1. Introduction

The development of high-power, narrow-band fiber lasers operating in aspectral wavelength range of about 0.98 μm is of great interest considering the prospect of their use ina number of important practical applications. There is a high demand for such lasers from the field of biomedical applications since the wavelength of 976 nm falls on the peak absorption of water and human blood. For this reason, laser radiation with a wavelength of 980 ± 10 nm is actively used in the fields of microsurgery, dentistry, and dermatology and for the treatment of post-surgery effects [

1,

2]. Recently, possible directions for replacing bulk glass lasers in the visible and UV ranges with fiber analogs have been widely discussed and studied. In this context, fiber lasers emitting a wavelength of 0.976 μm are extremely promising, since doubling the radiation frequency (output at~488 nm) makes it possible to offer an alternative to the argon laser, which is currently being widely used for medical applications [

3], and obtaining the fourth harmonic (output at ~244 nm) is an alternative to the excimer laser, which is in great demand for manufacturing the fiber Bragg gratings (FBGs) [

4] used in most laser all-fiber optical circuits. Compared to gas or solid-state lasers, which have bulky elements in the resonator, fiber lasers are distinguished by their low cost, compactness, reliability, and ease of driving and operation.

The key element of the fiber laser’s design is the active fiber, the properties of which largely determine the characteristics of the entire laser system. As is well known, Yb

3+ ions in silica glass have an intense luminescence band with a maximum at the wavelength of ~976 nm. In this regard, the active element of the resonator of fiber lasers emitting in the spectral region of about 980 nm is made on the basis of optical fibers with a core based on silica glass doped with Yb

2O

3. To date, a fairly large number of works are known that are dedicated to the creation of Yb-doped lasers with an operation wavelength of ~980 nm, which generate both continuous radiation from a few to hundreds of W [

5,

6,

7,

8,

9,

10] and pulsed radiation with a pulse duration from several nanoseconds to hundreds of femtoseconds [

11,

12,

13,

14,

15]. At the same time, often in pursuit of higher values of output power (for example, [

5]) or ultrashort durations of laser pulses (for example, [

11]), researchers do not pay detailed attention to the quality of the spectrum of the generated radiation nor the degree of its polarization, and thus, the scope of such sources is limited. An experimental demonstration of the conversion of laser radiation with a wavelength of ~980 nm into radiation of the visible and UV parts of the spectrum was realized only for an extremely small number of truly narrow-band laser sources of a continuous signal [

16,

17,

18], which differ due to a large number of bulk elements in the laser circuit, thereby eliminating the advantages circuits based on optical fibers.

The research and development of new types of lasers that make it possible to obtain a stable output of only one spectral component in a wavelength range of interest with an acceptable output power level (at least several milliwatts) are of enormous practical importance. The use of maximally narrow-band and linearly polarized laser radiation makes the process of nonlinear conversion more efficient, which is critical considering the relatively low efficiency (usually ~30%) of the nonlinear elements. The all-fiber design of the laser circuit makes it possible to further increase the overall efficiency of the entire system, ensure low production and operation costs, and, by controlling the waveguide parameters of the active fibers, guarantee the high quality of the output beam.

The solution to the problem of creating a narrow-band source of single-frequency radiation with a wavelength of 980 nm can be lasers of a new design—“random” lasers—one of the advantages of which is the generation of an extremely narrow spectral line [

19]. A distinctive feature of random lasers is a cavity consisting of an array of identical weakly reflecting FBGs induced in the glass of the fiber core directly during the fiber drawing process [

20]. Each individual FBG is inscribed using a phase mask in one pulse generated by an excimer UV laser, and a polymer coating is applied almost immediately to the irradiated section of the fiber. The key advantage of the in-line fabrication technique is the ability to quickly and inexpensively create arrays of many identical FBGs without compromising the mechanical strength of the fiber. The laser cavity produced in this way has a mechanical strength that is not inferior to the strength of a conventional silica fiber drawn in a standard polymer coating. Under the condition of precise control over the in-line fabrication process, the total reflection spectrum of the FBG array can be quite narrow (with minimal distortions), which results in the stability of the entire laser emission wavelength [

21]. Feedback in a random cavity is achieved due to the Rayleigh scattering effect, and the operating wavelength of the laser is determined by the reflection wavelength of the FBG array, which, in turn, depends on the period of the used phase mask [

22]. This extended design of a random cavity, in contrast to the classical fiber Fabry–Perot resonator, is not so demanding where amplifying the characteristics of the fiber is concerned; however, its use opens up extremely broad possibilities for obtaining laser generation, potentially at any wavelength, in the transparency region of quartz glass. To obtain laser oscillation in a random cavity, it is necessary to have a suitable pump source, the amplification in the active fiber at a chosen wavelength, and a sufficient total reflection coefficient of the FBGs’ array.

