Microwave Assisted Extraction of Bioactive Carbohydrates from Different Morphological Parts of Alfalfa (Medicago sativa L.)

Abstract

1. Introduction

2. Material and Methods

2.1. Reagents

2.2. Samples

2.3. Extraction Methods

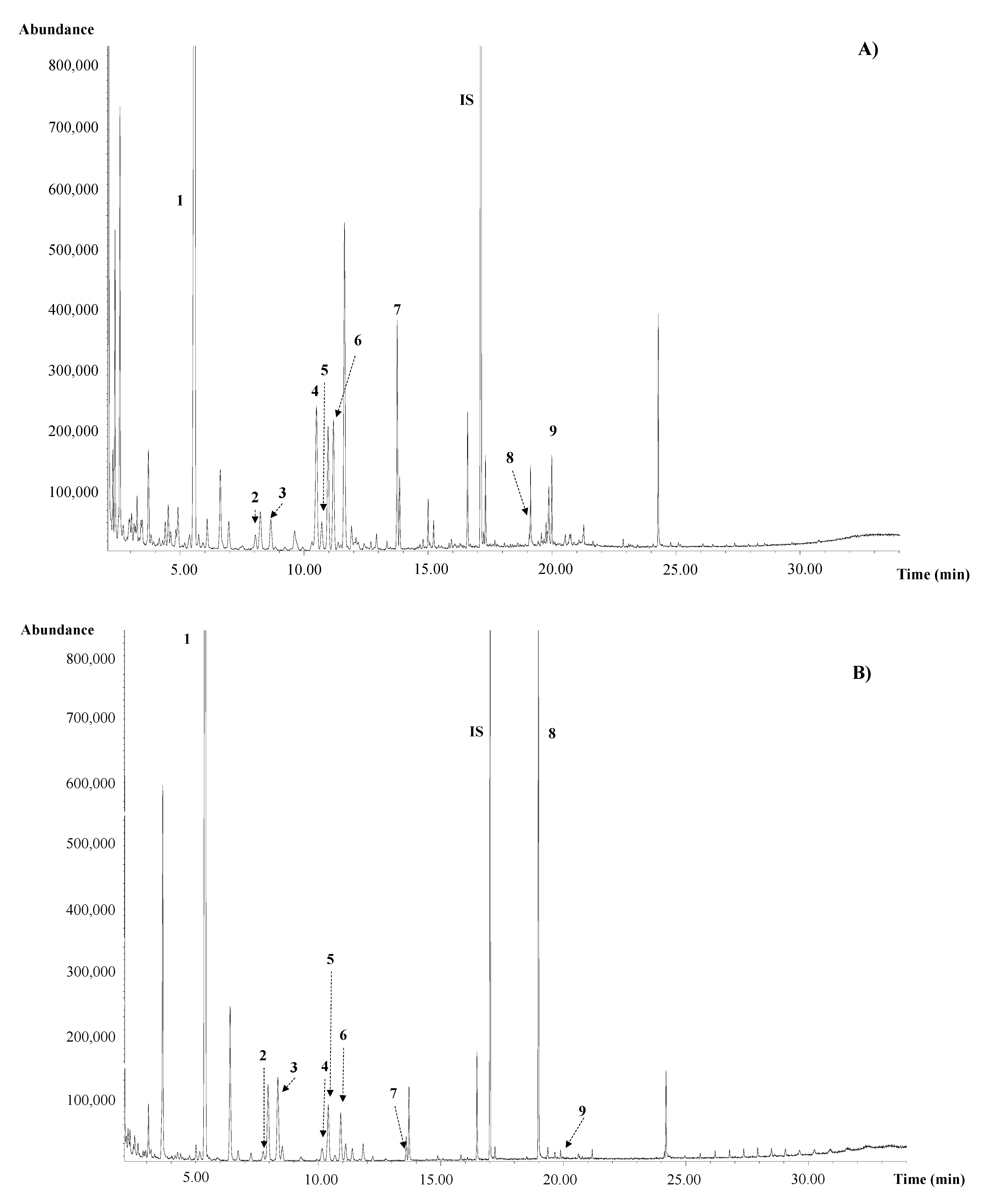

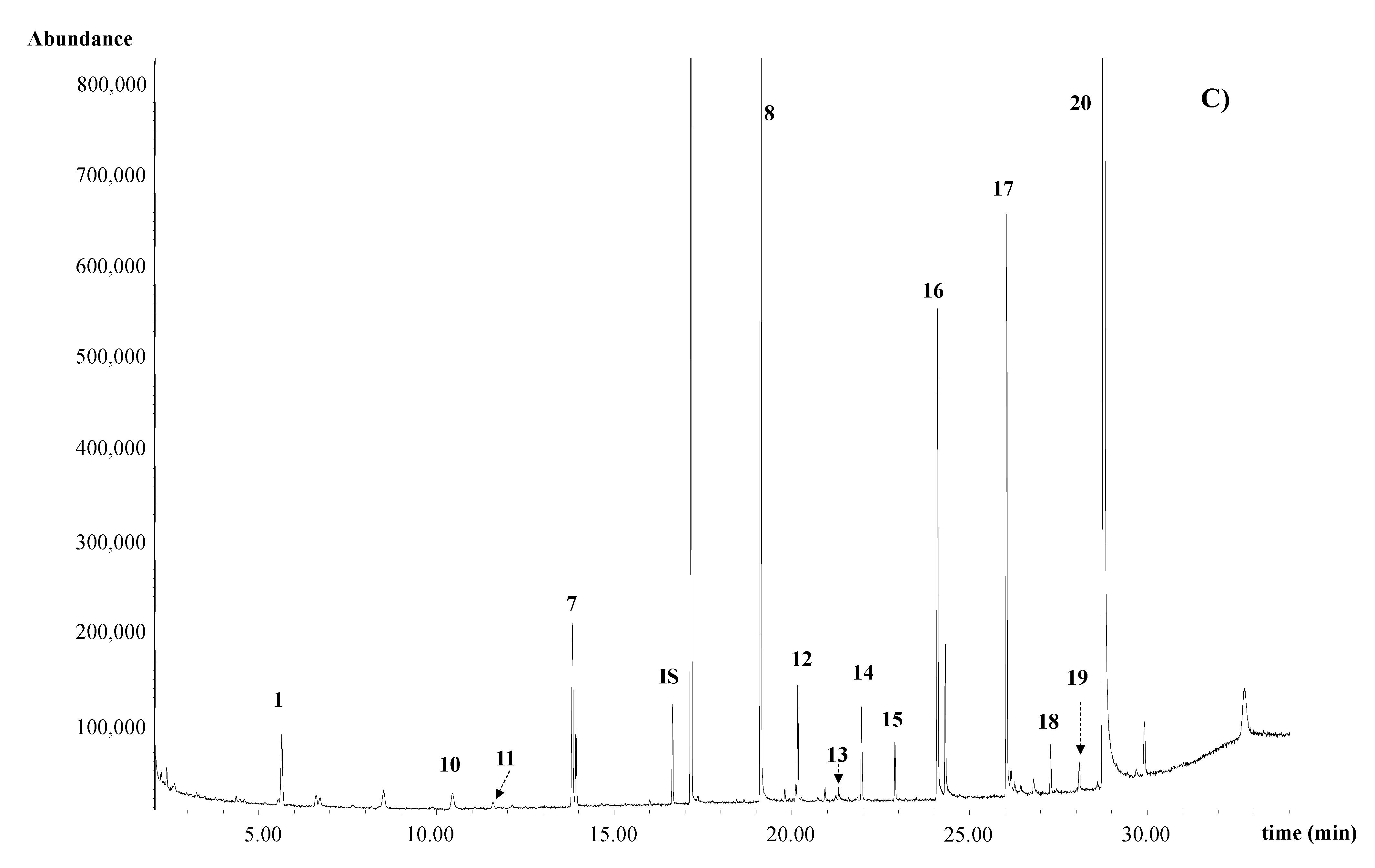

2.4. GC-MS Analysis

2.5. Thermal Stability

2.6. Statistical Analysis

3. Results and Discussion

3.1. Bioactive Carbohydrates Composition of Alfalfa Leaves, Stems and Seeds

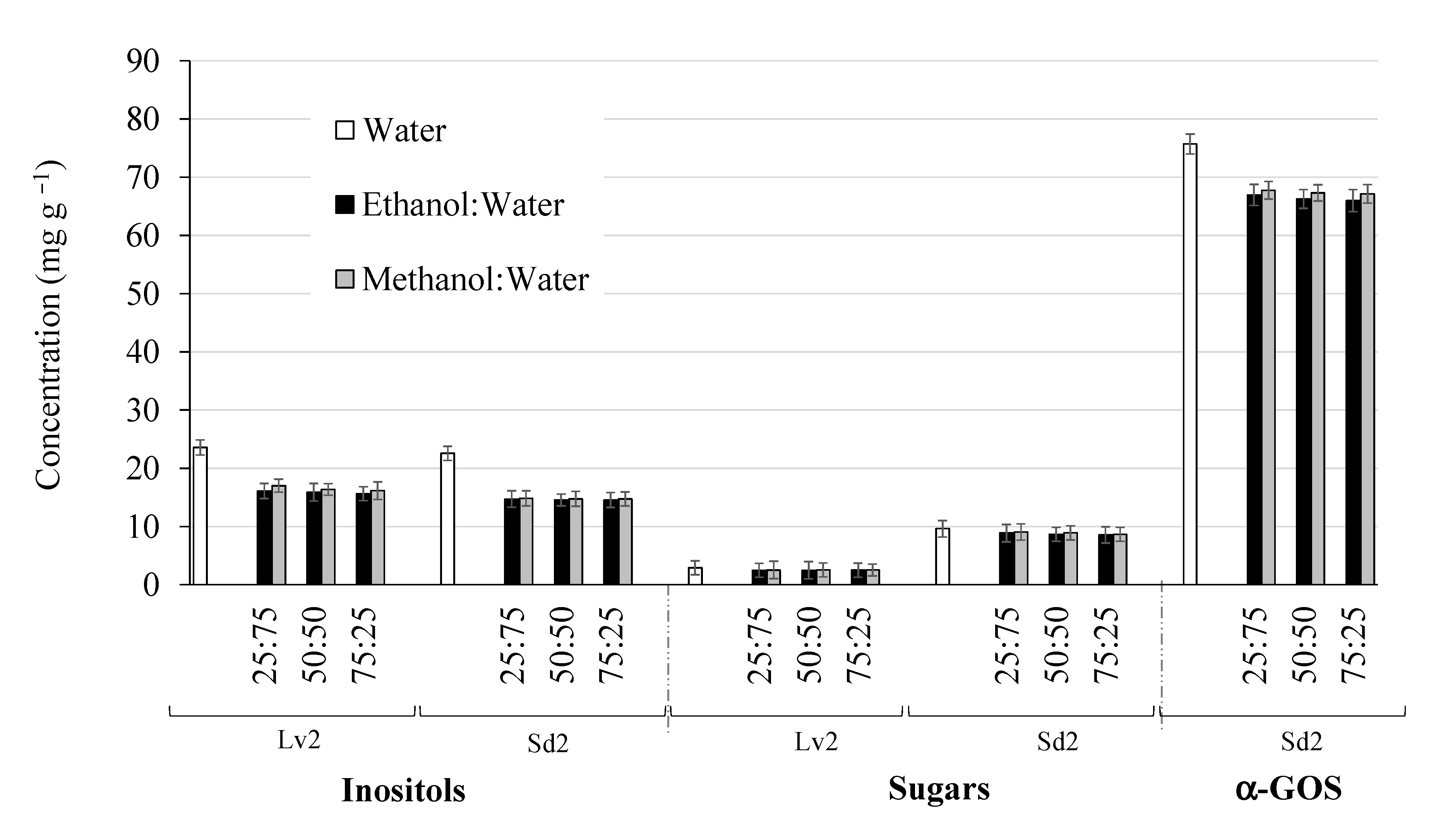

3.2. Optimization of SLE Method

3.3. Optimization of MAE Method

3.4. Comparison of SLE vs. MAE

3.5. Analysis of Bioactive Carbohydrates of Alfalfa Samples

