Chestnut Cultivar Identification through the Data Fusion of Sensory Quality and FT-NIR Spectral Data

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

- −

- raw chestnuts (r), as in the assessment system currently adopted by traders to evaluate chestnuts; it is a quick method, used even by official inspectors for the assignment under the Protected Designation of Origin;

- −

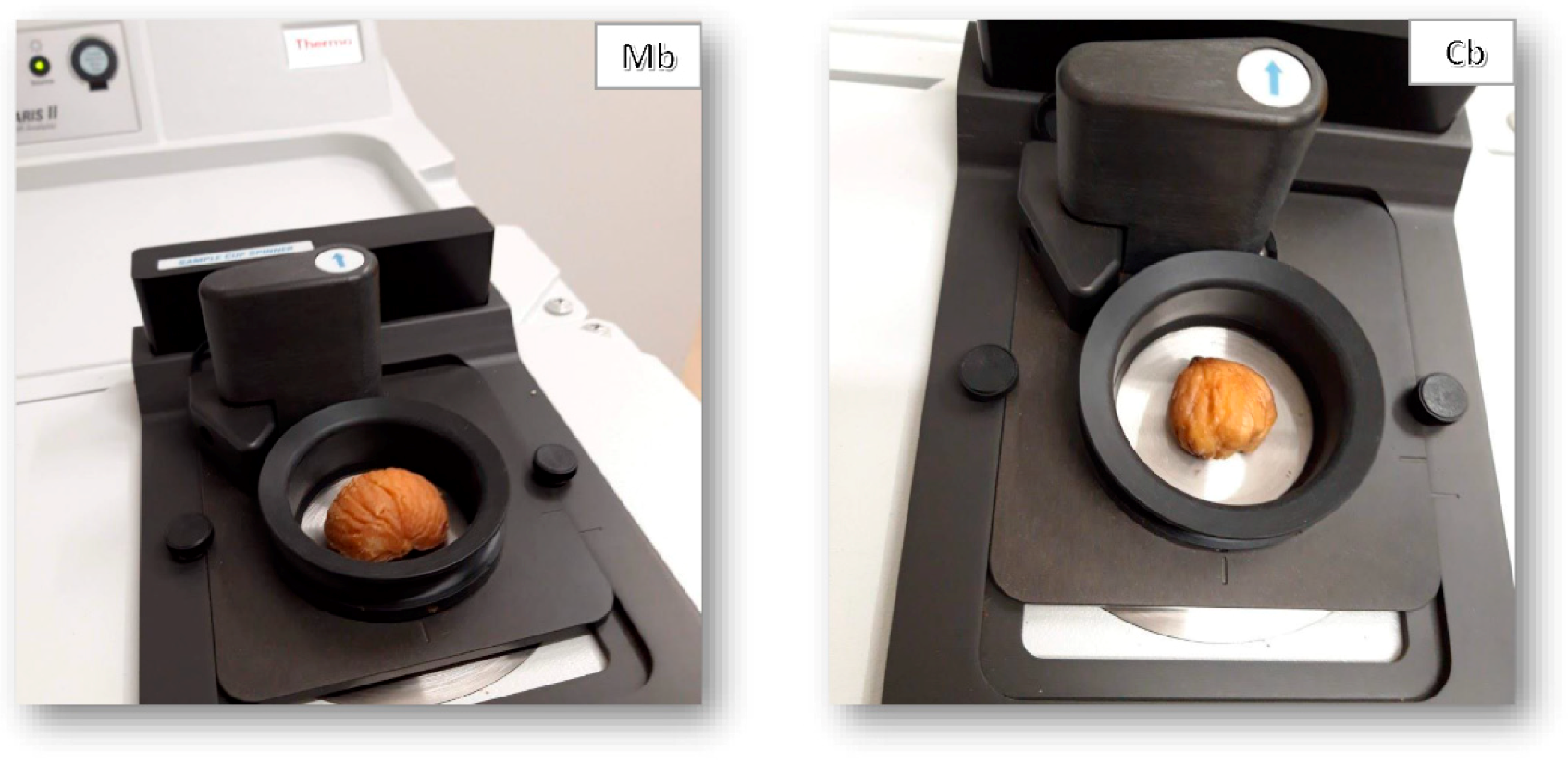

- boiled chestnuts (b), which represent the most widespread way of consumption; chestnuts, previously crosscut on the top, are boiled at 100 °C for 45 min [49].

