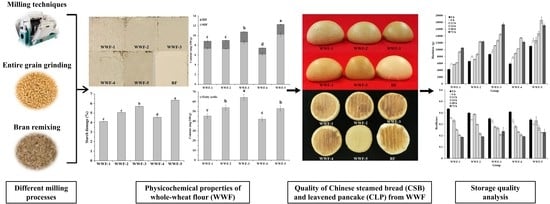

Effects of Different Pilot-Scale Milling Methods on Bioactive Components and End-Use Properties of Whole Wheat Flour

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wheat Grains and Chemicals

2.2. Pilot-Scale Milling Methods for Producing Whole Wheat Flour

2.3. Analysis of Particle Size Distribution

2.4. Analysis of Chemical Composition

2.5. Phenolic Acid Composition of Whole Wheat Flour

2.6. Analysis of Dough Properties

2.7. Preparation and Sensory Evaluation of Chinese Steamed Bread

2.8. Preparation and Sensory Evaluation of Chinese Leavened Pancakes

2.9. Short-Term Storage Quality of Chinese Steamed Bread

2.10. Statistical Analyses

3. Results and Discussions

3.1. Particle Sizes and Chemical Compositions of Whole Wheat Flours

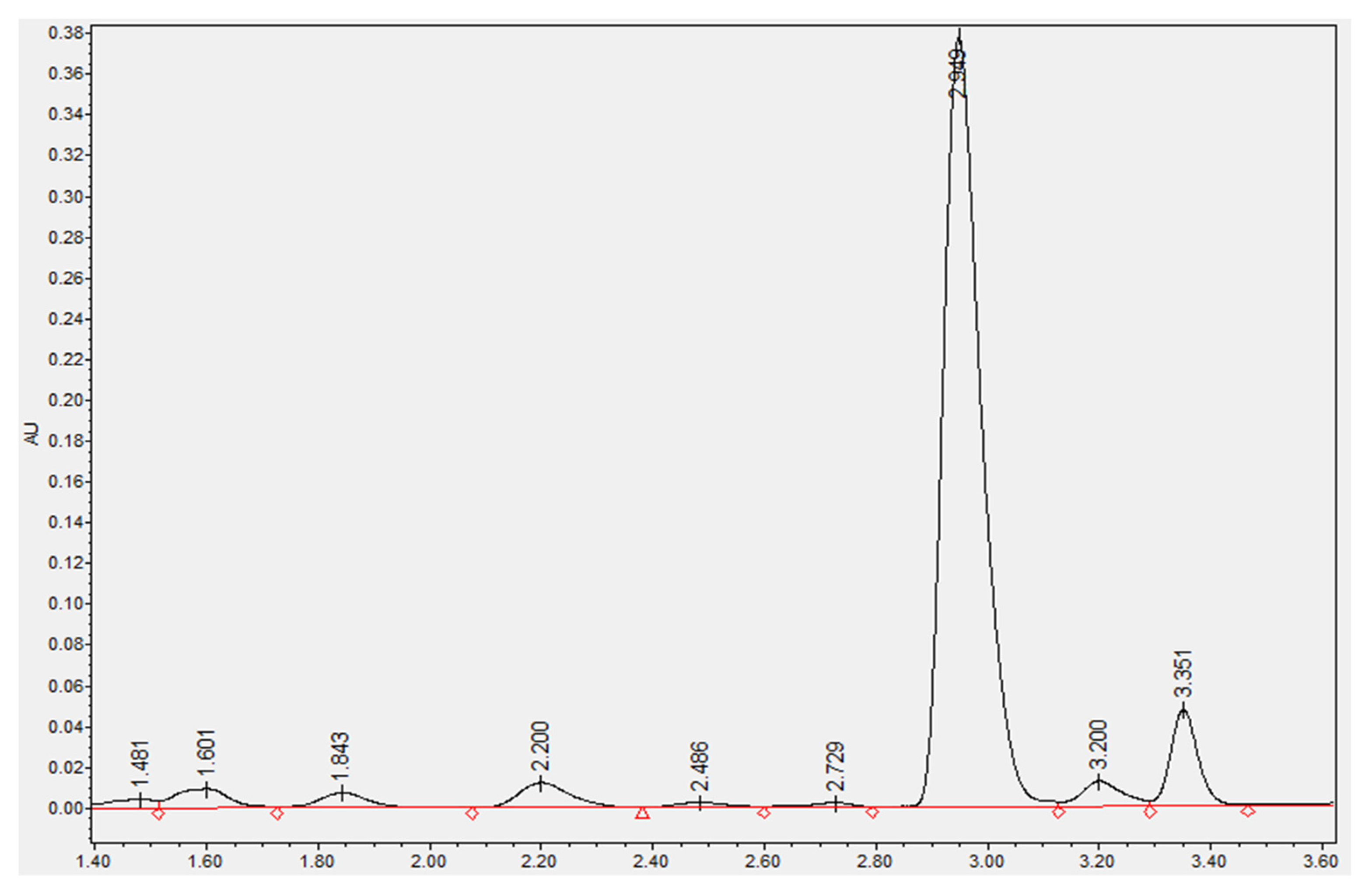

3.2. Phenolic Acid Compositions of Whole Wheat Flour

3.3. Rheological Properties of Doughs Made from Whole Wheat Flour

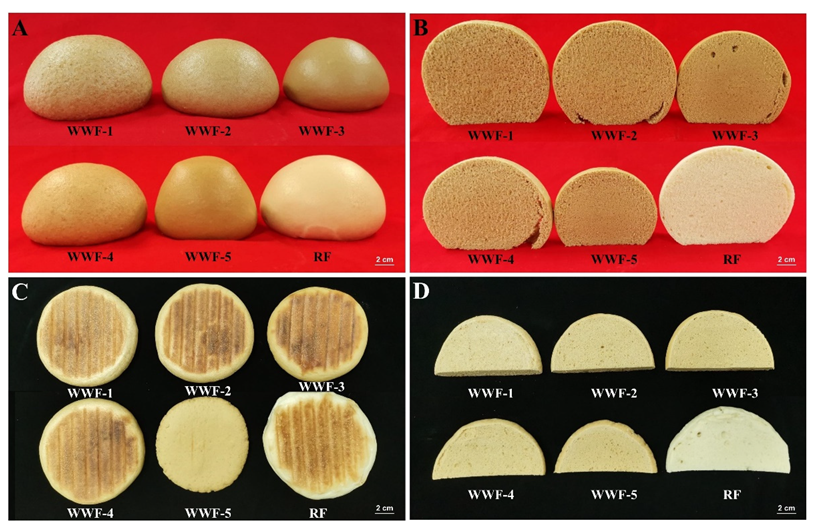

3.4. Sensory Properties of Chinese Steamed Bread and Chinese Leavened Pancakes

3.5. Correlation of Sensory Quality and Chemical Composition

3.6. Storage Quality of CSB