The development of a random laser for a wavelength range of ~980 nm requires suitable commercially available diode pump sources of sufficient power with an operational wavelength of ~910 nm, which can be used to obtain amplification in ytterbium-doped fibers near the maximum of the main luminescence band of Yb

3+ ions (976 nm). The photosensitivity of the core glass to UV laser radiation is a crucial condition for the manufacture of a random laser cavity in the process of fiber drawing. Previously, it was found that a standard SMF28 telecommunication fiber with a silica-based glass core doped with 3 mol% of GeO

2 showed sufficient photosensitivity for inducing contrast FBGs when irradiated with an excimer laser with a wavelength of 248 nm [

23]. At the same time, for fibers with a concentration from 4 to 7 mol% of P

2O

5 in the core, it was found that the addition of ~3 mol% of GeO

2 can profoundly (by more than an order of magnitude) increase their photosensitivity [

23,

24]. Thus, the high initial photosensitivity of fibers with a germanophosphosilicate glass core (five times higher than that in germanosilicate glass with 3 mol% of GeO

2) makes these fibers convenient for inscribing FBG arrays with a high contrast (at least 50 dB) using laser radiation at a wavelength of 248 nm. Another significant advantage of the GeO

2-P

2O

5-SiO

2 matrix is the presence of P

2O

5 glass in the core glass; the phosphorus addition reduces the clustering of Yb

3+ ions and prevents photodarkening of ytterbium-doped fibers under the high power of pump radiation.

Quite recently, our group has researched novel erbium and ytterbium fibers using a GeO

2-P

2O

5-SiO

2 core glass matrix, which were the basis for the fabrication of highlyefficient and narrow-band “random” lasers with an operation wavelength of 1547.6 nm [

23] and 1060 nm (slope efficiency 32%) [

24], respectively. Evolved from the previous advancement in fiber technology fabrication [

23,

24], this work has shown for the first time the possibility of achieving narrow-band lasing at a wavelength of 976 nm in the “random” laser cavity, which was based on the specially designed ytterbium-doped optical fiber with a germanophosphosilicate core.

2. Materials and Methods

The fiber preform was fabricated by the MCVD method with the deposition of all glass components from the gas phase. The highly volatile, high-purity liquid halides SiCl

4, POCl

3, GeCl

4, CCl

4, and C

2F

3Cl

3 and a low-volatile powder of Yb(thd)

3 (thd = 2,2,6,6-tetramethyl-3,5-heptanedionate) were used as precursors. The Yb

2O

3-GeO

2-P

2O

5-SiO

2 core glass was fabricated by the approach of a separate deposition of a porous GeO

2/P

2O

5/SiO

2 matrix layer followed by gas-phase impregnation of the layer with Yb

2O

3 and sintering of the Yb

2O

3/GeO

2/P

2O

5/SiO

2 porous layer in the presence of a chlorine precursor (CCl

4) to remove hydrogen-containing impurities formed at the stage of impregnation. A separate deposition of glass components and active dopant makes it possible to carry out the conversion of precursors into oxides under optimal conditions (temperature, gas-vapor mixture flow rate). The technique (a detailed description is given in papers [

25,

26]) ensures a precisely specified composition, homogeneity, and a high level of purity of the synthesized glasses, including the content of OH-group impurities, despite the use of YbC

33H

57O

6, which contains a large amount of hydrogen [

27]. A core ~1.3 mm in diameter was fabricated by depositing 6 thin layers of the core glass. After that, the tube was consolidated into a cylindrical preform, which, in turn, was jacketed to secure a cutoff wavelength of the first highest mode (LP

11) of 0.89 μm. The concentration of dopants in the synthesized core glass was 3 mol% of GeO

2, 4 mol% of P

2O

5, and less than 0.1 mol% of Yb

2O

3 (below the detection limit forYb

2O

3 by X-ray microanalysis).