2.2. Fruit Weight and Morphological Attributes

2.3. FT/NIR Spectral Acquisition

2.4. Sensory Analysis

2.5. Chemometrics

2.5.1. Spectral Pretreatments

2.5.2. Data Fusion

2.5.3. Classification Model Development

2.6. Data Handling and Statistical Analysis

3. Results and Discussion

3.1. Fruit Weight and Morphological Attributes

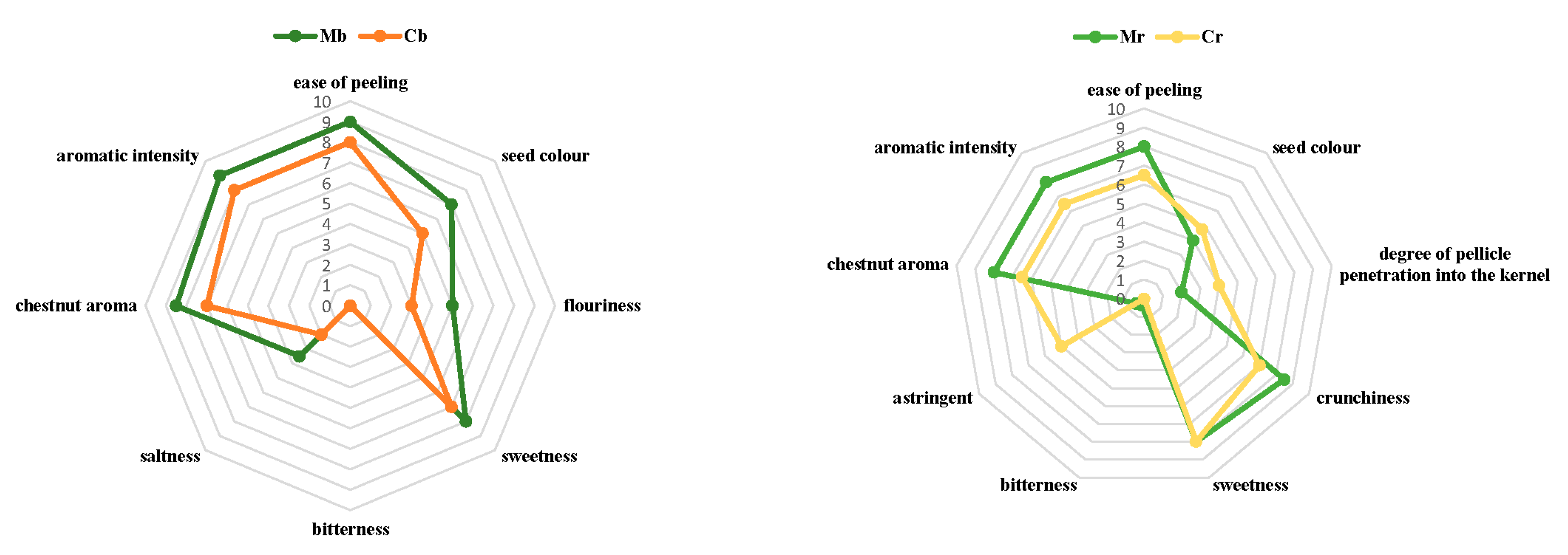

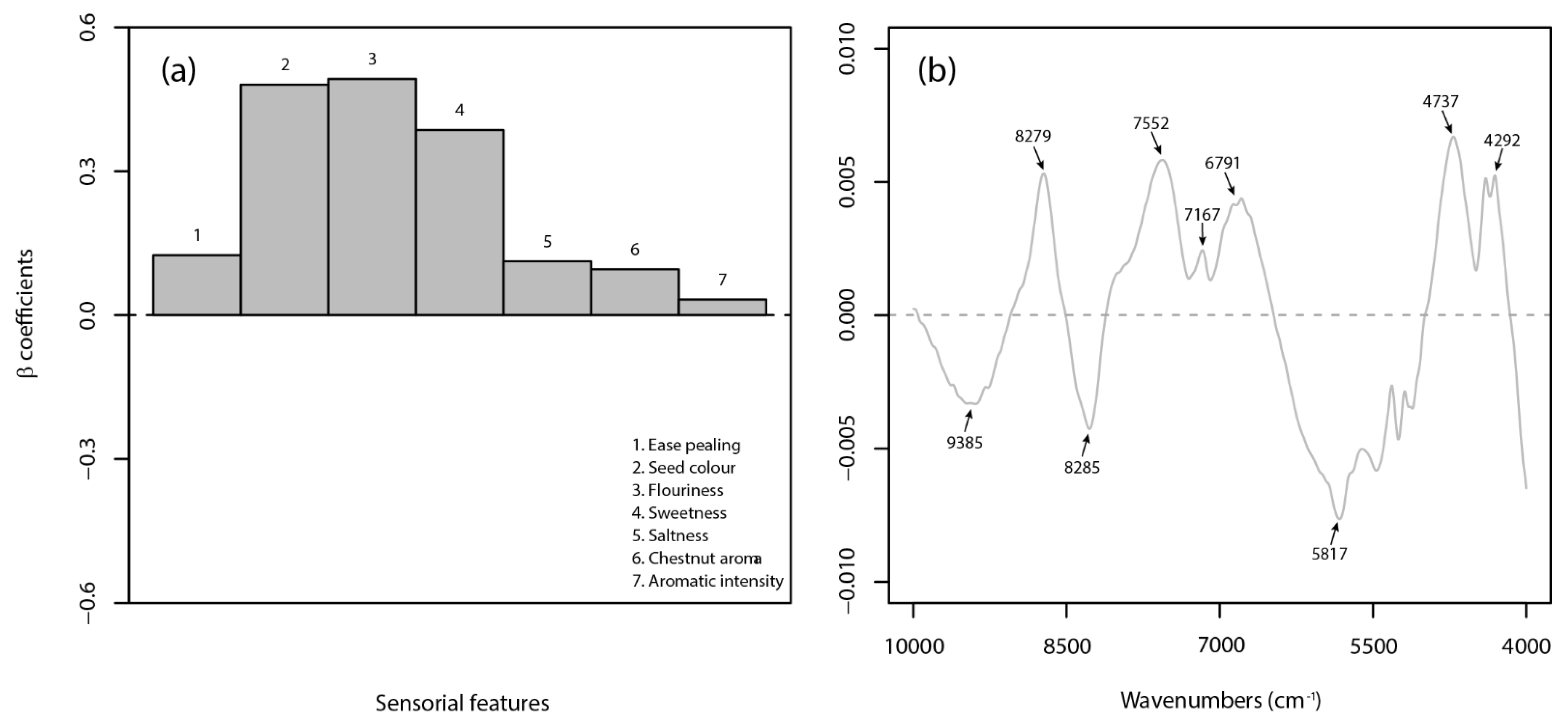

3.2. Sensory Analysis

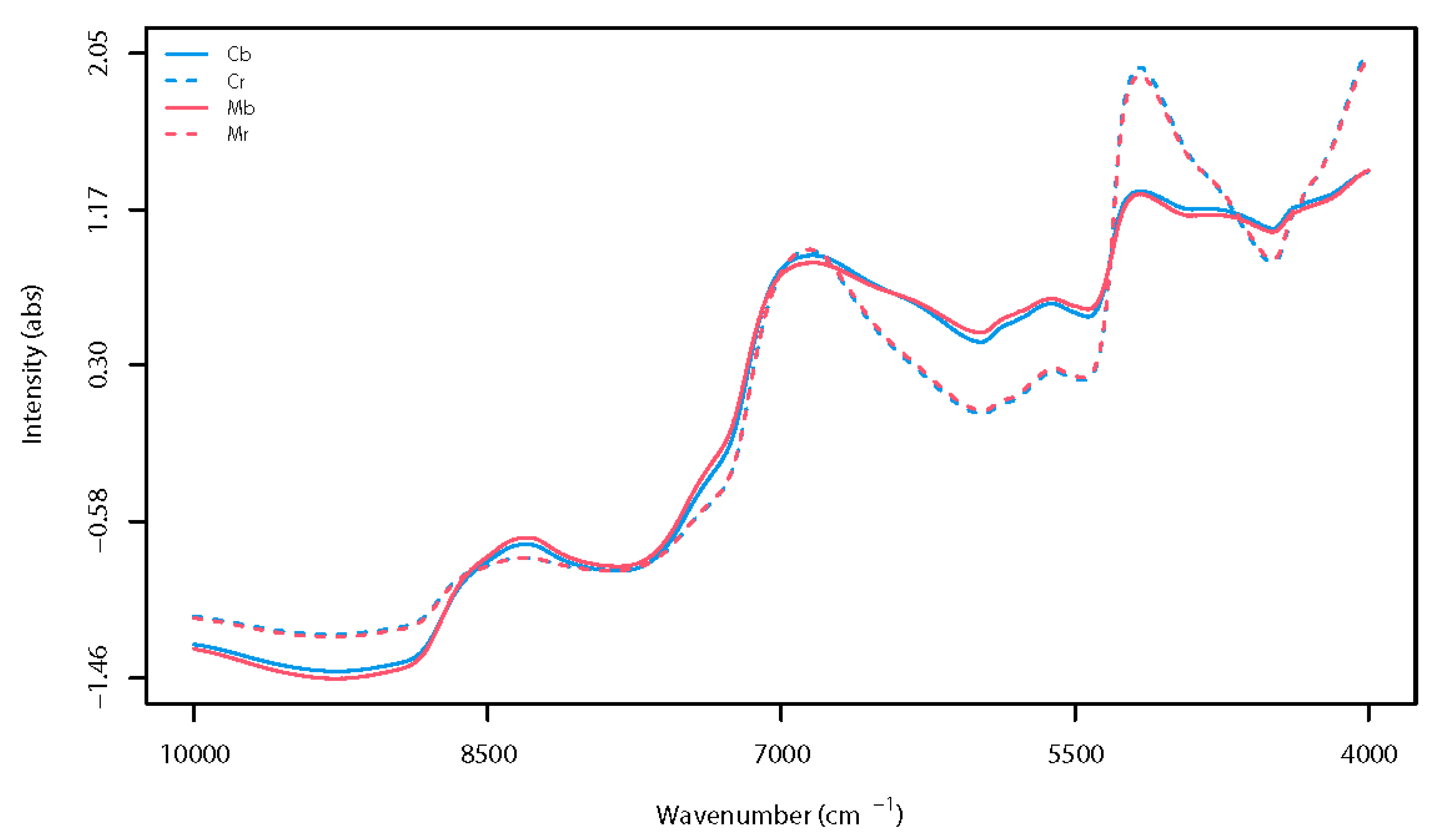

3.3. Overview of Spectra

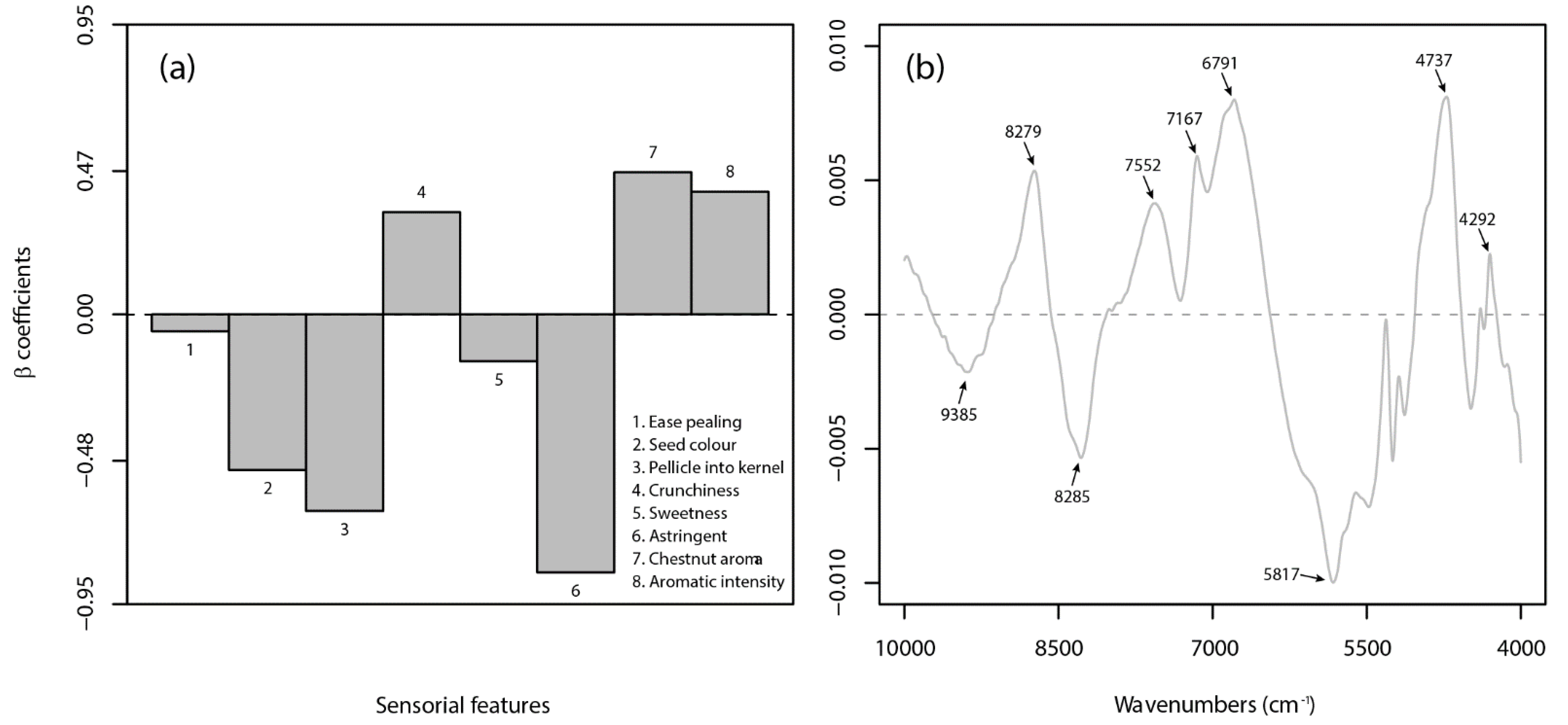

3.4. Classification Models

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beccaro, G.; Bounous, G.; de Biaggi, M.; Donno, D.; Torello Marinoni, D.; Zou, F.; Mellano, M.G. Botany, anatomy, and nut composition. In The Chestnut Handbook: Crop and Forest Management; Beccaro, G., Alma, A., Bounous, G., Gomes-Laranjo, J., Eds.; Taylor & Francis Group, LLC: Abingdon, UK, 2020; Chapter 2; pp. 5–32. [Google Scholar]

- Singh, S.R.; Rehman, M.U. Chestnut (Castanea sp.). Chapter 3 in Cultivate Minor Temperate Fruits Scientifically; Part I; Ghosh, S.N., Kumar, A., Eds.; CAB, Direct: Glasgow, UK, 2019; p. 422. [Google Scholar]

- Gomes-Laranjo, J.; Peixoto, F.; Costa, R.; Ferreira-Cardoso, J. Following Chestnut Footprints (Castanea spp.) Cultivation and cultures, Folklore and history, traditions and uses. Scr. Hortic. 2009, 9, 106–111. [Google Scholar]

- FAO. Food and Agriculture Organization of United Nations. 2020. Available online: http://faostat.fao.org/en/#data/QC (accessed on 15 June 2020).

