Dispersion Optimization of Silicon Nitride Waveguides for Efficient Four-Wave Mixing

Abstract

1. Introduction

2. Waveguide Dispersion Analysis Principle

3. Results and Discussion

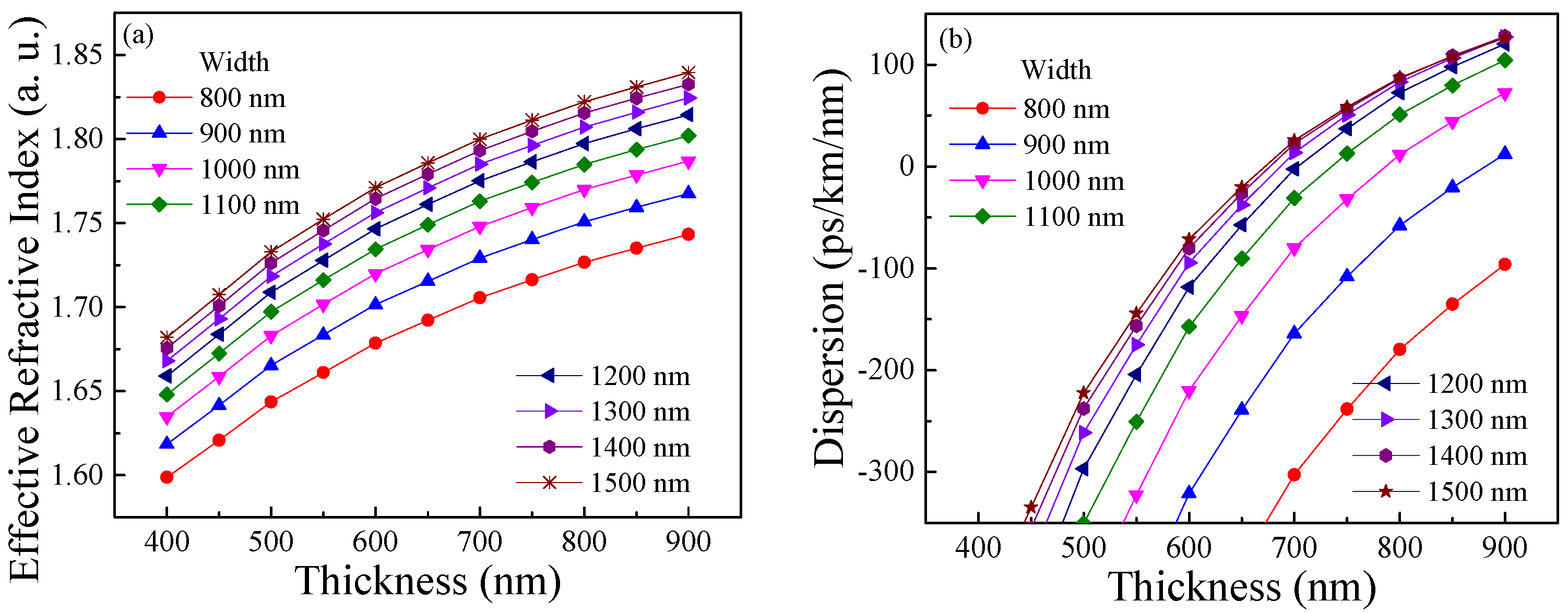

3.1. Waveguide Dispersion Optimiation

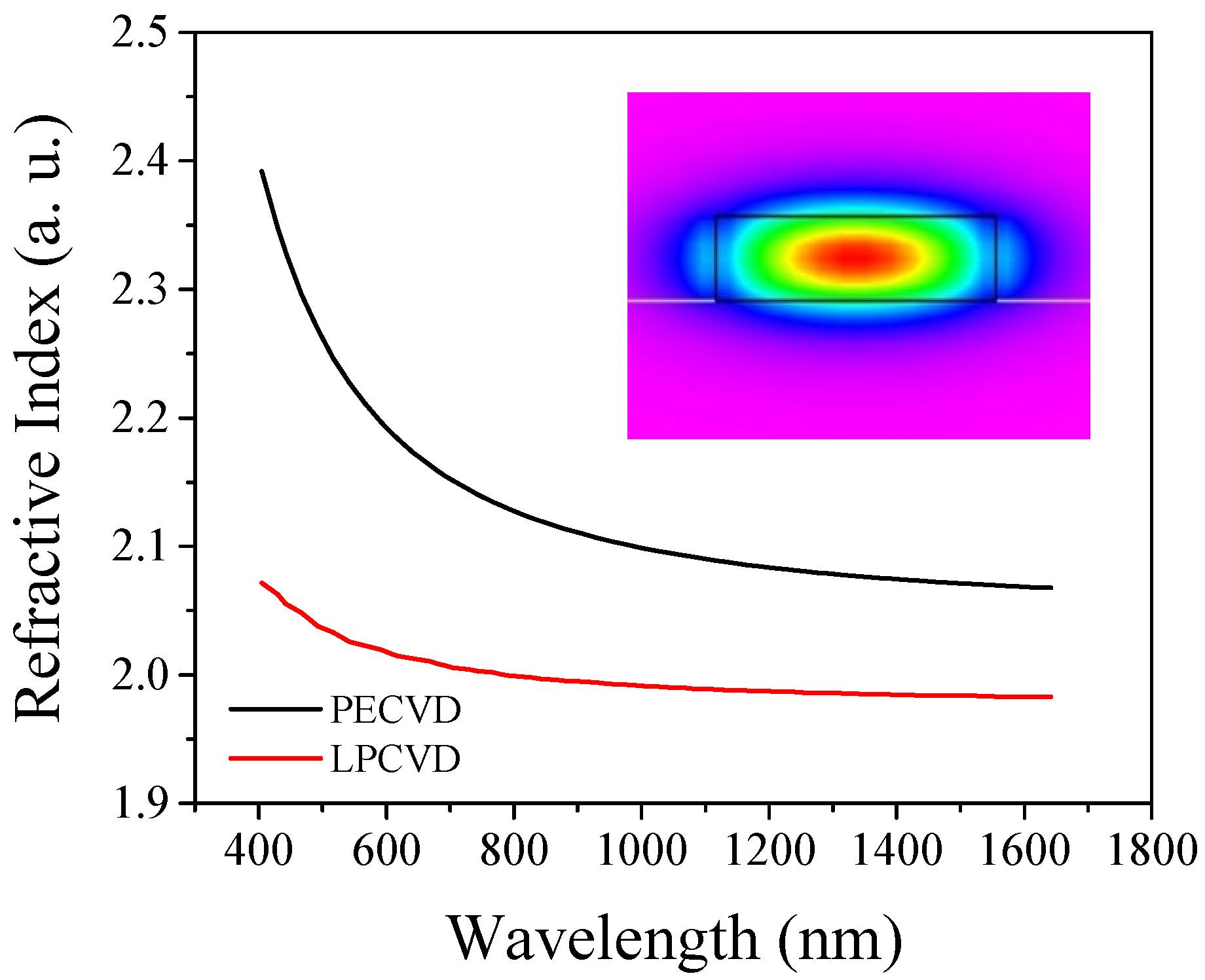

