Optimisation of the Extrusion Process through a Response Surface Methodology for Improvement of the Physical Properties and Nutritional Components of Whole Black-Grained Wheat Flour

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Experimental Design

2.3. Extrusion Cooking

2.4. Chemical Composition, Physicochemical Properties, and Texture Profile Analysis

2.4.1. Specific Volume

2.4.2. Expansion Ratio

2.4.3. Hardness and Fracturability

2.4.4. Water Absorption Index (WAI) and Water Solubility Index (WSI)

2.4.5. Protein Content

2.4.6. Ash Content

2.4.7. Microelements Content

2.4.8. Total Starch Content

2.5. Statistical Analysis

3. Results and Discussion

3.1. Effect of Barrel Temperature on Extrudate Quality

3.2. Effect of Feed Moisture Content on Extrudate Quality

3.3. Effect of the Feed Rate on Extrudate Quality

3.4. Diagnostic Checking of the Fitted Model and Surface Plots for Various Responses

3.4.1. Specific Volume

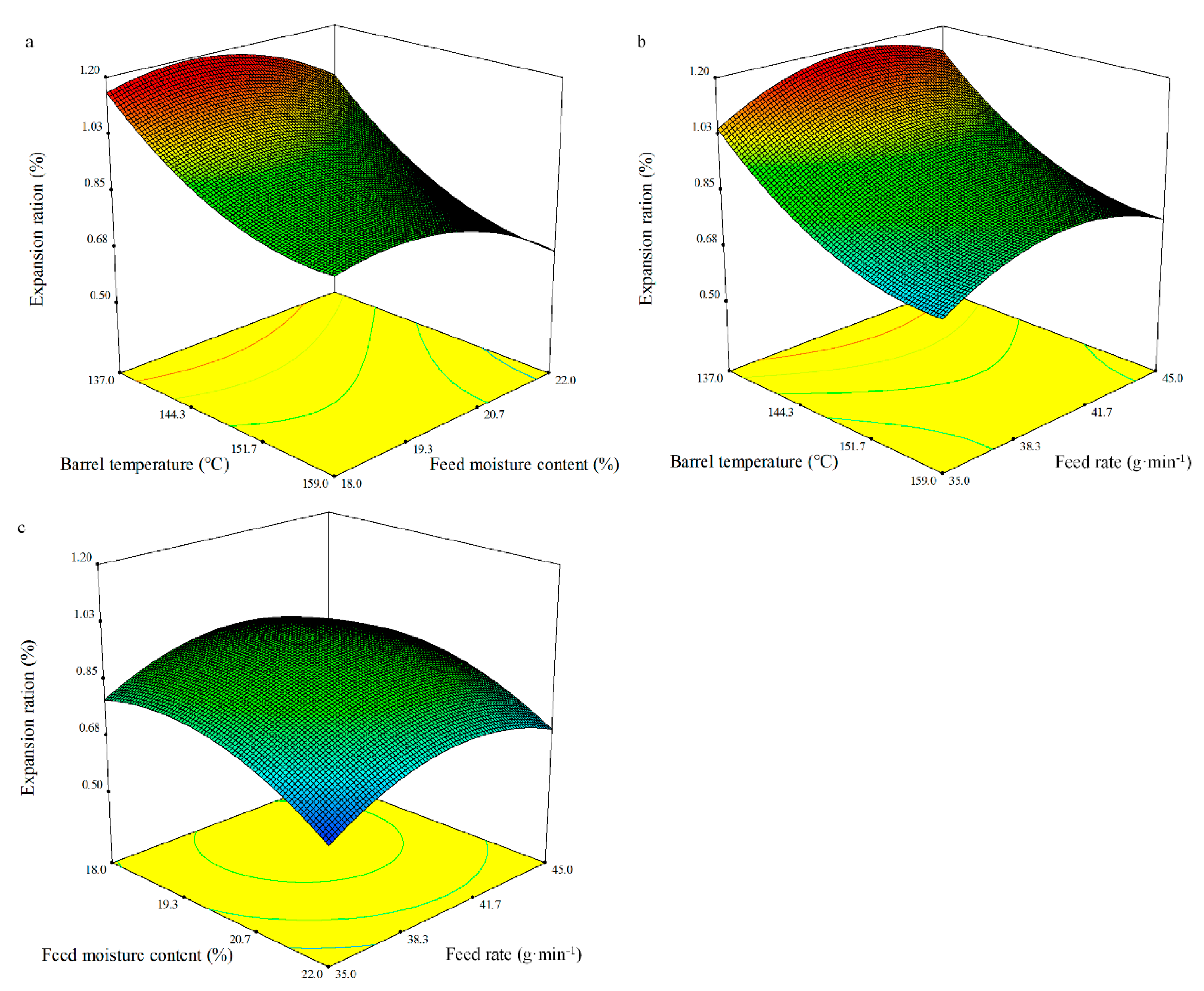

3.4.2. Expansion Ratio

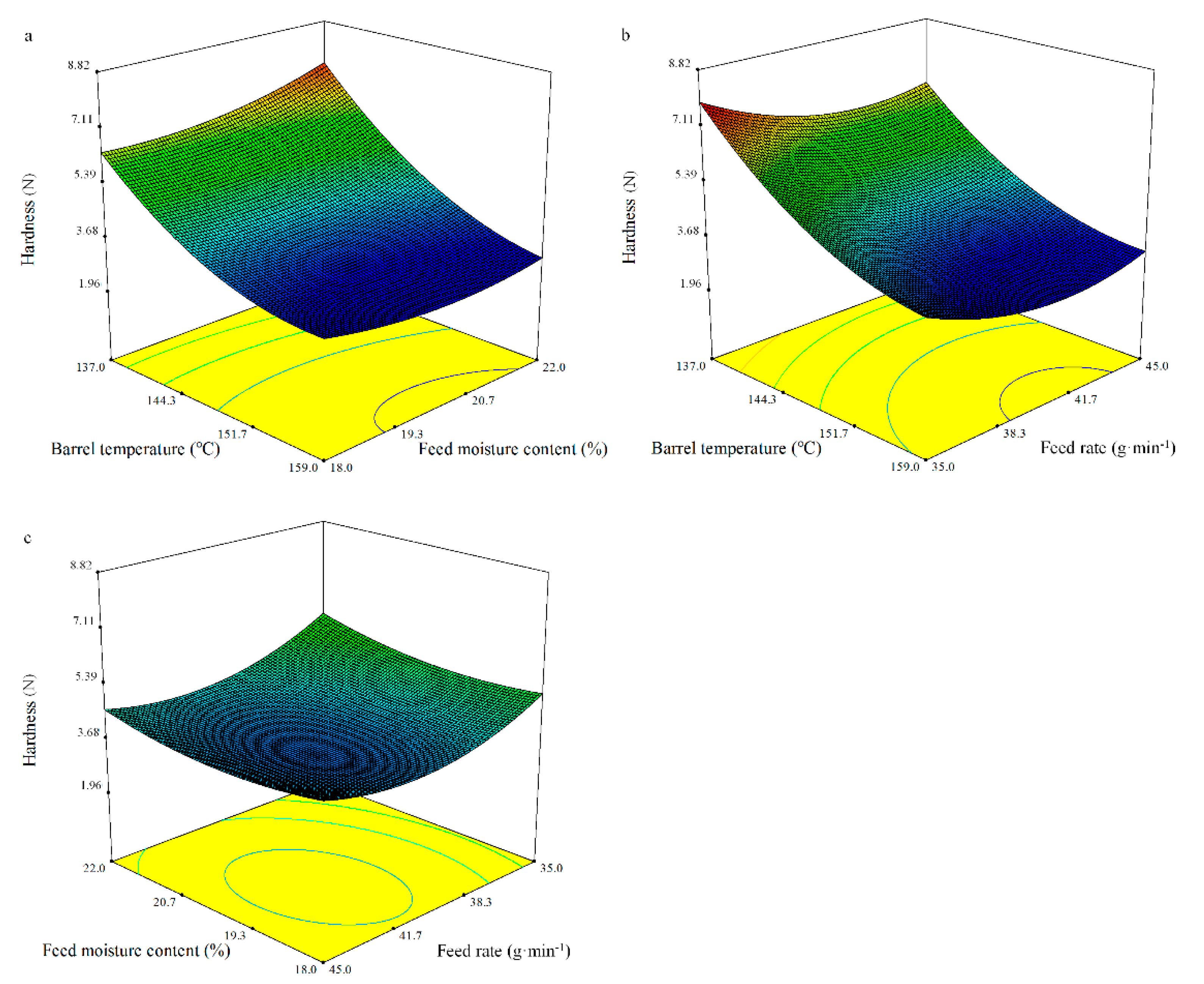

3.4.3. Hardness

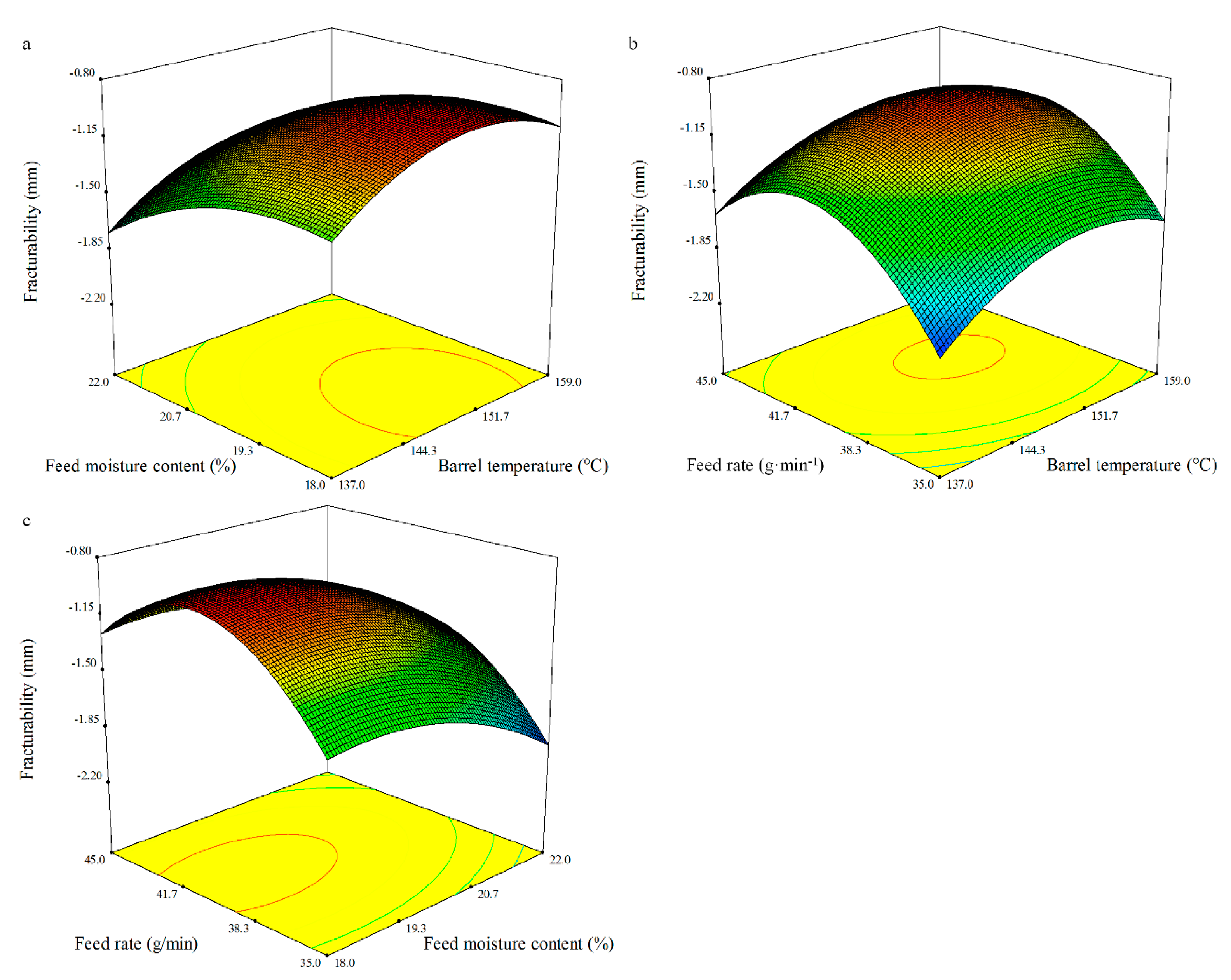

3.4.4. Fracturability

3.4.5. WAI

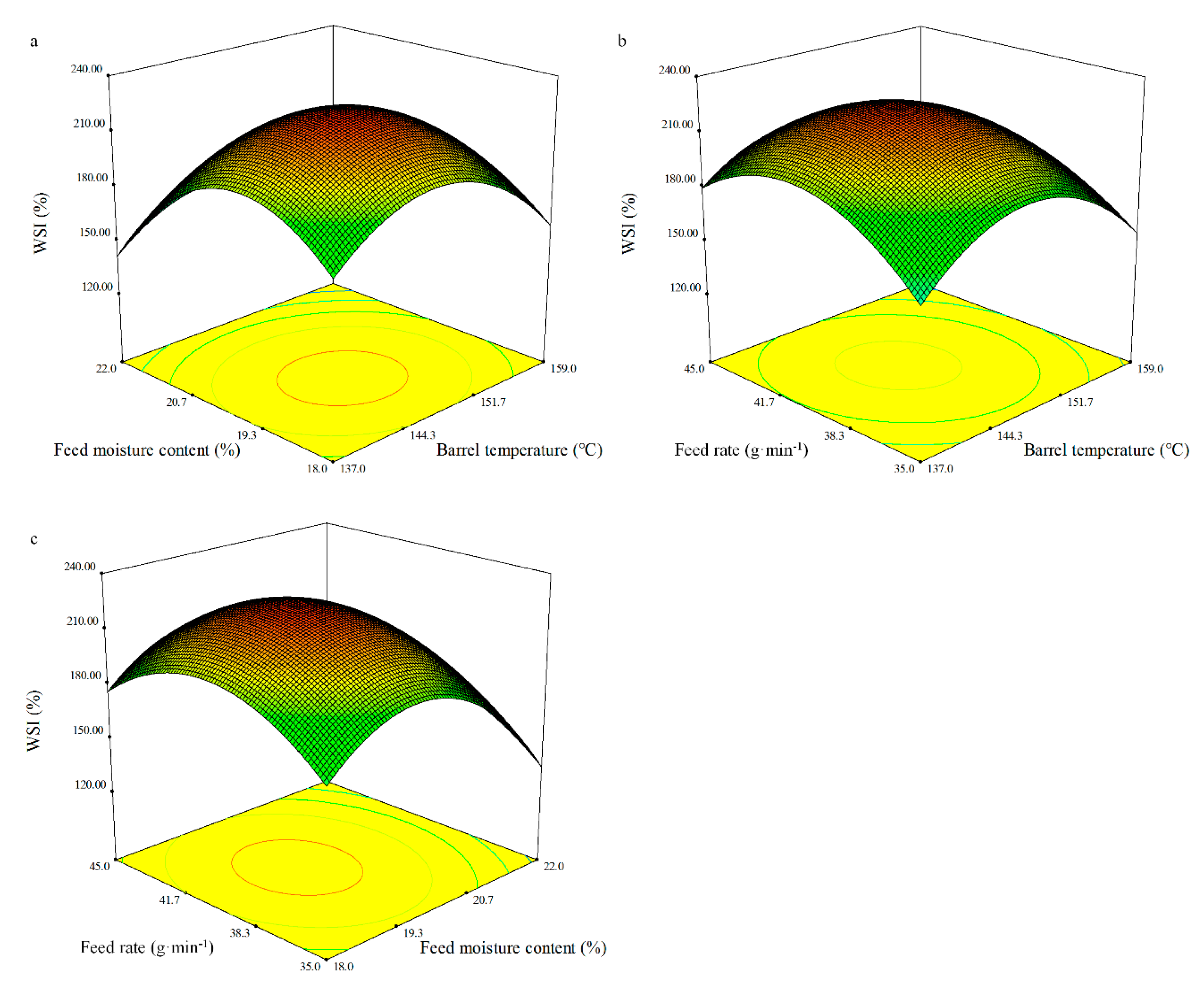

3.4.6. WSI

3.5. Optimisation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chandra, A.K.; Kumar, A.; Bharati, A.; Joshi, R.; Agrawal, A.; Kumar, S. Microbial-Assisted and Genomic-Assisted Breeding: A Two Way Approach for the Improvement of Nutritional Quality Traits in Agricultural Crops. 3 Biotech 2020, 10, 2. [Google Scholar] [CrossRef]

- Statista-The Statistic Portal 2020. Available online: www.statista.com/statistics/267268/production-of-wheat-worldwide-since-1990/ (accessed on 25 November 2020).

- Liu, H.; Wang, Z.H.; Li, F.C.; Li, K.Y.; Yang, N.; Yang, Y.; Huang, D.L.; Liang, D.L.; Zhao, H.B.; Mao, H.; et al. Grain Iron and Zinc Concentrations of Wheat and Their Relationships to Yield in Major Wheat Production Areas in China. Field Crops Res. 2014, 156, 151–160. [Google Scholar] [CrossRef]