- Borges, O.; Gonçalves, B.; Carvalho, J.S.; Correia, P.; Silva, A.P. Nutritional quality of chestnut (Castanea sativa Mill.) cultivars from Portugal. Food Chem. 2008, 106, 976–984. [Google Scholar] [CrossRef]

- Ros, E. Health Benefits of Nut Consumption. Nutrients 2010, 2, 652–682. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Neri, L.; Dimitri, G.; Sacchetti, G. Chemical composition and antioxidant activity of cured chestnuts from three sweet chestnut (Castanea sativa Mill.) ecotypes from Italy. J. Food Compos. Anal. 2010, 23, 23–29. [Google Scholar] [CrossRef]

- Dinis, L.T.; Oliveira, M.M.; Almeida, J.; Costa, R.; Gomes-Laranjo, J.; Peixoto, F. Antioxidant activities of chestnut nut of Castanea sativa Mill. (cultivar ‘Judia’) as function of origin ecosystem. Food Chem. 2012, 132, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Vella, F.M.; Laratta, B.; la Cara, F.; Morana, A. Recovery of bioactive molecules from chestnut (Castanea sativa Mill.) by-products through extraction by different solvents. Nat. Prod. Res. 2018, 32, 1022–1032. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Huang, X.; Zhangc, C.; Zhanga, M.; Huanga, C.; Yang, H. Amino acid composition and nutritional value evaluation of Chinese chestnut (Castanea mollissima Blume) and its protein subunit. RSC Adv. 2018, 8, 2653–2659. [Google Scholar] [CrossRef] [Green Version]

- Choupina, A. Nutritional and health potential of European chestnut. Rev. Ciênc. Agrár. 2019, 42, 801–807. [Google Scholar]

