Efficient Production of Dried Whole Peanut Fruits Based on Infrared Assisted Spouted Bed Drying

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Drying Methods

2.2.1. HD Process

2.2.2. ID Process

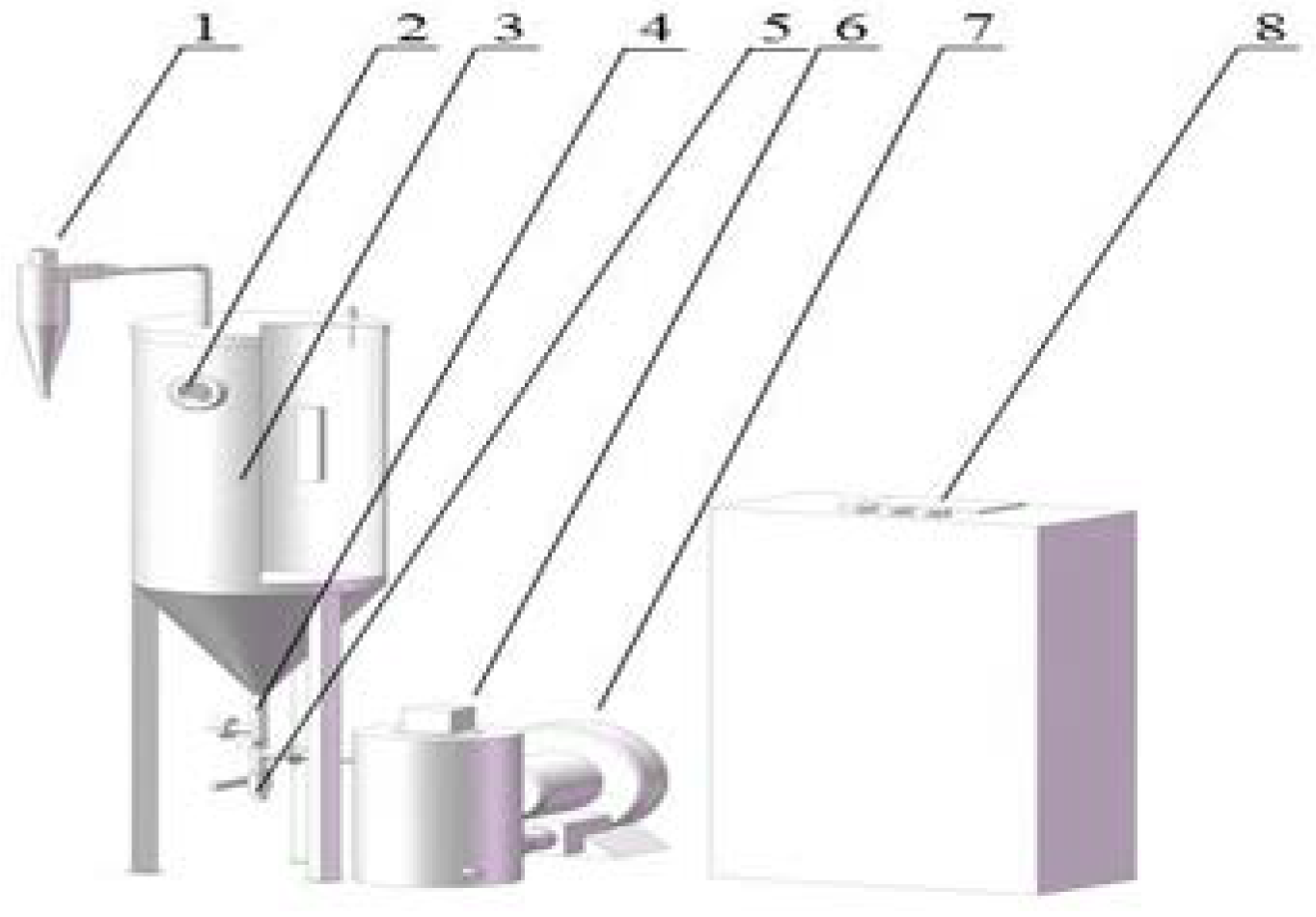

2.2.3. IR-SBD Process

2.3. Drying Characteristics Analysis

2.4. Microstructure by Scanning Electron Microscopy

2.5. Texture Analysis

2.6. Porosity Measurement

2.7. Fatty Acid Determination

2.8. Energy Consumption

