Wide Field-of-View, High-Resolution Endoscopic Lens Design with Low F-Number for Disposable Endoscopy

Abstract

1. Introduction

2. Materials and Methods

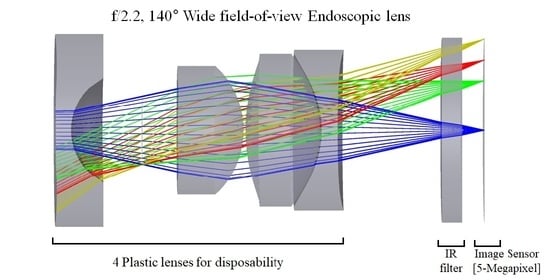

2.1. Design Concept

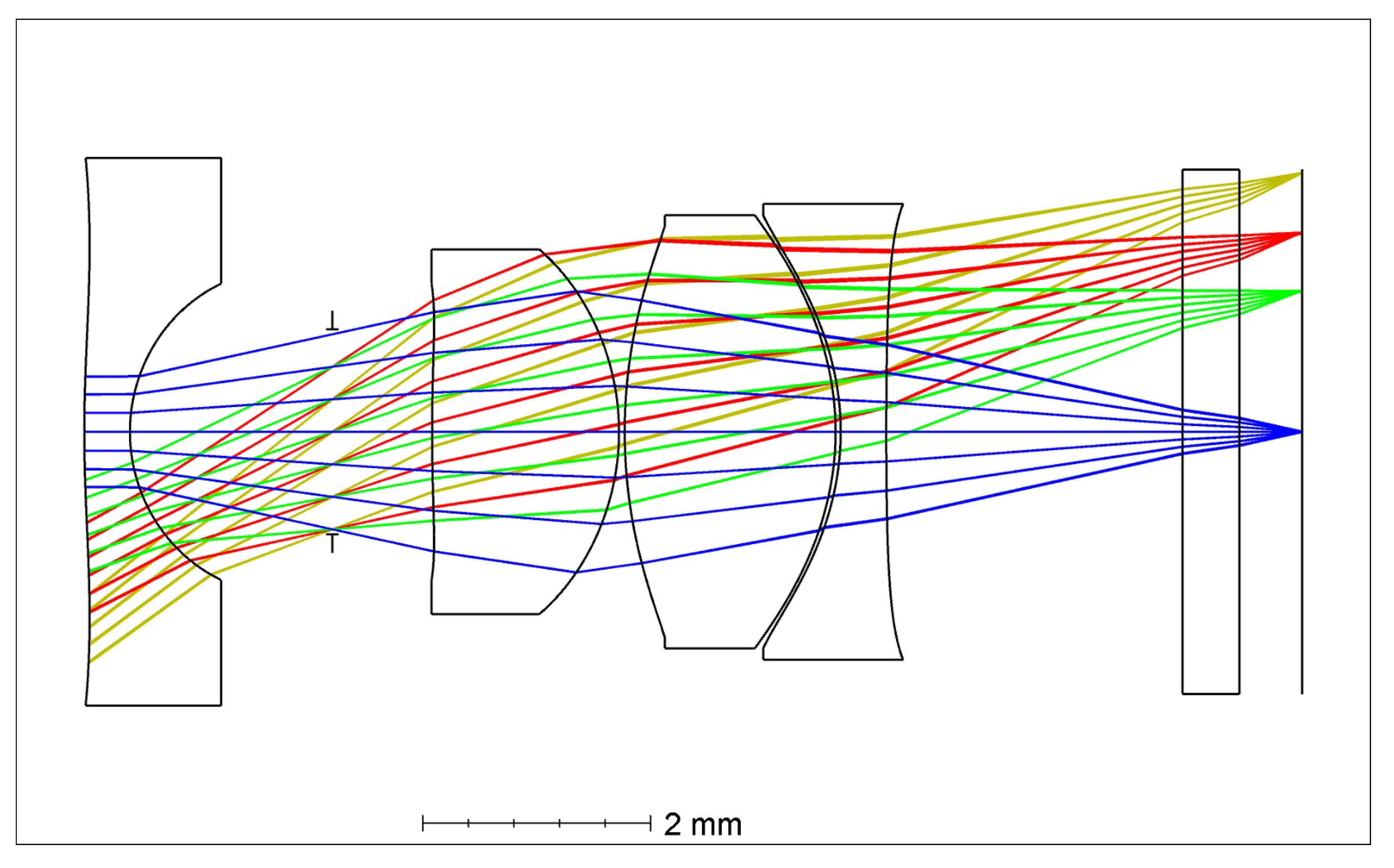

2.2. Design Method

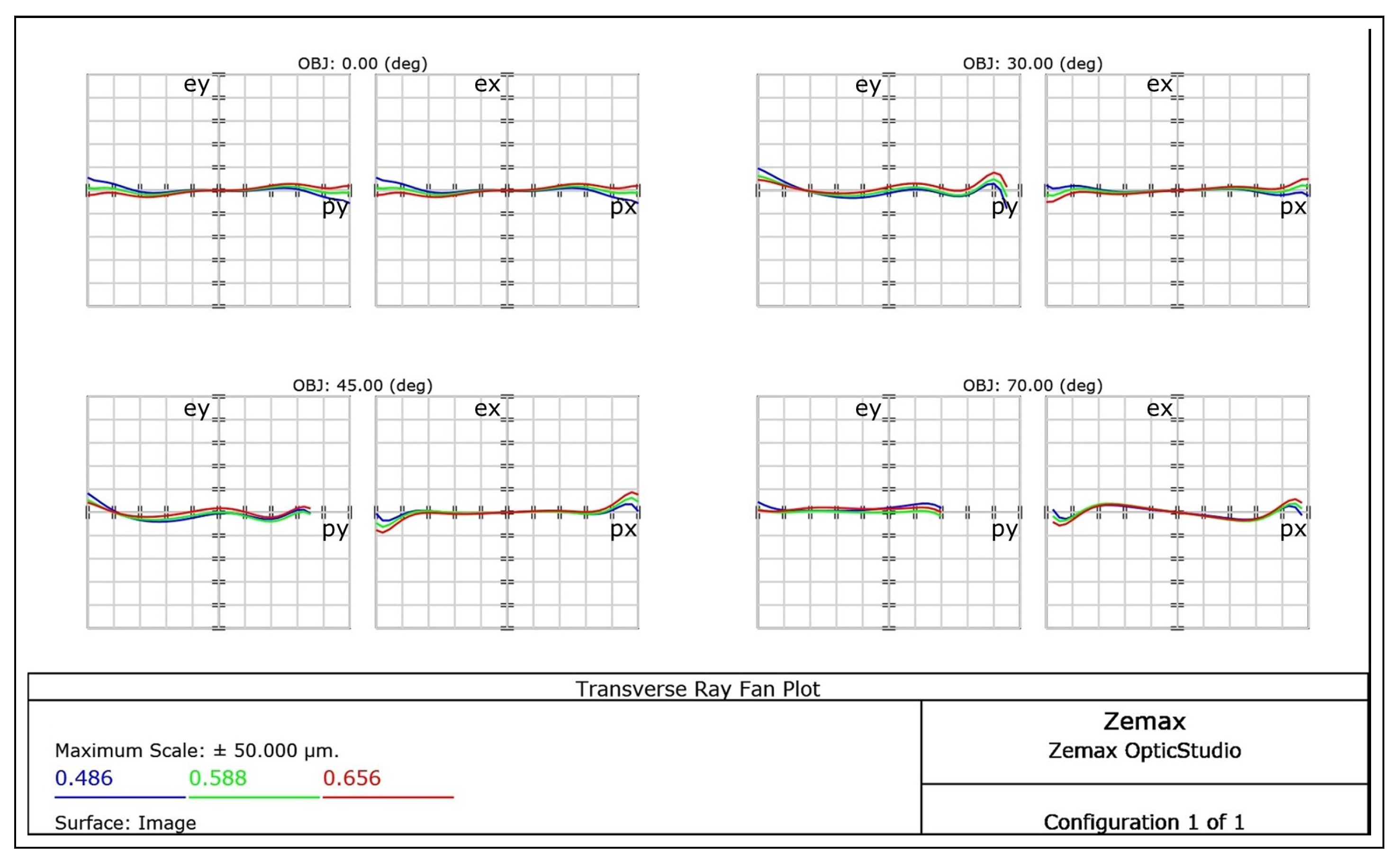

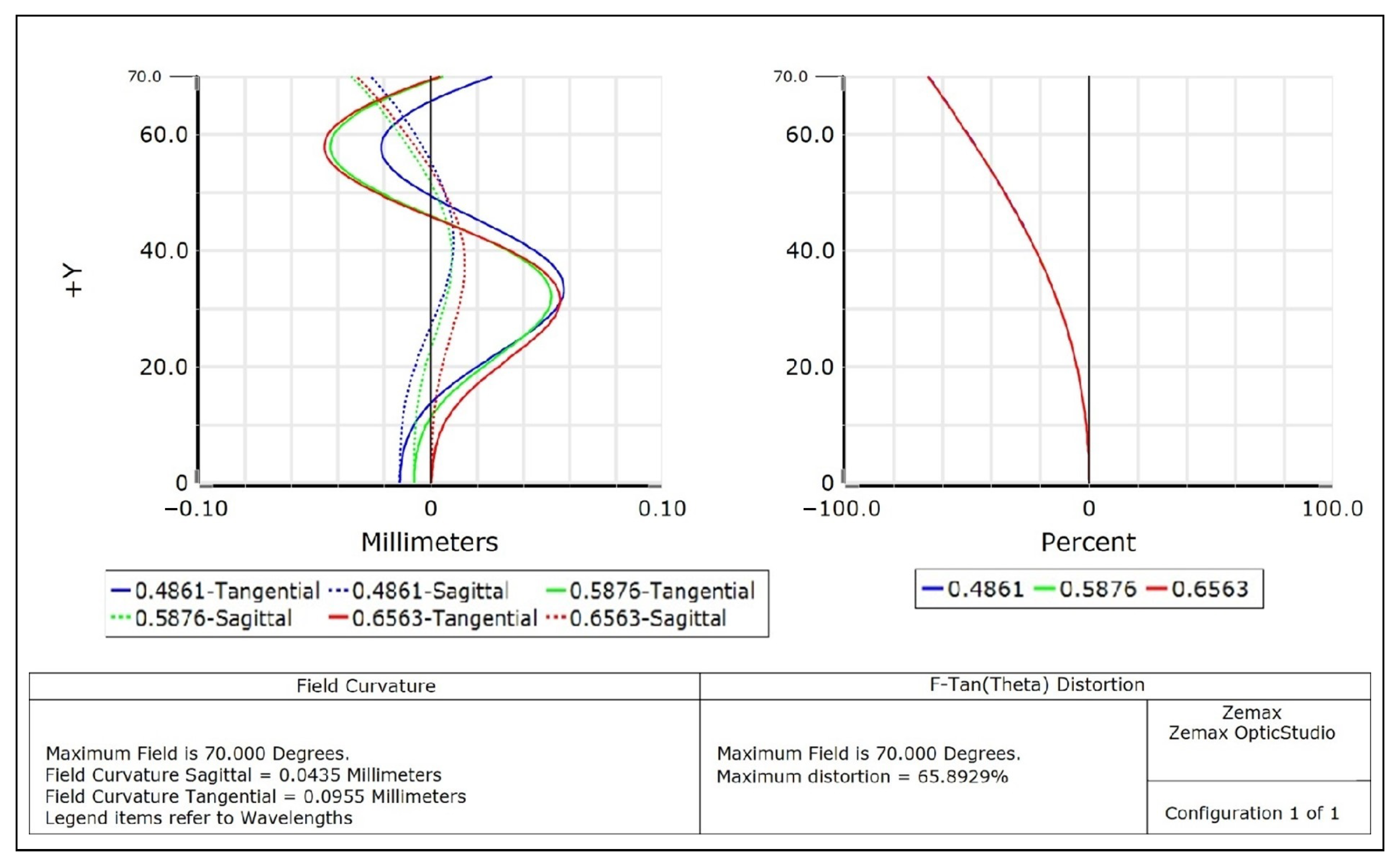