- Chang, X.; Liu, F.; Lin, Z.; Qiu, J.; Peng, C.; Lu, Y.; Guo, X. Phytochemical profiles and cellular antioxidant activities in Chestnut (Castanea mollissima BL.) kernels of five different cultivars. Molecules 2020, 25, 178. [Google Scholar] [CrossRef] [Green Version]

- Lo Piccolo, E.; Landi, M.; Ceccanti, C.; Mininni, A.N.; Marchetti, L.; Massai, R.; Guidi, L.; Remorini, D. Nutritional and nutraceutical properties of raw and traditionally obtained four from chestnut fruit grown in Tuscany. Eur. Food Res. Technol. 2020, 246, 1867–1876. [Google Scholar] [CrossRef]

- Xu, Z.; Meenu, M.; Chen, P.; Xu, B. Comparative study on phytochemical profiles and antioxidant capacities of chestnuts produced in different geographic area in China. Antioxidants 2020, 9, 190. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Vasconcelos, M.C.B.M.; Bennett, R.N.; Rosa, E.A.S.; Ferreira-Cardoso, J.V. Composition of European chestnut (Castanea sativa Mill.) and association with health effects: Fresh and processed products. J. Sci. Food Agric. 2010, 90, 1578–1589. [Google Scholar] [CrossRef] [PubMed]

- Massantini, R.; Moscetti, R.; Frangipane, M.T. Progress in evaluating chestnuts quality: A review of recent developments. Trends Food Sci. Technol. 2021, 113, 245–254. [Google Scholar] [CrossRef]

- Biancolillo, A.; de Luca, S.; Bassi, S.; Roudier, L.; Bucci, R.; Magrì, A.D.; Marini, F. Authentication of an Italian PDO hazelnut (“Nocciola Romana”) by NIR spectroscopy. ESPR 2018, 25, 28780–28786. [Google Scholar] [CrossRef] [PubMed]

