All-Fiber Gas Cavity Based on Anti-Resonant Hollow-Core Fibers Fabricated by Splicing with End Caps

Abstract

:1. Introduction

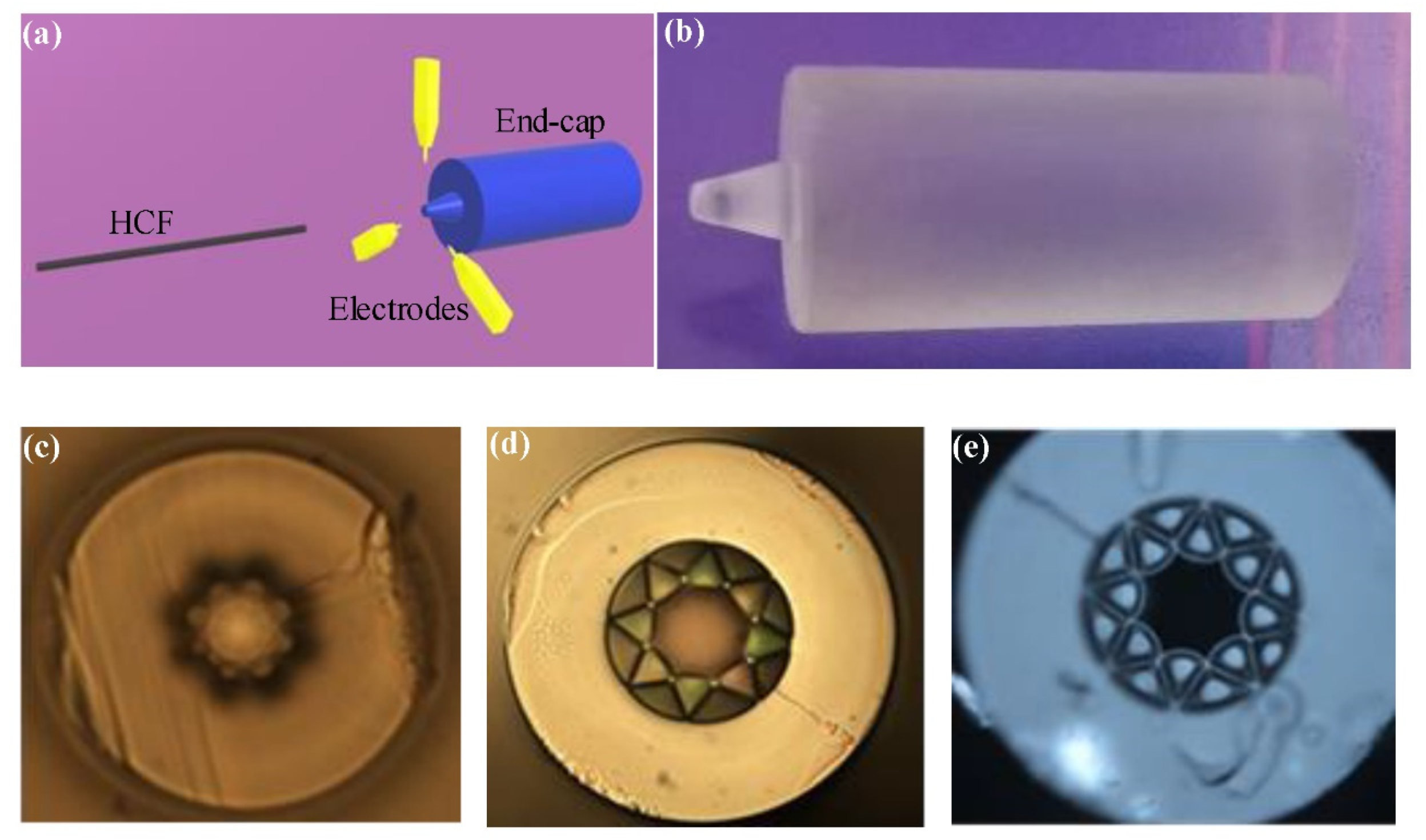

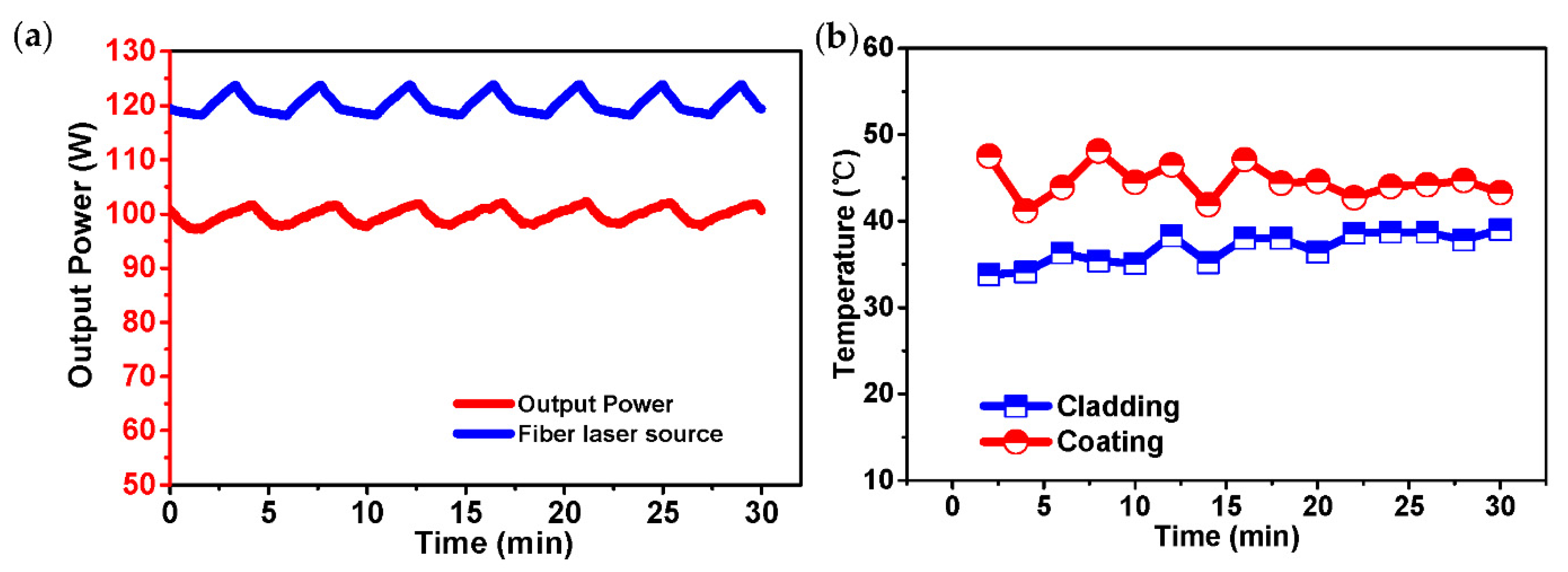

2. Fabrication

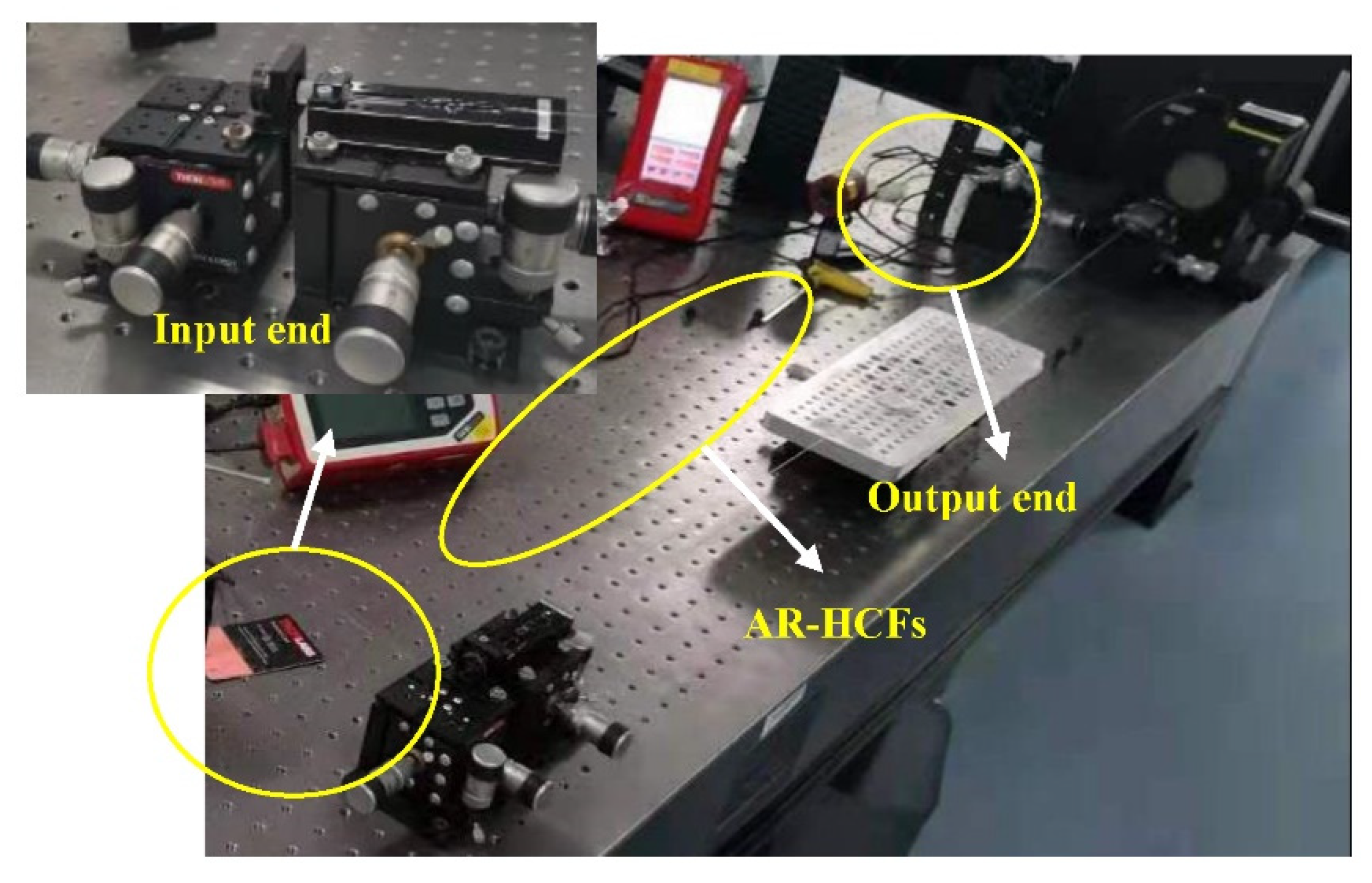

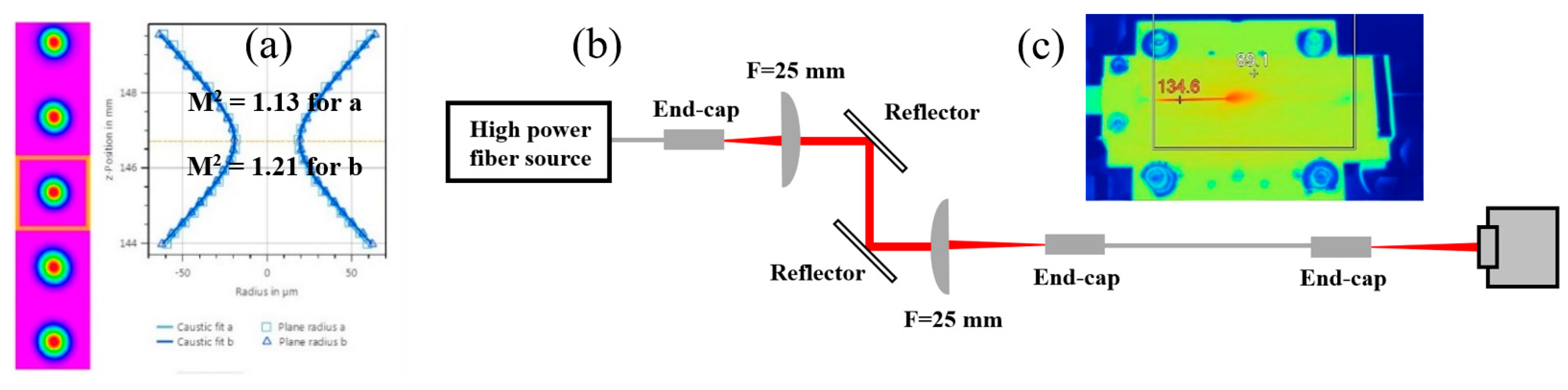

