Volatile Compounds in Monovarietal Wines of Two Amarone Della Valpolicella Terroirs: Chemical and Sensory Impact of Grape Variety and Origin, Yeast Strain and Spontaneous Fermentation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Grape Origins and Winemaking

2.2. Main Enological Parameters

2.3. Analysis of Volatile Compounds

2.4. Sensory Evaluation

2.5. Statistical Analyses

3. Results and Discussion

3.1. Main Enological Parameters

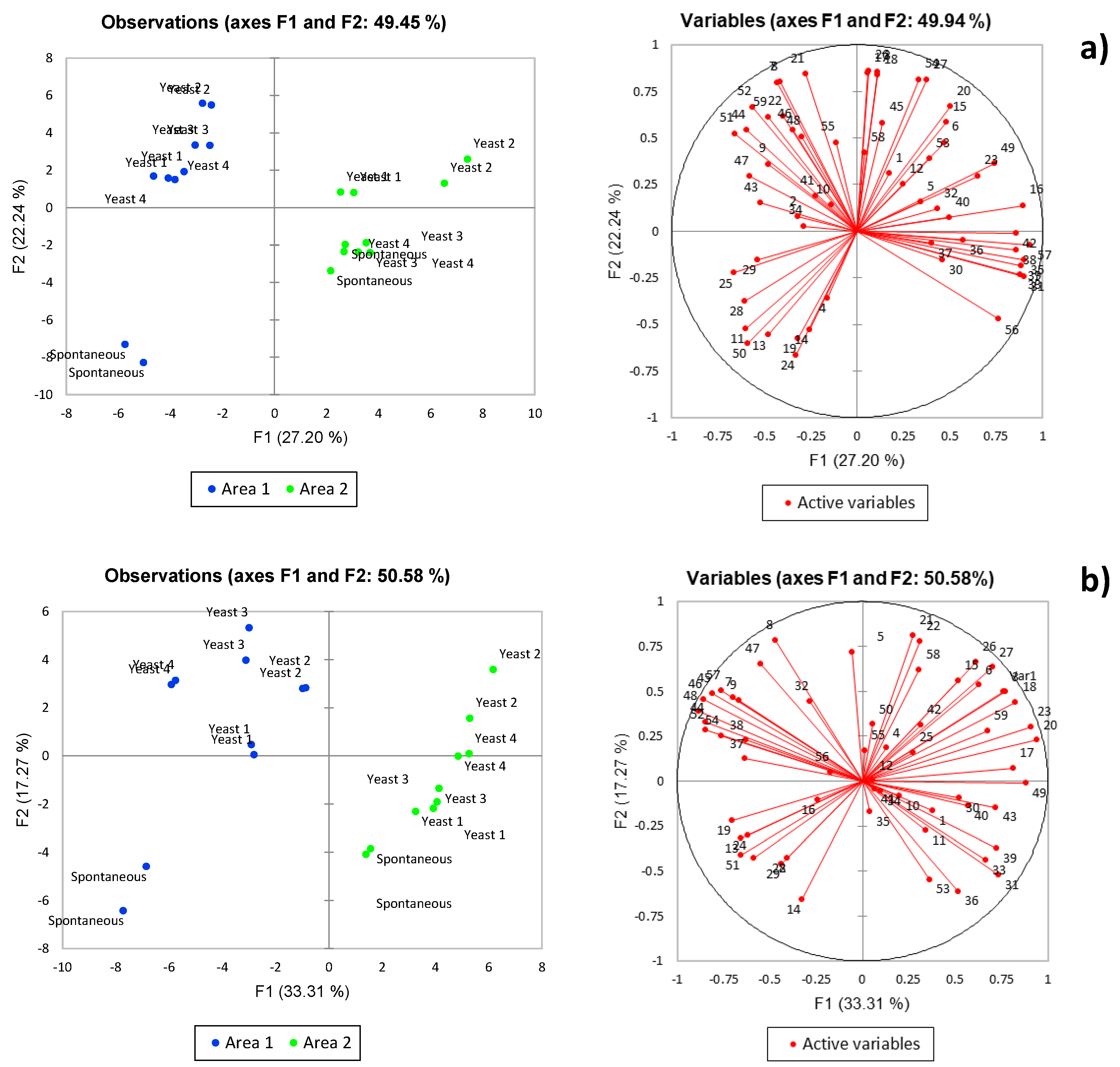

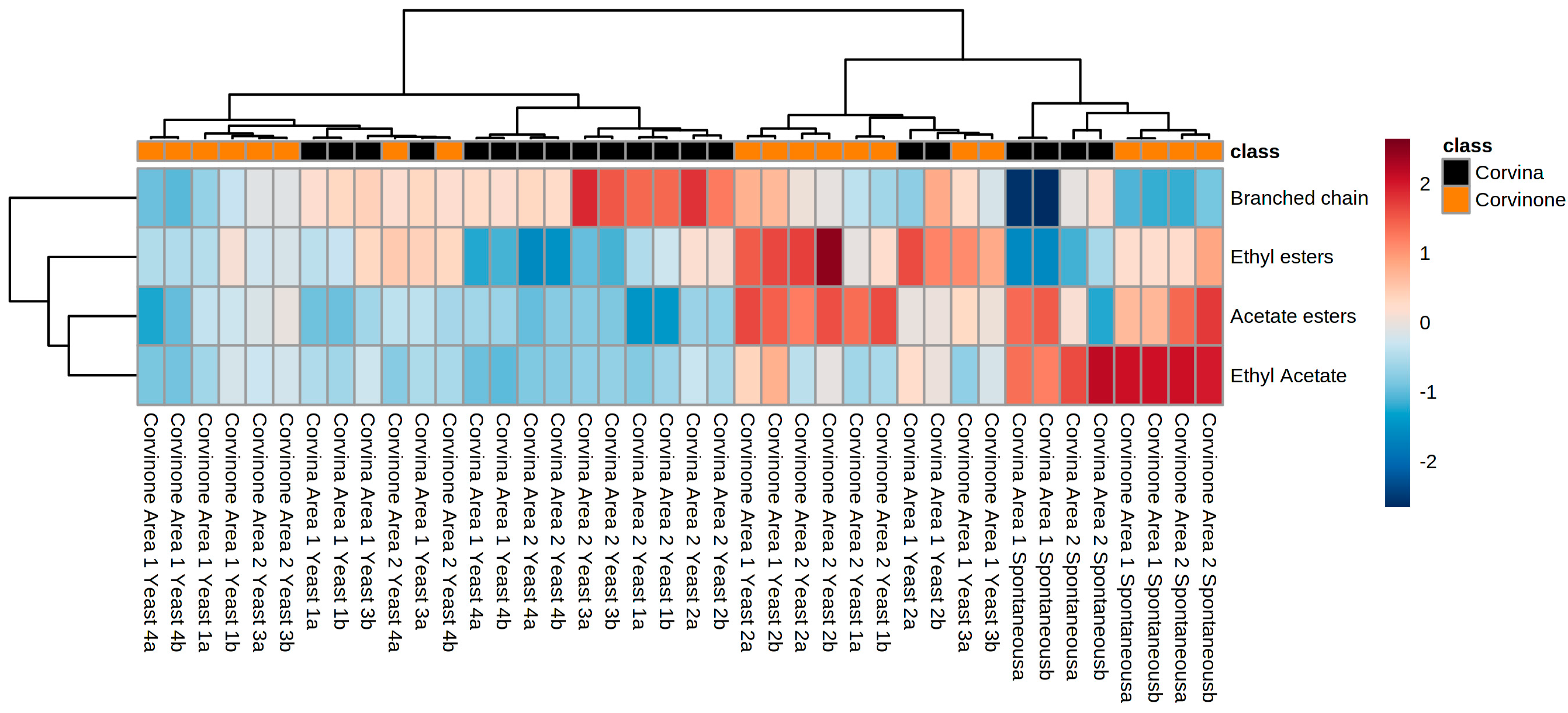

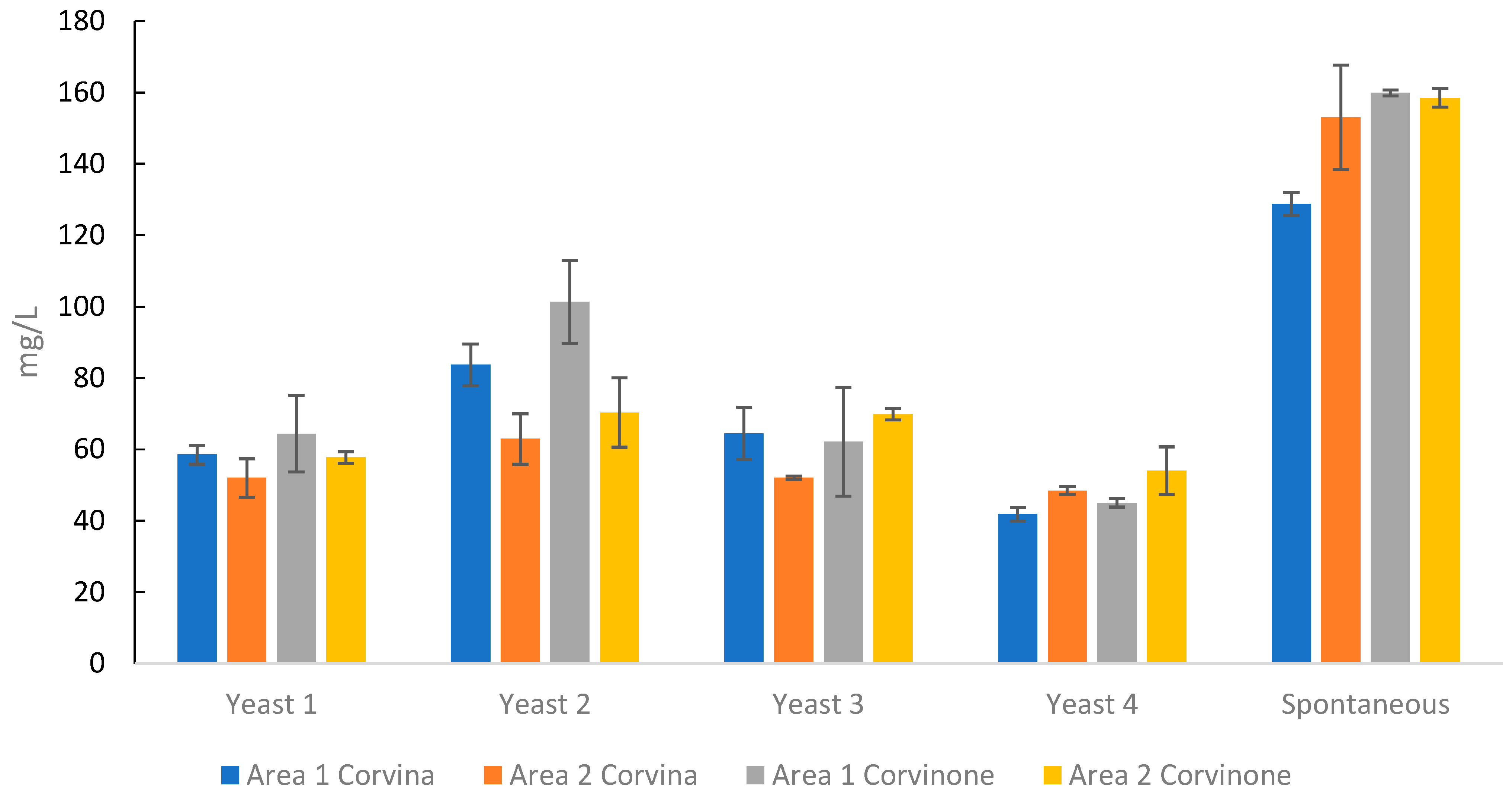

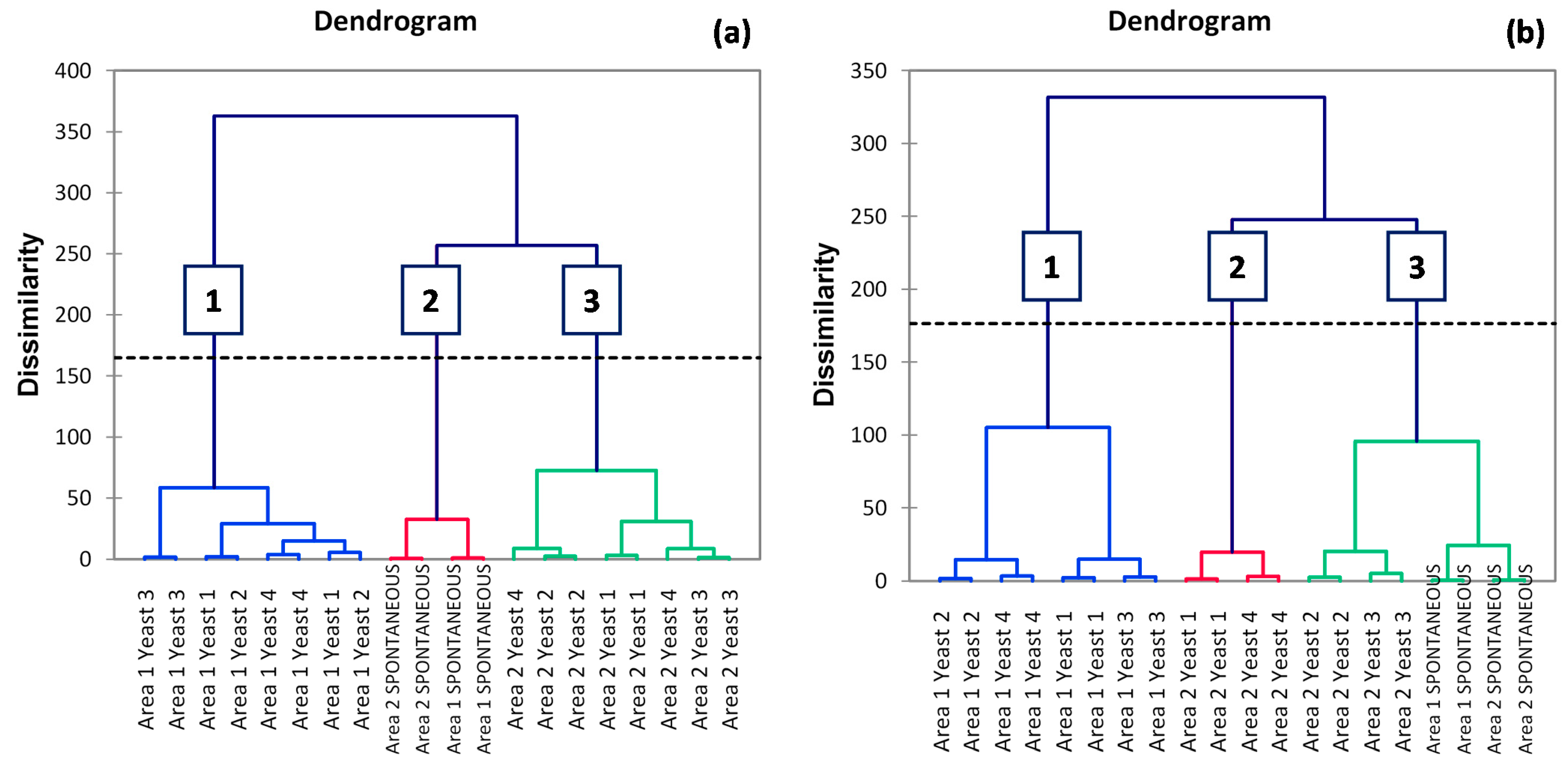

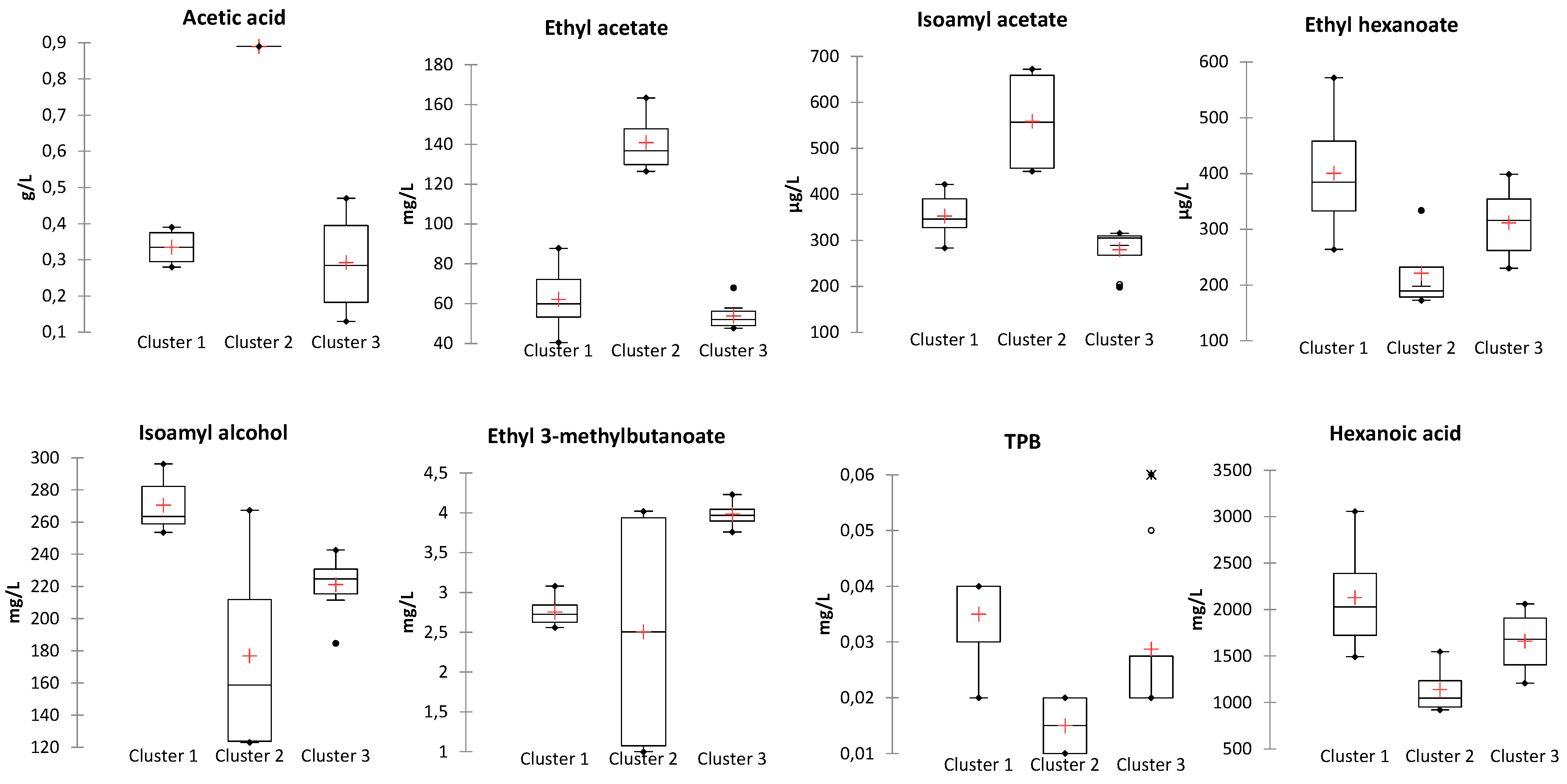

3.2. Volatile Compounds

3.3. Sensory Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Disciplinare di Produzione dei vini a Denominazione di Origine. Controllata e Garantita “Amarone della Valpolicella”. (Gazzetta Ufficiale 190, 14.08.2019); Ministero delle Politiche Agricole Alimentari e Forestali; Dipartimento delle Politiche Competitive, della Qualità Agroalimentare, Ippiche e della Pesca: Rome, Italy, 2019.