- Firmani, P.; la Piscopia, G.; Bucci, R.; Marini, F.; Biancolillo, A. Authentication of P.G.I. Gragnano pasta by near infrared (NIR) spectroscopy and chemometrics. Microchem. J. 2020, 152, 104339. [Google Scholar] [CrossRef]

- Chapman, J.; Elbourne, A.; Truong, V.K.; Newman, L.; Gangadoo, S.; Pathirannahalage, P.R.; Cheeseman, S.; Cozzolino, D. Sensomics—From conventional to functional NIR spectroscopy—Shining light over the aroma and taste of foods. Trends Food Sci. Technol. 2019, 91, 274–281. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Li, P.; Wang, W.; Zhang, J.; Zhou, W.; Zhou, Z. Non-Destructive Measurement of Sugar Content in Chestnuts Using Near-Infrared Spectroscopy; CCTA 2010; Part IV; IFIP AICT 347D; IFIP International Federation for Information Processing: Laxenburg, 2011; pp. 246–254. [Google Scholar]

- Li Xiaoyu, L.J.; Wei, W.; Wu, X.; Jun, Z.; Zhu, Z. Measurement of protein content in chestnuts using near infrared spectroscopy. J. Chem. Pharm. 2014, 6, 938–941. [Google Scholar]

- Hu, J.; Maa, X.; Liu, L.; Wub, Y.; Ouyang, J. Rapid evaluation of the quality of chestnuts using near-infrared reflectance spectroscopy. Food Chem. 2017, 231, 141–147. [Google Scholar] [CrossRef]

- Moscetti, R.; Haff, R.P.; Saranwong, S.; Monarca, D.; Cecchini, M.; Massantini, R. Nondestructive detection of insect infested chestnuts based on NIR spectroscopy. Postharvest Biol. Technol. 2014, 87, 88–94. [Google Scholar] [CrossRef]

- Moscetti, R.; Monarca, D.; Cecchini, M.; Haff, R.P.; Contini, M.; Massantini, R. Detection of Mold-Damaged Chestnuts by Near-Infrared Spectroscopy. Postharvest Biol. Technol. 2014, 93, 83–90. [Google Scholar] [CrossRef]

- Nardecchia, A.; Presutto, R.; Bucci, R.; Marini, F.; Biancolillo, A. Authentication of the geographical origin of “Vallerano” chestnut by near infrared spectroscopy coupled with chemometrics. Food Anal. Methods 2020, 13, 1782–1790. [Google Scholar] [CrossRef]

- Bedini, G.; Chakravartula, S.S.N.; Bastianelli, G.; Caccia, R.; Contarini, M.; Morales-Rodríguez, C.; Rossini, L.; Speranza, S.; Vannini, A.; Moscetti, R.; et al. Feasibility of FT-NIR spectroscopy and Vis/NIR hyperspectral imaging for sorting unsound chestnuts. Italus Hortus 2020, 27, 3–18. [Google Scholar] [CrossRef]

- Lapchareonsuk, R.; Sirisomboon, P. Sensory quality evaluation of rice using visible and shortwave near-infrared spectroscopy. Int. J. Food Prop. 2015, 18, 1128–1138. [Google Scholar] [CrossRef]

- Alhamdan, A.M.; Fickak, A.; Atia, A.R. Evaluation of sensory and texture profile analysis properties of stored Khalal Barhi dates nondestructively using Vis/NIR spectroscopy. J. Food Process. Eng. 2019, 42, e13215. [Google Scholar] [CrossRef]

- Németh, D.; Balázs, G.; Daood, H.G.; Kovács, Z.; Bodor, Z.; Zaukuu, J.L.Z.; Szentpéteri, V.; Kókai, Z.; Kappel, N. Standard analytical methods, sensory evaluation, NIRS and electronic tongue for sensing taste attributes of different melon varieties. Sensors 2019, 19, 5010. [Google Scholar] [CrossRef] [Green Version]

- Künsch, U.; Schärer, H.; Patrian, B.; Höhn, E.; Conedera, M.; Sassella, A.; Jermini, M.; Jelmini, G. Effects of roasting on chemical composition and quality of different chestnut (Castanea sativa Mill) varieties. J. Sci. Food Agric. 2001, 81, 1106–1112. [Google Scholar] [CrossRef]

- Mellano, M.G.; Beccaro, G.L.; Bounous, B.; Trasino, C.; Barrel, A. Morpho-Biological and Sensorial Quality Evaluation of Chestnut Cultivars in Aosta Valley (Italy). Acta Hortic. 2009, 815, 125–132. [Google Scholar] [CrossRef]

- Warmund, M.R.; Elmore, J.R.; Adhikari, K.; McGraw, S. Descriptive sensory analysis and free sugar contents of chestnut cultivars grown in North America. J. Sci. Food Agric. 2011, 91, 1940–1945. [Google Scholar] [CrossRef]

- Predieri, S.; Gatti, E.; Magli, M.; ì Bertazza, G.; Drago, S.; Raschi, A. Traditional chestnut cultivar quality assessment as a tool for food-tourism development in Tuscany Apennine mountain area. J. Food Sci. Eng. 2012, 2, 157–162. [Google Scholar] [CrossRef] [Green Version]

- Yang, F.; Liu, Q.; Pan, S.Y.; Xu, C.; Xiong, Y.L.L. Chemical composition and quality traits of Chinese chestnuts (Castanea mollissima) produced in different ecological regions. Food Biosci. 2015, 11, 33–42. [Google Scholar] [CrossRef]

- Zhu, F. Effect of Processing on Quality Attributes of Chestnut. Food Bioproc. Tech. 2016, 9, 1429–1443. [Google Scholar] [CrossRef]

- De Biaggi, M.; Rapalino, S.; Donno, D.; Mellano, M.G.; Beccaro, G.L. Genotype influence on chemical composition and sensory traits of chestnut in 18 cultivars grown on the same rootstock and at the same agronomic conditions. In Proceedings of the VI International Chestnut Symposium, Samsun, Turkey, 9–13 October 2017; pp. 215–220. [Google Scholar]

