Development of Catalysts for the Electrochemical CO2 Reduction Reaction

Abstract

1. Introduction

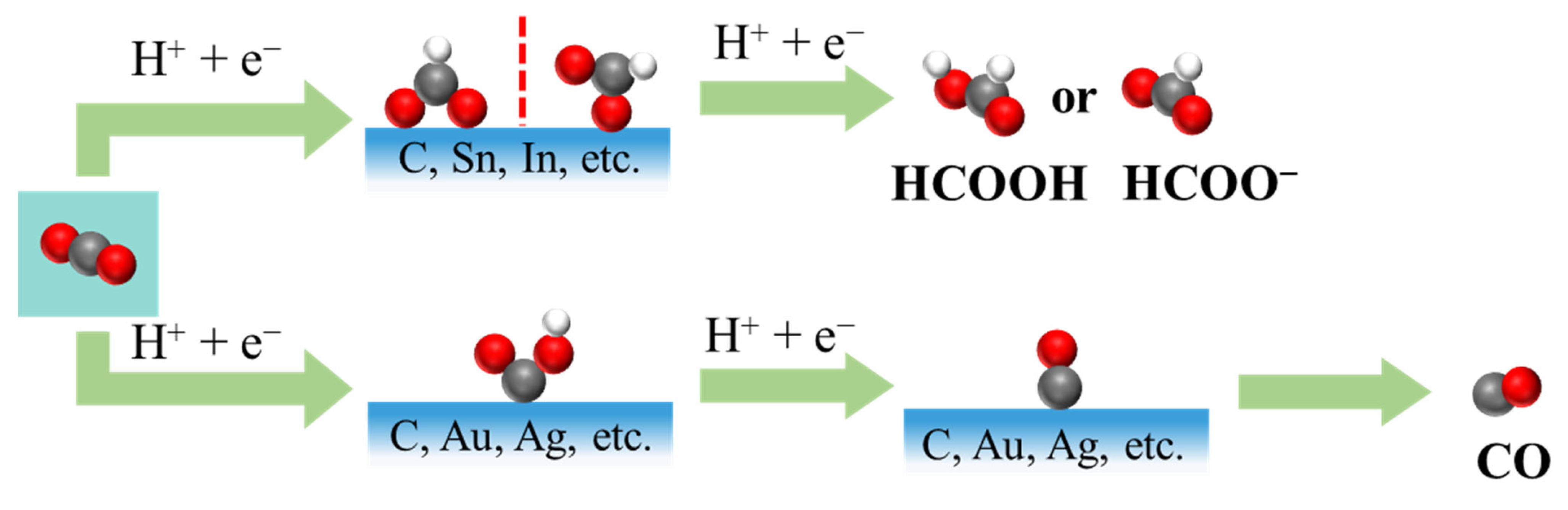

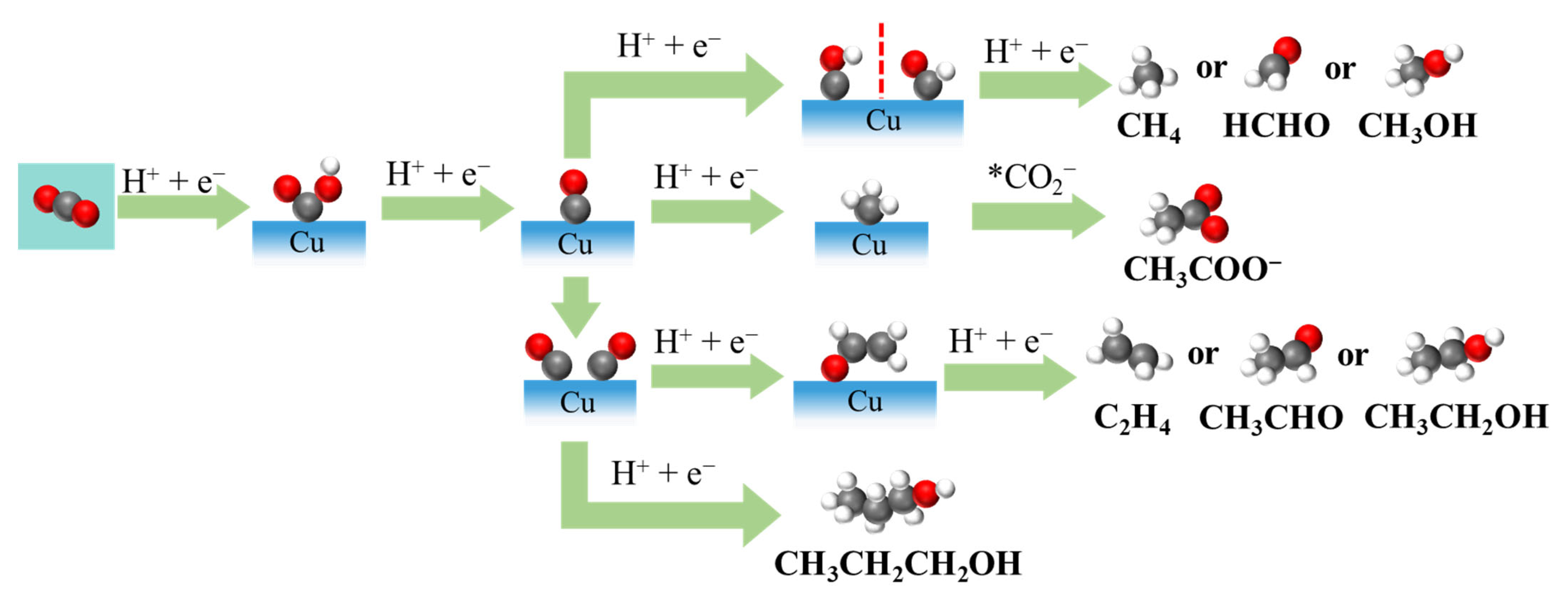

2. Mechanisms of the Electrochemical CO2 Reduction Reaction (eCO2RR)

2.1. Reaction Pathways

2.2. Crucial Performance Indicators

2.3. Key Influence Factors

2.4. In Situ Characterization Techniques

3. C1-Producing Electrocatalysts

3.1. Metal-Based Electrocatalysts

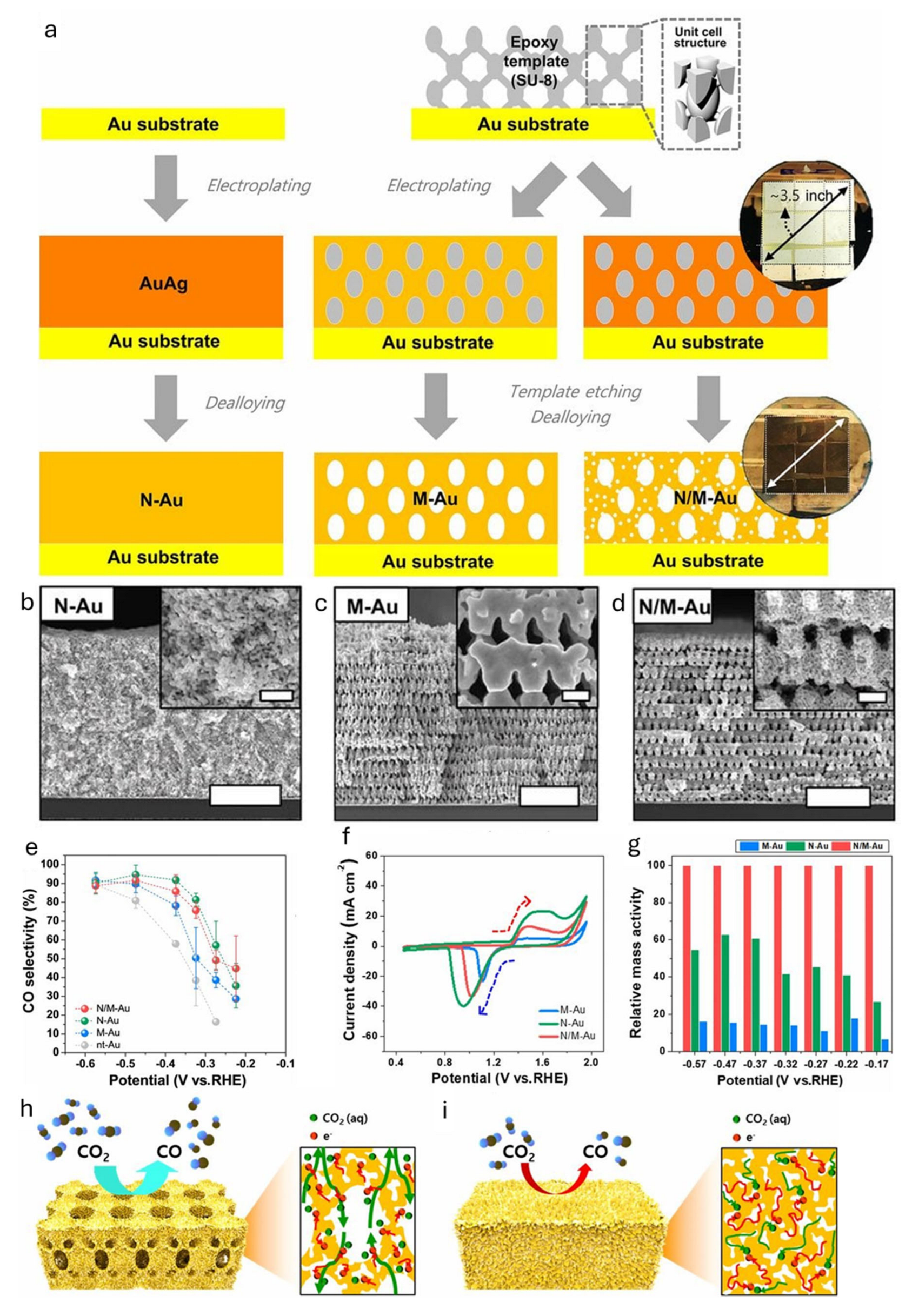

3.1.1. CO-Producing Metals

3.1.2. Formate-Producing Metals

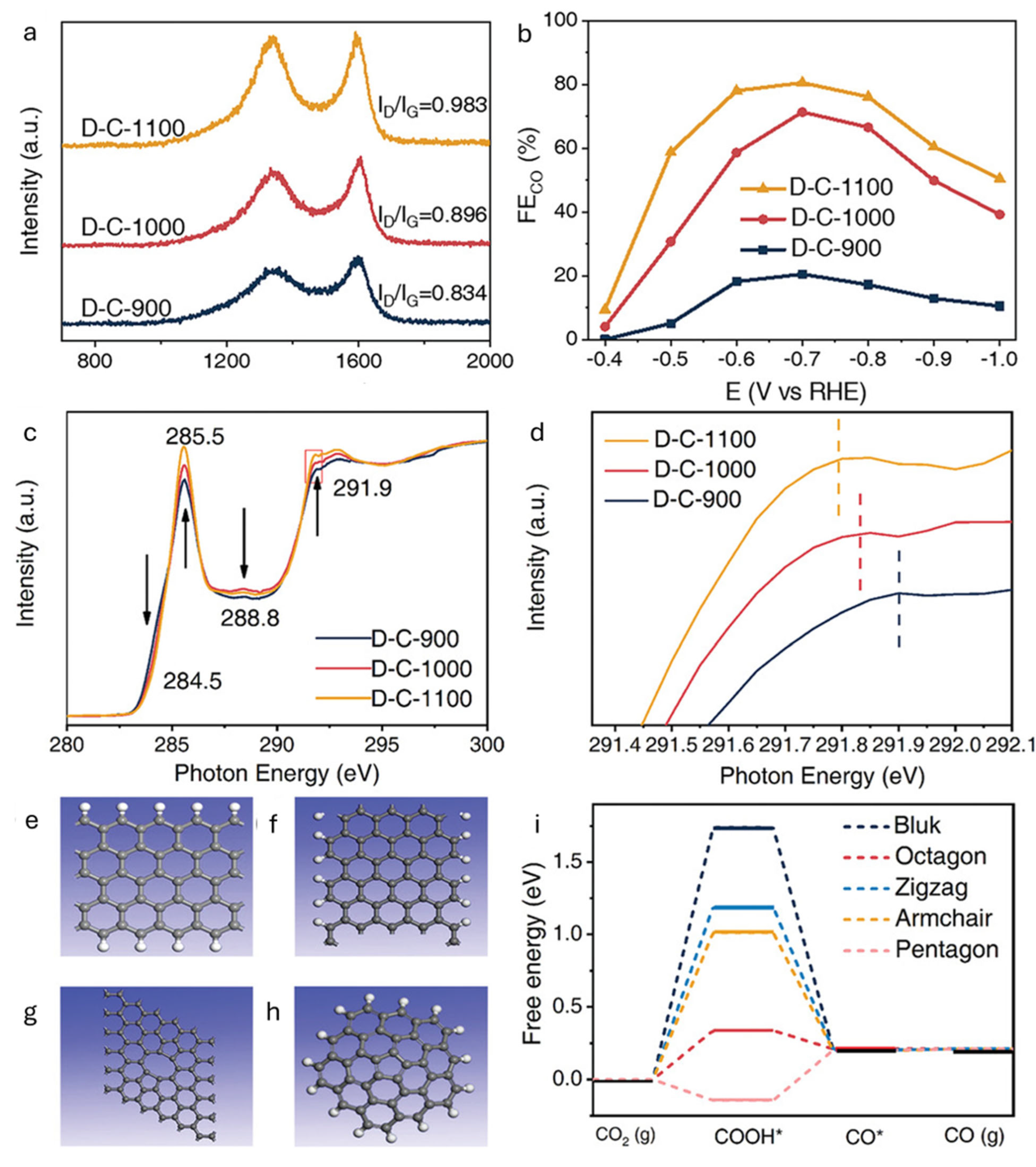

3.2. Metal-Free Electrocatalysts