2.9. Statistics Analysis

3. Results and Discussion

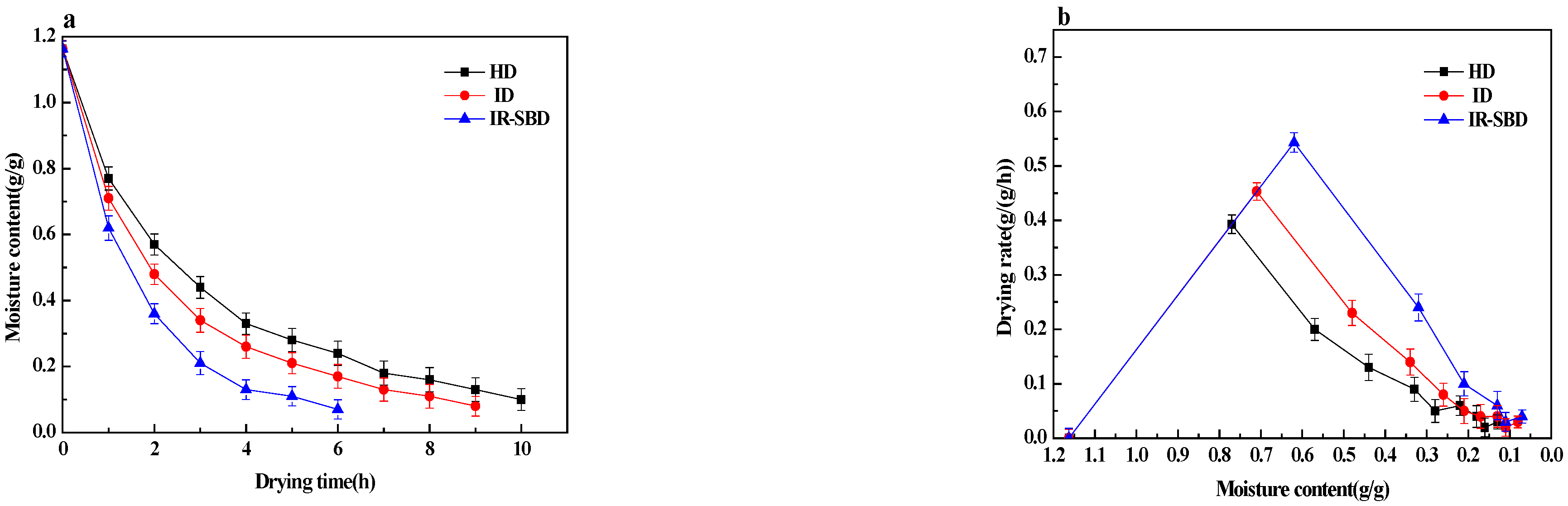

3.1. Drying Curves

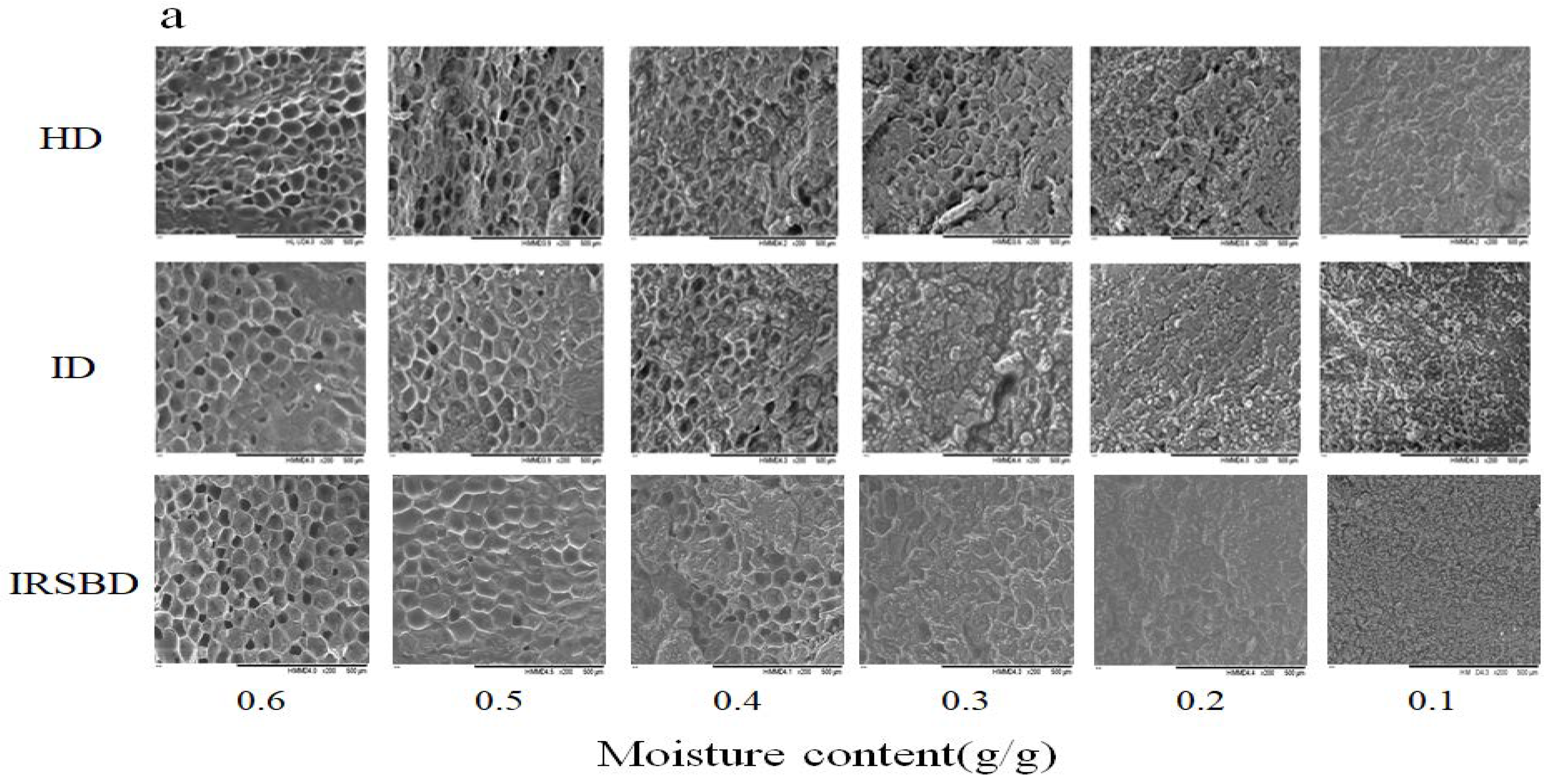

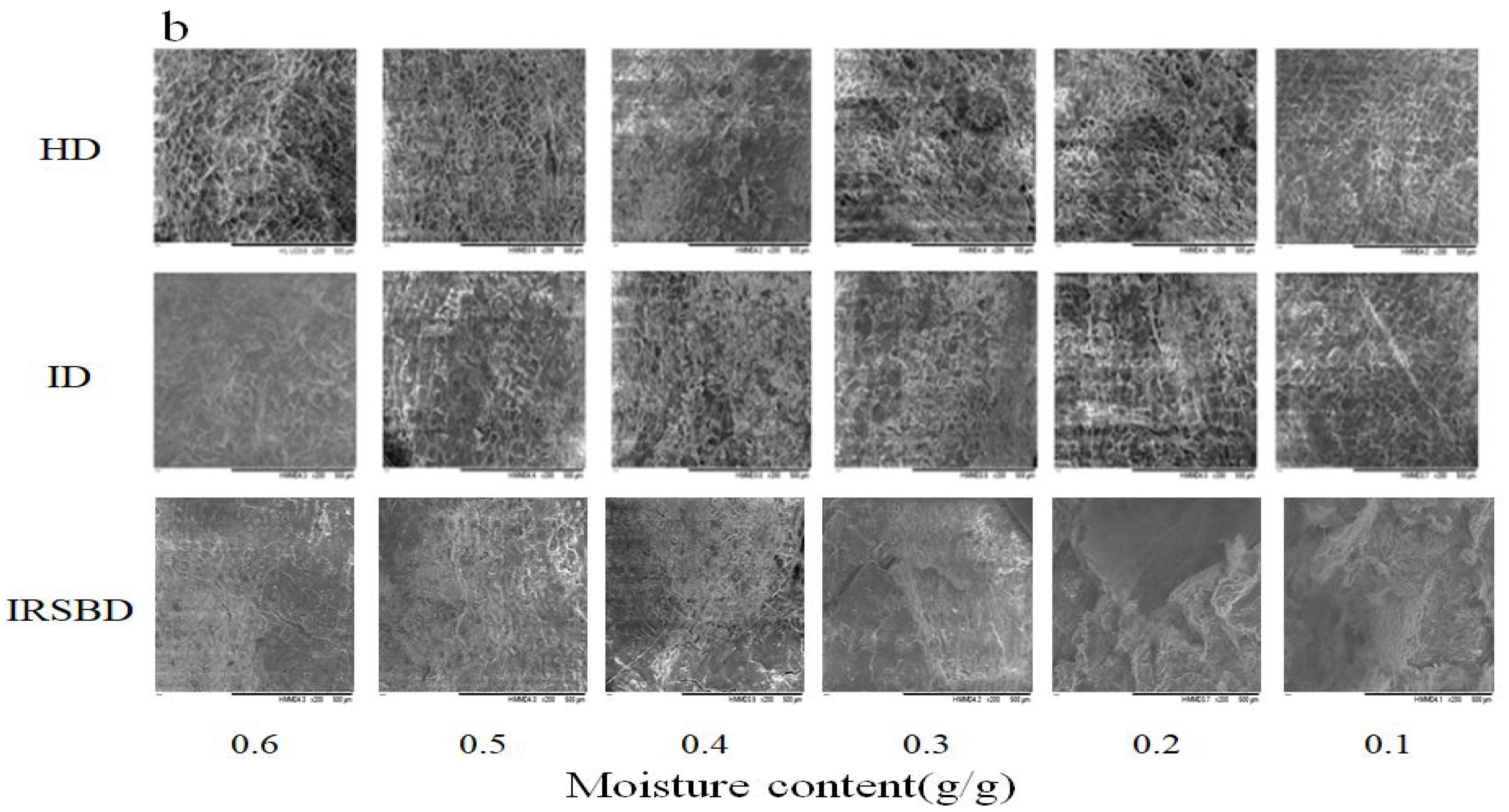

3.2. Microstructure Change

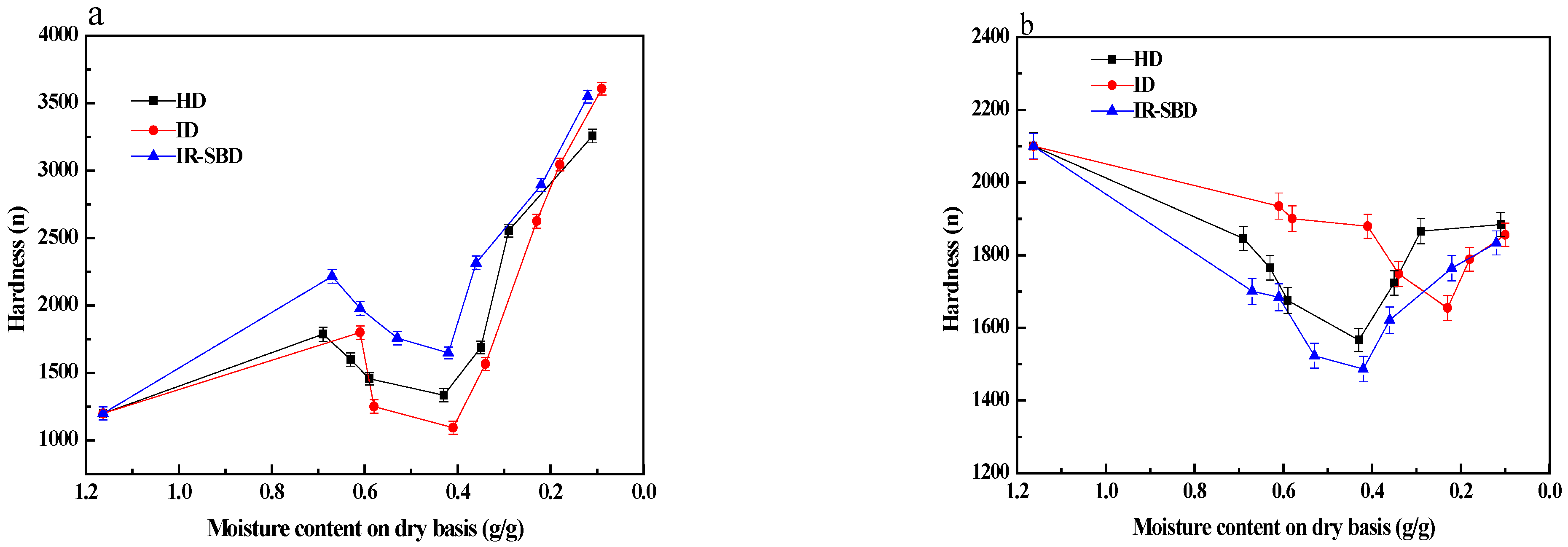

3.3. Hardness

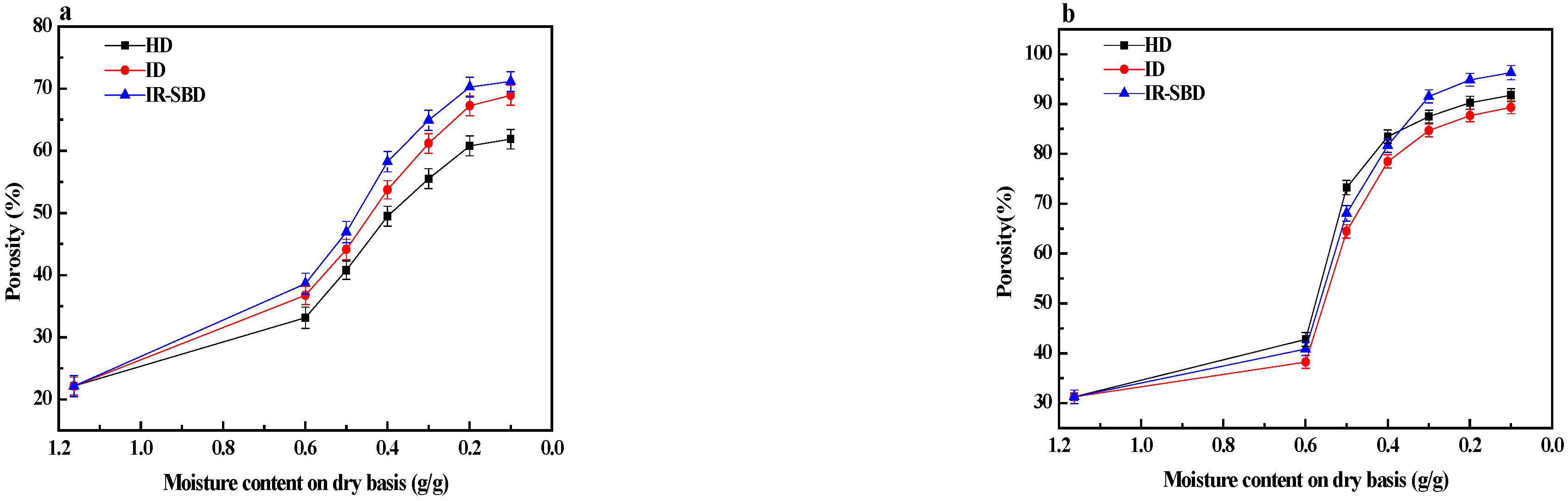

3.4. Porosity

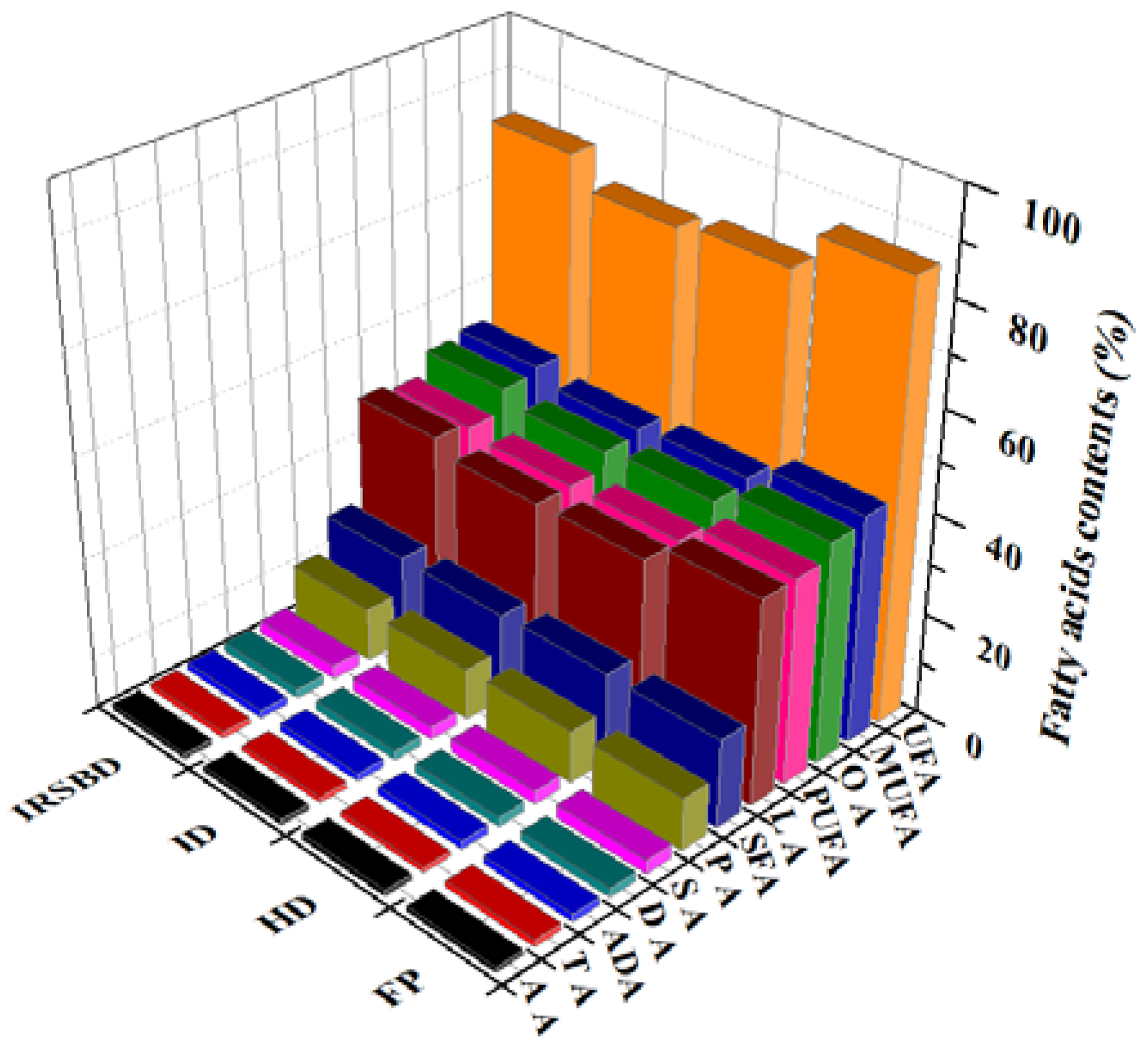

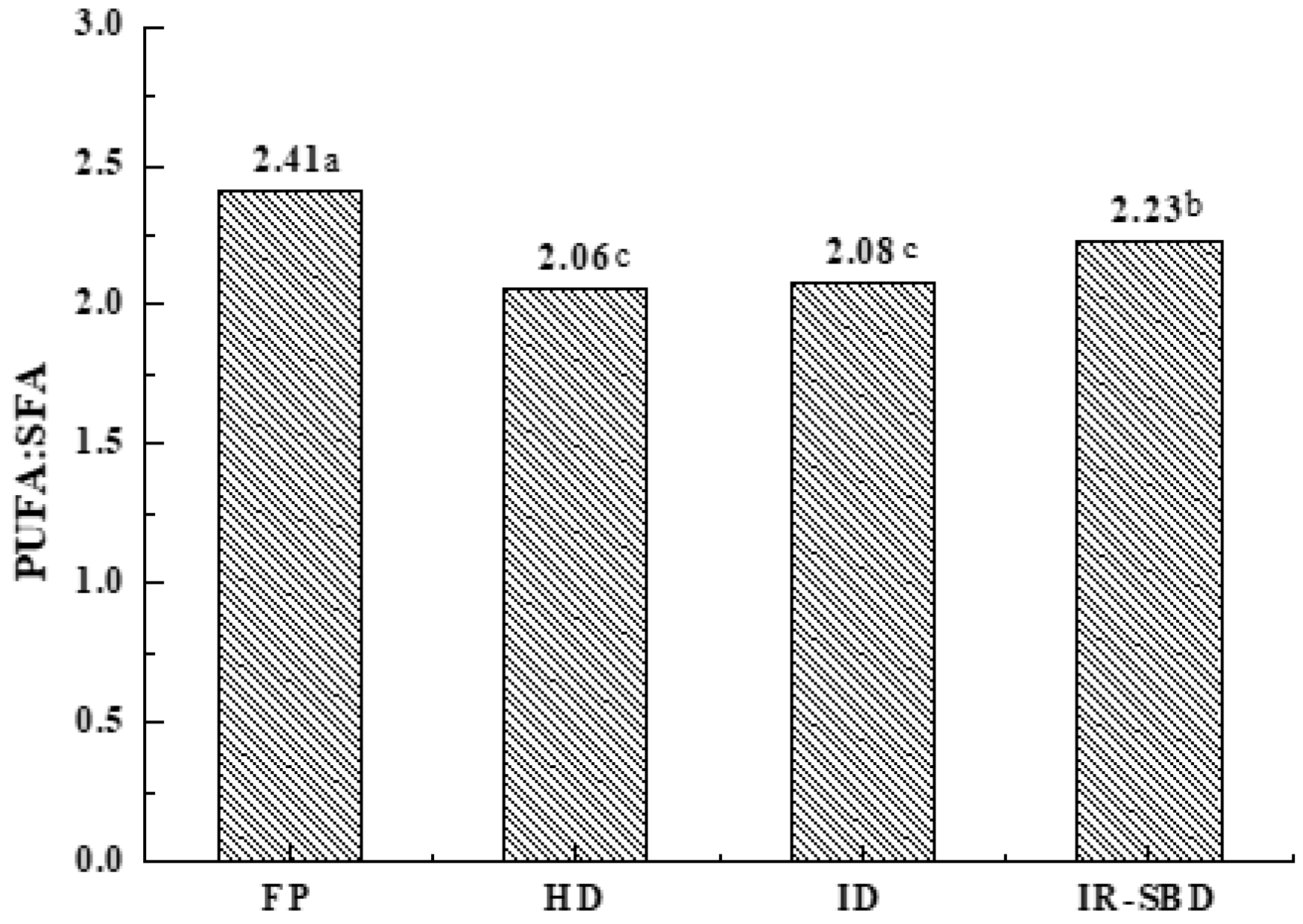

3.5. Fatty Acids

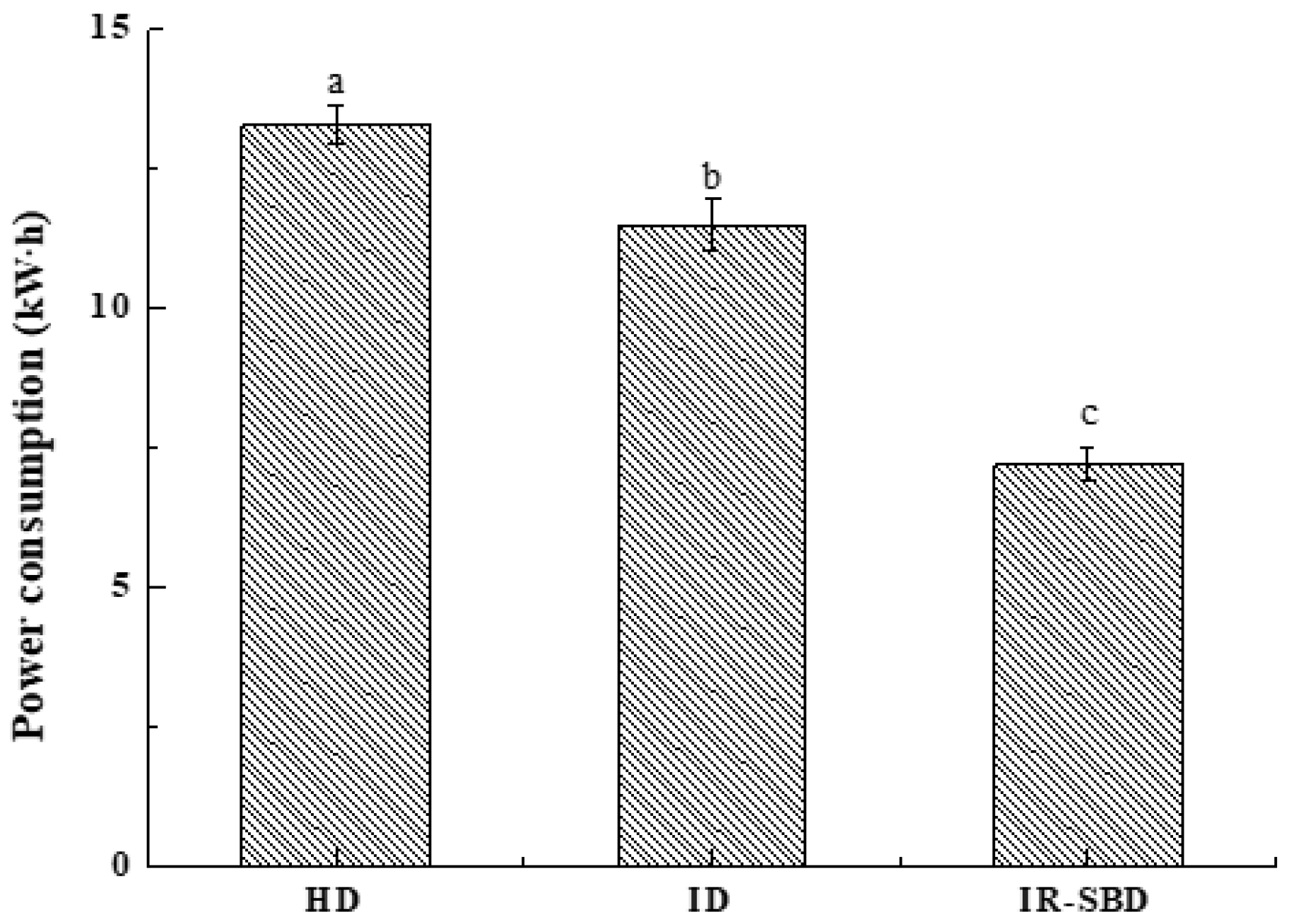

