Enhancing the Tribo-Mechanical Performance of LDPE Nanocomposites Utilizing Low Loading Fraction Al2O3/SiC Hybrid Nanostructured Oxide Fillers

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials

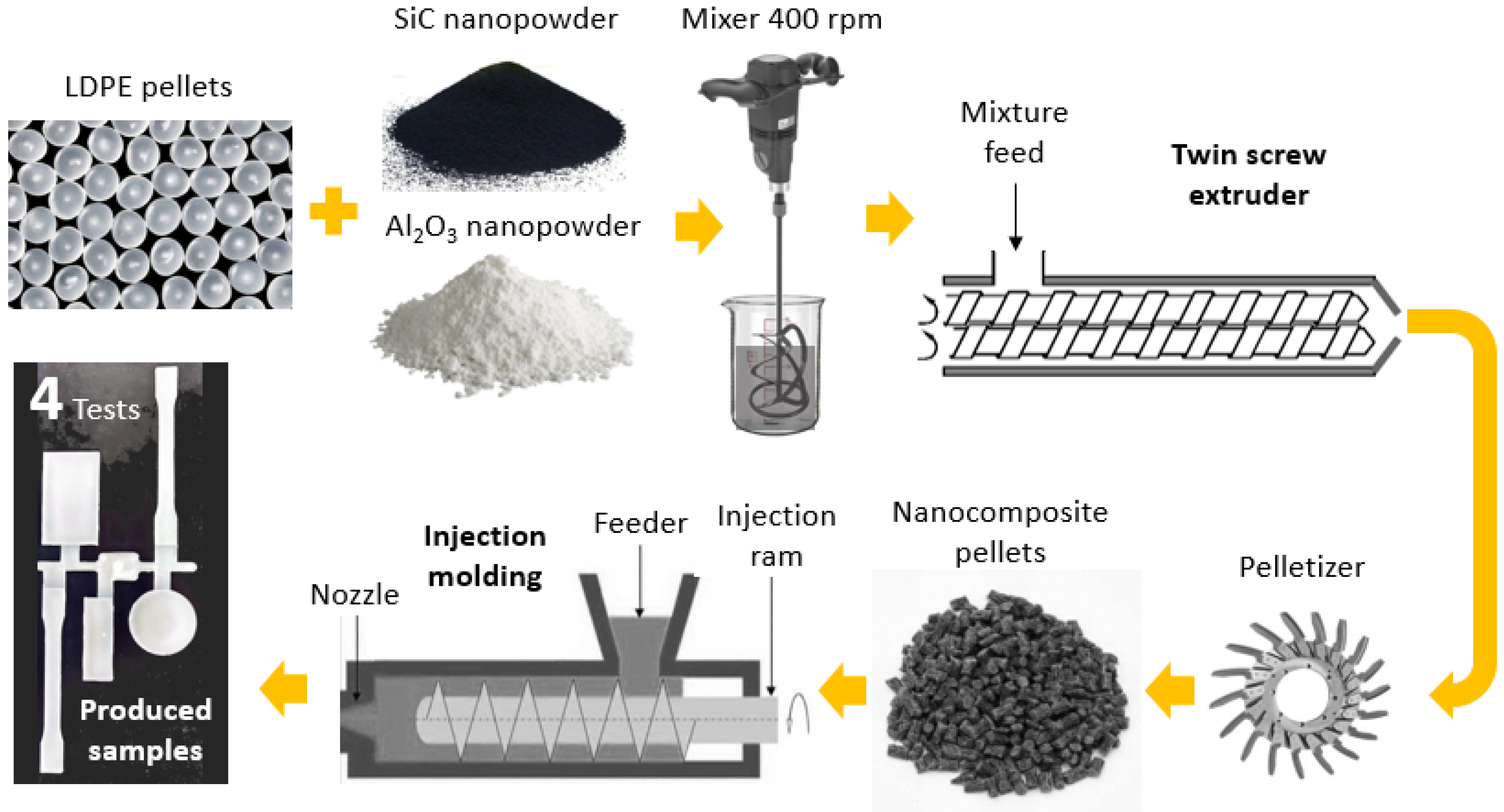

2.2. Samples Preparation

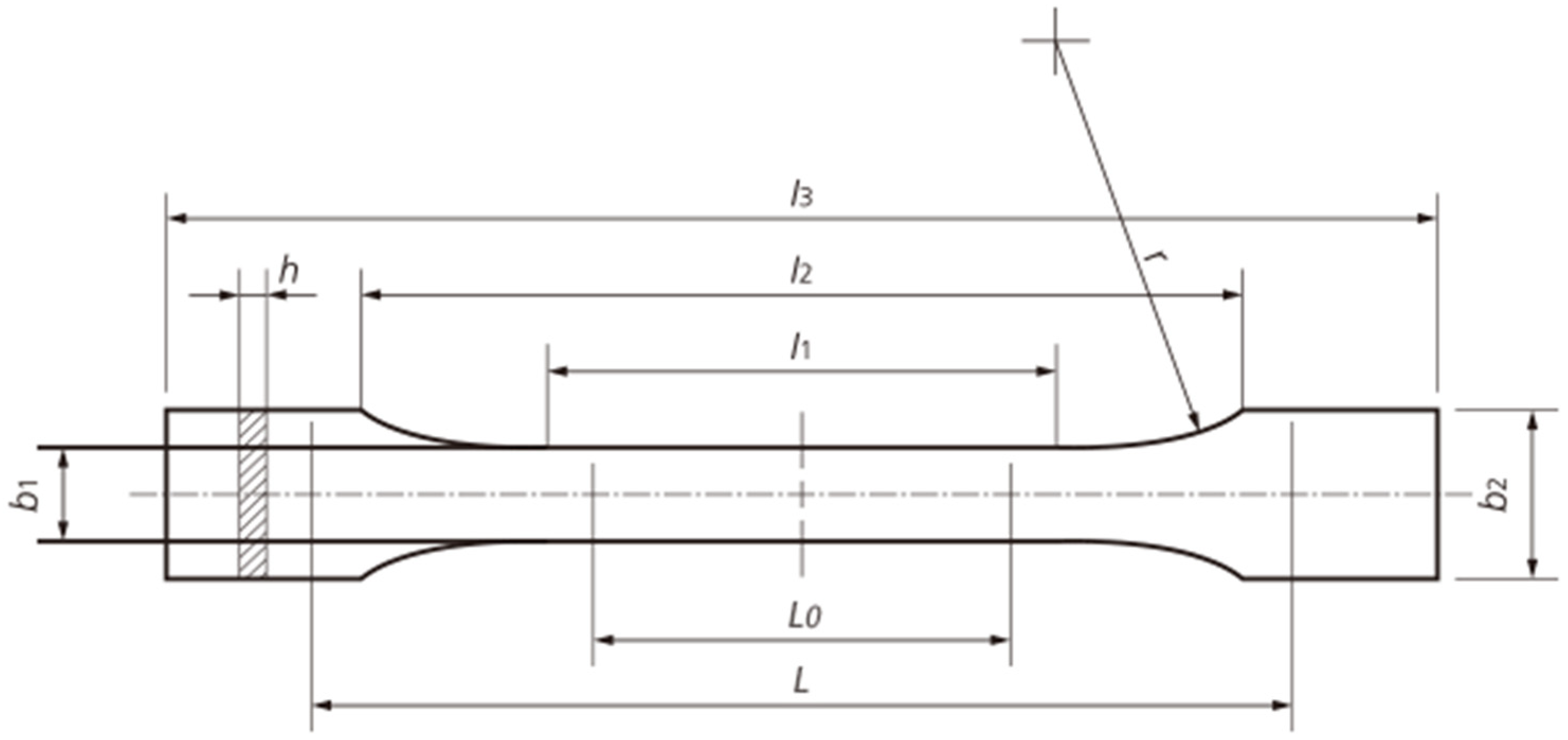

2.3. Characterization and Testing

3. Results and Discussion

3.1. Nanostructured Oxide Fillers Characterization

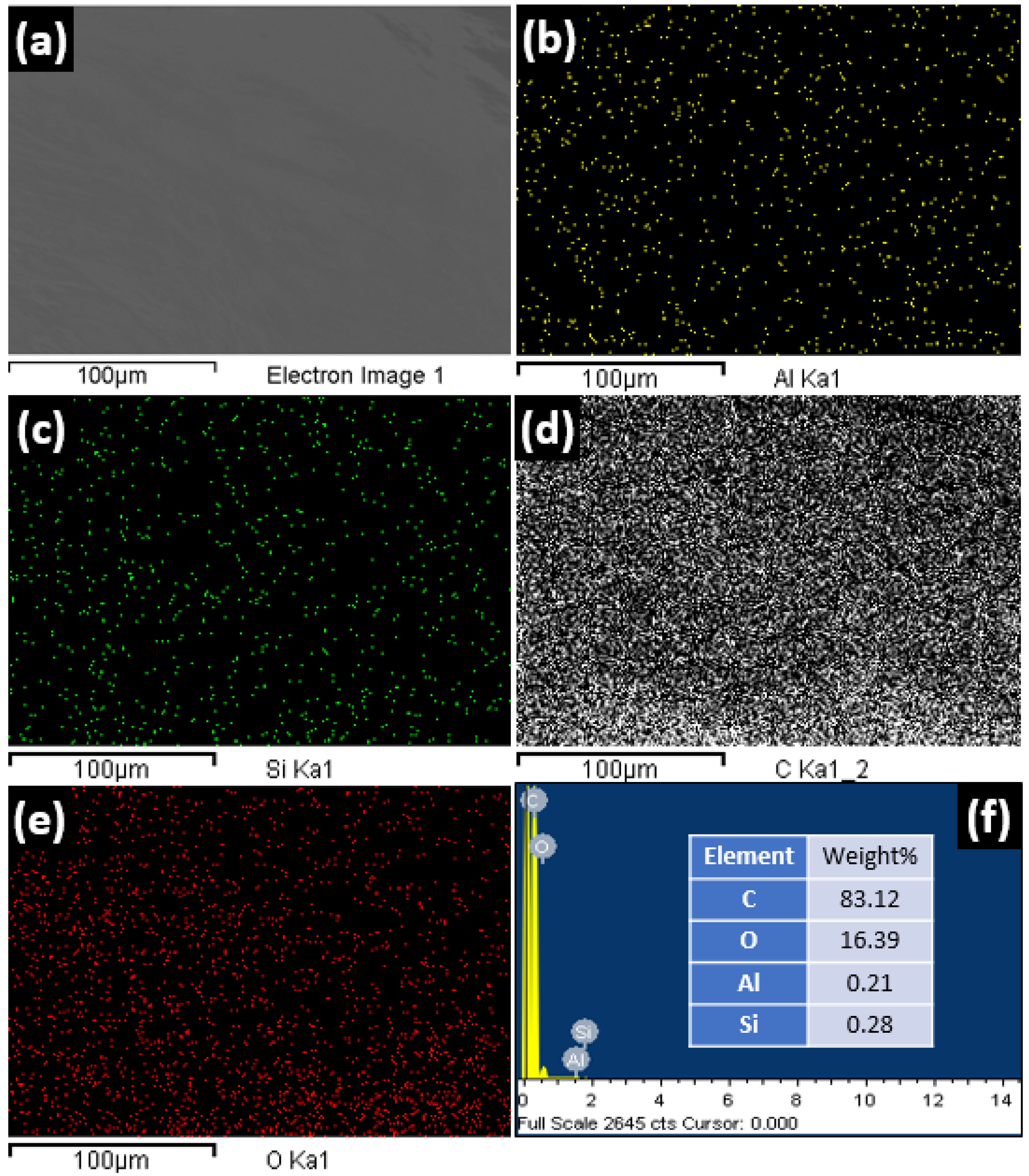

