Hydrophobic Starch-Based Films Using Potato Washing Slurries and Spent Frying Oil

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Recovery and Characterization of Potato Chip Spent Frying Oil

2.3. Starch-Based Film Production

2.4. Film Characterization

2.4.1. Wettability

2.4.2. Mechanical Properties

2.4.3. Fourier-Transform Infrared (FTIR) Spectroscopy Analysis

2.4.4. Proton Nuclear Magnetic Resonance Spectroscopy (1H NMR) Analysis

2.4.5. Chromatic Properties

2.4.6. Water Solubility

2.4.7. Water Vapor Transmission Rate

2.4.8. Statistical Analysis

3. Results and Discussion

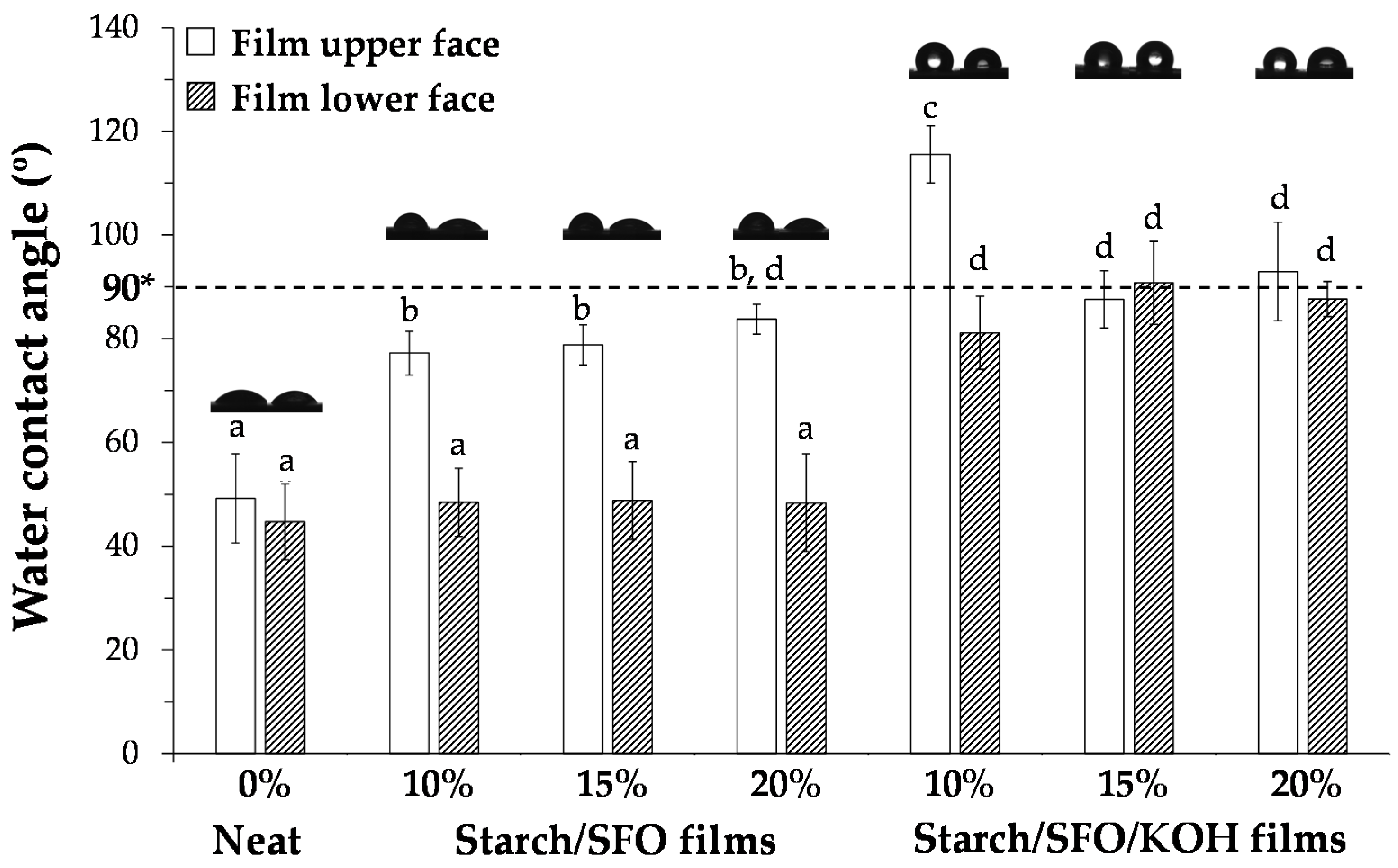

3.1. Wettability of Potato Starch/SFO/KOH-Based Films

