Combined Hot Air, Microwave, and Infrared Drying of Hawthorn Fruit: Effects of Ultrasonic Pretreatment on Drying Time, Energy, Qualitative, and Bioactive Compounds’ Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Laboratory Materials

2.2. Ultrasonic Pretreatment

2.3. Drying Types

2.3.1. Hot-Air Drying

2.3.2. Infrared-Hot-Air Drying

2.3.3. Microwave–Hot-Air Drying

2.3.4. Freeze Drying

2.4. Specific Energy (SE)

2.5. Quality Properties

2.5.1. Color

2.5.2. Shrinkage

2.5.3. Rehydration Ratio (RR)

2.6. Bioactive Compounds Properties

2.6.1. Measurement of the Antioxidant Capacity (AC) using the Diphenyl Picryl Hydrazine (DPPH) Method

2.6.2. Total Phenolic Content (TPC)

2.6.3. Total Flavonoid Content (TFC)

2.6.4. Measurement of pH

2.7. Statistics

3. Results and Discussion

3.1. Drying Time

3.2. Specific Energy (SE)

3.3. Quality Properties

3.3.1. Color

3.3.2. Shrinkage

3.3.3. Rehydration Ratio (RR)

3.4. Bioactive Compounds

3.4.1. Antioxidant Capacity (AC)

3.4.2. Total Phenol Content (TPC)

3.4.3. Total Flavonoid Content (TFC)

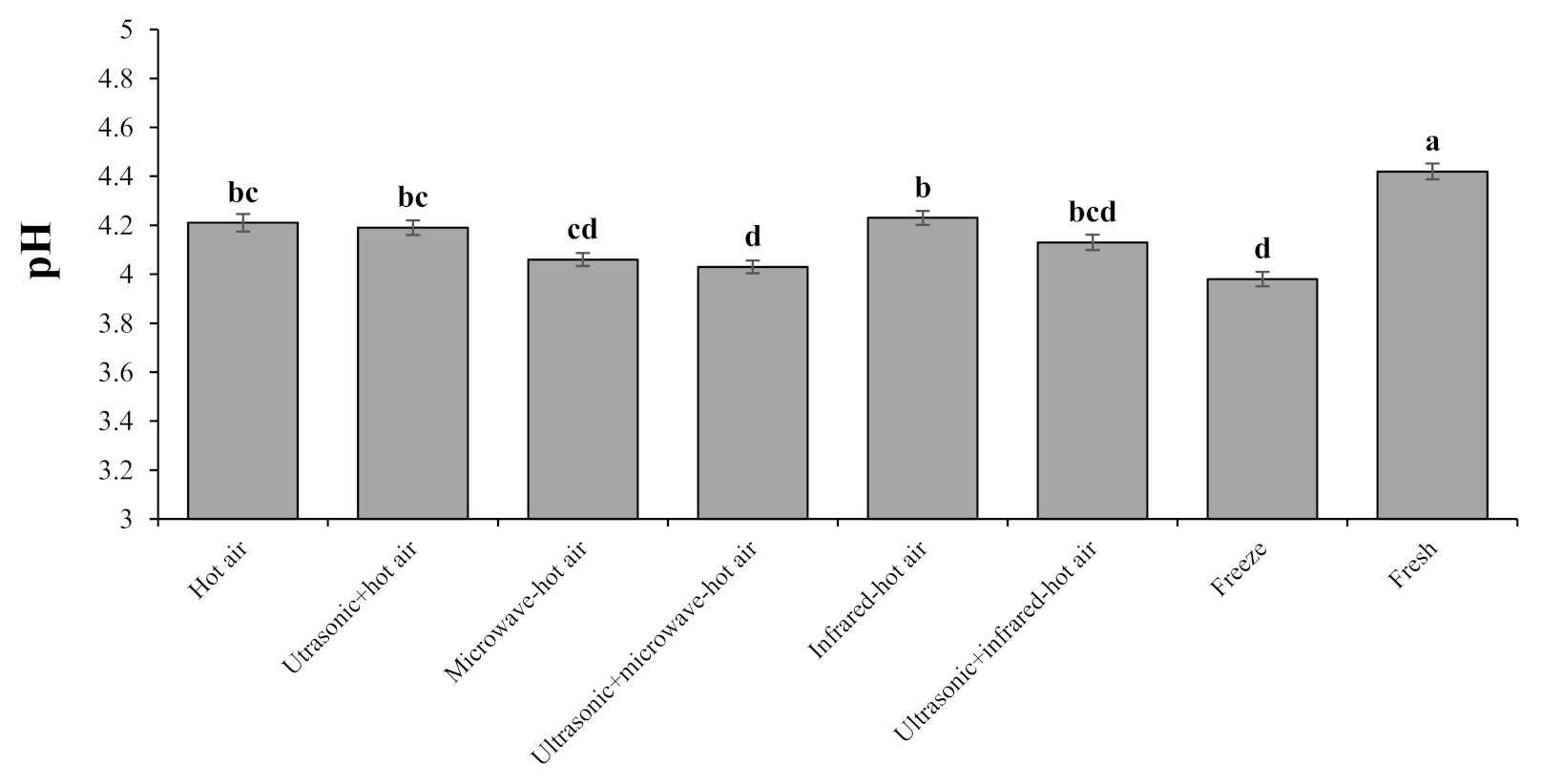

3.4.4. pH

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chayjan, R.A.; Kaveh, M.; Khayati, S. Modeling drying characteristics of hawthorn fruit under microwave- convective conditions. J. Food Process. Preserv. 2015, 39, 239–253. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Wu, Z.; Wan, N.; Yang, M. Dehydration of hawthorn fruit juices using ultrasound-assisted vacuum drying. Ultrason. Sonochem. 2020, 68, 105219. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Lv, Z.; Yang, W.; Zhang, C.; Chen, D.; Jiao, Z. Effect of dehydration techniques on bioactive compounds in hawthorn slices and their correlations with antioxidant properties. J. Food Sci. Technol. 2019, 56, 2446–2457. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Xiao, Y.; Lagnika, C.; Song, J.; Li, D.; Liu, C.; Jiang, N.; Zhang, M.; Duan, X. A comparative study of drying methods on physical characteristics, nutritional properties and antioxidant capacity of broccoli. Dry. Technol. 2020, 38, 1378–1388. [Google Scholar] [CrossRef]