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bakke, A.; Vickers, Z. Consumer Liking of Refined and Whole Wheat Breads. J. Food Sci. 2007, 72, S473–S480. [Google Scholar] [CrossRef] [PubMed]

- Jonnalagadda, S.S.; Harnack, L.; Hai Liu, R.; McKeown, N.; Seal, C.; Liu, S.; Fahey, G.C. Putting the Whole Grain Puzzle Together: Health Benefits Associated with Whole Grains—Summary of American Society for Nutrition 2010 Satellite Symposium. J. Nutr. 2011, 141, 1011S–1022S. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sang, S.; Idehen, E.; Zhao, Y.; Chu, Y. Emerging Science on Whole Grain Intake and Inflammation. Nutr. Rev. 2020, 78, 21–28. [Google Scholar] [CrossRef]

- Okarter, N.; Liu, C.-S.; Sorrells, M.E.; Liu, R.H. Phytochemical Content and Antioxidant Activity of Six Diverse Varieties of Whole Wheat. Food Chem. 2010, 119, 249–257. [Google Scholar] [CrossRef]

- Tian, W.; Hu, R.; Chen, G.; Zhang, Y.; Wang, W.; Li, Y. Potential Bioaccessibility of Phenolic Acids in Whole Wheat Products during In Vitro Gastrointestinal Digestion and Probiotic Fermentation. Food Chem. 2021, 362, 130135. [Google Scholar] [CrossRef] [PubMed]