- Bellincontro, A.; Matarese, F.; D’Onofrio, C.; Accordini, D.; Tosi, E.; Mencarelli, F. Management of postharvest grape withering to optimise the aroma of the final wine: A case study on Amarone. Food Chem. 2016, 213, 378–387. [Google Scholar] [CrossRef]

- Fedrizzi, B.; Tosi, E.; Simonato, B.; Finato, F.; Cipriani, M.; Caramia, G.; Zapparoli, G. Changes in wine aroma composition according to botrytized berry percentage: A preliminary study on Amarone wine. Food Technol. Biotechnol. 2010, 49, 429–536. [Google Scholar]

- Slaghenaufi, D.; Guardini, S.; Tedeschi, R.; Ugliano, M. Volatile terpenoids, norisoprenoids and benzenoids as markers of fine scale vineyard segmentation for Corvina grapes and wines. Food Res. Int. 2019, 125, 108507. [Google Scholar] [CrossRef]

- Luzzini, G.; Slaghenaufi, D.; Pasetto, F.; Ugliano, M. Influence of grape composition and origin, yeast strain and spontaneous fermentation on aroma profile of Corvina and Corvinone wines. Lebensm.-Wiss. Technol. 2021, 143, 111120. [Google Scholar] [CrossRef]

- Slaghenaufi, D.; Boscaini, A.; Prandi, A.; Dal Cin, A.; Zandonà, V.; Luzzini, G.; Ugliano, M. Influence of Different Modalities of Grape Withering on Volatile Compounds of Young and Aged Corvina Wines. Molecules 2020, 25, 2141. [Google Scholar] [CrossRef] [PubMed]

