

| PFN-OD10% | 91.43 | 0.36 | 7.12 |

| PFN-OD20% | 89.28 | 0.68 | 7.46 |

| PFN-OD30% | 86.93 | 0.96 | 7.87 |

| PFN-OD40% | 85.24 | 1.17 | 8.51 |

| PFN-OD50% | 83.46 | 1.37 | 8.89 |

| Samples | Hardness (N) | Springiness | Cohesiveness | Gumminess | Chewiness | Resilience |

|---|---|---|---|---|---|---|

| WFN | 7604.3 ± 68.1 a | 0.29 ± 0.01 a | 0.33 ± 0.01 d,e | 2697.6 ± 150.2 b,c | 780.7 ± 81.0 a | 0.25 ± 0.02 b,c |

| PFN-EDPF10% | 8675.4 ± 70.0 b | 0.30 ± 0.01 a | 0.30 ± 0.01 b | 2399.7 ± 246.0 a,b | 719.3 ± 74.5 a | 0.25 ± 0.01 b |

| PFN-EDPF20% | 9455.9 ± 9.9 c | 0.35 ± 0.01 c,d | 0.32 ± 0.01 c,d | 3186.6 ± 116.3 d,e | 1107.4 ± 80.0 b,c | 0.27 ± 0.01 c,d |

| PFN-EDPF30% | 11,601.7 ± 107.4 f | 0.38 ± 0.01 e | 0.34 ± 0.01 f,g | 3889.3 ± 194.4 f | 1503.5 ± 102.9 e | 0.29 ± 0.01 e,f |

| PFN-EDPF40% | 12,784.1 ± 193.2 g | 0.41 ± 0.01 f | 0.34 ± 0.00 f,g | 4348.6 ± 36.6 g | 1793.9 ± 20.7 f | 0.30 ± 0.01 f |

| PFN-EDPF50% | 15,325.6 ± 17.4 j | 0.46 ± 0.01 g | 0.36 ± 0.00 h | 5254.0 ± 274.9 i | 2388.2 ± 66.3 h | 0.33 ± 0.01 g |

| PFN-FDPF10% | 9867.0 ± 87.8 d | 0.30 ± 0.01 a | 0.31 ± 0.00 c | 2609.1 ± 448.5 b,c | 774.7 ± 149.2 a | 0.27 ± 0.00 d |

| PFN-FDPF20% | 10,805.6 ± 132.9 e | 0.32 ± 0.00 b | 0.32 ± 0.01 c,d | 3495.4 ± 4.6 e | 1123.6 ± 13.5 b,c | 0.28 ± 0.00 d |

| PFN-FDPF30% | 14,495.0 ± 36.0 i | 0.36 ± 0.02 d | 0.38 ± 0.01 i | 5678.0 ± 386.3 j | 2051.9 ± 90.1 g | 0.34 ± 0.01 g |

| PFN-FDPF40% | 15,737.9 ± 107.9 j | 0.43 ± 0.00 f | 0.38 ± 0.01 i | 6224.2 ± 234.8 k | 2645.4 ± 93.9 i | 0.36 ± 0.01 h |

| PFN-ODPF10% | 8517.4 ± 100.5 b | 0.30 ± 0.01 a | 0.29 ± 0.01 a,b | 2193.0 ± 189.6 a | 664.8 ± 81.3 a | 0.25 ± 0.01 b,c |

| PFN-ODPF20% | 9298.8 ± 17.3 c | 0.33 ± 0.00 b,c | 0.29 ± 0.01 a | 2364.6 ± 51.1 a,b | 790.7 ± 9.2 a | 0.23 ± 0.00 a |

| PFN-ODPF30% | 12,343.1 ± 179.6 g | 0.35 ± 0.01 c,d | 0.34 ± 0.00 f,g | 4143.6 ± 0.9 f,g | 1431.1 ± 21.3 d,e | 0.30 ± 0.00 e,f |

| PFN-ODPF40% | 13,591.0 ± 150.5 h | 0.49 ± 0.00 h | 0.35 ± 0.00 g | 4689.0 ± 7.6 h | 2536.5 ± 243.7 i | 0.30 ± 0.01 f |

| PFN-ODPF50% | 16,573.7 ± 301.9 k | 0.53 ± 0.02 i | 0.38 ± 0.00 i | 6379.3 ± 249.7 k | 3348.0 ± 6.8 j | 0.35 ± 0.01 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, H.; Zhou, J.; Yu, J.; Wang, S. Effect of Drying Methods on Properties of Potato Flour and Noodles Made with Potato Flour. Foods 2021, 10, 1115. https://doi.org/10.3390/foods10051115

Bao H, Zhou J, Yu J, Wang S. Effect of Drying Methods on Properties of Potato Flour and Noodles Made with Potato Flour. Foods. 2021; 10(5):1115. https://doi.org/10.3390/foods10051115

Chicago/Turabian StyleBao, Huan, Jiaping Zhou, Jinglin Yu, and Shujun Wang. 2021. "Effect of Drying Methods on Properties of Potato Flour and Noodles Made with Potato Flour" Foods 10, no. 5: 1115. https://doi.org/10.3390/foods10051115

APA StyleBao, H., Zhou, J., Yu, J., & Wang, S. (2021). Effect of Drying Methods on Properties of Potato Flour and Noodles Made with Potato Flour. Foods, 10(5), 1115. https://doi.org/10.3390/foods10051115