3.6. Energy Consumption

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Costa, C.A.; Bismara, R.A.; Boscariol, R.G.; Guidolin, C.S.; Leonardo, P. Phenolic acids and flavonoids of peanut by-products: Antioxidant capacityand antimicrobial effects. Food Chem. 2017, 237, 538–544. [Google Scholar]

- He, S.N.; Chen, Y.; Xiang, W.; Chen, X.W.; Wang, X.L.; Chen, Y. Carbon and nitrogen footprints accounting of peanut and peanut oil production in China. J. Clean. Prod. 2021, 291, 125964. [Google Scholar] [CrossRef]

- Araujo, W.; Goneli, A.; Correa, P.; Hartmann, C.; Martins, E. Mathematical modelling ofthin-layer drying in peanut fruit. Rev. Ciência Agronômica 2017, 48, 448–457. [Google Scholar]

- Qu, C.L.; Wang, X.K.; Wang, Z.W.; Yu, S.C.; Wang, D.X. Effect of Drying Temperatures on the Peanut Quality during Hot Air Drying. J. Oleo Sci. 2020, 69, 403–412. [Google Scholar] [CrossRef] [Green Version]

- Lee, Y.H.; Chin, S.K.; Chung, B.K. Drying characteristics and quality of lemon slices dried under Coulomb force-assisted heat pump drying. Dry. Technol. 2021, 39, 765–776. [Google Scholar] [CrossRef]

- Bagheri, H.; Kashaninejad, M.; Ziaiifar, A.M.; Aalami, M. Novel hybridized infrared-hot air method for roasting of peanut kernels. Innov. Food Sci. Emerg. Technol. 2016, 37, 106–114. [Google Scholar] [CrossRef]

- Nosrati, M.; Zare, D.; Singh, C.B.; Stroshine, R.L. New approach in determination ofmoisture diffusivity for roughrice components in combined far-infrared drying by finite element method. Dry. Technol. 2020, 38, 1721–1732. [Google Scholar] [CrossRef]

- Liu, Y.H.; Sun, C.Y.; Lei, Y.Q.; Yu, H.C.; Xi, H.H.; Duan, X. Contact ultrasound strengthened far-infrared radiation drying on pear slices: Effects on drying characteristics, microstructure, and quality attributes. Dry. Technol. 2019, 37, 745–758. [Google Scholar] [CrossRef]

