Rheological and Flow Behaviour of Yolk, Albumen and Liquid Whole Egg from Eggs of Six Different Poultry Species

Abstract

1. Introduction

2. Materials and Methods

2.1. Liquid Egg Products

2.2. Density Measurement

2.3. Viscosity and Shear Stress Measurement

2.4. Real Technical Elements

2.5. Statistical Analysis

3. Results and Discussion

3.1. Density Measurement

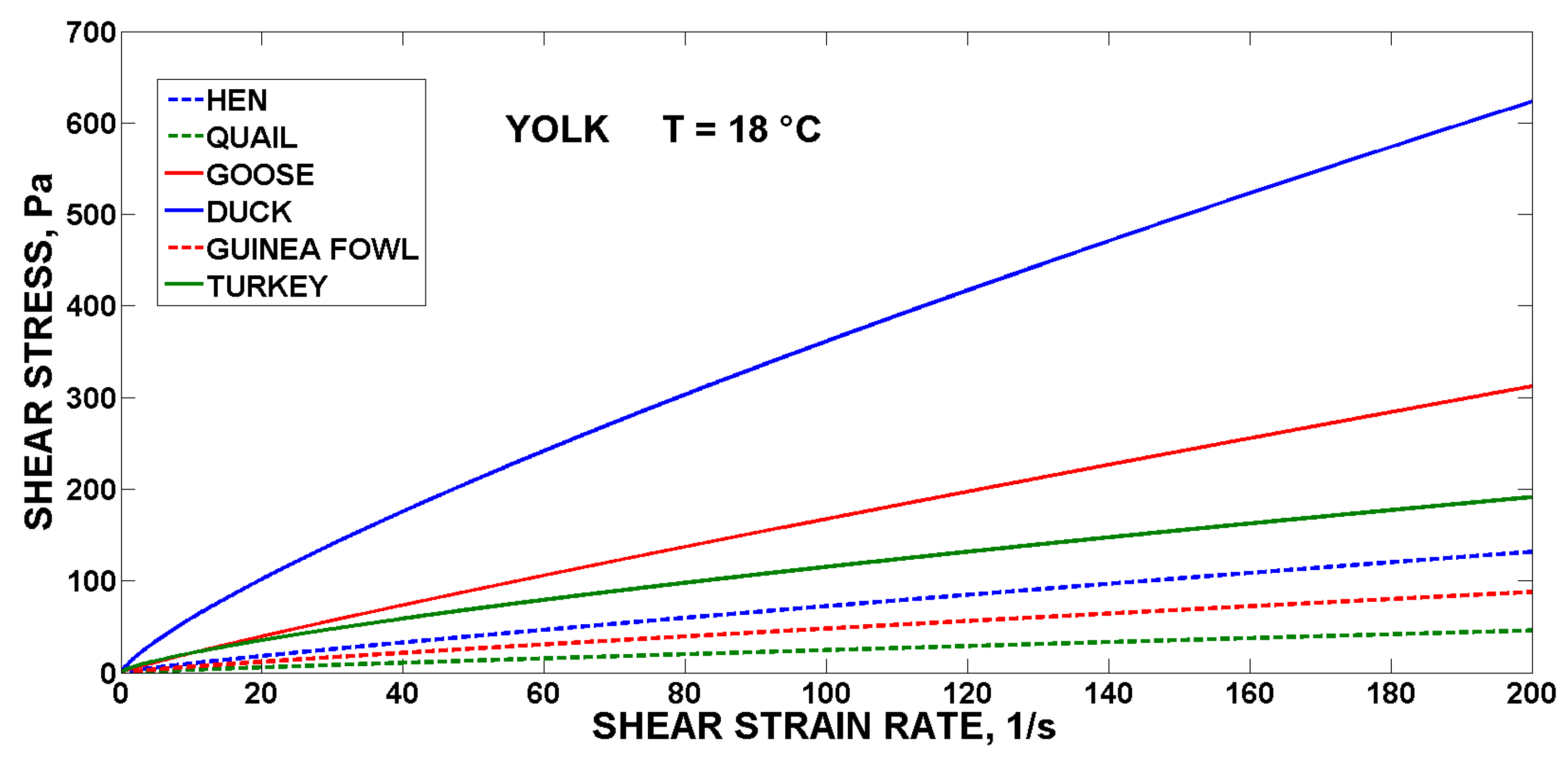

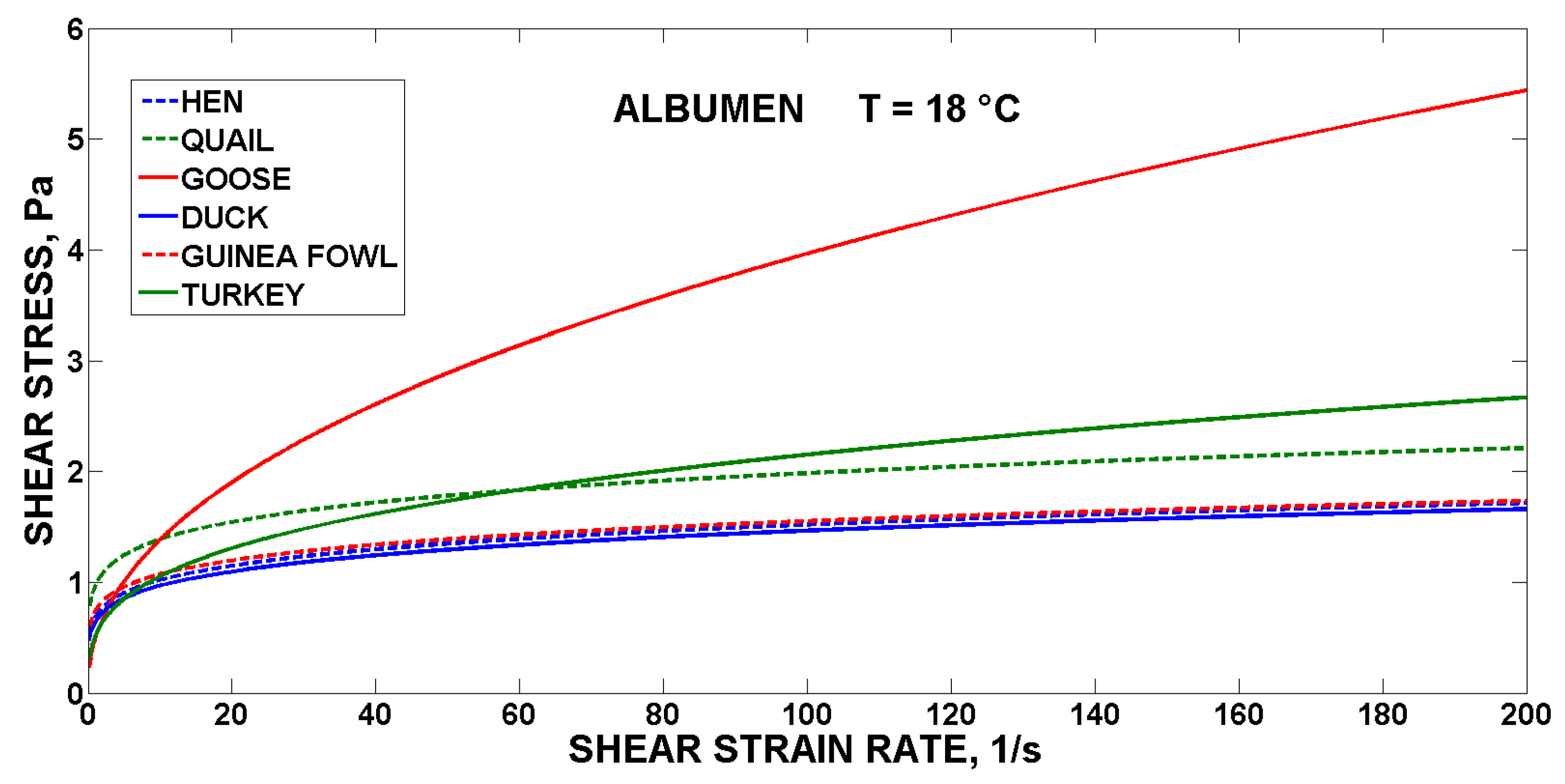

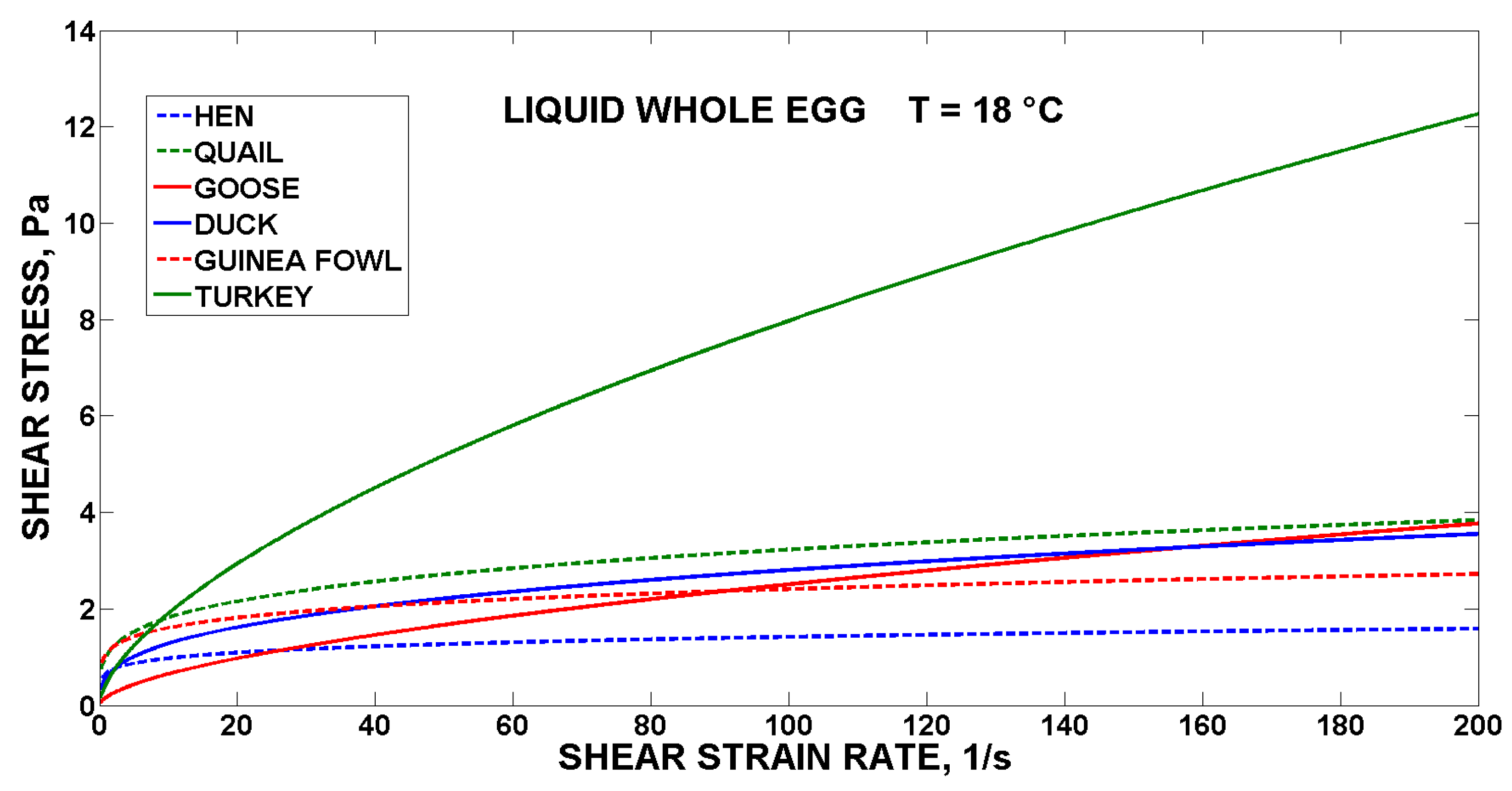