3.2.1. Defect-Decorated Carbon Catalysts

3.2.2. Heteroatom-Doped Carbon Catalysts

4. C2+-Producing Electrocatalysts

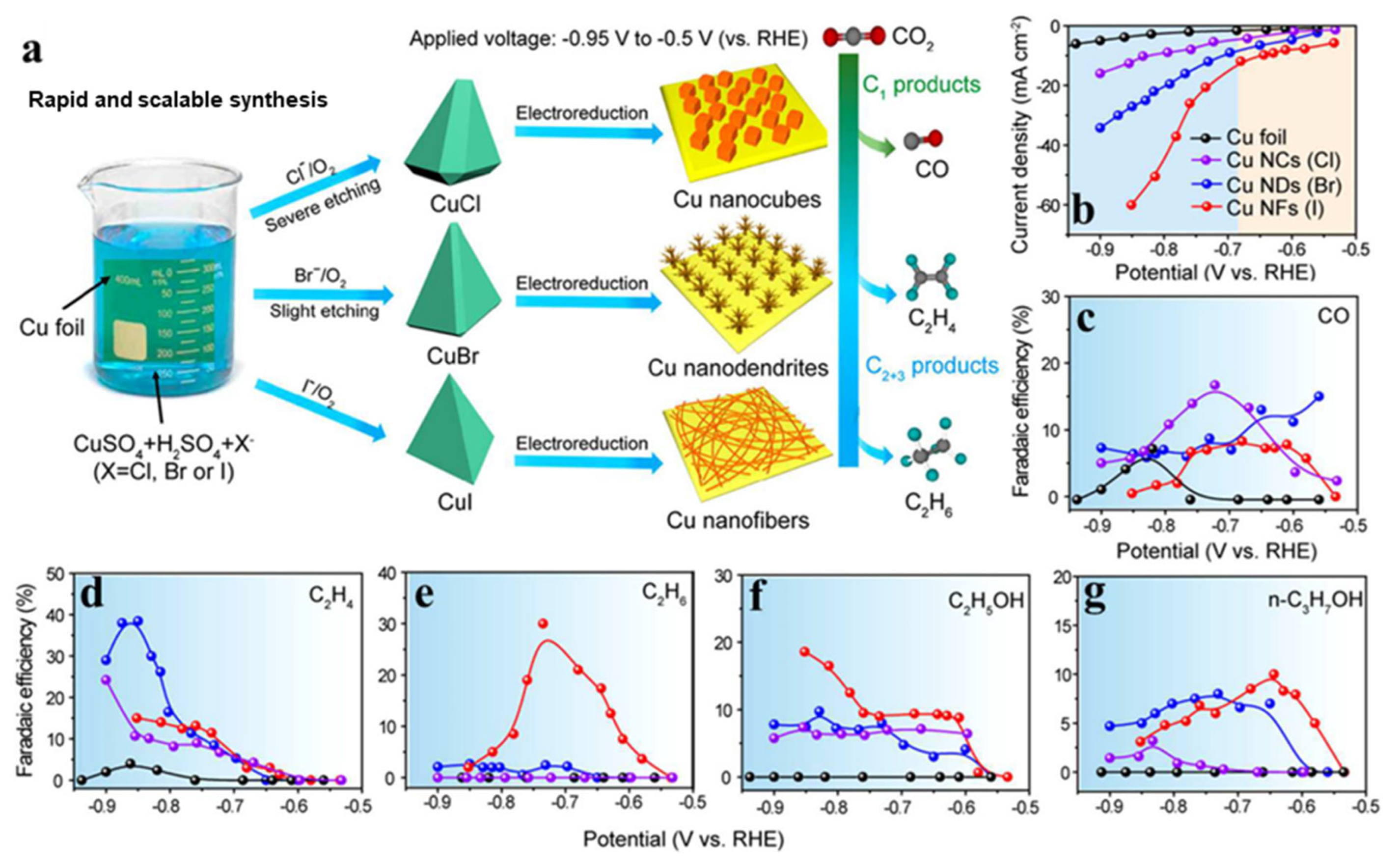

4.1. Metallic Cu and Cu-Derived Catalysts

4.2. Cu-Based Alloys and Composition-Tuned Catalysts

4.3. Cu Oxide-Derived Catalysts

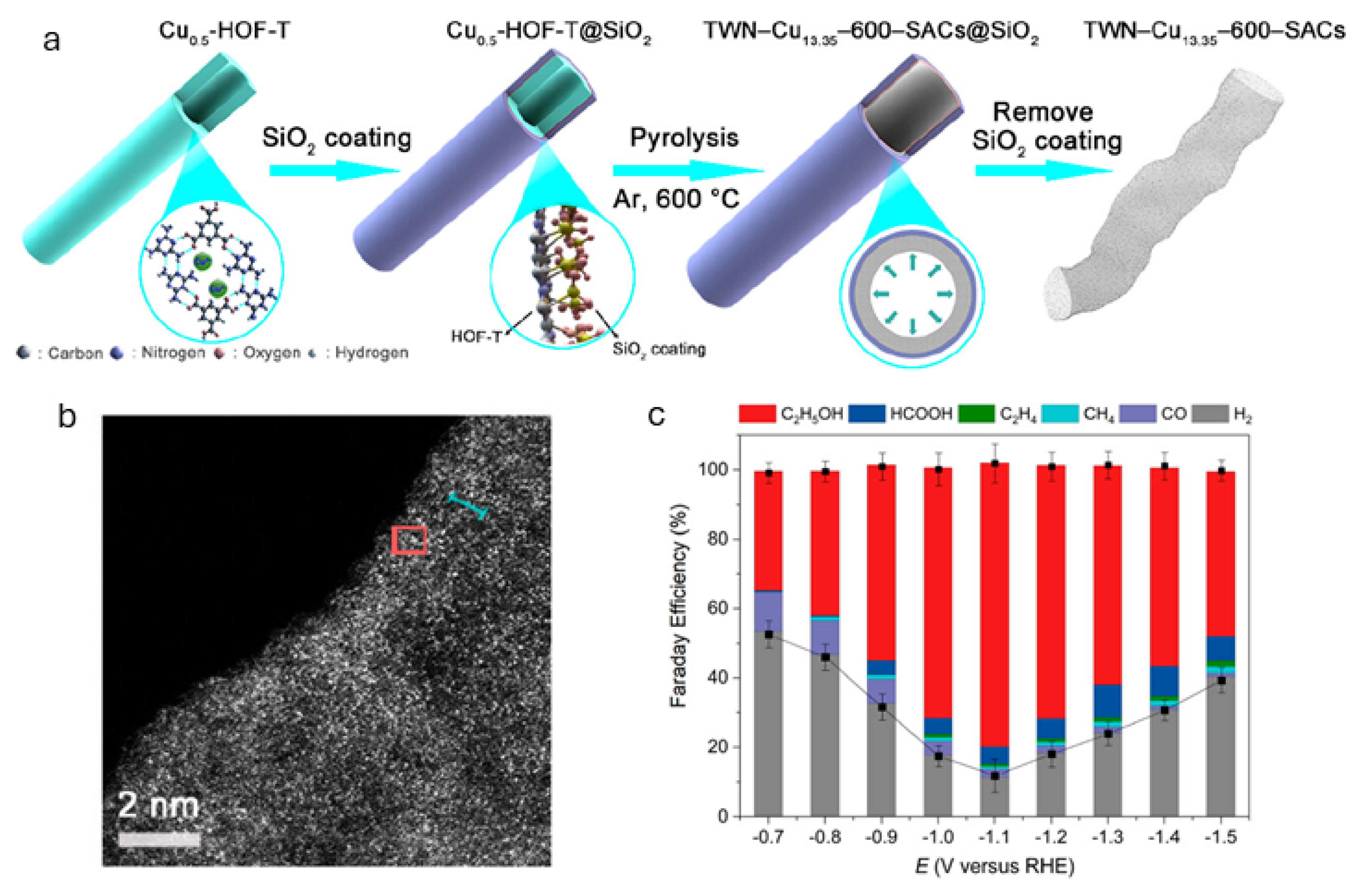

4.4. Single-Atom Cu Catalysts

5. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, J.; Huang, Y.; Ye, W.; Li, Y. CO2 Reduction: From the Electrochemical to Photochemical Approach. Adv. Sci. 2017, 4, 1700194. [Google Scholar] [CrossRef] [PubMed]