3.2. Nanocomposite Characterization

3.3. Mechanical Testing

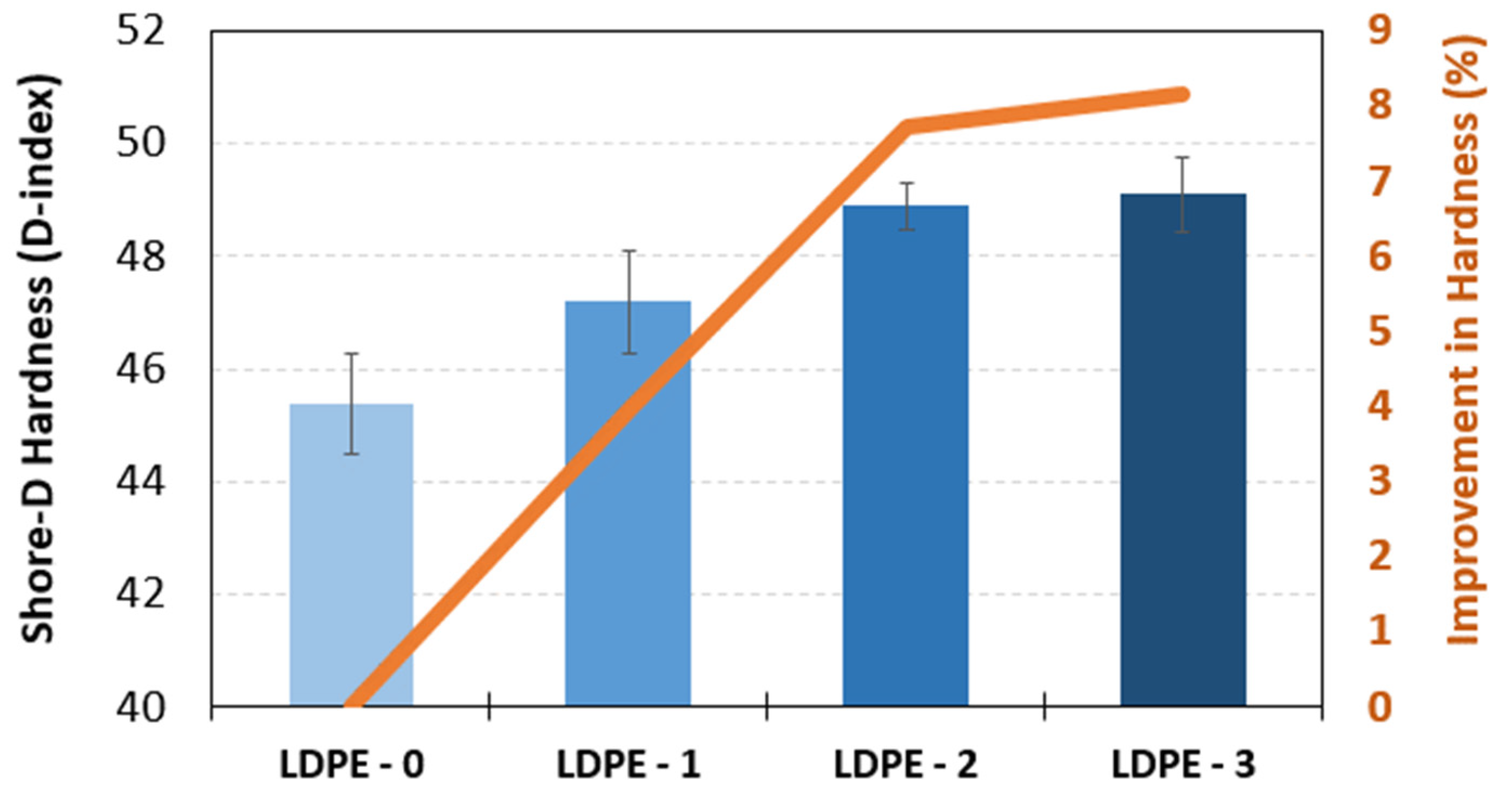

3.3.1. Shore-D Hardness Test

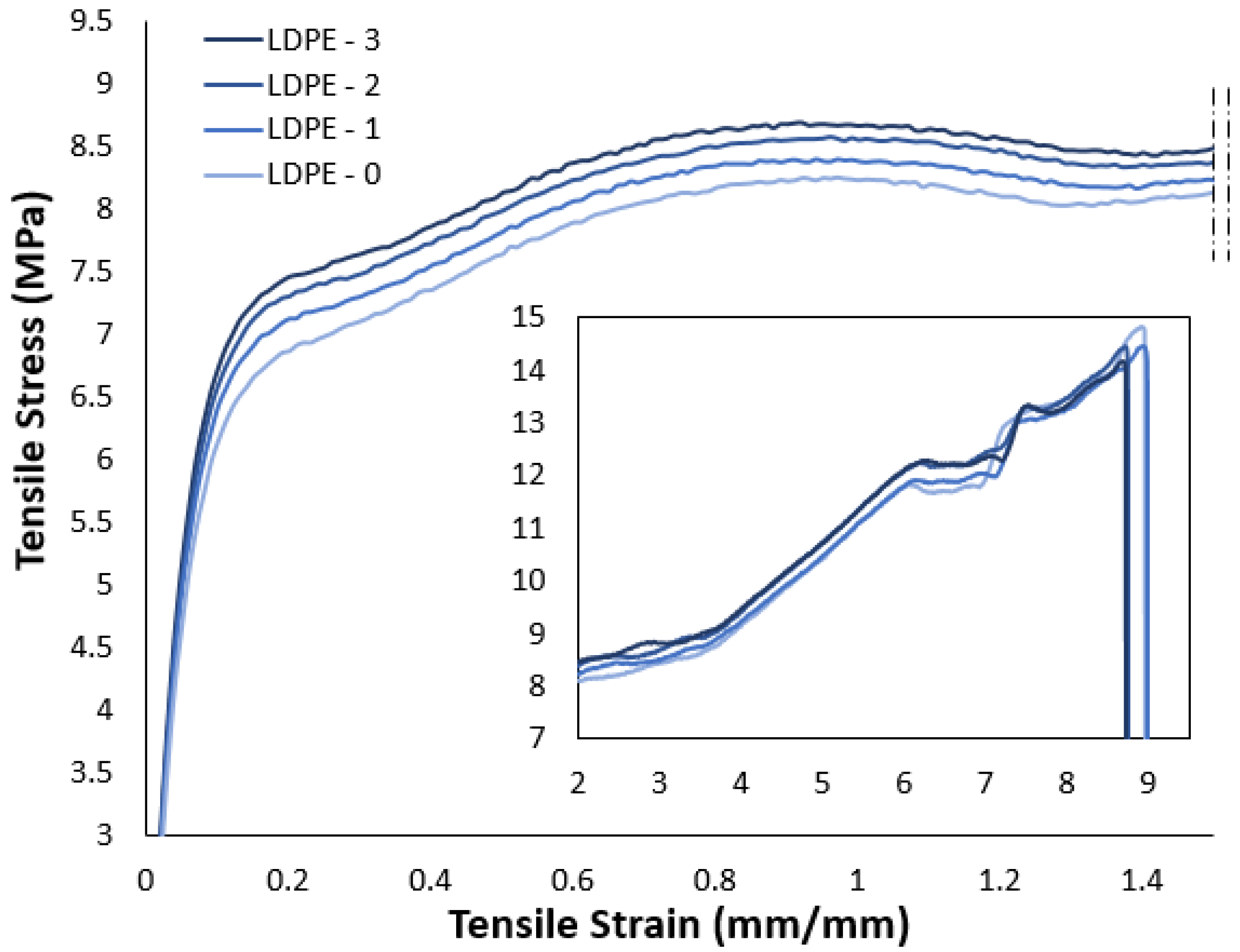

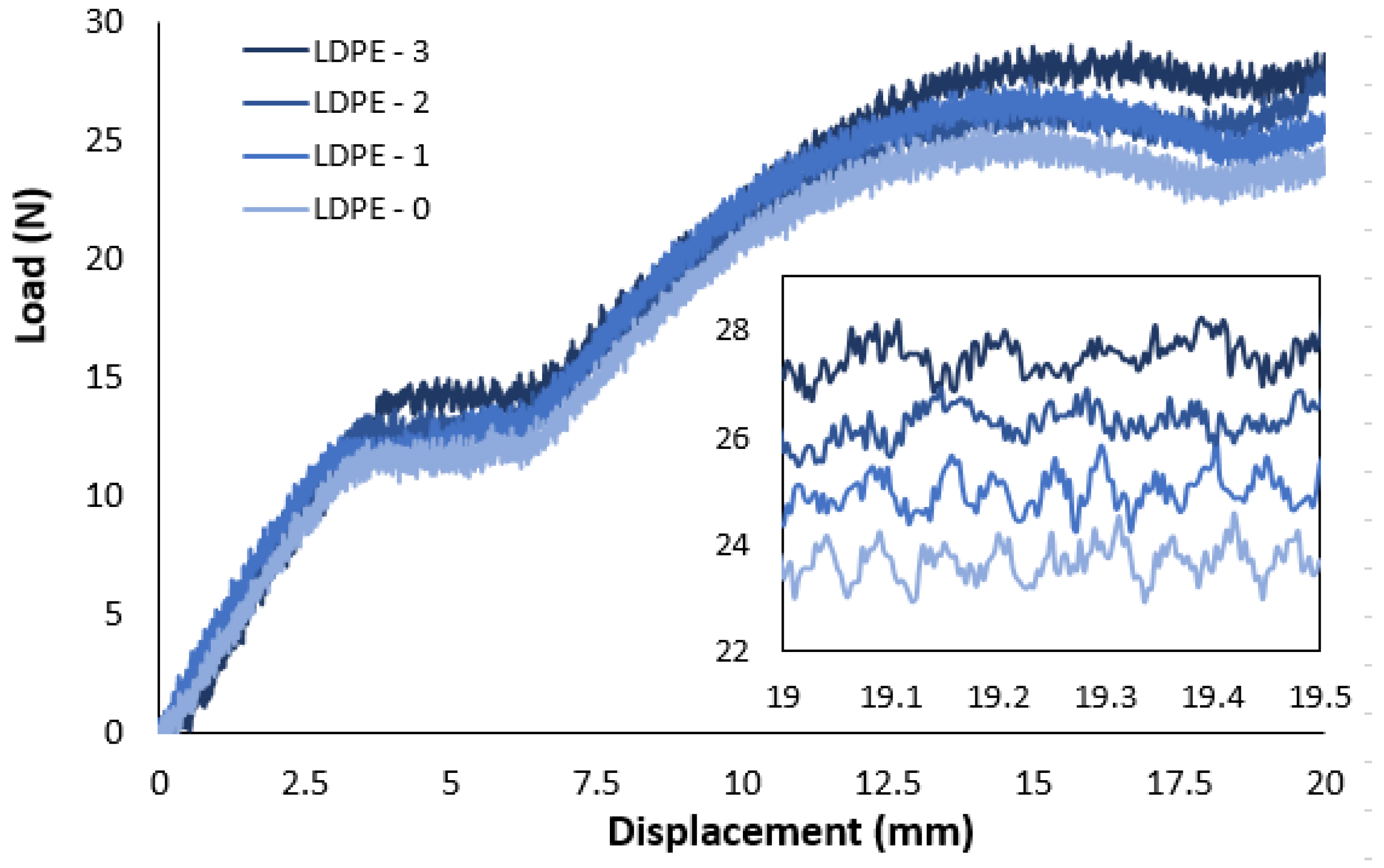

3.3.2. Tensile and Flextural Test

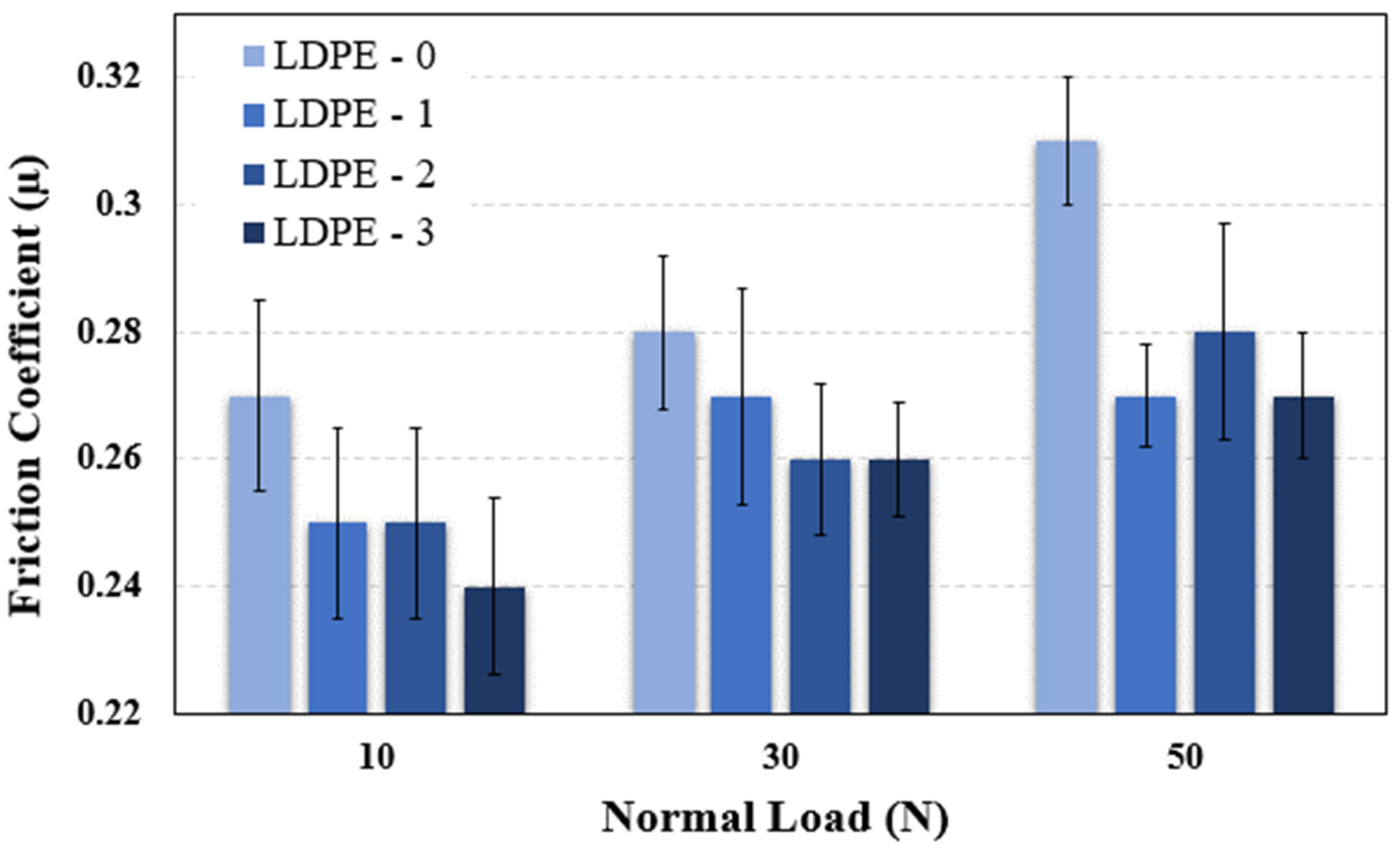

3.4. Tribological Performance

4. Conclusions

- Employing two rounds of extrusion shots before injection molding effectively produces homogeneous nanocomposite samples with well-dispersed low fraction additives.

- Incorporating alumina and silicon carbide nanoparticles into the LDPE matrix leads to increased tensile strength, yield strength and hardness. The study findings revealed improvements of 5.38%, 17.4% and 8.15%, respectively, for the LDPE + 0.5%Al2O3 + 0.5%SiC composite.

- The melt flow index (MFI) decreases as the hybrid filler content increases. The maximum reduction of 11.9% was observed for the LDPE + 0.5%Al2O3 + 0.5%SiC composite. This decrease in MFI can be attributed to the reduced mobility of the polymer molecular chains within the LDPE matrix.

- The lowest coefficient of friction was recorded for the LDPE + 0.5%Al2O3 + 0.5%SiC composite under a normal load of 10 N, which was approximately 12.5% lower than that of the neat LDPE, which is because the enhanced mechanical properties achieved by incorporating these nanoparticles.