- Szychowski, P.J.; Lech, K.; Sendra-Nadal, E.; Hernández, F.; Figiel, A.; Wojdyło, A.; Carbonell-Barrachina, A.A. Kinetics, biocompounds, antioxidant activity, and sensory attributes of quinces as affected by drying method. Food Chem. 2018, 255, 157–164. [Google Scholar] [CrossRef] [PubMed]

- Azam, S.M.R.; Zhanga, M.; Law, C.L.; Mujumdar, A.S. Effects of drying methods on quality attributes of peach (Prunus persica) leather. Dry. Technol. 2019, 37, 341–351. [Google Scholar] [CrossRef]

- Izli, N.; Izli, G.; Taskin, O. Drying kinetics, colour, total phenolic content and antioxidant capacity properties of kiwi dried by different methods. Food Meas. 2017, 11, 64–74. [Google Scholar] [CrossRef]

- Qiu, L.; Zhang, M.; Ju, T.; Wang, Y.; Chitrakar, B.; Wang, B. Effect of different drying methods on the quality of restructured rose flower (Rosa rugosa) chips. Dry. Technol. 2020, 38, 1632–1643. [Google Scholar] [CrossRef]

- Tregunno, N.B.; Goff, H.D. Osmodehydrofreezing of apples: Structural and textural effects. Food Res. Int. 2018, 29, 471–479. [Google Scholar] [CrossRef]

- Ren, F.; Perussello, C.A.; Zhang, Z.; Kerry, J.P.; Tiwari, B.K. Impact of ultrasound and blanching on functional properties of hot-air dried and freeze dried onions. LWT 2018, 87, 102–111. [Google Scholar] [CrossRef]

- Nowacka, M.; Wiktor, A.; Anuszewska, A.; Dadan, M.; Rybak, K.; Witrowa-Rajchert, D. The application of unconventional technologies as pulsed electric field, ultrasound and microwave-vacuum drying in the production of dried cranberry snacks. Ultrason. Sonochem. 2019, 56, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Abbaspour-Gilandeh, Y.; Kaveh, M.; Aziz, M. Ultrasonic-microwave and infrared assisted convective drying of carrot: Drying kinetic, quality and energy consumption. Appl. Sci. 2020, 10, 6309. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, L.; Feng, Y.; Zhou, C.; Yagoub, A.E.A.; Wahia, H.; Ma, H.; Zhang, J.; Sun, Y. Ultrasound freeze-thawing style pretreatment to improve the efficiency of the vacuum freeze-drying of okra (Abelmoschus esculentus (L.) Moench) and the quality characteristics of the dried product. Ultrason. Sonochem. 2021, 70, 105300. [Google Scholar] [CrossRef] [PubMed]