- Gomez-Coronado, F.; Almeida, A.S.; Santamaria, O.; Cakmak, I.; Poblaciones, M.J. Potential of Advanced Breeding Lines of Bread Making Wheat to Accumulate Grain Minerals (Ca, Fe, Mg and Zn) and Low Phytates under Mediterranean Conditions. J. Agron. Crop Sci. 2019, 205, 341–352. [Google Scholar] [CrossRef]

- Maltzahn, L.E.; Zenker, S.G.; Lopes, J.L.; Pereira, R.M.; Verdi, C.A.; Rother, V.; Busanello, C.; Viana, V.E.; Batista, B.L.; de Oliveira, A.C.; et al. Brazilian Genetic Diversity for Desirable and Undesirable Elements in the Wheat Grain. Biol. Trace Elem. Res. 2020. [Google Scholar] [CrossRef]

- International Food Policy Research Institute. Global Nutrition Report; IFPRI: Washington, DC, USA, 2017. [Google Scholar]

- International Food Policy Research Institute. Global Nutrition Report in the Context of COVID-19; IFPRI: Washington, DC, USA, 2020. [Google Scholar]

- Guo, Z.F.; Xu, P.; Zhang, Z.B.; Wang, D.W.; Jin, M.; Teng, A.P. Segregation Ratios of Colored Grains in Crossed Wheat. Aust. J. Crop Sci. 2011, 5, 589–594. [Google Scholar]

- Tian, S.Q.; Chen, Z.C.; Wei, Y.C. Measurement of Colour-Grained Wheat Nutrient Compounds and the Application of Combination Technology in Dough. J. Cereal Sci. 2018, 83, 63–67. [Google Scholar] [CrossRef]

- Ficco, D.B.; de Simone, V.; Colecchia, S.A.; Pecorella, I.; Platani, C.; Nigro, F.; Finocchiaro, F.; Papa, R.; de Vita, P. Genetic Variability in Anthocyanin Composition and Nutritional Properties of Blue, Purple, and Red Bread (Triticum aestivum L.) and Durum (Triticum turgidum L. ssp. turgidum convar. Durum) Wheats. J. Agric. Food Chem. 2014, 62, 8686–8695. [Google Scholar] [CrossRef]

- Ma, D.Y.; Li, Y.G.; Zhang, J.; Wang, C.Y.; Qin, H.X.; Ding, H.N.; Xie, Y.X.; Guo, T.C. Accumulation of Phenolic Compounds and Expression Profiles of Phenolic Acid Biosynthesis-Related Genes in Developing Grains of White, Purple, and Red Wheat. Front. Plant Sci. 2016, 7, 528. [Google Scholar] [CrossRef] [PubMed]

- Phuong, L.M.; Lachman, J.; Kotikova, Z.; Orsak, M.; Michlova, T.; Martinek, P. Selenium in Colour-Grained Winter Wheat and Spring Tritordeum. Plant Soil Environ. 2017, 63, 315–321. [Google Scholar]