- Bagger, A.; Ju, W.; Varela, A.S.; Strasser, P.; Rossmeisl, J. Electrochemical CO2 Reduction: A Classification Problem. ChemPhysChem 2017, 18, 3266–3273. [Google Scholar] [CrossRef] [PubMed]

- Ran, J.; Jaroniec, M.; Qiao, S.-Z. Cocatalysts in Semiconductor-based Photocatalytic CO2 Reduction: Achievements, Challenges, and Opportunities. Adv. Mater. 2018, 30, 1704649. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Fan, Q.; Xia, R.; Meyer, T.J. CO2 Reduction: From Homogeneous to Heterogeneous Electrocatalysis. Acc. Chem. Res. 2020, 53, 255–264. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, Z.-J.; Gong, J. Nanostructured Materials for Heterogeneous Electrocatalytic CO2 Reduction and their Related Reaction Mechanisms. Angew. Chem. Int. Ed. 2017, 56, 11326–11353. [Google Scholar] [CrossRef]

- Zhang, Y.-J.; Sethuraman, V.; Michalsky, R.; Peterson, A.A. Competition between CO2 Reduction and H2 Evolution on Transition-Metal Electrocatalysts. ACS Catal. 2014, 4, 3742–3748. [Google Scholar] [CrossRef]

- Lu, Q.; Jiao, F. Electrochemical CO2 reduction: Electrocatalyst, reaction mechanism, and process engineering. Nano Energy 2016, 29, 439–456. [Google Scholar] [CrossRef]

- Weekes, D.M.; Salvatore, D.A.; Reyes, A.; Huang, A.; Berlinguette, C.P. Electrolytic CO2 Reduction in a Flow Cell. Acc. Chem. Res. 2018, 51, 910–918. [Google Scholar] [CrossRef]

- Nam, D.-H.; De Luna, P.; Rosas-Hernández, A.; Thevenon, A.; Li, F.; Agapie, T.; Peters, J.C.; Shekhah, O.; Eddaoudi, M.; Sargent, E.H. Molecular enhancement of heterogeneous CO2 reduction. Nat. Mater. 2020, 19, 266–276. [Google Scholar] [CrossRef]

- He, J.; Johnson, N.J.J.; Huang, A.; Berlinguette, C.P. Electrocatalytic Alloys for CO2 Reduction. ChemSusChem 2018, 11, 48–57. [Google Scholar] [CrossRef]

- Raciti, D.; Wang, C. Recent Advances in CO2 Reduction Electrocatalysis on Copper. ACS Energy Lett. 2018, 3, 1545–1556. [Google Scholar] [CrossRef]