- Mierzwa, D.; Szadzinska, J.; Pawłowski, A.; Pashminehazar, R.; Kharaghani, A. Nonstationary convective drying of raspberries, assisted by microwaves and ultrasound. Dry. Technol. 2019, 37, 988–1001. [Google Scholar] [CrossRef]

- Horuz, E.; Jaafar, H.J.; Maskan, M. Ultrasonication as pretreatment for drying of tomato slices in a hot air–microwave hybrid oven. Dry. Technol. 2017, 35, 849–859. [Google Scholar] [CrossRef]

- Jiang, N.; Zhang, Z.; Li, D.; Liu, C.; Zhang, M.; Liu, C.; Wang, D.; Niu, L. Evaluation of freeze drying combined with microwave vacuum drying for functional okra snacks: Antioxidant properties, sensory quality, and energy consumption. LWT 2017, 82, 216–226. [Google Scholar] [CrossRef]

- Motevali, A.; Hashemi, S.J. The Effect of different pre-treatments on qualitative properties of freeze-dried feijoa fruit. Chin. J. Chem. Eng. 2017. [Google Scholar] [CrossRef]

- Colucci, D.; Fissore, D.; Rossello, C.; Carcel, J.A. On the effect of ultrasound-assisted atmospheric freeze-drying on the antioxidant properties of eggplant. Food Res. Int. 2018, 106, 580–588. [Google Scholar] [CrossRef] [PubMed]

- Dujmic, F.; Brnčić, M.; Karlović, S.; Bosiljkov, T.; Jeûek, D.; Tripalo, B.; Mofardin, I. Ultrasound-assisted infrared drying of pear slices: Textural issues. J. Food Process. Eng. 2013, 36, 397–406. [Google Scholar] [CrossRef]

- Babagoltabar, R. The Effect of Ultrasound on the Drying Rate of Tea Leaves. Master’s Thesis, University of Ilam, Ilam, Iran, 2013. (In Farsi). [Google Scholar]

- Motevali, A.; Tabatabaei, S.R. A Comparison between pollutants and greenhouse gas emissions from operation of different dryers based on energy consumption of power plants. J. Clean. Prod. 2017, 154, 445–461. [Google Scholar] [CrossRef]

- Kaveh, M.; Chayjan, R.A.; Taghinezhad, E.; Sharabiani, V.R.; Motevali, A. Evaluation of specific energy consumption and GHG emissions for different drying methods (Case study: Pistacia Atlantica). J. Clean. Prod. 2020, 259, 120963. [Google Scholar] [CrossRef]

- Abdoli, B.; Zare, D.; Jafari, A.; Chen, G. Evaluation of the air-borne ultrasound on fluidized bed drying of shelled corn: Effectiveness, grain quality, and energy consumption. Dry. Technol. 2018, 36, 1749–1766. [Google Scholar] [CrossRef]

- Kaveh, M.; Abbaspour-Gilandeh, Y.; Chen, G. Drying kinetic, quality, energy and exergy performance of hot air-rotary drum drying of green peas using adaptive neuro-fuzzy inference system. Food Bioprod. Process. 2020, 124, 168–183. [Google Scholar] [CrossRef]

- Zhang, Y.; Zielinska, M.; Vidyarthi, S.K.; Zhao, J.-H.; Pei, Y.-P.; Li, G.; Zheng, Z.-A.; Wu, M.; Gao, Z.-J.; Xiao, H.-W. Pulsed pressure pickling enhances acetic acid transfer, thiosulfinates degradation, color and ultrastructure changes of “Laba” garlic. Innov. Food Sci. Emerg. Technol. 2020, 65, 102438. [Google Scholar] [CrossRef]