A single-mode fiber (core diameter ~6 μm) with an outer cladding diameter of 125 μm was drawn from the jacketed preform. The refractive index difference of the core and cladding (core Δn) was 0.007;the intensitiesof the absorption band of Yb

3+ ions at the wavelengths from pumping (908 nm) and generation of a “random” laser (976 nm) were 3.7 and 22 dB/m, respectively. The high photosensitivity of the germanophosphosilicate glass matrix made it possible to inscribe a distributed FBG array in the fiber core during its drawing using the technique described in [

28]. The FBG was inscribed using pulsed radiation with a wavelength of 248 nm generated by an excimer KrF laser. A rectangular laser beam was focused with a cylindrical lens onto the phase mask surface with a period of 671.2 nm, behind which the irradiated part of the fiber was located at a distance of ~100 μm. The fiber drawing speed and the laser pulse repetition rate were synchronized so that each FBG had a fixed length of 10 mm and was inscribed in exactly 1 pulse. Thus, every meter of the drawn fiber contained 100 FBGs. In accordance with the period of the used phase mask and the waveguide parameters of the fiber, the reflection maximum of the gratings was near a wavelength of 976 nm. The average contrast level of the photoinduced FBGs (the difference between the maximum of the signal reflected by the grating and the Rayleigh scattering level) was 50 dB, and the reflection coefficient was about 0.05%. The weak reflection of each individual grating led to the need to use an extended array of several hundred gratings for the fabrication of the laser cavity. On the other hand, a fiber with a low concentration of ytterbium ions in the core and a low intensity of their absorption (in this work, it was ~22 dB/m at the maximum) is optimal for efficient pumping of a relatively long resonator (with a length of several meters). Thus, samples of resonators of the “random” laser with an initial length of 8 m were fabricated, consisting of several hundreds of low-reflecting gratings of the same type, which are distributed continuously along the length of a low-doped ytterbium fiber.

