Prototypes of Highly Effective Stress Balancing AlN Interlayers in MOVPE GaN-on-Si (111)

Abstract

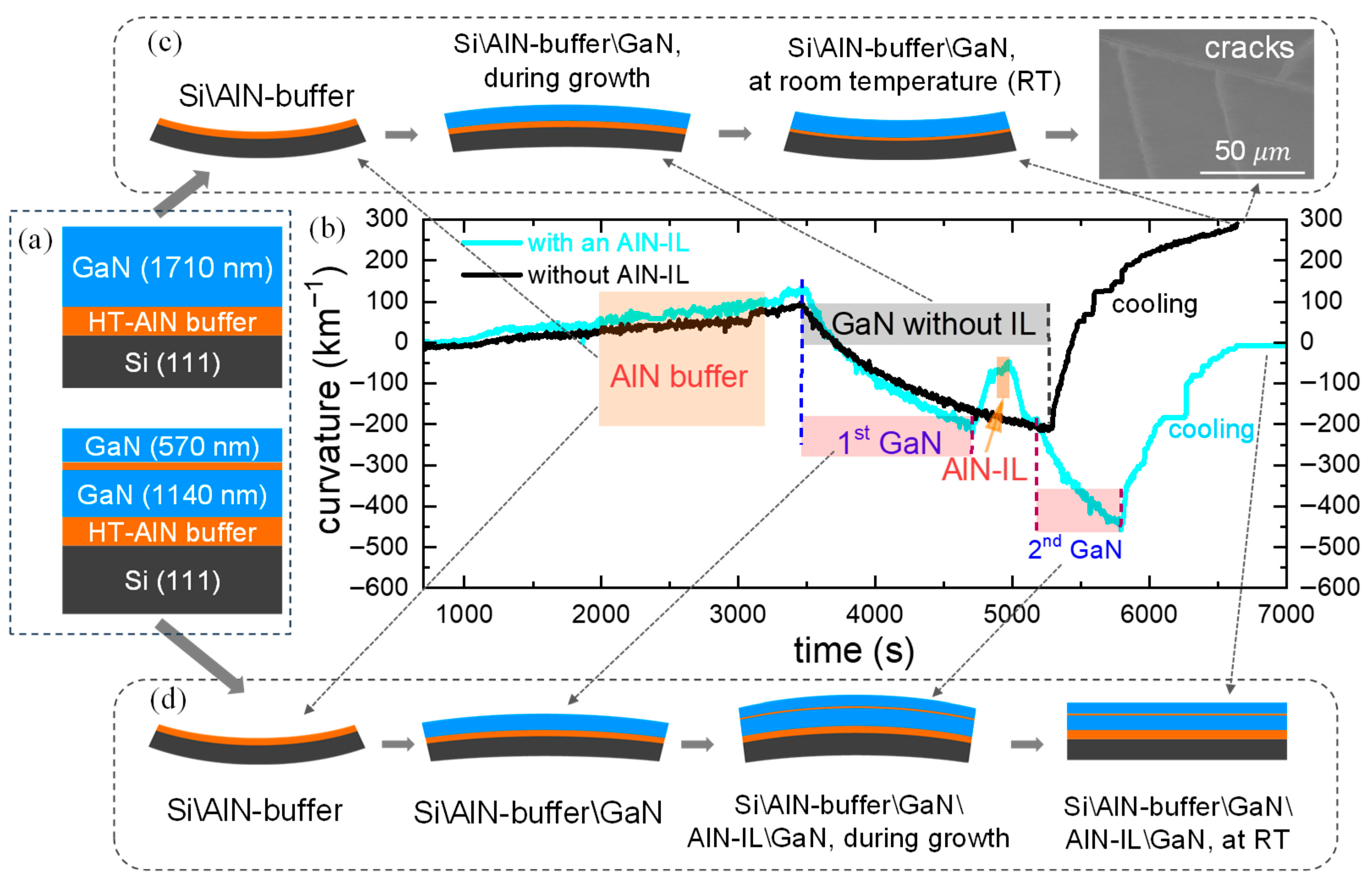

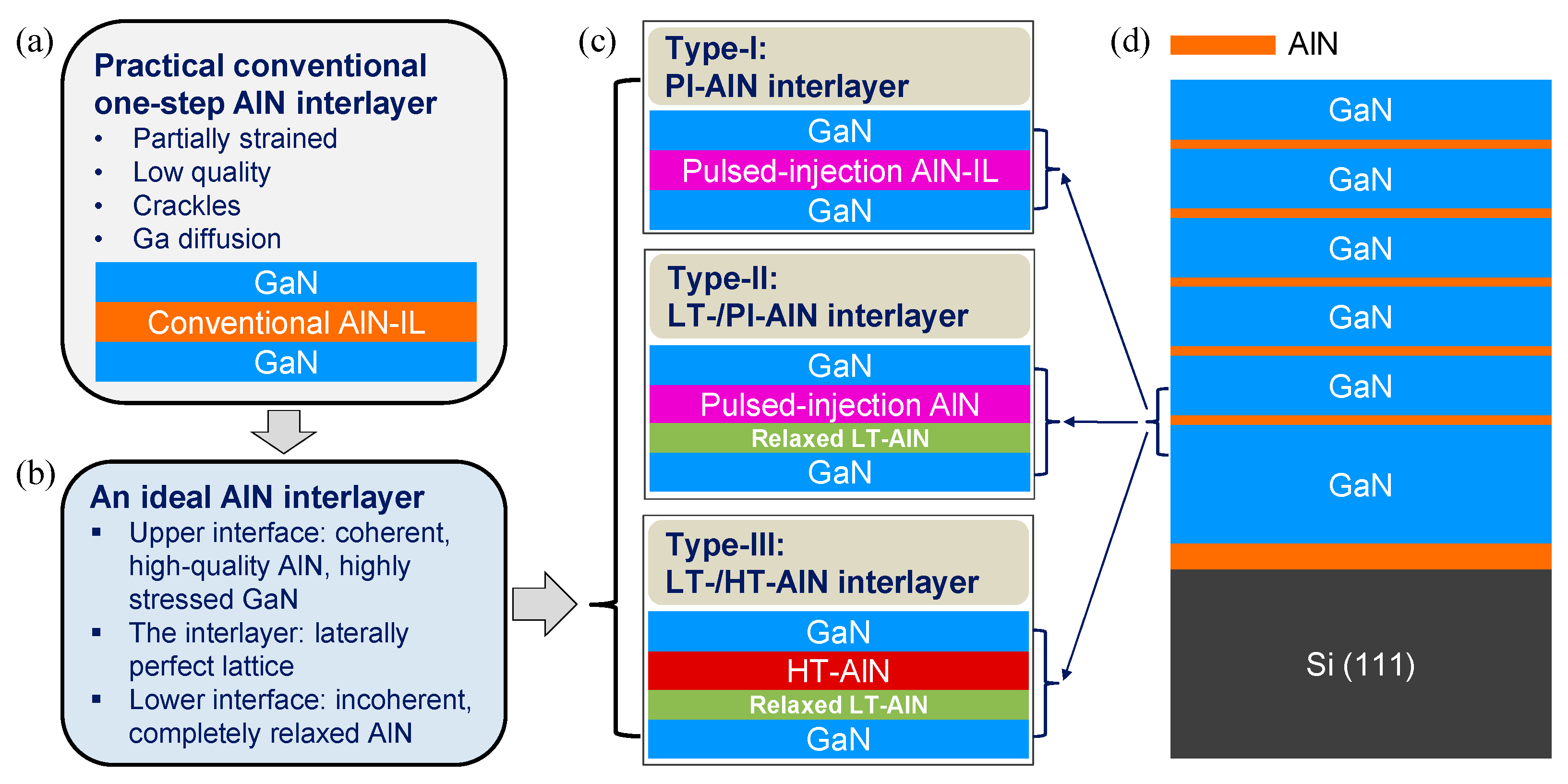