- Dehghannya, J.; Kadkhodaei, S.; Heshmatia, M.K.; Ghanbarzadeh, B. Ultrasound-assisted intensification of a hybrid intermittent microwave—Hot air drying process of potato: Quality aspects and energy consumption. Ultrasonics 2019, 96, 104–122. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Xiao, Y.; Lagnika, C.; Li, D.; Liu, C.; Jiang, N.; Song, J.; Zhang, M. A comparative evaluation of nutritional properties, antioxidant capacity and physical characteristics of cabbage (Brassica oleracea var. capitate Var L.) subjected to different drying methods. Food Chem. 2020, 309, 124935. [Google Scholar] [CrossRef]

- Taghinezhad, E.; Kaveh, M.; Szumny, A. Optimization and prediction of the drying and quality of turnip slices by convective-infrared dryer under various pretreatments by RSM and ANFIS methods. Foods 2021, 10, 284. [Google Scholar] [CrossRef]

- Lin, M.C.; Tsai, M.J.; Wen, K.C. Supercritical fluid extraction of flavonoids from Scutellariae Radix. J. Chromatogr. A 1999, 830, 387–395. [Google Scholar] [CrossRef]

- Darvishi, H.; Saba, M.K.; Behroozi-Khazaei, N.; Nourbakhsh, H. Improving quality and quantity attributes of grape juice concentrate (molasses) using ohmic heating. J. Food Sci. Technol. 2020, 57, 1362–1370. [Google Scholar] [CrossRef] [PubMed]

- Akowuah, G.A.; Ismail, Z.; Norhayati, I.; Sadikun, A. The effects of different extraction solvents of varying polarities on polyphenols of Orthosiphon stamineus and evaluation of the free radical-scavenging activity. Food Chem. 2005, 93, 311–317. [Google Scholar] [CrossRef]

- Kaveh, M.; Abbaspour-Gilandeh, Y. Impacts of hybrid (convective-infrared-rotary drum) drying on the quality attributes of green pea. J. Food Process. Eng. 2020, 43, e13424. [Google Scholar] [CrossRef]

- Marinova, D.; Ribarova, F.; Atanassova, M. Total phenolics and total flavonoids in Bulgarian fruits and vegetables. J. Univ. Chem. Technol. Metall. 2005, 40, 255–260. [Google Scholar]

- Beketove, E.V.; Pakhomov, V.P.P.; Nesterova, O.V. Improved method of flavonoid extraction from bird cherry fruits. Pharm. Chem. J. 2005, 39, 33–35. [Google Scholar] [CrossRef]

- Rodriguez, O.; Gomes, W.; Rodrigues, S.; Fernandes, F.A.N. Effect of acoustically assisted treatments of vitamins, antioxidant activity, organic acids and drying kinetics of pineapple. Ultrason. Sonochem. 2017, 35, 92–102. [Google Scholar] [CrossRef]

- Wen, A.; Xie, C.; Mazhar, M.; Zhu, Y.; Zeng, H.; Qin, L.; Zhu, Y. Comparative evaluation of drying methods on kinetics, biocompounds and antioxidant activity of Bacillus subtilis-fermented dehulled adlay. Dry. Technol. 2020, 38, 1505–1515. [Google Scholar] [CrossRef]

- Qiu, L.; Zhang, M.; Bhandari, B.; Wang, B. Effects of infrared freeze drying on volatile profile, FTIR molecular structure profile and nutritional properties of edible rose flower (Rosa rugosa flower). J. Sci. Food Agric. 2020, 100, 4791–4800. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Le, M.D. Influence of various drying conditions on phytochemical compounds and antioxidant activity of carrot peel. Beverages 2018, 4, 80. [Google Scholar] [CrossRef]

- Kaveh, M.; Abbaspour-Gilandeh, Y.; Nowacka, M. Comparison of different drying techniques and their carbon emissions in green peas. Chem. Eng. Process. Process. Int. 2021, 160, 108274. [Google Scholar] [CrossRef]

- Szadzińska, J.; Łechtańska, J.; Pashminehazar, R.; Kharaghani, A.; Tsotsas, E. Microwave- and ultrasound-assisted convective drying of raspberries: Drying kinetics and microstructural changes. Dry. Technol. 2019, 37, 1–12. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, M.; Adhikari, B.; Chen, J. A novel strategy for improving drying efficiency and quality of cream mushroom soup based on microwave pre-gelatinization and infrared freeze-drying. Innov. Food Sci. Emerg. Technol. 2020, 66, 102516. [Google Scholar] [CrossRef]