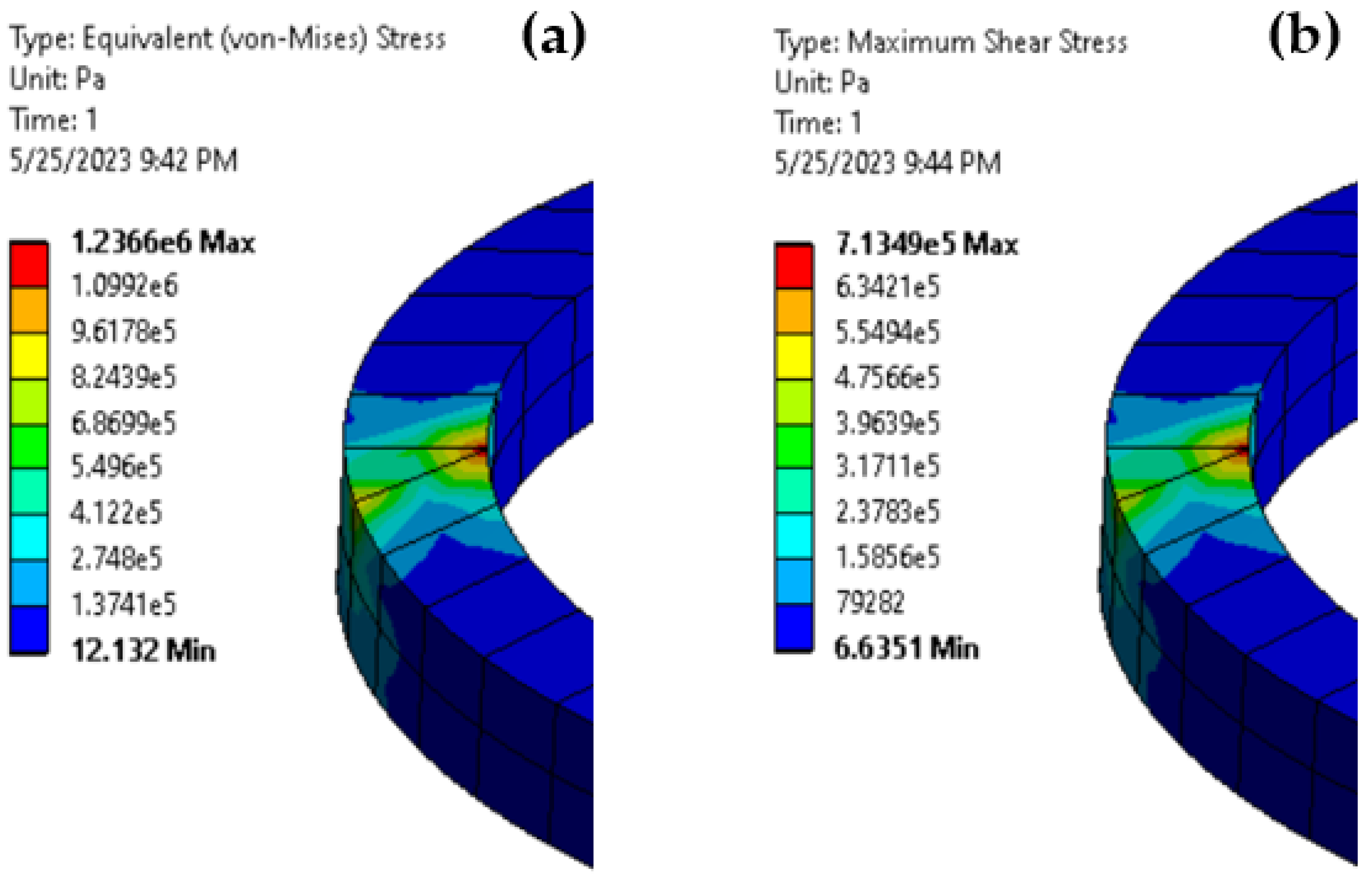

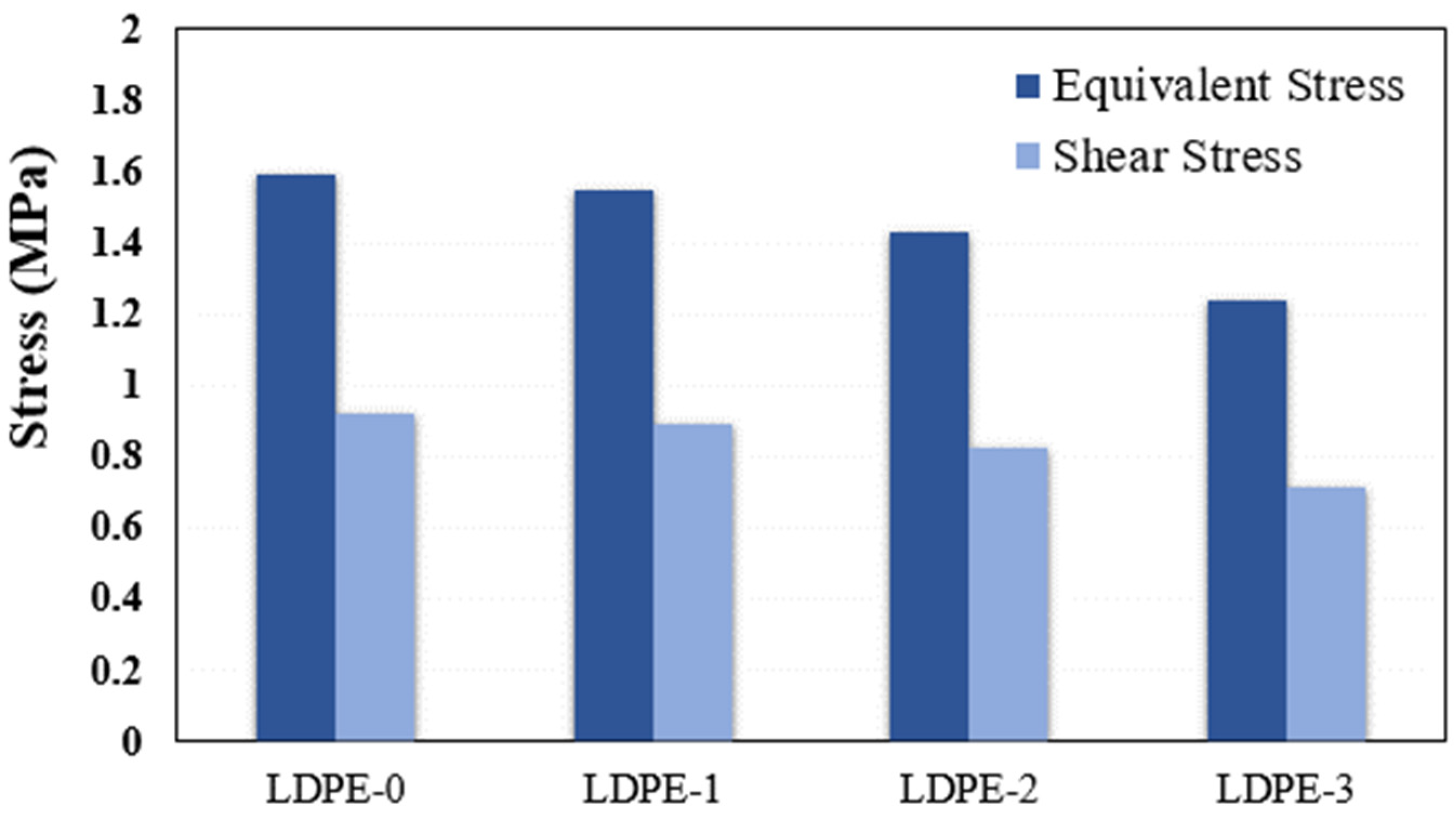

- The incorporation of a low fraction of Al2O3/SiC during the fabrication of composites increased the load-carrying capacity, as evidenced by the finite element analysis results. Consequently, the enhanced mechanical properties led to reduced stress generation and a lower wear rate.

- The application of aluminum oxide (Al2O3) and silicon carbide (SiC) nanoparticles as hybrid reinforcements in low-density polyethylene (LDPE) matrix offers the potential for lightweight materials with improved mechanical properties and enhanced tribological performance. These nanocomposites could find applications in various industries where strength, hardness and reduced friction are desired, opening up possibilities for more efficient and durable products.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mirizzi, L.; D’Arienzo, M.; Nisticò, R.; Fredi, G.; Diré, S.; Callone, E.; Dorigato, A.; Giannini, L.; Guerra, S.; Mostoni, S.; et al. Al2O3 decorated with polyhedral silsesquioxane units: An unconventional filler system for upgrading thermal conductivity and mechanical properties of rubber composites. Compos. Sci. Technol. 2023, 236, 109977. [Google Scholar] [CrossRef]