1. Introduction

2. Results and Discussion

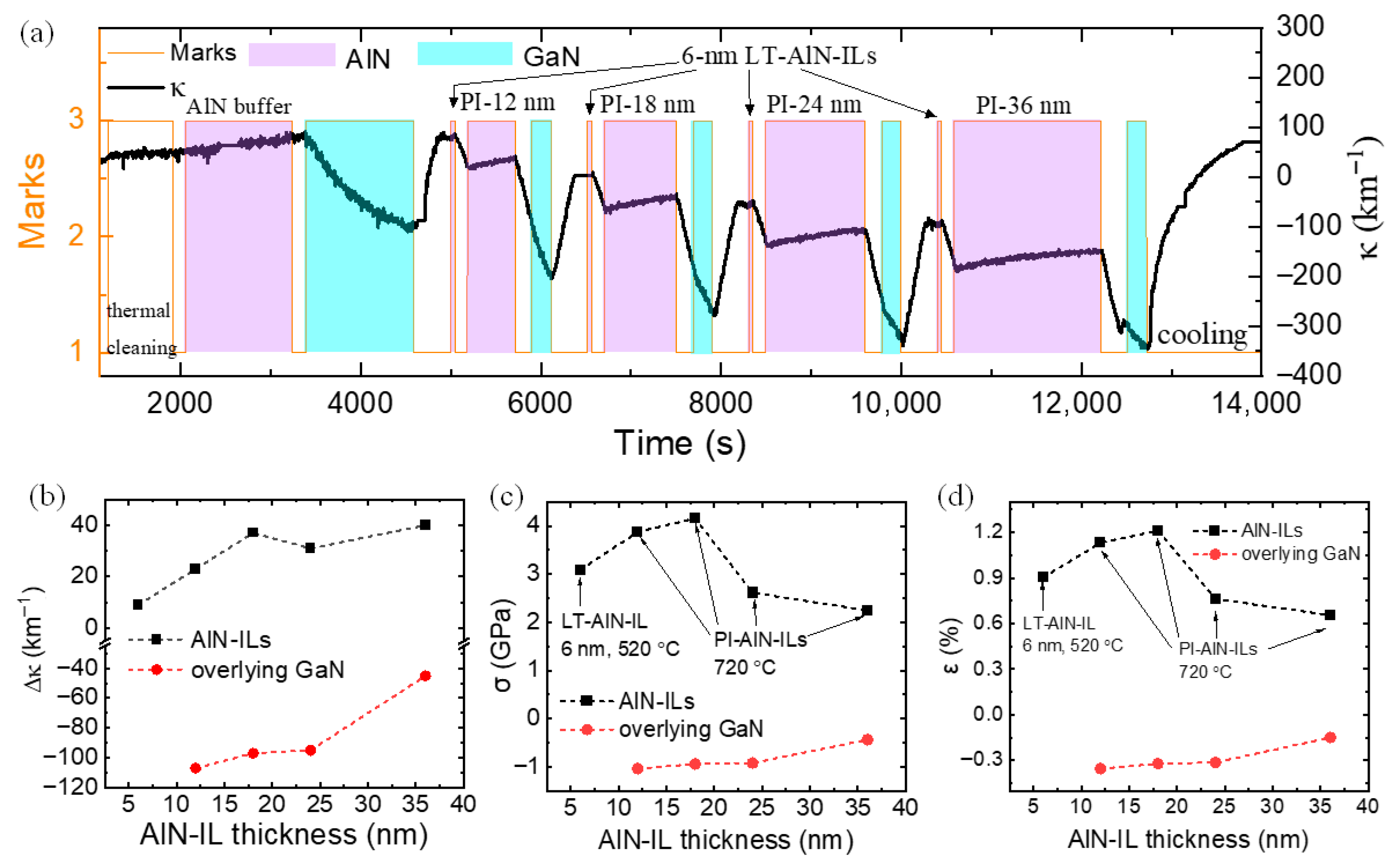

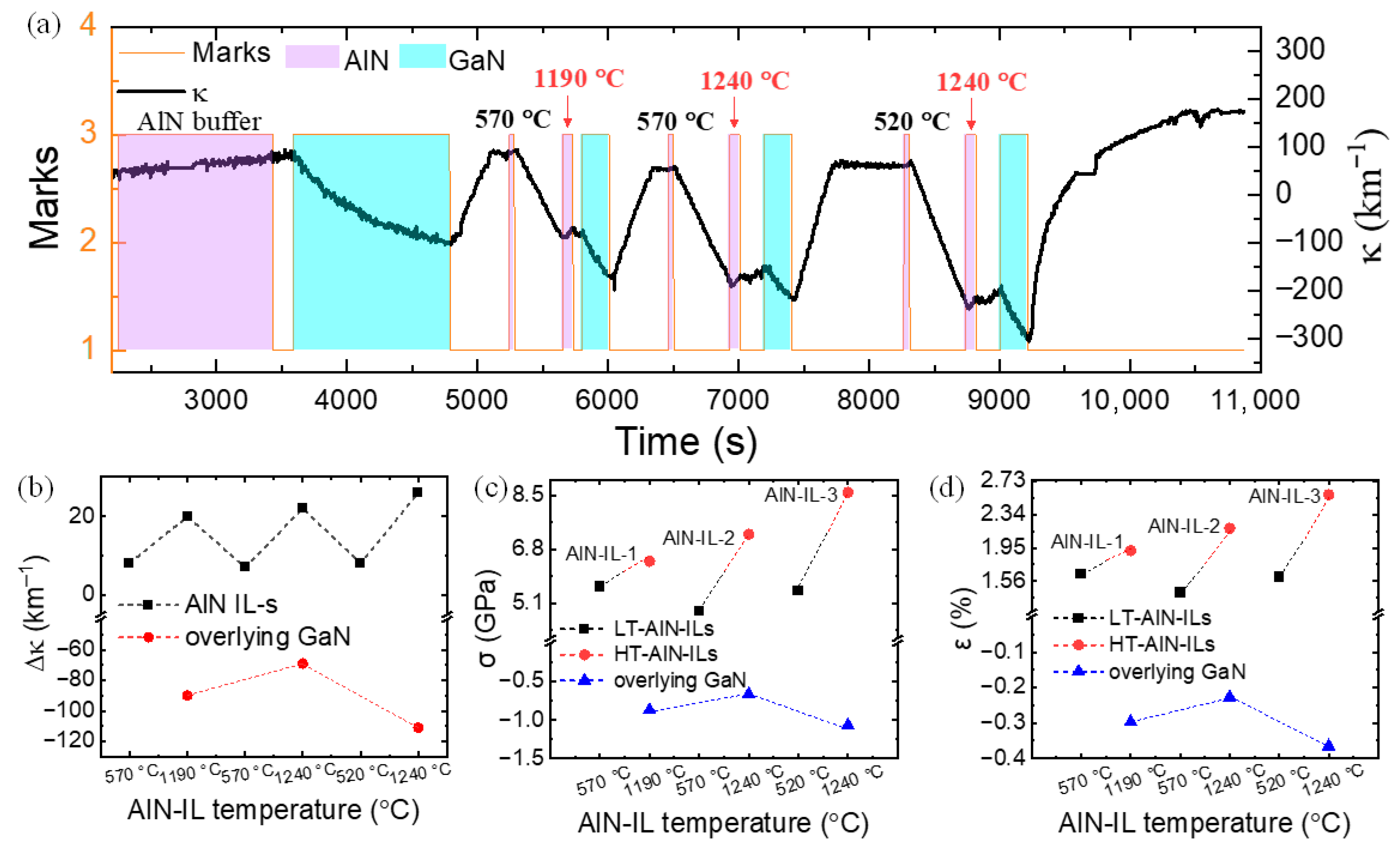

2.1. Pulsed-Injection Precursor