- Garza, A.J.; Bell, A.T.; Head-Gordon, M. Mechanism of CO2 Reduction at Copper Surfaces: Pathways to C2 Products. ACS Catal. 2018, 8, 1490–1499. [Google Scholar] [CrossRef]

- Todorova, T.K.; Schreiber, M.W.; Fontecave, M. Mechanistic Understanding of CO2 Reduction Reaction (CO2RR) Toward Multicarbon Products by Heterogeneous Copper-Based Catalysts. ACS Catal. 2020, 10, 1754–1768. [Google Scholar] [CrossRef]

- Li, X.; Wang, S.; Li, L.; Sun, Y.; Xie, Y. Progress and Perspective for In Situ Studies of CO2 Reduction. J. Am. Chem. Soc. 2020, 142, 9567–9581. [Google Scholar] [CrossRef]

- Hori, Y.; Wakebe, H.; Tsukamoto, T.; Koga, O. Electrocatalytic process of CO selectivity in electrochemical reduction of CO2 at metal electrodes in aqueous media. Electrochim. Acta 1994, 39, 1833–1839. [Google Scholar] [CrossRef]

- Hori, Y. Electrochemical CO2 Reduction on Metal Electrodes. In Modern Aspects of Electrochemistry; Vayenas, C.G., White, R.E., Gamboa-Aldeco, M.E., Eds.; Springer: New York, NY, USA, 2008; pp. 89–189. [Google Scholar]

- Yu, M.; Sui, P.-F.; Fu, X.-Z.; Luo, J.-L.; Liu, S. Specific Metal Nanostructures toward Electrochemical CO2 Reduction: Recent Advances and Perspectives. Adv. Energy Mater. 2023, 13, 2203191. [Google Scholar] [CrossRef]

- Vijay, S.; Ju, W.; Brückner, S.; Tsang, S.-C.; Strasser, P.; Chan, K. Unified mechanistic understanding of CO2 reduction to CO on transition metal and single atom catalysts. Nat. Catal. 2021, 4, 1024–1031. [Google Scholar] [CrossRef]

- Han, N.; Ding, P.; He, L.; Li, Y.; Li, Y. Promises of Main Group Metal-Based Nanostructured Materials for Electrochemical CO2 Reduction to Formate. Adv. Energy Mater. 2020, 10, 1902338. [Google Scholar] [CrossRef]

- Dutta, N.; Bagchi, D.; Chawla, G.; Peter, S.C. A Guideline to Determine Faradaic Efficiency in Electrochemical CO2 Reduction. ACS Energy Lett. 2024, 9, 323–328. [Google Scholar] [CrossRef]

- Zheng, T.; Jiang, K.; Wang, H. Recent Advances in Electrochemical CO2-to-CO Conversion on Heterogeneous Catalysts. Adv. Mater. 2018, 30, 1802066. [Google Scholar] [CrossRef]

- Tao, Z.; Pearce, A.J.; Mayer, J.M.; Wang, H. Bridge Sites of Au Surfaces Are Active for Electrocatalytic CO2 Reduction. J. Am. Chem. Soc. 2022, 144, 8641–8648. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Song, J.T.; Ryoo, H.; Kim, J.-G.; Chung, S.-Y.; Oh, J. Morphology-controlled Au nanostructures for efficient and selective electrochemical CO2 reduction. J. Mater. Chem. A 2018, 6, 5119–5128. [Google Scholar] [CrossRef]

- Hyun, G.; Song, J.T.; Ahn, C.; Ham, Y.; Cho, D.; Oh, J.; Jeon, S. Hierarchically porous Au nanostructures with interconnected channels for efficient mass transport in electrocatalytic CO2 reduction. Proc. Natl. Acad. Sci. USA 2020, 117, 5680–5685. [Google Scholar] [CrossRef] [PubMed]

- Kang, M.P.L.; Kolb, M.J.; Calle-Vallejo, F.; Yeo, B.S. The Role of Undercoordinated Sites on Zinc Electrodes for CO2 Reduction to CO. Adv. Funct. Mater. 2022, 32, 2111597. [Google Scholar] [CrossRef]

- Wang, W.-H.; Himeda, Y.; Muckerman, J.T.; Manbeck, G.F.; Fujita, E. CO2 Hydrogenation to Formate and Methanol as an Alternative to Photo- and Electrochemical CO2 Reduction. Chem. Rev. 2015, 115, 12936–12973. [Google Scholar] [CrossRef]

- Zhang, S.; Kang, P.; Meyer, T.J. Nanostructured Tin Catalysts for Selective Electrochemical Reduction of Carbon Dioxide to Formate. J. Am. Chem. Soc. 2014, 136, 1734–1737. [Google Scholar] [CrossRef]

- Li, X.; Wu, X.; Li, J.; Huang, J.; Ji, L.; Leng, Z.; Qian, N.; Yang, D.; Zhang, H. Sn-Doped Bi2O3 nanosheets for highly efficient electrochemical CO2 reduction toward formate production. Nanoscale 2021, 13, 19610–19616. [Google Scholar] [CrossRef]