- Francavilla, A.; Joye, I.J. Anthocyanins in Whole Grain Cereals and Their Potential Effect on Health. Nutrients 2020, 12, 2922. [Google Scholar] [CrossRef]

- Li, L.H.; Yang, G.P.; Ren, M.J.; Wang, Z.N.; Peng, Y.S.; Xu, R.H. Co-Regulation of Auxin and Cytokinin in Anthocyanin Accumulation during Natural Development of Purple Wheat Grains. J. Plant Growth Regul. 2020. [Google Scholar] [CrossRef]

- Morgounov, A.; Karaduman, Y.; Akin, B.; Aydogan, S.; Baenziger, P.S.; Bhatta, M.; Chudinov, V.; Dreisigacker, S.; Govindan, V.; Guler, S.; et al. Yield and Quality in Purple-Grained Wheat Isogenic Lines. Agronomy 2020, 10, 86. [Google Scholar] [CrossRef]

- Paznocht, L.; Buresova, B.; Kotikova, Z.; Martinek, P. Carotenoid Content of Extruded and Puffed Products Made of Colored-Grain Wheats. Food Chem. 2020, 340, 127951. [Google Scholar] [CrossRef]

- Paznocht, L.; Kotikova, Z.; Buresova, B.; Lachman, J.; Martinek, P. Phenolic Acids in Kernels of Different Coloured-Grain Wheat Genotypes. Plant Soil Environ. 2020, 66, 57–64. [Google Scholar] [CrossRef]

- Chen, X.; Li, X.; Zhu, X.; Wang, G.; Zhuang, K.; Wang, Y.; Ding, W. Optimization of Extrusion and Ultrasound-Assisted Extraction of Phenolic Compounds from Jizi439 Black Wheat Bran. Processes 2020, 8, 1153. [Google Scholar] [CrossRef]

- Saini, P.; Kumar, N.; Kumar, S.; Mwaurah, P.W.; Panghal, A.; Attkan, A.K.; Singh, V.K.; Garg, M.K.; Singh, V. Bioactive Compounds, Nutritional Benefits and Food Applications of Colored Wheat: A Comprehensive Review. Crit. Rev. Food Sci. 2020, 63, 1–14. [Google Scholar] [CrossRef]

- Li, W.D.; Beta, T.; Sun, S.C.; Corke, H. Protein Characteristics of Chinese Black-Grained Wheat. Food Chem. 2006, 98, 463–472. [Google Scholar] [CrossRef]

- Li, W.D.; Shan, F.; Sun, S.C.; Corke, H.; Beta, T. Free Radical Scavenging Properties and Phenolic Content of Chinese Black-Grained Wheat. J. Agric. Food Chem. 2005, 53, 8533–8536. [Google Scholar] [CrossRef]

