1. Introduction

The development of science has enabled humankind to further observe and study the universe. Therefore, the demand to observe darker and remote objects has increased, leading to the requirement of telescopes with larger apertures. As factors such as materials, manufacturing techniques, and transportation limit the feasibility of manufacturing a large, monolithic aperture mirror, alternative methods need to be developed. Recently, the use of a few smaller mirrors to function similarly to a large mirror has proven to be an effective plan by some successful telescope precedents such as Keck, SALT, and HET; the most noteworthy example is the James Webb Space Telescope (JWST) (successor of the Hubble Space Telescope) that was launched on 25 December 2021.

However, segmented design leads to new requirements, including that all the segments should be aligned to closely resemble the ideal monolithic mirror, which is termed as co-phasing of the segmented mirror. We assume that each segment has six rigid-body degrees of freedom: three translational (x, y, z) and three rotational (tx, ty, tz), of which three (x, y, tz) are considered stable owing to their mechanical support structure; it is unnecessary to align them with optical precision. The remaining three degrees of freedom are piston error (z), tip error (tx), and tilt error (ty), respectively. These three errors are called co-phasing errors. Detection and adjustment of co-phasing errors is the most critical issue for a segmented mirror because a co-phasing error at even the µm level can cause a significant decline in the performance of segmented telescopes. The influence of co-phasing errors on segmented mirrors has been studied [

1,

2]. It is reported that all segments should be carefully co-phased to avoid diffraction effects in the final image. The piston error should be within 100 nm in the case of Keck [

3]. The piston error should be maintained below

, where

is defined as the working wavelength of the telescope.

For ground-based segmented telescopes (such as Keck), the piston error can reach more than tens or even a hundred micrometers [

4]; for space-based segmented mirrors, considering the accident and instability of the unfold and locking equipment, the predicted piston error should be more than 1 mm.

The interference method is commonly used for optical detection. The advantage of optical interference is the impressive high measurement precision and the relative ease of application. It has been used in many high-precision detection fields, such as mirror-surface-figure measurement. Owing to its high measurement precision, interferometry has also been applied for the detection of co-phasing errors in segmented mirrors [

5,

6]. An advantage of the interference method is that it can simultaneously calculate piston, tip, and tilt errors. However, the problem of interference of monochromatic light still exists, because it cannot accurately measure the piston error over more than half a wavelength. For this problem, some excellent research about the dual-wave interfermeotro has been carried out [

7,

8]; furthermore, dual-wave or white light interference techniques can also be used to expand the detection range of co-phasing [

9,

10]. However, as the detection range is expanded, the detection error also increases. Usually, a large detection range can be applied to coarse phasing processes and a small detection range for fine phasing processes. However, for a large piston error (~1 mm), the coarse phasing process cannot transition to the fine phasing process owing to the enhancement of the detection error (laser monochromaticity, vibration, air disturbance, detector noise, etc.). To resolve this problem, we introduced a multi-wave interference plan based on the dual-wave interference technology using a tunable laser as the light source, i.e., the multiwavelength phase shift interference (MPI) method. The piston error converges step-wise through the dynamic adjustment strategy. Further, for the convenience of adjusting the mirror surface, we used a reference mirror to generate the reference light rather than shear interference to achieve the correct wavefront information of each segment of the mirror. The MPI method can realize a large detection range and satisfactory detection precision, and measure the entire aperture in a relatively short time. Furthermore, it does not affect the working time of the telescope as it only requires the laser source rather than starlight.

However, the drawback of interference method is that illuminating a large aperture at its center of curvature is often not possible; therefore, it is hard to measure all segments at one time in the engineering practice. Several different techniques of co-phasing in a segmented mirror have been studied, including the use of the Shark–Hartman sensor or pyramid sensor to measure the co-phasing error [

11,

12], and the application of the dispersion fringe sensor (DFS) and curvature sensor to detect the co-phasing in segments [

13,

14]. A few technologies do not need to use those special devices but only need a sample optical device; for example, the intensity information of the image plane is used to correct the co-phasing error by the computer arithmetic [

15,

16]. For the JWST co-phasing process, the Dispersed Hartmann Sensor (DHS) and DFS were used for the coarse phasing [

17], the piston capture range was designed as 300 μm, owing to the segment’s depth of focus being about 85 μm for JWST. However, compared with the interference method, those methods which use starlight could not achieve a larger capture range (>1 mm) of co-phasing detection than the interference method because, with starlight, it is hard to achieve great monochromaticity as with a laser source, while the large capture range can significantly increase the fault-tolerance of segmented mirrors; therefore, the MPI method is advisable in case a large capture range is required.

The segments used in this study are based on a pre-research project of the Ministry of Science and Technology of China. An optical system with a 6 m-aperture primary mirror with 20 segments was designed for this project. These segments were formed by using eight fan-shaped mirrors and 12 octagon mirrors owing to the requirement of this pre-research project; the geometrical shape is illustrated in Figure 2. To verify the validity of the MPI method, a series of experiments were conducted in a scaled-down segment system.

The remainder of the paper is organized as follows. In

Section 2, we introduce the theory and methodology of MPI.

Section 3 describes the simulation result and

Section 4 explains the experimental setup and result. Finally,

Section 5 and

Section 6 present the disccusion and conclusions.

2. Methodology

2.1. Phase Shift Interferometry Basis

We first introduce the principle of classical phase shift interference method. A diffraction limited optical system was assumed; the only optical aberrations considered were co-phasing errors (i.e., piston, tip, and tilt errors), and the light source was assumed to be monochromatic. We defined

as the coordinates in the image plane. Then, the intensity function in the image plane can be written as:

where

and

are the reference and test light fields, respectively, and can be expressed as the complex amplitude of plane wave as follows:

where

A,

B and

,

are the amplitude and phase of each wave, respectively,

is the phase speed in vacuum,

t is the time, and we assume

. Then, Equation (1) becomes:

or

where

is the interference fringe constant.