- Fouly, A.; Almotairy, S.M.; Aijaz, M.O.; Alharbi, H.F.; Abdo, H.S. Balanced Mechanical and Tribological Performance of High-Frequency-Sintered Al-SiC Achieved via Innovative Milling Route—Experimental and Theoretical Study. Crystals 2021, 11, 700. [Google Scholar] [CrossRef]

- Ahamed, T.; Brown, S.P.; Salehi, M. Investigate the role of biofilm and water chemistry on lead deposition onto and release from polyethylene: An implication for potable water pipes. J. Hazard. Mater. 2020, 400, 123253. [Google Scholar] [CrossRef]

- Avcioğlu, S. LDPE matrix composites reinforced with dysprosium-boron containing compounds for radiation shielding applications. J. Alloys Compd. 2022, 927, 166900. [Google Scholar] [CrossRef]

- Videira-Quintela, D.; Guillén, F.; Martin, O.; Montalvo, G. Antibacterial LDPE films for food packaging application filled with metal-fumed silica dual-side fillers. Food Packag. Shelf Life 2022, 31, 100772. [Google Scholar] [CrossRef]

- Polanský, R.; Kadlec, P.; Slepička, P.; Kolská, Z.; Švorčík, V. Testing the applicability of LDPE/HNT composites for cable core insulation. Polym. Test. 2019, 78, 105993. [Google Scholar] [CrossRef]

- Benabid, F.Z.; Mallem, O.K.; Zouai, F.; Cagiao, M.E.; Benachour, D. Effect of the Mechanical Treatment of Alumina on Thermal, Morphological and Dielectric Properties of LDPE/Al2O3 Composites. South African J. Chem. 2018, 71, 150–154. [Google Scholar] [CrossRef]