- Călinoiu, L.F.; Vodnar, D.C. Whole Grains and Phenolic Acids: A Review on Bioactivity, Functionality, Health Benefits and Bioavailability. Nutrients 2018, 10, 1615. [Google Scholar] [CrossRef] [Green Version]

- Călinoiu, L.F.; Cătoi, A.-F.; Vodnar, D.C. Solid-State Yeast Fermented Wheat and Oat Bran as A Route for Delivery of Antioxidants. Antioxidants 2019, 8, 372. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tian, W.; Chen, G.; Gui, Y.; Zhang, G.; Li, Y. Rapid Quantification of Total Phenolics and Ferulic Acid in Whole Wheat Using UV–Vis Spectrophotometry. Food Control 2021, 123, 107691. [Google Scholar] [CrossRef]

- Shewry, P.R.; Charmet, G.; Branlard, G.; Lafiandra, D.; Gergely, S.; Salgó, A.; Saulnier, L.; Bedő, Z.; Mills, E.N.C.; Ward, J.L. Developing New Types of Wheat with Enhanced Health Benefits. Trends Food Sci. Technol. 2012, 25, 70–77. [Google Scholar] [CrossRef]

- Heiniö, R.L.; Noort, M.W.J.; Katina, K.; Alam, S.A.; Sozer, N.; de Kock, H.L.; Hersleth, M.; Poutanen, K. Sensory Characteristics of Wholegrain and Bran-Rich Cereal Foods—A Review. Trends Food Sci. Technol. 2016, 47, 25–38. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Ho, K.K.H.Y.; Hayes, M.; Ferruzzi, M.G. The Roles of Food Processing in Translation of Dietary Guidance for Whole Grains, Fruits, and Vegetables. Annu. Rev. Food Sci. Technol. 2019, 10, 569–596. [Google Scholar] [CrossRef]

- Tebben, L.; Shen, Y.; Li, Y. Improvers and Functional Ingredients in Whole Wheat Bread: A Review of Their Effects on Dough Properties and Bread Quality. Trends Food Sci. Technol. 2018, 81, 10–24. [Google Scholar] [CrossRef]

- Gómez, M.; Gutkoski, L.C.; Bravo-Núñez, Á. Understanding Whole-Wheat Flour and Its Effect in Breads: A Review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3241–3265. [Google Scholar] [CrossRef]

- Noort, M.W.J.; van Haaster, D.; Hemery, Y.; Schols, H.A.; Hamer, R.J. The Effect of Particle Size of Wheat Bran Fractions on Bread Quality—Evidence for Fibre–Protein Interactions. J. Cereal Sci. 2010, 52, 59–64. [Google Scholar] [CrossRef]

- Wang, N.; Hou, G.G.; Dubat, A. Effects of Flour Particle Size on the Quality Attributes of Reconstituted Whole-Wheat Flour and Chinese Southern-Type Steamed Bread. LWT-Food Sci. Technol. 2017, 82, 147–153. [Google Scholar] [CrossRef]

- Coda, R.; Kärki, I.; Nordlund, E.; Heiniö, R.-L.; Poutanen, K.; Katina, K. Influence of Particle Size on Bioprocess Induced Changes on Technological Functionality of Wheat Bran. Food Microbiol. 2014, 37, 69–77. [Google Scholar] [CrossRef]

- Protonotariou, S.; Stergiou, P.; Christaki, M.; Mandala, I.G. Physical Properties and Sensory Evaluation of Bread Containing Micronized Whole Wheat Flour. Food Chem. 2020, 318, 126497. [Google Scholar] [CrossRef]

- Lin, S.; Jin, X.; Gao, J.; Qiu, Z.; Ying, J.; Wang, Y.; Dong, Z.; Zhou, W. Impact of Wheat Bran Micronization on Dough Properties and Bread Quality: Part I—Bran Functionality and Dough Properties. Food Chem. 2021, 353, 129407. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Liu, L.; Li, L.; Hao, C.; Zheng, X.; Bian, K.; Zhang, J.; Wang, X. Effects of Different Milling Processes on Whole Wheat Flour Quality and Performance in Steamed Bread Making. LWT Food Sci. Technol. 2015, 62, 310–318. [Google Scholar] [CrossRef]