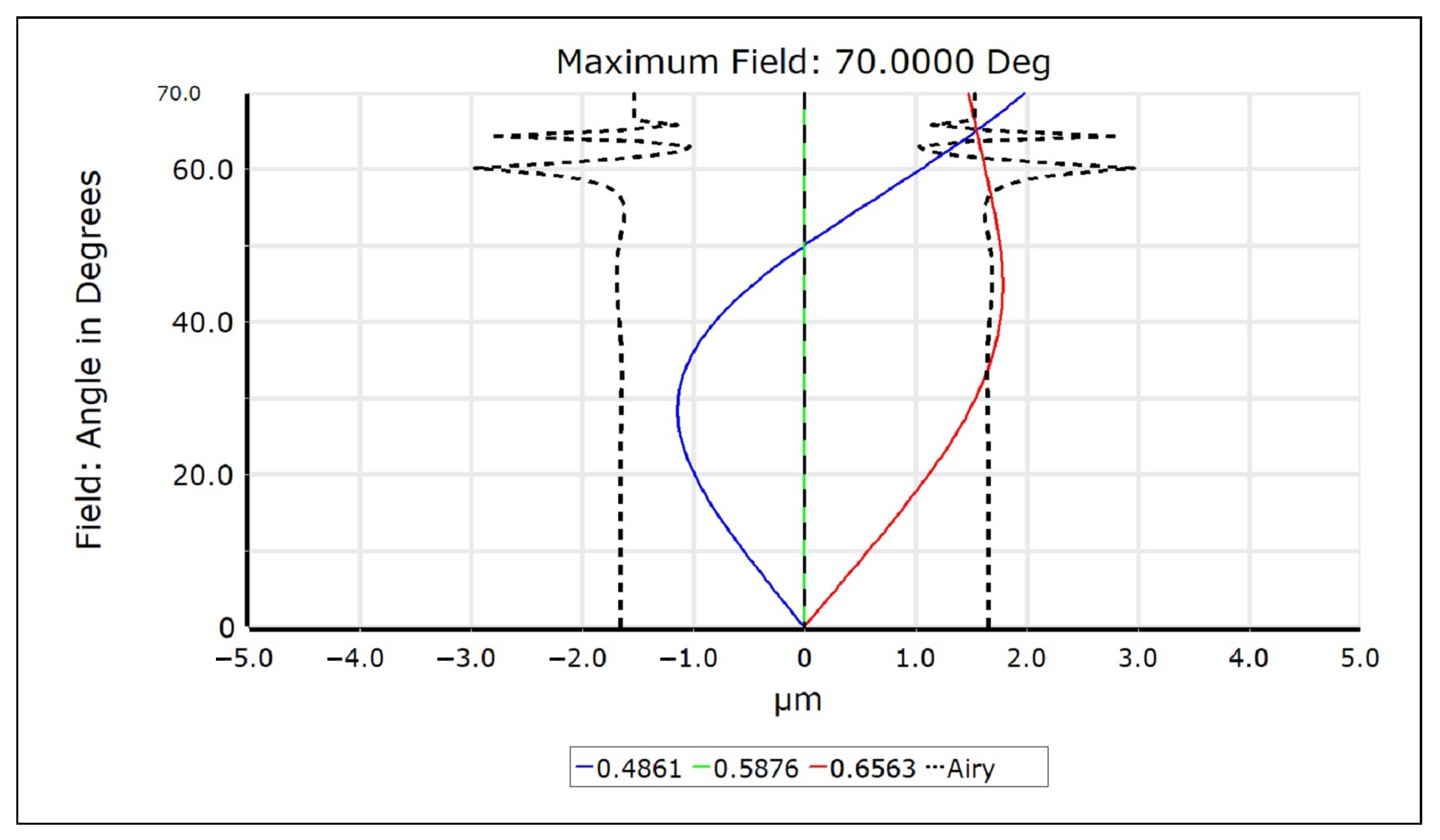

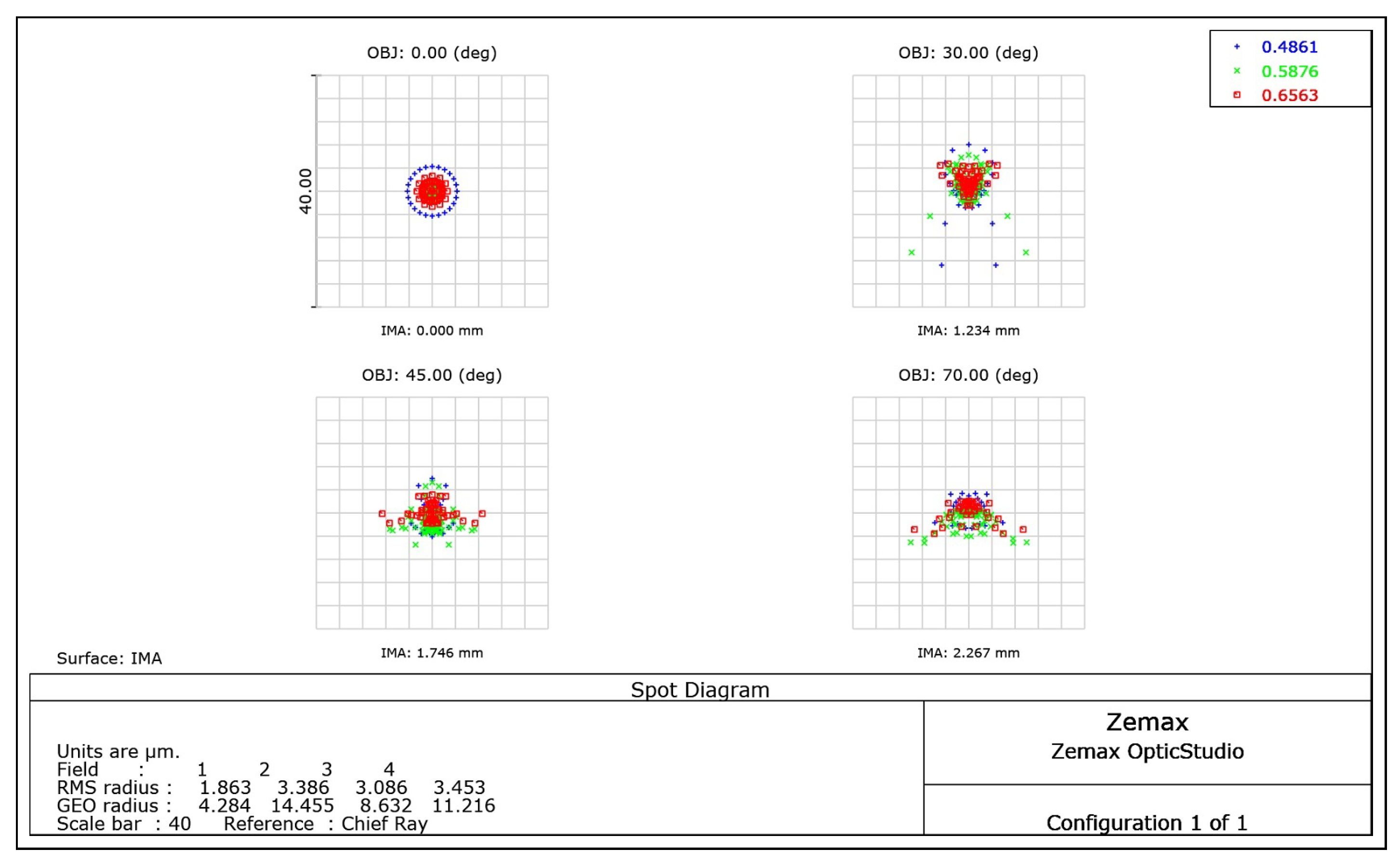

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lambert, R. Prevention of gastrointestinal cancer by surveillance endoscopy. EPMA J. 2010, 1, 473–483. [Google Scholar] [CrossRef] [PubMed]

- Göbel, W.; Kerr, J.N.D.; Nimmerjahn, A.; Helmchen, F. Miniaturized