- Li, W.D.; Beta, T. Flour and Bread from Black-, Purple-, and Blue-Colored Wheats. In Flour and Breads and Their Fortification in Health and Disease Prevention; Preedy, V.R., Watson, R.R., Patel, V.B., Eds.; Academic Press: Cambridge, MA, USA, 2011; pp. 59–67. [Google Scholar]

- Ma, D.Y.; Sun, D.X.; Zuo, Y.; Wang, C.Y.; Zhu, Y.J.; Guo, T.C. Diversity of Antioxidant Content and Its Relationship to Grain Color and Morphological Characteristics in Winter Wheat Grains. J. Integr. Agr. 2014, 13, 1258–1267. [Google Scholar] [CrossRef]

- Chen, Z. Analysis on the Distribution of Main Physicochemical Parameters of Color Wheat and Study on Its Layering Milling Technology. Agric. Sci. Technol. 2012, 13, 766–770. [Google Scholar]

- Saloni, S.; Venkatesh, C.; Aman, K.; Rohit, K.; Pragyanshu, K.; Kanthi, K.K.; Mahendra, B.; Monika, G. Anthocyanin Bio-Fortified Colored Wheat: Nutritional and Functional Characterization. PLoS ONE 2018, 13, e0194367. [Google Scholar] [CrossRef]

- Liu, Y.X.; Liu, M.M.; Zhang, Z.M. Research Progress in Breeding and Nutritional and Processing Quality of Black-Grain Wheat Varsities (Triticom aestivom L.). J. Triticeae Crops 2020, 40, 698–706. [Google Scholar]

- Liu, Y.; Qiu, J.; Yue, Y.; Li, K.; Ren, G. Dietary Black-Grained Wheat Intake Improves Glycemic Control and Inflammatory Profile in Patients with Type 2 Diabetes: A Randomized Controlled Trial. Ther. Clin. Risk Manag. 2018, 14, 247–256. [Google Scholar] [CrossRef]

- Okarter, N.; Liu, R.H. Health Benefits of Whole Grain Phytochemicals. Crit. Rev. Food Sci. Nutr. 2010, 50, 193–208. [Google Scholar] [CrossRef]

- Ficco, D.B.M.; Beleggia, R.; Pecorella, I.; Giovanniello, V.; Frenda, A.S.; Vita, P.D. Relationship between Seed Morphological Traits and Ash and Mineral Distribution along the Kernel Using Debranning in Durum Wheats from Different Geographic Sites. Foods 2020, 9, 1523. [Google Scholar] [CrossRef] [PubMed]

- Gómez, M.; Gutkoski, L.C.; Bravo-Núñez, Á. Understanding Whole-Wheat Flour and Its Effect in Breads: A Review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3241–3265. [Google Scholar] [CrossRef]

- Cheftel, J.C. Nutritional Effects of Extrusion-Cooking. Food Chem. 1986, 20, 263–283. [Google Scholar] [CrossRef]

- Tran, Q.D.; Hendriks, W.H.; van der Poel, A.F.B. Effects of Extrusion Processing on Nutrients in Dry Pet Food. J. Sci. Food Agric. 2008, 88, 1487–1493. [Google Scholar] [CrossRef]

- Altan, A.; Mccarthy, K.L.; Maskan, M. Extrusion Cooking of Barley Flour and Process Parameter Optimization by Using Response Surface Methodology. J. Sci. Food Agric. 2008, 88, 1648–1659. [Google Scholar] [CrossRef]

- Arora, B.; Yoon, A.; Sriram, M.; Singha, P.; Rizvi, S.S.H. Reactive Extrusion: A Review of the Physicochemical Changes in Food Systems. Innov. Food Sci. Emerg. 2020, 64, 102429. [Google Scholar] [CrossRef]

- Thymi, S.; Krokida, M.K.; Pappa, A.; Maroulis, Z.B. Structural Properties of Extruded Corn Starch. J. Food. Eng. 2005, 68, 519–526. [Google Scholar] [CrossRef]

- Drago, S.R.; Velasco-GonzÁlez, O.H.; Torres, R.L.; González, R.J.; Valencia, M.E. Effect of the Extrusion on Functional Properties and Mineral Dialyzability from Phaseolus Vulgaris Bean Flour. Plant Foods Hum. Nutr. 2007, 62, 43–48. [Google Scholar] [CrossRef]

- Jing, Y.; Chi, Y. Effects of Twin-Screw Extrusion on Soluble Dietary Fiber and Physicochemical Properties of Soybean Residue. Food Chem. 2013, 138, 884–889. [Google Scholar] [CrossRef] [PubMed]

- Gandhi, N.; Singh, B.; Singh, P.; Sharma, S. Functional, Rheological, Morphological, and Micro-Structural Properties of Extrusion-Processed Corn and Potato Starches. Starch Stärke 2020, 73, 2000140. [Google Scholar] [CrossRef]

- Wang, Q.F.; Li, L.M.; Zheng, X.L.; Xiong, X.Q. Effect of Extrusion Feeding Moisture on Dough, Nutritional, and Texture Properties of Noodles Fortified with Extruded Buckwheat Flour. J. Food Process. Pres. 2020, 44, e14978. [Google Scholar] [CrossRef]

- Singh, S.; Gamlath, S.; Wakeling, L. Nutritional Aspects of Food Extrusion: A Review. Int. J. Food Sci. Technol. 2007, 42, 916–929. [Google Scholar] [CrossRef]

- Anderson, A.K.; Ng, P.K.W. Changes in Disulfide and Sulfhydryl Contents and Electrophoretic Patterns of Extruded Wheat Flour Proteins. Cereal Chem. 2000, 77, 354–359. [Google Scholar] [CrossRef]

- Myat, L.; Ryu, G.H. Characteristics of Destarched Corn Fiber Extrudates for Ethanol Production. J. Cereal Sci. 2014, 60, 289–296. [Google Scholar] [CrossRef]

- Imran, M.; Anjum, F.M.; Butt, M.S.; Sheikh, M.A. Influence of Extrusion Processing on Tannin Reduction and Oil Loss in Flaxseed (Linum usitatissimum L.) Meal. J. Food Process. Pres. 2014, 38, 622–629. [Google Scholar] [CrossRef]

- Kristiawan, M.; Micard, V.; Maladira, P.; Alchamieh, C.; Maigret, J.-E.; Réguerre, A.-L.; Emin, M.A.; Della Valle, G. Multi-Scale Structural Changes of Starch and Proteins during Pea Flour Extrusion. Food Res. Int. 2018, 108, 203–215. [Google Scholar] [CrossRef]

- Brennan, M.A.; Derbyshire, E.; Tiwari, B.K.; Brennan, C.S. Ready-to-Eat Snack Products: The Role of Extrusion Technology in Developing Consumer Acceptable and Nutritious Snacks. Int. J. Food Sci. Technol. 2013, 48, 893–902. [Google Scholar] [CrossRef]

- Tabibloghmany, F.S.; Mazaheri Tehrani, M.; Koocheki, A. Optimization of the Extrusion Process through Response Surface Methodology for Improvement in Functional and Nutritional Properties of Soybean Hull. J. Food Sci. Technol. 2020, 57, 4054–4064. [Google Scholar] [CrossRef]

- Ding, Q.B.; Ainsworth, P.; Plunkett, A.; Tucker, G.; Marson, H. The Effect of Extrusion Conditions on the Functional and Physical Properties of Wheat-Based Expanded Snacks. J. Food Eng. 2006, 73, 142–148. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Borah, A.; Singh, K.K.; Patil, R.T. Effect of Selected Dehulled Legume Incorporation on Functional and Nutritional Properties of Protein Enriched Sorghum and Wheat Extrudates. J. Food Sci. Technol. 2012, 49, 572–579. [Google Scholar] [CrossRef]