- Guan, E.; Yang, Y.; Pang, J.; Zhang, T.; Li, M.; Bian, K. Ultrafine Grinding of Wheat Flour: Effect of Flour/Starch Granule Profiles and Particle Size Distribution on Falling Number and Pasting Properties. Food Sci. Nutr. 2020, 8, 2581–2587. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F. Influence of Ingredients and Chemical Components on the Quality of Chinese Steamed Bread. Food Chem. 2014, 163, 154–162. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Wang, X.; Zheng, X.; Tian, S.; Liu, C.; Li, L.; Ding, Y. Improvement of the Quality of Steamed Bread by Supplementation of Wheat Germ from Milling Process. J. Cereal Sci. 2014, 60, 589–594. [Google Scholar] [CrossRef]

- Su, D.; Ding, C.; Li, L.; Su, D.; Zheng, X. Effect of Endoxylanases on Dough Properties and Making Performance of Chinese Steamed Bread. Eur. Food Res. Technol. 2005, 220, 540–545. [Google Scholar] [CrossRef]

- Tian, W.; Ehmke, L.; Miller, R.; Li, Y. Changes in Bread Quality, Antioxidant Activity, and Phenolic Acid Composition of Wheats During Early-Stage Germination. J. Food Sci. 2019, 84, 457–465. [Google Scholar] [CrossRef]

- Luna-Vital, D.; Luzardo-Ocampo, I.; Cuellar-Nuñez, M.L.; Loarca-Piña, G.; Gonzalez de Mejia, E. Maize Extract Rich in Ferulic Acid and Anthocyanins Prevents High-Fat-Induced Obesity in Mice by Modulating SIRT1, AMPK and IL-6 Associated Metabolic and Inflammatory Pathways. J. Nutr. Biochem. 2020, 79, 108343. [Google Scholar] [CrossRef] [PubMed]

- Tian, W.; Chen, G.; Zhang, G.; Wang, D.; Tilley, M.; Li, Y. Rapid Determination of Total Phenolic Content of Whole Wheat Flour Using Near-Infrared Spectroscopy and Chemometrics. Food Chem. 2021, 344, 128633. [Google Scholar] [CrossRef] [PubMed]

- AACC Approved Methods of Analysis, 11th Edition—AACC Method 76-33.01. Damaged Starch—Amperometric Method by SDmatic. Available online: https://www.cerealsgrains.org/resources/Methods/Pages/76Starch.aspx (accessed on 21 October 2021).

- GB 5009.88-2014. Available online: https://www.chinesestandard.net/China/Chinese.aspx/GB5009.88-2014 (accessed on 21 October 2021).

- AACC Approved Methods of Analysis, 11th Edition—AACC Method 32-07.01. Soluble, Insoluble, and Total Dietary Fiber in Foods and Food Products. Available online: https://www.cerealsgrains.org/resources/Methods/Pages/32Fiber.aspx (accessed on 21 October 2021).

- GB/T 5510-2011. Available online: http://www.gb-gbt.cn/PDF.aspx/GBT5510-2011 (accessed on 21 October 2021).

- Tian, W.; Wilson, T.L.; Chen, G.; Guttieri, M.J.; Nelson, N.O.; Fritz, A.; Smith, G.; Li, Y. Effects of Environment, Nitrogen, and Sulfur on Total Phenolic Content and Phenolic Acid Composition of Winter Wheat Grain. Cereal Chem. 2021, 98, 903–911. [Google Scholar] [CrossRef]

- Tian, W.; Chen, G.; Tilley, M.; Li, Y. Changes in Phenolic Profiles and Antioxidant Activities during the Whole Wheat Bread-Making Process. Food Chem. 2021, 345, 128851. [Google Scholar] [CrossRef]

- AACC Approved Methods of Analysis, 11th Edition—AACC Method 54-21.02. Rheological Behavior of Flour by Farinograph: Constant Flour Weight Procedure. Available online: https://www.cerealsgrains.org/resources/Methods/Pages/54PhysicalDoughTests.aspx (accessed on 21 October 2021).