Generally, some phase shift is needed in Equation (5) to calculate

[

7]. For example, for the four-step phase shift,

where

n is the number of frames in one time measurement,

I1 to

I4 was calculated by Equation (4) when

in Equation (4) is equal to 0, π/2, π, 3π/2 respectively.

The phase shift interference method can conveniently detect the wavefront of the telescope in the image plane, and subsequently obtain the co-phasing error information of segmented mirrors after

has been unwrapped; the real wavefront

becomes as follows:

or

where

is the period number to be wrapped and the unwrapped phase function

is continuous.

k is the wave number and

is the profile function of the entire segmented mirror that contains the co-phasing error information.

When piston error exists, the profile function is not continuous on the edge, and the difference of is exceptionally large between the edges of each segment so that the piston error calculated by is limited to the range [−1/2λ, 1/2λ], which is defined as the detection range of the interference method.

2.2. Synthetic Wavelength Basis

For the multiwavelength situation, Equation (7) can be written as:

where

for tow wavelength is equal to the real profile of segmented mirrors when

and

are assumed to have no ambuguity.

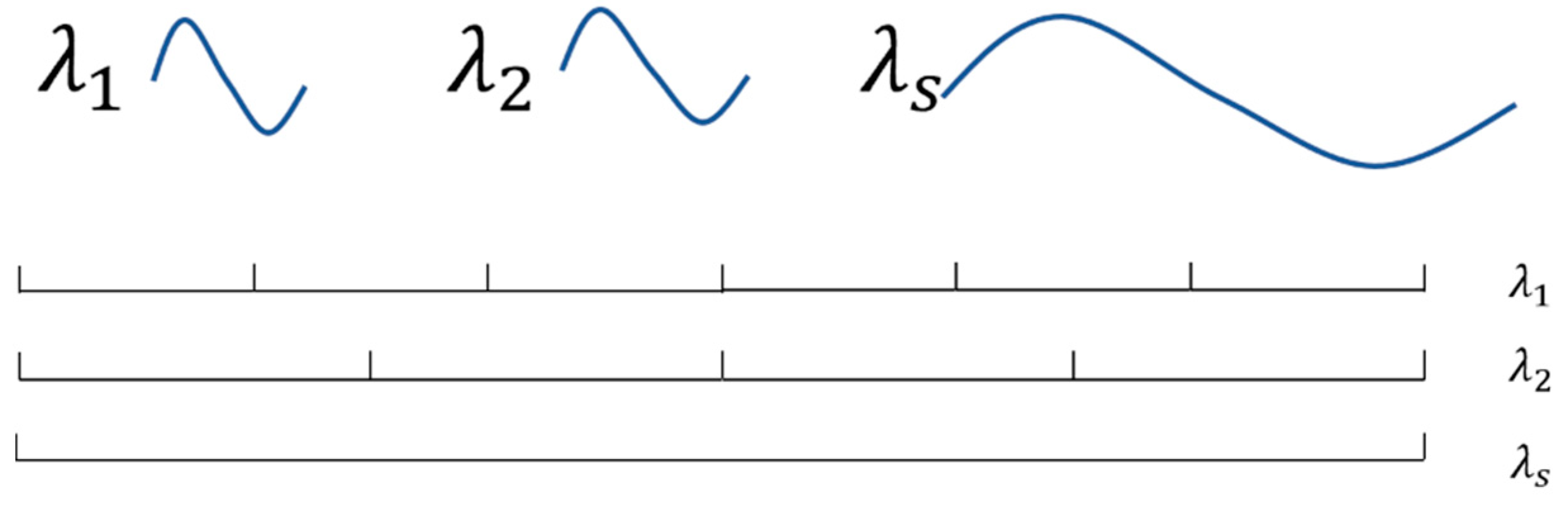

As shown in

Figure 1, we define the synthetic wavelength

as:

where

is assumed; when the difference between

and

is significantly small, the synthetic wavelength

is sufficiently large to guarantee that the piston error between the segments is lesser than

.

Both equations of Equation (8) were multiplied by

, and then, the second equation was subtracted from the first equation.

or

Equation (10) is similar to Equation (7), which means that can be unwrapped with no ambiguity in the difference between the two wavelengths if the synthetic wavelength is significantly large.

If the measurement errors (system error, environmental interference, detector noise, etc.) are considered, using the largest synthetic wavelength to measure all piston errors is not a wise choice because the synthetic wavelength method leads to increased measurement errors. Therefore, we used a continuously tunable laser as the interference light source to obtain an adjustable measurement range. A suitable range that is slightly larger than the piston error can achieve the best detection precision.