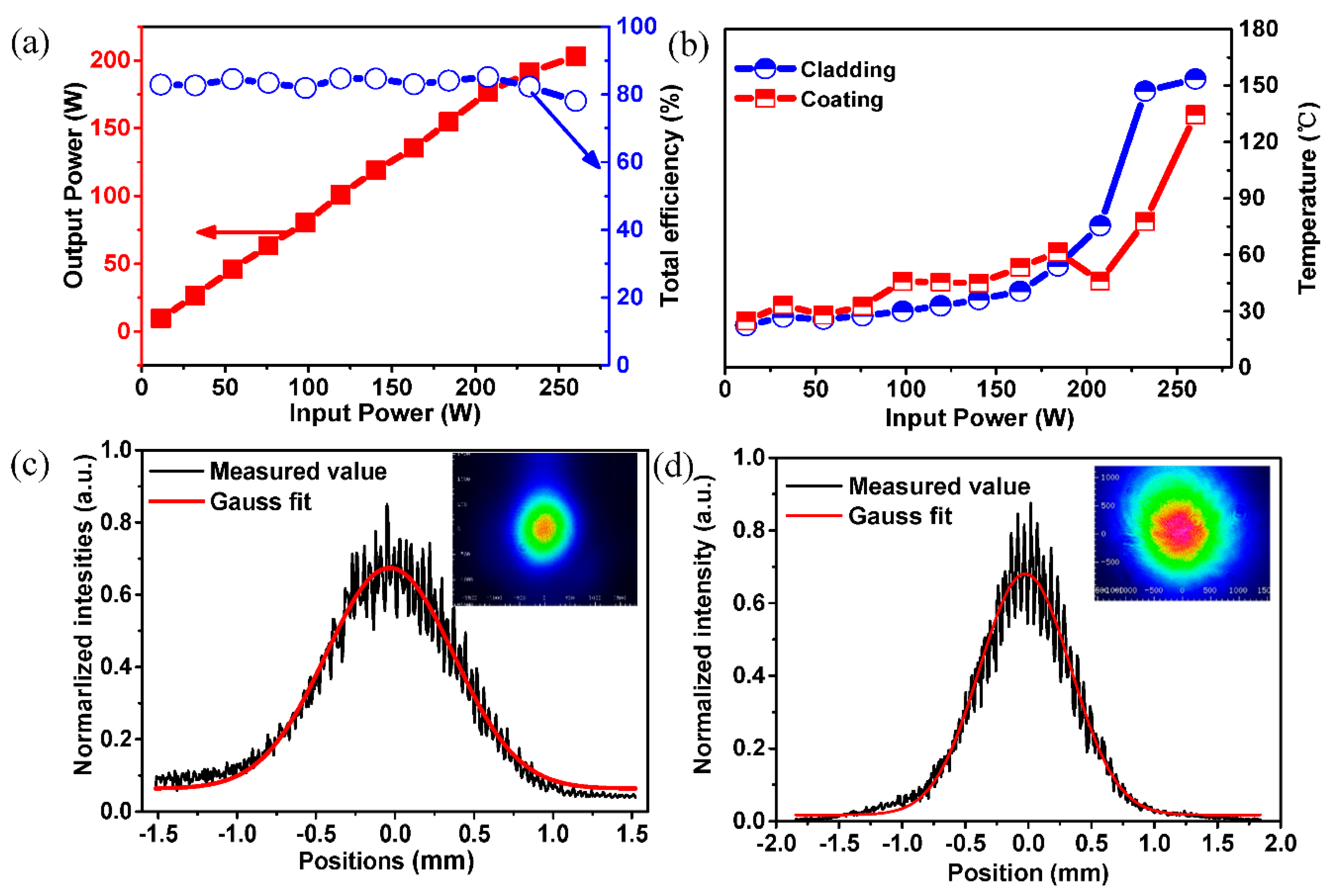

3. Experiments

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pryamikov, A.D.; Biriukov, A.S.; Kosolapov, A.F.; Plotnichenko, V.G.; Semjonov, S.L.; Dianov, E.M. Demonstration of a waveguide regime for a silica hollow-core microstructured optical fiber with a negative curvature of the core boundary in the spectral region >3.5 μm. Opt. Express 2011, 19, 1441–1448. [Google Scholar] [CrossRef]

- Yu, F.; Wadsworth, W.J.; Knight, J.C. Low loss silica hollow core fibers for 3–4 μm spectral region. Opt. Express 2012, 20, 11153. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kolyadin, A.N.; Kosolapov, A.F.; Pryamikov, A.D.; Biriukov, A.S.; Plotnichenko, V.G.; Dianov, E.M. Light transmission in negative curvature hollow core fiber in extremely high material loss region. Opt. Express 2013, 21, 9514–9519. [Google Scholar] [CrossRef] [PubMed]