- AACC Approved Methods of Analysis, 11th Edition—AACC Method 54-10.01. Extensigraph Method, General. Available online: https://www.cerealsgrains.org/resources/Methods/Pages/54PhysicalDoughTests.aspx (accessed on 21 October 2021).

- Chen, F.; He, Z.; Chen, D.; Zhang, C.; Zhang, Y.; Xia, X. Influence of Puroindoline Alleles on Milling Performance and Qualities of Chinese Noodles, Steamed Bread and Pan Bread in Spring Wheats. J. Cereal Sci. 2007, 45, 59–66. [Google Scholar] [CrossRef]

- Huang, S.; Quail, K.; Moss, R.; Best, J. Objective Methods for the Quality Assessment of Northern-Style Chinese Steamed Bread. J. Cereal Sci. 1995, 21, 49–55. [Google Scholar] [CrossRef]

- De Brier, N.; Delcour, J.A. Pearling Affects the Lipid Content and Composition and Lipase Activity Levels of Wheat (Triticum aestivum L.) Roller Milling Fractions. Cereal Chem. 2017, 94, 588–593. [Google Scholar] [CrossRef]

- Adom, K.K.; Sorrells, M.E.; Liu, R.H. Phytochemical Profiles and Antioxidant Activity of Wheat Varieties. J. Agric. Food Chem. 2003, 51, 7825–7834. [Google Scholar] [CrossRef] [PubMed]

- Tian, W.; Li, Y. Phenolic Acid Composition and Antioxidant Activity of Hard Red Winter Wheat Varieties. J. Food Biochem. 2018, 42, e12682. [Google Scholar] [CrossRef]

- Liu, R.H. Whole Grain Phytochemicals and Health. J. Cereal Sci. 2007, 46, 207–219. [Google Scholar] [CrossRef]

- Sang, S.; Landberg, R. The Chemistry behind Health Effects of Whole Grains. Mol. Nutr. Food Res. 2017, 61, 1770074. [Google Scholar] [CrossRef] [Green Version]

- Brewer, L.R.; Kubola, J.; Siriamornpun, S.; Herald, T.J.; Shi, Y.-C. Wheat Bran Particle Size Influence on Phytochemical Extractability and Antioxidant Properties. Food Chem. 2014, 152, 483–490. [Google Scholar] [CrossRef] [PubMed]

- Rosa, N.N.; Barron, C.; Gaiani, C.; Dufour, C.; Micard, V. Ultra-Fine Grinding Increases the Antioxidant Capacity of Wheat Bran. J. Cereal Sci. 2013, 57, 84–90. [Google Scholar] [CrossRef]

- Granato, D.; Shahidi, F.; Wrolstad, R.; Kilmartin, P.; Melton, L.D.; Hidalgo, F.J.; Miyashita, K.; van Camp, J.; Alasalvar, C.; Ismail, A.B.; et al. Antioxidant Activity, Total Phenolics and Flavonoids Contents: Should We Ban in Vitro Screening Methods? Food Chem. 2018, 264, 471–475. [Google Scholar] [CrossRef]

- Harnly, J. Antioxidant Methods. J. Food Compos. Anal. 2017, 64, 145–146. [Google Scholar] [CrossRef]

- Sanz Penella, J.M.; Collar, C.; Haros, M. Effect of Wheat Bran and Enzyme Addition on Dough Functional Performance and Phytic Acid Levels in Bread. J. Cereal Sci. 2008, 48, 715–721. [Google Scholar] [CrossRef]

- Okusu, H.; Otsubo, S.; Dexter, J. Wheat Milling and Flour Quality Analysis for Noodles in Japan. In Asian Noodles; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; pp. 57–73. ISBN 9780470179222. [Google Scholar]

- Rosell, C.M.; Santos, E.; Collar, C. Mixing Properties of Fibre-Enriched Wheat Bread Doughs: A Response Surface Methodology Study. Eur. Food Res. Technol. 2006, 223, 333–340. [Google Scholar] [CrossRef]

