Assessment of Sensory and Texture Profiles of Grape Seeds at Real Maturity Stages Using Image Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Image Acquisition and Appearance Measurements

2.3. Sensory Analysis of Grape Seeds

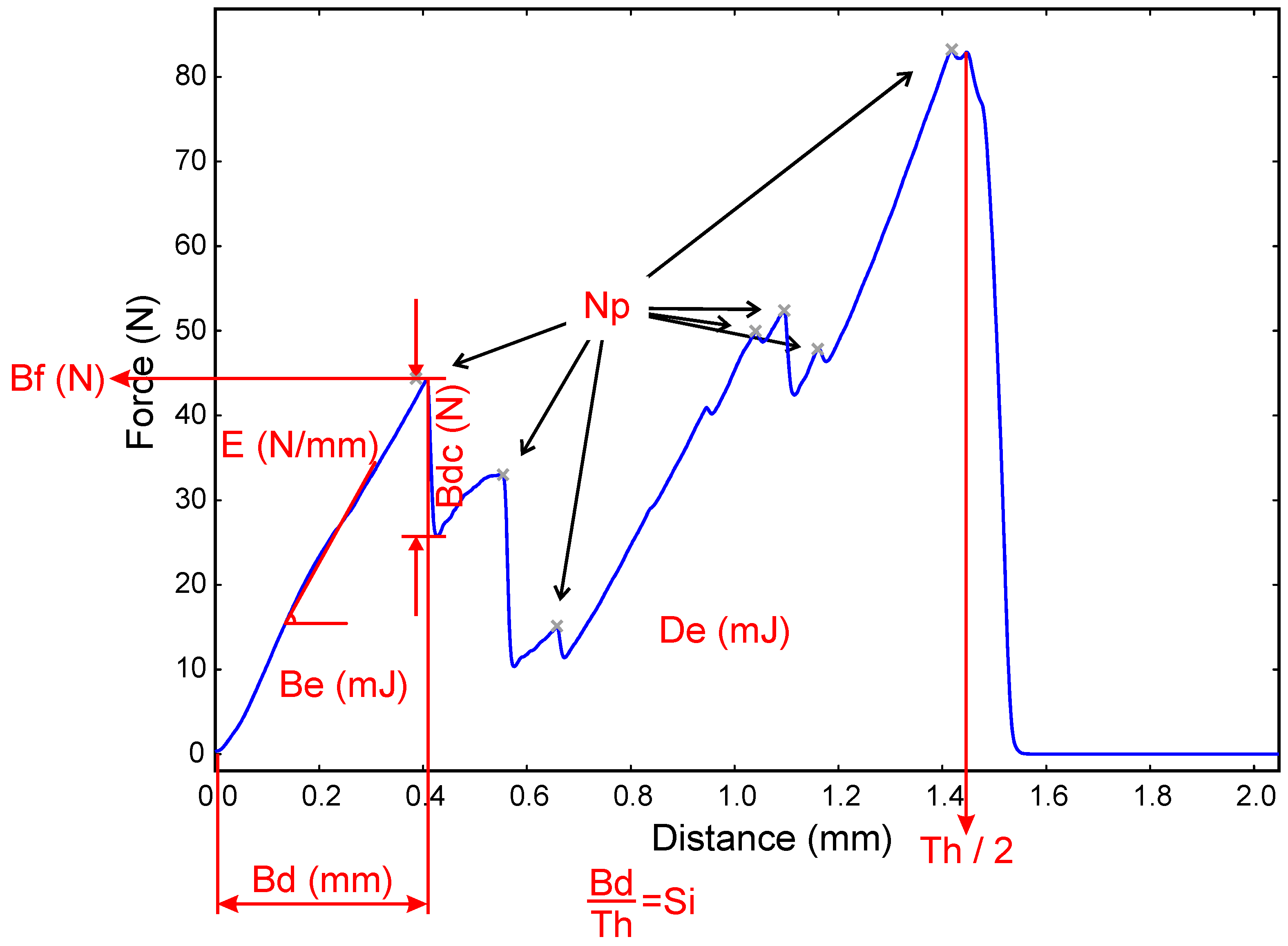

2.4. Instrumental Texture Analysis

2.5. Statistical Analysis

3. Results and Discussion

3.1. General Parameters

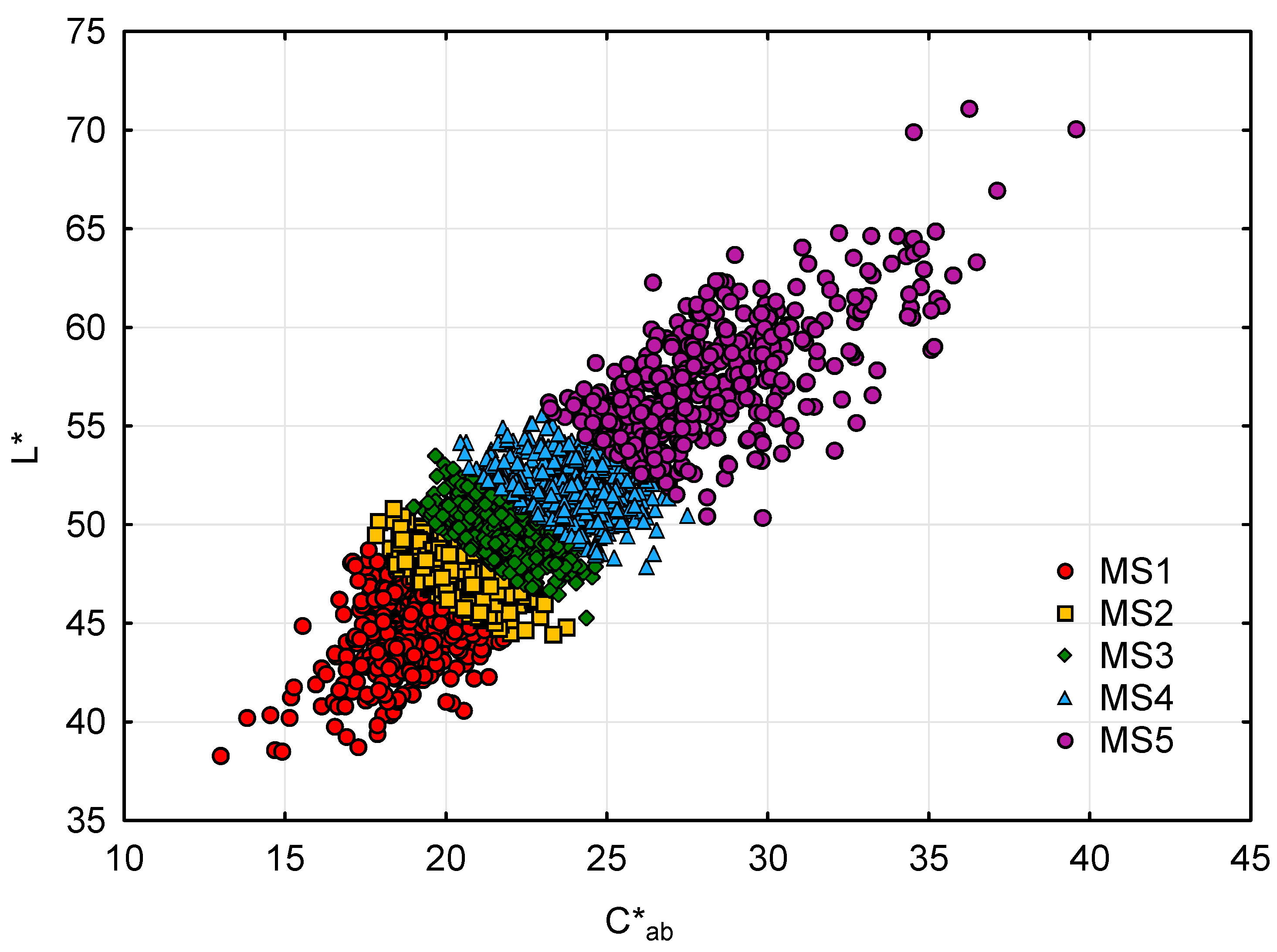

3.2. DigiEye® Classification

3.3. Sensory Descriptive Analysis Procedure