- Ding, W.; Wang, Y.Y.; Gao, S.F.; Wang, M.L.; Wang, P. Recent Progress in Low-Loss Hollow-Core Anti-Resonant Fibers and Their Applications. IEEE J. Sel. Top. Quantum Electron. 2020, 264, 4400312. [Google Scholar] [CrossRef]

- Jones, A.M.; Nampoothiri, A.V.V.; Ratanavis, A.; Fiedler, T.; Rudolph, W. Mid-infrared gas filled photonic crystal fiber laser based on population inversion. Opt. Express 2011, 19, 2309–2316. [Google Scholar] [CrossRef]

- Nampoothiri, A.V.V.; Jones, A.M.; Fourcade-Dutin, C.; Mao, C.; Dadashzadeh, N.; Baumgart, B.; Wang, Y.Y.; Alharbi, M.; Bradley, T.; Campbell, N. Hollow-core Optical Fiber Gas Lasers HOFGLAS: A review. Opt. Mater. Express 2012, 2, 948. [Google Scholar] [CrossRef] [Green Version]

- Benabid, F. Stimulated Raman Scattering in Hydrogen-Filled Hollow-Core Photonic Crystal Fiber. Science 2002, 298, 399–402. [Google Scholar] [CrossRef]

- Gladyshev, A.V.; Kosolapov, A.F.; Khudyakov, M.M.; Yatsenko, Y.P.; Kolyadin, A.N.; Krylov, A.A.; Pryamikov, A.D.; Biriukov, A.S.; Likhachev, M.E.; Bufetov, I.A. 4.4 μm Raman laser based on hollow-core silica fibre. Quantum Electron. 2017, 47, 491–494. [Google Scholar] [CrossRef]

- Gladyshev, A.V.; Kosolapov, A.F.; Khudyakov, M.M.; Yatsenko, Y.; Kolyadin, A.N.; Krylov, A.A.; Pryamikov, A.; Biriukov, A.S.; Likhachev, M.E.; Bufetov, I.A. 2.9, 3.3 and 3.5 μm Raman Lasers Based on Revolver Hollow-Core Silica Fiber Filled by H2/D2 Gas Mixture. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 0903008. [Google Scholar] [CrossRef]

- Li, Z.; Huang, W.; Cui, Y.; Wang, Z. Efficient mid-infrared cascade Raman source in methane-filled hollow-core fibers operating at 2.8 μm. Opt. Lett. 2018, 43, 4671–4674. [Google Scholar] [CrossRef]

- Ling, C.; Gao, S.F.; Peng, Z.G.; Wang, X.C.; Pu, W. High peak power 2.8 μm Raman laser in a methane-filled negative-curvature fiber. Opt. Express 2018, 26, 5609. [Google Scholar]

- Wei, H.; Cui, Y.; Zhixian, L.; Zhiyue, Z.; Zefeng, W. 1.56 μm and 2.86 μm Raman lasers based on gas-filled anti-resonance hollow-core fiber. Chin. Opt. Lett. 2019, 7, 71406. [Google Scholar]

- Astapovich, M.S.; Gladyshev, A.V.; Khudyakov, M.M.; Kosolapov, A.F.; Likhachev, M.E.; Bufetov, I.A. Watt-level Nanosecond 4.42-μm Raman Laser Based on Silica Fiber. IEEE Photonic Technol. Lett. 2019, 1, 78–81. [Google Scholar] [CrossRef]

- Wang, Z.; Belardi, W.; Yu, F.; Wadsworth, W.J.; Knight, J.C. Efficient diode-pumped mid-infrared emission from acetylene-filled hollow-core fiber. Opt. Express 2014, 22, 21872. [Google Scholar] [CrossRef]

- Hassan, M.R.A.; Fei, Y.; Wadsworth, W.J.; Knight, J.C. Cavity-based mid-IR fiber gas laser pumped by a diode laser. Optica 2016, 3, 218. [Google Scholar] [CrossRef]

- Xu, M.; Fei, Y.; Jonathan, K. Mid-infrared 1 W hollow-core fiber gas laser source. Opt. Lett. 2017, 42, 4055–4058. [Google Scholar] [CrossRef]

- Zhou, Z.; Ni, T.; Zhixian, L.; Wei, H.; Zefeng, W.; Wuming, W.; Weihong, H. High-power tunable mid-infrared fiber gas laser source by acetylene-filled hollow-core fibers. Opt. Express 2018, 26, 19144. [Google Scholar] [CrossRef]