- Xie, L.; Mujumdar, A.S.; Zhang, Q.; Wang, J.; Liu, S.X.; Deng, L.Z.; Wang, D.; Xiao, H.W.; Liu, Y.H.; Gao, Z.J. Pulsed vacuum drying of wolfberry: Effects of infrared radiation heating and electronic panel contact heating methods on drying kinetics, color profile, and volatile compounds. Dry. Technol. 2017, 35, 1312–1326. [Google Scholar] [CrossRef]

- Duan, X.; Zhang, M.; Ren, G.Y.; Zhou, S.Q.; Zhao, L.J.; Xu, Y.M. Drying models and quality changes of rose subjected to infrared assisted spouted bed drying. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 238–245. [Google Scholar]

- Li, L.L.; Chen, J.L.; Zhou, S.Q.; Ren, G.Y.; Duan, X. Quality evaluation of probiotics enriched Chinese yam snacks produced using infrared-assisted spouted bed drying. J. Food Process. Preserv. 2021, 45, 1–9. [Google Scholar] [CrossRef]

- Manshadi, A.D.; Peighambardoust, S.H.; Damirchi, S.A.; Niakousari, M. Effect of infrared-assisted spouted bed drying of flaxseed on the quality characteristics of its oil extracted by different methods. J. Sci. Food Agric. 2020, 100, 74–80. [Google Scholar] [CrossRef]

- Lewis, M.; Trabelsi, S.; Nelson, S. Assessing the utility of microwave kernel moisturesensing in peanut drying. Appl. Eng. Agric. 2016, 32, 707–712. [Google Scholar]

- Wang, N.F.; Qian, W.; Zhou, Y.B. Effect of Drying Methods on the Antioxidant Activity of Peanut Flour Fermented with Lactobacillus casei LC35. Adv. Mater. Res. 2012, 1915, 1095–1098. [Google Scholar] [CrossRef]

- Manbeck, H.; Nelson, G.; Lynd, J.; Mason, M. Anaerobic and Aerobic Vacuum Techniques for Mycotoxin-Free Peanut Drying. Trans. ASAE 1970, 13, 93–98. [Google Scholar] [CrossRef]

- AOAC. Moisture in Dried Fruits: Method 934.06. In Official Methods of Analysis of AOAC International, 17th ed.; Horowitz, W., Ed.; Association of Official Analytical Chemists International: Gaithersburg, MD, USA, 2000; p. 382. [Google Scholar]

- Zeng, S.Y.; Du, Z.L.; Lv, W.Q.; Li, D.; Su, D.B.; Lv, H.Z. Experimental study on thehygrothermal dynamics of peanut (Arachis hypogaea Linn.) in the process of superposition and variable temperature drying. Dry. Technol. 2021, 26, 1–17. [Google Scholar] [CrossRef]

- Sun, J.L.; Zhang, X.Y.; Qiu, X.J.; Zhu, X.Y.; Zhang, T.; Yang, J.X.; Zhang, X.; Lv, Y.; Wang, H.H. Hyperspectral data for predicting moisture content and distribution in scallops during continuous and intermittent drying. Dry. Technol. 2020, 42, 1–14. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Ma, L.; Yu, H.; Tan, X.; Liu, J. Effect of far-infrared radiation temperature on drying characteristics and quality of Flos Lonicerae. Food Sci. 2017, 38, 69–76. [Google Scholar]

- Feng, Y.B.; Tan, C.P.; Zhou, C.S.; Yagoub, A.; Xu, B.G.; Sun, Y.H.; Ma, H.L.; Xu, X.; Yu, X.J. Effect of freeze-thaw cycles pretreatment on the vacuum freeze-drying process and physicochemical properties of the dried garlic slices. Food Chem. 2020, 324, 2–10. [Google Scholar] [CrossRef]

- Ren, G.Y.; Zhang, L.D.; Zeng, F.L.; Li, Y.B.; Li, L.L.; Duan, X. Effects of hot air drying temperature and tempering time on the properties of maize starch. Int. J. Agric. Biol. Eng. 2020, 13, 236–241. [Google Scholar]

- Duan, X.; Liu, W.C.; Ren, G.Y.; Yang, X.T. Effects of different drying methods on thephysical characteristics and flavor of dried hawthorns (Crataegus spp.). Dry. Technol. 2017, 35, 1412. [Google Scholar] [CrossRef]

- Dilmac, M.; Altuntas, E. Selected Some Engineering Properties of Peanut and Its Kernel. Int. J. Food Eng. 2012, 8, 1–12. [Google Scholar] [CrossRef]

- Alizehi, M.H.; Niakousari, M.; Fazaeli, M.; Iraji, M. Modeling of vacuum- and ultrasound-assisted osmodehydration of carrot cubes followed by combined infrared and spouted bed drying using artificial neural network and regression models. J. Food Process. Eng. 2020, 43, e13563. [Google Scholar] [CrossRef]

- Serowik, M.; Figiel, A.; Nejman, M.; Pudlo, A.; Chorazyk, D.; Kopec, W.; Krokosz, D.; Rychlicka-Rybska, J. Drying characteristics and properties of microwave-assisted spouted bed dried semi-refined carrageenan. J. Food Eng. 2018, 221, 20–28. [Google Scholar] [CrossRef]

- Malekjani, N.; Jafari, S.M. Simulation of food drying processes by Computational Fluid Dynamics (CFD); recent advances and approaches. Trends Food Sci. Technol 2018, 78, 206–223. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, L.; Yang, T.Y.; Ma, Y.; McClements, D.J.; Ren, F.; Tian, Y.Q.; Jin, Z.Y. A review of structural transformations and properties changes in starch during thermal processing of foods. Food Hydrocoll. 2021, 113, 2–13. [Google Scholar] [CrossRef]

- Wu, B.G.; Guo, X.Y.; Guo, Y.T.; Ma, H.L.; Zhou, C.S. Enhancing jackfruit infrared drying by combining ultrasound treatments: Effect on drying characteristics, quality properties and microstructure. Food Chem. 2021, 358, 129845. [Google Scholar] [CrossRef] [PubMed]