3.6. Stability Study

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Ratiu, I.A.; Al-Suod, H.; Ligor, M.; Monedeiro, F.; Buszewski, B. Effects of growth conditions and cultivability on the content of cyclitols in Medicago sativa. Int. J. Environm. Sci.Technol. 2020, 18, 33–48. [Google Scholar] [CrossRef]

- Martínez, R.; Kapravelou, G.; Porres, J.M.; Melesio, A.M.; Heras, L.; Cantarero, S.; Gribblec, F.M.; Parker, H.; Aranda, P.; López-Jurado, M. Medicago sativa L., a functional food to relieve hypertension and metabolic disorders in a spontaneously hypertensive rat model. J. Funct. Foods 2016, 26, 470–484. [Google Scholar] [CrossRef]

- Sahni, P.; Sharma, S. Influence of processing treatments on cooking quality, functional properties, antinutrients, bioactive potential and mineral profile of alfalfa. LWT 2020, 132, 109890. [Google Scholar] [CrossRef]

- Hong, Y.H.; Chao, W.W.; Chen, M.L.; Lin, B.F. Ethyl acetate extracts of alfalfa (Medicago sativa L.) sprouts inhibit lipopolysaccharide-induced inflammation in vitro and in vivo. J. Biomed. Sci. 2009, 16, 64. [Google Scholar] [CrossRef] [PubMed]

- Silva, L.R.; Pereira, M.J.; Azevedo, J.; Gonçalves, R.F.; Valentão, P.; de Pinho, P.G.; Andrade, P.G. Glycine max (L.) Merr., Vigna radiata L. and Medicago sativa L. sprouts: A natural source of bioactive compounds. Food Res. Int. 2013, 50, 167–175. [Google Scholar] [CrossRef]