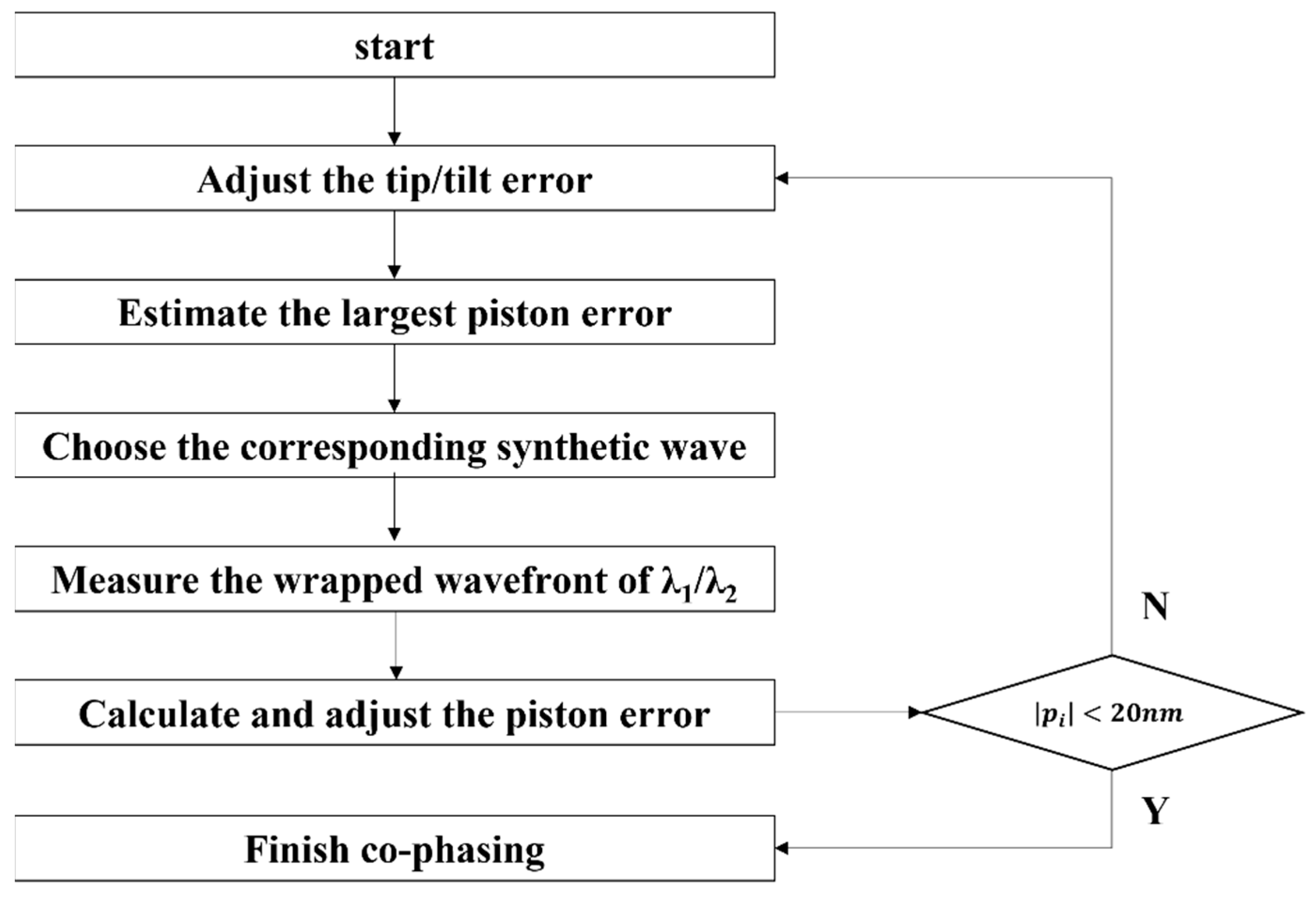

2.3. Co-Phasing by MPI Method

The profile function

in the segmented mirrors with no aberration but co-phasing error can be expressed as:

where

is the pupil function of each segment,

and

are the center coordinates of each segment, and (

) are the tip/tilt and piston errors for each segment, respectively.

N is the number of segments.