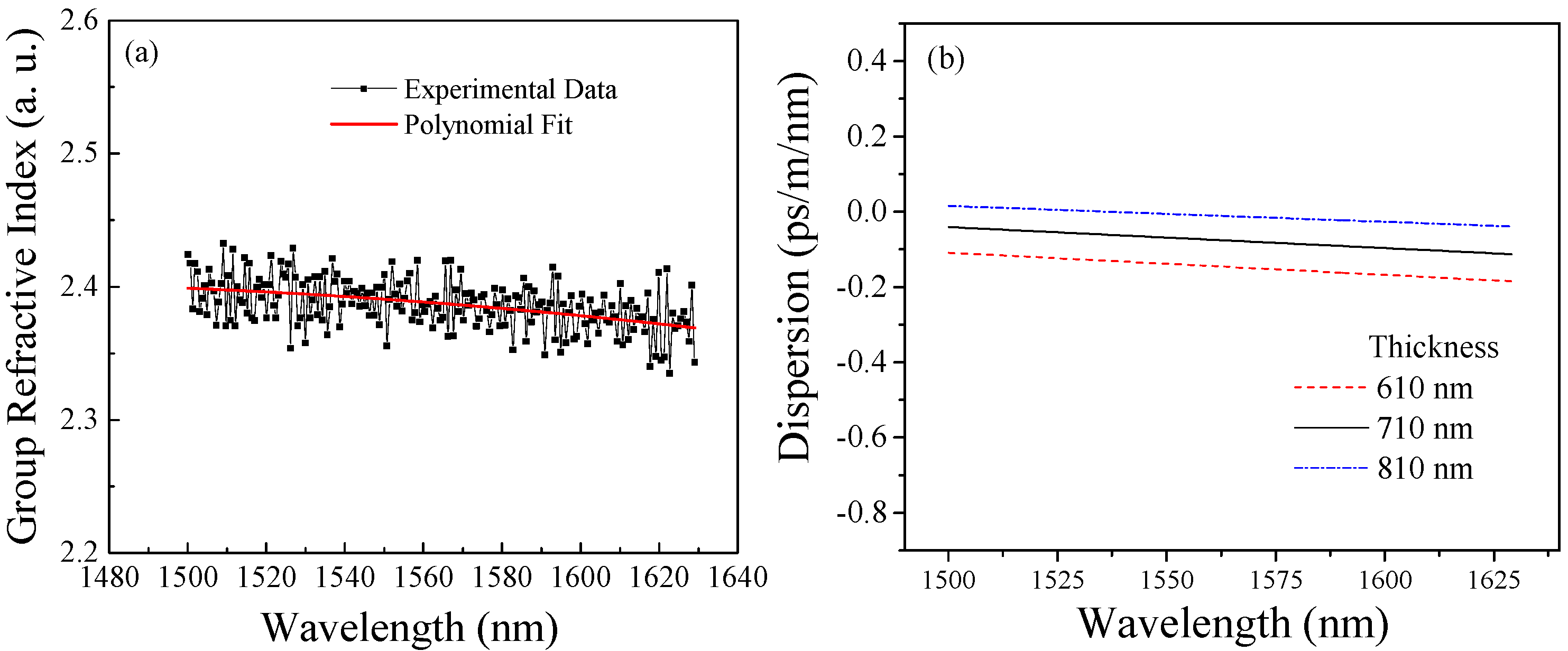

3.1.1. Dispersion of Silicon Nitride Thin Film Waveguide of PECVD

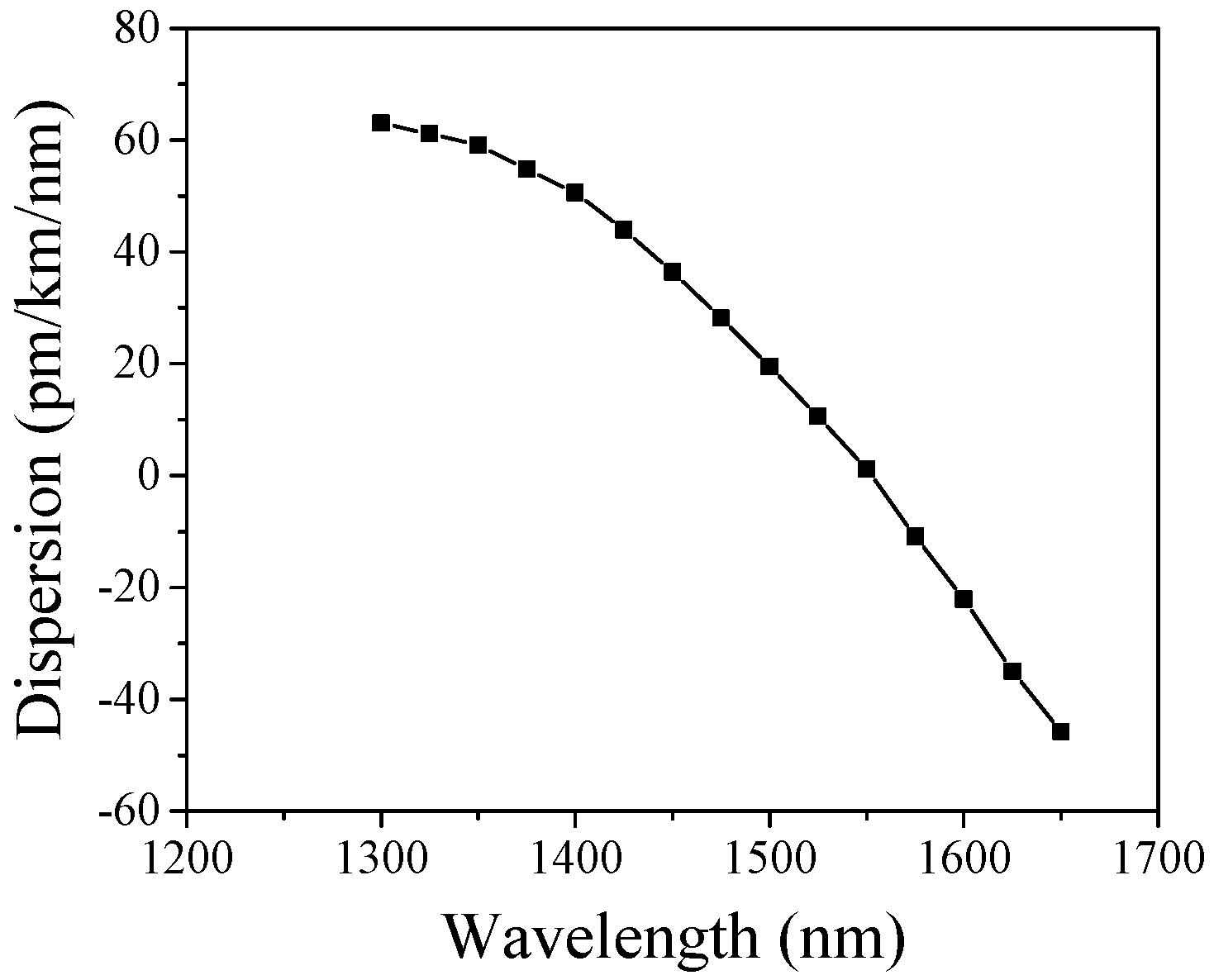

3.1.2. Dispersion of Silicon Nitride Thin Film Waveguide of LPCVD

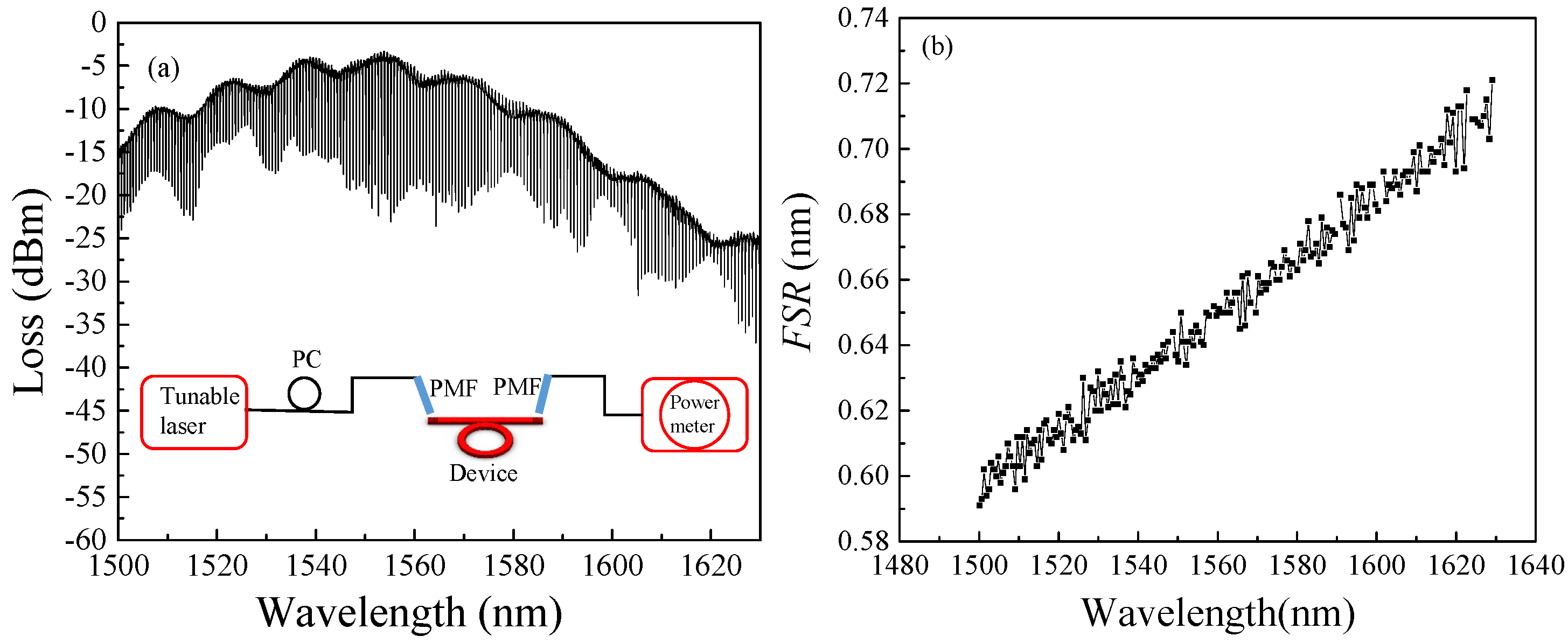

3.2. Waveguide Fabrication and Experimental Characterization

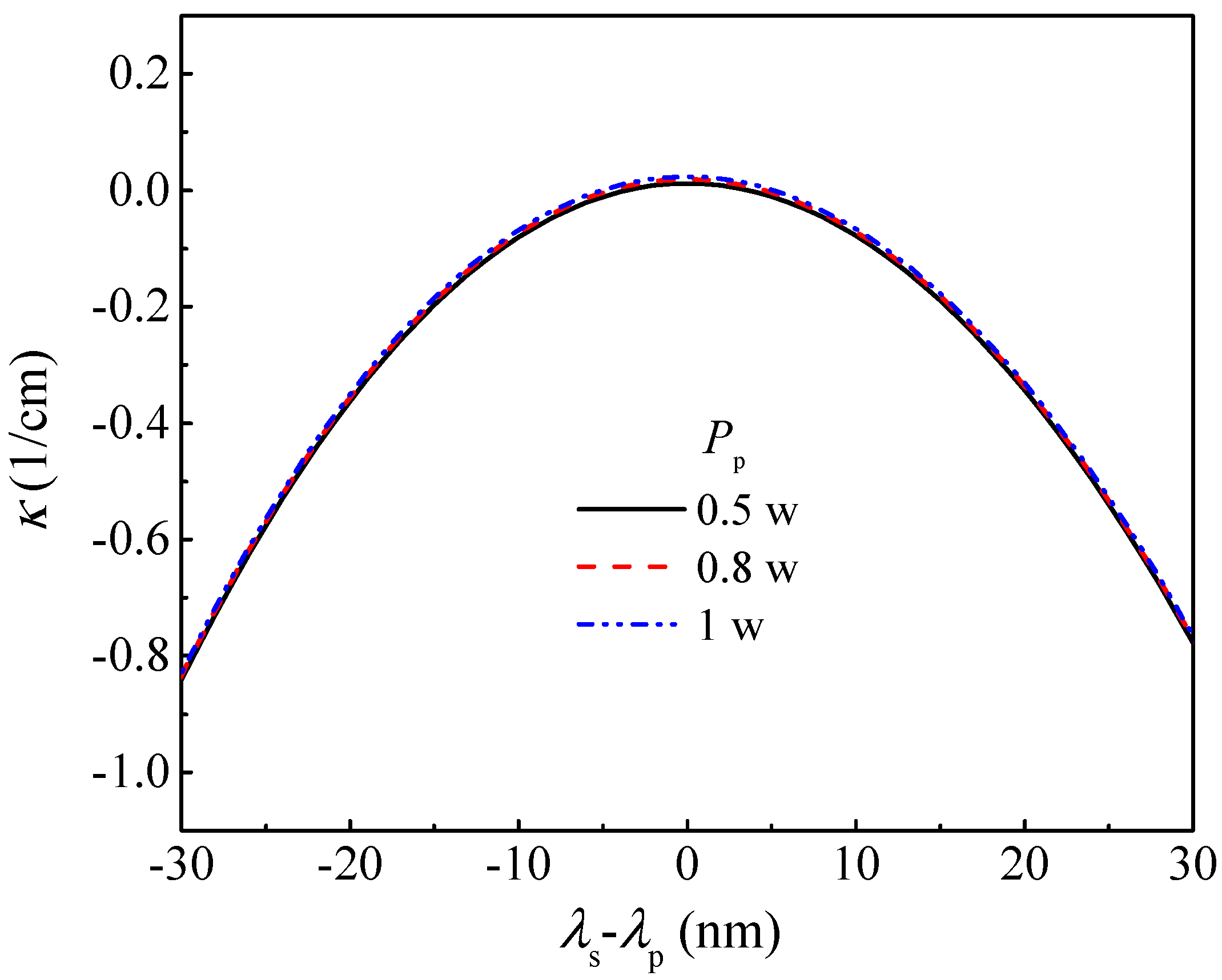