- Shewale, S.R.; Rajoriya, D.; Bhavya, M.L.; Umesh Hebbar, H. Application of radiofrequency heating and low humidity air for sequential drying of apple slices: Process intensification and quality improvement. LWT 2021, 135, 109904. [Google Scholar] [CrossRef]

- Saifullah, M.; McCullum, R.; McCluskey, A.; Vuong, Q. Effects of different drying methods on extractable phenolic compounds and antioxidant properties from lemon myrtle dried leaves. Heliyon 2019, 5, e03044. [Google Scholar]

- Feng, Y.; Xu, B.; Yagoub, A.E.A.; Ma, H.; Sun, Y.; Xu, X.; Yu, X.; Zhou, C. Role of drying techniques on physical, rehydration, flavor, bioactive compounds and antioxidant characteristics of garlic. Food Chem. 2020, 343, 128404. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Bi, J.; Wu, X.; Yi, J.; Zhou, L.; Zhou, Y. Drying kinetics and quality attributes of jujube (Zizyphus jujuba Miller) slices dried by hot-air and short- and medium-wave infrared radiation. LWT 2015, 64, 759–766. [Google Scholar] [CrossRef]

- Szadzińska, J.; Mierzwa, D.; Pawłowski, A.; Musielak, G.; Pashminehazar, R.; Kharaghani, A. Ultrasound- and microwave-assisted intermittent drying of red beetroot. Dry. Technol. 2020, 38, 93–107. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Kaveh, M.; Fatemi, H.; Hernández-Hernández, J.L.; Fuentes-Penna, A.; Hernández-Hernández, M. Evaluation of the changes in thermal, qualitative, and antioxidant properties of terebinth (Pistacia Atlantica) fruit under different drying methods. Agronomy 2020, 10, 1378. [Google Scholar] [CrossRef]

- Fathabadi, M.; Tabatabaekoloor, R.; Motevali, A. Modeling and comparison of color changes and shrinkage of thin layer drying of red beetroot in different dryers. Iran. J. Food Sci. Technol. 2020, 16, 127–142. (In Farsi) [Google Scholar]

- Dehghannya, J.; Bozorghi, S.; Heshmati, M.K. Low temperature hot air drying of potato cubes subjected to osmotic dehydration and intermittent microwave: Drying kinetics, energy consumption and product quality indexes. Heat Mass Transf. 2018, 54, 929–954. [Google Scholar] [CrossRef]

- Aydogdu, A.; Sumnu, G.; Sahin, S. Effects of microwave-infrared combination drying on quality of eggplants. Food Bioprocess. Technol. 2015, 8, 1198–1210. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, D.; Zhong, X.; Pei, Z.; Tian, Y.; Xiang, D.; Cao, J.; Shen, X.; Li, C. Quality and protein degradation of golden pompano (Trachinotus blochii) fillets during four drying methods. LWT 2020, 130, 109638. [Google Scholar]

- Li, Y.; Wan, N.; Wu, Z.; Wang, X.; Yang, M. A three-stage microwave-vacuum, pulsed-vacuum, and vacuum drying method for lotus seeds. J. Food Process. Preserv. 2020, 44, e14896. [Google Scholar] [CrossRef]

- Alizehi, M.H.; Niakousari, M.; Fazaeli, M.; Iraji, M. Modeling of vacuum- and ultrasound-assisted osmodehydration of carrot cubes followed by combined infrared and spouted bed drying using artificial neural network and regression models. J. Food Process. Eng. 2020, 43, e13563. [Google Scholar] [CrossRef]

- Dehghannya, J.; Aghazade-Khoie, E.; Heshmati, M.K.; Ghanbarzadeh, B. Influence of ultrasound intensification on the continuous and pulsed microwave during convective drying of apple. Int. J. Fruit Sci. 2020, 20 (Suppl. S3), S1751–S1764. [Google Scholar] [CrossRef]

- Turkmen, F.; Karasu, S.; Karadag, A. Effects of different drying methods and temperature on the drying behavior and quality attributes of cherry laurel fruit. Processes 2020, 8, 761. [Google Scholar]

- Kaveh, M.; Abbaspour-Gilandeh, Y.; Fatemi, H.; Chen, G. Impact of different drying methods on the drying time, energy and quality of green peas. J. Food Process. Preserv. 2021, e15503. [Google Scholar] [CrossRef]