two-photon microscope based on a flexible coherent fiber bundle and a gradient-index lens objective. Opt. Lett. 2004, 29, 2521–2523. [Google Scholar] [CrossRef] [PubMed]

- Akhoundi, F.; Qin, Y.; Peyghambarian, N.; Barton, J.K.; Kieu, K. Compact fiber-based multi-photon endoscope working at 1700 nm. Biomed. Opt. Express 2018, 9, 2326–2335. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Wang, J.; Tian, G.; Yuan, J.; Liu, Q.; Fu, L. Five-lens, easy-to-implement miniature objective for a fluorescence confocal microendoscope. Opt. Express 2016, 24, 473–484. [Google Scholar] [CrossRef] [PubMed]

- Zaman, M.A.; Büyükalp, Y. Design of a high numerical aperture achromatic objective lens for endomicroscopy. Opt. Eng. 2019, 58, 075101. [Google Scholar] [CrossRef]

- Yoon, J.; Joseph, J.; Waterhouse, D.J.; Luthman, A.S.; Gordon, G.S.D.; Pietro, M.D.; Januszewicz, W.; Fitzgerald, R.C.; Bohndiek, S.E. A clinically translatable hyperspectral endoscopy (HySE) system for imaging the gastrointestinal tract. Nat. Commmun. 2019, 10, 1902. [Google Scholar] [CrossRef] [PubMed]