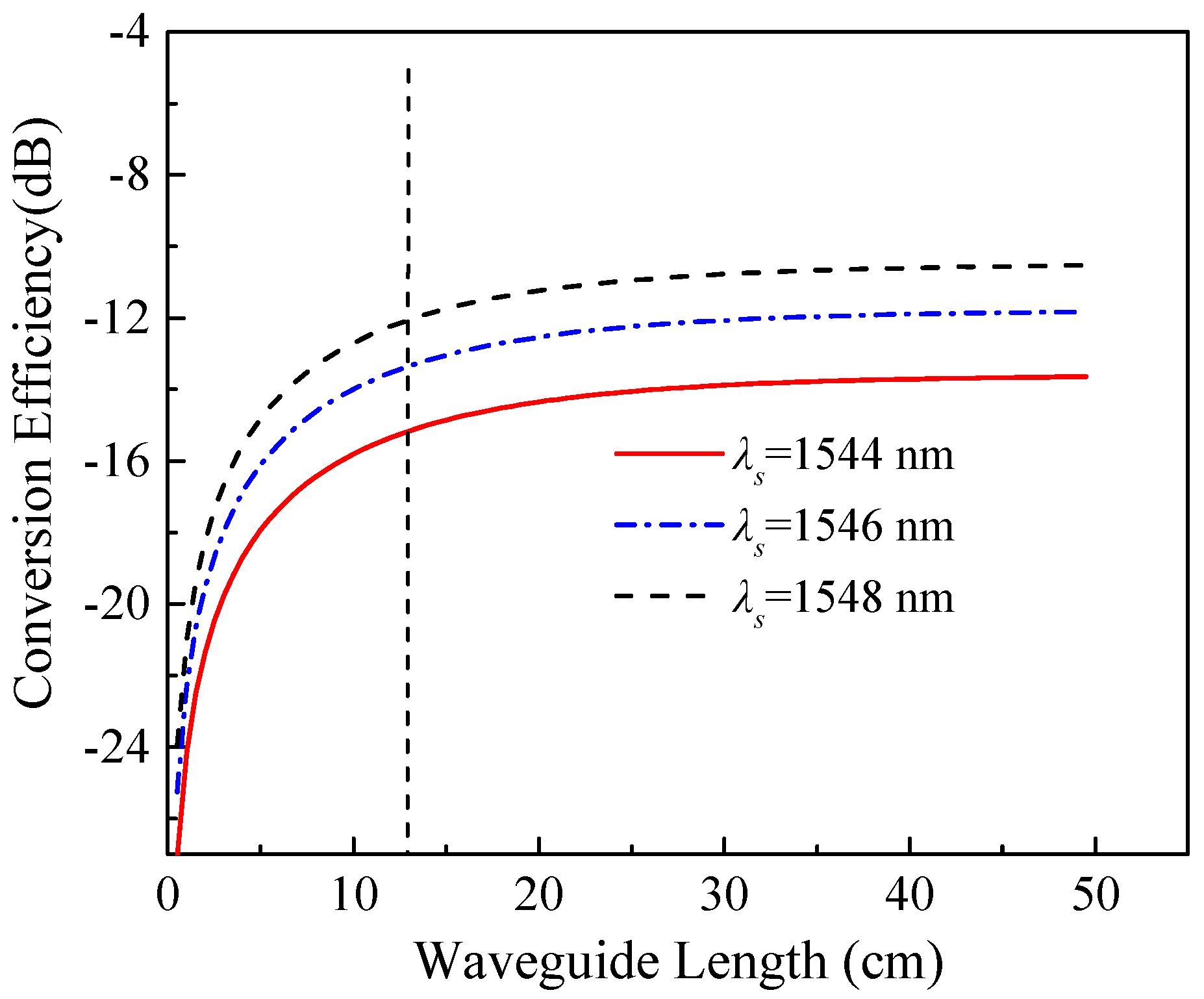

3.3. Phase Mismatch and Conversion Efficiency of the Waveguide

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Helt, L.G.; Liscidini, M.; Sipe, J.E. How Does It Scale? Comparing Quantum and Classical Nonlinear Optical Processes in Integrated Devices. J. Opt. Soc. Am. B 