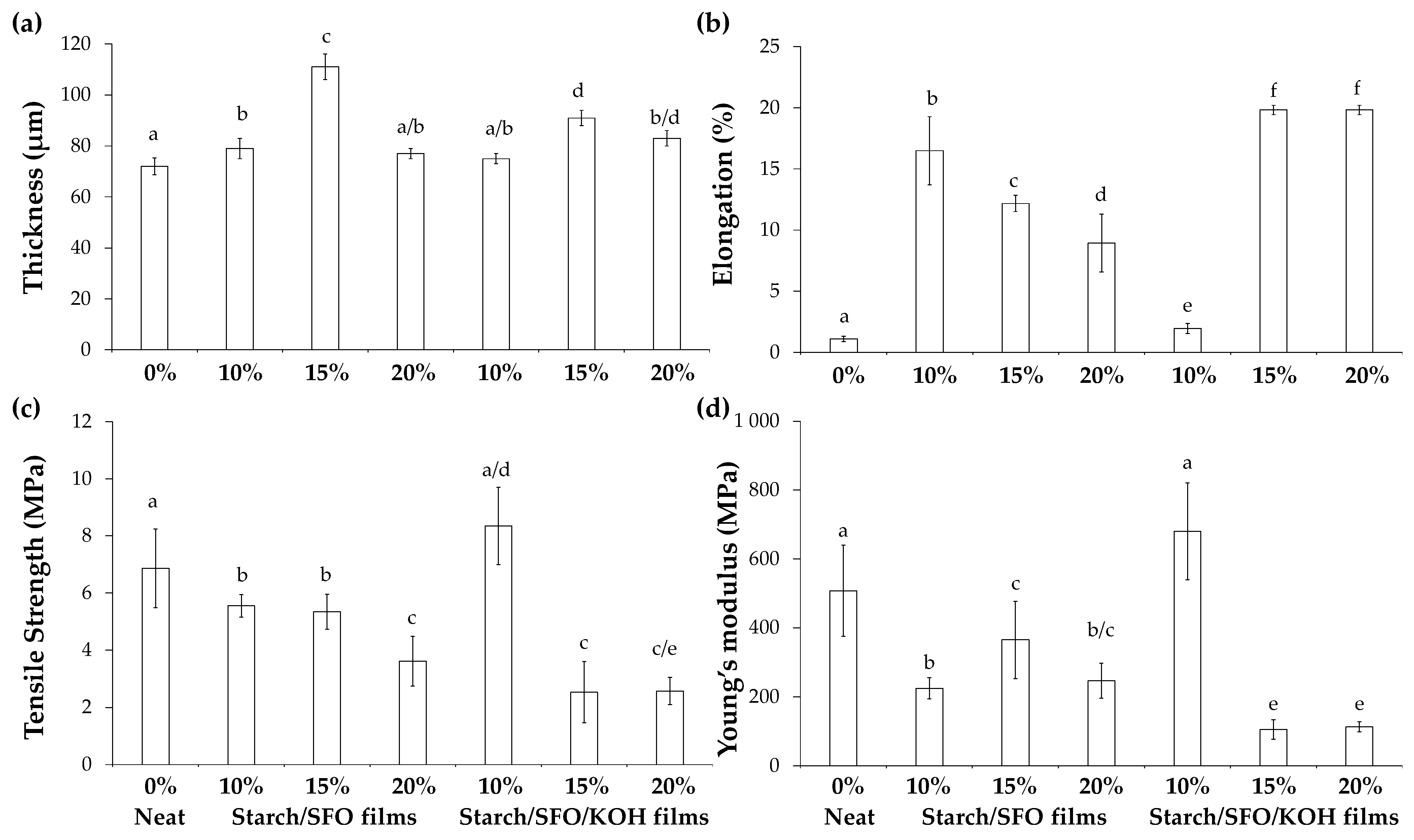

3.2. Thickness and Mechanical Properties of Potato Starch/SFO/KOH-Based Films

3.3. Structural Characterization of Potato Starch/15% SFO/KOH-Based Films

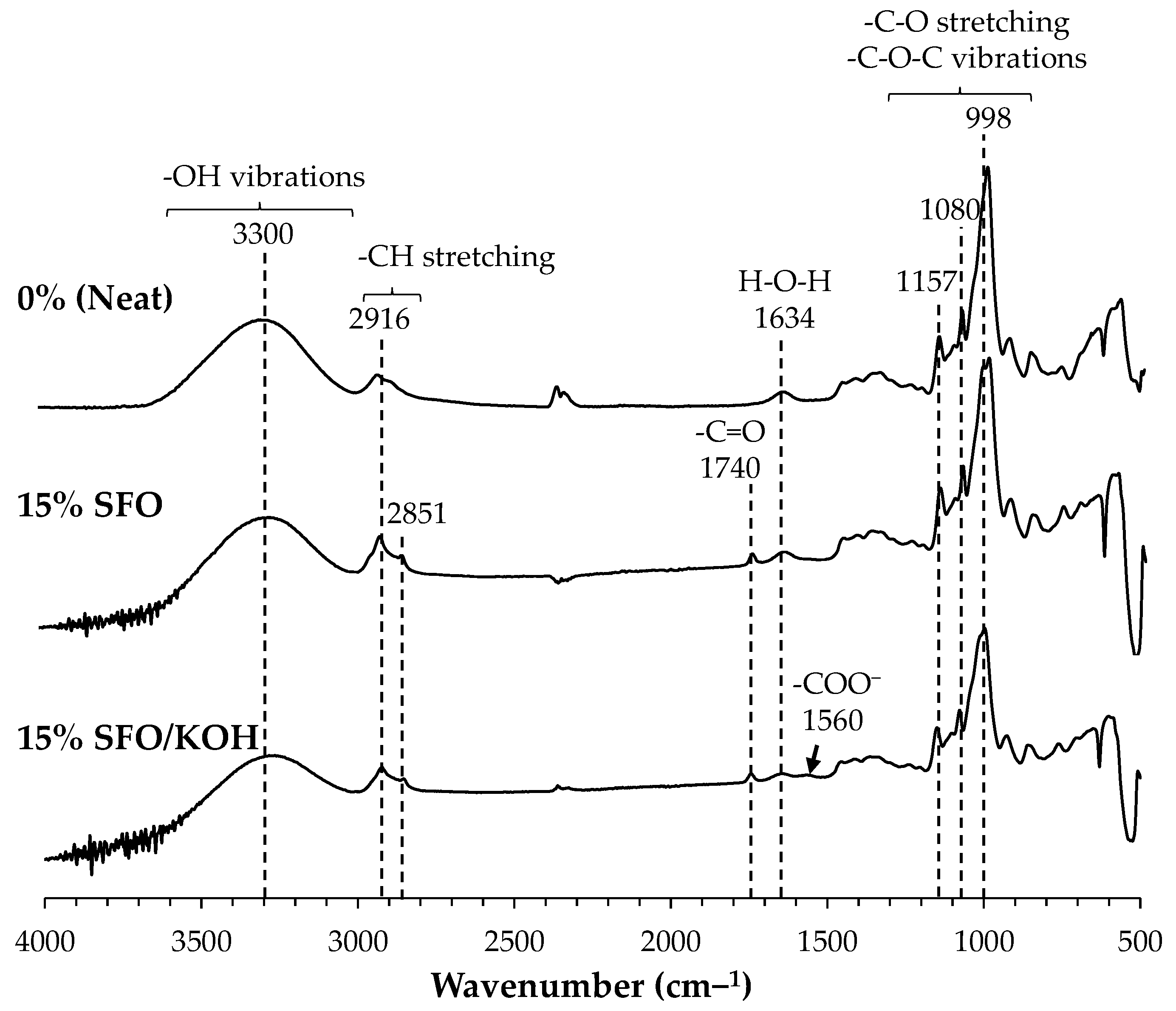

3.3.1. FTIR Analysis

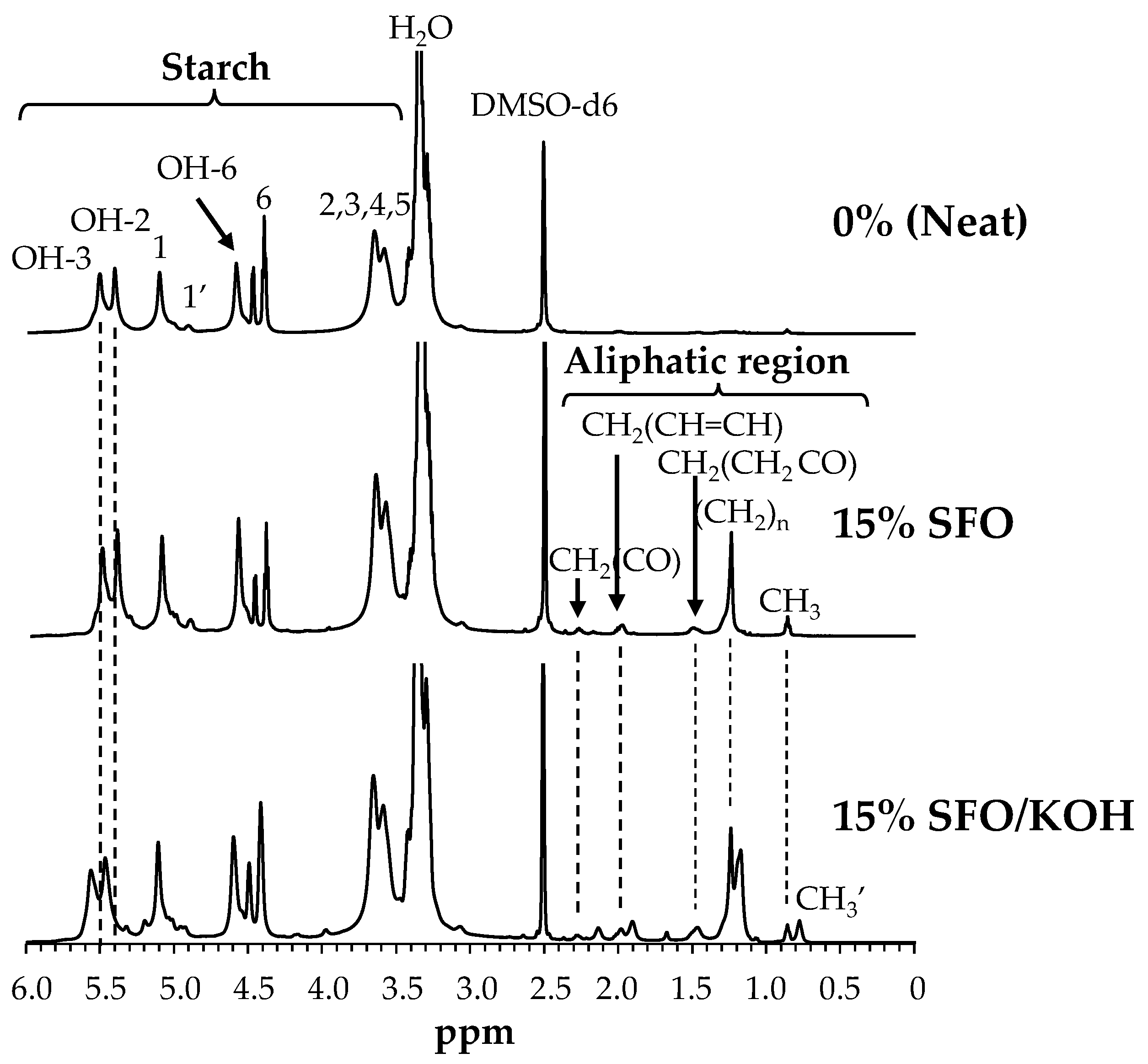

3.3.2. 1H NMR Analysis

3.4. Chromatic Properties of Potato Starch/15% SFO/KOH-Based Films

3.5. Solubility and Water Vapor Barrier Properties of Potato Starch/15% SFO/KOH-Based Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Copeland, L.; Blazek, J.; Salman, H.; Tang, M. Form and functionality of starch. Food Hydrocoll. 2009, 23, 1527–1534. [Google Scholar] [CrossRef]