- Bora, K.S.; Sharma, A. Phytochemical and pharmacological potential of Medicago sativa: A review. Pharm. Biol. 2011, 49, 211–220. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.G.; Huang, M.Y.; Gao, P.Y.; Liu, C.F.; Sun, Y.Q.; Lv, M.C.; Yaod, G.D.; Zhang, L.X.; Li, D.Q. Bioactive constituents from Medicago sativa L. with antioxidant, neuroprotective and acetylcholinesterase inhibitory activities. J. Funct. Foods. 2018, 45, 371–380. [Google Scholar] [CrossRef]

- Wrona, O.; Rafińska, K.; Walczak-Skierska, J.; Mozeński, C.; Buszewski, B. Extraction and Determination of Polar Bioactive Compounds from Alfalfa (Medicago sativa L.) Using Supercritical Techniques. Molecules 2019, 24, 4608. [Google Scholar] [CrossRef]

- Horbowicz, M.; Obendorf, R.L.; McKersie, B.D.; Viands, D.R. Soluble saccharides and cyclitols in alfalfa (Medicago sativa L.) somatic embryos, leaflets, and mature seeds. Plant Sci. 1995, 109, 191–198. [Google Scholar] [CrossRef]

- Marín-Manzano, M.C.; Hernandez-Hernandez, O.; Diez-Municio, M.; Delgado-Andrade, C.; Moreno, F.J.; Clemente, A. Prebiotic properties of non-fructosylated α-galactooligosaccharides from pea (Pisum sativum L.) using infant fecal slurries. Foods 2020, 9, 921. [Google Scholar] [CrossRef]

- den Ende, W.V. Multifunctional fructans and raffinose familyoligosaccharides. Front. Plant Sci. 2013, 4, 247. [Google Scholar]

- Davani-Davari, D.; Negahdaripour, M.; Karimzadeh, I.; Seifan, M.; Mohkam, M.; Masoumi, S.J.; Berenjian, A.; Ghasemi, Y. Prebiotics: Definition, Types, Sources, Mechanisms, and Clinical Applications. Foods 2019, 8, 92. [Google Scholar] [CrossRef]

- Hernández-Hernández, O.; Ruiz-Aceituno, L.; Sanz, M.L.; Martínez-Castro, I. Determination of free inositols and other low molecular weight carbohydrates in vegetables. J. Agric. Food Chem. 2011, 59, 2451–2455. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Aceituno, L.; Rodríguez-Sánchez, S.; Ruiz-Matute, A.I.; Ramos, L.; Soria, A.C.; Sanz, M.L. Optimization of a biotechnological procedure for selective fractionation of bioactive inositols in edible legume extracts. J. Sci. Food Agric. 2013, 93, 2797–2803. [Google Scholar] [CrossRef] [PubMed]

- Al-Suod, H.; Ratiu, I.-A.; Ligor, M.; Ligor, T.; Buszewski, B. Determination of sugars and cyclitols isolated from various morphological parts of Medicago sativa L. J. Sep. Sci. 2017, 41, 1118–1128. [Google Scholar] [CrossRef]

- Carrero-Carralero, C.; Mansukhani, D.; Ruiz-Matute, A.I.; Martínez-Castro, I.; Ramos, L.; Sanz, M.L. Extraction and characterization of low molecular weight bioactive carbohydrates from mung bean (Vigna radiata). Food Chem. 2018, 266, 146–154. [Google Scholar] [CrossRef]

- Mena-García, A.; Ruiz-Matute, A.I.; Soria, A.C.; Sanz, M.L. Green techniques for extraction of bioactive carbohydrates. Trends Anal. Chem. 2019, 119, 115612–115622. [Google Scholar] [CrossRef]

- Zuluaga, A.M.; Mena-García, A.; Chito-Trujillo, D.; Rada-Mendoza, M.; Sanz, M.L.; Ruiz-Matute, A.I. Development of a microwave-assisted extraction method for the recovery of bioactive inositols from lettuce (Lactuca sativa) byproducts. Electrophoresis 2020, 41, 1804–1811. [Google Scholar] [CrossRef] [PubMed]

- Hadkar, U.; Dhruv, N.; Malode, Y.; Chavan, B. Microwave assisted extraction of phytoconstituents. Asian J. Phytomed. Clin. Res. 2013, 2, 73–86. [Google Scholar]

