Repair of Small-Area Delamination in Carbon Fiber-Reinforced Polymer through Small Drilled Hole and Carbon Nanotubes-Reinforced Resin Pre-Coating Technique

Abstract

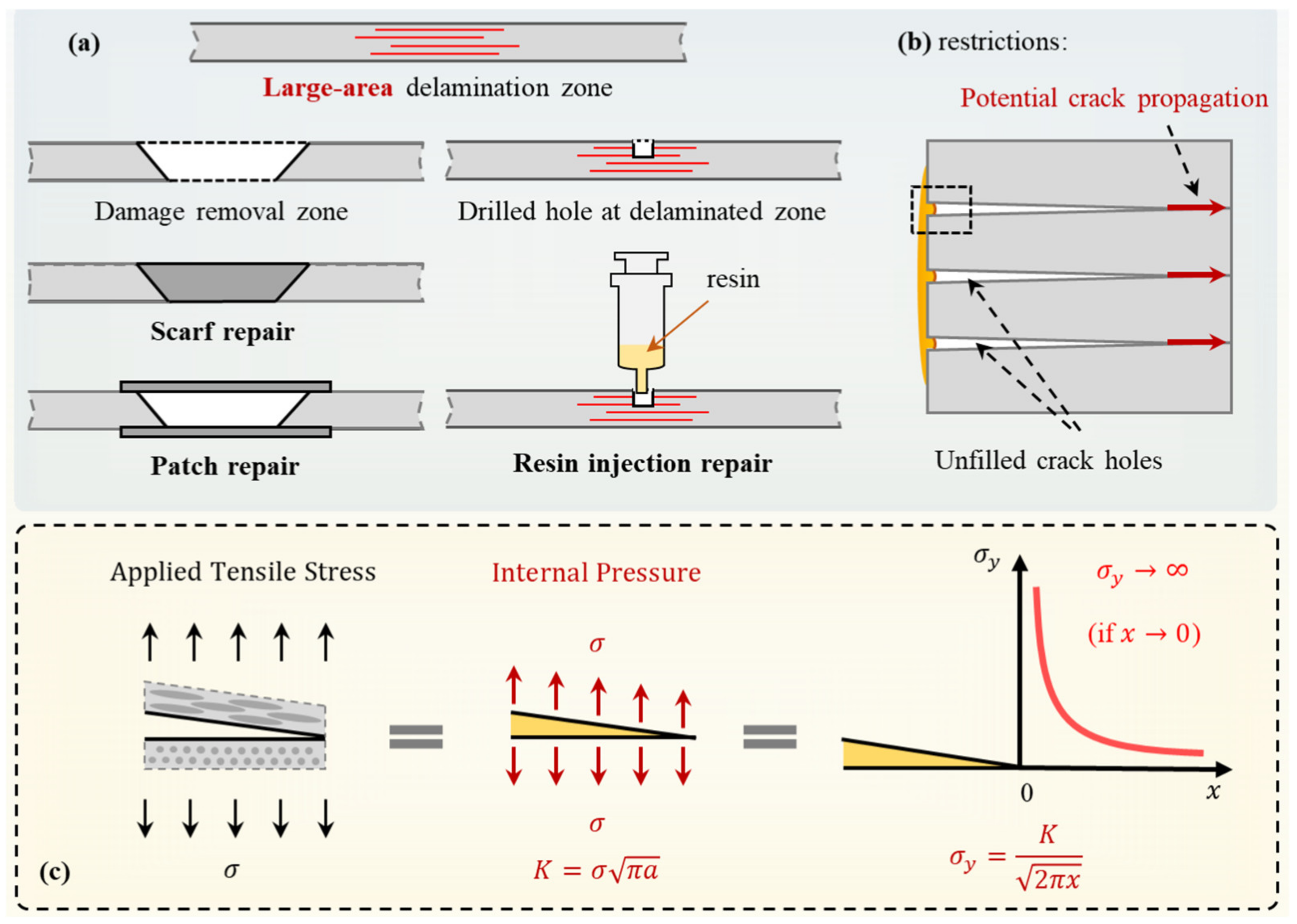

1. Introduction

2. Results and Discussion

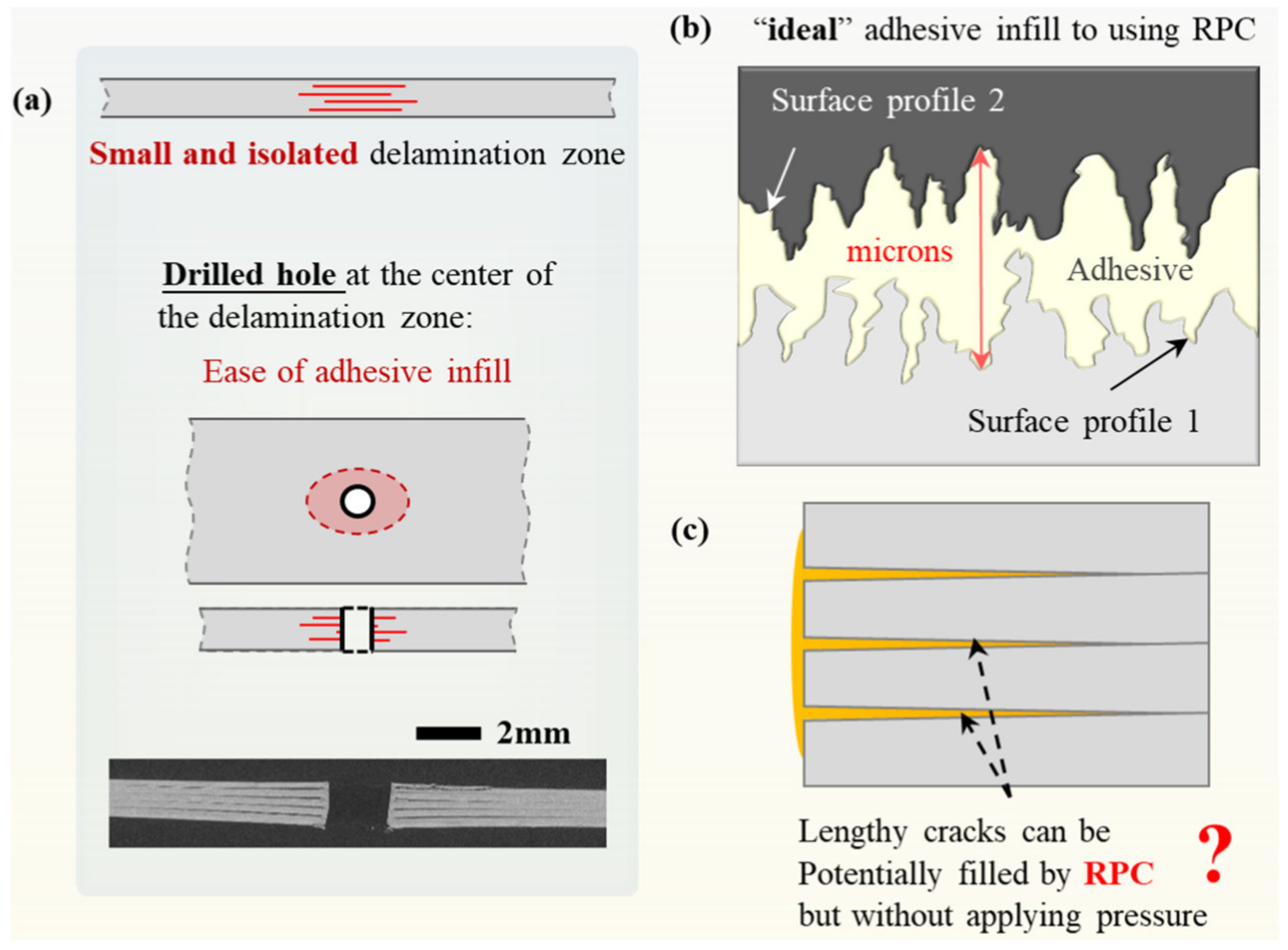

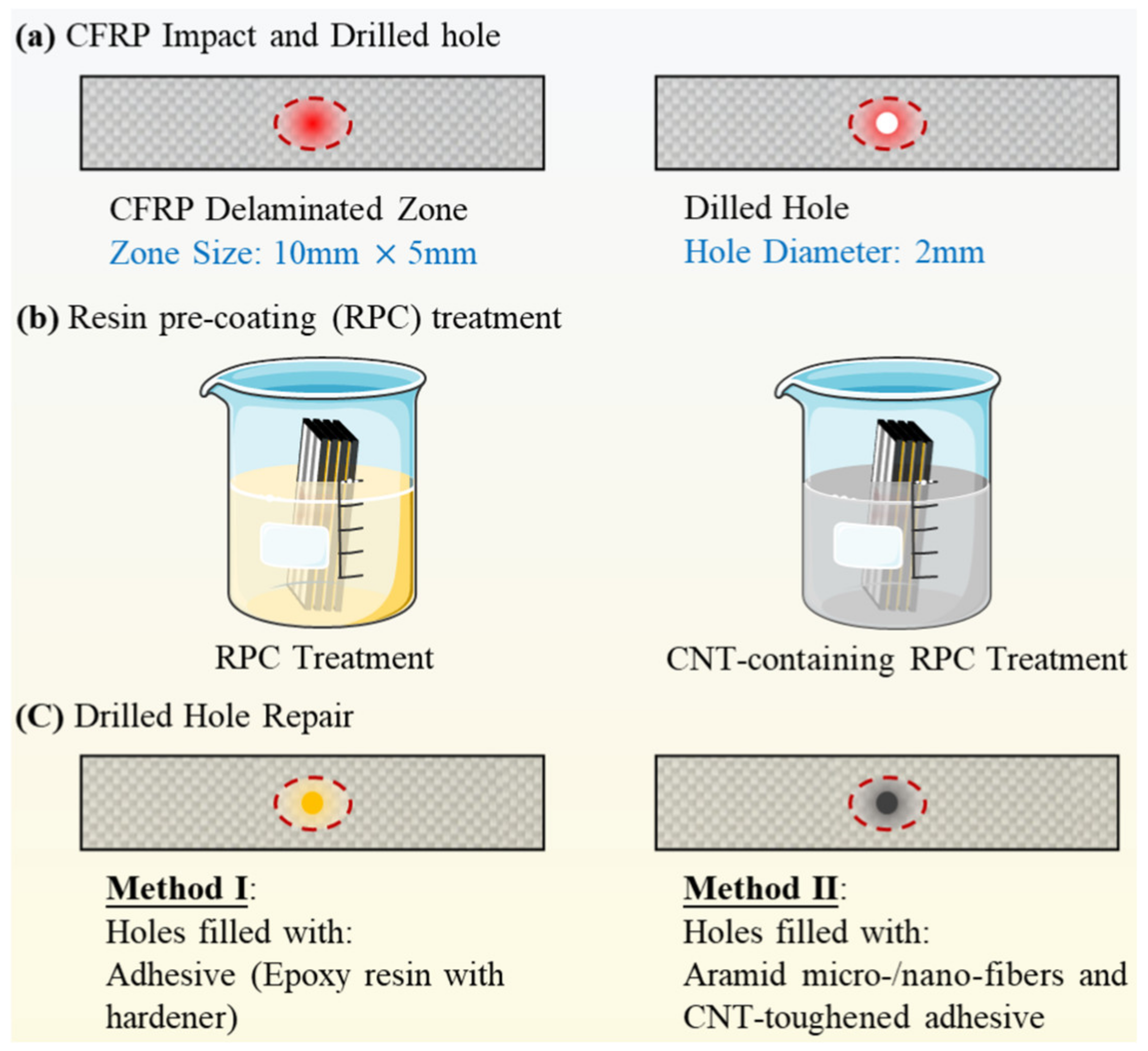

2.1. Feasibility and Detailed Steps for Small-Area Delamination Repairs

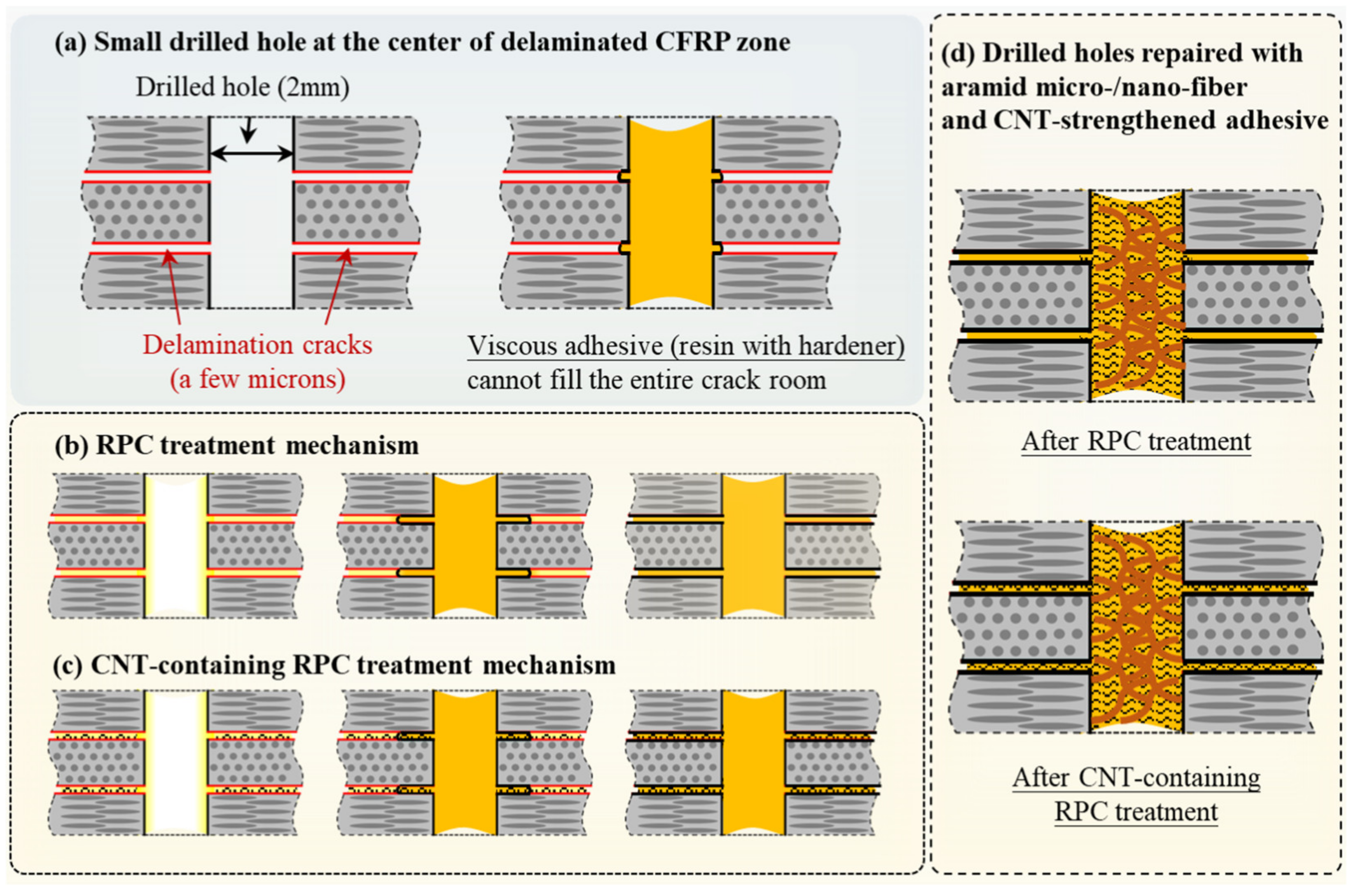

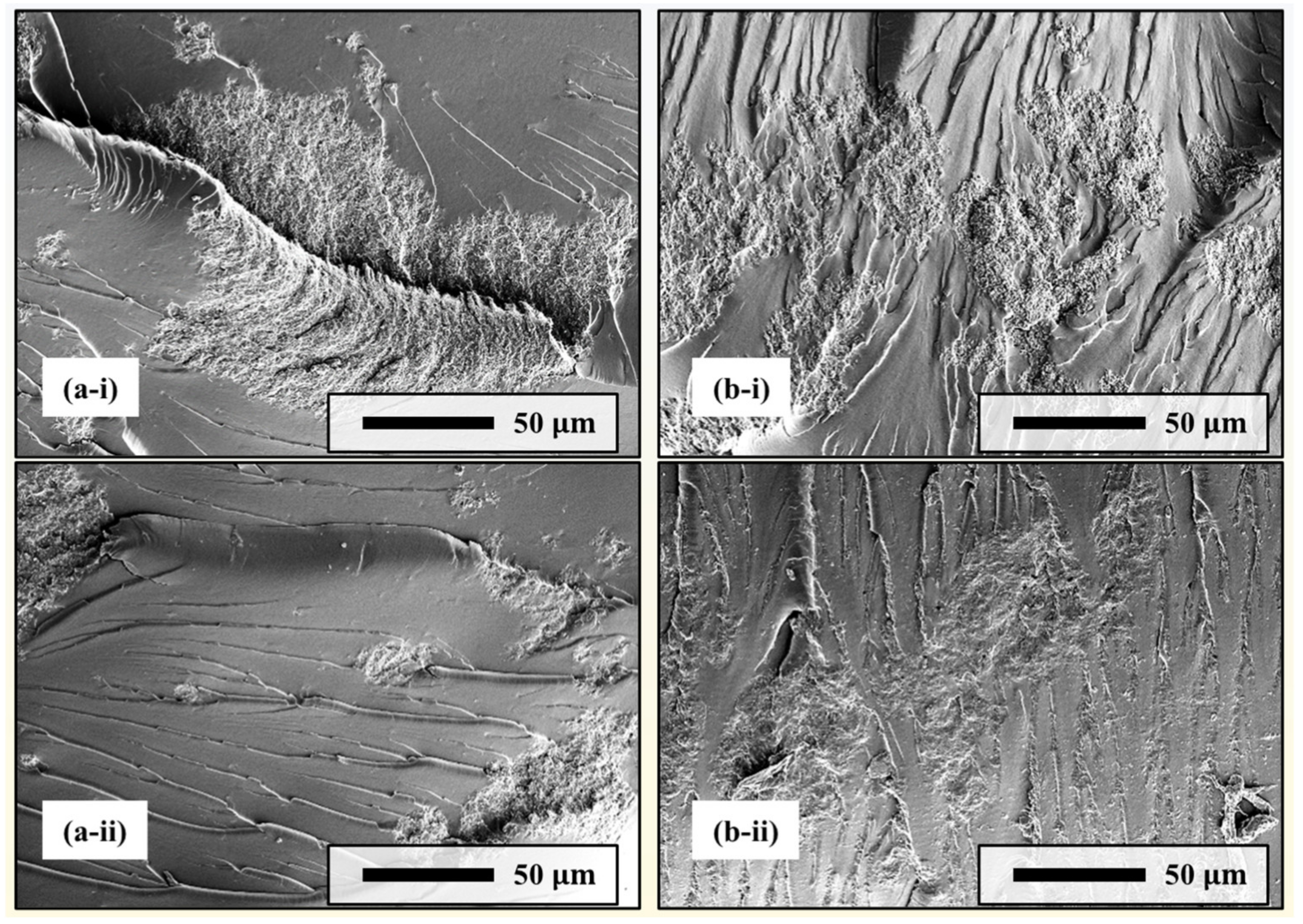

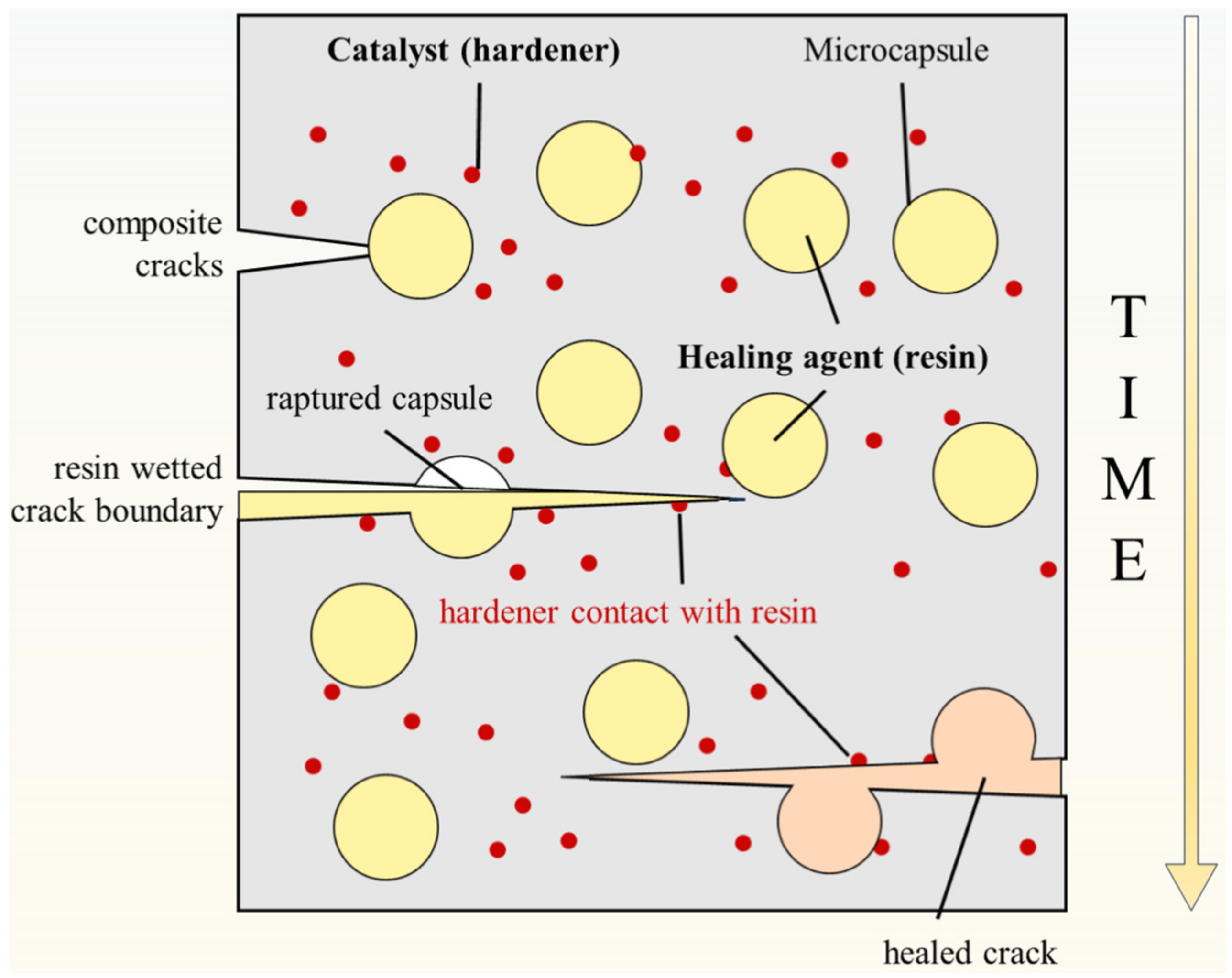

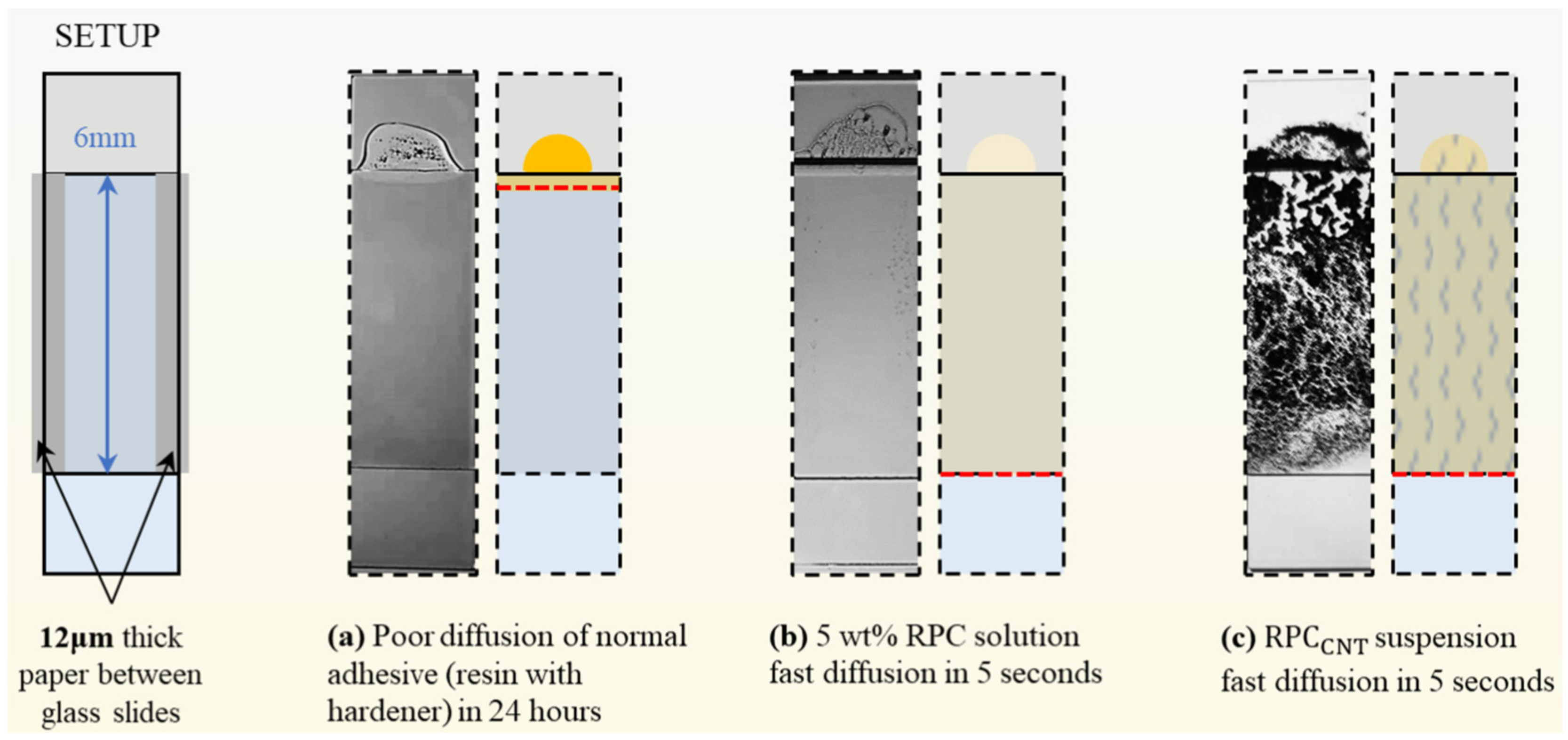

2.1.1. Pressureless Repair of Sharp Delamination Crack Tips Using RPCCNT Suspension

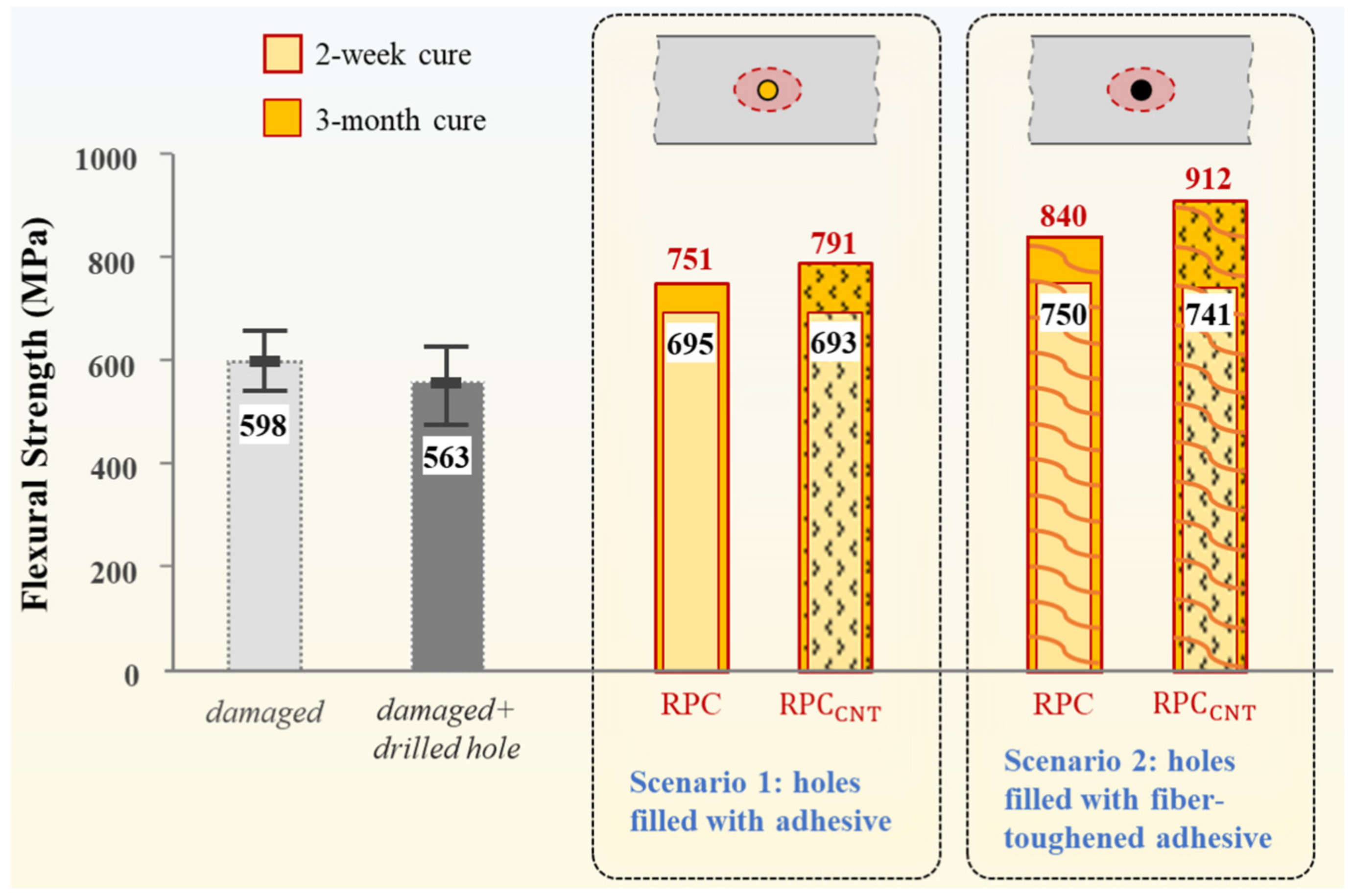

2.1.2. Effects of Small Drilling Hole on Flexural Strength of CFRP Specimens