- Tsang, Y.; Kumar, V.; Samadar, P.; Yang, Y.; Lee, J.; Ok, Y.; Song, H.; Kim, K.; Kwon, E.; Jeon, Y. Production of bioplastic through food waste valorization. Environ. Int. 2019, 127, 625–644. [Google Scholar] [CrossRef]

- Jogi, K.; Bhat, R. Valorization of food processing wastes and by-products for bioplastic production. Sustain. Chem. Pharm. 2020, 18, 100326. [Google Scholar] [CrossRef]

- Cazon, P.; Velazquez, G.; Ramirez, J.; Vazquez, M. Polysaccharide-based films and coatings for food packaging: A review. Food Hydrocoll. 2017, 68, 136–148. [Google Scholar] [CrossRef]

- Ashogbon, A.; Akintayo, E. Recent trend in the physical and chemical modification of starches from different botanical sources: A review. Starch-Starke 2014, 66, 41–57. [Google Scholar] [CrossRef]

- Lopes, J.; Gonçalves, I.; Nunes, C.; Teixeira, B.; Mendes, R.; Ferreira, P.; Coimbra, M.A. Potato peel phenolics as additives for developing active starch-based films with potential to pack smoked fish fillets. Food Packag. Shelf Life 2021, 28, 100644. [Google Scholar] [CrossRef]

- Oliveira, G.; Gonçalves, I.; Barra, A.; Nunes, C.; Ferreira, P.; Coimbra, M. Coffee silverskin and starch-rich potato washing slurries as raw materials for elastic, antioxidant, and UV-protective biobased films. Food Res. Int. 2020, 138, 109733. [Google Scholar] [CrossRef]

- Gonçalves, I.; Lopes, J.; Barra, A.; Hernandez, D.; Nunes, C.; Kapusniak, K.; Kapusniak, J.; Evtyugin, D.; da Silva, J.; Ferreira, P.; et al. Tailoring the surface properties and flexibility of starch-based films using oil and waxes recovered from potato chips byproducts. Int. J. Biol. Macromol. 2020, 163, 251–259. [Google Scholar] [CrossRef]

- Jimenez, A.; Fabra, M.; Talens, P.; Chiralt, A. Edible and Biodegradable Starch Films: A Review. Food Bioprocess Technol. 2012, 5, 2058–2076. [Google Scholar] [CrossRef]

- Zhang, Z.; Macquarrie, D.; Clark, J.; Matharu, A. Chemical modification of starch and the application of expanded starch and its esters in hot melt adhesive. RSC Adv. 2014, 4, 41947–41955. [Google Scholar] [CrossRef]

- Haroon, M.; Wang, L.; Yu, H.; Abbasi, N.M.; Zain-ul-Abdin; Saleem, M.; Khan, R.; Ullah, R.; Chen, Q.; Wu, J. Chemical modification of starch and its application as an adsorbent material. RSC Adv. 2016, 6, 78264–78285. [Google Scholar] [CrossRef]

- Cunha, A.; Gandini, A. Turning polysaccharides into hydrophobic materials: A critical review. Part 2. Hemicelluloses, chitin/chitosan, starch, pectin and alginates. Cellulose 2010, 17, 1045–1065. [Google Scholar] [CrossRef]

- Masina, N.; Choonara, Y.; Kumar, P.; du Toit, L.; Govender, M.; Indermun, S.; Pillay, V. A review of the chemical modification techniques of starch. Carbohydr. Polym. 2017, 157, 1226–1236. [Google Scholar] [CrossRef]

- Zarski, A.; Ptak, S.; Siemion, P.; Kapusniak, J. Esterification of potato starch by a biocatalysed reaction in an ionic liquid. Carbohydr. Polym. 2016, 137, 657–663. [Google Scholar] [CrossRef]

- Zarski, A.; Bajer, K.; Zarska, S.; Kapusniak, J. From high oleic vegetable oils to hydrophobic starch derivatives: I. Development and structural studies. Carbohydr. Polym. 2019, 214, 124–130. [Google Scholar] [CrossRef] [PubMed]