- Ruiz-Aceituno, L.; García-Sarrió, M.J.; Alonso-Rodriguez, B.; Ramos, L.; Sanz, M.L. Extraction of bioactive carbohydrates from artichoke (Cynara scolymus L.) external bracts using microwave assisted extraction and pressurized liquid extraction. Food Chem. 2016, 196, 1156–1162. [Google Scholar] [CrossRef] [PubMed]

- Zuluaga, A.M.; Mena-García, A.; Soria Monzón, A.C.; Rada-Mendoza, M.; Chito, D.M.; Ruiz-Matute, A.I.; Sanz, M.L. Microwave assisted extraction of inositols for the valorization of legume by-products. LWT 2020, 133, 109971. [Google Scholar] [CrossRef]

- Zhang, H.-F.; Yang, X.-H.; Wang, Y. Microwave assisted extraction of secondary metabolites from plants: Current status and future directions. Trends Food Sci Technol. 2011, 22, 672–688. [Google Scholar] [CrossRef]

- Mandal, V.; Mohan, Y.; Hemalatha, S. Microwave Assisted Extraction – An Innovative and Promising Extraction Tool for Medicinal Plant Research. Pharmacogn. Rev. 2007, 1, 7–18. [Google Scholar]

- Chemat, F.; Vian, M.A.; Fabiano-Tixier, A.S.; Nutrizio, M.; Režek Jambrak, A.; Munekata, P.E.S.; Lorenzo, J.M.; Barba, F.J.; Binelloe, A.; Cravotto, G. A review of sustainable and intensified techniques for extraction of food and natural products. Green Chem. 2020, 22, 2325–2353. [Google Scholar] [CrossRef]

- Camel, V. Microwave-assisted solvent extraction of environmental samples. Trends Anal. Chem. 2000, 19, 229–248. [Google Scholar] [CrossRef]

- Cravotto, G.; Boffa, L.; Mantegna, S.; Perego, P.; Avogadro, M.; Cintas, P. Improved extraction of vegetable oils under high-intensity ultrasound and/or microwaves. Ultrason. Sonochem. 2008, 15, 898–902. [Google Scholar] [CrossRef]

- Soria, A.C.; Ruiz-Aceituno, L.; Ramos, L.; Sanz, M.L. Microwave Assisted Extraction of Polysaccharides. In Polysaccharides: Bioactivity and Biotechnology; Mérillon, J.M., Ramawat, K.G., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 987–1008. ISBN 978-3-319-03751-6. [Google Scholar]

- Alexandru, L.; Binello, A.; Mantegna, S.; Boffa, L.; Chemat, F.; Cravotto, G. Efficient green extraction of polyphenols from post-harvested agro-industry vegetal sources in Piedmont. C. R. Chim. 2014, 17, 212–217. [Google Scholar] [CrossRef]

- Prakash Maran, J.; Sivakumar, V.; Thirugnanasambandham, K.; Sridhar, R. Optimization of microwave assisted extraction of pectin from orange peel. Carbohyd. Polym. 2013, 97, 703–709. [Google Scholar] [CrossRef] [PubMed]

- Eskilsson, C.S.; Björklund, E. Analytical-scale microwave-assisted extraction. J. Chromatogr. A 2000, 902, 227–250. [Google Scholar] [CrossRef]

- Passos, C.P.; Coimbra, M.A. Microwave superheated water extraction of polysaccharides from spent coffee grounds. Carbohydr. Polym. 2013, 94, 626–633. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Sánchez, S.; Martín-Ortiz, A.; Carrero-Carralero, C.; Ramos, S.; Sanz, M.L.; Soria, A.C. Pressurised liquid extraction of Aglaonema sp. iminosugars: Bioactivity, cell viability and thermal stability. Food Chem. 2016, 204, 62–69. [Google Scholar] [CrossRef] [PubMed]

- Jing, Y.; Lang, S.; Wang, D.; Xue, H.; Wang, X.-F. Functional characterization of galactinol synthase and raffinose synthase in desiccation tolerance acquisition in developing Arabidopsis seeds. J. Plant Physiol. 2018, 230, 109–121. [Google Scholar] [CrossRef] [PubMed]

- Florez, N.; Conde, E.; Dominguez, H. Microwave assisted water extraction of plant compounds. J. Chem. Technol. Biotechnol. 2015, 90, 590–607. [Google Scholar] [CrossRef]

- López-Molina, D.; Navarro-Martínez, M.D.; Rojas Melgarejo, F.; Hiner, A.N.P.; Chazarra, S.; Rodríguez-López, J.N. Molecular properties and prebiotic effect of inulin obtained from artichoke (Cynara scolymus L.). Phytochemistry 2005, 66, 1476–1484. [Google Scholar]