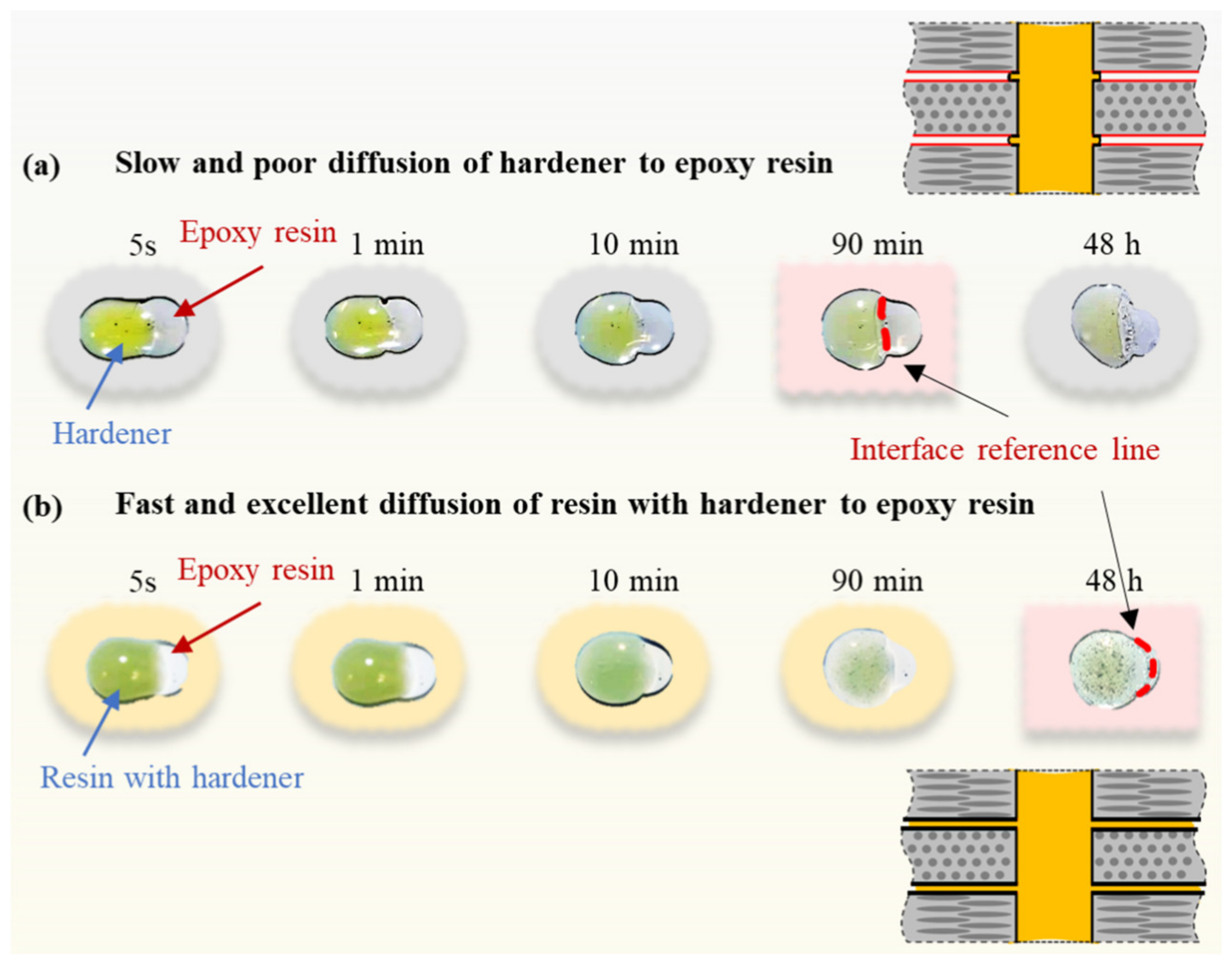

2.1.3. Surface Contact Curing of Resin Filled by RPC

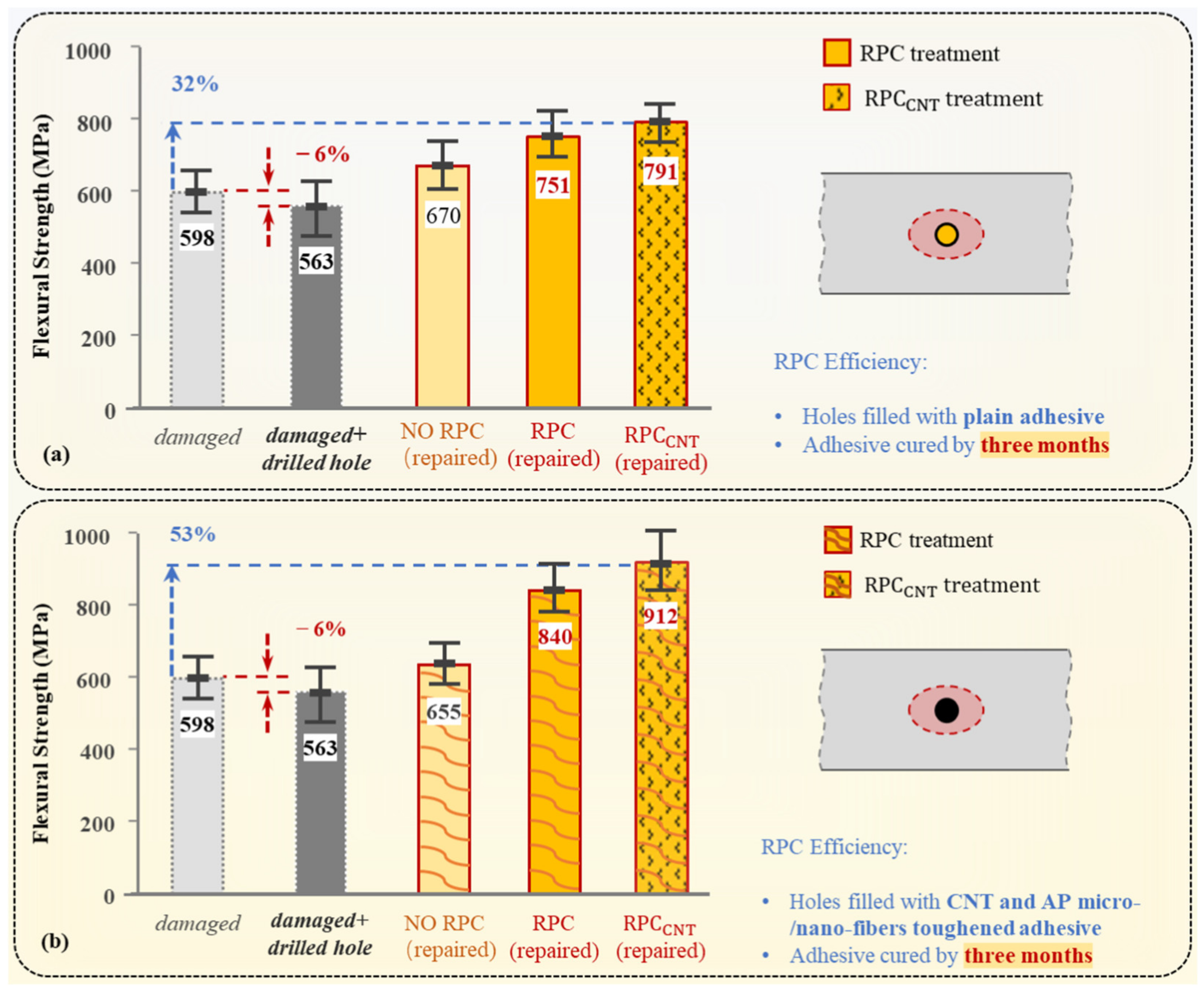

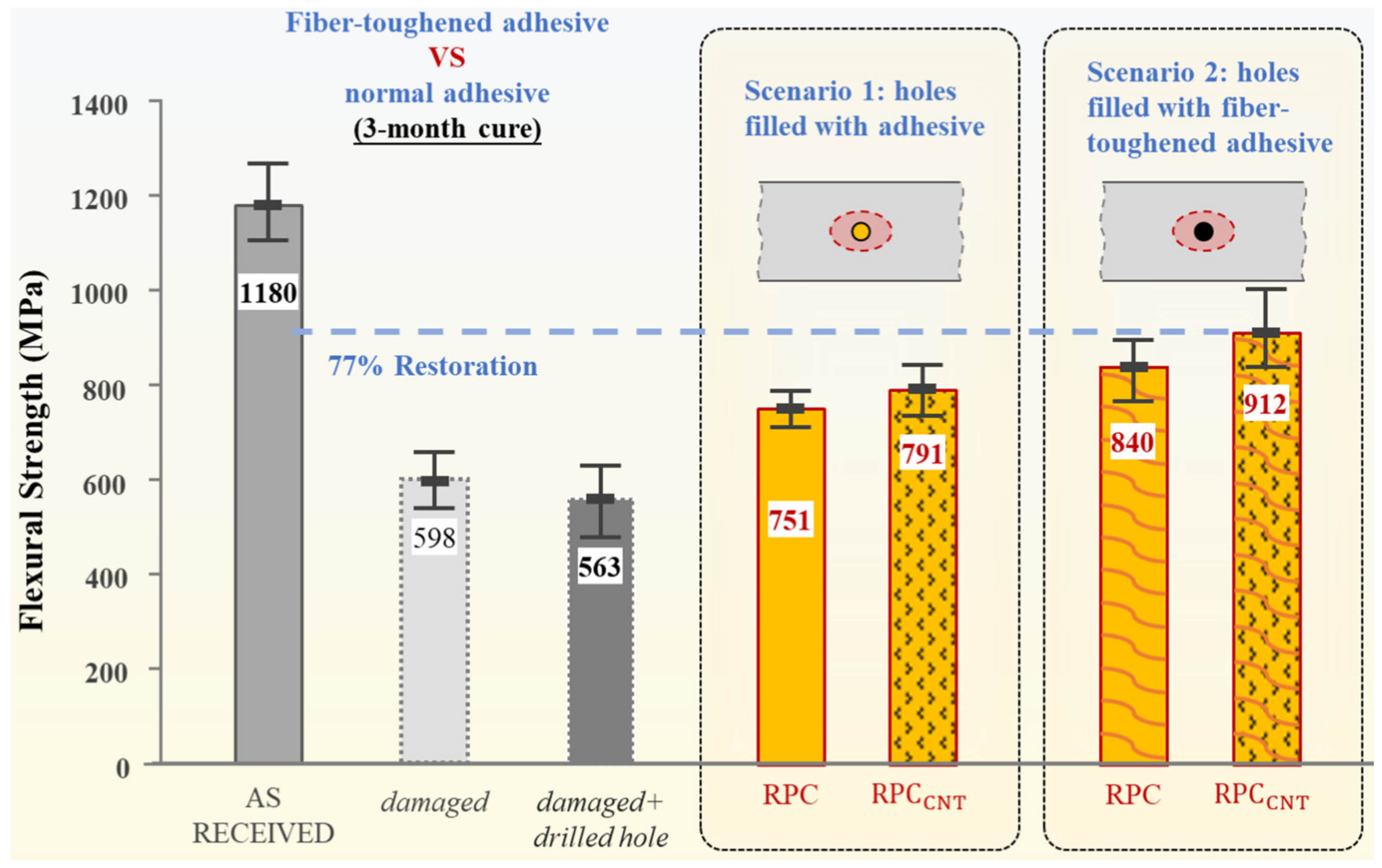

2.2. Results

2.2.1. Delamination Repairs Using Resin Pre-Coating (RPC) Solution and RPCCNT Suspension

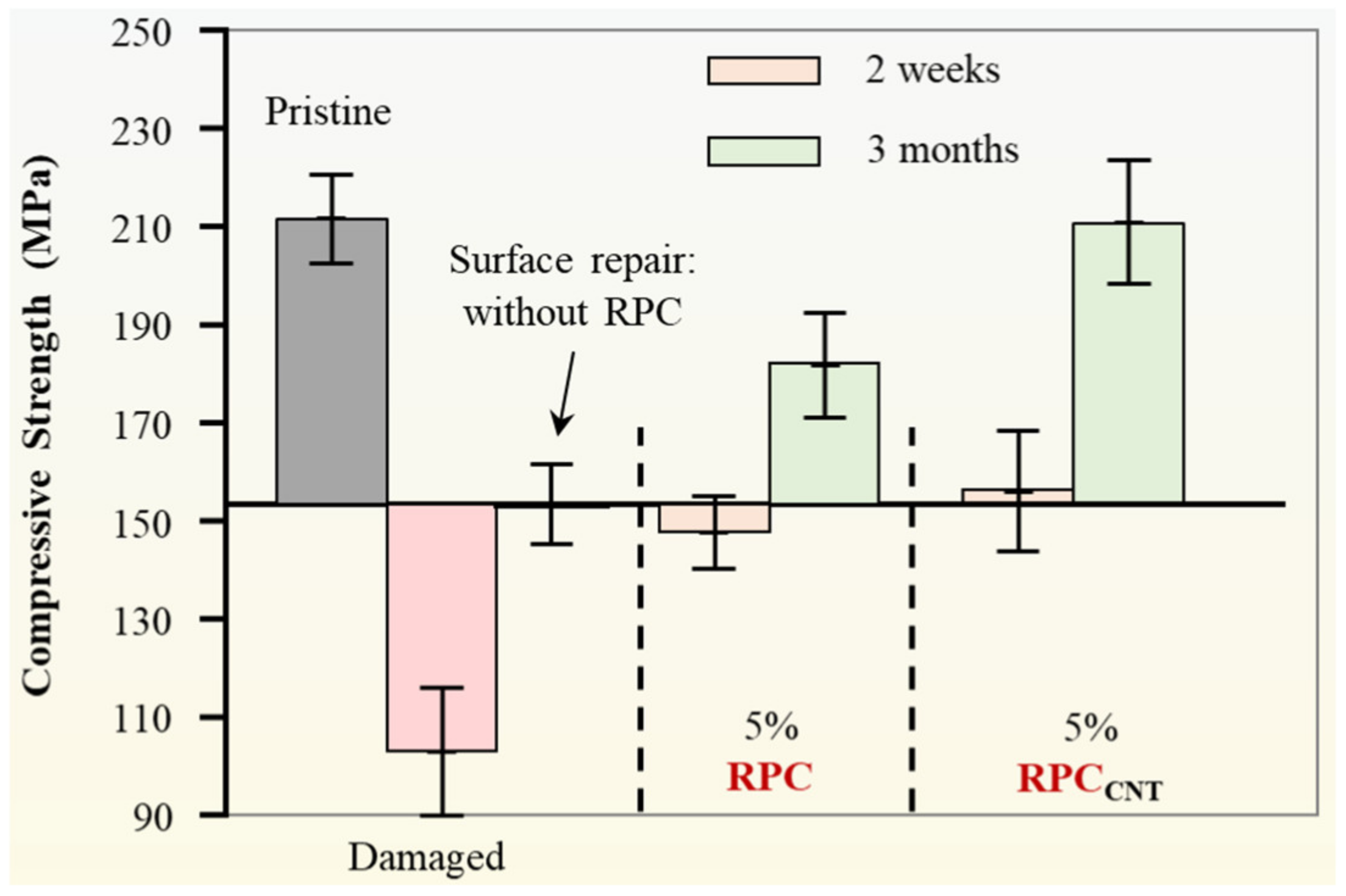

2.2.2. Curing Time Periods Required by RPC and RPCCNT Repair Methods

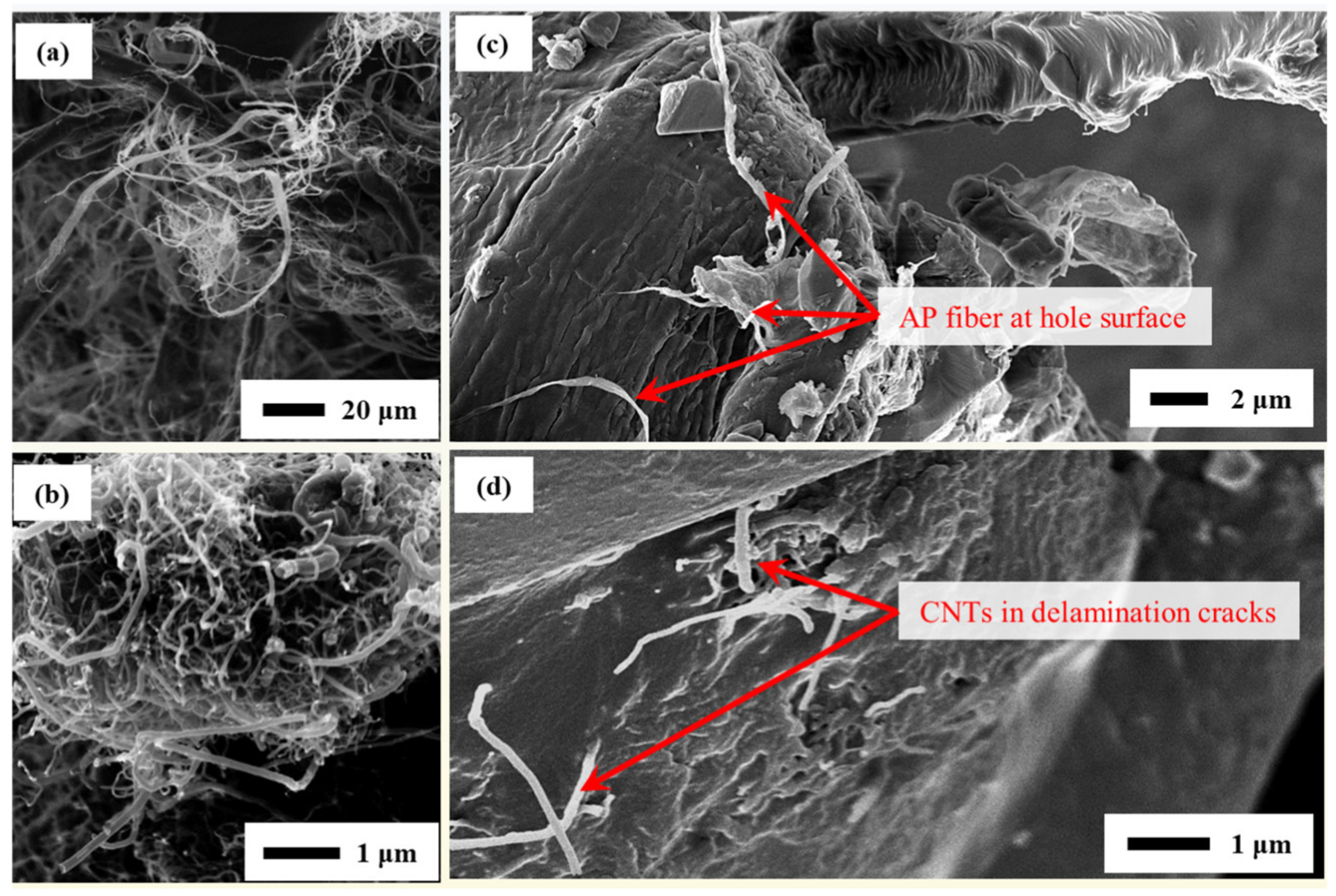

2.2.3. CNT and Micro-/Nano-Fiber Toughened Epoxy for the Drilled Hole

3. Materials and Methods

4. Conclusions

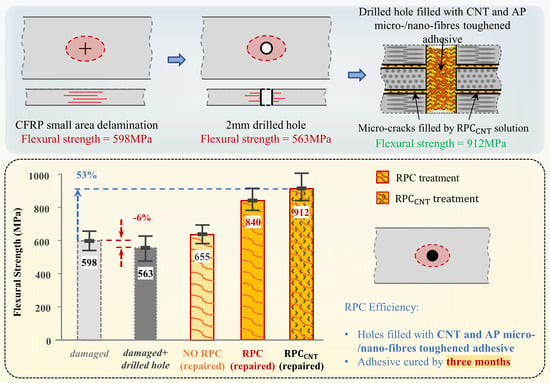

- The introduction of a small drilled hole (2 mm in diameter) at the center of the delamination zone did not