- Zarski, A.; Bajer, K.; Raszkowska-Kaczor, A.; Rogacz, D.; Zarska, S.; Kapusniak, J. From high oleic vegetable oils to hydrophobic starch derivatives: II. Physicochemical, processing and environmental properties. Carbohydr. Polym. 2020, 243, 116499. [Google Scholar] [CrossRef]

- Fang, J.; Fowler, P.; Sayers, C.; Williams, P. The chemical modification of a range of starches under aqueous reaction conditions. Carbohydr. Polym. 2004, 55, 283–289. [Google Scholar] [CrossRef]

- Chi, H.; Xu, K.; Wu, X.; Chen, Q.; Xue, D.; Song, C.; Zhang, W.; Wang, P. Effect of acetylation on the properties of corn starch. Food Chem. 2008, 106, 923–928. [Google Scholar] [CrossRef]

- Pietrzyk, S.; Juszczak, L.; Fortuna, T.; Ciemniewska, A. Effect of the oxidation level of corn starch on its acetylation and physicochemical and rheological properties. J. Food Eng. 2014, 120, 50–56. [Google Scholar] [CrossRef]

- Diop, C.; Li, H.; Xie, B.; Shi, J. Effects of acetic acid/acetic anhydride ratios on the properties of corn starch acetates. Food Chem. 2011, 126, 1662–1669. [Google Scholar] [CrossRef] [PubMed]

- Le, P.T.; Nguyen, K.T. Hydrophobizing cellulose surfaces via catalyzed transesterification reaction using soybean oil and starch. Heliyon 2020, 6, e05559. [Google Scholar] [CrossRef]

- Junistia, L.; Sugih, A.; Manurung, R.; Picchioni, F.; Janssen, L.; Heeres, H. Synthesis of Higher Fatty Acid Starch Esters using Vinyl Laurate and Stearate as Reactants. Starch-Starke 2008, 60, 667–675. [Google Scholar] [CrossRef]

- Hermawan, E.; Rosyanti, L.; Megasari, L.; Sugih, A.K.; Muljana, H. Transesterification of Sago Starch Using Various Fatty Acid Methyl Esters in Densified CO2. Int. J. Chem. Eng. Appl. 2015, 6, 152–155. [Google Scholar] [CrossRef]

- Guthrie, J. Concerted mechanism for alcoholysis of esters: An examination of the requirements. J. Am. Chem. Soc. 1991, 113, 3941–3949. [Google Scholar] [CrossRef]

- Schuchardt, U.; Sercheli, R.; Vargas, R. Transesterification of vegetable oils: A review. J. Braz. Chem. Soc. 1998, 9, 199–210. [Google Scholar] [CrossRef]

- Cruz, M.; Bastos, R.; Pinto, M.; Ferreira, J.; Santos, J.; Wessel, D.; Coelho, E.; Coimbra, M. Waste mitigation: From an effluent of apple juice concentrate industry to a valuable ingredient for food and feed applications. J. Clean. Prod. 2018, 193, 652–660. [Google Scholar] [CrossRef]

- Goswami, G.; Bora, R.; Rathore, M.S. Oxidation of cooking oils due to repeated frying and human health. Int. J. Sci. Technol. Manag. 2015, 4, 495–501. [Google Scholar]

- Degennes, P. Weitting—Statics and dynamics. Rev. Mod. Phys. 1985, 57, 827–863. [Google Scholar] [CrossRef]

- Luchese, C.; Garrido, T.; Spada, J.; Tessaro, I.; de la Caba, K. Development and characterization of cassava starch films incorporated with blueberry pomace. Int. J. Biol. Macromol. 2018, 106, 834–839. [Google Scholar] [CrossRef]

- Petronilho, S.; Neves, B.; Melo, T.; Oliveira, S.; Alves, E.; Barros, C.; Nunes, F.; Coimbra, M.; Domingues, M. Characterization of Non-Volatile Oxidation Products Formed from Triolein in a Model Study at Frying Temperature. J. Agric. Food Chem. 2021, 69, 3466–3478. [Google Scholar] [CrossRef] [PubMed]