- Salehi, B.; Zucca, P.; Orhan, I.E.; Azzini, E.; Adetunji, C.O.; Mohammed, S.A.; Ahmad, Z. Allicin and health: A comprehensive review. Trends Food Sci. Technol. 2019, 86, 502–516. [Google Scholar]

- Valadez-Carmona, L.; Plazola-Jacinto, C.P.; Hernández-Ortega, M.; Hernández-Navarro, M.D.; Villarreal, F.; Necoechea-Mondragón, H.; OrtizMoreno, A.; Ceballos-Reyes, G. Effects of microwaves, hot air and freeze-drying on the phenolic compounds, antioxidant capacity, enzyme activity and microstructure of cacao pod husks (Theobroma cacao L.). Innov. Food Sci. Emerg. Technol. 2017, 41, 378–386. [Google Scholar] [CrossRef]

- Kayacan, S.; Karasu, S.; Akman, P.K.; Goktas, H.; Doymaz, I.; Sagdıc, O. Effect of different drying methods on total bioactive compounds, phenolic profile, in vitro bioaccessibility of phenolic and HMF formation of persimmon. LWT 2020, 118, 108830. [Google Scholar] [CrossRef]

- Tomsone, L.; Galoburda, R.; Kruma, Z.; Cinkmanis, I. Characterization of dried horseradish leaves pomace: Phenolic compounds profile and antioxidant capacity, content of organic acids, pigments and volatile compounds. Eur. Food Res. Technol. 2020, 246, 1647–1660. [Google Scholar]

- Chandra, A.; Kumar, S.; Tarafdar, A.; Nema, P.K. Ultrasonic and osmotic pretreatments followed by convective and vacuum drying of papaya slices. J. Sci. Food Agric. 2020, 101, 2264–2272. [Google Scholar] [CrossRef]

- Rashid, M.T.; Ma, H.; Jatoi, M.A.; Wali, A.; El-Mesery, H.S.; Ali, Z.; Sarpong, F. Effect of infrared drying with multifrequency ultrasound pretreatments on the stability of phytochemical properties, antioxidant potential, and textural quality of dried sweet potatoes. J. Food Biochem. 2019, 43, e12809. [Google Scholar] [CrossRef] [PubMed]

- Lim, Y.Y.; Murtijaya, J. Antioxidant Properties of Phyllanthus Amarus Extracts as Affected by Different Drying Methods. LWT 2007, 40, 1664–1669. [Google Scholar] [CrossRef]

- Reyes, A.; Mahn, A.; Guzman, C.; Antoniz, D. Analysis of the drying of broccoli florets in a fluidized pulsed bed. Dry. Technol. 2012, 30, 1368–1376. [Google Scholar] [CrossRef]

- Li, L.; Zhang, M.; Wang, W. Ultrasound-assisted osmotic dehydration pretreatment before pulsed fluidized bed microwave freeze-drying (PFBMFD) of Chinese yam. Food Biosci. 2020, 35, 100548. [Google Scholar] [CrossRef]

- Vega‑Gálvez, A.; Poblete, J.; Quispe‑Fuentes, I.; Uribe, E.; Bilbao‑Sainz, C.; Pastén, A. Chemical and bioactive characterization of papaya (Vasconcellea pubescens) under different Dry. Technologies: Evaluation of antioxidant and antidiabetic potential. Food Measure. 2019, 13, 1980–1990. [Google Scholar] [CrossRef]

- Bozkir, H.; Tekgül, Y.; Erten, E.S. Effects of tray drying, vacuum infrared drying, and vacuum microwave drying techniques on quality characteristics and aroma profile of orange peels. J. Food Process. Eng. 2020, 44, e13611. [Google Scholar]

- Mohammadi, I.; Tabatabaekoloor, R.; Motevali, A. Investigating some quality and thermodynamic parameters of kiwifruit thin layer drying in an air recycling dryer equipped with heat pump. Iran. J. Biosyst. Eng. 2019, 50, 331–342. [Google Scholar]

| Energy Consumption at Dryer | Reference |

|---|---|

| Et (hot air) = Equations (2) + Equations (3) | [21] |

| Et (microwave–hot-air) = Equations (2) + Equations (3) + Equations (5) | [22] |

| Et (infrared–hot air) = Equations (3) + Equations (4) | [21] |

| Et (ultrasonic + hot air) = Equations (3) + Equations (4) + Equations (7) | [23] |

| Et (ultrasonic + microwave–hot-air) = Equations (2) + Equations (3) + Equations (5) + Equations (7) | [12] |