significantly weaken the CFRP specimens (20 mm in width), but it did provide access to the internal delamination cracks required by the RPC method.

- The RPC solution, consisting of 90 m/m% acetone and 10 m/m% resin, exhibited excellent penetration properties without requiring pressure. The repair results with and without RPC demonstrate that the acetone-rich RPC solution played a significant role in successful delamination repairs.

- The CNT-containing RPC suspension, or RPCCNT, was found to be more effective due to CNT-toughening and strengthening of the filled adhesive. The RPC solution was able to transport CNT deep into narrow cracks.

- The contact curing experiments indicated that a resin and hardener mixture in contact with resin (without hardener) favored the “diffusion of polymerization” more than simple hardener and resin contact. A long curing period (>2 weeks), such as 3 months, was found to be necessary for complete contact curing, depending on the depth of the delamination cracks.

- The CNT and AP micro-/nano-fibers-toughened epoxy for the drilled hole provided additional benefits due to fiber strengthening.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shiekh, P.A.; Mohammed, S.A.; Gupta, S.; Das, A.; Meghwani, H.; Maulik, S.K.; Banerjee, S.K.; Kumar, A. Oxygen releasing and antioxidant breathing cardiac patch delivering exosomes promotes heart repair after myocardial infarction. Chem. Eng. J. 2022, 428, 132490. [Google Scholar] [CrossRef]