- Carneiro-Carvalho, A.; Vilela, A.; Ferreira-Cardoso, J.; Marques, T.; Anjos, R.; Gomes-Laranjo, J.; Pinto, T. Productivity, chemical composition and sensory quality of “Martaínha” chestnut variety treated with Silicon. CYTA. J. Food 2019, 17, 316–323. [Google Scholar]

- Yang, Q.; Kan, L.; Wu, Y.; Liu, Y.; Ouyang, J. Influence of nutritional components on the texture characteristics and sensory properties of cooked chestnut kernel. J. Food Process. Preserv. 2019, 43, e14112. [Google Scholar] [CrossRef]

- Mendoza, F.A.; Cichy, K.; Lu, R.; Kelly, J.D. Evaluation of Canning Quality Traits in Black Beans (Phaseolus vulgaris L.) by Visible/Near-Infrared Spectroscopy. Food Bioproc. Technol. 2014, 7, 2666–2678. [Google Scholar] [CrossRef]

- Alexandrakis, D.; Downey, G.; Scannell, A.G.M. Rapid Non-destructive Detection of Spoilage of Intact Chicken Breast Muscle Using Near-infrared and Fourier Transform Mid-infrared Spectroscopy and Multivariate Statistics. Food Bioproc. Technol. 2012, 5, 338–347. [Google Scholar] [CrossRef]

- Woodcock, T.; Fagan, C.C.; O’Donnell, C.P.; Downey, G. Application of Near and Mid-Infrared Spectroscopy to Determine Cheese Quality and Authenticity. Food Bioproc. Technol. 2008, 1, 117–129. [Google Scholar] [CrossRef]

- Strani, L.; Grassi, S.; Casiraghi, E.; Alamprese, C.; Marini, F. Milk Renneting: Study of Process Factor Influences by FT-NIR Spectroscopy and Chemometrics. Food Bioproc. Technol. 2019, 12, 954–963. [Google Scholar] [CrossRef]

- Borràs, E.; Ferré, J.; Boqué, R.; Mestres, M.; Aceña, L.; Busto, O. Data fusion methodologies for food and beverage authentication and quality assessment—A review. Anal. Chim. Acta 2015, 891, 1–14. [Google Scholar] [CrossRef]

- Ballabio, D.; Robotti, E.; Grisoni, F.; Quasso, F.; Bobba, M.; Vercelli, S.; Gosetti, F.; Calabrese, G.; Sangiorgi, E.; Orlandi, M.; et al. Chemical profiling and multivariate data fusion methods for the identification of the botanical origin of honey. Food Chem. 2018, 266, 79–89. [Google Scholar] [CrossRef] [PubMed]

- Sanaeifar, A.; Jafari, A.; Golmakani, M.T. Fusion of dielectric spectroscopy and computer vision for quality characterization of olive oil during storage. Comput. Electron. Agric. 2018, 145, 142–152. [Google Scholar] [CrossRef]

- Li, Y.; Xiong, Y.; Min, S. Data fusion strategy in quantitative analysis of spectroscopy relevant to olive oil adulteration. Vib. Spectrosc. 2019, 101, 20–27. [Google Scholar] [CrossRef]

- Mendez, J.; Mendoza, L.; Cruz-Tirado, J.P.; Quevedo, R.; Siche, R. Trends in application of NIR and hyperspectral imaging for food authentication. Sci. Agropecu. 2019, 10, 143–161. [Google Scholar] [CrossRef]

- Tahir, H.E.; Arslan, M.; Mahunu, G.K.; Shi, J.; Zou, X.; Mohammed, G.K.; Gasmalla, M.A.A.; Mariod, A.A. Data Fusion Approach Improves the Prediction of Single Phenolic Compounds in Honey: A Study of NIR and Raman Spectroscopies. eFood 2020, 1, 173–180. [Google Scholar] [CrossRef] [Green Version]

- Beccaro, G.L.; Donno, D.; Lione, G.G.; de Biaggi, M.; Gamba, G.; Rapalino, S.; Riondato, I.; Gonthier, P.; Mellano, M.G. Castanea spp. agrobiodiversity conservation: Genotype influence on chemical and sensorial traits of cultivars grown on the same clonal rootstock. Foods 2020, 9, 1062. [Google Scholar] [CrossRef] [PubMed]

- Yurtlu, Y.B.; Serdar, U.; Yesiloglu, E. Physical Properties of Some Chestnut Cultivars Produced in Black Sea Region of Turkey. Acta Hortic. 2014, 1019, 249–255. [Google Scholar] [CrossRef]

- Mohsenin, N.N. Physical Properties of Plant and Animal Material; Gordon and Breach Science Publishers Inc.: New York, NY, USA, 1980. [Google Scholar]

- Donno, D.; Beccaro, G.; Mellano, M.; Torello Marinoni, D.; Cerutti, A.; Canterino, S.; Bounous, G. Application of sensory, nutraceutical and genetic techniques to create a quality profile of ancient apple cultivars. J. Food Qual. 2012, 35, 169–181. [Google Scholar] [CrossRef]

- ISO. Sensory Analysis. General Guidance for the Design of Test Rooms; ISO 8589. 2007. Available online: https://www.iso.org/standard/36385.html (accessed on 3 September 2021).

- ISO. Sensory Analysis. Methodology. General Guidance for Establishing a Sensory Profile; UNI EN ISO 13299. 2016. Available online: https://www.iso.org/standard/58042.html (accessed on 3 September 2021).

- Mellano, M.G.; Rapalino, S.; Donno, D. Sensory profiles of Castanea sativa cultivars and eurojapanese hybrids. Castanea 2017, 2, 8–9. [Google Scholar]

- UPOV. Guidelines for the Conduct of Tests for Distinctness, Uniformity and Stability. Chestnut (Castanea sativa Mill.). TG/124/4 (ed.). (Geneve: International Union for the Protection of New Varieties of Plants). 2017. Available online: https://www.upov.int/en/publications/tg-rom/tg124/tg_124_3.pdf (accessed on 3 September 2021).