- Xu, X.; Xu, Y.; Wang, N.; Zhou, Y. Effects of Superfine Grinding of Bran on the Properties of Dough and Qualities of Steamed Bread. J. Cereal Sci. 2018, 81, 76–82. [Google Scholar] [CrossRef]

- Wang, C.-C.; Yang, Z.; Guo, X.-N.; Zhu, K.-X. Effects of Insoluble Dietary Fiber and Ferulic Acid on the Quality of Steamed Bread and Gluten Aggregation Properties. Food Chem. 2021, 364, 130444. [Google Scholar] [CrossRef] [PubMed]

- Palacios, H.R.; Schwarz, P.B.; D’Appolonia, B.L. Effect of α-Amylases from Different Sources on the Retrogradation and Recrystallization of Concentrated Wheat Starch Gels: Relationship to Bread Staling. J. Agric. Food Chem. 2004, 52, 5978–5986. [Google Scholar] [CrossRef]

- Liu, W.; Brennan, M.; Serventi, L.; Brennan, C. Effect of Wheat Bran on Dough Rheology and Final Quality of Chinese Steamed Bread. Cereal Chem. J. 2017, 94, 581–587. [Google Scholar] [CrossRef]

- Rezaei, S.; Najafi, M.A.; Haddadi, T. Effect of Fermentation Process, Wheat Bran Size and Replacement Level on Some Characteristics of Wheat Bran, Dough, and High-Fiber Tafton Bread. J. Cereal Sci. 2019, 85, 56–61. [Google Scholar] [CrossRef]

| Sample | SDF (g/100 g) | IDF (g/100 g) | TDF (g/100 g) | Fatty Acids (mg/100 g) | Damaged Starch (%) | Protein (%) |

|---|---|---|---|---|---|---|

| WWF-1 | 7.35 ± 0.16c | 1.50 ± 0.24b | 8.85 ± 0.07c | 45.3 ± 2.26c | 4.12 ± 0.06e | 14.6 ± 0.06bc |

| WWF-2 | 7.27 ± 0.02c | 1.73 ± 0.02ab | 9.00 ± 0.05c | 53.9 ± 2.61b | 5.06 ± 0.01c | 15.0 ± 0.04a |

| WWF-3 | 8.64 ± 0.30b | 2.12 ± 0.12a | 10.76 ± 0.17b | 64.4 ± 2.85a | 5.71 ± 0.07b | 14.8 ± 0.14ab |

| WWF-4 | 6.18 ± 0.28d | 1.28 ± 0.14b | 7.46 ± 0.27d | 42.1 ± 2.10c | 4.56 ± 0.08d | 14.1 ± 0.11d |

| WWF-5 | 10.24 ± 0.40a | 2.03 ± 0.05a | 12.27 ± 0.45a | 53.0 ± 1.98b | 6.35 ± 0.01a | 13.5 ± 0.07e |

| Sample | Vanillic Acid (µg/g) | Syringic Acid (µg/g) | para-Coumaric Acid (µg/g) | trans-Ferulic Acid (µg/g) | Sinapic Acid (µg/g) | cis-Ferulic Acid (µg/g) |

|---|---|---|---|---|---|---|

| WWF-1 | 29.57 ± 0.80b | 17.20 ± 0.68b | 18.50 ± 0.81ab | 720.16 ± 4.58bc | 77.47 ± 1.22abc | 75.08 ± 0.63b |

| WWF-2 | 31.22 ± 0.83ab | 16.76 ± 0.87bc | 17.82 ± 0.89ab | 742.15 ± 14.62b | 80.97 ± 2.10a | 73.48 ± 1.40b |

| WWF-3 | 30.18 ± 1.54b | 14.47 ± 0.53c | 13.30 ± 0.65c | 534.90 ± 6.83d | 78.49 ± 2.18ab | 50.81 ± 1.41c |

| WWF-4 | 27.72 ± 1.43b | 14.75 ± 0.99bc | 15.81 ± 0.57bc | 647.33 ± 23.64c | 70.65 ± 2.94c | 65.77 ± 1.81b |

| WWF-5 | 34.35 ± 3.97a | 19.64 ± 2.46a | 19.87 ± 4.37a | 1002.11 ± 101.04a | 73.57 ± 6.81bc | 111.25 ± 16.03a |