- Singh, R.K.R.; Majumdar, R.K.; Venkateshwarlu, G. Effect of Process Conditions on Physico-Chemical and Sensory Properties of Fish-Cereal-Based Extruded Snack-Like Products. J. Food Process. Pres. 2014, 38, 68–82. [Google Scholar] [CrossRef]

- Moraru, C.I.; Kokini, J.L. Nucleation and Expansion During Extrusion and Microwave Heating of Cereal Foods. Compr. Rev. Food Sci. Food Saf. 2003, 2, 120–138. [Google Scholar] [CrossRef] [PubMed]

- Anderson, A.K.; Ng, P.K.W. Physical and Microstructural Properties of Wheat Flour Extrudates as Affected by Vital Gluten Addition and Process Conditions. Food Sci. Biotechnol. 2003, 12, 23–28. [Google Scholar]

- Kirby, A.R.; Ollett, A.L.; Parker, R.; Smith, A.C. An Experimental Study of Screw Configuration Effects in the Twin-Screw Extrusion-Cooking of Maize Grits. J. Food Eng. 1988, 8, 247–272. [Google Scholar] [CrossRef]

- Sarifudin, A.; Assiry, A.M. Some Physicochemical Properties of Dextrin Produced by Extrusion Process. J. Saudi Soc. Agric. Sci. 2014, 13, 100–106. [Google Scholar] [CrossRef]

- Roye, C.; Henrion, M.; Chanvrier, H.; de Roeck, K.; de Bondt, Y.; Liberloo, I.; King, R.; Courtin, C.M. Extrusion-Cooking Modifies Physicochemical and Nutrition-Related Properties of Wheat Bran. Foods 2020, 9, 738. [Google Scholar] [CrossRef] [PubMed]

- Vaz, L.C.M.A.; Arêas, J.A.G. Recovery and Upgrading Bovine Rumen Protein by Extrusion: Effect of Lipid Content on Protein Disulphide Cross-Linking, Solubility and Molecular Weight. Meat Sci. 2010, 84, 39–45. [Google Scholar] [CrossRef]

- Mosibo, O.K.; Ferrentino, G.; Alam, M.R.; Morozova, K.; Scampicchio, M. Extrusion Cooking of Protein-Based Products: Potentials and Challenges. Crit. Rev. Food Sci. Nutr. 2020, 65, 1–35. [Google Scholar] [CrossRef] [PubMed]

- Angelis, D.D.; Kaleda, A.; Pasqualone, A.; Vaikma, H.; Tamm, M.; Tammik, M.L.; Squeo, G.; Summo, C. Physicochemical and Sensorial Evaluation of Meat Analogues Produced from Dry-Fractionated Pea and Oat Proteins. Foods 2020, 9, 1754. [Google Scholar] [CrossRef]

- Guldiken, B.; Yovchev, A.; Nosworthy, M.G.; Stone, A.K.; House, J.D.; Hood-Niefer, S.; Nickerson, M.T. Effect of Extrusion Conditions on the Physical Properties of Desi Chickpea-Barley Extrudates and Quality Attributes of Their Resulting Flours. J. Texture Stud. 2020, 51, 300–307. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, B.; Wei, Y.; Li, S. Effects of Specific Mechanical Energy on Soy Protein Aggregation during Extrusion Process Studied by Size Exclusion Chromatography Coupled with Multi-Angle Laser Light Scattering. J. Food Eng. 2013, 115, 220–225. [Google Scholar] [CrossRef]

- Koch, L.; Hummel, L.; Schuchmann, H.P.; Emin, M.A. Improving the Emulsifying Properties of Whey Protein Isolate-Citrus Pectin Blends by a Novel Reactive Extrusion Approach. J. Food Eng. 2018, 223, 175–188. [Google Scholar] [CrossRef]

- Pasqualone, A.; Costantini, M.; Coldea, T.E.; Summo, C. Use of Legumes in Extrusion Cooking: A Review. Foods 2020, 9, 958. [Google Scholar] [CrossRef]

- Camire, M.E. Chemical Changes during Extrusion Cooking. In Process-Induced Chemical Changes in Food. Advances in Experimental Medicine and Biology; Shahidi, F., Ho, C.T., van Chuyen, N., Eds.; Springer: Boston, MA, USA, 1998; p. 434. [Google Scholar]

- Chen, F.L.; Chen, X.Y.; Wang, X.C.; Yin, J.; Zhao, X.Y. Relationship between Wheat Quality and Physicochemical Properties of Extruded Expansion Product. Sci. Agric. Sin. 2013, 78, 4336–4343. [Google Scholar]

- Zahari, I.; Ferawati, F.; Helstad, A.; Ahlstrom, C.; Ostbring, K.; Rayner, M.; Purhagen, J.K. Development of High-Moisture Meat Analogues with Hemp and Soy Protein Using Extrusion Cooking. Foods 2020, 9, 772. [Google Scholar] [CrossRef] [PubMed]

- Ramzan, Y.; Hafeez, M.B.; Khan, S.; Nadeem, M.; Batool, S.; Ahmad, J. Biofortification with Zinc and Iron Improves the Grain Quality and Yield of Wheat Crop. Int. J. Plant Prod. 2020, 14, 501–510. [Google Scholar] [CrossRef]

- van den Einde, R.M.; van der Veen, M.E.; Bosman, H.; van der Goot, A.J.; Boom, R.M. Modeling Macromolecular Degradation of Corn Starch in a Twin Screw Extruder. J. Food Eng. 2005, 66, 147–154. [Google Scholar] [CrossRef]

- Bu, C.W. Operating Parameters’ Influence on the Specific Volume of Extrusion Puffed Food. Appl. Mech. Mater. 2011, 55, 966–969. [Google Scholar] [CrossRef]

- Nyombaire, G.; Siddiq, M.; Dolan, K.D. Physico-Chemical and Sensory Quality of Extruded Light Red Kidney Bean (Phaseolus vulgaris L.) Porridge. LWT Food Sci. Technol. 2011, 44, 1597–1602. [Google Scholar] [CrossRef]

- Badrie, N.; Mellowes, W.A. Texture and Microstructure of Cassava (Manihot Esculenta Crantz) Flour Extrudate. J. Food Sci. 2010, 56, 1319–1322. [Google Scholar] [CrossRef]

- Kumar, A.; Samuel, D.V.K.; Jha, S.K.; Sinha, J.P. Twin Screw Extrusion of Sorghum and Soya Blends: A Response Surface Analysis. J. Agric. Sci. Technol. 2015, 17, 649–662. [Google Scholar]