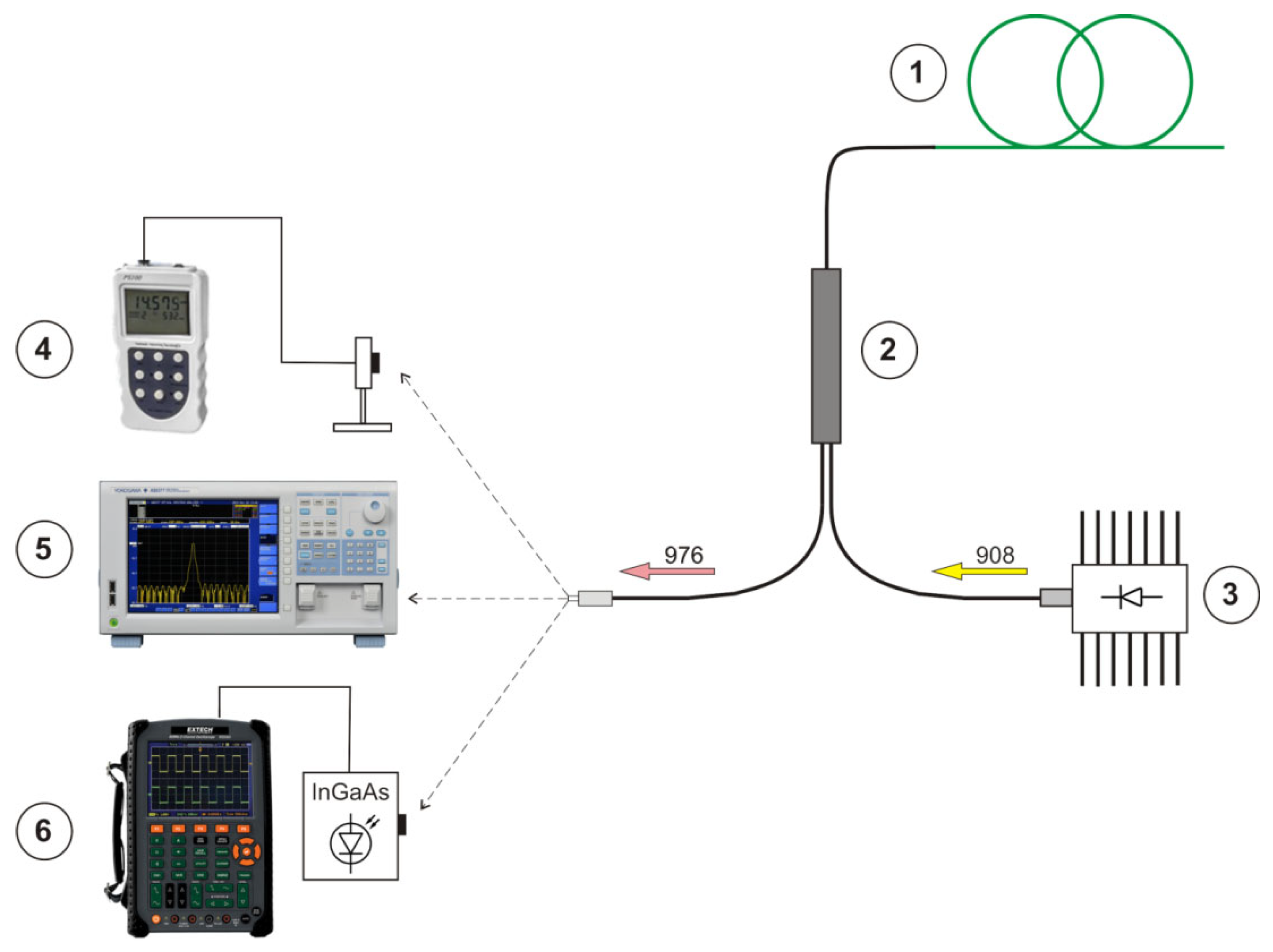

The scheme of the experimental setup, which was used to study the characteristics of the “random” laser, is depicted in

Figure 1. In this work, a “backward” laser pumping scheme was used: laser cavity “1”, which is a segment of the ytterbium-doped fiber with an FBG array inscribed inside, was connected through a filter–multiplexer (FWDM) “2” to a pump source “3”, generating radiation at a wavelength of 908 nm (QPhotonics QFLD-905-200S). Radiation with a wavelength of 976 nm, generated by the “random” laser, was output through the corresponding port of the filter–multiplexer. The choice of the wavelength for the pump source (908 nm) was due to the use of a three-level scheme for oscillating an ytterbium laser at a wavelength of 976 nm. To measure the output power, a power meter “4” (CNILaser PS100) was used. This device was also used to monitor the values of the laser output power in real time with an interval of 1 s. The laser emission spectra were recorded using an optical spectrum analyzer “5” (Yokogawa AQ6370C) with a maximum resolution of 0.02 nm. The study of laser power fluctuations within short time intervals is of particular interest. For these measurements, a high-speed photodetector “6” based on an InGaAs photodiode was used, the signal from which was fed to an Extech MS6060 digital oscilloscope. All studies of resonator samples were carried out at constant room temperature (295 K).

3. Results

In the present work, the following performance characteristics of “random” lasers were investigated: optical spectrum, power of the output of the laser depending on the power of the pump radiation and the length of the cavity, and power fluctuations for various cavity configurations.

The first sample, for which the abovementioned measurements were carried out, had a cavity length of 8 m. Let us analyze the shape of the optical spectra of this laser depending on the pump power introduced into the cavity. As depicted in

Figure 2, two laser emission spectra were measured at pump powers of 30 and 70 mW, respectively. The lasing threshold for this particular resonator was recorded at an input pump power of about 30 mW; therefore, curve “1” characterizes the laser spectrum near the threshold. Curve “2” corresponds to the emission spectrum of the laser being generated at a pump power of 70 mW, which is more than two times higher than the threshold. It should be noted that when using segments of the same ytterbium fiber and the same length (8 m), but not containing arrays of weakly reflecting gratings, no signs of the appearance of laser generation were discovered, even at the maximum value of the introduced pump power of ~120 mW. Thus, the probability of the occurrence of parasitic oscillation at the end of the fiber or splicing points was excluded, and confirmation of the “random” resonator lasing was obtained [

29,

30].

It can be seen from

Figure 2 that the position of the intensity maximum (975.94 nm) does not change with increasing pump power and laser output power, which can be explained by the absence of any significant temperature heating of the cavity, obviously due to the uniform absorption of pump radiation along its entire length. The initial shape of the spectral line of the laser with a prominent narrow peak (half-width ~0.05 nm) is also retained at pump powers significantly higher than the threshold.