- Potapova, E.V.; Seryogina, E.S.; Dremin, V.V.; Stavtsev, D.D.; Kozlov, I.O.; Zherebtsov, E.A.; Mamoshin, A.V.; Ivanov, Y.V.; Dunaev, A.V. Laser speckle contrast imaging of blood microcirculation in pancreatic tissues during laparoscopic interventions. Quantum Electron. 2020, 50, 33–40. [Google Scholar] [CrossRef]

- Zheng, C.; Lau, L.W.; Cha, J. Dual-display laparoscopic laser speckle contrast imaging for real-time surgical assistance. Biomed. Opt. Express 2018, 9, 5962–5981. [Google Scholar] [CrossRef] [PubMed]

- Bumstead, J.R.; Park, J.J.; Rosen, I.A.; Kraft, A.W.; Wright, P.W.; Reisman, M.D.; Côté, D.C.; Culver, J.P. Designing a large field-of-view two-photon microscope using optical invariant analysis. Neurophotonics 2018, 5, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Jerome, W.G.; Price, R.L. Basic Confocal Microscopy, 2nd ed.; Springer: Cham, Switzerland, 2018; pp. 191–192. [Google Scholar]

- Chang, S.; Kim, D.; Kwon, H.-S. Compact wide-angle capsule endoscopic lens design. Appl. Opt. 2020, 59, 3595–3600. [Google Scholar] [CrossRef] [PubMed]

- Han, P.; Tseng, Y.-C.; Tsai, C.-M. Wide field of view lens design with uniform image illumination in capsule endoscope system. Microsyst. Technol. 2018, 1–8. [Google Scholar] [CrossRef]

- Dallaire, X.; Thibault, S. Design of a foveated wide-angle endoscopic lens. Opt. Eng. 2016, 55, 1–8. [Google Scholar] [CrossRef]

- Cogal, O.; Leblebici, Y. An insect eye inspired miniaturized multi-camera system for endoscopic imaging. IEEE Trans. Biomed. Circuits Syst. 2017, 11, 212–224. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-H.; Hsiao, L.-J.; Hsaio, J.-T.; Lin, H.Y. Front view and panoramic side view videoscope lens system design. Appl. Opt. 2014, 53, H146–H152. [Google Scholar] [CrossRef] [PubMed]

- Kose, T.; Ben-Mrad, R. Optical design of a 2× zoom lens for miniature imaging systems. Opt. Eng. 2019, 58, 085107. [Google Scholar] [CrossRef]

- Chen, P.; Gao, X. Optical design of the 13 mega-pixels mobile phone camera. In Proceedings of the 2016 3rd International Conference on Materials Engineering, Manufacturing Technology and Control, Taiyuan, China, 27–28 February 2016; pp. 835–840. [Google Scholar]

- Kovaleva, J.; Peters, F.T.M.; van der Mei, H.C.; Degener, J.E. Transmission of infection by flexible gastrointestinal endoscopy and bronchoscopy. Clin. Microbiol. Rev. 2013, 26, 231–254. [Google Scholar] [CrossRef] [PubMed]

- Wippermann, F.C.; Beckert, E.; Dannberg, P.; Messerschmidt, B.; Seyffert, G. Disposable low-cost video endoscopes for straight and oblique viewing direction with simplified integration. In Design and Quality for Biomedical Technologies III, Proceedings of the SPIE BiOS, San Francisco, CA, USA, 23–28 January 2010; International Society for Optics and Photonics: Bellingham, WA, USA, 2010; Volume 7556, pp. 25–34. [Google Scholar]

- Shim, D.; Yeon, J.; Yi, J.; Park, J.; Park, S.N.; Lee, N. A wide-angle camera module for disposable endoscopy. Opt. Rev. 2016, 23, 596–600. [Google Scholar] [CrossRef]

- Pedrotti, F.L.; Pedrotti, L.M.; Pedrotti, L.S. Introduction to Optics, 3rd ed.; Cambridge University Press: Cambridge, UK, 2017; pp. 70–71. [Google Scholar]

- Chabay, R.W.; Sherwood, B.A. Matter and Interactions, 4th ed.; Wiley: Hoboken, NJ, USA, 2015; p. 978. [Google Scholar]

- Khanicheh, A.; Shergill, A.K. Endoscope design for the future. Tech. Gastrointest. Endosc. 2019, 21, 167–173. [Google Scholar] [CrossRef]

- OmniVision Technologies, Co. Available online: https://www.ovt.com/sensors/OV5695 (accessed on 14 July 2020).