| Sample | Water Absorption (%) | Development time (min) | Stability (min) | Energy (cm2) | Extensibility (mm) | Maximum Resistance (BU) |

|---|---|---|---|---|---|---|

| WWF-1 | 68.4 ± 0.1c | 4.7 ± 0.0b | 6.0 ± 0.1a | 47.0 ± 0.3b | 132.9 ± 0.5b | 229.8 ± 1.8b |

| WWF-2 | 69.8 ± 0.1b | 4.9 ± 0.0ab | 4.7 ± 0.0b | 52.8 ± 0.2a | 140.0 ± 0.8a | 249.0 ± 3.9a |

| WWF-3 | 68.0 ± 0.1c | 5.1 ± 0.1a | 4.8 ± 0.1b | 49.0 ± 0.3b | 142.1 ± 0.9a | 227.6 ± 2.3b |

| WWF-4 | 64.8 ± 0.3d | 3.8 ± 0.1c | 3.8 ± 0.1c | 39.5 ± 0.3c | 133.6 ± 0.5b | 193.0 ± 1.9c |

| WWF-5 | 73.0 ± 0.3a | 4.8 ± 0.1b | 2.1 ± 0.0d | 38.3 ± 0.3c | 105.9 ± 0.4c | 243.8 ± 3.1a |

| Sample | Specific Volume (20) | Stress Relaxation (35) | Skin Color (10) | Smoothness (10) | Shape (10) | Structure (15) | Total Score (100) |

|---|---|---|---|---|---|---|---|

| WWF-1 | 14a | 21a | 0a | 5d | 8a | 9b | 57a |

| WWF-2 | 14a | 19b | 0a | 7b | 7b | 11a | 57a |

| WWF-3 | 9b | 19b | 0a | 8a | 7b | 9b | 52b |

| WWF-4 | 14a | 21a | 0a | 6c | 7b | 11a | 59a |

| WWF-5 | 9b | 13c | 0a | 7b | 5c | 8c | 42c |

| RF | 20 | 33 | 9 | 9 | 8 | 14 | 93 |

| Sample | Appearance (20) | Stress Relaxation (35) | Structure (20) | Stickiness (15) | Taste and Flavor (10) | Total Score (100) |

|---|---|---|---|---|---|---|

| WWF-1 | 16a | 20c | 16a | 13a | 5b | 70a |

| WWF-2 | 14b | 20c | 14b | 11bc | 4c | 63b |

| WWF-3 | 12c | 20c | 12c | 8d | 3d | 55c |

| WWF-4 | 16a | 20c | 14b | 10c | 6a | 66b |

| WWF-5 | 6d | 20c | 10d | 7d | 2e | 45d |

| RF | 18 | 32 | 16 | 12 | 9 | 87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, W.; Tong, J.; Zhu, X.; Martin, P.F.; Li, Y.; He, Z.; Zhang, Y. Effects of Different Pilot-Scale Milling Methods on Bioactive Components and End-Use Properties of Whole Wheat Flour. Foods 2021, 10, 2857. https://doi.org/10.3390/foods10112857

Tian W, Tong J, Zhu X, Martin PF, Li Y, He Z, Zhang Y. Effects of Different Pilot-Scale Milling Methods on Bioactive Components and End-Use Properties of Whole Wheat Flour. Foods. 2021; 10(11):2857. https://doi.org/10.3390/foods10112857

Chicago/Turabian StyleTian, Wenfei, Jingyang Tong, Xiaoyue Zhu, Philipp Fritschi Martin, Yonghui Li, Zhonghu He, and Yan Zhang. 2021. "Effects of Different Pilot-Scale Milling Methods on Bioactive Components and End-Use Properties of Whole Wheat Flour" Foods 10, no. 11: 2857. https://doi.org/10.3390/foods10112857

APA StyleTian, W., Tong, J., Zhu, X., Martin, P. F., Li, Y., He, Z., & Zhang, Y. (2021). Effects of Different Pilot-Scale Milling Methods on Bioactive Components and End-Use Properties of Whole Wheat Flour. Foods, 10(11), 2857. https://doi.org/10.3390/foods10112857