- Zhong, X.; Zhong, Z.; Liang, S.; Zeng, G.; Cheng, S.; Deng, H.; Lin, Z. Towards a broad-operation window for stable CO2 electroreduction to HCOOH by a design involving upcycling electroplating sludge-derived Sn@N/P-doped carbon. Environ. Sci. Nano 2022, 9, 511–522. [Google Scholar] [CrossRef]

- Ma, W.; Xie, S.; Zhang, X.-G.; Sun, F.; Kang, J.; Jiang, Z.; Zhang, Q.; Wu, D.-Y.; Wang, Y. Promoting electrocatalytic CO2 reduction to formate via sulfur-boosting water activation on indium surfaces. Nat. Commun. 2019, 10, 892. [Google Scholar] [CrossRef]

- Xue, D.; Xia, H.; Yan, W.; Zhang, J.; Mu, S. Defect Engineering on Carbon-Based Catalysts for Electrocatalytic CO2 Reduction. Nano-Micro Lett. 2020, 13, 5. [Google Scholar] [CrossRef]

- Zhu, J.; Mu, S. Defect Engineering in Carbon-Based Electrocatalysts: Insight into Intrinsic Carbon Defects. Adv. Funct. Mater. 2020, 30, 2001097. [Google Scholar] [CrossRef]

- Kim, C.; Talapaneni, S.N.; Dai, L. Porous carbon materials for CO2 capture, storage and electrochemical conversion. Mater. Rep. Energy 2023, 3, 100199. [Google Scholar] [CrossRef]

- Zhai, Q.; Huang, H.; Lawson, T.; Xia, Z.; Giusto, P.; Antonietti, M.; Jaroniec, M.; Chhowalla, M.; Baek, J.-B.; Liu, Y.; et al. Recent Advances on Carbon-Based Metal-Free Electrocatalysts for Energy and Chemical Conversions. Adv. Mater. 2024, 36, 2405664. [Google Scholar] [CrossRef] [PubMed]

- Mondal, S.; Mohanty, B.; Nurhuda, M.; Dalapati, S.; Jana, R.; Addicoat, M.; Datta, A.; Jena, B.K.; Bhaumik, A. A Thiadiazole-Based Covalent Organic Framework: A Metal-Free Electrocatalyst toward Oxygen Evolution Reaction. ACS Catal. 2020, 10, 5623–5630. [Google Scholar] [CrossRef]

- Yuan, R.; Dong, Y.; Hou, R.; Shang, L.; Zhang, J.; Zhang, S.; Chen, X.; Song, H. Structural transformation of porous and disordered carbon during ball-milling. Chem. Eng. J. 2023, 454, 140418. [Google Scholar] [CrossRef]

- Argirusis, C.; Alizadeh, N.; Katsanou, M.-Ε.; Argirusis, N.; Sourkouni, G. Advances in Metal-Organic Frameworks (MOFs) for Rechargeable Batteries and Fuel Cells. Batteries 2025, 11, 192. [Google Scholar] [CrossRef]

- Wang, W.; Shang, L.; Chang, G.; Yan, C.; Shi, R.; Zhao, Y.; Waterhouse, G.I.N.; Yang, D.; Zhang, T. Intrinsic Carbon-Defect-Driven Electrocatalytic Reduction of Carbon Dioxide. Adv. Mater. 2019, 31, 1808276. [Google Scholar] [CrossRef]

- Rasool, F.; Pirzada, B.M.; Talib, S.H.; Alkhidir, T.; Anjum, D.H.; Mohamed, S.; Qurashi, A. In Situ Growth of Interfacially Nanoengineered 2D-2D WS2/Ti3C2Tx MXene for the Enhanced Performance of Hydrogen Evolution Reactions. ACS Appl. Mater. Interfaces 2024, 16, 14229–14242. [Google Scholar] [CrossRef]

- Ayyub, M.M.; Rao, C.N.R. Borocarbonitrides As Metal-Free Electrocatalysts for the Electrochemical Reduction of CO2. Chem. Mater. 2022, 34, 6626–6635. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, W.; Ma, C.; Zhang, C.; Li, C.; Hong, Y.; Sun, Y.; Niu, J.; Guo, S.; Yao, S. Nitrogen/Phosphorus/Fluorine Heteroatoms Codoped Carbon Nanotube Networks as Free-Standing Cathode for Rechargeable Li-CO2 Batteries. ACS Appl. Nano Mater. 2025, 8, 1499–1507. [Google Scholar] [CrossRef]

- Jiang, M.; Yu, X.; Yang, H.; Chen, S. Optimization strategies of preparation of biomass-derived carbon electrocatalyst for boosting oxygen reduction reaction: A minireview. Catalysts 2020, 10, 1472. [Google Scholar] [CrossRef]