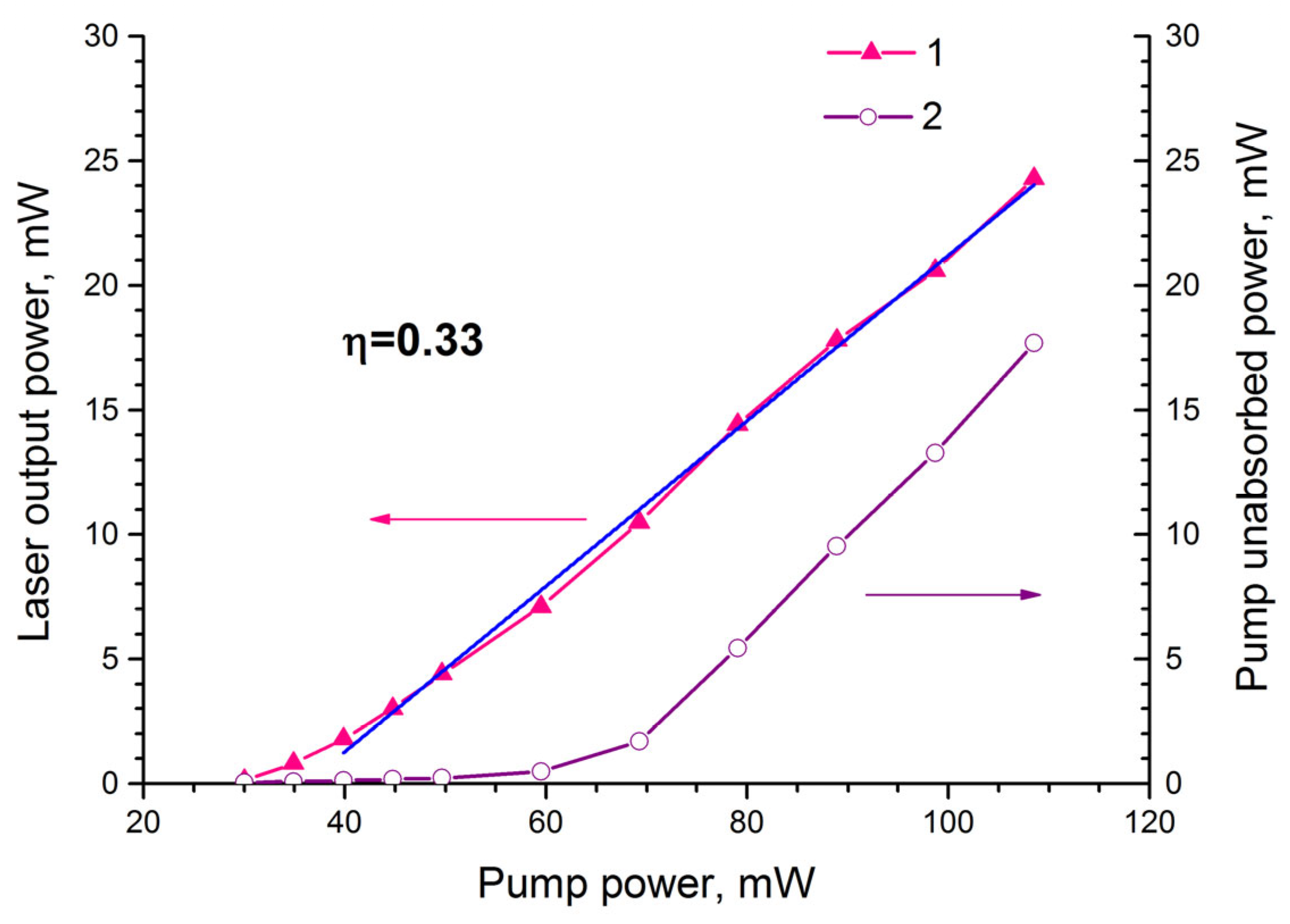

To estimate the efficiency of the “random” laser cavity, we studied the dependence of the output power from it on the input power (

Figure 3, curve “1”). It can be seen that this dependence, at pump powers above 40 mW, is approximated with good accuracy by a straight line, from the slope of which, adifferential efficiency value of 33% was calculated for a cavity with a length of 8 m. It is also important to clarify that the studied laser in the experiments generated radiation only in the direction opposite from that of the pump radiation input. Part of the pump power that was introduced into the cavity was not absorbed and exited from the fiber end; this was opposite to the direction of propagation of the laser radiation. With an increase in power, the fraction of unabsorbed pumping increased (

Figure 3, curve 2), which was associated with a decrease in the intensity (“bleaching”) of the absorption band of Yb

3+ ions under the pump radiation. The maximum power at the output of the laser reached 25 mW, and its value is quite comparable with the parameters of commercially available semiconductor single-frequency lasers, which generatein the wavelength range of ~975 nm.