- Aabid, A.; Hrairi, M.; Ali, J.S.M. Optimization of composite patch repair for center-cracked rectangular plate using design of experiments method. Mater. Today Proc. 2020, 27, 1713–1719. [Google Scholar] [CrossRef]

- Fong, L.S.; Winlaw, D.S.; Orr, Y. Is the modified single-patch repair superior to the double-patch repair of complete atrioventricular septal defects? Interact. Cardiovasc. Thorac. Surg. 2019, 28, 427–431. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, D.V.; Padma, S.R.; Idapalapati, S. Comparative study of composite scarf and strap joints for equivalent repair signature under uniaxial tension. Compos. Part A Appl. Sci. Manuf. 2022, 158, 106950. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; De Moura, M.F.S.F.; Pinto, A.M.G.; Morais, J.J.L.; Domingues, J.J.M.S. Modelling the tensile fracture behaviour of CFRP scarf repairs. Compos. Part B Eng. 2009, 40, 149–157. [Google Scholar] [CrossRef]

- Gunnion, A.J.; Herszberg, I. Parametric study of scarf joints in composite structures. Compos. Struct. 2006, 75, 364–376. [Google Scholar] [CrossRef]

- Yang, L.; Yang, Y.; He, S.; Chen, G.; Ao, C.; Zhang, W. Scarf patch repair of honeycomb sandwich composites and its simulation optimisation. Plast. Rubber Compos. 2021, 50, 307–314. [Google Scholar] [CrossRef]

- Sun, C.; Zhao, W.; Zhou, J.; Altenaiji, M.; Cantwell, W.J.; Wang, Q.Y.; Guan, Z.W. Mechanical behaviour of composite laminates repaired with a stitched scarf patch. Compos. Struct. 2021, 255, 112928. [Google Scholar] [CrossRef]

- Jiang, H.; Ren, Y.; Zhang, S.; Liu, Z.; Yu, G.; Xiang, J. Damage and perforation resistance behaviors induced by projectile impact load on bonding-patch repaired and scarf-patch repaired composite laminates. Int. J. Damage Mech. 2019, 28, 502–537. [Google Scholar] [CrossRef]

- Guan, W.; Su, Y.; Tong, G. Static and Fatigue Properties of Scarf Patch Repaired Composite Laminates: An Experimental Study. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 677, p. 022010. [Google Scholar]

- Feng, W.; Xu, F.; Yuan, J.; Zang, Y.; Zhang, X. Focusing on in-service repair to composite laminates of different thicknesses via scarf-repaired method. Compos. Struct. 2019, 207, 826–835. [Google Scholar] [CrossRef]