- Sun, H. Lens Design: A Practical Guide; CRC Press: Boca Raton, FL, USA, 2017; pp. 117–118, 228–232, 324–325. [Google Scholar]

- Song, S.H. Optical System for Surveillance Camera Using Aspherical Surface. KR Patent Application 20050118139, November 2005. [Google Scholar]

- Prada, J.; Cordes, C.; Harms, C.; Lang, W. Design and Manufacturing of a Disposable, Cyclo-Olefin Copolymer, Microfluidic Biosensor. Proceedings 2018, 2, 810. [Google Scholar] [CrossRef]

- Schaub, M.; Schwiegerling, J.; Fest, E.; Shepard, R.H.; Symmons, A. Molded Optics: Design and Manufacture, 1st ed.; CRC Press: Boca Raton, FL, USA, 2011; p. 24. [Google Scholar]

- Bax, M.R.; Shahidi, R. Real-time lens distortion correction: Speed, accuracy and efficiency. Opt. Eng. 2014, 53, 113103. [Google Scholar] [CrossRef]

| Item | Specifications |

|---|---|

| f-number | 2.2 |

| Field-of-view | 140 deg |

| Working distance | 15 mm |

| Half image height | 2.3 mm |

| Total track length | <10 mm |

| Relative illumination | >0.6 |

| MTF | >0.2 at 180 lp/mm |

| Surface | Radius (mm) | Thickness (mm) | Material | Aspheric Coefficient | |||

|---|---|---|---|---|---|---|---|

| 4th | 6th | 8th | 10th | ||||

| L1 | 12.190 | 0.400 | APL5014CL | −0.012 | |||

| 1.450 | 1.777 | −0.022 | 0.027 | −0.016 | |||

| Stop | Infinity | 0.875 | |||||

| L2 | 15.480 | 1.640 | APL5014CL | −0.014 | |||

| −2.190 | 0.050 | ||||||

| L3 | 4.520 | 1.850 | APL5014CL | ||||

| −2.590 | 0.045 | ||||||

| L4 | −2.450 | 0.400 | OKP-A2 | ||||

| 57.130 | 2.600 | ||||||

| IR filter | Infinity | 0.500 | BK7 | ||||

| Infinity | 0.550 | ||||||

| Image | Infinity | ||||||

| Item | Target | Result |

|---|---|---|

| f-number | 2.2 | 2.2 |

| Field-of-view | 140 deg | 140 deg |

| Working distance | 15 mm | 15 mm |

| Half image height | 2.3 mm | 2.3 mm |

| Total track length | <10 mm | 10.68 mm |

| Relative illumination | >0.6 | >0.68 |

| MTF at 180 lp/mm | >0.2 | >0.2 |

| Item | Tolerances |

|---|---|

| Surface tolerances | |

| Radius | ±1 fringe |

| Thickness | ±0.005 mm |

| Tilt X | ±0.05 deg |

| Tilt Y | ±0.05 deg |

| S+A Irregularity | ±0.5 |

| Element tolerances | |

| Decenter X | ±0.003 mm |

| Decenter Y | ±0.003 mm |

| Tilt X | ±0.05 deg |

| Tilt Y | ±0.05 deg |

| Index tolerances | |

| Index | ±0.001 |

| Abbe % | ±1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.; Chang, S.; Kwon, H.-S. Wide Field-of-View, High-Resolution Endoscopic Lens Design with Low F-Number for Disposable Endoscopy. Photonics 2021, 8, 89. https://doi.org/10.3390/photonics8040089

Kim D, Chang S, Kwon H-S. Wide Field-of-View, High-Resolution Endoscopic Lens Design with Low F-Number for Disposable Endoscopy. Photonics. 2021; 8(4):89. https://doi.org/10.3390/photonics8040089

Chicago/Turabian StyleKim, Dongmok, Sehui Chang, and Hyuk-Sang Kwon. 2021. "Wide Field-of-View, High-Resolution Endoscopic Lens Design with Low F-Number for Disposable Endoscopy" Photonics 8, no. 4: 89. https://doi.org/10.3390/photonics8040089

APA StyleKim, D., Chang, S., & Kwon, H.-S. (2021). Wide Field-of-View, High-Resolution Endoscopic Lens Design with Low F-Number for Disposable Endoscopy. Photonics, 8(4), 89. https://doi.org/10.3390/photonics8040089