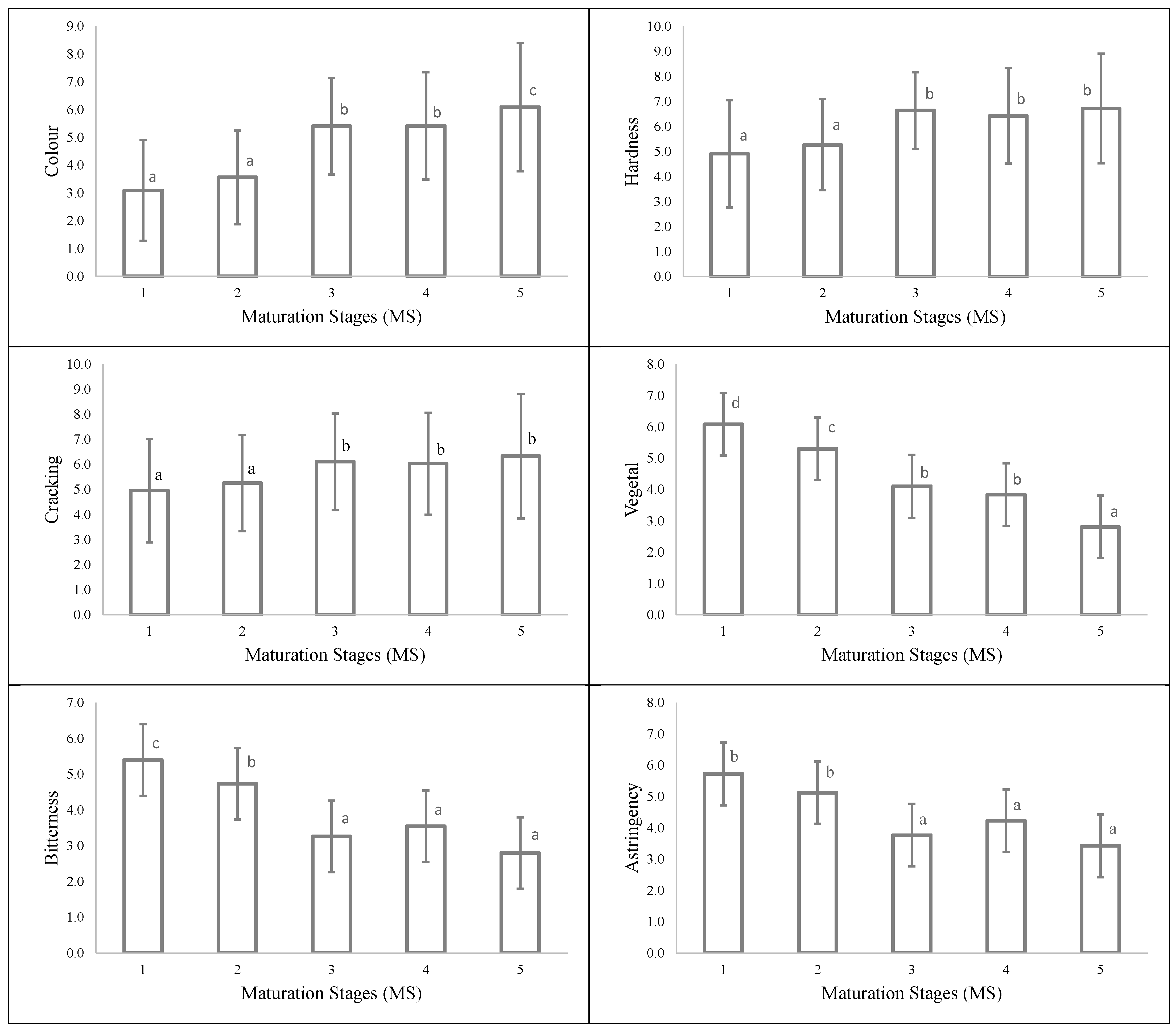

3.3.1. Training Sessions

3.3.2. Evaluation of Panellist Performances

3.3.3. Accurate Evaluation of the Sensory Parameters at Each Maturation Stage

3.4. Evolution of Instrumental Textural Parameters along the Grape Seed Ripening

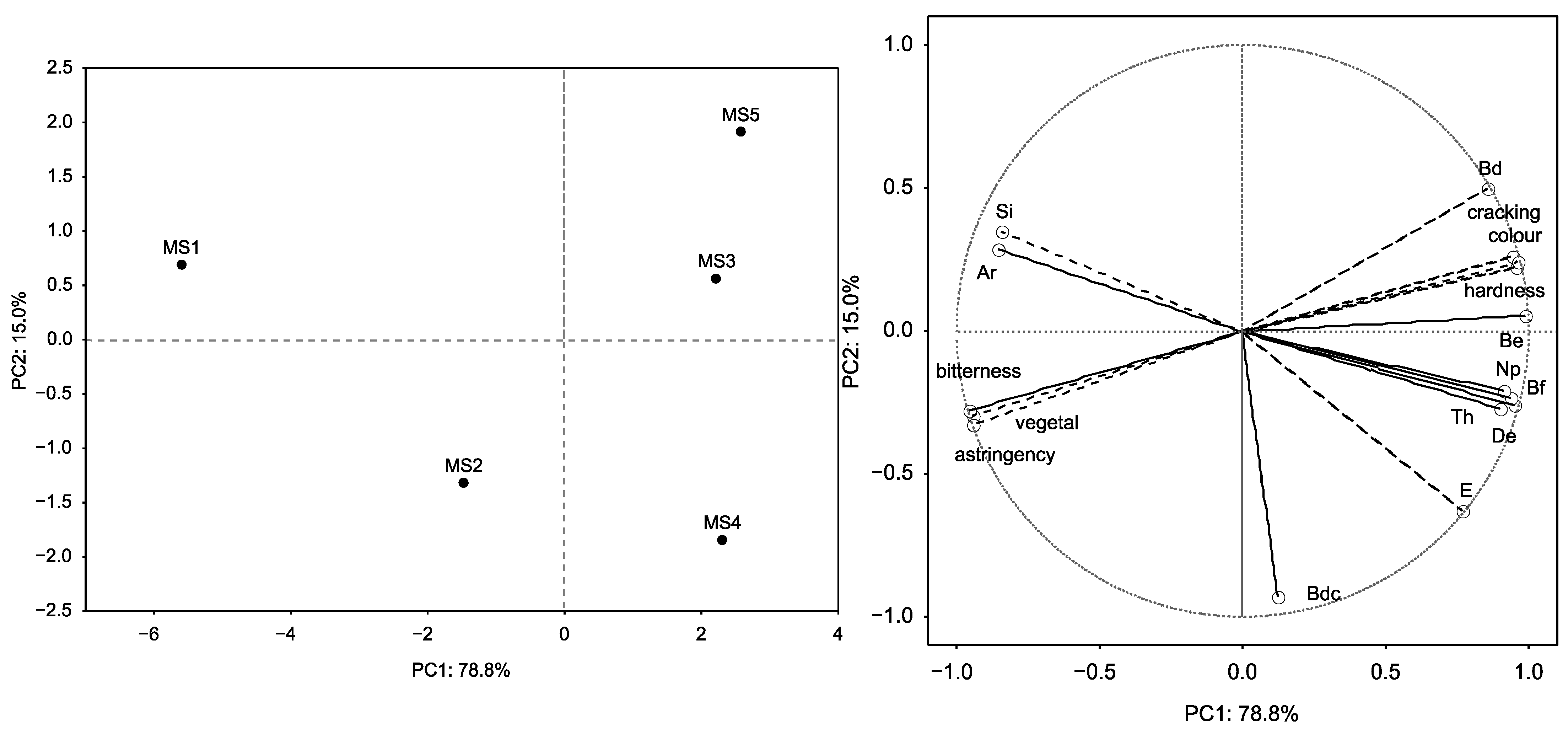

3.5. Correlation between Sensory and Instrumental Analyses of Grape Seeds

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- López, M.I.; Sánchez, M.T.; Díaz, A.; Ramírez, P.; Morales, J. Influence of a deficit irrigation regime during ripening on berry composition in grapevines (Vitis vinifera L.) grown in semi-arid areas. Int. J. Food Sci. Nutr. 2007, 58, 491–507. [Google Scholar] [CrossRef]

- Mori, K.; Sugaya, S.; Gemma, H. Decreased anthocyanin biosynthesis in grape berries grown under elevated night temperature condition. Sci. Hortic. 2005, 105, 319–330. [Google Scholar] [CrossRef]

- Boulton, R. The copigmentation of anthocyanins and its role in the color of red wine: A critical review. Am. J. Enol. Vitic. 2001, 52, 67–87. [Google Scholar]

- Soares, S.; Brandão, E.; Mateus, N.; de Freitas, V. Sensorial properties of red wine polyphenols: Astringency and bitterness. Crit. Rev. Food Sci. Nutr. 2017, 57, 937–948. [Google Scholar] [CrossRef]

- Su, P.F.; Yuan, C.L.; Yang, L.; Zhou, Y.L.; Yan, X.Y. Effect of different harvest dates on the quality of pinot noir grape and the resulting wine. Mod. Food Sci. Technol. 2016, 32, 234–240. [Google Scholar]