- Chee, C.Y.; Song, N.L.; Abdullah, L.C.; Choong, T.S.Y.; Ibrahim, A.; Chantara, T.R. Characterization of mechanical properties: Low-density polyethylene nanocomposite using nanoalumina particle as filler. J. Nanomater. 2012, 2012, 118. [Google Scholar] [CrossRef]

- Wu, Y.; Dong, C.; Yuan, C.; Bai, X.; Zhang, L.; Tian, Y. MWCNTs filled high-density polyethylene composites to improve tribological performance. Wear 2021, 477, 203776. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E.; Hnatchuk, N.; Perez, J.M. Improvement of Scratch and Wear Resistance of Polymers by Fillers Including Nanofillers. Nanomaterials 2017, 7, 66. [Google Scholar] [CrossRef]

- Panin, S.V.; Kornienko, L.A.; Alexenko, V.O.; Buslovich, D.G.; Bochkareva, S.A.; Lyukshin, B.A. Increasing Wear Resistance of UHMWPE by Loading Enforcing Carbon Fibers: Effect of Irreversible and Elastic Deformation, Friction Heating, and Filler Size. Materials 2020, 13, 338. [Google Scholar] [CrossRef]

- Kayode Aliyu, I.; Abdul Samad, M.; Al-Qutub, A.M. Friction and wear behavior of ultra-high molecular weight polyethylene/graphene nanoplatelets nanocomposite coatings at elevated temperatures. J. Eng. Tribol. 2021, 236, 1782–1788. [Google Scholar] [CrossRef]

- Zhang, L.; Qi, H.; Li, G.; Wang, D.; Wang, T.; Wang, Q.; Zhang, G. Significantly enhanced wear resistance of PEEK by simply filling with modified graphitic carbon nitride. Mater. Des. 2017, 129, 192–200. [Google Scholar] [CrossRef]

- Fouly, A.; Alnaser, I.A.; Assaifan, A.K.; Abdo, H.S. Evaluating the Performance of 3D-Printed PLA Reinforced with Date Pit Particles for Its Suitability as an Acetabular Liner in Artificial Hip Joints. Polymers 2022, 14, 3321. [Google Scholar] [CrossRef]

- Pelto, J.; Verho, T.; Ronkainen, H.; Kaunisto, K.; Metsäjoki, J.; Seitsonen, J.; Karttunen, M. Matrix morphology and the particle dispersion in HDPE nanocomposites with enhanced wear resistance. Polym. Test. 2019, 77, 105897. [Google Scholar] [CrossRef]

- Liu, T.; Li, B.; Lively, B.; Eyler, A.; Zhong, W.H. Enhanced wear resistance of high-density polyethylene composites reinforced by organosilane-graphitic nanoplatelets. Wear 2014, 309, 43–51. [Google Scholar] [CrossRef]

- Burris, D.L.; Boesl, B.; Bourne, G.R.; Sawyer, W.G.; Burris, D.L.; Boesl, B.; Bourne, G.R.; Sawyer, W.G. Polymeric Nanocomposites for Tribological Applications. Macromol. Mater. Eng. 2007, 292, 387–402. [Google Scholar] [CrossRef]

- Burris, D.L.; Zhao, S.; Duncan, R.; Lowitz, J.; Perry, S.S.; Schadler, L.S.; Sawyer, W.G. A route to wear resistant PTFE via trace loadings of functionalized nanofillers. Wear 2009, 267, 653–660. [Google Scholar] [CrossRef]

- Pelto, J.; Heino, V.; Karttunen, M.; Rytöluoto, I.; Ronkainen, H. Tribological performance of high density polyethylene (HDPE) composites with low nanofiller loading. Wear 2020, 460–461, 203451. [Google Scholar] [CrossRef]

- Noorunnisa Khanam, P.; Al-Maadeed, M.A.; Mrlik, M. Improved flexible, controlled dielectric constant material from recycled LDPE polymer composites. J. Mater. Sci. Mater. Electron. 2016, 27, 8848–8855. [Google Scholar] [CrossRef]

- Deepak, D.; Goyal, N.; Rana, P.; Gupta, V.K. Effect of varying reinforcement content on the mechanical properties of hemp-recycled HDPE composites. Mater. Today Proc. 2019, 18, 5286–5291. [Google Scholar] [CrossRef]

- Samad, U.A.; Alam, M.A.; Abdo, H.S.; Anis, A.; Al-Zahrani, S.M. Synergistic Effect of Nanoparticles: Enhanced Mechanical and Corrosion Protection Properties of Epoxy Coatings Incorporated with SiO2 and ZrO2. Polymers 2023, 15, 3100. [Google Scholar] [CrossRef] [PubMed]

- Abdo, H.S.; Seikh, A.H. Correlation of Microstructure with Compression Behaviour of Al5083/ZrC Nanocomposites Fabricated Through Spark Plasma Sintering. Trans. Indian Inst. Met. 2022, 75, 2273–2280. [Google Scholar] [CrossRef]

- Abdo, H.S.; Samad, U.A.; Abdo, M.S.; Alkhammash, H.I.; Aijaz, M.O. Electrochemical Behavior of Inductively Sintered Al/TiO2 Nanocomposites Reinforced by Electrospun Ceramic Nanofibers. Polymers 2021, 13, 4319. [Google Scholar] [CrossRef]

- Bedi, P.; Singh, R.; Ahuja, I.P.S. Effect of SiC/Al2O3 particle size reinforcement in recycled LDPE matrix on mechanical properties of FDM feed stock filament. Virtual Phys. Prototyp. 2018, 13, 246–254. [Google Scholar] [CrossRef]

- De Abreu Ferreira Cardoso, B.F.; Ramos, F.J.H.T.V.; Da Silveira, P.H.P.M.; De Oliveira, A.G.B.A.M.; Da Silva Figueiredo, A.B.H.; Gomes, A.V.; Da Veiga, V.F. Mechanical and ballistic characterization of high-density polyethylene composites reinforced with alumina and silicon carbide particles. J. Met. Mater. Miner. 2022, 32, 42–49. [Google Scholar] [CrossRef]

- Hayun, S.; Paris, V.; Mitrani, R.; Kalabukhov, S.; Dariel, M.P.; Zaretsky, E.; Frage, N. Microstructure and mechanical properties of silicon carbide processed by Spark Plasma Sintering (SPS). Ceram. Int. 2012, 38, 6335–6340. [Google Scholar] [CrossRef]

- Naga, S.M.; El-Maghraby, H.F.; Elgamhoudy, M.; Saleh, M.A. Characterization and origin of failure of SiC/ZTA composites. Int. J. Refract. Met. Hard Mater. 2018, 73, 53–57. [Google Scholar] [CrossRef]