3.2. Viscosity and Shear Stress Measurement and Modelling

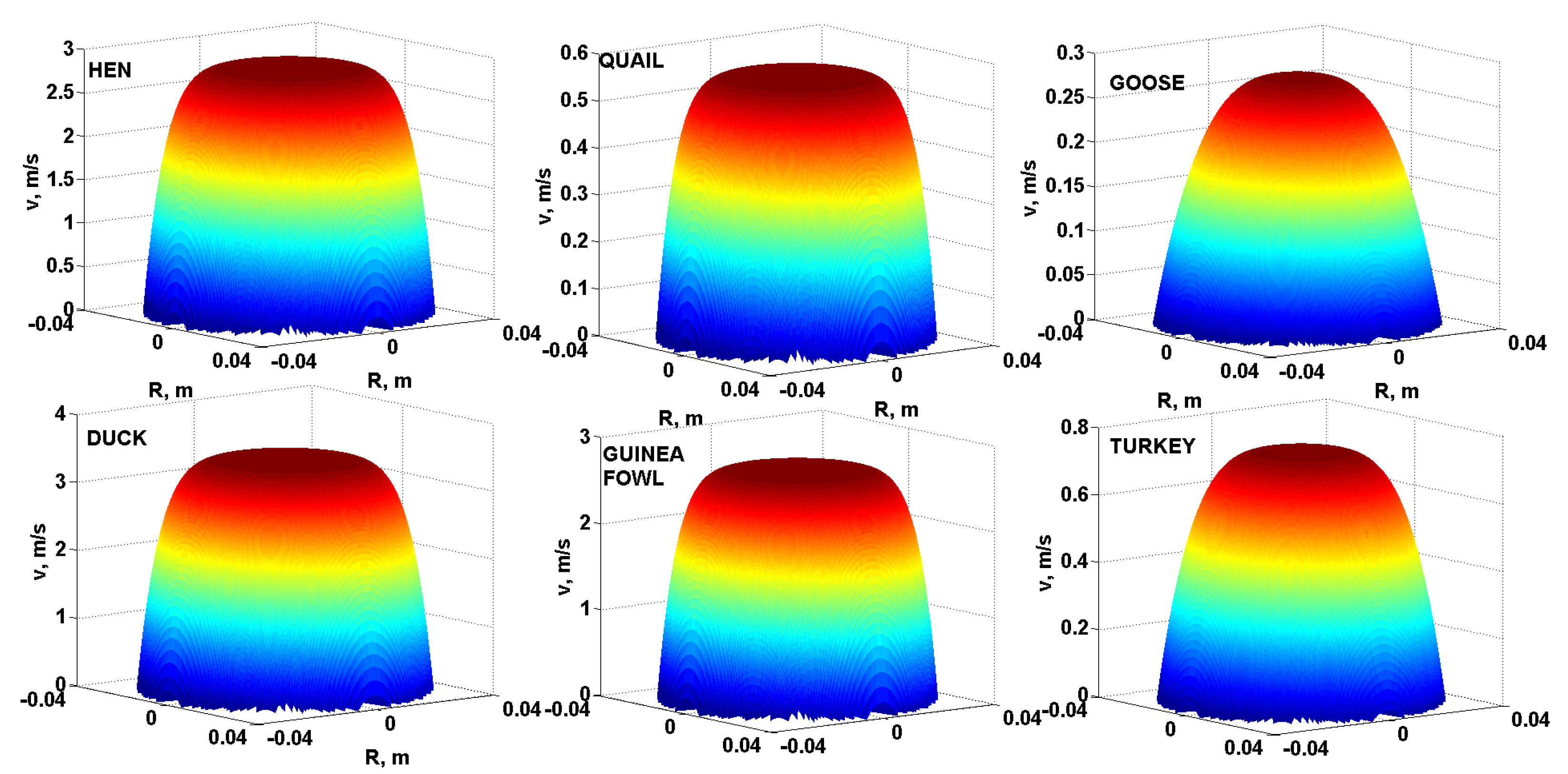

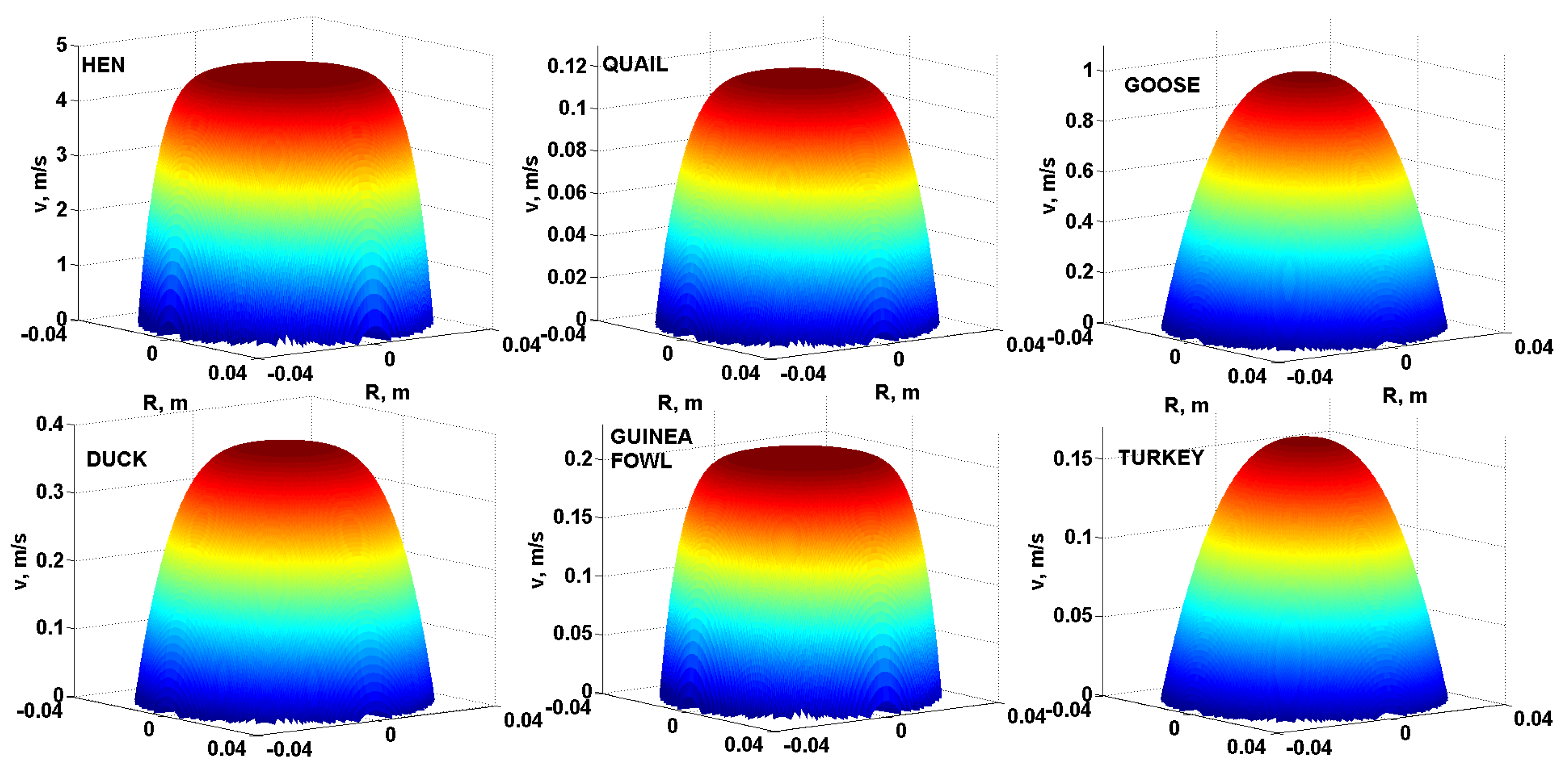

3.3. Pipe Flow Velocity Modelling

3.4. Determination of Flow Type

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hasler, C.M. The changing face of functional foods. J. Am. Coll. Nutr. 2000, 19, 499–506. [Google Scholar] [CrossRef]

- De Jesús, M.N.; Zanqui, A.B.; Valderrama, P.; Tanamati, A.; Maruyama, S.A.; de Souza, N.E.; Matsushita, M. Sensory and physico-chemical