- Law, K. Definitions for Hydrophilicity, Hydrophobicity, and Superhydrophobicity: Getting the Basics Right. J. Phys. Chem. Lett. 2014, 5, 686–688. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, I.; Hernandez, D.; Cruz, C.; Lopes, J.; Barra, A.; Nunes, C.; da Silva, J.; Ferreira, P.; Coimbra, M. Relevance of genipin networking on rheological, physical, and mechanical properties of starch-based formulations. Carbohydr. Polym. 2021, 254, 117236. [Google Scholar] [CrossRef] [PubMed]

- Jimenez, A.; Fabra, M.; Talens, P.; Chiralt, A. Phase transitions in starch based films containing fatty acids. Effect on water sorption and mechanical behaviour. Food Hydrocoll. 2013, 30, 408–418. [Google Scholar] [CrossRef]

- Cerna, M.; Barros, A.; Nunes, A.; Rocha, S.; Delgadillo, I.; Copikova, J.; Coimbra, M. Use of FT-IR spectroscopy as a tool for the analysis of polysaccharide food additives. Carbohydr. Polym. 2003, 51, 383–389. [Google Scholar] [CrossRef]

- Gomez, N.; Abonia, R.; Cadavid, H.; Vargas, I. Chemical and Spectroscopic Characterization of a Vegetable Oil used as Dielectric Coolant in Distribution Transformers. J. Braz. Chem. Soc. 2011, 22, 2292–2303. [Google Scholar] [CrossRef]

- Siyamak, S.; Laycock, B.; Luckman, P. Synthesis of starch graft-copolymers via reactive extrusion: Process development and structural analysis. Carbohydr. Polym. 2020, 227, 115066. [Google Scholar] [CrossRef]

- Muscat, D.; Adhikari, R.; McKnight, S.; Guo, Q.; Adhikari, B. The physicochemical characteristics and hydrophobicity of high amylose starch-glycerol films in the presence of three natural waxes. J. Food Eng. 2013, 119, 205–219. [Google Scholar] [CrossRef]

- Ballesteros-Mártinez, L.; Pérez-Cervera, C.; Andrade-Pizarro, R. Effect of glycerol and sorbitol concentrations on mechanical, optical, and barrier properties of sweet potato starch film. NFS J. 2020, 20, 1–9. [Google Scholar] [CrossRef]

| Starch-Based Films | Real Image | L* | a* | b* | ΔE |

|---|---|---|---|---|---|

| 0% (neat) |  | 86.76 ± 0.42 a | 1.54 ± 0.04 a | −1.64 ± 0.16 a | - |

| 15% SFO |  | 87.06 ± 0.32 a | 1.27 ± 0.07 b | −0.99 ± 0.29 b | 0.75 |

| 15% SFO/KOH |  | 86.66 ± 0.35 a | 0.89 ± 0.07 c | 0.23 ± 0.31 c | 1.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petronilho, S.; Oliveira, A.; Domingues, M.R.; Nunes, F.M.; Coimbra, M.A.; Gonçalves, I. Hydrophobic Starch-Based Films Using Potato Washing Slurries and Spent Frying Oil. Foods 2021, 10, 2897. https://doi.org/10.3390/foods10122897

Petronilho S, Oliveira A, Domingues MR, Nunes FM, Coimbra MA, Gonçalves I. Hydrophobic Starch-Based Films Using Potato Washing Slurries and Spent Frying Oil. Foods. 2021; 10(12):2897. https://doi.org/10.3390/foods10122897

Chicago/Turabian StylePetronilho, Sílvia, André Oliveira, M. Rosário Domingues, Fernando M. Nunes, Manuel A. Coimbra, and Idalina Gonçalves. 2021. "Hydrophobic Starch-Based Films Using Potato Washing Slurries and Spent Frying Oil" Foods 10, no. 12: 2897. https://doi.org/10.3390/foods10122897

APA StylePetronilho, S., Oliveira, A., Domingues, M. R., Nunes, F. M., Coimbra, M. A., & Gonçalves, I. (2021). Hydrophobic Starch-Based Films Using Potato Washing Slurries and Spent Frying Oil. Foods, 10(12), 2897. https://doi.org/10.3390/foods10122897