- Slaghenaufi, D.; Peruch, E.; De Cosmi, M.; Nouvelet, L.; Ugliano, M. Volatile and phenolic composition of monovarietal red wines of Valpolicella appellations. Oeno One 2021, 55, 279–294. [Google Scholar] [CrossRef]

- Bayonove, C. L’arome varietal: Le potentiel aromatique du raisin. In Oenologie: Fondements Scientifiques et Technologiques; Flanzy, C., Ed.; Lavoisier Tec & Doc: Paris, France, 1998; pp. 165–181. [Google Scholar]

- Kotseridis, Y.; Baumes, R. Identification of Impact Odorants in Bordeaux Red Grape Juice, in the Commercial Yeast Used for Its Fermentation, and in the Produced Wine. J. Agric. Food Chem. 2000, 48, 400–406. [Google Scholar] [CrossRef] [PubMed]

- Etievant, P.X. Wine. In Volatile Compounds; Maarse, H., Ed.; M. Dekker: New York, NY, USA, 1991; pp. 483–546. [Google Scholar]

- Ferreira, V. Volatile aroma compounds and wine sensory attributes. In Managing Wine Quality; Reynolds, A.G., Ed.; Woodhead Publishing Series: Amsterdam, The Netherlands, 2010; pp. 3–28. [Google Scholar]

- Seguin, G. Ecosystems of the great red wines produced in the maritime climate of Bordeaux. In Proceedings of the Symposium on Maritime Climate Winegrowing; Department of Horticultural Sciences, Cornell University: Ithica, NY, USA, 1988. [Google Scholar]

- Parker, M.; Capone, D.; Francis, I. Aroma Precursors in Grapes and Wine: Flavor Release during Wine Production and Consumption. J. Agric. Food Chem. 2017, 66, 2281–2286. [Google Scholar] [CrossRef]

- Ugliano, M.; Henschke, P. Yeasts and Wine Flavour. In Wine Chemistry and Biochemistry; Moreno-Arribas, M.V., Polo., C., Eds.; Springer: New York, NY, USA, 2009; pp. 313–392. [Google Scholar]

- Slaghenaufi, D.; Indorato, C.; Troiano, E.; Luzzini, G.; Felis, G.; Ugliano, M. Fate of Grape-Derived Terpenoids in Model Systems Containing Active Yeast Cells. J. Agric. Food Chem. 2020, 68, 13294–13301. [Google Scholar] [CrossRef] [PubMed]

- Robinson, A.; Boss, P.; Solomon, P.; Trengove, R.; Heymann, H.; Ebeler, S. Origins of Grape and Wine Aroma. Part 1. Chemical Components and Viticultural Impacts. J. Enol. Vitic. 2014, 65, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Antalick, G.; Šuklje, K.; Blackman, J.; Meeks, C.; Deloire, A.; Schmidtke, L. Influence of Grape Composition on Red Wine Ester Profile: Comparison between Cabernet Sauvignon and Shiraz Cultivars from Australian Warm Climate. J. Agric. Food Chem. 2015, 63, 4664–4672. [Google Scholar] [CrossRef]

- Lambrechts, M.; Pretorius, I. Yeast and its Importance to Wine Aroma—A Review. S. Afr. J. Enol. Vitic. 2000, 21, 97–129. [Google Scholar] [CrossRef] [Green Version]

- Moio, L.; Ugliano, M.; Genovese, A.; Gambuti, A.; Pessina, R.; Piombino, P. Effect of Antioxidant Protection of Must on Volatile Compounds and Aroma Shelf Life of Falanghina (Vitis vinifera L.) Wine. J. Agric. Food Chem. 2004, 52, 891–897. [Google Scholar] [CrossRef]

- Genovese, A.; Caporaso, N.; Moio, L. Influence of Yeast Strain on Odor-Active Compounds in Fiano Wine. Appl. Sci. 2021, 11, 7767. [Google Scholar] [CrossRef]

- Varela, C.; Barker, A.; Tran, T.; Borneman, A.; Curtin, C. Sensory profile and volatile aroma composition of reduced alcohol Merlot wines fermented with Metschnikowia pulcherrima and Saccharomyces uvarum. Int. J. Food Microbiol. 2017, 252, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Varela, C.; Bartel, C.; Espinase Nandorfy, D.; Bilogrevic, E.; Tran, T.; Heinrich, A.; Balzan, T.; Bindon, K.; Borneman, A. Volatile aroma composition and sensory profile of Shiraz and Cabernet Sauvignon wines produced with novel Metschnikowia pulcherrima yeast starter cultures. Aust. J. Grape Wine Res. 2021, 27, 406–418. [Google Scholar] [CrossRef]

- Swiegers, J.P. Modulation of volatile sulfur compounds by wine yeast. Appl. Microbiol. Biotechnol. 2007, 74, 954–960.er. [Google Scholar] [CrossRef]

- Ugliano, M.; Travis, B.; Francis, I.; Henschke, P. Volatile Composition and Sensory Properties of Shiraz Wines as Affected by Nitrogen Supplementation and Yeast Species: Rationalizing Nitrogen Modulation of Wine Aroma. J. Agric. Food Chem. 2010, 58, 12417–12425. [Google Scholar] [CrossRef] [PubMed]

- Binati, R.; Lemos Junior, W.; Luzzini, G.; Slaghenaufi, D.; Ugliano, M.; Torriani, S. Contribution of non-Saccharomyces yeasts to wine volatile and sensory diversity: A study on Lachancea thermotolerans, Metschnikowia spp. and Starmerella bacillaris strains isolated in Italy. Int. J. Food Microbiol. 2020, 318, 108470. [Google Scholar] [CrossRef]

- Tufariello, M.; Fragasso, M.; Pico, J.; Panighel, A.; Castellarin, S.; Flamini, R.; Grieco, F. Influence of Non-Saccharomyces on Wine Chemistry: A Focus on Aroma-Related Compounds. Molecules 2021, 26, 644. [Google Scholar] [CrossRef]

- Zenoni, S.; Fasoli, M.; Guzzo, F.; Santo, S.; Amato, A.; Anesi, A.; Commisso, M.; Herderich, M.; Ceoldo, S.; Avesani, L.; et al. Disclosing the molecular basis of the postharvest life of berry in different grapevinegenotypes. Plant Physiol. 2016, 172, 1821–1843. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zamboni, A.; Minoia, L.; Ferrarini, A.; Tornielli, G.B.; Zago, E.; Delledonne, M.; Pezzotti, M. Molecular analysis of post-harvest withering in grape by AFLP transcriptional profiling. J. Exp. Bot. 2008, 59, 4145–4159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bely, M.; Rinaldi, A.; Dubourdieu, D. Influence of assimilable nitrogen on volatile acidity production by Saccharomyces cerevisiae during high sugar fermentation. J. Biosci. Bioeng. 2003, 96, 507–512. [Google Scholar] [CrossRef]

- Mateo, J.; Jiménez, M.; Pastor, A.; Huerta, T. Yeast starter cultures affecting wine fermentation and volatiles. Food Res. Int. 2001, 34, 307–314. [Google Scholar] [CrossRef]

- Boss, P.K.; Böttcher, C.; Davies, C. Various Influences of Harvest Date and Fruit Sugar Content on Different Wine Flavor and Aroma Compounds. Am. J. Enol. Vitic. 2014, 65, 341–353. [Google Scholar] [CrossRef]

- Slaghenaufi, D.; Ugliano, M. Norisoprenoids, Sesquiterpenes and Terpenoids Content of Valpolicella Wines During Aging: Investigating Aroma Potential in Relationship to Evolution of Tobacco and Balsamic Aroma in Aged Wine. Front. Chem. 2018, 6, 66. [Google Scholar] [CrossRef] [Green Version]

- Alegre, Y.; Sáenz-Navajas, M.; Hernández-Orte, P.; Ferreira, V. Rapid strategies for the determination of sensory and chemical differences between a wealth of similar wines. Eur. Food Res. Technol. 2017, 243, 1295–1309. [Google Scholar] [CrossRef]

- Parr, W.; Heatherbell, D.; White, K.G. Demystifying Wine Expertise: Olfactory Threshold, Perceptual Skill and Semantic Memory in Expert and Novice Wine Judges. Chem. Senses 2002, 27, 747–755. [Google Scholar] [CrossRef]

- Barbanti, D.; Mora, B.; Ferrarini, R.; Tornielli, G.; Cipriani, M. Effect of various thermo-hygrometric conditions on the withering kinetics ofg rapes used for the production of “Amarone” and “Recioto” wines. J. Food Eng. 2008, 85, 350–358. [Google Scholar] [CrossRef]

- Amerine MARoessler, E.B. Wines: Their Sensory Evaluation; W. H. Freeman & Co.: New York, NY, USA, 1980. [Google Scholar]

- Celik, Z.D.; Karaoglan, S.Y.; Darıcı, M.; Kelebek, H.; İşçi, B.; Kaçar, E.; Altındişli, A.; Cabaroglu, T. Effects of terroir on the terpene compounds of Muscat of Bornova Native white grape variety grown in Turkey. BIO Web Conf. 2015, 5, 01004. [Google Scholar] [CrossRef] [Green Version]

- Sabon, I.; De Revel, G.; Kotseridis, Y.; Bertrand, A. Determination of volatile compounds in Grenache wines in relation with different terroirs in the Rhone Valley. J. Agric. Food Chem. 2002, 50, 6341–6345. [Google Scholar] [CrossRef] [PubMed]

- Villanova, M.; Zamuz, S.; Vilariño, F.; Sieiro, C. Effect of terroir on the volatiles of Vitis vinifera cv. Albariño. J. Agric. Food Chem. 2007, 87, 1252–1256. [Google Scholar] [CrossRef]

- Úbeda, C.; del Barrio-Galán, R.; Peña-Neira, Á.; Medel-Marabolí, M.; Durán-Guerrero, E. Location Effects on the Aromatic Composition of Monovarietal cv. Carignan Wines. Am. J. Enol. Vitic. 2017, 68, 390–399. [Google Scholar] [CrossRef]

- Black, C.; Parker, M.; Siebert, T.; Capone, D.; Francis, I. Terpenoids and their role in wine flavour: Recent advances. Aust. J. Grape Wine Res. 2015, 21, 582–600. [Google Scholar] [CrossRef]

- Marais, J.; van Wyk, C.; Rapp, A. Effect of Sunlight and Shade on Norisoprenoid Levels in Maturing Weisser Riesling and Chenin blanc Grapes and Weisser Riesling wines. S. Afr. J. Enol. Vitic. 1992, 13, 23–32. [Google Scholar]

- Marais, J.J.; van Wyk, C. Effect of Grape Maturity and Juice Treatments on Terpene. S. Afr. J. Enol. Vitic. 1986, 7, 26–35. [Google Scholar]