2012, 29, 2199–2212. [Google Scholar] [CrossRef]

- Wu, C.; Huang, J.; Ou, D.; Liao, T.; Chiu, Y.; Shih, M.; Lin, Y.; Chu, A.; Lee, C. Efficient Wavelength Conversion with Low Operation Power in a Ta2O5-Based Micro-Ring Resonator. Opt. Lett. 2017, 42, 4804–4807. [Google Scholar] [CrossRef]

- McMillan, J.F.; Yu, M.; Kwong, D.; Wong, C.W. Observation of Four-Wave Mixing in Slow-Light Silicon Photonic Crystal Waveguides. Opt. Express 2010, 18, 15484–15497. [Google Scholar] [CrossRef][Green Version]

- Yakuhina, A.; Kadochkin, A.; Svetukhin, V.; Gorelov, D.; Generalov, S.; Amelichev, V. Investigation of Side Wall Roughness Effect on Optical Losses in a Multimode Si3N4 Waveguide Formed on a Quartz Substrate. Photonics 2020, 7, 104. [Google Scholar] [CrossRef]

- Moss, D.J.; Morandotti, R.; Gaeta, A.L.; Lipson, M. New CMOS-Compatible Platforms Based on Silicon Nitride and Hydex for Nonlinear Optics. Nat. Photonics 2013, 7, 597–607. [Google Scholar] [CrossRef]