- Antonić, B.; Jančíková, S.; Dordević, D.; Tremlová, B. Grape Pomace Valorization: A Systematic Review and Meta-Analysis. Foods 2020, 9, 1627. [Google Scholar] [CrossRef]

- Quijada-Morín, N.; García-Estévez, I.; Nogales-Bueno, J.; Rodríguez-Pulido, F.J.; Heredia, F.J.; Rivas-Gonzalo, J.C.; Escribano-Bailón, M.T.; Hernández-Hierro, J.M. Trying to set up the flavanolic phases during grape seed ripening: A spectral and chemical approach. Talanta 2016, 160, 556–561. [Google Scholar] [CrossRef]

- Rodríguez-Pulido, F.J.; González-Miret, M.L.; Heredia, F.J. Application of imaging techniques for the evaluation of phenolic maturity of grape seeds. Opt. Pura y Apl. 2017, 50, 1–11. [Google Scholar] [CrossRef]

- Rodríguez-Pulido, F.J.; Ferrer-Gallego, R.; González-Miret, M.L.; Rivas-Gonzalo, J.C.; Escribano-Bailón, M.T.; Heredia, F.J. Preliminary study to determine the phenolic maturity stage of grape seeds by computer vision. Anal. Chim. Acta 2012, 732, 78–82. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Pulido, F.J.; Gómez-Robledo, L.; Melgosa, M.; Gordillo, B.; González-Miret, M.L.; Heredia, F.J. Ripeness estimation of grape berries and seeds by image analysis. Comp. Electron. Agric. 2012, 82, 128–133. [Google Scholar] [CrossRef]

- Priyashantha, H.; Höjer, A.; Saedén, K.H.; Lundh, Å.; Johansson, M.; Bernes, G.; Geladi, P.; Hetta, M. Use of near-infrared hyperspectral (NIR-HS) imaging to visualize and model the maturity of long-ripening hard cheeses. J. Food Eng. 2020, 264, 109687. [Google Scholar] [CrossRef]

- Siripatrawan, U.; Makino, Y. Simultaneous assessment of various quality attributes and shelf life of packaged bratwurst using hyperspectral imaging. Meat Sci. 2018, 146, 26–33. [Google Scholar] [CrossRef] [PubMed]

- Foca, G.; Masino, F.; Antonelli, A.; Ulrici, A. Prediction of compositional and sensory characteristics using RGB digital images and multivariate calibration techniques. Anal. Chim Acta 2011, 706, 238–245. [Google Scholar] [CrossRef]

- Barbieri, S.; Bendini, A.; Balestra, F.; Palagano, R.; Rocculi, P.; Gallina Toschi, T. Sensory and instrumental study of Taralli, a typical Italian bakery product. Eur. Food Res. Technol. 2018, 244, 73–82. [Google Scholar] [CrossRef]

- Cejudo-Bastante, M.J.; Rivero-Granados, F.J.; Heredia, F.J. Improving the color and aging aptitude of Syrah wines in warm climate by wood–grape mix maceration. Eur. Food Res. Technol. 2017, 243, 575–582. [Google Scholar] [CrossRef]

- Luo, M.R.; Cui, G.L.; Li, C. Entitled Apparatus and Method for Measuring Colour (DigiEye System). Derby University Enterprises Limited. British Patent Application No. 0124683.4, 4 October 2001. [Google Scholar]

- CIE. ISO 11664-2: Commission Internationale de l’Éclairage; Standard Illuminants for Colorimetry: Vienna, Austria, 2007. [Google Scholar]

- Heredia, F.J.; González-Miret, M.L.; Álvarez, C.; Ramírez, A. Registro N° SE-01298; DigiFood: Sevilla, Spain, 2006. [Google Scholar]

- The Mathworks. MATLAB R2019a; The MathWorks Inc.: Natik, MA, USA, 2019. [Google Scholar]

- Statistica, StatSoft Inc. STATISTICA (Data Analysis Software System); StatSoft Inc.: Tulsa, OK, USA, 2007. [Google Scholar]

- Le Moigne, M.; Maury, C.; Bertrand, D.; Jourjon, F. Sensory and instrumental characterisation of Cabernet Franc grapes according to ripening stages and growing location. Food Qual. Pref. 2008, 19, 220–231. [Google Scholar] [CrossRef]

- Ramos-Pineda, A.M.; García-Estévez, I.; Dueñas, M.; Escribano-Bailón, M.T. Effect of the addition of mannoproteins on the interaction between wine flavonols and salivary proteins. Food Chem. 2018, 264, 226–232. [Google Scholar] [CrossRef]