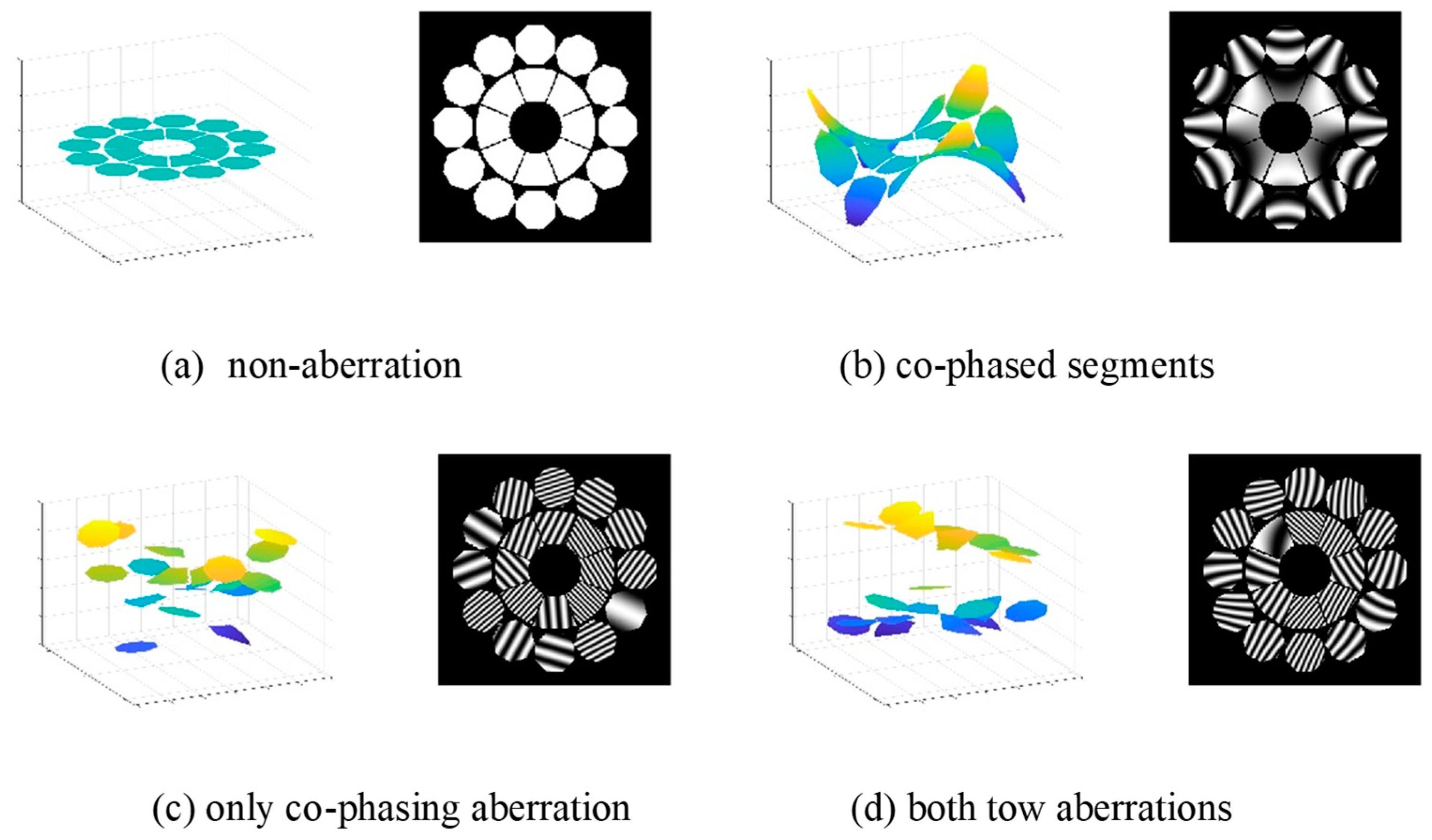

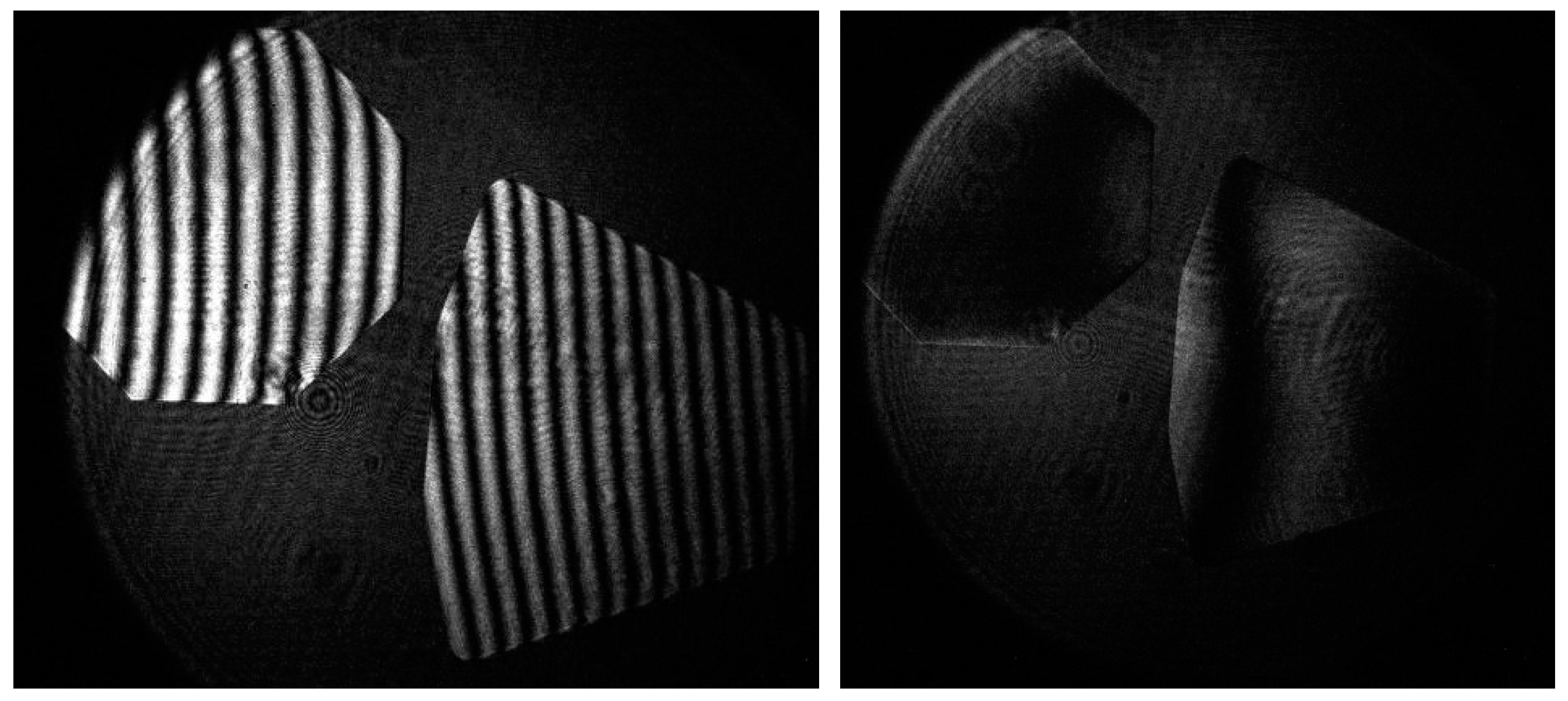

It should be noted that for the interference null-test when no aberration is assumed, the wavefront functions of spherical or aspherical mirrors become a perfect plane and no interference fringe appears, as shown in

Figure 2. In this study, the segmented mirror system was formed by combining fan-shaped and octangle-shaped mirrors, and the geometrical shape of the segments was designed for the convenience of the unfolding process.

Figure 2.

Simulated image of the profile function , (a) with no aberration, (b) with system aberration of RMS = 240 nm in the case of segments, (c) with co-phasing aberration, piston < 0.01 mm and tip/tilt < 0.01 rad, and (d) with both aberrations of (b,c).

Figure 2.