- Ugliano, M.; Bartowky, E.; McCarthy, J.; Moio, L.; Henschke, P. Hydrolysis and Transformation of Grape Glycosidically Bound Volatile Compounds during Fermentation with Three Saccharomyces Yeast Strains. J. Agric. Food Chem. 2006, 54, 6322–6331. [Google Scholar] [CrossRef] [PubMed]

- Lloyd, N.; Capone, D.; Ugliano, M.; Taylor, D.; Skouroumounis, G.; Sefton, M.; Elsey, G. Formation of Damascenone under both Commercial and Model Fermentation Conditions. J. Agric. Food Chem. 2011, 59, 1338–1343. [Google Scholar] [CrossRef]

- Kruis, A.J.; Levisson, M.; Mars, A.E.; der Ploeg, M.; Garcés Daza, F.; Ellena VKengen, S.W.M.; der Oost, J.; Weusthuis, R.A. Ethyl acetate production by the elusive alcohol acetyltransferase from yeast. Metab. Eng. 2017, 41, 92–101. [Google Scholar] [CrossRef]

- Löser, C.; Urit, T. Perspectives for the biotechnological production of ethyl acetate by yeasts. Appl. Microbiol. Biotechnol. 2014, 98, 5397–5415. [Google Scholar] [CrossRef] [PubMed]

- Fleet, G. Wine Microbiology and Biotechnology; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- Valentin, D.C.; Nestrud, M.; Abdi, H. Projective Mapping and Sorting Tasks. In Descriptive Analysis in Sensory Evaluation; Hort, J., Kemp, S., Hollowood, T., Eds.; Wiley-Blackwell: London, UK, 2016. [Google Scholar]

- Francesca, N.; Gaglio, R.; Alfonzo, A.; Settanni, L.; Corona, O.M.; Romano, R.; Piccolo, A.; Moschetti, G. The Wine: Typicality or mere diversity? The effect of spontaneous. Agric. Sci. Procedia 2016, 8, 769–773. [Google Scholar]

- Romano, P.; Fiore, C.; Paraggio, M.; Caruso, M.; Capece, A. Function of yeast species and strains in wine flavour. Int. J. Food Microbiol. 2003, 86, 169–180. [Google Scholar] [CrossRef]

- Zorhe, D.; Erten, H. The influence of Kloeckera apiculata and Candida pulcherrima yeasts on wine fermentation. Process Biochem. 2002, 38, 318–324. [Google Scholar] [CrossRef]

| Glucose and Fructose (g/L) | pH | PAN 1 (mg/L) | AMMONIA (mg/L) | YAN 2 (mg/L) | |

|---|---|---|---|---|---|

| Mean ± sd | Mean ± sd | Mean ± sd | Mean ± sd | Mean ± sd | |

| Area 1 Corvina | 243.8 ± 3.1c | 3.17 ± 0.03c | 111.9 ± 7.8c | 36.8 ± 2.4c | 142.2 ± 9.3c |

| Area 2 Corvina | 291.2 ± 3.6a | 3.36 ± 0.04a | 105.0 ± 5.4c | 46.3 ± 6.2b | 143.1 ± 6.4c |

| Area 1 Corvinone | 235.1 ± 2.4d | 3.02 ± 0.01d | 149.3 ± 8.4a | 73.9 ± 4.4a | 210.1 ± 11.3a |

| Area 2 Corvinone | 254.9 ± 4.2b | 3.25 ± 0.01b | 124.1 ± 9.1b | 49.9 ± 3.6b | 165.1 ± 11.8b |

| Yeast 1 | Yeast 2 | Yeast 3 | Yeast 4 | Spontaneous | ||

|---|---|---|---|---|---|---|

| mean ± sd | mean ± sd | mean ± sd | mean ± sd | mean ± sd | ||

| Area 1 Corvina | Total acidity (g/L of tartaric acid) | 6.7 ± 0.1b | 7.7 ± 0.1a | 6.7 ± 0.1b | 7.4 ± 0.1a | 7.8 ± 1.9a |

| pH | 3.01 ± 0.01b | 3.08 ± 0.01a | 3.07 ± 0.01a | 3.07 ± 0.01a | 3.09 ± 0.02a | |

| Acetic acid (g/L) | 0.28 ± 0.02c | 0.30 ± 0.00c | 0.37 ± 0.04b | 0.39 ± 0.01b | 0.89 ± 0.01a | |

| Ethanol (% v/v) | 14.77 ± 0.31a | 14.69 ± 0.09a | 14.82 ± 0.42a | 14.66 ± 0.31a | 14.65 ± 0.30a | |

| Area 2 Corvina | Total acidity (g/L of tartaric acid) | 7.6 ± 0.7b | 10.3 ± 0.3a | 7.8 ± 0.1b | 7.6 ± 0.2b | 7.8 ± 0b |

| pH | 2.98 ± 0.01a | 2.99 ± 0.01a | 2.98 ± 0.02a | 2.98 ± 0.00a | 2.92 ± 0.01b | |

| Acetic acid (g/L) | 0.20 ± 0.11c | 0.47 ± 0.18b | 0.37 ± 0.18b | 0.13 ± 0.01c | 0.89 ± 0.06a | |

| Ethanol (% v/v) | 17.91 ± 0.40a | 17.73 ± 0.09a | 17.86 ± 0.11a | 17.68 ± 0.08a | 17.41 ± 0.24a | |

| Area 1 Corvinone | Total acidity (g/L of tartaric acid) | 5.8 ± 0.1c | 7.2 ± 0.2a | 6.4 ± 0b | 6 ± 0b | 6.2 ± 0.3b |

| pH | 3.35 ± 0.06a | 3.30 ± 0.01a | 3.32 ± 0.01a | 3.31 ± 0.02a | 3.23 ± 0.01b | |

| Acetic acid (g/L) | 0.50 ± 0.04c | 0.60 ± 0.07b | 0.59 ± 0.01b | 0.44 ± 0.03d | 0.85 ± 0.01a | |

| Ethanol (% v/v) | 14.34 ± 0.17a | 14.17 ± 0.35a | 14.24 ± 0.31a | 14.54 ± 0.09a | 14.16 ± 0.02a | |

| Area 2 Corvinone | Total acidity (g/L of tartaric acid) | 6.6 ± 0.37b | 7.81 ± 0.1a | 6.62 ± 0.1b | 7.04 ± 0.0b | 6.84 ± 0.4b |

| pH | 3.21 ± 0.01a | 3.22 ± 0.01a | 3.22 ± 0.01a | 3.23 ± 0.01a | 3.21 ± 0.0a | |

| Acetic acid (g/L) | 0.23 ± 0.01c | 0.41 ± 0.21b | 0.28 ± 0.02b | 0.21 ± 0.02c | 0.82 ± 0.01a | |

| Ethanol (% v/v) | 15.50 ± 0.12a | 15.41 ± 0.03a | 15.31 ± 0.41a | 15.32 ± 0.21a | 15.51 ± 0.5a |

| Yeast 1 | Yeast 2 | Yeast 3 | Yeast 4 | Spontaneous | |

|---|---|---|---|---|---|

| mean ± sd | mean ± sd | mean ± sd | mean ± sd | mean ± sd | |

| Alcohols | |||||

| 1-Butanol | 371.05 ± 14.63 | 241.87 ± 9.91 | 186.51 ± 6.10 | 241.95 ± 3.30 | 146.94 ± 2.74 |

| 2-Butanol | 4090.42 ± 127.27 | 4366.08 ± 114.18 | 7199.53 ± 88.06 | 4483.68 ± 86.56 | 4814.56 ± 106.43 |

| 1-Pentanol | 41.94 ± 2.13 | 44.76 ± 0.83 | 46.75 ± 2.60 | 46.35 ± 3.87 | 52.11 ± 0.41 |

| Isoamyl alcohol (mg/L) | 260.1 ± 5.16 | 270.95 ± 10.67 | 294.79 ± 1.93 | 256.68 ± 4.26 | 123.5 ± 0.57 |

| Phenylethyl alcohol (mg/L) | 24.75 ± 0.92 | 17.69 ± 0.4 | 20.82 ± 0.61 | 23.56 ± 2.11 | 9.50 ± 0.15 |

| Methionol | 105.27 ± 4.96 | 84.92 ± 5.44 | 123.47 ± 14.62 | 143.71 ± 3.83 | 33.01 ± 1.29 |

| C6 alcohols | |||||

| 1-Hexanol | 954.18 ± 9.50 | 948.77 ± 8.58 | 902.40 ± 8.26 | 853.42 ± 15.13 | 768.00 ± 24.98 |

| trans-3-Hexen-1-ol | 9.30 ± 0.02 | 9.92 ± 0.94 | 10.55 ± 0.59 | 11.07 ± 0.26 | 6.79 ± 0.35 |

| cis-3-Hexen-1-ol | 43.27 ± 1.94 | 40.99 ± 0.93 | 44.51 ± 1.95 | 39.98 ± 1.09 | 40.64 ± 1.39 |

| cis-2-Hexen-1-ol | 18.26 ± 0.17 | 15.85 ± 0.70 | 16.41 ± 1.18 | 16.84 ± 0.79 | 16.23 ± 1.92 |

| Acetate esters | |||||

| Isoamyl acetate | 287.14 ± 4.84 | 417.00 ± 6.83 | 365.18 ± 25.42 | 342.91 ± 3.76 | 663.35 ± 12.79 |

| n-Hexyl acetate | 19.11 ± 0.08 | 51.72 ± 2.94 | 18.96 ± 0.12 | 17.36 ± 0.36 | 23.57 ± 1.29 |

| 2-Phenylethyl acetate | 23.91 ± 2.09 | 18.75 ± 0.72 | 19.87 ± 0.37 | 23.83 ± 2.04 | 44.81 ± 0.71 |

| Ethyl acetate (mg/L) | 58.49 ± 2.7 | 83.66 ± 5.86 | 64.52 ± 7.29 | 41.86 ± 1.93 | 128.73 ± 3.26 |

| Branched-chain fatty acids ethyl esters | |||||

| Ethyl 2-methylbutanoate | 3.41 ± 0.12 | 2.73 ± 1.39 | 3.38 ± 0.01 | 3.17 ± 0.23 | 0.90 ± 0.14 |

| Ethyl 3-methylbutanoate | 2.57 ± 0.01 | 2.95 ± 0.19 | 2.73 ± 0.08 | 2.79 ± 0.21 | 1.05 ± 0.07 |

| Fatty acids ethyl esters | |||||

| Ethyl butanoate | 260.10 ± 29.42 | 422.74 ± 22.32 | 251.05 ± 11.19 | 184.12 ± 0.15 | 95.45 ± 1.34 |

| Ethyl hexanoate | 361.31 ± 15.52 | 555.12 ± 23.57 | 414.17 ± 24.71 | 271.97 ± 11.41 | 176.53 ± 5.61 |