- Cui, Y.; Huang, W.; Wang, Z.; Wang, M.; Zhou, Z.; Li, Z.; Gao, S.; Wang, Y.; Pu, W. 4.3 μm fiber laser in CO2 fibers. Optica 2019, 6, 951–954. [Google Scholar] [CrossRef]

- Aghbolagh, F.B.A.; Nampoothiri, V.; Debord, B.; Gerome, F.; Vincetti, L.; Benabid, F.; Rudolph, W. Mid IR hollow core fiber gas laser emitting at 4.6 um. Opt. Lett. 2019, 44, 383–386. [Google Scholar] [CrossRef] [PubMed]

- Fedorov, V.V.; Mirov, S.B.; Gallian, A.; Badikov, D.V.; Voronov, A.A. 3.77–5.05-μm tunable solid-state lasers based on Fe2+-doped ZnSe crystals operating at low and room temperatures. IEEE J. Quantum Electron. 2006, 42, 907–917. [Google Scholar] [CrossRef]

- Chang, T.; Wood, O. An optically pumped CO2 laser. IEEE J. Quantum Electron. 1972, 8, 598. [Google Scholar] [CrossRef]

- Vurgaftman, I.; Meyer, J.R. Analysis of limitations to wallplug efficiency and output power for quantum cascade lasers. J. Appl. Phys. 2006, 99, 123101–123108. [Google Scholar] [CrossRef]

- Maes, F.; Fortin, V.; Bernier, M.; Vallée, R. 5.6 W monolithic fiber laser at 3.55 μm. Opt. Lett. 2017, 42, 2054. [Google Scholar] [CrossRef] [PubMed]

- Maes, F.; Fortin, V.; Poulain, S.; Poulain, M.; Vallée, R. Room-temperature fiber laser at 3.92 μm. Optica 2018, 5, 761. [Google Scholar] [CrossRef]

- Fortin, V.; Jobin, F.; Larose, M.; Bernier, M.; Vallée, R. 10-W-level monolithic dysprosium-doped fiber laser at 3.24 μm. Opt. Lett. 2019, 44, 491–494. [Google Scholar] [CrossRef]

- Drich, S.H.; Rothhardt, J.; Demmler, S.; Tschernajew, M.; Hoffmann, A.; Krebs, M.; Liem, A.; Vries, O.D.; Pl Tner, M.; Fabian, S. Scalability of components for kW-level average power few-cycle lasers. Appl. Opt. 2016, 55, 1636–1640. [Google Scholar]

- Yu, F.; Wu, D.; Wang, Y.; Li, Q.; Chen, S. Delivery of CW laser power up to 300 watts at 1 μm by uncooled low-loss antiresonant hollow-core fiber. Opt. Express 2020, 29, 1492–1501. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, J.; Ye, X.; Cui, Y.; Huang, W.; Li, H.; Zhou, Z.; Wang, M.; Chen, Z.; Wang, Z. All-Fiber Gas Cavity Based on Anti-Resonant Hollow-Core Fibers Fabricated by Splicing with End Caps. Photonics 2021, 8, 371. https://doi.org/10.3390/photonics8090371

Shi J, Ye X, Cui Y, Huang W, Li H, Zhou Z, Wang M, Chen Z, Wang Z. All-Fiber Gas Cavity Based on Anti-Resonant Hollow-Core Fibers Fabricated by Splicing with End Caps. Photonics. 2021; 8(9):371. https://doi.org/10.3390/photonics8090371

Chicago/Turabian StyleShi, Jing, Xinyu Ye, Yulong Cui, Wei Huang, Hao Li, Zhiyue Zhou, Meng Wang, Zilun Chen, and Zefeng Wang. 2021. "All-Fiber Gas Cavity Based on Anti-Resonant Hollow-Core Fibers Fabricated by Splicing with End Caps" Photonics 8, no. 9: 371. https://doi.org/10.3390/photonics8090371

APA StyleShi, J., Ye, X., Cui, Y., Huang, W., Li, H., Zhou, Z., Wang, M., Chen, Z., & Wang, Z. (2021). All-Fiber Gas Cavity Based on Anti-Resonant Hollow-Core Fibers Fabricated by Splicing with End Caps. Photonics, 8(9), 371. https://doi.org/10.3390/photonics8090371