- Myers, R.; Montgomery, D.C. Response Surface Methodology: Process and Products Optimization Using Designed Experiments, 2nd ed.; Wiley: Hoboken, NJ, USA, 2002; pp. 1–302. [Google Scholar]

| Treatments | Zones/°C | Average | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| T1 | 60 | 120 | 140 | 150 | 160 | 126 |

| T2 | 60 | 130 | 155 | 165 | 175 | 137 |

| T3 | 60 | 140 | 170 | 180 | 190 | 148 |

| T4 | 60 | 150 | 185 | 195 | 205 | 159 |

| T5 | 60 | 160 | 200 | 210 | 220 | 170 |

| Run | Coded Variables | Actual Variables | ||||

|---|---|---|---|---|---|---|

| X1 | X2 | X3 | Barrel Temperature (°C) a | Feed Moisture Content (%) | Feed Rate (g·min−1) | |

| 1 | −1 | 0 | 1 | 137 | 20 | 45 |

| 2 | −1 | −1 | 0 | 137 | 18 | 40 |

| 3 | −1 | 1 | 0 | 137 | 22 | 40 |

| 4 | −1 | 0 | −1 | 137 | 20 | 35 |

| 5 | 0 | −1 | 1 | 148 | 18 | 45 |

| 6 | 0 | 0 | 0 | 148 | 20 | 40 |

| 7 | 0 | 0 | 0 | 148 | 20 | 40 |

| 8 | 0 | 0 | 0 | 148 | 20 | 40 |

| 9 | 0 | 1 | 1 | 148 | 22 | 45 |

| 10 | 0 | −1 | −1 | 148 | 18 | 35 |

| 11 | 0 | 1 | −1 | 148 | 22 | 35 |

| 12 | 1 | 0 | 1 | 159 | 20 | 45 |

| 13 | 1 | −1 | 0 | 159 | 18 | 40 |

| 14 | 1 | 1 | 0 | 159 | 22 | 40 |

| 15 | 1 | 0 | −1 | 159 | 20 | 35 |

| Feed Moisture Content (%) | Feed Rate (g·min−1) | Screw Speed (r·min−1) | |

|---|---|---|---|

| BGW | WGW | ||

| 20.0% | 20.0 | 16.7 | 12.4 |

| 30.0 | 20.0 | 16.7 | |

| 40.0 | 26.0 | 21.6 | |

| 50.0 | 34.7 | 27.1 | |

| 60.0 | 46.1 | 33.2 | |

| 22.5% | 20.0 | 16.7 | 12.5 |

| 30.0 | 23.2 | 18.6 | |

| 40.0 | 30.7 | 22.1 | |

| 50.0 | 39.2 | 28.5 | |

| 60.0 | 51.7 | 34.6 | |

| 25.0% | 20.0 | 16.7 | 12.5 |

| 30.0 | 22.3 | 18.3 | |

| 40.0 | 30.7 | 24.2 | |

| 50.0 | 45.5 | 30.5 | |

| 60.0 | 63.2 | 37.3 | |

| Barrel Temperature (°C) a | Specific Volume (m3·kg−1) | Expansion Ratio (%) | Hardness (N) | |||

|---|---|---|---|---|---|---|

| BGW | WGW | BGW | WGW | BGW | WGW | |

| T1 | 5.07 ± 0.21 Aa | 4.85 ± 0.06 Aa | 1.58 ± 0.06 Aa | 1.49 ± 0.03 Aa | 7.88 ± 0.36 Ab | 8.95 ± 0.49 Aa |

| T2 | 4.69 ± 0.17 Aa | 4.53 ± 0.09 Aa | 1.23 ± 0.04 Ba | 1.15 ± 0.04 Ba | 4.38 ± 0.43 Ca | 4.74 ± 0.51 Ca |

| T3 | 3.32 ± 0.06 Ba | 3.68 ± 0.03 Ba | 1.00 ± 0.08 Ba | 0.82 ± 0.07 Ca | 3.80 ± 0.55 Ca | 4.09 ± 0.32 Ca |

| T4 | 2.36 ± 0.06 Ca | 2.69 ± 0.04 Ca | 0.72 ± 0.04 Ca | 0.68 ± 0.08 Ca | 5.50 ± 0.45 Ba | 6.50 ± 0.51 Ba |

| T5 | 1.58 ± 0.04 Da | 1.71 ± 0.03 Da | 0.56 ± 0.07 Ca | 0.42 ± 0.07 Da | 7.43 ± 0.59 Aa | 8.36 ± 0.63 Aa |

| Fracturability (mm) | WAI (%) | WSI (%) | ||||

| T1 | −1.68 ± 0.08 Ba | −1.89 ± 0.07 Cb | 5434.00 ± 70.71 Bb | 5647.00 ± 72.33 Ba | 195.32 ± 16.21 Ba | 134.56 ± 12.93 Ca |

| T2 | −1.31 ± 0.11 Aa | −1.53 ± 0.04 Ba | 6168.00 ± 59.40 Ab | 6368.00 ± 82.63 Aa | 212.82 ± 20.27 Ba | 162.34 ± 24.61 BCa |

| T3 | −0.99 ± 0.18 Aa | −0.84 ± 0.03 Aa | 6486.00 ± 73.54 Ab | 6754.00 ± 84.85 Aa | 234.00 ± 28.40 Ba | 188.80 ± 18.95 Ba |

| T4 | −1.26 ± 0.09 Aa | −1.43 ± 0.08 Ba | 6294.00 ± 68.43 Ab | 6523.00 ± 60.32 Aa | 238.34 ± 20.21 Ba | 200.54 ± 20.12 Ba |

| T5 | −1.76 ± 0.10 Ba | −1.86 ± 0.12 Ca | 6063.00 ± 50.42 Ab | 6332.00 ± 77.86 Aa | 265.25 ± 17.14 Aa | 245.32 ± 17.24 Aa |

| Protein content (%) | Ash content (%) | Fe content (mg⋅kg−1) | ||||

| Unextruded | 16.53 ± 0.01 Aa | 14.24 ± 0.09 Ab | 1.71 ± 0.01 Aa | 1.53 ± 0.06 Ab | 33.56 ± 1.32 Bb | 43.76 ± 0.34 Ba |

| T1 | 16.45 ± 0.12 Aa | 14.34 ± 0.11 Ab | 1.73 ± 0.04 Aa | 1.55 ± 0.04 Ab | 45.85 ± 0.98 Ab | 53.53 ± 1.31 Aa |

| T2 | 16.32 ± 0.10 Aa | 14.46 ± 0.24 Ab | 1.75 ± 0.06 Aa | 1.52 ± 0.05 Ab | 47.32 ± 1.21 Ab | 54.37 ± 1.15 Aa |

| T3 | 16.75 ± 0.09 Aa | 14.52 ± 0.18 Ab | 1.74 ± 0.05 Aa | 1.57 ± 0.08 Ab | 43.54 ± 2.01 Ab | 52.98 ± 1.05 Aa |

| Zn content (mg⋅kg−1) | Cu content (mg⋅kg−1) | Mn content (mg⋅kg−1) | ||||

| Unextruded | 37.54 ± 0.72 Aa | 24.53 ± 0.21 Ab | 6.02 ± 0.19 Ba | 4.73 ± 0.05 Bb | 48.67 ± 0.40 Ba | 45.32 ± 0.97 Ab |

| T1 | 37.98 ± 1.03 Aa | 25.06 ± 0.97 Ab | 6.97 ± 0.16 Aa | 5.63 ± 0.14 Ab | 54.36 ± 1.86 Aa | 46.86 ± 1.54 Ab |

| T2 | 38.73 ± 2.35 Aa | 24.75 ± 1.21 Ab | 6.85 ± 0.17 Aa | 5.57 ± 0.27 Ab | 56.75 ± 1.54 Aa | 47.37 ± 2.13 Ab |

| T3 | 37.06 ± 1.32 Aa | 25.57 ± 1.03 Ab | 7.02 ± 0.23 Aa | 5.60 ± 0.26 Ab | 55.37 ± 1.23 Aa | 45.96 ± 1.06 Ab |