- Ikeda, K.; Saperstein, R.E.; Alic, N.; Fainman, Y. Thermal and Kerr Nonlinear Properties of Plasma-Deposited Silicon Nitride/Silicon Dioxide Waveguides. Opt. Express 2008, 16, 12987–12994. [Google Scholar] [CrossRef]

- Boller, K.; van Rees, A.; Fan, Y.; Mak, J.; Lammerink, R.E.M.; Franken, C.A.A.; van der Slot, P.J.M.; Marpaung, D.A.I.; Fallnich, C.; Epping, J.P.; et al. Hybrid Integrated Semiconductor Lasers with Silicon Nitride Feedback Circuits. Photonics 2020, 7, 4. [Google Scholar] [CrossRef]

- Feng, J.; Akimoto, R.A. Three-Dimensional Silicon Nitride Polarizing Beam Splitter. IEEE Photonics Technol. Lett. 2014, 26, 706–709. [Google Scholar] [CrossRef]

- Herr, T.; Hartinger, K.; Riemensberger, J.; Wang, C.Y.; Gavartin, E.; Holzwarth, R.; Gorodetsky, M.L.; Kippenberg, T.J. Universal Formation Dynamics and Noise of Kerr-Frequency Combs in Microresonators. Nat. Photonics 2012, 6, 480–487. [Google Scholar] [CrossRef]

- Pfeiffer, M.H.P.; Herkommer, C.; Liu, J.; Guo, H.; Karpov, M.; Lucas, E.; Zervas, M.; Kippenberg, T.J. Octave-Spanning Dissipative Kerr Soliton Frequency Combs in Si3N4 Microresonators. Optica 2017, 4, 684–691. [Google Scholar] [CrossRef]

- Halir, R.; Okawachi, Y.; Levy, J.S.; Foster, M.A.; Lipson, M.; Gaeta, A.L. Ultrabroadband Supercontinuum Generation in a CMOS-Compatible Platform. Opt. Lett. 2012, 37, 1685–1687. [Google Scholar] [CrossRef]

- Tan, D.T.H.; Ikeda, K.; Sun, P.C.; Fainman, Y. Group Velocity Dispersion and Self Phase Modulation in Silicon Nitride Waveguides. Appl. Phys. Lett. 2010, 96, 611016. [Google Scholar] [CrossRef]

- Kruckel, C.J.; Torres-Company, V.; Andrekson, P.A.; Spencer, D.T.; Bauters, J.F.; Heck, M.J.R.; Bowers, J.E. Continuous Wave-Pumped Wavelength Conversion in Low-Loss Silicon Nitride Waveguides. Opt. Lett. 2015, 40, 875–878. [Google Scholar] [CrossRef]

- Yao, Z.; Wan, Y.; Bu, R.; Zheng, Z. Improved Broadband Dispersion Engineering in Coupled Silicon Nitride Waveguides with a Partially Etched Gap. Appl. Opt. 2019, 58, 8007–8012. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Herkommer, C.; Billat, A.; Grassani, D.; Zhang, C.; Pfeiffer, M.H.P.; Weng, W.; Bres, C.; Kippenberg, T.J. Mid-infrared Frequency Comb via Coherent Dispersive Wave Generation in Silicon Nitride Nanophotonic Waveguides. Nat. Photonics 2018, 12, 496. [Google Scholar] [CrossRef]

- Okawachi, Y.; Lamont, M.R.E.; Luke, K.; Carvalho, D.O.; Yu, M.; Lipson, M.; Gaeta, A.L. Bandwidth Shaping of Microresonator-Based Frequency Combs via Dispersion Engineering. Opt. Lett. 2014, 39, 3535–3538. [Google Scholar] [CrossRef] [PubMed]

- Kruckel, C.J.; Fulop, A.; Ye, Z.; Andrekson, P.A.; Torres-Company, V. Optical Bandgap Engineering in Nonlinear Silicon Nitride Waveguides. Opt. Express 2017, 25, 15370–15380. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Gao, S.; Li, Z.; Xie, Y.; He, S. Dispersion Engineering of a Silicon-Nanocrystal-Based Slot Waveguide for Broadband Wavelength Conversion. Appl. Opt. 2011, 50, 1260–1265. [Google Scholar] [CrossRef]

- Zhang, L.; Yue, Y.; Xiao-Li, Y.; Wang, J.; Beausoleil, R.G.; Willner, A.E. Flat and Low Dispersion in Highly Nonlinear Slot Waveguides. Opt. Express 2010, 18, 13187–13193. [Google Scholar] [CrossRef]