Supply Method Grown AlN Interlayers

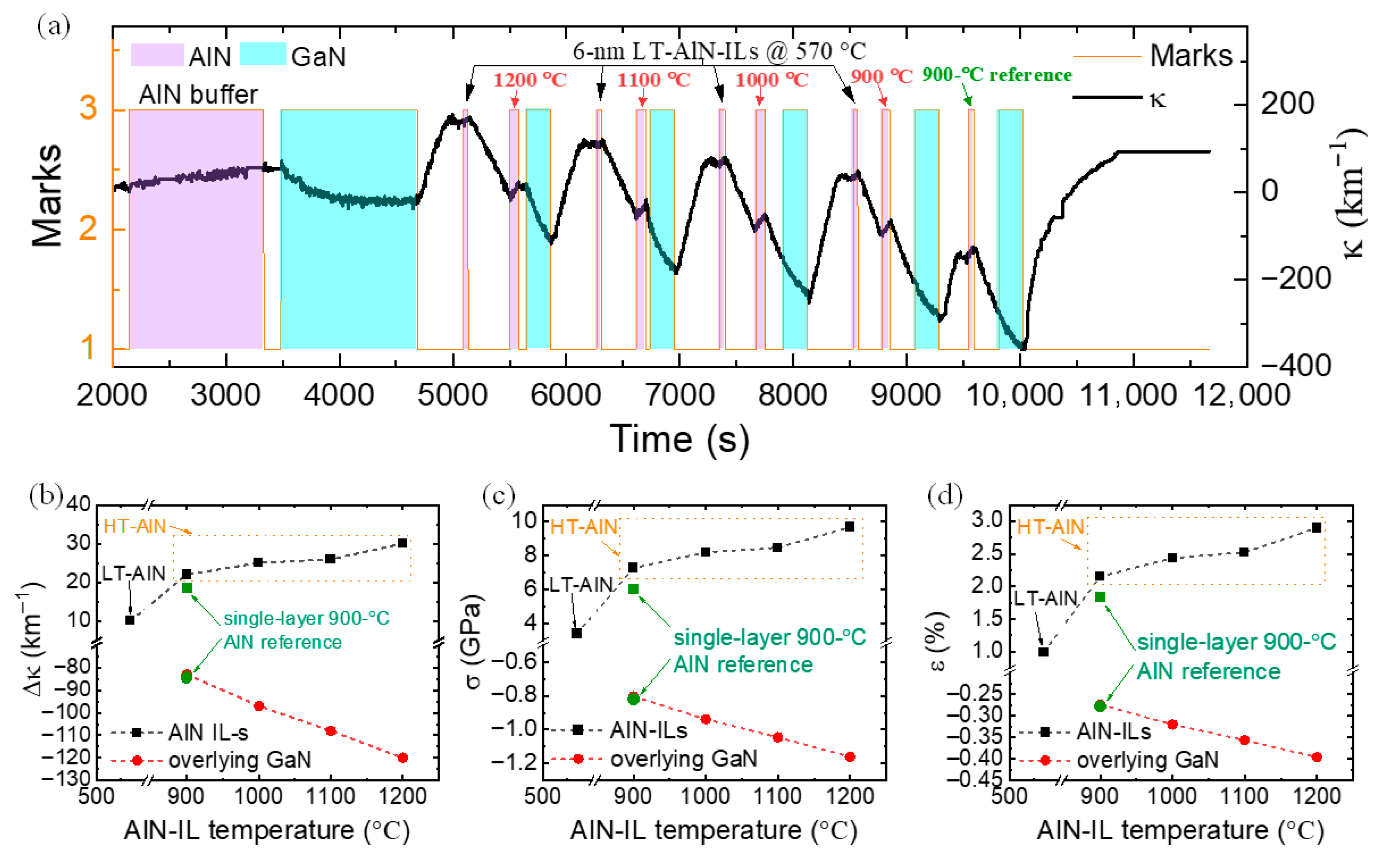

2.2. LT-AlN/Pulsed-Injection AlN Interlayers

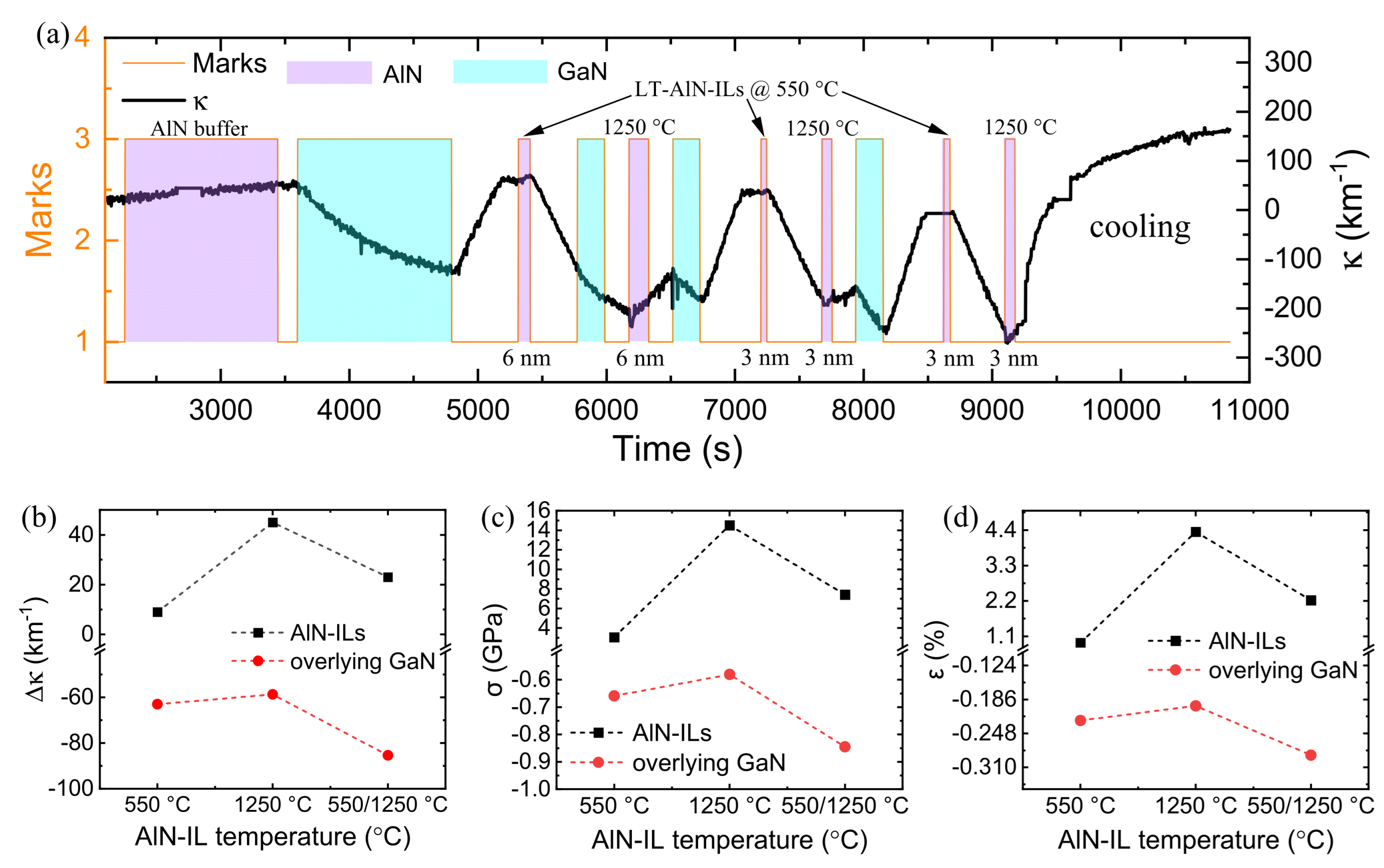