- Michalska, A.; Wojdylo, A.; Lech, K.; Łysiak, G.P.; Figiel, A. Physicochemical properties ofwhole fruit plum powders obtained using different drying technologies. Food Chem. 2016, 207, 223–232. [Google Scholar] [CrossRef]

- Atanasov, A.G.; Sabharanjak, S.M.; Zengin, G.; Mollica, A.; Szostak, A.; Simirgiotis, M.; Huminiecki, L.; Horbanczuk, O.; Nabavi, S.M.; Mocan, A. Pecan nuts: A review of reported bioactivities and health effects. Trends Food Sci. Technol 2018, 71, 246–257. [Google Scholar] [CrossRef]

- Abbas, A.; Anowarul, M.; Hidayu, N.; Ahmadilfitri, N. Effect of heating on oxidationstability and fatty acid composition of microwave roasted groundnut seed oil. J. Food Sci. Technol. 2017, 54, 4335–4343. [Google Scholar] [CrossRef]

- Shi, R.; Guo, Y.; Vriesekoop, F.; Yuan, Q.P.; Zhao, S.N.; Liang, H. Improving oxidative stability of peanut oil under microwave treatment and deep fat frying by stearic acid-surfacant-tea polyphenols complex. Eur. J. Lipid Sci. Technol. 2015, 117, 1008–1015. [Google Scholar] [CrossRef]

- The World Health Organization. Guidelines: Saturated Fatty Acid and Trans-Fatty Acid Intake for Adults and Children; The World Health Organization Europe: Copenhagen, Denmark, 2018. [Google Scholar]

- Xiao, H.W.; Mujumdar, A.S. Importance of Drying in Support Human Welfare. Dry. Technol. 2020, 38, 1542–1543. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.L.; Bai, J.W.; Wang, S.X.; Meng, J.S.; Wang, H.; Yu, X.L.; Gao, Z.J.; Xiao, H.W. Prediction of energy and exergy of mushroom slices drying in hot air impingementdryer by artificial neural network. Dry. Technol. 2020, 38, 1959–1970. [Google Scholar] [CrossRef]

- Bagheri, H.; Kashaninejad, M.; Ziaiifar, A.M.; Aalami, M. Textural, color and sensory attributes of peanut kernels as affected by infrared roasting method. Inf. Process. Agric. 2019, 6, 255–264. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Khoshtaghaza, M.H.; Amirnejat, H. Comparison of energy consumption and specific energy requirements of different methods for drying mushroom slices. Energy 2011, 36, 6433–6441. [Google Scholar] [CrossRef]

| Drying Method | Drying Temperature (°C) | Drying Time (h) | Drying Energy Consumption (kW·h) |

|---|---|---|---|

| IR-SBD | 50 | 10.67 ± 0.32 a | 12.84 ± 0.49 a |

| 55 | 9.23 ± 0.25 b | 11.18 ± 0.39 b | |

| 60 | 8.34 ± 0.23 c | 10.03 ± 0.31 c | |

| 65 | 7.26 ± 0.23 d | 8.71 ± 0.28 d | |

| 70 | 6.12 ± 0.21 e | 7.34 ± 0.25 e | |

| 75 | 5.50 ± 0.16 f | 7.29 ± 0.22 f | |

| 80 | 5.01 ± 0.12 g | 7.87 ± 0.29 g |

| HD | ID | IR-SBD | p Value | ||

|---|---|---|---|---|---|

| drying time (h) | 10.10 ± 0.32 a | 9.11 ± 0.26 b | 6.07 ± 0.22 c | <0.05 | |

| Hardness(n) | peanut kernel | 3256.25 ± 206.68 a | 3607.22 ± 221.97 b | 3548.49 ± 229.65 b | <0.05 |

| peanut shell | 1879.02 ± 69.63 a | 1855.15 ± 91.49 a | 1831.33 ± 72.04 a | >0.05 | |

| Porosity (%) | peanut kernel | 61.88 ± 4.85 a | 68.81 ± 5.53 b | 71.15 ± 4.10 b | <0.05 |

| peanut shell | 91.73 ± 5.64 a | 89.33 ± 4.86 b | 96.24± 5.92 c | <0.05 | |

| Fatty acids (%) | 77.85 ± 4.21 a | 76.57 ± 4.15 a | 82.13 ± 4.35 b | <0.05 | |

| Energy consumption (kW·h) | 13.31 ± 0.53 a | 11.52 ± 0.48 b | 7.21 ± 0.23 c | <0.05 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, K.; Li, L.; Ren, G.; Duan, X.; Cao, W.; Qiu, C. Efficient Production of Dried Whole Peanut Fruits Based on Infrared Assisted Spouted Bed Drying. Foods 2021, 10, 2383. https://doi.org/10.3390/foods10102383

Zhu K, Li L, Ren G, Duan X, Cao W, Qiu C. Efficient Production of Dried Whole Peanut Fruits Based on Infrared Assisted Spouted Bed Drying. Foods. 2021; 10(10):2383. https://doi.org/10.3390/foods10102383

Chicago/Turabian StyleZhu, Kaiyang, Linlin Li, Guangyue Ren, Xu Duan, Weiwei Cao, and Caixia Qiu. 2021. "Efficient Production of Dried Whole Peanut Fruits Based on Infrared Assisted Spouted Bed Drying" Foods 10, no. 10: 2383. https://doi.org/10.3390/foods10102383

APA StyleZhu, K., Li, L., Ren, G., Duan, X., Cao, W., & Qiu, C. (2021). Efficient Production of Dried Whole Peanut Fruits Based on Infrared Assisted Spouted Bed Drying. Foods, 10(10), 2383. https://doi.org/10.3390/foods10102383