- Lai, W.L.; Saeedipour, H.; Goh, K.L. Experimental assessment of drilling-induced damage in impacted composite laminates for resin-injection repair: Influence of open/blind hole-hole interaction and orientation. Compos. Struct. 2021, 271, 114153. [Google Scholar] [CrossRef]

- Lai, W.L.; Saeedipour, H.; Goh, K.L. Mechanical properties of low-velocity impact damaged carbon fibre reinforced polymer laminates: Effects of drilling holes for resin-injection repair. Compos. Struct. 2020, 235, 111806. [Google Scholar] [CrossRef]

- Thunga, M.; Bauer, A.; Obusek, K.; Meilunas, R.; Akinc, M.; Kessler, M.R. Injection repair of carbon fiber/bismaleimide composite panels with bisphenol E cyanate ester resin. Compos. Sci. Technol. 2014, 100, 174–181. [Google Scholar] [CrossRef]

- Lee, J.H.; Ge, J.C.; Song, J.H. Study on burr formation and tool wear in drilling CFRP and its hybrid composites. Appl. Sci. 2021, 11, 384. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, M.; Liu, K.; Yuan, K.; He, J. Experimental analysis and prediction of CFRP delamination caused by ice impact. Eng. Fract. Mech. 2022, 273, 108757. [Google Scholar] [CrossRef]

- Irwin, G.R. Linear fracture mechanics, fracture transition, and fracture control. Eng. Fract. Mech. 1968, 1, 241–257. [Google Scholar] [CrossRef]

- Han, G.; Tan, B.; Cheng, F.; Wang, B.; Leong, Y.K.; Hu, X. CNT toughened aluminium and CFRP interface for strong adhesive bonding. Nano Mater. Sci. 2022, 4, 266–275. [Google Scholar] [CrossRef]

- Wang, B.; Hu, X.; Hui, J.; Lu, P.; Jiang, B. CNT-reinforced adhesive joint between grit-blasted steel substrates fabricated by simple resin pre-coating method. J. Adhes. 2018, 94, 529–540. [Google Scholar] [CrossRef]

- Wang, B.; Bai, Y.; Hu, X.; Lu, P. Enhanced epoxy adhesion between steel plates by surface treatment and CNT/short-fibre reinforcement. Compos. Sci. Technol. 2016, 127, 149–157. [Google Scholar] [CrossRef]

- Han, G.; Yuan, B.; Hu, X. Restoration of Compressive Strength of CFRP Plates with Edge Delamination through CNT Crack-Bridging Deposited by Resin Pre-Coating Solution. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107798. [Google Scholar] [CrossRef]

- Yu, X.; Shen, W.; Zhu, L.; Natsuki, T. The tensile properties and repair behavior of glass fiber reinforced polymer using resin pre-coating technology. Text. Res. J. 2023, 93, 5187–5197. [Google Scholar] [CrossRef]

- Ji, Y.; Chen, Y.; Han, X.; Hu, X.; Yuan, B.; Qiao, Y. Effect of acetone on mechanical properties of epoxy used for surface treatment before adhesive bonding. Polym. Test. 2020, 86, 106492. [Google Scholar] [CrossRef]

- Perez, N. Linear Elastic Fracture Mechanics; Springer: New York, NY, USA, 2004; pp. 39–72. [Google Scholar]

- Ricotta, M.; Quaresimin, M.; Talreja, R. Mode I strain energy release rate in composite laminates in the presence of voids. Compos. Sci. Technol. 2008, 68, 2616–2623. [Google Scholar] [CrossRef][Green Version]

- Roucou, D.; Diani, J.; Brieu, M.; Mbiakop-Ngassa, A. Critical strain energy release rate for rubbers: Single edge notch tension versus pure shear tests. Int. J. Fract. 2019, 216, 31–39. [Google Scholar] [CrossRef]

- Lerpiniere, A.; Caron, J.F.; Diaz, A.D.; Sab, K. The LS1 model for delamination propagation in multilayered materials at 0°/θ° interfaces: A comparison between experimental and finite elements strain energy release rates. Int. J. Solids Struct. 2014, 51, 3973–3986. [Google Scholar] [CrossRef]

- Song, S.H.; Paulino, G.H.; Buttlar, W.G. A bilinear cohesive zone model tailored for fracture of asphalt concrete considering viscoelastic bulk material. Eng. Fract. Mech. 2006, 73, 2829–2848. [Google Scholar] [CrossRef]

- Choi, H.; Park, K.; Paulino, G.H. Mixed-mode fatigue crack growth using cohesive zone modeling. Eng. Fract. Mech. 2020, 240, 107234. [Google Scholar] [CrossRef]

- Xu, J.; Lin, T.; Davim, J.P.; Chen, M.; El Mansori, M. Wear behavior of special tools in the drilling of CFRP composite laminates. Wear 2021, 476, 203738. [Google Scholar] [CrossRef]

- Xu, C.; Wang, Y.; Xu, J.; Liu, X. Design of internal-chip-removal drill for CFRP drilling and study of influencing factors of drilling quality. Int. J. Adv. Manuf. Technol. 2020, 106, 1657–1669. [Google Scholar] [CrossRef]

- Kwon, B.C.; Mai, N.D.D.; Cheon, E.S.; Ko, S.L. Development of a step drill for minimization of delamination and uncut in drilling carbon fiber reinforced plastics (CFRP). Int. J. Adv. Manuf. Technol. 2020, 106, 1291–1301. [Google Scholar] [CrossRef]

- Qiu, X.; Li, P.; Li, C.; Niu, Q.; Chen, A.; Ouyang, P.; Ko, T.J. New compound drill bit for damage reduction in drilling CFRP. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 6, 75–87. [Google Scholar] [CrossRef]

- Su, F.; Zheng, L.; Sun, F.; Wang, Z.; Deng, Z.; Qiu, X. Novel drill bit based on the step-control scheme for reducing the CFRP delamination. J. Mater. Process. Technol. 2018, 262, 157–167. [Google Scholar] [CrossRef]

- Kanu, N.J.; Gupta, E.; Vates, U.K.; Singh, G.K. Self-healing composites: A state-of-the-art review. Compos. Part A Appl. Sci. Manuf. 2019, 121, 474–486. [Google Scholar] [CrossRef]

- Patrick, J.F.; Robb, M.J.; Sottos, N.R.; Moore, J.S.; White, S.R. Polymers with autonomous life-cycle control. Nature 2016, 540, 363–370. [Google Scholar] [CrossRef]

- ASTM D3410/D3410M-16e1; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials with Unsupported Gage Section by Shear Loading. ASTM International: West Conshohocken, PA, USA, 2006.

- Thunga, M.; Larson, K.; Lio, W.; Weerasekera, T.; Akinc, M.; Kessler, M.R. Low viscosity cyanate ester resin for the injection repair of hole-edge delaminations in bismaleimide/carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 2013, 52, 31–37. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, G.; Hu, X. Repair of Small-Area Delamination in Carbon Fiber-Reinforced Polymer through Small Drilled Hole and Carbon Nanotubes-Reinforced Resin Pre-Coating Technique. Inorganics 2023, 11, 454. https://doi.org/10.3390/inorganics11120454

Han G, Hu X. Repair of Small-Area Delamination in Carbon Fiber-Reinforced Polymer through Small Drilled Hole and Carbon Nanotubes-Reinforced Resin Pre-Coating Technique. Inorganics. 2023; 11(12):454. https://doi.org/10.3390/inorganics11120454

Chicago/Turabian StyleHan, Gang, and Xiaozhi Hu. 2023. "Repair of Small-Area Delamination in Carbon Fiber-Reinforced Polymer through Small Drilled Hole and Carbon Nanotubes-Reinforced Resin Pre-Coating Technique" Inorganics 11, no. 12: 454. https://doi.org/10.3390/inorganics11120454

APA StyleHan, G., & Hu, X. (2023). Repair of Small-Area Delamination in Carbon Fiber-Reinforced Polymer through Small Drilled Hole and Carbon Nanotubes-Reinforced Resin Pre-Coating Technique. Inorganics, 11(12), 454. https://doi.org/10.3390/inorganics11120454