- Castro-Puyana, M.; Marina, M.L.; Plaza, M. Water as green extraction solvent: Principles and reasons for its use. Curr. Opin. Green Sust. Chem. 2017, 5, 31–36. [Google Scholar] [CrossRef]

- Eggleston, G.; Vercellotti, J.R. Degradation of sucrose, glucose and fructose in concentrated aqueous solutions under constant pH conditions at elevated temperature. J. Carbohydr. Chem. 2000, 19, 1305–1318. [Google Scholar] [CrossRef]

- Möller, M.; Harnisch, F.; Schröder, U. Microwave-assisted hydrothermal degradation of fructose and glucose in subcritical water. Biomass Bioenergy 2012, 39, 389–398. [Google Scholar] [CrossRef]

- Sanz, M.L.; del Castillo, M.D.; Corzo, N.; Olano, A. Formation of Amadori Compounds in Dehydrated Fruits. J. Agric. Food Chem. 2001, 49, 5228–5231. [Google Scholar] [CrossRef] [PubMed]

- Villamiel, M.; Martínez-Castro, I.; Corzo, N.; Olano, A. Quantitative determination of carbohydrates in orange juice by gas chromatography. Eur. Food Res. Technol. 1998, 206, 48–51. [Google Scholar] [CrossRef]

| No | t (min) | T (°C) | s (g) | Inositols (mg·g−1) | Sugars (mg·g−1) | α-GOS (mg·g−1) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Leaves | Seeds | Leaves | Seeds | Seeds | |||||||||

| SLE | MAE | SLE | MAE | SLE | MAE | SLE | MAE | SLE | MAE | ||||

| 1 | 32.5 | 80.0 | 0.3 | 21.5 (1.0) b | 29.6 (1.3) a | 16.9 (0.6) a | 14.7 (0.4) b | 3.5 (0.1) b | 4.8 (0.1) a | 14.1 (0.1) a | 12.7 (0.4) b | 84.7 (0.7) b | 107.0 (2.1) a |

| 2 | 5.0 | 40.0 | 0.3 | 18.4 (0.8) b | 36.2 (0.6) a,#,* | 11.5 (0.4) b | 14.6 (0.5) a | 3.2 (0.1) a | 3.8 (0.1) a,# | 6.67 (0.2) b | 12.4 (0,2) a | 11.4 (0.4) b | 78.6 (1.9) a |

| 3 | 5.0 | 80.0 | 0.5 | 14.7 (0.6) b | 30.9 (1.3) a | 12.8 (0.3) b | 13.7(0.4) a,# | 3.4 (0.1) a | 3.3 (0.1) a | 12.5 (0.5) b | 15.1 (0.4) a,# | 113.7 (3.5) b | 138.4(2.6) a,& |

| 4 | 60.0 | 120.0 | 0.3 | 14.6 (0.4) b | 30.8 (0.9) a | 17.9 (0.4) a | 16.8 (0.8) a | 5.1 (0.1) a | 4.8 (0.1) a | 14.9 (0.3) a | 13.3 (0.6) b | 155.2 (6.0) a | 91.4 (0.8) b |

| 5 | 32.5 | 120.0 | 0.1 | 15.5 (0.1) b | 37.5 (1.8) a | 28.4 (0.4) b | 29.5 (0.6) a | 6.82 (0.02) a | 6.7 (0.1) a | 8.859 (0.4) b | 9.8 (0.4) a | 50.6 (2.0) b | 62.4 (0.4) a |

| 6 | 32.5 | 80.0 | 0.3 | 20.7 (1.1) b | 31.7 (1.3) a | 14.6 (0.4) a | 14.7 (0.5) a | 5.2 (0.1) a | 4.9 (0.1) a | 13.7 (0.2) a | 11.6 (0.3) b | 80.3 (1.2) b | 91.1 (0.5) a |

| 7 | 5.0 | 80.0 | 0.1 | 20.1 (0.3) b | 30.9 (1.2) a | 27.5 (0.4) b | 29.4 (0.5) a | 9.02 (0.02) a | 8.4 (0.1) b | 9.1 (0.3) a | 9.8 (0.6) a | 28.1 (0.7) b | 64.0 (0.7) a |

| 8 | 32.5 | 120.0 | 0.5 | 21.8 (0.7) b | 29.7 (1.3) a | 11.6 (0.4) b | 14.0 (0.5) a | 3.69 (0.04) a | 3.4 (0.1) a | 11.5 (0.5) b | 16.7 (0.8) a | 84.4 (0.6) b | 119.5 (1.0) a |

| 9 | 32.5 | 40.0 | 0.1 | 20.4 (0.4) b | 38.4 (0.6) a | 28.2 (0.5) b | 29.5 (0.9) a | 5.8 (0.1) b | 7.0 (0.2) a | 10.8 (0.4) b | 12.1 (0.2) a | 36.3 (0.5) b | 40.6 (0.2) a |