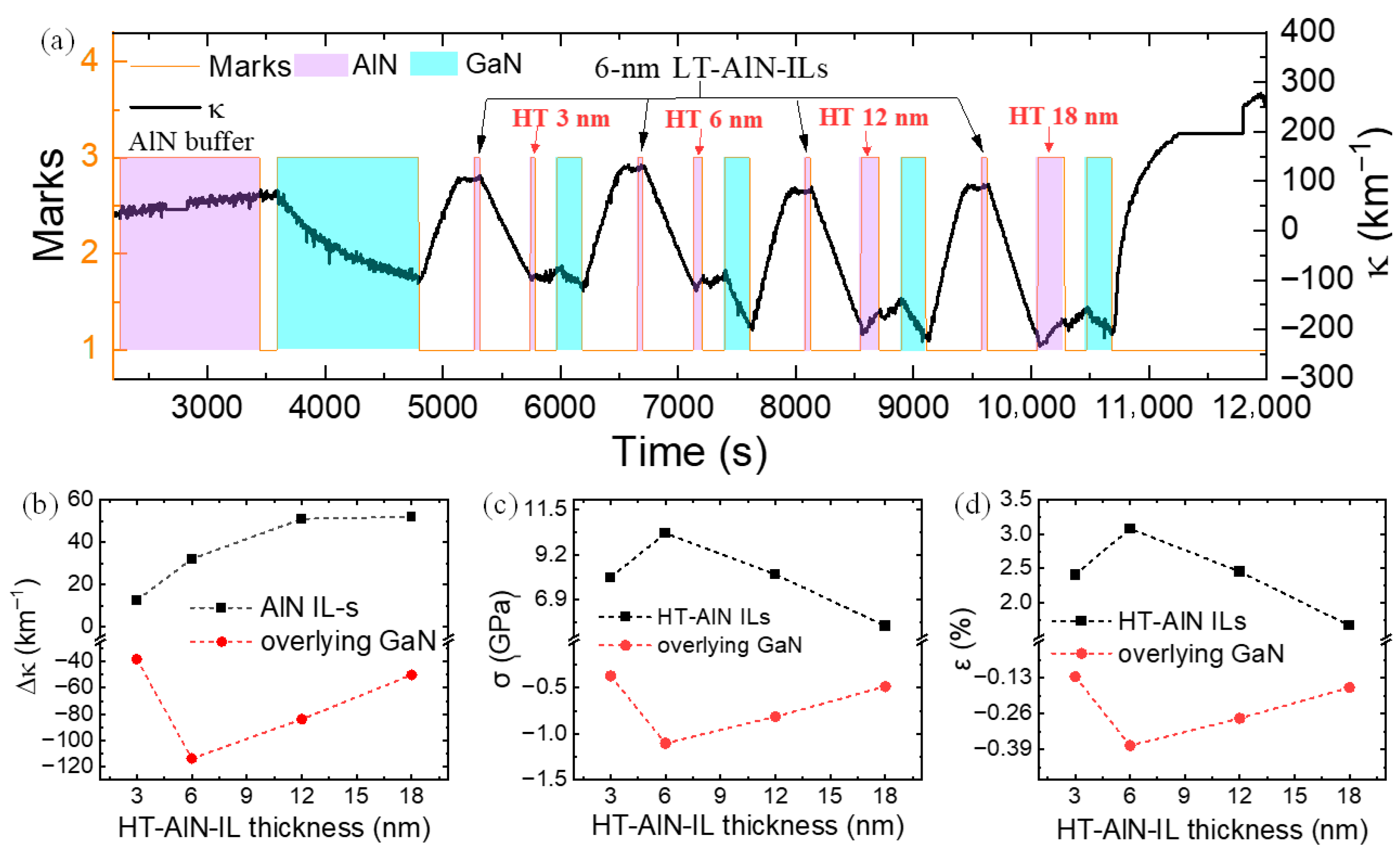

2.3. LT/HT-AlN Interlayers

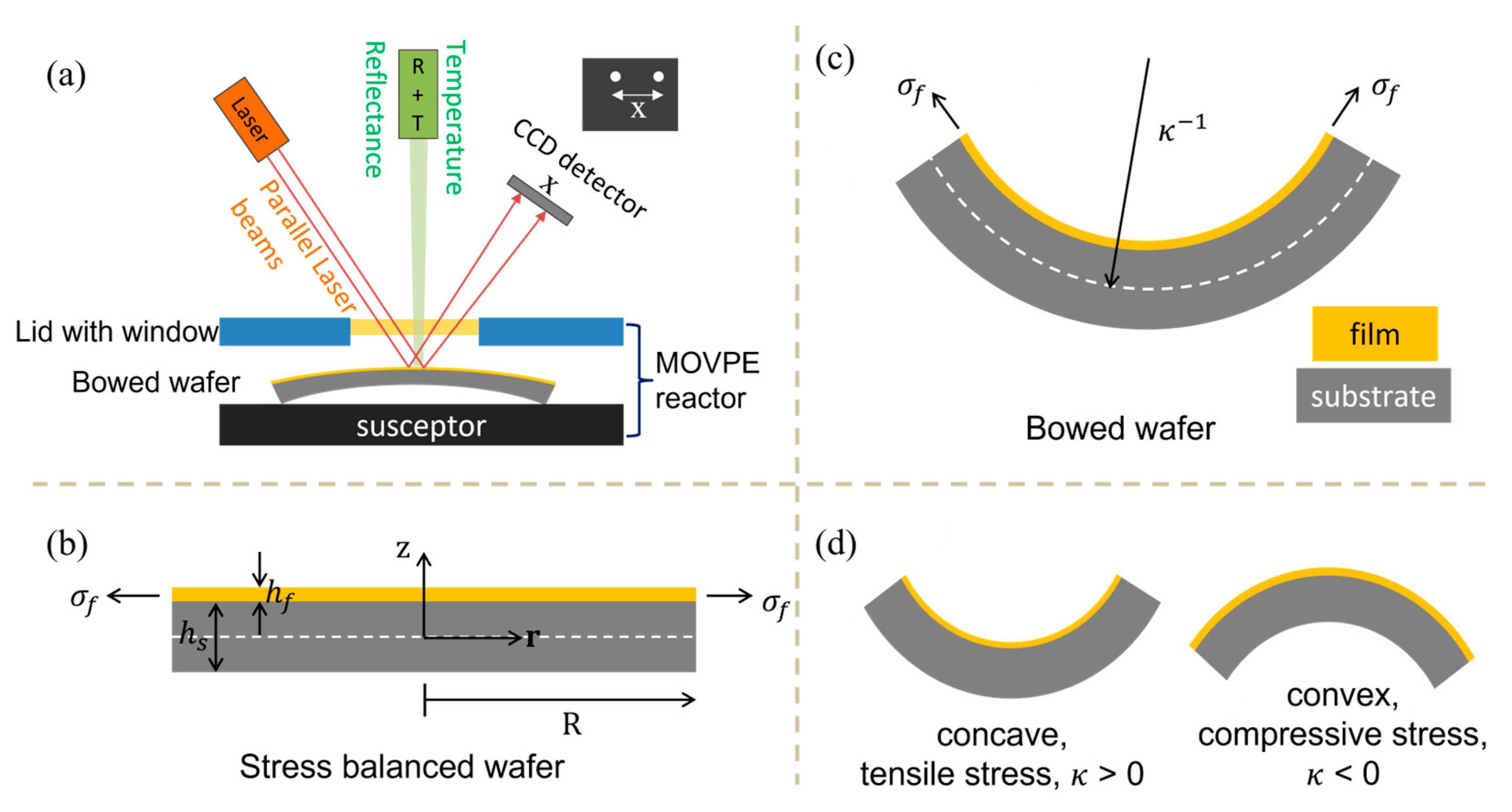

3. Materials and Methods

4. Conclusions

- (1)

- A single-layer AlN interlayer grown by using the precursor pulsed-injection supply technique (PI-AlN-IL).

- (2)

- A composite interlayer consisting of an underlying low-temperature AlN (LT-AlN) and upper PI-AlN-IL, which was noted as LT-/PI-AlN-IL.

- (3)

- A composite interlayer formed by an underlying LT-AlN and an overlying HT-AlN (LT-/HT-AlN-IL).