One of the most important investigations of this work was to study the effect of the cavity length on the output characteristics of the “random” laser. To minimize the instabilities related to unabsorbed pump power, these measurements were carried out at a pump power level of 40 mW. As shown in

Figure 4, a reduction in length from the initial 8 to 5 m did not reveal any noticeable decrease in the output power of the laser. However, a further reduction in the resonator length was accompanied by a decrease in the output power; the power level declined especially sharply for resonator lengths shorter than 4 m.

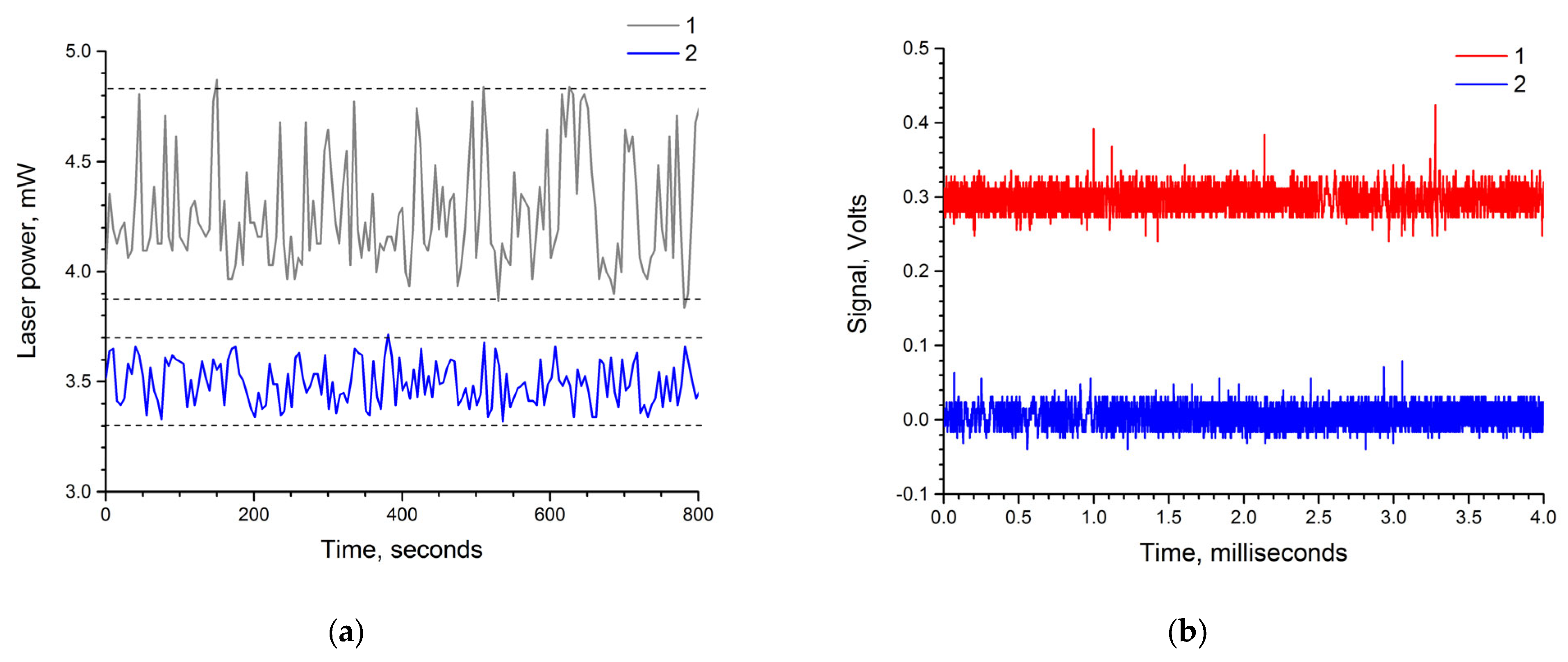

On the other hand, with a decrease in the resonator length, the tendency fora decrease in the amplitude of output power fluctuations was revealed. The result of a comparative study of the stability of the output power for resonators of different lengths is shown in