| 10 | 5.0 | 120.0 | 0.3 | 19.5 (0.3) b | 29.1 (1.2) a | 14.8 (0.3) b | 17.5 (0.03) a | 5.2 (0.1) a | 5.0 (0.1) a | 12.3 (0.3) b | 15.4 (0.1) a | 99.0 (1.1) b | 154.1 (0.6) a |

| 11 | 60.0 | 80.0 | 0.1 | 14.3 (0.5)b | 29.8 (0.2) a | 31.2 (0.8) a | 30.9 (0.4) a | 6.79 (0.02) a | 6.05 (0.01) a | 16.7 (0.4) a | 11.7 (0.2) b | 96.1 (2.9) a | 97.0 (0.8) a |

| 12 | 32.5 | 80.0 | 0.3 | 21.1(0.02) b | 29.3 (1.1) a | 15.8 (0.3) a | 13.9 (0.1) a | 5.34 (0.03) a | 5.1 (0.1) a | 13.9 (0.4) a | 12.5 (0.5) b | 81.1 (1.6) b | 106.2 (0.9) a |

| 13 | 60.0 | 40.0 | 0.3 | 14.3 (0.4) b | 26.2 (0.2) a | 15.7 (0.4) a | 15.7 (0.9) a | 3.0 (0.1) b | 5.2 (0.2) a | 18.2 (0.5) b | 13.5 (0.2) a | 76.3 (0.4) b | 101.0 (2.3) a |

| 14 | 60.0 | 80.0 | 0.5 | 16.8 (0.8) b | 27.3 (1.0) a | 12.5 (0.2) b,& | 13.6 (0.3) a | 3.72 (0.04) a | 3.25 (0.04) a | 13.5 (0.5) b,& | 14.6 (0.6) a | 190.8 (2.1) b,# | 270.6 (2.4) a |

| 15 | 32.5 | 40.0 | 0.5 | 31.4 (0.4) a,& | 28.5 (1.1) b | 12.2 (0.4) b | 13.5 (0.2) a | 4.4 (0.1)a,# | 4.1 (0.1) a | 11.8 (0.5) b | 17.4 (0.6) a | 156.6 (0.8) b | 186.0 (1.7) a |

| SLE | MAE | ||||

|---|---|---|---|---|---|

| Response Variable | Model Equation | R2 | Model Equation | R2 | |

| Leaves | R1 | R1 = 4.174 + 0.066*T + 0.566*t + 52.000*s − 0.459*Ts − 0.087*t2 | 57.8 | R1 = 43.614 − 0.086*T − 0.270*t − 12.625*s + 0.003*Tt | 59.2 |

| Seeds | R1 | R1 = 38.005 + 0.049*t − 120.411*s + 131.518*s2 | 97.2 | R1 = 42.741 − 0.082*t − 136.683*s+ 0.001*t2 + 160.721*s2 | 98.8 |

| R2 | R2 = −12.385 + 1.210*t + 209.000*s | 66.4 | R2 = 54.903 − 0.785*t + 135.017*s + 4.509*ts | 65.7 | |

| Leaves | Stems | Seeds | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lv1 | Lv2 | Lv3 | Lv4 | St1 | St2 | St3 | St4 | Sd1 | Sd2 | Sd3 | Sd4 | Sd5 | |

| Pinitol | 31.0 a (1.4) | 30.1 a (0.4) | 24.3 b (0.6) | 24.2 b (0.1) | 19.3 b (1.2) | 22.5 a (0.9) | 15.5 c (0.8) | 19.5 b (0.6) | 2.3 c (0.1) | 2.5 b (0.1) | 2.7 a (0.1) | 2.3 c (0.1) | 2.5 b (0.1) |

| Fructose | 0.7 d (0.1) | 0.9 c (0.1) | 1.7 a (0.1) | 1.5 b (0.1) | 1.1 d (0.1) | 3.0 a (0.2) | 1.4 c (0.1) | 1.8 b (0.2) | - | - | - | - | - |

| Ononitol | 1.0 c (0.1) | 4.6 a (0.1) | 1.6 b (0.1) | 1.1 c (0.1) | 1.1 b (0.1) | 1.4 a (0.1) | 1.4 a (0.1) | 1.0 b (0.1) | - | - | - | - | - |

| Glucose | 0.9 d (0.1) | 2.4 a (0.1) | 1.2 b (0.1) | 1.0 c (0.1) | 1.2 c (0.1) | 2.4 a (0.1) | 1.5 b (0.1) | 1.1 c (0.1) | - | - | - | - | - |