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GaN | Gallium nitride |

| AlN | Aluminum nitride |

| MOVPE | Metal-organic vapor phase epitaxy |

| PI | Pulsed injection |

| LT | Low temperature |

| HT | High temperature |

| IL | Interlayer |

| HEMT | High-electron-mobility transistor |

| LED | Light-emitting diode |

| CMOS | Complementary Metal–Oxide Semiconductor |

| SiC | Silicon Carbide |

References

- Wu, N.; Xing, Z.; Li, S.; Luo, L.; Zeng, F.; Li, G. GaN-based power high-electron-mobility transistors on Si substrates: From materials to devices. Semicond. Sci. Technol. 2023, 38, 063002. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhang, J.; Wu, S.; Jia, L.; Yang, X.; Liu, Y.; Zhang, Y.; Sun, Q. A review on the GaN-on-Si power electronic devices. Fundam. Res. 2022, 2, 462–475. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, C.; Zhu, M.; Zhang, Y.; Zou, X. A review on GaN-based two-terminal devices grown on Si substrates. J. Alloys Compd. 2021, 869, 159214. [Google Scholar] [CrossRef]

- Morimoto, Y.; Uchiho, K.; Ushio, S. Vapor Phase Epitaxial Growth of GaN on GaAs, GaP, Si, and Sapphire Substrates from GaBr3 and NH3. J. Electrochem. Soc. 1973, 120, 1783. [Google Scholar] [CrossRef]

- Semond, F.; Damilano, B.; Vézian, S.; Grandjean, N.; Leroux, M.; Massies, J. GaN grown on Si(111) substrate: From two-dimensional growth to quantum well assessment. Appl. Phys. Lett. 1999, 75, 82–84. [Google Scholar] [CrossRef]

- Bläsing, J.; Reiher, A.; Dadgar, A.; Diez, A.; Krost, A. The origin of stress reduction by low-temperature AlN interlayers. Appl. Phys. Lett. 2002, 81, 2722–2724. [Google Scholar] [CrossRef]

- Zhang, Z.-Z.; Yang, J.; Zhao, D.-G.; Liang, F.; Chen, P.; Liu, Z.-S. Influence of the lattice parameter of the AlN buffer layer on the stress state of GaN film grown on (111) Si. Chin. Phys. B 2023, 32, 028101. [Google Scholar] [CrossRef]

- Deura, M.; Nakahara, T.; Lee, W.C.; Momose, T.; Nakano, Y.; Sugiyama, M.; Shimogaki, Y. Effect of layer structure of AlN interlayer on the strain in GaN layers during metal-organic vapor phase epitaxy on Si substrates. J. Appl. Phys. 2023, 133, 165301. [Google Scholar] [CrossRef]

- Lin, P.-J.; Tien, C.-H.; Wang, T.-Y.; Chen, C.-L.; Ou, S.-L.; Chung, B.-C.; Wuu, D.-S. On the Role of AlN Insertion Layer in Stress Control of GaN on 150-mm Si (111) Substrate. Crystals 2017, 7, 134. [Google Scholar] [CrossRef]

- Hisyam, M.I.; Shuhaimi, A.; Norhaniza, R.; Mansor, M.; Williams, A.; Hussin, M.R.M. Study of AlN Epitaxial Growth on Si (111) Substrate Using Pulsed Metal–Organic Chemical Vapour Deposition. Crystals 2024, 14, 371. [Google Scholar] [CrossRef]

- Wośko, M.; Szymański, T.; Paszkiewicz, B.; Pokryszka, P.; Paszkiewicz, R. MOVPE growth conditions optimization for AlGaN/GaN/Si heterostructures with SiN and LT-AlN interlayers designed for HEMT applications. J. Mater. Sci. Mater. Electron. 2019, 30, 4111–4116. [Google Scholar] [CrossRef]

- Amano, H.; Iwaya, M.; Hayashi, N.; Kashima, T.; Nitta, S.; Wetzel, C.; Akasaki, I. Control of Dislocations and Stress in AlGaN on Sapphire Using a Low Temperature Interlayer. Phys. Status Solidi 1999, 216, 683–689. [Google Scholar] [CrossRef]

- Lin, Y.; Yang, M.; Wang, W.; Lin, Z.; Li, G. A low-temperature AlN interlayer to improve the quality of GaN epitaxial films grown on Si substrates. CrystEngComm 2016, 18, 8926–8932. [Google Scholar] [CrossRef]

- Luo, W.; Wang, X.; Guo, L.; Xiao, H.; Wang, C.; Ran, J.; Li, J.; Li, J. The effect of low temperature AlN interlayers on the growth of GaN epilayer on Si (111) by MOCVD. Superlattices Microstruct. 2008, 44, 153–159. [Google Scholar] [CrossRef]

- Zheng, W.; Guo, D.; Yuan, Y. Ultra-wide-bandgap semiconductors: Opportunities and challenges. Eur. Phys. J. Spéc. Top. 2025, 234, 225–230. [Google Scholar] [CrossRef]

- Jiang, Q.; Lewins, C.J.; Allsopp, D.W.E.; Bowen, C.R.; Wang, W.N.; Satka, A.; Priesol, J.; Uherek, F. Enhanced Photoluminescence from InGaN/GaN Quantum Wells on A GaN/Si(111) Template with Extended Three-Dimensional GaN Growth on Low-Temperature AlN Interlayer. Jpn. J. Appl. Phys. 2013, 52, 061002. [Google Scholar] [CrossRef]

- Liu, W.; Wang, J.F.; Zhu, J.J.; Jiang, D.S.; Yang, H. Influence of AlN thickness on strain evolution of GaN layer grown on high-temperature AlN interlayer. J. Phys. D Appl. Phys. 2007, 40, 5252. [Google Scholar] [CrossRef]

- Liu, C.; Kumamoto, A.; Suzuki, M.; Wang, H.; Sodabanlu, H.; Sugiyama, M.; Nakano, Y. Effects of hydrogen etching on stress control in AlN interlayer inserted GaN MOVPE on Si. Semicond. Sci. Technol. 2017, 32, 075003. [Google Scholar] [CrossRef]