| Extrusion Variables | Treatments | Total Starch Content (%) | |

|---|---|---|---|

| BGW | WGW | ||

| Barrel temperature (°C) a | Unextruded | 57.50 ± 0.69 Ab | 69.64 ± 0.54 Aa |

| T1 | 55.43 ± 0.64 ABb | 67.52 ± 0.86 ABa | |

| T2 | 54.51 ± 0.41 BCb | 66.55 ± 0.63 BCa | |

| T3 | 52.29 ± 0.80 CDb | 64.49 ± 0.61 CDa | |

| T4 | 51.30 ± 0.79 Db | 63.77 ± 0.76 Da | |

| T5 | 50.39 ± 0.70 Db | 62.67± 0.42 Da | |

| Feed moisture content (%) | Unextruded | 57.50 ± 0.69 Ab | 69.64 ± 0.54 Aa |

| 15.0 | 55.47 ± 0.53 ABb | 67.63 ± 0.73 ABa | |

| 17.5 | 54.69 ± 0.55 BCb | 66.92 ± 0.47 BCa | |

| 20.0 | 52.76 ± 0.54 CDb | 64.93 ± 0.85 CDa | |

| 22.5 | 52.46 ± 0.79 CDb | 64.49 ± 0.51 Da | |

| 25.0 | 51.86 ± 0.76 Db | 63.92 ± 0.73 Da | |

| Feed rate (g·min−1) | Unextruded | 57.50 ± 0.69 Ab | 69.64 ± 0.54 Aa |

| 20.0 | 55.60 ± 0.66 ABb | 67.76 ± 0.65 ABa | |

| 30.0 | 54.73 ± 0.60 BCb | 66.88 ± 0.76 BCa | |

| 40.0 | 53.03 ± 0.72 CDb | 64.79 ± 0.75 CDa | |

| 50.0 | 52.41 ± 0.77 CDb | 64.30 ± 0.69 CDa | |

| 60.0 | 51.93 ± 0.76 Db | 63.74 ± 0.68 Da | |

| Feed Moisture Content (%) | Specific Volume (m3·kg−1) | Expansion Ratio (%) | Hardness (N) | |||

|---|---|---|---|---|---|---|

| BGW | WGW | BGW | WGW | BGW | WGW | |

| 15.0 | 1.36 ± 0.08 Cb | 2.16 ± 0.06 Ca | 0.51 ± 0.06 Ca | 0.36 ± 0.02 Bb | 6.60 ± 0.42 Aa | 6.91 ± 0.30 Aa |

| 17.5 | 2.56 ± 0.10 Bb | 3.02 ± 0.05 Ba | 0.78 ± 0.03 Ba | 0.68 ± 0.03 Ab | 4.53 ± 0.33 Ca | 4.43 ± 0.30 Ca |

| 20.0 | 3.21 ± 0.08 Ab | 3.48 ± 0.05 Aa | 0.99 ± 0.05 Aa | 0.75 ± 0.01 Ab | 3.80 ± 0.42 Ca | 4.00 ± 0.25 Ca |

| 22.5 | 2.46 ± 0.07 Bb | 2.87 ± 0.04 Ba | 0.72 ± 0.06 Ba | 0.65 ± 0.04 Aa | 5.38 ± 0.36 Bb | 4.56 ± 0.45 Ca |

| 25.0 | 1.45 ± 0.05 Cb | 2.22 ± 0.06 Ca | 0.54 ± 0.04 Ca | 0.42 ± 0.03 Ba | 5.47 ± 0.32 Bb | 5.15 ± 0.18 Ba |

| Fracturability (mm) | WAI (%) | WSI (%) | ||||

| 15.0 | −2.11 ± 0.09 Ca | −1.92 ± 0.09 Ca | 5465.00 ± 70.32 Cb | 5576.00 ± 50.75 Cb | 275.45 ± 18.75 Aa | 255.34 ± 19.46 Aa |

| 17.5 | −1.04 ± 0.06 Aa | −0.93 ± 0.05 Aa | 6056.00 ± 60.34 Ba | 6357.00 ± 64.35 Ba | 220.16 ± 16.87 Ba | 207.54 ± 15.75 Ba |

| 20.0 | −1.00 ± 0.08 Aa | −0.85 ± 0.04 Aa | 6485.00 ± 57.98 Ab | 6786.00 ± 60.85 Aa | 235.23 ± 22.34 Ba | 186.57 ± 20.71 Bb |

| 22.5 | −1.47 ± 0.07 Ba | −1.38 ± 0.06 Ba | 6542.00 ± 82.79 Ab | 6897.00 ± 71.21 Aa | 157.06 ± 15.70 Ca | 155.56 ± 24.77 Ca |

| 25.0 | −1.95 ± 0.06 Ca | −1.86 ± 0.04 Ca | 6638.00 ± 46.18 Ab | 7089.00 ± 50.91 Aa | 138.65 ± 25.18 Ca | 140.62 ± 11.12 Ca |

| Protein content (%) | Ash content (%) | Fe content (mg⋅kg−1) | ||||

| Unextruded | 16.53 ± 0.01 Aa | 14.24 ± 0.09 Ab | 1.71 ± 0.01 Aa | 1.53 ± 0.06 Ab | 33.56 ± 1.32 Bb | 43.76 ± 0.34 Ba |

| 20.0 | 16.35 ± 0.05 Aa | 14.26 ± 0.05 Ab | 1.72 ± 0.05 Aa | 1.55 ± 0.04 Ab | 42.76 ± 1.01 Ab | 52.96 ± 1.76 Aa |

| 22.5 | 16.64 ± 0.06 Aa | 14.38 ± 0.07 Ab | 1.68 ± 0.08 Aa | 1.49 ± 0.04 Ab | 43.65 ± 1.06 Ab | 53.06 ± 2.14 Aa |

| 25.0 | 16.28 ± 0.08 Aa | 14.50 ± 0.09 Ab | 1.75 ± 0.05 Aa | 1.51 ± 0.08 Ab | 43.97 ± 1.12 Ab | 54.13 ± 2.42 Aa |

| Zn content (mg⋅kg−1) | Cu content (mg⋅kg−1) | Mn content (mg⋅kg−1) | ||||

| Unextruded | 37.54 ± 0.72 Aa | 24.53 ± 0.21 Ab | 6.02 ± 0.19 Ba | 4.73 ± 0.05 Bb | 48.67 ± 0.40 Aa | 45.32 ± 0.97 Ab |

| 20.0 | 37.86 ± 0.79 Aa | 25.43 ± 1.02 Ab | 6.85 ± 0.14 Aa | 5.57 ± 0.36 Ab | 50.13 ± 0.43 Aa | 46.32 ± 1.76 Ab |

| 22.5 | 38.79 ± 1.13 Aa | 23.86 ± 0.87 Ab | 6.73 ± 0.28 Aa | 5.74 ± 0.68 Ab | 51.24 ± 0.75 Aa | 47.52 ± 1.86 Ab |

| 25.0 | 39.75 ± 1.65 Aa | 25.07 ± 1.21 Ab | 6.71 ± 0.12 Aa | 5.63 ± 0.32 Ab | 49.53 ± 1.04 Aa | 45.97 ± 2.01 Aa |

| Feed Rate (g·min−1) | Specific Volume (m3·kg−1) | Expansion Ratio (%) | Hardness (N) | |||

|---|---|---|---|---|---|---|

| BGW | WGW | BGW | WGW | BGW | WGW | |

| 20.0 | 2.38 ± 0.04 Ca | 2.21 ± 0.01 Ca | 0.66 ± 0.07 Ba | 0.53 ± 0.04 Ba | 7.38 ± 0.31 Aa | 7.01 ± 0.30 Aa |

| 30.0 | 2.87 ± 0.04 Ba | 2.86 ± 0.06 Ba | 0.72 ± 0.04 Ba | 0.70 ± 0.03 Aa | 4.34 ± 0.30 Ca | 4.45 ± 0.43 Ca |

| 40.0 | 3.26 ± 0.06 Ab | 3.48 ± 0.03 Aa | 0.97 ± 0.03 Aa | 0.72 ± 0.05 Ab | 3.83 ± 0.35 Ca | 4.06 ± 0.32 Ca |

| 50.0 | 2.82 ± 0.05 Bb | 3.01 ± 0.03 Ba | 0.73 ± 0.05 Ba | 0.66 ± 0.04 Aa | 4.55 ± 0.42 Ca | 4.63 ± 0.36 Ca |