| myo-Inositol | 1.1 c (0.1) | 2.3 a (0.1) | 1.6 b (0.1) | 1.7 b (0.1) | 1.0 a (0.1) | 1.0 a (0.1) | 1.0 a (0.1) | 1.1 a (0.1) | 2.7 b (0.1) | 3.1 a (0.1) | 3.2 a (0.1) | 2.8 b (0.1) | 3.1 a (0.1) |

| Sucrose | - | - | 1.9 a (0.1) | 1.7 b (0.1) | 2.8 a (0.1) | 2.6 b (0.1) | 1.7 d (0.1) | 2.4 c (0.1) | 11.7 b (0.1) | 10.5 d (0.1) | 11.0 c (0.4) | 12.5 a (0.1) | 12.5 a (0.2) |

| Galactinol | - | - | - | - | - | - | - | - | 5.2 c,d (0.1) | 5.3 b,c (0.3) | 5.5 a (0.1) | 5.1 d (0.1) | 5.4 a,b (0.1) |

| Digalactosyl-inositol | - | - | - | - | - | - | - | - | 5.1 c (0.1) | 6.4 a (0.4) | 5.3 b,c (0.1) | 5.2 c (0.1) | 5.4 b (0.2) |

| Raffinose | - | - | - | - | - | - | - | - | 7.9 c (0.1) | 8.4 a (0.1) | 8.4 a (0.1) | 7.6 d (0.1) | 8.0 b (0.1) |

| Digalactosyl-inositol | - | - | - | - | - | - | - | - | 5.9 c (0.2) | 7.0 a (0.1) | 7.0 a (0.1) | 5.9 c (0.1) | 6.9 b (0.1) |

| Digalactosyl-inositol | - | - | - | - | - | - | - | - | - | 5.2 a,b (0.1) | 5.2 a,b (0.1) | 5.1 b (0.1) | 5.3 a (0.1) |

| Stachyose | - | - | - | - | - | - | - | - | 48.8 e (0.6) | 74.8 b (0.9) | 84.7 a (5.7) | 49.8 d (0.4) | 70.0 c (1.6) |

| Lv2 | Sd2 | ||||

|---|---|---|---|---|---|

| Sampling Time (days) | Inositols | Sugars | Inositols | α-GOS | Sugars |

| 0 | 36.8 (0.6) a | 3.5 (0.07) a | 28.3 (0.5) a | 83.2 (1.0) a | 10.5 (0.2) a |

| 5 | 35.8 (0.2) b | 3.16 (0.02) b | 27.9 (0.4) a,b | 80.8 (1.3) b | 8.2 (0.1) b |

| 12 | 35.0 (0.1) b,c | 3.07 (0.08) b,c | 27.4 (0.3) b,c | 79.8 (1.0) b,c | 8.0 (0.1) b |

| 19 | 34.8 (0.2) c,d | 2.98 (0.02) c | 27.3 (0.2) c | 79.3 (0.5) c | 8.0 (0.2) b |

| 26 | 34.5 (0.1) d | 2.81 (0.01) c | 27.2 (0.1) c | 79.1(0.5) c | 7.9 (0.1) b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solarte, D.A.; Ruiz-Matute, A.I.; Chito-Trujillo, D.M.; Rada-Mendoza, M.; Sanz, M.L. Microwave Assisted Extraction of Bioactive Carbohydrates from Different Morphological Parts of Alfalfa (Medicago sativa L.). Foods 2021, 10, 346. https://doi.org/10.3390/foods10020346

Solarte DA, Ruiz-Matute AI, Chito-Trujillo DM, Rada-Mendoza M, Sanz ML. Microwave Assisted Extraction of Bioactive Carbohydrates from Different Morphological Parts of Alfalfa (Medicago sativa L.). Foods. 2021; 10(2):346. https://doi.org/10.3390/foods10020346

Chicago/Turabian StyleSolarte, Daniela Alejandra, Ana Isabel Ruiz-Matute, Diana M. Chito-Trujillo, Maite Rada-Mendoza, and María Luz Sanz. 2021. "Microwave Assisted Extraction of Bioactive Carbohydrates from Different Morphological Parts of Alfalfa (Medicago sativa L.)" Foods 10, no. 2: 346. https://doi.org/10.3390/foods10020346

APA StyleSolarte, D. A., Ruiz-Matute, A. I., Chito-Trujillo, D. M., Rada-Mendoza, M., & Sanz, M. L. (2021). Microwave Assisted Extraction of Bioactive Carbohydrates from Different Morphological Parts of Alfalfa (Medicago sativa L.). Foods, 10(2), 346. https://doi.org/10.3390/foods10020346