| Ethyl octanoate | 171.19 ± 15.40 | 309.87 ± 24.84 | 247.56 ± 2.04 | 148.21 ± 7.71 | 89.70 ± 3.05 |

| Ethyl lactate | 225.35 ± 7.00 | 236.10 ± 20.09 | 284.54 ± 2.35 | 203.32 ± 12.91 | 359.76 ± 0.62 |

| Ethyl decanoate | 65.28 ± 5.73 | 42.70 ± 1.45 | 45.31 ± 2.35 | 14.25 ± 1.29 | 17.94 ± 0.08 |

| Other esters | |||||

| Ethyl 3-hydroxybutanoate | 148.56 ± 7.57 | 247.18 ± 15.42 | 227.89 ± 12.49 | 139.87 ± 6.30 | 78.60 ± 2.91 |

| Ethyl 2-hydroxyhexanoate | 0.42 ± 0.02 | 1.23 ± 0.16 | 1.52 ± 0.10 | 1.01 ± 0.00 | 0.53 ± 0.01 |

| Fatty acids | |||||

| 3-Methylbutanoic acid | 424.86 ± 19.17 | 310.26 ± 9.60 | 439.13 ± 20.92 | 414.41 ± 11.50 | 547.27 ± 5.76 |

| Hexanoic acid | 1824.83 ± 50.37 | 2973.50 ± 117.13 | 2209.76 ± 14.81 | 1509.15 ± 23.80 | 941.09 ± 29.54 |

| Octanoic acid | 3537.02 ± 193.32 | 4631.18 ± 308.33 | 4100.89 ± 2.94 | 3219.52 ± 27.57 | 2216.20 ± 164.18 |

| Terpenoids | |||||

| cis-Linaloloxide | 0.55 ± 0.05 | 0.10 ± 0.01 | 0.08 ± 0.02 | 0.02 ± 0.00 | 0.68 ± 0.03 |

| trans-Linaloloxide | 0.96 ± 0.07 | 0.03 ± 0.01 | 0.05 ± 0.03 | 0.16 ± 0.13 | 0.62 ± 0.04 |

| Linalool | 5.76 ± 1.00 | 6.98 ± 0.42 | 5.81 ± 0.36 | 5.07 ± 0.13 | 5.06 ± 0.10 |

| Geraniol | 2.23 ± 0.13 | 3.50 ± 0.69 | 3.35 ± 0.62 | 2.67 ± 0.14 | 3.01 ± 0.32 |

| α-Terpineol | 3.50 ± 0.00 | 3.90 ± 0.52 | 2.82 ± 0.33 | 3.22 ± 0.13 | 2.81 ± 0.40 |

| β-Citronellol | 26.76 ± 3.07 | 8.57 ± 1.70 | 13.30 ± 1.49 | 16.31 ± 0.43 | 15.69 ± 1.77 |

| α-Phellandrene | 3.35 ± 0.27 | 3.66 ± 0.16 | 3.16 ± 0.06 | 1.26 ± 0.06 | 3.20 ± 0.14 |

| α-Terpinen | 0.13 ± 0.01 | 0.16 ± 0.01 | 0.11 ± 0.01 | 0.45 ± 0.07 | 0.14 ± 0.00 |

| β-Myrcene | 4.36 ± 0.35 | 5.65 ± 0.35 | 3.89 ± 0.23 | 2.83 ± 0.04 | 4.80 ± 1.10 |

| Limonene | 0.74 ± 0.04 | 0.93 ± 0.08 | 0.63 ± 0.04 | 0.67 ± 0.02 | 0.78 ± 0.16 |

| 1,4-Cineole | nd | nd | 0.04 ± 0.00 | 0.43 ± 0.03 | 0.09 ± 0.01 |

| 1,8-Cineole | 0.08 ± 0.00 | 0.04 ± 0.06 | 0.13 ± 0.01 | 0.05 ± 0.01 | 0.08 ± 0.01 |

| p-Cymene | 0.32 ± 0.01 | 0.39 ± 0.01 | 0.28 ± 0.02 | 0.52 ± 0.02 | 0.39 ± 0.01 |

| Terpinolene | 0.47 ± 0.08 | 0.59 ± 0.02 | 0.45 ± 0.07 | 0.52 ± 0.01 | 0.52 ± 0.04 |

| Terpinen-4-ol | 0.48 ± 0.04 | 0.47 ± 0.09 | 1.21 ± 0.15 | 14.11 ± 0.01 | 0.75 ± 0.07 |

| Norisoprenoids | |||||

| β-Damascenone | 8.33 ± 1.56 | 8.38 ± 1.17 | 5.09 ± 0.30 | 6.87 ± 0.16 | 6.01 ± 0.81 |

| 3-Hydroxy-β-damascone | 0.21 ± 0.01 | 0.40 ± 0.04 | 0.28 ± 0.09 | 0.36 ± 0.04 | 0.30 ± 0.01 |

| Vitispirane | 3.45 ± 0.21 | 3.88 ± 0.18 | 2.66 ± 0.04 | 3.62 ± 0.02 | 3.10 ± 0.99 |

| TPB | 0.04 ± 0.01 | 0.04 ± 0.00 | 0.03 ± 0.01 | 0.04 ± 0.00 | 0.02 ± 0.00 |

| TDN | 0.73 ± 0.03 | 0.78 ± 0.13 | 0.50 ± 0.06 | 0.69 ± 0.03 | 0.57 ± 0.07 |

| Benzenoids and others | |||||

| Benzyl alcohol | 279.52 ± 13.31 | 296.78 ± 13.09 | 316.75 ± 7.83 | 307.61 ± 26.40 | 251.22 ± 11.33 |

| Vanillin | 5.50 ± 0.00 | 5.52 ± 0.12 | 5.43 ± 0.15 | 5.54 ± 0.16 | 2.00 ± 0.07 |

| Ethyl vanillate | 127.88 ± 5.50 | 119.02 ± 3.81 | 123.33 ± 3.86 | 124.45 ± 2.86 | 126.81 ± 5.37 |

| Methyl vanillate | 5.46 ± 0.20 | 8.72 ± 0.63 | 5.17 ± 0.76 | 6.23 ± 0.23 | 5.49 ± 0.52 |

| Benzaldehyde | 16.14 ± 1.19 | 20.31 ± 1.63 | 16.66 ± 0.59 | 17.85 ± 0.70 | 70.95 ± 7.71 |

| Eugenol | 7.01 ± 0.04 | 7.32 ± 0.02 | 7.26 ± 0.00 | 7.14 ± 0.22 | 6.45 ± 0.49 |

| Methyl salicylate | 0.99 ± 0.16 | 1.12 ± 0.31 | 0.63 ± 0.01 | 0.74 ± 0.05 | 0.39 ± 0.07 |

| 2,6-Dimethoxyphenol | 5.30 ± 0.55 | 5.42 ± 0.37 | 6.29 ± 0.16 | 6.39 ± 0.18 | 5.02 ± 0.16 |

| Furfural | 1.38 ± 0.06 | 1.24 ± 0.09 | 1.89 ± 0.00 | 1.17 ± 0.18 | 0.69 ± 0.04 |

| γ-Decalactone | 2.36 ± 0.16 | 2.41 ± 0.13 | 2.27 ± 0.00 | 2.73 ± 0.01 | 2.15 ± 0.19 |

| δ-Decalactone | 32.99 ± 2.51 | 31.19 ± 1.33 | 28.78 ± 1.27 | 30.24 ± 3.59 | 23.71 ± 2.13 |

| Yeast 1 | Yeast 2 | Yeast 3 | Yeast 4 | Spontaneous | |

|---|---|---|---|---|---|

| mean ± sd | mean ± sd | mean ± sd | mean ± sd | mean ± sd | |

| Alcohols | |||||

| 1-Butanol | 441.60 ± 12.31 | 220.49 ± 9.52 | 190.27 ± 8.34 | 205.29 ± 9.91 | 290.30 ± 14.21 |

| 2-Butanol | 3487.83 ± 19.06 | 4174.76 ± 194.86 | 4787.57 ± 1.14 | 3691.44 ± 374.75 | 5230.78 ± 139.41 |

| 1-Pentanol | 36.54 ± 3.17 | 46.36 ± 2.33 | 47.77 ± 6.75 | 43.88 ± 3.17 | 53.30 ± 16.89 |

| Isoamyl alcohol (mg/L) | 224.67 ± 6.78 | 229.71 ± 18.30 | 223.20 ± 16.50 | 207.07 ± 31.67 | 230.41 ± 52.37 |

| Phenylethyl alcohol (mg/L) | 23.78 ± 0.78 | 21.43 ± 0.24 | 21.91 ± 0.45 | 21.16 ± 0.71 | 22.77 ± 0.71 |

| Methionol | 102.96 ± 3.90 | 98.07 ± 9.43 | 127.90 ± 5.51 | 153.40 ± 17.46 | 162.44 ± 107.20 |

| C6 alcohols | |||||

| 1-Hexanol | 838.43 ± 25.46 | 781.33 ± 10.08 | 712.71 ± 4.66 | 798.18 ± 16.11 | 763.07 ± 26.74 |

| trans-3-Hexen-1-ol | 7.30 ± 0.41 | 7.90 ± 0.24 | 6.53 ± 0.43 | 7.31 ± 0.42 | 6.82 ± 1.25 |

| cis-3-Hexen-1-ol | 38.18 ± 3.79 | 39.27 ± 1.43 | 34.32 ± 0.60 | 38.98 ± 1.32 | 39.13 ± 4.83 |

| cis-2-Hexen-1-ol | 16.33 ± 1.27 | 16.70 ± 0.50 | 15.82 ± 0.24 | 16.70 ± 0.08 | 16.24 ± 0.14 |

| Acetate esters | |||||

| Isoamyl acetate | 201.22 ± 3.98 | 310.27 ± 1.60 | 305.31 ± 3.94 | 302.26 ± 18.75 | 342.06 ± 165.76 |

| n-Hexyl acetate | 20.18 ± 1.35 | 38.97 ± 1.15 | 22.50 ± 2.48 | 22.36 ± 1.57 | 32.38 ± 3.58 |

| 2-Phenylethyl acetate | 22.27 ± 0.41 | 25.38 ± 1.02 | 22.87 ± 1.31 | 14.91 ± 2.82 | 19.87 ± 0.33 |

| Ethyl acetate (mg/L) | 51.97 ± 5.39 | 62.89 ± 7.08 | 52.04 ± 0.48 | 48.51 ± 1.12 | 153.00 ± 14.63 |

| Branched-chain fatty acids ethyl esters | |||||

| Ethyl 2-methylbutanoate | 3.50 ± 0.09 | 3.86 ± 0.68 | 3.99 ± 0.11 | 2.22 ± 0.13 | 1.80 ± 0.33 |