- Shen, X.Q.; Takahashi, T.; Ide, T.; Shimizu, M. Strain states in GaN films grown on Si(111) and Si(110) substrates using a thin AlN/GaN superlattice interlayer. Phys. Status Solidi 2014, 11, 473–476. [Google Scholar] [CrossRef]

- Shen, X.Q.; Takahashi, T.; Kawashima, H.; Ide, T.; Shimizu, M. Realization of compressively strained GaN films grown on Si(110) substrates by inserting a thin AlN/GaN superlattice interlayer. Appl. Phys. Lett. 2012, 101, 031912. [Google Scholar] [CrossRef]

- Wang, H.; Liang, H.; Wang, Y.; Ng, K.; Deng, D.; Lau, K. Effects of AlGaN/AlN Stacked Interlayers on GaN Growth on Si (111. Chin. Phys. Lett. 2010, 27, 038103. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, C.; Lin, J.; Jia, C.; Li, G. Threading dislocations reduction of GaN-on-Si by introducing AlN/3D-GaN with SiN interlayer for photodetectors. Mater. Sci. Semicond. Process. 2024, 172, 108089. [Google Scholar] [CrossRef]

- Liu, C.; Akihito, K.; Sodabanlu, H.; Ning, C.-Z.; Sugiyama, M.; Nakano, Y. Evolution of Crystal Quality and Stress in MOVPE GaN-on-Si (111) induced by AlN interlayers. Vacuum 2025, Submitted. [Google Scholar]

- Dadgar, A.; Krost, A.; Christen, J.; Bastek, B.; Bertram, F.; Krtschil, A.; Hempel, T.; Bläsing, J.; Haboeck, U.; Hoffmann, A. MOVPE growth of high-quality AlN. J. Cryst. Growth 2006, 297, 306–310. [Google Scholar] [CrossRef]

- Yang, J.-S.; Sodabanlu, H.; Waki, I.; Sugiyama, M.; Nakano, Y.; Shimogaki, Y. Process design of the pulse injection method for low-temperature metal organic vapor phase epitaxial growth of AlN at 800 °C. J. Cryst. Growth 2009, 311, 383–388. [Google Scholar] [CrossRef]

- Kröncke, H.; Figge, S.; Aschenbrenner, T.; Hommel, D. Growth of AlN by pulsed and conventional MOVPE. J. Cryst. Growth 2013, 381, 100–106. [Google Scholar] [CrossRef]

- Sanchez, A.M.; Pacheco, F.J.; Molina, S.I.; Stemmer, J.; Aderhold, J.; Graul, J. Critical thickness of high-temperature AIN interlayers in GaN on sapphire (0001). J. Electron. Mater. 2001, 30, L17–L20. [Google Scholar] [CrossRef]

- Shen, X.Q.; Takahashi, T.; Ide, T.; Shimizu, M. Mechanisms of the micro-crack generation in an ultra-thin AlN/GaN superlattice structure grown on Si(110) substrates by metalorganic chemical vapor deposition. J. Appl. Phys. 2015, 118, 125307. [Google Scholar] [CrossRef]

- Feng, Y.; Wei, H.; Yang, S.; Chen, Z.; Wang, L.; Kong, S.; Zhao, G.; Liu, X. Competitive growth mechanisms of AlN on Si (111) by MOVPE. Sci. Rep. 2014, 4, 6416. [Google Scholar] [CrossRef]

- Stoney, G.G. The tension of metallic films deposited by electrolysis. Proc. R. Soc. London Ser. A Contain. Pap. A Math. Phys. Character 1909, 82, 172–175. [Google Scholar] [CrossRef]

| Interlayer Types | V/III Ratio | Temperature (°C) | Thickness (nm) |

|---|---|---|---|

| Conventional AlN-IL | 1503 | 900 | ~9 |

| S1: PI-AlN-ILs (sample A) | - | 720 | 3/6/9/12/25/37/conventional-AlN-IL (from bottom to top) |

| S2: LT-/PI-AlN ILs (sample B) | 1503 | LT-AlN: 520 PI-AlN: 720 | LT-AlN: 6 PI-AlN: 12/18/24/36 |

| S3: LT-/HT-AlN ILs (samples C–F) | 1503 | LT-AlN: 520, 570 (sample C-F) HT-AlN:

| LT-AlN: 6 HT-AlN: 3/6/12/18 (sample F) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Li, G.; Sodabanlu, H.; Sugiyama, M.; Nakano, Y. Prototypes of Highly Effective Stress Balancing AlN Interlayers in MOVPE GaN-on-Si (111). Inorganics 2025, 13, 302. https://doi.org/10.3390/inorganics13090302

Liu C, Li G, Sodabanlu H, Sugiyama M, Nakano Y. Prototypes of Highly Effective Stress Balancing AlN Interlayers in MOVPE GaN-on-Si (111). Inorganics. 2025; 13(9):302. https://doi.org/10.3390/inorganics13090302

Chicago/Turabian StyleLiu, Cai, Gaomin Li, Hassanet Sodabanlu, Masakazu Sugiyama, and Yoshiaki Nakano. 2025. "Prototypes of Highly Effective Stress Balancing AlN Interlayers in MOVPE GaN-on-Si (111)" Inorganics 13, no. 9: 302. https://doi.org/10.3390/inorganics13090302

APA StyleLiu, C., Li, G., Sodabanlu, H., Sugiyama, M., & Nakano, Y. (2025). Prototypes of Highly Effective Stress Balancing AlN Interlayers in MOVPE GaN-on-Si (111). Inorganics, 13(9), 302. https://doi.org/10.3390/inorganics13090302