Figure 5a. Reducing the resonator length from 6 m to 1.8 m reduces power fluctuations by more than half: the calculated standard deviation value decreased from 0.25 to 0.1 mW, respectively. In addition, a “random” laser with a cavity length of 1.8 m generates radiation in an almost continuous mode (

Figure 5b), since the constant component of the signal assumes at least 90%. More importantly, the absence of periodic oscillations in the time dependence of the signal can be noticed, which is aclear characteristic of ytterbium lasers operating in a pulsed mode [

31,

32]. If we consider the work of [

32], upconversion processes (the transfer of excitation energy between closely spaced neighboring ions) are the main reason for the appearance of spontaneous pulsed lasing in ytterbium fiber lasers. The concentration of Yb

3+ ions in the studied fiber was significantly lower than in the fibers studied in [

31,

32]. In this regard, the probability of the occurrence of upconversion processes is minimal, and, consequently, there is no transition from the continuous to pulsed laser output.

A common feature of the samples of “random” lasers studied in this research was the preservation for a long time (tens of minutes) of a relatively high level of the constant component in the optical signal generated by them. From the point of view of the prospects for using a narrow-band laser as a source of reference emission, its stability is a critical parameter, and, inthis case, it is sensible to opt for the shortest “random” resonator. However, the inevitable decrease in the laser efficiency and an increase in the lasing threshold (up to values exceeding the maximal available pump power level) can become significant restraint factors. One of the possible ways to compensate for the negative consequences of shortening the resonator length is considered in this work: the resonator of a “random” laser of 1.8 m long was proposed to be modified using a single, “deeply” inscribed Bragg grating, the reflection peak of which exactly coincides in wavelength with the maximum reflection of the FBGs’ array in the cavity.

Figure 6 shows a clearer comparison of the reflection spectra of an array of low-reflecting FBGs and a single FBG of 10 mm long used for the experiments. This FBG was inscribed in the commercially available Corning HI 1060 fiber by using a standard phase mask technique. The single FBG had a reflectivity of ~90% and was spliced to the 1.8 m long resonator of the “random” laser on the side opposite from the direction of the input of the pump radiation. Since the numerical apertures of the studied Yb-doped fiber and the Corning HI 1060 fiber were approximately the same (~0.14), the optical losses induced during splicing (i.e., intracavity losses) were negligibly low, i.e., less than 0.1 dB.

Thus, part of the energy of radiation with a wavelength of 976 nm that passed through the resonator was returned and amplified. The addition of the separate FBG in the 1.8 m long cavity of the “random” laser led not only to a two-fold increase in its differential efficiency from 7 to 15% (

Figure 7a) but also improved its stability by the same factor, reducing the amplitude of the output power fluctuations from 10 to 5% (

Figure 7b).

5. Conclusions

The possibility of obtaining efficient lasing with narrow-band radiation at a wavelength of 976 nm in a “random” resonator based on an extended array of low-reflecting FBGs inscribed in the core of an ytterbium fiber during the fiber drawing process has been demonstrated for the first time. To induce FBGs with UV irradiation during the drawing process, increased photosensitivity was required of the fiber core glass, which was achieved by co-doping the core glass with germanium and phosphorus oxides.

In a “random” resonator, the dependence of the output characteristics on the fiber length was studied. It was shown that with an increase in the length of the laser cavity, its slope efficiency first increases, reaching a maximum value (33%) at a length of about 5 m, and remains at the same level at longer lengths. At the same time, as the length of the “random” cavity increases, the amplitude of power fluctuations at the output of the laser increases linearly, which significantly limits its use as a source of reference radiation.

It turned out to be possible to solve the problem and thus increase the stability of the output power by adding a separate FBG to the resonator circuit on the side opposite from the pump input direction. Provided that the reflection wavelengths of a single FBG and an array of FBGs of the “random” resonator are precisely matched, eventually not only stability but also the laser efficiency will be significantly improved in it. Therefore, in a “random” resonator of 1.8 m long with a 90% reflectivity FBG spliced at the end, the laser slope efficiency turned out to be approximately two times higher and, at the same time, the level of fluctuations in the output power is two times lower than in a resonator of the same length without the separate grating.

It has been demonstrated that an ytterbium-doped fiber laser with a “random” resonator is capable of operating at room temperature in a continuous-wave mode for a long time (at least tens of minutes), which is extremely important from the point of view of the prospects for its use as a source of reference radiation.