- Le Moigne, M.; Symoneaux, R.; Jourjon, F. How to follow grape maturity for wine professionals with a seasonal judge training? Food Qual. Pref. 2008, 19, 672–681. [Google Scholar] [CrossRef]

- Cadot, Y.; Miñana-Castelló, M.T.; Chevalier, M. Anatomical, histological, and histochemical changes in grape seeds from Vitis vinifera L. cv Cabernet franc during fruit development. J. Agric. Food Chem. 2006, 54, 9206–9215. [Google Scholar]

- Letaief, H.; Rolle, L.; Gerbi, V. Mechanical behavior of winegrapes under compression tests. Am. J. Enol. Vitic. 2008, 59, 323–329. [Google Scholar]

- Bautista-Ortín, A.B.; Rodríguez-Rodríguez, P.; Gil-Muñoz, R.; Jiménez-Pascual, E.; Busse-Valverde, N.; Martínez-Cutillas, A.; López-Roca, J.M.; Gómez-Plaza, E. Influence of berry ripeness on concentration, qualitative composition and extractability of grape seed tannins. Austr. J. Grape Wine Res. 2012, 18, 123–130. [Google Scholar] [CrossRef]

- Segade, S.R.; Torchio, F.; Gerbi, V.; Quijada-Morín, N.; García-Estévez, I.; Giacosa, S.; Escribano-Bailón, M.T.; Rolle, L. Impact of postharvest dehydration process of winegrapes on mechanical and acoustic properties of the seeds and their relationship with flavanol extraction during simulated maceration. Food Chem. 2016, 199, 893–901. [Google Scholar] [CrossRef]

- Letaief, H.; Rolle, L.; Gerbi, V. Sensory and instrumental texture measurements for assessing grape seed parameters during fruit development. J. Sci. Food Agric. 2013, 93, 2531–2540. [Google Scholar] [CrossRef] [PubMed]

- Rolle, L.; Giacosa, S.; Torchio, F.; Segade, S.R. Changes in acoustic and mechanical properties of Cabernet Sauvignon seeds during ripening. Am. J. Enol. Vitic. 2012, 63, 413–418. [Google Scholar] [CrossRef]

| Parameter | Abbreviation | Definition |

|---|---|---|

| Number of peaks | Np | Number of peaks registered during the assay. For avoiding slight fluctuations in the signal, a smooth on the raw data for eliminating the smallest peaks was applied. |

| Breaking force (N) | Bf | Force applied on the seed just before breaking. It is a measure of the hardness of the seed. |

| Breaking decline (N) | Bdc | Force difference the probe exerts just before and after grape seed breaks. It gives an estimation of how brittle the grape seed is. |

| Elasticity (N/mm) | E | Elasticity of the seed before breaking. It is measured as the slope of the graph from inception until it breaks. To avoid some fluctuations in the beginning of the test, the calculation starts from the point where the force reaches 10 N. |

| Breaking energy (mJ) | Be | Energy that must be applied to break the seed. It is defined as the area under the curve from the beginning of the test until the break. |

| Deformation energy (mJ) | De | Energy that must be applied to compress the seed up to 50% of its thickness. It is the area under the entire test curve. |

| Thickness (mm) | Th | As the test ends at half the thickness, the thickness is calculated by multiplying the distance the probe travels by two. |

| Breaking distance (mm) | Bd | How much the seed must be deformed to be broken. |

| Strain index (%) | Si | Relative measure of the breaking distance. Calculated by dividing the breaking distance by the thickness of the seed. |

| Area ratio (%) | Ar | Ratio between the breaking energy and the deformation energy at 50%. |

| Sampling | Weight (g) | Caliber (cm) | Veraison (%) | °Baumé | pH | Acidity (g/L) |

|---|---|---|---|---|---|---|

| 25 days BH | 1.50 ± 0.13 a | 1.15 ± 0.12 a | 33 ± 4 a | 9.5 ± 0.2 a | 2.79 ± 0.07 a | 15.23 ± 0.09 a |

| 15 days BH | 1.86 ± 0.16 d | 1.14 ± 0.15 a | 92 ± 9 b | 10.3 ± 0.1 b | 3.04 ± 0.02 b | 9.31 ± 0.21 b |