- Sun, X.; Dai, D.; Thylén, L.; Wosinski, L. Double-Slot Hybrid Plasmonic Ring Resonator Used for Optical Sensors and Modulators. Photonics 2015, 2, 1116–1130. [Google Scholar] [CrossRef]

- Baets, R.; Subramanian, A.Z.; Clemmen, S.; Kuyken, B.; Bienstman, P.; Le Thomas, N.; Roelkens, G.; Van Thourhout, D.; Helin, P.; Severi, S. Silicon Photonics: Silicon Nitride Versus Silicon-On-Insulator. In Proceedings of the 2016 Optical Fiber Communications Conference and Exhibition (OFC), Anaheim, CA, USA, 20–22 March 2016; p. Th3J.1. [Google Scholar]

- Mao, S.C.; Tao, S.H.; Xu, Y.L.; Sun, X.W.; Yu, M.B.; Lo, G.Q.; Kwong, D.L. Low Propagation Loss SiN Optical Waveguide Prepared by Optimal Low-Hydrogen Module. Opt. Express 2008, 16, 20809–20816. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Hong, J.; Spring, A.M.; Yokoyama, S. Fabrication of a High-Q Factor Ring Resonator Using LSCVD Deposited Si3N4 Film. Opt. Mater. Express 2017, 7, 2182–2187. [Google Scholar] [CrossRef]

- Hong, J.; Spring, A.M.; Qiu, F.; Yokoyama, S. A High Efficiency Silicon Nitride Waveguide Grating Coupler with a Multilayer Bottom Reflector. Sci. Rep. 2019, 9, 12988. [Google Scholar] [CrossRef]

- Yin, Y.; Yin, X.; Zhang, X.; Yan, G.; Wang, Y.; Wu, Y.; An, J.; Wang, L.; Zhang, D. High-Q-Factor Silica-Based Racetrack Microring Resonators. Photonics 2021, 8, 43. [Google Scholar] [CrossRef]

- Hansryd, J.; Andrekson, P.A.; Westlund, M.; Li, J.; Hedekvist, P. Fiber-Based Optical Parametric Amplifiers and Their Applications. IEEE J. Sel. Top. Quantum Electron. 2002, 8, 506–520. [Google Scholar] [CrossRef]

- Gao, S.M.; Li, Z.Q.; Zhang, X.Z. Power-Attenuated Optimization for Four-Wave Mixing-Based Wavelength Conversion in Silicon Nanowire Waveguides. J. Electromagn. Wave 2010, 24, 1255–1265. [Google Scholar] [CrossRef]

- Jia, L.; Geng, M.; Zhang, L.; Yang, L.; Chen, P.; Wang, T.; Liu, Y. Wavelength Conversion Based on Degenerate-Four-Wave-Mixing with Continuous-Wave Pumping in Silicon Nanowire Waveguide. Opt. Commun. 2009, 282, 1659–1663. [Google Scholar] [CrossRef]

- An, L.; Liu, H.; Sun, Q.; Huang, N.; Wang, Z. Wavelength Conversion in Highly Nonlinear Silicon-Organic Hybrid Slot Waveguides. Appl. Opt. 2014, 53, 4886–4893. [Google Scholar] [CrossRef] [PubMed]

- Jin, B.; Yuan, J.; Yu, C.; Sang, X.; Wei, S.; Zhang, X.; Wu, Q.; Farrell, G. Efficient and Broadband Parametric Wavelength Conversion in a Vertically Etched Silicon Grating without Dispersion Engineering. Opt. Express 2014, 22, 6257–6268. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, Y.; Hong, Y.; Hong, J.; Lu, G.-W. Dispersion Optimization of Silicon Nitride Waveguides for Efficient Four-Wave Mixing. Photonics 2021, 8, 161. https://doi.org/10.3390/photonics8050161

Hong Y, Hong Y, Hong J, Lu G-W. Dispersion Optimization of Silicon Nitride Waveguides for Efficient Four-Wave Mixing. Photonics. 2021; 8(5):161. https://doi.org/10.3390/photonics8050161

Chicago/Turabian StyleHong, Yaping, Yixiao Hong, Jianxun Hong, and Guo-Wei Lu. 2021. "Dispersion Optimization of Silicon Nitride Waveguides for Efficient Four-Wave Mixing" Photonics 8, no. 5: 161. https://doi.org/10.3390/photonics8050161

APA StyleHong, Y., Hong, Y., Hong, J., & Lu, G.-W. (2021). Dispersion Optimization of Silicon Nitride Waveguides for Efficient Four-Wave Mixing. Photonics, 8(5), 161. https://doi.org/10.3390/photonics8050161