| 60.0 | 2.37 ± 0.03 Ca | 2.32 ± 0.05 Ca | 0.62 ± 0.05 Ba | 0.43 ± 0.03 Bb | 5.33 ± 0.20 Bb | 6.09 ± 0.24 Ba |

| Fracturability (mm) | WAI (%) | WSI (%) | ||||

| 20.0 | −2.18 ± 0.06 Cb | −1.63 ± 0.05 Ca | 6335.00 ± 57.98 Aa | 6468.00 ± 73.36 Aa | 190.32 ± 23.32 Ba | 202.18 ± 13.60 Ba |

| 30.0 | −1.31 ± 0.08 Ba | −0.96 ± 0.06 Aa | 6285.00 ± 37.59 Aa | 6407.00 ± 70.71 Aa | 214.57 ± 16.31 Ba | 216.80 ± 24.89 Ba |

| 40.0 | −0.95 ± 0.07 Aa | −0.85 ± 0.03 Aa | 6403.00 ± 53.74 Ab | 6602.00 ± 78.26 Aa | 235.68 ± 16.59 Ba | 186.53 ± 25.48 Bb |

| 50.0 | −1.45 ± 0.09 Ba | −1.26 ± 0.05 Ba | 6123.00 ± 44.34 Aa | 6353.00 ± 86.34 Aa | 250.54 ± 20.87 Ba | 235.43 ± 20.65 Ba |

| 60.0 | −2.03 ± 0.14 Cb | −1.68 ± 0.08 Ca | 5746.00 ± 57.63 Ba | 5976.00 ± 68.55 Ba | 312.32 ± 18.65 Aa | 315.63 ± 16.54 Aa |

| Protein content (%) | Ash content (%) | Fe content (mg⋅kg−1) | ||||

| Unextruded | 16.53 ± 0.01 Aa | 14.24 ± 0.09 Ab | 1.71 ± 0.01 Aa | 1.53 ± 0.06 Ab | 33.56 ± 1.32 Bb | 43.76 ± 0.34 Ba |

| 20.0 | 16.82 ± 0.11 Aa | 14.34 ± 0.02 Ab | 1.75 ± 0.02 Aa | 1.55 ± 0.02 Ab | 41.36 ± 1.62 Ab | 54.17 ± 0.84 Aa |

| 30.0 | 16.63 ± 0.10 Aa | 14.57 ± 0.07 Ab | 1.74 ± 0.02 Aa | 1.52 ± 0.02 Ab | 42.43 ± 1.43 Ab | 55.19 ± 1.30 Aa |

| 40.0 | 16.45 ± 0.08 Aa | 14.62 ± 0.08 Ab | 1.73 ± 0.03 Aa | 1.56 ± 0.02 Ab | 40.78 ± 1.25 Ab | 53.24 ± 2.45 Aa |

| Zn content (mg⋅kg−1) | Cu content (mg⋅kg−1) | Mn content (mg⋅kg−1) | ||||

| Unextruded | 37.54 ± 0.72 Aa | 24.53 ± 0.21 Ab | 6.02 ± 0.19 Ba | 4.73 ± 0.05 Bb | 48.67 ± 0.40 Aa | 45.32 ± 0.97 Ab |

| 20.0 | 37.24 ± 2.11 Aa | 24.16 ± 0.33 Ab | 6.86 ± 0.10 Aa | 5.03 ± 0.25 Ab | 49.84 ± 0.41 Aa | 44.28 ± 0.55 Ab |

| 30.0 | 37.96 ± 0.34 Aa | 25.36 ± 2.05 Ab | 7.01 ± 0.24 Aa | 5.12 ± 0.21 Ab | 50.98 ± 1.06 Aa | 45.73 ± 0.61 Ab |

| 40.0 | 38.32 ± 0.54 Aa | 26.22 ± 2.63 Ab | 6.95 ± 0.11 Aa | 5.87 ± 0.24 Ab | 52.55 ± 2.12 Aa | 46.27 ± 1.64 Ab |

| Source | Sum of Squares | |||||

|---|---|---|---|---|---|---|

| Specific Volume (m3·kg−1) | Expansion Ratio (%) | Hardness (N) | Fracturability (mm) | WAI (%) | WSI (%) | |

| Model | 6.95 **** | 0.39 **** | 36.61 **** | 1.95 **** | 1.53*106 ** | 2.06*104 *** |

| Barrel temperature (X1) | 4.61 **** | 0.23 **** | 27.71 **** | 0.12 *** | 3.61*105 ** | 644.94 * |

| Feed moisture content (X2) | 0.35 **** | 0.05 ** | 0.33 | 0.34 **** | 2.26*105 ** | 2.46*103 ** |

| Feed rate (X3) | 0.03 ** | 6.61*10−3 * | 1.64 ** | 0.17 *** | 6.60*103 | 106.43 |

| Barrel temperature × Feed moisture content (X1X2) | 0.23*10−3 | 0.90*10−3 | 0.423 * | 0.40*10−3 | 4.29*104 | 5.95 |

| Barrel temperature × Feed rate (X1X3) | 2.50*10−3 | 0.23*10−3 | 0.068 | 2.03*10−3 | 1.44*103 | 133.52 |

| Feed moisture content × Feed rate (X2X3) | 0.23*10−3 | 0.40*10−3 | 0.036 | 0.40*10−3 | 285.72 | 0.10 |

| Barrel temperature × barrel temperature (X12) | 0.77 **** | 0.03 *** | 2.84 *** | 0.25 **** | 7.05*105 *** | 5.07*103 *** |

| Feed moisture content × feed moisture content (X22) | 0.53 **** | 0.03 *** | 0.61 * | 0.12 *** | 1.17*105 * | 7.01*103 **** |

| Feed rate × feed rate (X32) | 0.74 **** | 0.04 *** | 2.36 *** | 0.83 **** | 1.63*104 | 3.35*103 *** |

| Lack of fit | 4.88*10−3 | 5.73*10−3 | 0.36 | 0.02 | 9.23*104 | 370.34 |

| Pure error | 2.28*10−3 | 1.48*10−3 | 0.76 | 6.12*10−3 | 3.30*104 | 265.37 |

| CV (%) | 1.06 | 3.65 | 5.23 | 4.43 | 2.20 | 5.43 |

| R2 | 0.98 | 0.96 | 0.97 | 0.97 | 0.83 | 0.93 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Liu, M.; Huang, S.; Zhang, Z. Optimisation of the Extrusion Process through a Response Surface Methodology for Improvement of the Physical Properties and Nutritional Components of Whole Black-Grained Wheat Flour. Foods 2021, 10, 437. https://doi.org/10.3390/foods10020437

Liu Y, Liu M, Huang S, Zhang Z. Optimisation of the Extrusion Process through a Response Surface Methodology for Improvement of the Physical Properties and Nutritional Components of Whole Black-Grained Wheat Flour. Foods. 2021; 10(2):437. https://doi.org/10.3390/foods10020437

Chicago/Turabian StyleLiu, Yuxiu, Miaomiao Liu, Shuhua Huang, and Zhengmao Zhang. 2021. "Optimisation of the Extrusion Process through a Response Surface Methodology for Improvement of the Physical Properties and Nutritional Components of Whole Black-Grained Wheat Flour" Foods 10, no. 2: 437. https://doi.org/10.3390/foods10020437

APA StyleLiu, Y., Liu, M., Huang, S., & Zhang, Z. (2021). Optimisation of the Extrusion Process through a Response Surface Methodology for Improvement of the Physical Properties and Nutritional Components of Whole Black-Grained Wheat Flour. Foods, 10(2), 437. https://doi.org/10.3390/foods10020437