| Ethyl 3-methylbutanoate | 4.07 ± 0.08 | 3.96 ± 0.09 | 4.08 ± 0.21 | 3.83 ± 0.10 | 3.97 ± 0.08 |

| Fatty acids ethyl esters | |||||

| Ethyl butanoate | 232.99 ± 3.66 | 244.30 ± 3.06 | 170.31 ± 6.74 | 160.74 ± 7.11 | 172.36 ± 21.39 |

| Ethyl hexanoate | 342.78 ± 2.55 | 391.36 ± 10.20 | 280.57 ± 14.14 | 232.48 ± 3.34 | 265.86 ± 95.90 |

| Ethyl octanoate | 232.65 ± 16.50 | 296.96 ± 3.34 | 201.46 ± 6.02 | 152.80 ± 1.60 | 182.44 ± 49.89 |

| Ethyl lactate | 244.39 ± 18.96 | 246.63 ± 7.59 | 236.89 ± 3.22 | 193.08 ± 7.44 | 336.42 ± 28.96 |

| Ethyl decanoate | 70.89 ± 1.82 | 82.04 ± 7.63 | 56.46 ± 3.37 | 29.78 ± 6.25 | 36.49 ± 4.51 |

| Other esters | |||||

| Ethyl 3-hydroxybutanoate | 105.64 ± 6.74 | 134.61 ± 0.52 | 65.35 ± 0.66 | 77.05 ± 16.40 | 83.53 ± 2.35 |

| Ethyl 2-hydroxyhexanoate | 0.25 ± 0.02 | 0.54 ± 0.06 | 0.43 ± 0.00 | 0.46 ± 0.04 | 0.36 ± 0.24 |

| Fatty acids | |||||

| 3-Methylbutanoic acid | 318.40 ± 7.15 | 328.26 ± 33.71 | 388.00 ± 3.51 | 319.32 ± 21.51 | 269.95 ± 123.81 |

| Hexanoic acid | 2030.04 ± 44.08 | 1844.35 ± 46.25 | 1451.38 ± 138.40 | 1316.03 ± 152.40 | 1338.87 ± 293.02 |

| Octanoic acid | 4261.98 ± 68.70 | 3990.88 ± 62.36 | 3355.84 ± 49.80 | 3190.36 ± 183.16 | 3272.96 ± 553.04 |

| Terpenoids | |||||

| cis-Linaloloxide | 0.09 ± 0.01 | 0.09 ± 0.03 | 0.07 ± 0.04 | 0.04 ± 0.01 | 0.06 ± 0.01 |

| trans-Linaloloxide | 0.24 ± 0.01 | 0.06 ± 0.02 | 0.05 ± 0.01 | 0.03 ± 0.00 | 0.09 ± 0.00 |

| Linalool | 6.45 ± 0.63 | 12.31 ± 0.06 | 10.42 ± 0.35 | 10.16 ± 0.02 | 8.81 ± 0.21 |

| Geraniol | 2.81 ± 0.11 | 4.25 ± 0.16 | 3.03 ± 0.06 | 3.21 ± 0.21 | 3.02 ± 0.49 |

| α-Terpineol | 5.21 ± 0.01 | 10.13 ± 0.52 | 6.46 ± 0.33 | 4.42 ± 0.26 | 3.98 ± 0.16 |

| β-Citronellol | 14.28 ± 0.25 | 10.02 ± 0.18 | 9.40 ± 0.81 | 9.18 ± 0.39 | 9.02 ± 1.48 |

| α-Phellandrene | 5.70 ± 0.23 | 10.37 ± 0.98 | 5.92 ± 0.57 | 6.62 ± 0.26 | 6.70 ± 0.28 |

| α-Terpinen | 0.20 ± 0.00 | 0.68 ± 0.54 | 0.20 ± 0.00 | 0.19 ± 0.01 | 0.20 ± 0.01 |

| β-Myrcene | 7.31 ± 0.43 | 13.46 ± 1.27 | 7.69 ± 0.74 | 8.59 ± 0.34 | 8.70 ± 0.36 |

| Limonene | 1.38 ± 0.05 | 2.51 ± 0.14 | 1.36 ± 0.11 | 1.46 ± 0.10 | 1.26 ± 0.02 |

| 1,4-Cineole | 0.00 ± 0.00 | 0.05 ± 0.00 | 0.08 ± 0.00 | 0.06 ± 0.01 | 0.06 ± 0.00 |

| 1,8-Cineole | 0.12 ± 0.02 | 0.19 ± 0.01 | 0.09 ± 0.00 | 0.09 ± 0.01 | 0.08 ± 0.01 |

| p-Cymene | 0.39 ± 0.04 | 0.55 ± 0.01 | 0.45 ± 0.03 | 0.40 ± 0.03 | 0.34 ± 0.10 |

| Terpinolene | 0.84 ± 0.05 | 1.64 ± 0.23 | 0.84 ± 0.05 | 0.85 ± 0.04 | 0.75 ± 0.05 |

| Terpinen-4-ol | 1.23 ± 0.04 | 1.17 ± 0.06 | 2.44 ± 0.20 | 1.59 ± 0.18 | 1.16 ± 1.12 |

| Norisoprenoids | |||||

| β-Damascenone | 3.34 ± 0.13 | 5.00 ± 0.26 | 2.81 ± 0.16 | 2.89 ± 0.13 | 2.23 ± 0.20 |

| 3-Hydroxy-β-damascone | 0.31 ± 0.04 | 0.13 ± 0.02 | 0.16 ± 0.01 | 0.16 ± 0.01 | 0.29 ± 0.08 |

| Vitispirane | 1.83 ± 0.08 | 4.01 ± 0.18 | 1.59 ± 0.07 | 1.56 ± 0.12 | 0.76 ± 0.21 |

| TPB | 0.02 ± 0.00 | 0.06 ± 0.01 | 0.02 ± 0.00 | 0.02 ± 0.00 | 0.01 ± 0.00 |

| TDN | 0.32 ± 0.02 | 0.75 ± 0.06 | 0.24 ± 0.03 | 0.23 ± 0.03 | 0.13 ± 0.00 |

| Benzenoids and others | |||||

| Benzyl alcohol | 199.41 ± 1.32 | 223.31 ± 21.96 | 193.43 ± 0.15 | 233.75 ± 2.73 | 256.88 ± 5.20 |

| Vanillin | 4.97 ± 0.02 | 4.97 ± 0.06 | 4.90 ± 0.19 | 4.87 ± 0.15 | 4.88 ± 0.14 |

| Ethyl vanillate | 135.24 ± 4.24 | 143.78 ± 4.97 | 137.46 ± 5.40 | 140.60 ± 7.06 | 143.45 ± 4.02 |

| Methyl vanillate | 4.71 ± 0.10 | 6.05 ± 0.60 | 5.92 ± 0.39 | 6.00 ± 0.80 | 4.39 ± 0.20 |

| Benzaldehyde | 15.42 ± 0.74 | 15.45 ± 0.39 | 15.60 ± 0.86 | 16.59 ± 1.25 | 15.47 ± 1.19 |

| Eugenol | 6.55 ± 0.35 | 6.28 ± 0.01 | 5.46 ± 0.01 | 5.14 ± 0.17 | 6.00 ± 0.02 |

| Methyl salicylate | 3.64 ± 0.07 | 5.73 ± 0.09 | 2.32 ± 0.05 | 2.99 ± 0.08 | 2.35 ± 0.17 |

| 2,6-Dimethoxyphenol | 6.51 ± 0.01 | 6.57 ± 0.69 | 5.51 ± 0.16 | 5.30 ± 0.45 | 5.78 ± 0.89 |

| Furfural | 1.68 ± 0.11 | 2.06 ± 0.35 | 1.54 ± 0.08 | 1.43 ± 0.12 | 1.53 ± 0.13 |

| γ-Decalactone | 2.60 ± 0.14 | 2.25 ± 0.01 | 2.36 ± 0.15 | 2.44 ± 0.07 | 2.26 ± 0.01 |

| δ-Decalactone | 25.14 ± 8.63 | 21.78 ± 2.94 | 25.17 ± 3.28 | 23.91 ± 0.01 | 23.58 ± 1.71 |

| Yeast 1 | Yeast 2 | Yeast 3 | Yeast 4 | Spontaneous | |

|---|---|---|---|---|---|

| mean ± sd | mean ± sd | mean ± sd | mean ± sd | mean ± sd | |

| Alcohols | |||||

| 1-Butanol | 326.74 ± 172.01 | 228.80 ± 28.38 | 158.29 ± 15.66 | 100.38 ± 4.53 | 141.27 ± 17.97 |

| 2-Butanol | 5643.65 ± 610.53 | 4982.00 ± 428.99 | 5859.68 ± 54.54 | 3285.67 ± 159.30 | 10321.02 ± 654.72 |

| 1-Pentanol | 48.14 ± 0.59 | 43.09 ± 3.20 | 46.67 ± 7.15 | 59.99 ± 4.31 | 42.16 ± 1.04 |

| Isoamyl alcohol (mg/L) | 254.28 ± 83.86 | 27.14 ± 10.10 | 28.44 ± 27.64 | 200.64 ± 13.64 | 179.62 ± 7.03 |

| Phenylethyl alcohol (mg/L) | 21.33 ± 0.99 | 19.42 ± 0.03 | 19.27 ± 2.09 | 20.95 ± 0.99 | 14671 ± 1.35 |

| Methionol | 221.98 ± 5.51 | 135.32 ± 28.73 | 222.60 ± 31.58 | 389.66 ± 73.67 | 51.24 ± 15.38 |

| C6 alcohols | |||||

| 1-Hexanol | 2020.95 ± 110.53 | 1940.31 ± 3.38 | 1737.24 ± 135.60 | 1701.42 ± 125.04 | 1710.03 ± 34.29 |

| trans-3-Hexen-1-ol | 27.90 ± 1.53 | 27.90 ± 0.91 | 29.85 ± 0.43 | 25.66 ± 1.57 | 17.26 ± 3.01 |

| cis-3-Hexen-1-ol | 17.83 ± 0.05 | 20.29 ± 1.92 | 19.81 ± 1.68 | 18.76 ± 1.36 | 19.12 ± 4.82 |

| cis-2-Hexen-1-ol | 16.54 ± 0.03 | 15.05 ± 0.83 | 14.73 ± 0.55 | 16.21 ± 0.88 | 15.78 ± 1.07 |

| Acetate esters | |||||

| Isoamyl acetate | 382.14 ± 9.68 | 707.32 ± 20.52 | 482.77 ± 29.00 | 258.90 ± 31.35 | 547.90 ± 4.36 |

| n-Hexyl acetate | 17.77 ± 0.84 | 14.17 ± 1.07 | 8.98 ± 0.74 | 12.35 ± 2.60 | 11.60 ± 0.49 |