Simulated image of the profile function , (a) with no aberration, (b) with system aberration of RMS = 240 nm in the case of segments, (c) with co-phasing aberration, piston < 0.01 mm and tip/tilt < 0.01 rad, and (d) with both aberrations of (b,c).

Based on the phase-shifting and multiwavelength methods previously discussed, the profile function expressed by Equation (11) can be calculated. A mask with several holes was applied to limit the pupil function as a circle for the requirement of using Zernike polynomial to fit the wavefront.

The profile function

contains the information of the co-phasing error required to calculate the tip/tilt errors. Differentiating x and y on both sides of Equation (11) respectively, we obtain the expressions:

and

During the experiment, the tip/tilt errors were calculated by the weighted average of least squares, fitting value by each line data in the mask.

The piston error can be obtained by calculating the average value of each data in the mask, considering the hypothesis that the mask center point is also the rotation center of each segment. However, in the common case, this assumption is not tenable, and the tip/tilt errors affect the result of the piston error; therefore, during experiments, the piston error is usually detected after the tip/tilt errors are adjusted to a small value.

where the tip/tilt errors are assumed to tend to zero, and

is the piston error of the segment

. It should be noted that the only concerned result is the difference between the segments but not the absolute value of each

.

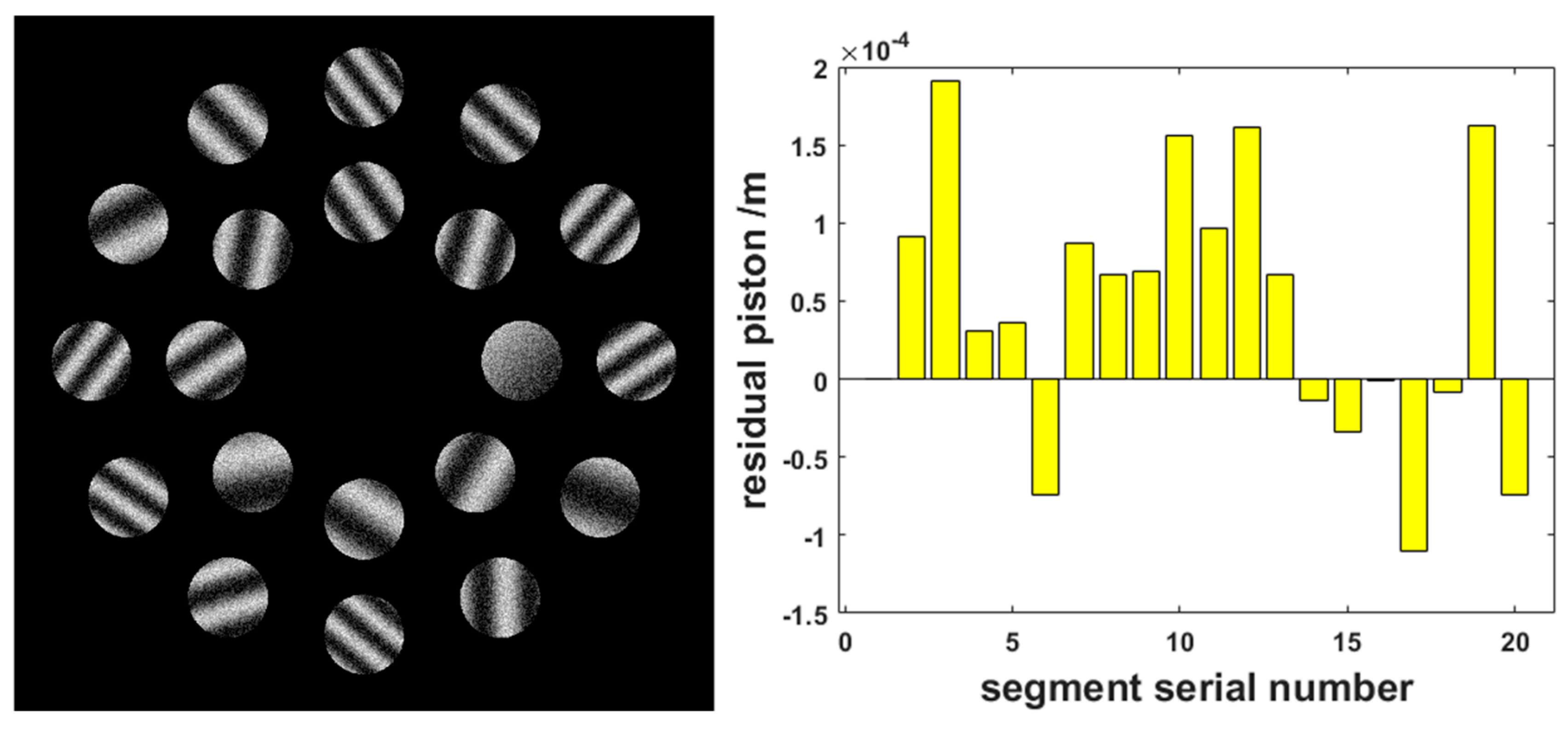

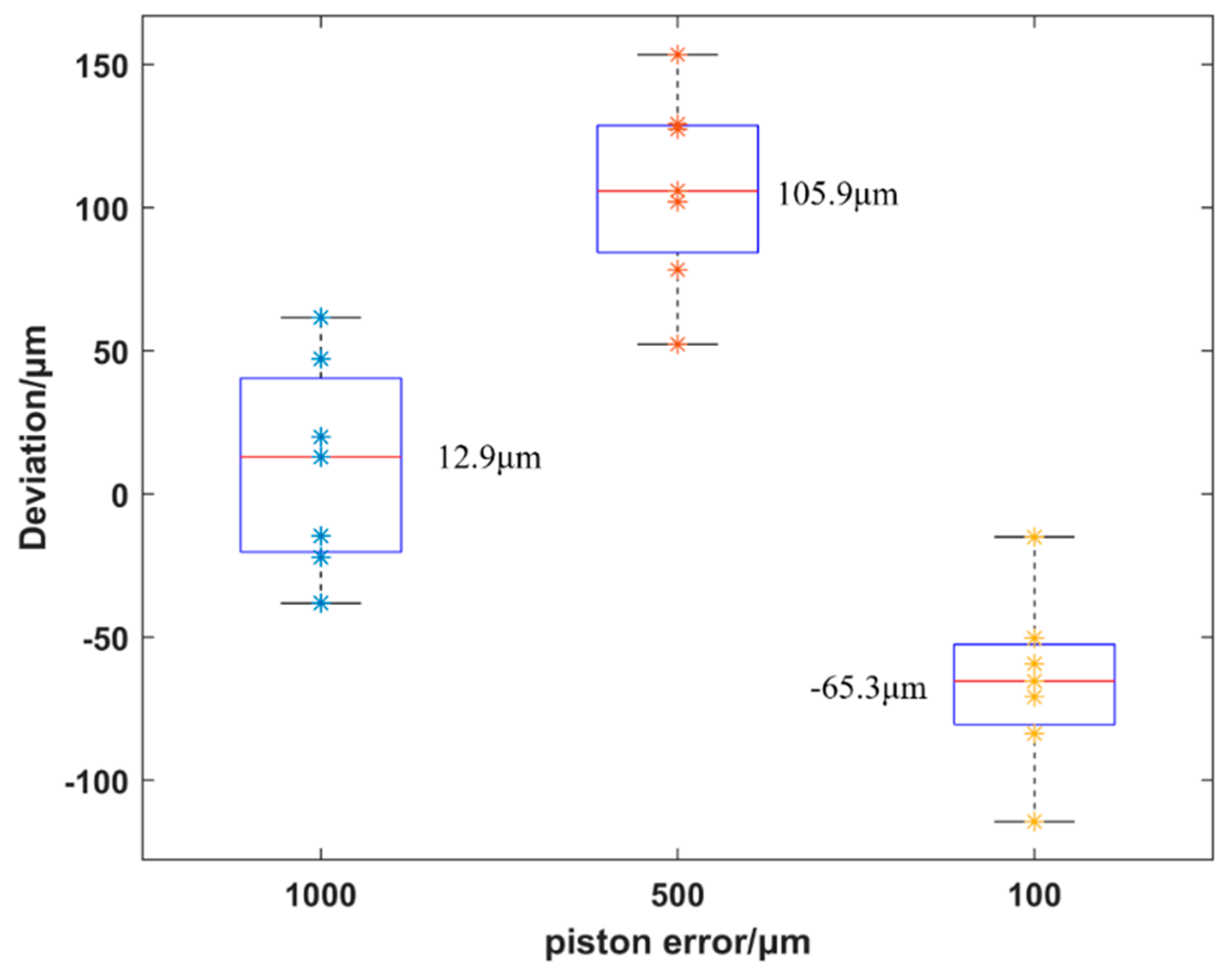

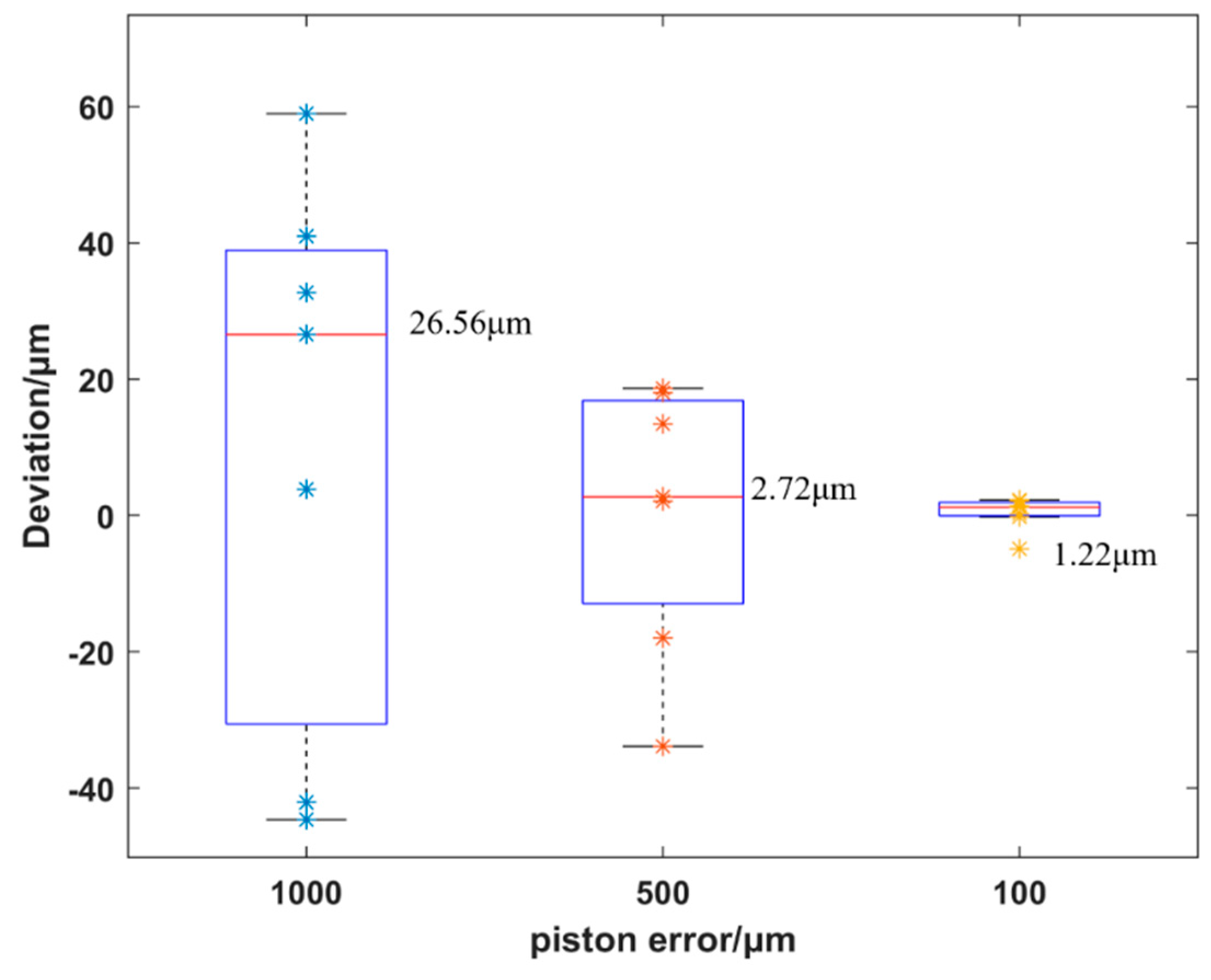

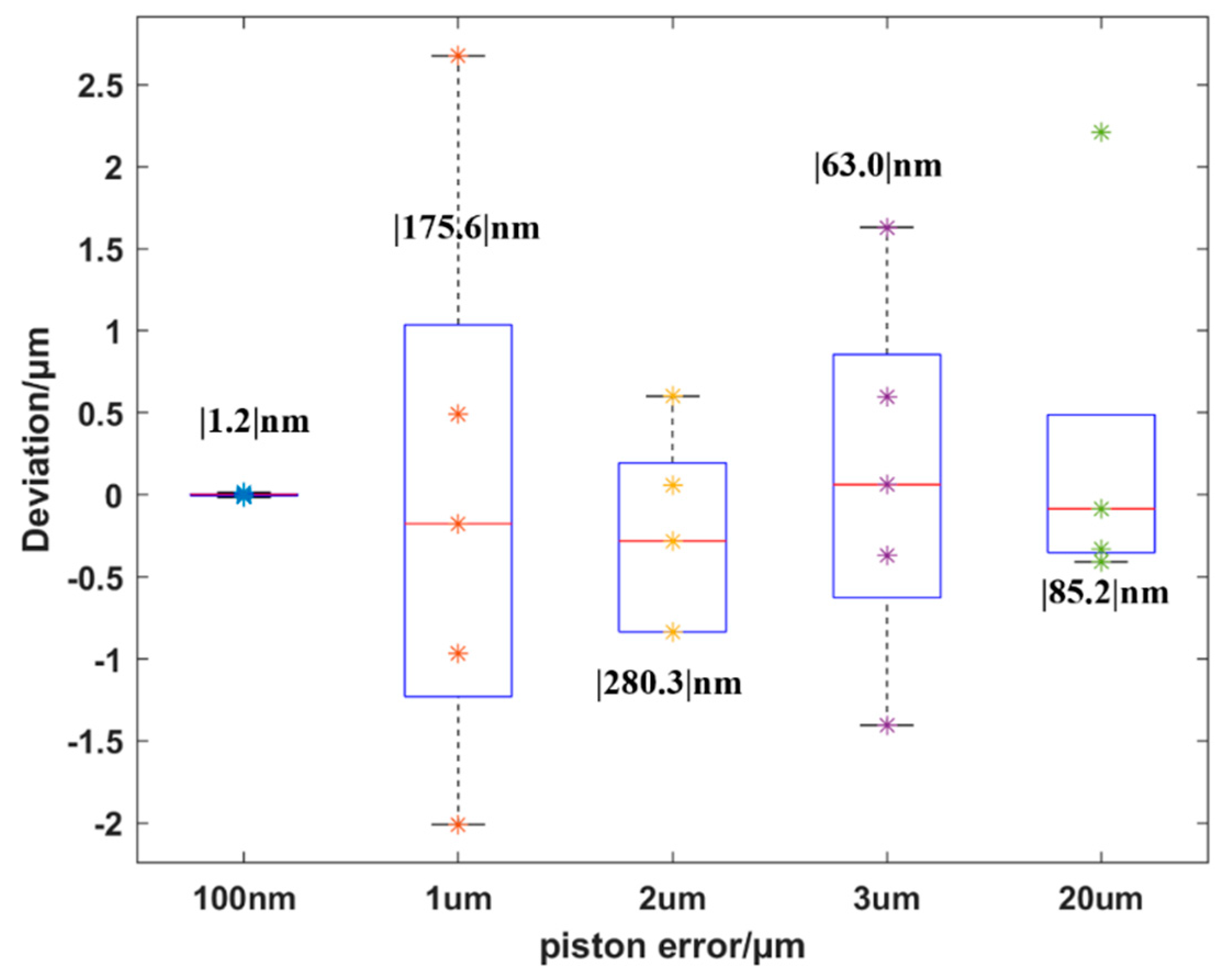

5. Discussion

The result of

Section 4 indicates that the MPI method can successfully co-phase the segmented mirrors even though the original piston error was set to a large number (~1 mm). The practical detection precision for piston could finally achieve 1.2 nm when the single wavelength was used to detect the piston within [−1/2

λ, 1/2

λ]. In comparison, the broad band Shake−Harman method’s capture range was 100 μm [

9] and its precision was 26 nm, and the capture ranges of the DHS and DFS methods for the JWST’s coarse phasing were 100 and 300 μm respectively [

15].