| 7 days BH | 1.72 ± 0.14 c | 1.58 ± 0.15 d | 92 ± 4 b | 11.7 ± 0.3 c | 3.50 ± 0.03 c | 8.24 ± 0.06 c |

| H | 1.62 ± 0.16 b | 1.35 ± 0.11 c | 100 ± 4 c | 12.3 ± 0.0 d | 3.37 ± 0.01 d | 7.44 ± 0.04 d |

| 15 days AH | 1.53 ± 0.20 a | 1.26 ± 0.09 b | 100 ± 3 c | 14.5 ± 0.1 e | 3.74 ± 0.01 e | 6.10 ± 0.02 e |

| Attributes | Definitions | Standard | Sessions | Concentration | Dilutions for Ranking |

|---|---|---|---|---|---|

| Vegetal aroma | Green vegetable and stick sensation | cis-3-hexenal:IBMP | 1st, 2nd | 70:50 mg/L | |

| 3rd | 35:25 mg/L | 1/2, 1/2.5, 1/3.5, 1/5, 1/10 | |||

| Bitterness | Characteristic taste of bile, quinine y other alkaloids | Caffeine | 1st, 2nd | 1 g/L | |

| 3rd | 2.5 g/L | 1/1, 1/1.25, 1/1.5, 1/2.5, 1/5 | |||

| Astringency | Mechanical difficulty in passing the upper lip through the upper incisors after having passed the seed homogenate between the upper lip and incisors | Tannic acid | 1st, 2nd | 1 g/L | |

| 3rd | 2 g/L | 1/1, 1/1.25, 1/1.5, 1/2.5, 1/5 | |||

| Color | Color evaluation from greenish yellow to brown-green to brown to dark brown to brown-black | Farnsworth–Munsell 100 Hue Test | |||

| Hardness | Force necessary to break the seeds between the molars | High: ripe grape | |||

| Cracking | Auditory sensation that accompanies the total breakage of the seeds | Low: soft, seeds do not crack or break. Medium: seeds break but do not crack. High: seeds break and crack. | |||

| Interaction | Color | Hardness | Cracking | Vegetal | Bitterness | Astringency |

|---|---|---|---|---|---|---|

| Sample effect | 0.000 * | 0.000 * | 0.000 * | 0.000 * | 0.000 * | 0.000 * |

| Session effect | 0.539 | 0.982 | 0.526 | 0.996 | 0.726 | 0.798 |

| Judge effect | <0.001 * | <0.001 * | 0.000 * | 0.000 * | 0.000 * | 0.000 * |

| Sample × session | 0.000 * | 0.000 * | 0.028 * | 0.000 * | 0.000 * | <0.001 * |

| Judge × sample | 0.348 | 0.002 * | 0.001 * | 0.003 * | <0.001 * | <0.001 * |

| Judge × session | 0.997 | 0.942 | 0.051 | 0.957 | 0.916 | 0.999 |

| Textural Parameter | MS1 | MS2 | MS3 | MS4 | MS5 |

|---|---|---|---|---|---|

| Np | 3.66 ± 1.39 a | 3.92 ± 1.26 ab | 4.40 ± 1.48 ab | 4.58 ± 1.65 b | 4.18 ± 1.29 ab |

| Bf | 50.42 ± 11.30 a | 54.24 ± 9.14 ab | 58.18 ± 9.67 b | 59.82 ± 12.49 b | 56.78 ± 14.29 b |

| Bdc | 20.04 ± 8.10 a | 20.88 ± 7.18 a | 20.21 ± 6.65 a | 22.93 ± 9.23 a | 18.82 ± 8.66 a |

| E | 98.11 ± 16.90 a | 104.92 ± 15.04 ab | 105.68 ± 13.20 ab | 111.32 ± 18.59 b | 103.70 ± 17.84 ab |

| Be | 13.75 ± 5.30 a | 14.74 ± 4.16 ab | 16.71 ± 5.17 b | 16.66 ± 5.20 ab | 16.60 ± 6.56 ab |

| De | 36.01 ± 9.08 a | 72.93 ± 11.76 b | 77.82 ± 14.14 bc | 80.74 ± 15.26 c | 78.30 ± 17.29 bc |

| Th | 2.19 ± 0.26 a | 3.17 ± 0.27 b | 3.22 ± 0.26 b | 3.24 ± 0.34 b | 3.27 ± 0.33 b |

| Bd | 0.53 ± 0.11 a | 0.54 ± 0.08 a | 0.57 ± 0.09 a | 0.55 ± 0.08 a | 0.57 ± 0.12 a |