| 2-Phenylethyl acetate | 35.58 ± 0.69 | 29.21 ± 0.07 | 25.74 ± 1.08 | 24.61 ± 1.47 | 42.36 ± 1.78 |

| Ethyl acetate (mg/L) | 64.37 ± 10.73 | 101.32 ± 11.63 | 62.12 ± 15.22 | 44.99 ± 1.17 | 159.83 ± 0.86 |

| Branched-chain fatty acids ethyl esters | |||||

| Ethyl 2-methylbutanoate | 1.80 ± 0.35 | 3.57 ± 0.21 | 2.46 ± 0.31 | 1.21 ± 0.21 | 0.89 ± 0.16 |

| Ethyl 3-methylbutanoate | 3.13 ± 0.01 | 3.10 ± 0.16 | 3.22 ± 0.13 | 3.06 ± 0.09 | 3.19 ± 0.10 |

| Fatty acids ethyl esters | |||||

| Ethyl butanoate | 159.71 ± 5.76 | 206.20 ± 1.07 | 184.08 ± 12.60 | 168.03 ± 9.72 | 125.35 ± 16.24 |

| Ethyl hexanoate | 288.88 ± 34.73 | 441.20 ± 3.88 | 371.86 ± 22.02 | 294.37 ± 1.03 | 136.72 ± 21.62 |

| Ethyl octanoate | 130.27 ± 11.62 | 204.82 ± 17.71 | 182.78 ± 16.91 | 117.46 ± 7.09 | 63.44 ± 3.55 |

| Ethyl lactate | 467.73 ± 59.32 | 685.54 ± 32.99 | 502.66 ± 4.44 | 415.45 ± 8.14 | 1047.19 ± 10.42 |

| Ethyl decanoate | 31.85 ± 2.35 | 45.66 ± 2.81 | 54.99 ± 2.70 | 29.99 ± 3.01 | 6.92 ± 1.84 |

| Other esters | |||||

| Ethyl 3-hydroxybutanoate | 219.48 ± 14.79 | 291.85 ± 20.39 | 373.57 ± 19.01 | 169.63 ± 3.90 | 36.88 ± 0.49 |

| Ethyl 2-hydroxyhexanoate | 0.40 ± 0.10 | 1.36 ± 0.03 | 1.22 ± 0.02 | 0.66 ± 0.03 | 0.22 ± 0.09 |

| Fatty acids | |||||

| 3-Methylbutanoic acid | 323.93 ± 49.67 | 364.47 ± 17.78 | 486.21 ± 29.49 | 253.57 ± 14.10 | 363.79 ± 279.85 |

| Hexanoic acid | 1882.76 ± 89.07 | 2938.93 ± 68.25 | 2359.40 ± 124.09 | 1986.87 ± 33.29 | 1022.20 ± 80.26 |

| Octanoic acid | 3576.79 ± 173.28 | 4432.38 ± 27.19 | 4197.55 ± 25.65 | 3798.66 ± 22.14 | 1735.40 ± 831.93 |

| Terpenoids | |||||

| cis-Linaloloxide | 0.11 ± 0.08 | 0.06 ± 0.02 | 0.08 ± 0.04 | 0.05 ± 0.02 | 0.95 ± 1.24 |

| trans-Linaloloxide | 0.07 ± 0.01 | 0.03 ± 0.01 | 0.08 ± 0.08 | 0.04 ± 0.01 | 0.32 ± 0.26 |

| Linalool | 4.36 ± 0.19 | 5.06 ± 0.50 | 4.49 ± 0.30 | 1.55 ± 0.07 | 5.05 ± 0.25 |

| Geraniol | 0.83 ± 0.25 | 1.14 ± 0.26 | 1.15 ± 0.21 | 1.32 ± 0.17 | 1.10 ± 0.17 |

| α-Terpineol | 3.19 ± 0.57 | 3.57 ± 0.53 | 4.06 ± 0.67 | 3.37 ± 0.04 | 3.39 ± 0.11 |

| β-Citronellol | 5.62 ± 1.79 | 4.58 ± 0.16 | 7.25 ± 0.38 | 3.68 ± 0.04 | 3.53 ± 0.64 |

| α-Phellandrene | 1.08 ± 0.01 | 1.38 ± 0.07 | 1.74 ± 0.17 | 0.41 ± 0.01 | 2.19 ± 0.42 |

| α-Terpinen | 0.06 ± 0.01 | 0.09 ± 0.01 | 0.09 ± 0.02 | 0.22 ± 0.02 | 0.10 ± 0.01 |

| β-Myrcene | 1.40 ± 0.03 | 1.80 ± 0.09 | 2.26 ± 0.23 | 2.64 ± 0.11 | 2.85 ± 0.54 |

| Limonene | 0.40 ± 0.01 | 0.46 ± 0.02 | 0.61 ± 0.11 | 0.85 ± 0.04 | 0.69 ± 0.08 |

| 1,4-Cineole | 0.03 ± 0.01 | 0.02 ± 0.00 | nd | nd | nd |

| 1,8-Cineole | 0.09 ± 0.01 | 0.08 ± 0.01 | nd | nd | 0.09 ± 0.01 |

| p-Cymene | 0.16 ± 0.02 | 0.24 ± 0.01 | 0.22 ± 0.03 | 0.26 ± 0.03 | 0.25 ± 0.03 |

| Terpinolene | 0.27 ± 0.03 | 0.33 ± 0.01 | 0.35 ± 0.02 | 0.53 ± 0.02 | 0.36 ± 0.02 |

| Terpinen-4-ol | 0.11 ± 0.01 | 0.12 ± 0.01 | 0.82 ± 0.02 | 0.10 ± 0.00 | 0.26 ± 0.06 |

| Norisoprenoids | |||||

| β-Damascenone | 5.46 ± 0.07 | 5.45 ± 0.92 | 10.30 ± 0.28 | 7.93 ± 1.32 | 9.07 ± 0.06 |

| 3-Hydroxy-β-damascone | 0.18 ± 0.02 | 0.16 ± 0.05 | 0.26 ± 0.01 | 0.24 ± 0.01 | 0.14 ± 0.01 |

| Vitispirane | 9.77 ± 0.66 | 10.79 ± 1.84 | 11.99 ± 3.46 | 16.45 ± 0.47 | 13.37 ± 0.69 |

| TPB | 0.07 ± 0.01 | 0.08 ± 0.01 | 0.18 ± 0.01 | 0.17 ± 0.01 | 0.12 ± 0.02 |

| TDN | 1.81 ± 0.01 | 1.76 ± 0.37 | 3.69 ± 0.21 | 3.70 ± 0.01 | 2.78 ± 0.42 |

| Benzenoids and others | |||||

| Benzyl alcohol | 45.93 ± 4.19 | 35.16 ± 1.95 | 44.49 ± 2.60 | 56.89 ± 5.24 | 72.90 ± 2.55 |

| Vanillin | 6.06 ± 0.25 | 5.94 ± 0.22 | 5.94 ± 0.06 | 5.88 ± 0.17 | 6.04 ± 0.08 |

| Ethyl vanillate | 182.83 ± 18.82 | 172.96 ± 1.77 | 189.04 ± 7.86 | 170.44 ± 4.26 | 191.00 ± 20.58 |

| Methyl vanillate | 11.69 ± 0.74 | 9.33 ± 0.24 | 14.28 ± 1.34 | 11.61 ± 0.53 | 12.30 ± 0.12 |

| Benzaldehyde | 14.50 ± 0.22 | 14.30 ± 0.19 | 15.03 ± 0.21 | 14.75 ± 0.00 | 14.60 ± 0.14 |

| Eugenol | 1.90 ± 0.01 | 1.88 ± 0.13 | 2.01 ± 0.28 | 1.88 ± 0.11 | 1.88 ± 0.11 |

| Methyl salicylate | 1.52 ± 0.18 | 1.57 ± 0.25 | 3.92 ± 0.01 | 3.05 ± 0.06 | 2.48 ± 0.12 |

| 2,6-Dimethoxyphenol | 5.28 ± 0.06 | 5.07 ± 0.12 | 4.83 ± 0.37 | 5.04 ± 0.39 | 6.11 ± 0.27 |

| Furfural | 0.67 ± 0.07 | 1.04 ± 0.72 | 0.97 ± 0.10 | 0.97 ± 0.04 | 0.63 ± 0.15 |

| γ-Decalactone | 2.47 ± 0.17 | 3.30 ± 0.28 | 3.09 ± 0.32 | 2.32 ± 0.11 | 2.34 ± 0.02 |

| δ-Decalactone | 17.63 ± 3.57 | 23.47 ± 2.17 | 20.19 ± 1.21 | 18.71 ± 0.62 | 14.87 ± 0.81 |

| Yeast 1 | Yeast 2 | Yeast 3 | Yeast 4 | Spontaneous | |

|---|---|---|---|---|---|

| mean ± sd | mean ± sd | mean ± sd | mean ± sd | mean ± sd | |

| Alcohols | |||||

| 1-Butanol | 435.89 ± 5.62 | 246.54 ± 7.13 | 202.54 ± 3.61 | 161.62 ± 28.98 | 203.59 ± 32.91 |

| 2-Butanol | 3865.04 ± 40.39 | 4224.78 ± 295.96 | 4888.37 ± 123.11 | 4074.09 ± 56.97 | 4692.72 ± 419.96 |

| 1-Pentanol | 69.68 ± 10.63 | 53.39 ± 3.74 | 51.05 ± 1.63 | 40.72 ± 1.02 | 36.36 ± 1.58 |

| Isoamyl alcohol (mg/L) | 25.80 ± 8.01 | 32.46 ± 25010 | 266.04 ± 4.14 | 312.92 ± 9.35 | 218.75 ± 2.01 |

| Phenylethyl alcohol (mg/L) | 21.67 ± 0.30 | 26.48 ± 2.34 | 20.01 ± 0.02 | 24.69 ± 1.02 | 15.01 ± 0.06 |

| Methionol | 116.97 ± 4.76 | 217.18 ± 60.02 | 129.93 ± 9.23 | 259.07 ± 18.89 | 69.61 ± 2.59 |

| C6 alcohols | |||||

| 1-Hexanol | 1149.65 ± 29.59 | 1424.44 ± 70.95 | 1054.97 ± 33.81 | 1154.77 ± 40.13 | 1189.48 ± 53.31 |

| trans-3-Hexen-1-ol | 15.01 ± 1.16 | 19.05 ± 1.02 | 13.65 ± 0.96 | 18.31 ± 0.26 | 13.40 ± 1.28 |

| cis-3-Hexen-1-ol | 11.12 ± 0.28 | 15.55 ± 0.16 | 11.72 ± 0.59 | 15.26 ± 0.30 | 13.78 ± 1.94 |