Although the interference method still has some problems for application in engineering practice, for example, it is hard to illuminate a large aperture at its center of curvature, and for the aspherical mirror, to modulate the spherical wave to an aspherical wave, a Computer-Generated Hologram (CGH) or a compensation lens group is required; the MPI method is still a valuable method for the segment co-phasing, owing to the large capture range and the high precision.

6. Conclusions

In this study, we introduced the MPI method to measure the co-phasing errors of segmented mirrors, aiming to solve large-piston-error detection problems, which usually occur when the space-based segmented mirrors undergo unfolding or are subject to certain accidents (such as small meteorite impact). The existing detection methods can hardly detect a piston error of more than 1 mm; therefore, this study aimed to detect a large range of piston errors with satisfactory precision.

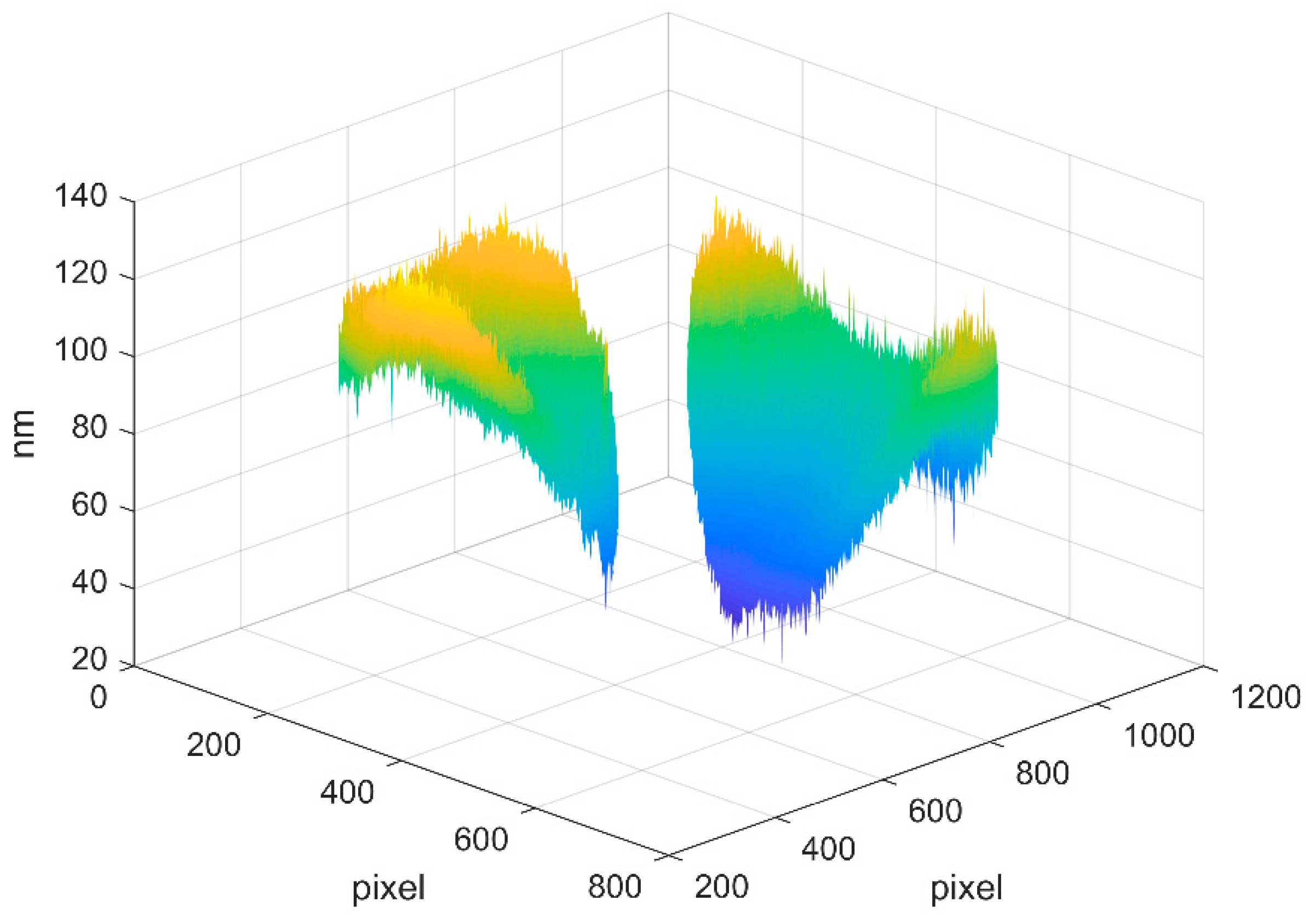

In the simulation, piston and tip/tilt errors were both added to a 20-segment system with noise, and the achieved detection precision of piston error was approximately 12.9 nm when SNR was 14 dB, and the contrast ratio was 0.2. Hence, the robustness of the MPI method was confirmed. In the experiment, two spherical segmented mirrors were applied (one of them was the reference mirror). The other mirror had a piston error of approximately 1 mm owing to the 6-DOF parallel platform. After the dynamic adjustment by the MPI method, the original piston was successfully adjusted to less than a quarter of a single wavelength, and in the monochromatic interference, the final detection precision of the piston was approximately 1.2 nm. Furthermore, owing to the dynamic adjustment strategy, the detection range obtained was greater than 5 mm.

The MPI method showed satisfactory potential for detection of the co-phasing errors of the segmented mirror, As this method has the advantages of simultaneous calculation of the tip/tilt and piston errors with high precision, large detection range, a relatively simple optical system and measurement process, and an individual light source without affecting the working time of the telescope, it is expected to have a significant impact on future research in the field of segmented mirrors, and should have possible applications in the fields of development of more powerful telescopes and space exploration.