- Serdar, U.; Bounous, G.; Ertürk, U.; Akyuz, B.; Fulbright, D.W. Evaluation of the descriptive characteristics of chestnut. Acta Hortic. 2018, 1220, 35–44. [Google Scholar] [CrossRef]

- Biancolillo, A.; Bucci, R.; Magrì, A.L.; Magrì, A.D.; Marini, F. Data-fusion for multiplatform characterization of an Italian craft beer aimed at its authentication. Anal. Chim. Acta 2014, 820, 23–31. [Google Scholar] [CrossRef]

- Moscetti, R.; Saeys, W.; Keresztes, J.C.; Goodarzi, M.; Cecchini, M.; Danilo, M.; Massantini, R. Hazelnut Quality Sorting Using High Dynamic Range Short-Wave Infrared Hyperspectral Imaging. Food Bioproc. Technol. 2015, 8, 1593–1604. [Google Scholar] [CrossRef]

- Oyedele, O.A.; Oladipo, I.O.; Elegbeleye, K.E. Investigation INTO Some Physical Properties of Chestnut Grown in Nigeria. Int. J. Eng. Res. 2013, 2, 3269–3277. [Google Scholar]

- Hwang, J.Y.; Hwang, I.K.; Park, J.B. Analysis of physicochemical factors related to the automatic pellicle removal in Korean chestnut (Castanea crenata). J. Agric. Food Chem. 2001, 49, 6045–6049. [Google Scholar] [CrossRef]

- Huang, R.; Xu, C. An overview of the perception and mitigation of astringency associated with phenolic compounds. Compr. Rev. Food Sci. Food Saf. 2020, 20, 1036–1074. [Google Scholar] [CrossRef]

- Poljak, I.; Vahcic, N.; Gacic, M.; Idžojtic, M. Morphology and chemical composition of fruits of the traditional Croatian chestnut variety ‘Lovran Marron’. Food Technol. Biotechnol. 2016, 54, 189–199. [Google Scholar] [CrossRef]

- Riondato, I.; Akyüz, B.; Beccaro, G.; Casey, J.; Conedera, M.; Coulié, J.; Diamandis, S.; Gomes-Laranjo, J.; Nishio, S.; Ramos-Cabrer, A. Cultivars list and breeding. In The Chestnut Handbook: Crop and Forest Management; Beccaro, G., Alma, A., Bounous, G., Gomes-Laranjo, J., Eds.; Taylor & Francis Group, LLC: Abingdon, UK, 2020; Chapter 4; pp. 52–117. [Google Scholar]

- Poljak, I.; Vahcic, N.; Vidakovi´c, A.; Tumpa, K.; Žarkovic, I.; Idžojtic, M. Traditional Sweet Chestnut and Hybrid Varieties: Chemical Composition, Morphometric and Qualitative Nut Characteristics. Agronomy 2021, 11, 516. [Google Scholar] [CrossRef]

- Contador, L.; Robles, B.; Shinya, P.; Medel, M.; Pinto, C.; Reginato, G.; Infante, R. Characterization of texture attributes of raw almond using a trained sensory panel. Fruits 2015, 70, 231–237. [Google Scholar] [CrossRef] [Green Version]

- Büning-Pfaue, H. Analysis of water in food by near infrared spectroscopy. Food Chem. 2003, 82, 107–115. [Google Scholar] [CrossRef]

- Sinelli, N.; Benedetti, S.; Bottega, G.; Riva, M.; Buratti, S. Evaluation of the optimal cooking time of rice by using FT-NIR spectroscopy and an electronic nose. J. Cereal Sci. 2006, 44, 137–143. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, G.; Wu, Y.; Yang, Z.; Ouyang, J. Influence of amylose on the pasting and gel texture properties of chestnut starch during thermal processing. Food Chem. 2019, 294, 378–383. [Google Scholar] [CrossRef]

- Workman, J.; Weyer, L. Practical Guide to Interpretive Near-Infrared Spectroscopy; CRC Press: London, UK, 2008. [Google Scholar]

- Corona, P. Communicating facts, findings and thinking to support evidence-based strategies and decisions. Ann. Silvic. Res. 2018, 42, 1–2. [Google Scholar]

| Descriptors | Sensory Attribute Definitions | Standards and Reference Materials |

|---|---|---|

| ease of peeling | ease of peeling the shell and pellicle away from the nut | different level of adherence of shell/pellicle to the nut (value 0 corresponds to hard, while value 10 corresponds to easy) |

| seed color | external color of the seed, after removing the pellicle | seed color with a degree of darkness (value 0 corresponds to a light color seed, while value 10 corresponds to dark) |

| degree of pellicle penetration into the kernel | degree of penetration of seed coat into the embryo | value 0 corresponds to a no penetration, while value 10 corresponds to strong penetration (visible > 2.0 mm) |

| crunchiness | amount of noise generated when the sample is chewed at a fast rate with the back teeth | value 0 corresponds to a dried apple piece, while 10 corresponds to a fresh celery piece |

| astringent | sensation of drying, drawing-up or puckering of any of the mouth surfaces | diluted tannic acid solution (0.06–2 mg/mL) |

| flouriness | amount of dry, fine, powdery particles that coat the mouth during chewing. | different level of graininess of chestnut flour (from coarse to fine) |

| sweetness | basic taste associated with sugar (sucrose) | diluted sucrose solution (0.5–6 g/L) |

| bitterness | basic taste associated with caffeine | diluted caffeine solution (0.03–0.2 g/L) |

| saltness | basic taste associated with salt | diluted salt solution (0.3–3 g/L) |