| cis-2-Hexen-1-ol | 16.00 ± 0.44 | 15.68 ± 0.33 | 16.11 ± 0.35 | 17.28 ± 0.94 | 15.07 ± 0.94 |

| Acetate esters | |||||

| Isoamyl acetate | 702.55 ± 31.55 | 689.58 ± 45.25 | 450.43 ± 15.25 | 373.92 ± 23.64 | 708.08 ± 37.99 |

| n-Hexyl acetate | 10.75 ± 1.54 | 12.18 ± 3.84 | 8.81 ± 2.03 | 17.77 ± 0.24 | 14.02 ± 2.14 |

| 2-Phenylethyl acetate | 26.14 ± 2.51 | 26.53 ± 2.86 | 14.21 ± 1.85 | 14.32 ± 2.01 | 32.92 ± 2.21 |

| Ethyl acetate (mg/L) | 57.70 ± 1.62 | 70.32 ± 9.73 | 69.85 ± 1.60 | 54.02 ± 6.67 | 158.50 ± 2.59 |

| Branched-chain fatty acids ethyl esters | |||||

| Ethyl 2-methylbutanoate | 1.83 ± 0.04 | 2.53 ± 0.04 | 2.31 ± 0.14 | 2.93 ± 0.09 | 1.12 ± 0.08 |

| Ethyl 3-methylbutanoate | 3.11 ± 0.14 | 3.10 ± 0.13 | 3.21 ± 0.16 | 2.95 ± 0.08 | 3.10 ± 0.18 |

| Fatty acids ethyl esters | |||||

| Ethyl butanoate | 267.28 ± 27.74 | 366.95 ± 11.50 | 201.25 ± 3.67 | 241.66 ± 12.76 | 262.34 ± 21.33 |

| Ethyl hexanoate | 415.84 ± 14.28 | 567.81 ± 45.25 | 358.27 ± 11.13 | 439.93 ± 23.36 | 364.84 ± 50.11 |

| Ethyl octanoate | 221.11 ± 6.07 | 320.36 ± 68.82 | 236.13 ± 6.18 | 282.17 ± 7.74 | 198.47 ± 11.00 |

| Ethyl lactate | 226.73 ± 7.34 | 443.77 ± 29.85 | 206.46 ± 8.03 | 277.63 ± 36.13 | 531.84 ± 41.32 |

| Ethyl decanoate | 51.72 ± 7.74 | 85.86 ± 5.85 | 67.95 ± 2.79 | 75.81 ± 10.45 | 48.74 ± 6.30 |

| Other esters | |||||

| Ethyl 3-hydroxybutanoate | 198.08 ± 5.95 | 266.81 ± 20.89 | 215.93 ± 5.90 | 168.82 ± 12.93 | 128.57 ± 28.39 |

| Ethyl 2-hydroxyhexanoate | 0.31 ± 0.04 | 1.42 ± 0.04 | 0.66 ± 0.06 | 0.84 ± 0.06 | 0.33 ± 0.04 |

| Fatty acids | |||||

| 3-Methylbutanoic acid | 374.47 ± 10.27 | 432.56 ± 57.91 | 364.05 ± 17.82 | 459.10 ± 2.18 | 282.97 ± 14.81 |

| Hexanoic acid | 2194.09 ± 377.72 | 3172.54 ± 401.13 | 2056.21 ± 65.63 | 2299.39 ± 149.00 | 1868.12 ± 27.08 |

| Octanoic acid | 4021.06 ± 130.90 | 5095.48 ± 359.10 | 3948.40 ± 101.82 | 4166.92 ± 87.94 | 3786.14 ± 46.03 |

| Terpenoids | |||||

| cis-Linaloloxide | 0.07 ± 0.02 | 0.11 ± 0.06 | 0.10 ± 0.01 | 0.04 ± 0.01 | 0.08 ± 0.01 |

| trans-Linaloloxide | 0.08 ± 0.07 | 0.04 ± 0.00 | 0.03 ± 0.00 | 0.08 ± 0.00 | 0.05 ± 0.01 |

| Linalool | 5.34 ± 0.19 | 6.44 ± 0.05 | 6.30 ± 0.29 | 6.52 ± 0.52 | 5.55 ± 0.66 |

| Geraniol | 1.09 ± 0.20 | 1.67 ± 0.24 | 1.75 ± 0.21 | 1.75 ± 0.26 | 1.68 ± 0.30 |

| α-Terpineol | 3.08 ± 0.07 | 4.18 ± 0.11 | 4.30 ± 0.32 | 3.51 ± 0.13 | 3.41 ± 0.30 |

| β-Citronellol | 10.93 ± 0.36 | 6.57 ± 0.17 | 7.82 ± 0.84 | 7.94 ± 0.42 | 6.92 ± 0.28 |

| α-Phellandrene | 2.90 ± 0.16 | 2.79 ± 0.04 | 3.07 ± 0.18 | 3.45 ± 0.35 | 2.97 ± 0.24 |

| α-Terpinen | 0.09 ± 0.01 | 0.14 ± 0.12 | 0.05 ± 0.00 | 0.06 ± 0.01 | 0.05 ± 0.01 |

| β-Myrcene | 3.76 ± 0.21 | 3.68 ± 0.04 | 3.98 ± 0.24 | 4.48 ± 0.45 | 3.89 ± 0.27 |

| Limonene | 0.68 ± 0.05 | 0.66 ± 0.08 | 0.71 ± 0.04 | 0.72 ± 0.04 | 0.67 ± 0.03 |

| 1,4-Cineole | 0.04 ± 0.00 | nd | nd | nd | nd |

| 1,8-Cineole | 0.09 ± 0.00 | 0.11 ± 0.01 | 0.10 ± 0.01 | 0.08 ± 0.01 | 0.09 ± 0.01 |

| p-Cymene | 0.24 ± 0.01 | 0.16 ± 0.01 | 0.15 ± 0.00 | 0.15 ± 0.00 | 0.17 ± 0.02 |

| Terpinolene | 0.33 ± 0.05 | 0.22 ± 0.03 | 0.31 ± 0.01 | 0.29 ± 0.02 | 0.27 ± 0.03 |

| Terpinen-4-ol | 1.59 ± 0.03 | 0.05 ± 0.01 | 0.06 ± 0.01 | 0.05 ± 0.00 | 0.06 ± 0.01 |

| Norisoprenoids | |||||

| β-Damascenone | 3.19 ± 0.08 | 2.77 ± 0.15 | 2.87 ± 0.04 | 3.03 ± 0.25 | 2.54 ± 0.23 |

| 3-Hydroxy-β-damascone | 0.12 ± 0.01 | 0.15 ± 0.00 | 0.10 ± 0.01 | 0.11 ± 0.01 | 0.15 ± 0.05 |

| Vitispirane | 3.56 ± 0.28 | 4.42 ± 0.14 | 3.43 ± 0.14 | 3.54 ± 0.17 | 3.44 ± 0.23 |

| TPB | 0.02 ± 0.00 | 0.02 ± 0.00 | 0.02 ± 0.00 | 0.02 ± 0.00 | 0.02 ± 0.00 |

| TDN | 0.33 ± 0.04 | 0.34 ± 0.03 | 0.24 ± 0.01 | 0.26 ± 0.01 | 0.26 ± 0.02 |

| Benzenoids and others | |||||

| Benzyl alcohol | 39.17 ± 0.30 | 34.19 ± 1.61 | 31.11 ± 3.26 | 52.14 ± 5.28 | 56.54 ± 0.81 |

| Vanillin | 5.45 ± 0.07 | 5.54 ± 0.16 | 5.49 ± 0.21 | 5.60 ± 0.21 | 5.50 ± 0.14 |

| Ethyl vanillate | 177.78 ± 4.48 | 185.85 ± 22.39 | 145.92 ± 19.79 | 184.34 ± 21.53 | 180.38 ± 33.66 |

| Methyl vanillate | 10.56 ± 0.22 | 13.24 ± 0.30 | 11.47 ± 0.72 | 12.80 ± 1.77 | 12.04 ± 1.13 |

| Benzaldehyde | 14.50 ± 0.09 | 15.03 ± 0.69 | 14.19 ± 0.49 | 14.84 ± 0.24 | 14.80 ± 0.11 |

| Eugenol | 1.26 ± 0.01 | 1.26 ± 0.01 | 1.16 ± 0.06 | 1.26 ± 0.01 | 1.68 ± 0.01 |

| Methyl salicylate | 0.64 ± 0.07 | 0.77 ± 0.04 | 0.63 ± 0.13 | 0.64 ± 0.08 | 0.37 ± 0.02 |

| 2,6-Dimethoxyphenol | 6.70 ± 0.42 | 5.66 ± 0.53 | 5.11 ± 0.65 | 6.98 ± 0.03 | 5.99 ± 0.37 |

| Furfural | 1.79 ± 0.08 | 2.10 ± 0.10 | 1.62 ± 0.12 | 1.86 ± 0.19 | 1.35 ± 0.19 |

| γ-Decalactone | 2.25 ± 0.00 | 3.20 ± 0.16 | 2.47 ± 0.30 | 3.02 ± 0.11 | 2.32 ± 0.08 |

| δ-Decalactone | 22.06 ± 0.52 | 28.68 ± 4.83 | 16.57 ± 2.34 | 28.13 ± 2.51 | 23.11 ± 2.44 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luzzini, G.; Slaghenaufi, D.; Ugliano, M. Volatile Compounds in Monovarietal Wines of Two Amarone Della Valpolicella Terroirs: Chemical and Sensory Impact of Grape Variety and Origin, Yeast Strain and Spontaneous Fermentation. Foods 2021, 10, 2474. https://doi.org/10.3390/foods10102474

Luzzini G, Slaghenaufi D, Ugliano M. Volatile Compounds in Monovarietal Wines of Two Amarone Della Valpolicella Terroirs: Chemical and Sensory Impact of Grape Variety and Origin, Yeast Strain and Spontaneous Fermentation. Foods. 2021; 10(10):2474. https://doi.org/10.3390/foods10102474

Chicago/Turabian StyleLuzzini, Giovanni, Davide Slaghenaufi, and Maurizio Ugliano. 2021. "Volatile Compounds in Monovarietal Wines of Two Amarone Della Valpolicella Terroirs: Chemical and Sensory Impact of Grape Variety and Origin, Yeast Strain and Spontaneous Fermentation" Foods 10, no. 10: 2474. https://doi.org/10.3390/foods10102474

APA StyleLuzzini, G., Slaghenaufi, D., & Ugliano, M. (2021). Volatile Compounds in Monovarietal Wines of Two Amarone Della Valpolicella Terroirs: Chemical and Sensory Impact of Grape Variety and Origin, Yeast Strain and Spontaneous Fermentation. Foods, 10(10), 2474. https://doi.org/10.3390/foods10102474