characteristics of desserts prepared with egg products processed by freeze and spray drying. Food Sci. Technol. 2013, 33, 549–554. [Google Scholar] [CrossRef][Green Version]

- Juszczak, L.; Fortuna, T.; Kośla, A. Sensory and rheological properties of Polish commercial mayonnaise. Nahrung 2003, 47, 232–235. [Google Scholar] [CrossRef] [PubMed]

- Kumbár, V.; Nedomová, Š.; Trnka, J.; Buchar, J.; Pytel, R. Effect of storage duration on the rheological properties of goose liquid egg products and eggshell membranes. Poult. Sci. 2016, 95, 1693–1701. [Google Scholar] [CrossRef] [PubMed]

- Telis-Romero, J.; Thomaz, C.E.P.; Bernardi, M.; Telis, V.R.N.; Gabas, A.L. Rheological properties and fluid dynamics of egg yolk. J. Food Eng. 2006, 74, 191–197. [Google Scholar] [CrossRef]

- Cabral, R.A.F.; Telis, V.R.N.; Park, K.J.; Telis-Romero, J. Friction losses in valves and fittings for liquid food products. Food Bioprod. Process. 2011, 89, 375–382. [Google Scholar] [CrossRef]

- Kumbár, V.; Strnková, J.; Nedomová, Š.; Buchar, J. Fluid dynamics of liquid egg products. J. Biol. Phys. 2015, 41, 303–311. [Google Scholar] [CrossRef]

- Aguilar, J.M.; Batista, A.P.; Nunes, M.C.; Cordobés, F.; Raymundo, A.; Guerrero, A. From egg yolk/κ-Carrageenan dispersions to gel systems: Linear viscoelasticity and texture analysis. Food Hydrocoll. 2011, 25, 654–658. [Google Scholar] [CrossRef]

- Telis, V.R.N.; Kieckbusch, T.G. Viscoelasticity of frozen/thawed egg yolk. J. Food Sci. 1997, 62, 548–550. [Google Scholar] [CrossRef]