| Si | 0.24 ± 0.05 a | 0.17 ± 0.03 b | 0.18 ± 0.03 b | 0.17 ± 0.03 b | 0.18 ± 0.04 b |

| Ar | 0.39 ± 0.13 a | 0.20 ± 0.05 b | 0.22 ± 0.06 b | 0.21 ± 0.07 b | 0.21 ± 0.08 b |

| Np | Bf | Bdc | E | Be | De | Th | Bd | Si | Ar | Color | Hardness | Cracking | Vegetal | Bitterness | Astringency | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Np | 1.00 | |||||||||||||||

| Bf | 0.99 | 1.00 | ||||||||||||||

| Bdc | 0.47 | 0.42 | 1.00 | |||||||||||||

| E | 0.90 | 0.91 | 0.72 | 1.00 | ||||||||||||

| Be | 0.93 | 0.95 | 0.13 | 0.74 | 1.00 | |||||||||||

| De | 0.83 | 0.90 | 0.24 | 0.83 | 0.87 | 1.00 | ||||||||||

| Th | 0.77 | 0.86 | 0.18 | 0.79 | 0.83 | 1.00 | 1.00 | |||||||||

| Bd | 0.63 | 0.68 | −0.38 | 0.33 | 0.87 | 0.70 | 0.70 | 1.00 | ||||||||

| Si | −0.73 | −0.82 | −0.28 | −0.82 | −0.75 | −0.98 | −0.99 | −0.57 | 1.00 | |||||||

| Ar | −0.71 | −0.80 | −0.21 | −0.78 | −0.76 | −0.98 | −0.99 | −0.61 | 1.00 | 1.00 | ||||||

| Color | 0.82 | 0.85 | −0.06 | 0.58 | 0.96 | 0.78 | 0.74 | 0.91 | −0.64 | −0.66 | 1.00 | |||||

| Hardness | 0.86 | 0.89 | −0.03 | 0.62 | 0.99 | 0.80 | 0.77 | 0.92 | −0.66 | −0.68 | 0.99 | 1.00 | ||||

| Cracking | 0.84 | 0.87 | −0.06 | 0.60 | 0.98 | 0.81 | 0.78 | 0.93 | −0.67 | −0.69 | 1.00 | 1.00 | 1.00 | |||

| Vegetal | −0.78 | −0.82 | 0.14 | −0.55 | −0.95 | −0.80 | −0.78 | −0.94 | 0.68 | 0.70 | −0.99 | −0.98 | −0.99 | 1.00 | ||

| Bitterness | −0.80 | −0.84 | 0.12 | −0.57 | −0.96 | −0.82 | −0.79 | −0.95 | 0.69 | 0.71 | −0.99 | −0.99 | −1.00 | 1.00 | 1.00 | |

| Astringency | −0.77 | −0.81 | 0.18 | −0.52 | −0.95 | −0.80 | −0.79 | −0.97 | 0.68 | 0.71 | −0.98 | −0.98 | −0.99 | 0.99 | 1.00 | 1.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cejudo-Bastante, M.J.; Rodríguez-Pulido, F.J.; Heredia, F.J.; González-Miret, M.L. Assessment of Sensory and Texture Profiles of Grape Seeds at Real Maturity Stages Using Image Analysis. Foods 2021, 10, 1098. https://doi.org/10.3390/foods10051098

Cejudo-Bastante MJ, Rodríguez-Pulido FJ, Heredia FJ, González-Miret ML. Assessment of Sensory and Texture Profiles of Grape Seeds at Real Maturity Stages Using Image Analysis. Foods. 2021; 10(5):1098. https://doi.org/10.3390/foods10051098

Chicago/Turabian StyleCejudo-Bastante, María Jesús, Francisco J. Rodríguez-Pulido, Francisco J. Heredia, and M. Lourdes González-Miret. 2021. "Assessment of Sensory and Texture Profiles of Grape Seeds at Real Maturity Stages Using Image Analysis" Foods 10, no. 5: 1098. https://doi.org/10.3390/foods10051098

APA StyleCejudo-Bastante, M. J., Rodríguez-Pulido, F. J., Heredia, F. J., & González-Miret, M. L. (2021). Assessment of Sensory and Texture Profiles of Grape Seeds at Real Maturity Stages Using Image Analysis. Foods, 10(5), 1098. https://doi.org/10.3390/foods10051098