| chestnut aroma | intensity of aroma of chestnut products | taste of chestnut |

| aromatic intensity | characteristic flavor of chestnut at the seed break | aromatics commonly associated with chestnut |

| Attribute | Cultivar | Mean | SD 3 | CV 4 (%) |

|---|---|---|---|---|

| Weight (g) | M 1 | 16.66 a | 2.78 | 16.70 |

| C 2 | 7.68 b | 1.18 | 15.30 | |

| Length (mm) | M | 40.15 a | 2.61 | 6.49 |

| C | 29.74 b | 1.80 | 6.05 | |

| Width (mm) | M | 30.89 a | 1.41 | 4.55 |

| C | 14.81 b | 1.77 | 11.95 | |

| Thickness (mm) | M | 21.82 a | 2.84 | 13.02 |

| C | 14.37 b | 1.90 | 13.25 | |

| Geometric mean diameter (mm) | M | 29.87 a | 1.76 | 5.89 |

| C | 18.42 b | 1.79 | 9.74 | |

| Arithmetic mean diameter (mm) | M | 30.95 a | 1.67 | 5.40 |

| C | 19.64 b | 1.65 | 8.38 | |

| Surface area (mm2) | M | 2809.91 a | 335.54 | 11.94 |

| C | 1074.99 b | 202.21 | 18.81 | |

| Sphericity (%) | M | 0.75 a | 0.04 | 5.59 |

| C | 0.62 b | 0.04 | 7.10 | |

| Volume (mm3) | M | 14,214.35 a | 2583.40 | 18.17 |

| C | 3384.49 b | 920.04 | 27.18 |

| Attribute | Cultivar | Mean | Median | SD | Range | CV (%) |

|---|---|---|---|---|---|---|

| ease of peeling | Mb | 8.94 | 9.00 | 0.13 | 8.5–9.0 | 1.43 |

| Cb | 7.87 | 8.00 | 0.17 | 7.5–8.0 | 2.16 | |

| seed color | Mb | 6.95 | 7.00 | 0.14 | 6.5–7.2 | 2.06 |

| Cb | 4.92 | 5.00 | 0.16 | 4.6–5.2 | 3.12 | |

| flouriness | Mb | 4.94 | 5.00 | 0.19 | 4.5–5.3 | 3.82 |

| Cb | 2.94 | 3.00 | 0.17 | 2.5–3.3 | 5.55 | |

| sweetness | Mb | 7.99 | 8.00 | 0.13 | 7.7–8.0 | 1.60 |

| Cb | 7.02 | 7.00 | 0.11 | 6.8–7.3 | 1.58 | |

| saltness | Mb | 3.37 | 3.50 | 0.24 | 3–3.8.0 | 6.78 |

| Cb | 2.03 | 2.00 | 0.12 | 1.8–2.0 | 6.20 | |

| chestnut aroma | Mb | 8.57 | 8.50 | 0.31 | 8.0–9.0 | 3.60 |

| Cb | 6.95 | 7.00 | 0.16 | 6.5–7.2 | 2.23 | |

| aromatic intensity | Mb | 9.03 | 9.00 | 0.25 | 8.7–10 | 2.79 |

| Cb | 7.95 | 8.00 | 0.11 | 7.6–8.0 | 1.43 | |

| subjective judgement | Mb | 8.96 | 9.00 | 0.18 | 8.5–9.5 | 2.01 |

| Cb | 6.95 | 7.00 | 0.10 | 6.7–7.0 | 1.40 |

| Type of Model | Features | Matrix Type | Model Acronym | LVs | Captured Variance (%) | Sensitivity | Specificity | Accuracy | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X-Block | Y-Block | CA 1 | CV 2 | CA | CV | CA | CV | |||||

| Sensory based | 5 | Raw | Sr | 3 | 87.34 | 84.37 | 0.96 | 0.96 | 0.98 | 0.98 | 0.97 | 0.97 |

| Boiled | Sb | 3 | 89.93 | 76.84 | 0.95 | 0.94 | 0.95 | 0.96 | 0.95 | 0.95 | ||

| Spectral based | 3112 | Raw | Nr | 3 | 99.39 | 89.90 | 0.99 | 0.98 | 0.97 | 0.98 | 0.98 | 0.98 |

| Boiled | Nb | 3 | 99.53 | 34.91 | 0.90 | 0.82 | 0.80 | 0.74 | 0.85 | 0.78 | ||

| Data fusion based | 3117 | Raw | Fr | 3 | 99.28 | 90.03 | 0.99 | 0.98 | 1.00 | 0.99 | 1.00 | 0.99 |

| Boiled | Fb | 7 | 99.93 | 84.40 | 0.98 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corona, P.; Frangipane, M.T.; Moscetti, R.; Lo Feudo, G.; Castellotti, T.; Massantini, R. Chestnut Cultivar Identification through the Data Fusion of Sensory Quality and FT-NIR Spectral Data. Foods 2021, 10, 2575. https://doi.org/10.3390/foods10112575

Corona P, Frangipane MT, Moscetti R, Lo Feudo G, Castellotti T, Massantini R. Chestnut Cultivar Identification through the Data Fusion of Sensory Quality and FT-NIR Spectral Data. Foods. 2021; 10(11):2575. https://doi.org/10.3390/foods10112575

Chicago/Turabian StyleCorona, Piermaria, Maria Teresa Frangipane, Roberto Moscetti, Gabriella Lo Feudo, Tatiana Castellotti, and Riccardo Massantini. 2021. "Chestnut Cultivar Identification through the Data Fusion of Sensory Quality and FT-NIR Spectral Data" Foods 10, no. 11: 2575. https://doi.org/10.3390/foods10112575

APA StyleCorona, P., Frangipane, M. T., Moscetti, R., Lo Feudo, G., Castellotti, T., & Massantini, R. (2021). Chestnut Cultivar Identification through the Data Fusion of Sensory Quality and FT-NIR Spectral Data. Foods, 10(11), 2575. https://doi.org/10.3390/foods10112575