- Tserveni-Goussi, A.; Fortomaris, P. Production and Quality of Quail, Pheasant, Goose and Turkey Eggs for Uses Other Than Human Consumption. In Improving the Safety and Quality of Eggs and Egg Products, 1st ed.; Nys, Y., Bain, M., Van Imerseel, F., Eds.; Woodhead Publishing: Cambridge, UK, 2011; pp. 509–537. [Google Scholar] [CrossRef]

- Ketyam, B.; Imsilp, K.; Poapolathep, A.; Poapolathep, S.; Jermnak, U.; Phaochoosak, N.; Tanhan, P. Health risk associated with the consumption of duck egg containing endosulfan residues. Environ. Monit. Assess. 2016, 188, 270. [Google Scholar] [CrossRef] [PubMed]

- Kokoszyński, D. Guinea Fowl, Goose, Turkey, Ostrich, and Emu Eggs. In Egg Innovations and Strategies for Improvements, 1st ed.; Hester, P., Ed.; Academic Press: Cambridge, MA, USA, 2016; Volume 4, pp. 33–43. ISBN 978-0-12800-879-9. [Google Scholar]

- Song, K.T.; Choi, S.H.; Oh, H.R. A comparison of egg quality of pheasant, chukar, quail and guinea fowl. Asian-Australas. J. Anim. Sci. 2000, 13, 986–990. [Google Scholar] [CrossRef]

- Techathuvanan, C.; D’Souza, D.H. High intensity ultrasound for Salmonella enteritidis inactivation in culture and liquid whole eggs. J. Food Sci. 2018, 83, 1733–1739. [Google Scholar] [CrossRef] [PubMed]

- Hemphill, T.; Campos, W.; Pilehvari, A. Yield-power law model more accurately predicts mud rheology. Oil Gas J. 1993, 91, 45–50. [Google Scholar]

- Alamprese, C.; Iametti, S.; Rossi, M.; Bergonzi, D. Role of pasteurisation heat treatments on rheological and protein structural characteristics of fresh egg pasta. Eur. Food Res. Technol. 2005, 221, 759–767. [Google Scholar] [CrossRef]

- Nguyen, Q.H.; Nguyen, N.D. Incompressible Non-Newtonian Fluid Flows. In Continuum Mechanics—Progress in Fundamentals and Engineering Applications, 1st ed.; Gan, Y., Ed.; InTech: Shanghai, China, 2012; pp. 47–72. ISBN 978-953-51-0447-6. [Google Scholar]

- Přidal, A.; Trávníček, P.; Kudělka, J.; Nedomová, Š.; Ondrušíková, S.; Trost, D.; Kumbár, V. A Rheological analysis of biomaterial behaviour as a tool to detect the dilution of heather honey. Materials 2021, 14, 2472. [Google Scholar] [CrossRef] [PubMed]

- Parington, E. Stainless Steels in the Food and Beverage Industry, 1st ed.; Euro Inox: Luxembourg, 2008; pp. 1–24. ISBN 978-2-87997-191-9. [Google Scholar]

- Meuer, H.; Egbers, C. Changes in density and viscosity of chicken egg albumen and yolk during incubation. J. Exp. Zoöl. 1990, 255, 16–21. [Google Scholar] [CrossRef]

- Cao, D.; Feng, F.; Xiong, C.; Li, J.; Xue, H.; Zhao, Y.; Wang, Y.; Tu, Y.; Zhao, Y. Changes in lipid properties of duck egg yolks under extreme processing conditions. Poult. Sci. 2021, 100, 101140. [Google Scholar] [CrossRef]

- Cybulska, J.; Mierczyńska, J.; Pieczywek, P.; Stasiak, M.; Zdunek, A. Effect of divalent metal ions on rheological properties of polysaccharide matrix from apple pomace. Food Sci. Technol. Qual. 2016, 22, 103–113. [Google Scholar] [CrossRef]

- Panaite, T.D.; Mironeasa, S.; Iuga, M.; Vlaicu, P.A. Liquid egg products characterization during storage as a response of novel phyto-additives added in hens diet. Emir. J. Food Agric. 2019, 31, 304–314. [Google Scholar] [CrossRef]

- Kumbár, V.; Kouřilová, V.; Dufková, R.; Votava, J.; Hřivna, L. Rheological and pipe flow properties of chocolate masses at different temperatures. Foods 2021, 10, 2519. [Google Scholar] [CrossRef]

- Wijedasa, W.M.R.M.; Wickramasinghe, Y.H.S.T.; Vidanarachchi, J.K.; Himali, S.M.C. Comparison of egg quality characteristics of different poultry species. J. Agric. Sci. 2020, 12, 331–342. [Google Scholar] [CrossRef]