| Et (ultrasonic + infrared–hot air) = Equations (3) + Equations (4) + Equations (7) | [12] |

| Et (freeze) = Equations (8) | [4] |

| SOV | df | Time | SE | Color | Shrinkage | RR |

|---|---|---|---|---|---|---|

| Drying method | 6 | 562,525.00 ** | 44,198.96 ** | 461.47 ** | 844.35 ** | 0.348 ** |

| Error | 14 | 136.87 | 32.71 | 0.45 | 1.94 | 0.00 |

| CV | 3.24 | 3.47 | 0.70 | 3.34 | 1.75 |

| Drying Method | Time (min) | SE (MJ/kg) |

|---|---|---|

| Hot air | 450 7.58 b | 245.70 7.58 b |

| Microwave–hot-air | 70 1.5 f | 64.95 5.12 f |

| Infrared–hot air | 175 3.0 d | 122.16 6.77 d |

| Ultrasonic + hot air | 370 6.0 c | 194.80 6.98 c |

| Ultrasonic + Microwave–hot-air | 45 1.0 g | 47.57 4.44 g |

| Ultrasonic + Infrared–hot air | 130 3.0 e | 89.95 5.99 e |

| Freeze | 1280 11.5 a | 388.03 9.10 a |

| SOV | df | AC | TPC | TFC | pH |

|---|---|---|---|---|---|

| Drying method | 7 | 825.95 ** | 315.25 ** | 1009.75 ** | 0.058 ** |

| Error | 16 | 0.40 | 0.62 | 1.69 | 0.000 |

| CV | 1.37 | 4.07 | 2.38 | 2.12 |

| Drying | AC (%) | TPC (mg GAE/gdw) | TFC (mg QE/gdw) |

|---|---|---|---|

| Fresh (no drying) | 33.32 1.20 a | 79.82 2.42 a | 72.72 2.88 a |

| Hot air | 5.98 0.94 h | 29.56 1.99 h | 27.26 2.16 h |

| Microwave–hot air | 22.23 0.85 d | 58.51 2.32 d | 46.39 3.25 d |

| Infrared–hot air | 11.83 1.10 f | 40.51 3.21 f | 36.49 2.09 f |

| Ultrasonic + hot air | 9.45 1.15 g | 36.28 2.09 g | 28.56 3.52 g |

| Ultrasonic + microwave–hot air | 26.38 1.31 c | 68.22 2.28 c | 51.17 2.48 c |

| Ultrasonic + infrared–hot air | 14.79 0.82 e | 52.56 3.19 e | 39.43 1.99 e |

| Freeze | 30.69 1.13 b | 73.07 2.95 b | 65.93 2.02 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbaspour-Gilandeh, Y.; Kaveh, M.; Fatemi, H.; Aziz, M. Combined Hot Air, Microwave, and Infrared Drying of Hawthorn Fruit: Effects of Ultrasonic Pretreatment on Drying Time, Energy, Qualitative, and Bioactive Compounds’ Properties. Foods 2021, 10, 1006. https://doi.org/10.3390/foods10051006

Abbaspour-Gilandeh Y, Kaveh M, Fatemi H, Aziz M. Combined Hot Air, Microwave, and Infrared Drying of Hawthorn Fruit: Effects of Ultrasonic Pretreatment on Drying Time, Energy, Qualitative, and Bioactive Compounds’ Properties. Foods. 2021; 10(5):1006. https://doi.org/10.3390/foods10051006

Chicago/Turabian StyleAbbaspour-Gilandeh, Yousef, Mohammad Kaveh, Hamideh Fatemi, and Muhammad Aziz. 2021. "Combined Hot Air, Microwave, and Infrared Drying of Hawthorn Fruit: Effects of Ultrasonic Pretreatment on Drying Time, Energy, Qualitative, and Bioactive Compounds’ Properties" Foods 10, no. 5: 1006. https://doi.org/10.3390/foods10051006

APA StyleAbbaspour-Gilandeh, Y., Kaveh, M., Fatemi, H., & Aziz, M. (2021). Combined Hot Air, Microwave, and Infrared Drying of Hawthorn Fruit: Effects of Ultrasonic Pretreatment on Drying Time, Energy, Qualitative, and Bioactive Compounds’ Properties. Foods, 10(5), 1006. https://doi.org/10.3390/foods10051006