- Yu, W.; Gu, S.; Fu, Y.; Xiong, S.; Pan, C.; Liu, Y.; Yu, G. Carbazole-decorated covalent triazine frameworks: Novel nonmetal catalysts for carbon dioxide fixation and oxygen reduction reaction. J. Catal. 2018, 362, 1–9. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, Z.; Suo, J.; Liao, L.; Li, L.; Yu, Z.; Zhang, H.; Valtchev, V.; Qiu, S.; Fang, Q. Exploring metal-free ionic covalent organic framework nanosheets as efficient OER electrocatalysts via cationic-π interactions. Chem. Eng. J. 2023, 478, 147403. [Google Scholar] [CrossRef]

- Tan, D.; Zhang, J.; Yao, L.; Tan, X.; Cheng, X.; Wan, Q.; Han, B.; Zheng, L.; Zhang, J. Multi-shelled CuO microboxes for carbon dioxide reduction to ethylene. Nano Res. 2020, 13, 768–774. [Google Scholar] [CrossRef]

- Altaf, N.; Liang, S.; Huang, L.; Wang, Q. Electro-derived Cu-Cu2O nanocluster from LDH for stable and selective C2 hydrocarbons production from CO2 electrochemical reduction. J. Energy Chem. 2020, 48, 169–180. [Google Scholar] [CrossRef]

- Rayer, A.V.; Reid, E.; Kataria, A.; Luz, I.; Thompson, S.J.; Lail, M.; Zhou, J.; Soukri, M. Electrochemical carbon dioxide reduction to isopropanol using novel carbonized copper metal organic framework derived electrodes. J. CO2 Util. 2020, 39, 101159. [Google Scholar] [CrossRef]

- Ebaid, M.; Jiang, K.; Zhang, Z.; Drisdell, W.S.; Bell, A.T.; Cooper, J.K. Production of C2/C3 Oxygenates from Planar Copper Nitride-Derived Mesoporous Copper via Electrochemical Reduction of CO2. Chem. Mater. 2020, 32, 3304–3311. [Google Scholar] [CrossRef]

- Xiao, C.; Zhang, J. Architectural Design for Enhanced C2 Product Selectivity in Electrochemical CO2 Reduction Using Cu-Based Catalysts: A Review. ACS Nano 2021, 15, 7975–8000. [Google Scholar] [CrossRef]

- Kuhl, K.P.; Cave, E.R.; Abram, D.N.; Jaramillo, T.F. New insights into the electrochemical reduction of carbon dioxide on metallic copper surfaces. Energy Environ. Sci. 2012, 5, 7050–7059. [Google Scholar] [CrossRef]

- Wang, H.; Matios, E.; Wang, C.; Luo, J.; Lu, X.; Hu, X.; Li, W. Rapid and Scalable Synthesis of Cuprous Halide-Derived Copper Nano-Architectures for Selective Electrochemical Reduction of Carbon Dioxide. Nano Lett. 2019, 19, 3925–3932. [Google Scholar] [CrossRef]

- Quan, Z.; Wang, Y.; Fang, J. High-Index Faceted Noble Metal Nanocrystals. Acc. Chem. Res. 2013, 46, 191–202. [Google Scholar] [CrossRef]

- Woldu, A.R. From low to high-index facets of noble metal nanocrystals: A way forward to enhance the performance of electrochemical CO2 reduction. Nanoscale 2020, 12, 8626–8635. [Google Scholar] [CrossRef]

- Xia, W.; Xie, Y.; Jia, S.; Han, S.; Qi, R.; Chen, T.; Xing, X.; Yao, T.; Zhou, D.; Dong, X.; et al. Adjacent Copper Single Atoms Promote C–C Coupling in Electrochemical CO2 Reduction for the Efficient Conversion of Ethanol. J. Am. Chem. Soc. 2023, 145, 17253–17264. [Google Scholar] [CrossRef]

- Yang, C.-H.; Nosheen, F.; Zhang, Z.-C. Recent progress in structural modulation of metal nanomaterials for electrocatalytic CO2 reduction. Rare Met. 2021, 40, 1412–1430. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Josipovic, L.; Alyones, D.; Roybal, S.; Sun, Q.; Fei, Y.; Zhou, M.; Luo, H. Development of Catalysts for the Electrochemical CO2 Reduction Reaction. Inorganics 2025, 13, 276. https://doi.org/10.3390/inorganics13080276

Josipovic L, Alyones D, Roybal S, Sun Q, Fei Y, Zhou M, Luo H. Development of Catalysts for the Electrochemical CO2 Reduction Reaction. Inorganics. 2025; 13(8):276. https://doi.org/10.3390/inorganics13080276

Chicago/Turabian StyleJosipovic, Lucija, Deema Alyones, Shawn Roybal, Quanwen Sun, Yuhuan Fei, Meng Zhou, and Hongmei Luo. 2025. "Development of Catalysts for the Electrochemical CO2 Reduction Reaction" Inorganics 13, no. 8: 276. https://doi.org/10.3390/inorganics13080276

APA StyleJosipovic, L., Alyones, D., Roybal, S., Sun, Q., Fei, Y., Zhou, M., & Luo, H. (2025). Development of Catalysts for the Electrochemical CO2 Reduction Reaction. Inorganics, 13(8), 276. https://doi.org/10.3390/inorganics13080276