- Bondoc, O.L.; Ebron, A.O.; Ramos, A.R.; Santiago, R.C. Comparison of egg quality traits in different poultry species and breeds. Philipp. J. Vet. Med. 2020, 57, 2020–2235. [Google Scholar]

- Lichovnikova, M. The effect of dietary calcium source, concentration and particle size on calcium retention, eggshell quality and overall calcium requirement in laying hens. Br. Poult. Sci. 2007, 48, 71–75. [Google Scholar] [CrossRef]

- Liu, W.; Wang, F.; Guo, L.; Huang, L.; Zhao, W.; Lu, X. Design and performance test of low-temperature pasteurization equipment for experiment. Trans. Chin. Soc. Agric. Mach. 2013, 44, 158–160. [Google Scholar] [CrossRef]

- Gut, J.A.W.; Pinto, J.M.; Gabas, A.L.; Telis-Romero, J. Continuous pasteurization of egg yolk: Thermophysical properties and process simulation. J. Food Process Eng. 2005, 28, 181–203. [Google Scholar] [CrossRef]

- Icier, F.; Bozkurt, H. Ohmic heating of liquid whole egg: Rheological behaviour and fluid dynamics. Food Bioprocess Technol. 2011, 4, 1253–1263. [Google Scholar] [CrossRef]

- Bozkurt, H.; Icier, F. The change of apparent viscosity of liquid whole egg during ohmic and conventional heating. J. Food Process Eng. 2012, 35, 120–133. [Google Scholar] [CrossRef]

- Denys, S.; Pieters, J.G.; Dewettinck, K. Computational fluid dynamics analysis of combined conductive and convective heat transfer in model eggs. J. Food Eng. 2004, 63, 281–290. [Google Scholar] [CrossRef]

- Singh, J.; Sharma, H.K.; Premi, M.; Kumari, K. Effect of storage conditions of egg on rheological properties of liquid whole egg. J. Food Sci. Technol. 2014, 51, 543–550. [Google Scholar] [CrossRef] [PubMed]

- Dodge, D.W.; Metzner, A.B. Turbulent flow of non-Newtonian systems. AIChE J. 1959, 5, 189–204. [Google Scholar] [CrossRef]

- Shahsavand, A.; Nozari, Y. Simulation of a continuous thermal sterilization process in the presence of solid particles. Sci. Iran. 2009, 16, 29–40. [Google Scholar]

- Meister, C.; Velten, K.; Methner, F. Modelling and simulation of bottle rinsing. Int. J. Food Sci. Technol. 2012, 47, 1468–1478. [Google Scholar] [CrossRef]

- Laca, A.; Paredes, B.; Díaz, M. Thermal behaviour of lyophilized egg yolk and egg yolk fractions. J. Food Eng. 2011, 102, 77–86. [Google Scholar] [CrossRef]

- Martynenko, A.; Astatkie, T.; Satanina, V. Novel hydrothermodynamic food processing technology. J. Food Eng. 2015, 152, 8–16. [Google Scholar] [CrossRef]