- ASTM D1238-13; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D2240-15; Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2015, 2015. [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM International, 2022. [CrossRef]

- ASTM G99-17; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- Mallakpour, S.; Dinari, M. Enhancement in thermal properties of poly(vinyl alcohol) nanocomposites reinforced with Al2O3 nanoparticles. J. Reinf. Plast. Compos. 2013, 32, 217–224. [Google Scholar] [CrossRef]

- Junaedi, H.; Baig, M.; Dawood, A.; Albahkali, E.; Almajid, A. Mechanical and Physical Properties of Short Carbon Fiber and Nanofiller-Reinforced Polypropylene Hybrid Nanocomposites. Polymers 2020, 12, 2851. [Google Scholar] [CrossRef]

- Khamaj, A.; Farouk, W.M.; Shewakh, W.M.; Abu-Oqail, A.M.I.; Wagih, A.; Abu-Okail, M. Effect of lattice structure evolution on the thermal and mechanical properties of Cu–Al2O3/GNPs nanocomposites. Ceram. Int. 2021, 47, 16511–16520. [Google Scholar] [CrossRef]

- Dhabale, R.; Jatti, V.S. A bio-material: Mechanical behaviour of LDPE-Al2O3-TiO2. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012043. [Google Scholar] [CrossRef]

- Padmanabhan, M.; Thokal, M. Comparison of Mechanical Properties of Al2O3 And Low Density Polyethylene (LDPE). Int. J. Eng. Res. 2013, 3, 224–227. [Google Scholar]

- Chang, L.; Zhang, Z.; Zhang, H.; Friedrich, K. Effect of nanoparticles on the tribological behaviour of short carbon fibre reinforced poly(etherimide) composites. Tribol. Int. 2005, 38, 966–973. [Google Scholar] [CrossRef]

- Khun, N.W.; Zhang, H.; Lim, L.H.; Yue, C.Y.; Hu, X.; Yang, J. Tribological properties of short carbon fibers reinforced epoxy composites. Friction 2014, 2, 226–239. [Google Scholar] [CrossRef]

- Fouly, A.; Alkalla, M.G. Effect of low nanosized alumina loading fraction on the physicomechanical and tribological behavior of epoxy. Tribol. Int. 2020, 152, 106550. [Google Scholar] [CrossRef]

- Campos-Sanabria, V.; Hernández-Sierra, M.T.; Bravo-Sánchez, M.G.; Aguilera-Camacho, L.D.; García-Miranda, J.S.; Moreno, K.J. Tribological and mechanical characterization of PMMA/HAp nanocomposites obtained by free-radical polymerization. MRS Adv. 2018, 3, 3763–3768. [Google Scholar] [CrossRef]

- Kuminek, T.; Aniołek, K.; Młyńczak, J. A numerical analysis of the contact stress distribution and physical modelling of abrasive wear in the tram wheel-frog system. Wear 2015, 328–329, 177–185. [Google Scholar] [CrossRef]

- Lu, G.; Shi, X.; Zhang, J.; Zhou, H.; Xue, Y.; Ibrahim, A.M.M. Effects of surface composite structure with micro-grooves and Sn-Ag-Cu on reducing friction and wear of Ni3Al alloys. Surf. Coatings Technol. 2020, 387, 125540. [Google Scholar] [CrossRef]

- Alnaser, I.A.; Abdo, H.S.; Abdo, M.S.; Alkalla, M.; Fouly, A. Effect of Synthesized Titanium Dioxide Nanofibers Weight Fraction on the Tribological Characteristics of Magnesium Nanocomposites Used in Biomedical Applications. Nanomaterials 2023, 13, 294. [Google Scholar] [CrossRef]

- Ibrahim, A.M.M.; Shi, X.; Zhang, A.; Yang, K.; Zhai, W. Tribological Characteristics of NiAl Matrix Composites with 1.5 wt% Graphene at Elevated Temperatures: An Experimental and Theoretical Study. Tribol. Trans. 2015, 58, 1076–1083. [Google Scholar] [CrossRef]

| Samples Code | Composition in wt% | Temperature (°C) | ||||

|---|---|---|---|---|---|---|

| LDPE | Al2O3 | SiC | Onset | Peak | Final | |

| LDPE-0 | 100% | 0% | 0% | 454.3 | 474.65 | 488 |

| LDPE-1 | 99.8% | 0.10% | 0.10% | 453.7 | 474.31 | 499 |

| LDPE-2 | 99.5% | 0.25% | 0.25% | 453.5 | 474.57 | 501 |

| LDPE-3 | 99.0% | 0.50% | 0.50% | 453.8 | 474.13 | 500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alnaser, I.A.; Fouly, A.; Aijaz, M.O.; Mohammed, J.A.; Elsheniti, M.B.; Ragab, S.A.; Abdo, H.S. Enhancing the Tribo-Mechanical Performance of LDPE Nanocomposites Utilizing Low Loading Fraction Al2O3/SiC Hybrid Nanostructured Oxide Fillers. Inorganics 2023, 11, 354. https://doi.org/10.3390/inorganics11090354

Alnaser IA, Fouly A, Aijaz MO, Mohammed JA, Elsheniti MB, Ragab SA, Abdo HS. Enhancing the Tribo-Mechanical Performance of LDPE Nanocomposites Utilizing Low Loading Fraction Al2O3/SiC Hybrid Nanostructured Oxide Fillers. Inorganics. 2023; 11(9):354. https://doi.org/10.3390/inorganics11090354

Chicago/Turabian StyleAlnaser, Ibrahim A., Ahmed Fouly, Muhammad Omer Aijaz, Jabair A. Mohammed, Mahmoud B. Elsheniti, Sameh A. Ragab, and Hany S. Abdo. 2023. "Enhancing the Tribo-Mechanical Performance of LDPE Nanocomposites Utilizing Low Loading Fraction Al2O3/SiC Hybrid Nanostructured Oxide Fillers" Inorganics 11, no. 9: 354. https://doi.org/10.3390/inorganics11090354

APA StyleAlnaser, I. A., Fouly, A., Aijaz, M. O., Mohammed, J. A., Elsheniti, M. B., Ragab, S. A., & Abdo, H. S. (2023). Enhancing the Tribo-Mechanical Performance of LDPE Nanocomposites Utilizing Low Loading Fraction Al2O3/SiC Hybrid Nanostructured Oxide Fillers. Inorganics, 11(9), 354. https://doi.org/10.3390/inorganics11090354