| Poultry Species | Density ρ, kg·m−3 | ||

|---|---|---|---|

| Yolk | Albumen | LWE | |

| Hen | 1027.7 c,d ± 0.70 | 1038.1 j ± 0.96 | 1033.2 f,g ± 0.81 |

| Quail | 1021.0 b ± 0.57 | 1038.4 j ± 0.75 | 1031.7 e,f ± 0.90 |

| Goose | 1031.9 e,f ± 0.42 | 1035.5 h,i ± 0.62 | 1033.8 g,h ± 0.60 |

| Duck | 1009.3 a ± 0.54 | 1038.2 j ± 0.55 | 1029.1 d ± 0.73 |

| Guinea fowl | 1027.4 c,d ± 0.71 | 1042.6 k ± 0.67 | 1035.7 i ± 0.63 |

| Turkey | 1026.4 c ± 0.67 | 1037.7 j ± 0.50 | 1031.4 e ± 0.79 |

| Poultry Species | Egg Liquid | Ostwald-de Waele Model | ||||

|---|---|---|---|---|---|---|

| K, Pa·s n | n, - | R2 | SSE | RMSE | ||

| Hen | Yolk | 1.3594 | 0.8632 | 0.9996 | 1.1240 | 0.2737 |

| Albumen | 0.6824 | 0.1740 | 0.8311 | 0.3516 | 0.1438 | |

| LWE | 0.6696 | 0.1631 | 0.8789 | 0.3932 | 0.1521 | |

| Quail | Yolk | 0.3769 | 0.9065 | 0.9965 | 7.0460 | 0.6438 |

| Albumen | 0.9670 | 0.1561 | 0.8124 | 1.2170 | 0.2675 | |

| LWE | 1.0201 | 0.2501 | 0.7583 | 3.5930 | 0.4597 | |

| Goose | Yolk | 2.6780 | 0.8982 | 0.9990 | 3.2030 | 0.4964 |

| Albumen | 0.4831 | 0.4570 | 0.9415 | 1.7940 | 0.3249 | |

| LWE | 0.1674 | 0.5877 | 0.9381 | 0.8657 | 0.2257 | |

| Duck | Yolk | 9.6730 | 0.7861 | 0.9960 | 10.550 | 1.0270 |

| Albumen | 0.6389 | 0.1802 | 0.8801 | 0.7986 | 0.2167 | |

| LWE | 0.5832 | 0.3410 | 0.8647 | 1.7160 | 0.3177 | |

| Guinea fowl | Yolk | 0.8542 | 0.8745 | 0.9976 | 6.0971 | 0.6173 |

| Albumen | 0.7387 | 0.1610 | 0.8930 | 0.4580 | 0.1641 | |

| LWE | 1.0720 | 0.1758 | 0.8526 | 1.4450 | 0.2915 | |

| Turkey | Yolk | 3.9770 | 0.7310 | 0.9985 | 3.3050 | 0.5042 |

| Albumen | 0.5139 | 0.3109 | 0.8712 | 1.7240 | 0.3184 | |

| LWE | 0.4557 | 0.6214 | 0.9880 | 1.8801 | 0.3325 | |

| Poultry Species | Pipe Diameter | Reynolds Number Re | ||

|---|---|---|---|---|

| Yolk | Albumen | LWE | ||

| Hen | 80 mm | 0.93 | 2.03 × 104 | 5.36 × 104 |

| 50 mm | 0.20 | 57.12 | 104.80 | |

| Quail | 80 mm | 15.42 | 830.48 | 29.39 |

| 50 mm | 3.42 | 1.26 | 0.43 | |

| Goose | 80 mm | 0.20 | 123.45 | 1387.41 |

| 50 mm | 0.04 | 9.86 | 175.16 | |

| Duck | 80 mm | 0.01 | 2.88 × 104 | 257.77 |

| 50 mm | 0.001 | 97.61 | 10.23 | |

| Guinea fowl | 80 mm | 2.68 | 1.86 × 104 | 105.86 |

| 50 mm | 0.57 | 33.83 | 0.32 | |

| Turkey | 80 mm | 0.05 | 1075.40 | 36.29 |

| 50 mm | 0.01 | 32.69 | 5.00 | |

| Poultry Species | Pipe Diameter | Yolk | Albumen | LWE |

|---|---|---|---|---|

| Hen | 80 mm | L | T | T |

| 50 mm | L | L | L | |

| Quail | 80 mm | L | L | L |

| 50 mm | L | L | L | |

| Goose | 80 mm | L | L | L |

| 50 mm | L | L | L | |

| Duck | 80 mm | L | T | L |

| 50 mm | L | L | L | |

| Guinea fowl | 80 mm | L | T | L |

| 50 mm | L | L | L | |

| Turkey | 80 mm | L | L | L |

| 50 mm | L | L | L |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumbár, V.; Ondrušíková, S.; Trost, D.; Polcar, A.; Nedomová, Š. Rheological and Flow Behaviour of Yolk, Albumen and Liquid Whole Egg from Eggs of Six Different Poultry Species. Foods 2021, 10, 3130. https://doi.org/10.3390/foods10123130

Kumbár V, Ondrušíková S, Trost D, Polcar A, Nedomová Š. Rheological and Flow Behaviour of Yolk, Albumen and Liquid Whole Egg from Eggs of Six Different Poultry Species. Foods. 2021; 10(12):3130. https://doi.org/10.3390/foods10123130

Chicago/Turabian StyleKumbár, Vojtěch, Sylvie Ondrušíková, Daniel Trost, Adam Polcar, and Šárka Nedomová. 2021. "Rheological and Flow Behaviour of Yolk, Albumen and Liquid Whole Egg from Eggs of Six Different Poultry Species" Foods 10, no. 12: 3130. https://doi.org/10.3390/foods10123130

APA StyleKumbár, V., Ondrušíková, S., Trost, D., Polcar, A., & Nedomová, Š. (2021). Rheological and Flow Behaviour of Yolk, Albumen and Liquid Whole Egg from Eggs of Six Different Poultry Species. Foods, 10(12), 3130. https://doi.org/10.3390/foods10123130