Recent Advancement of Anti-Resonant Hollow-Core Fibers for Sensing Applications

Abstract

1. Introduction

2. Principle and Various Structure of AR-HCFs

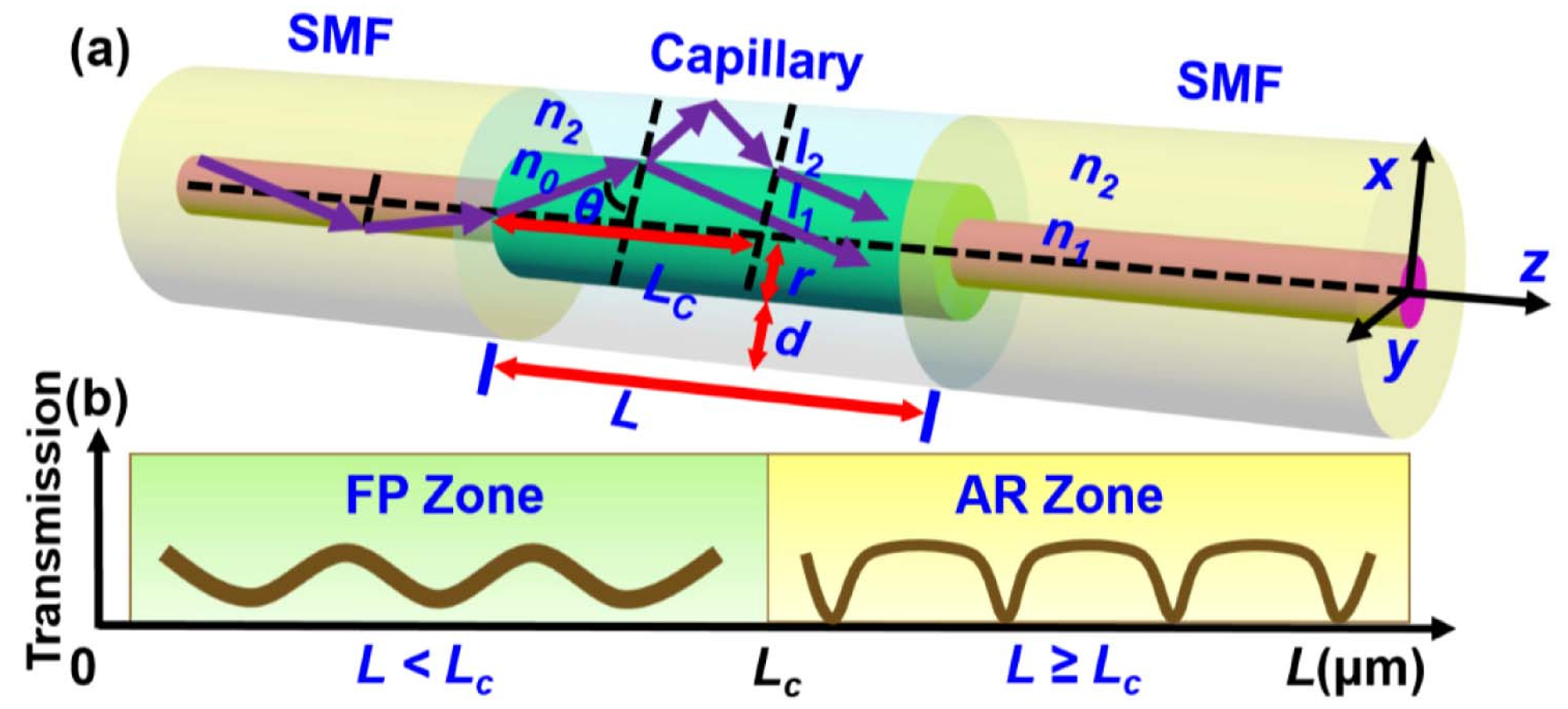

2.1. Principle of Light Propagation in AR-HCFs

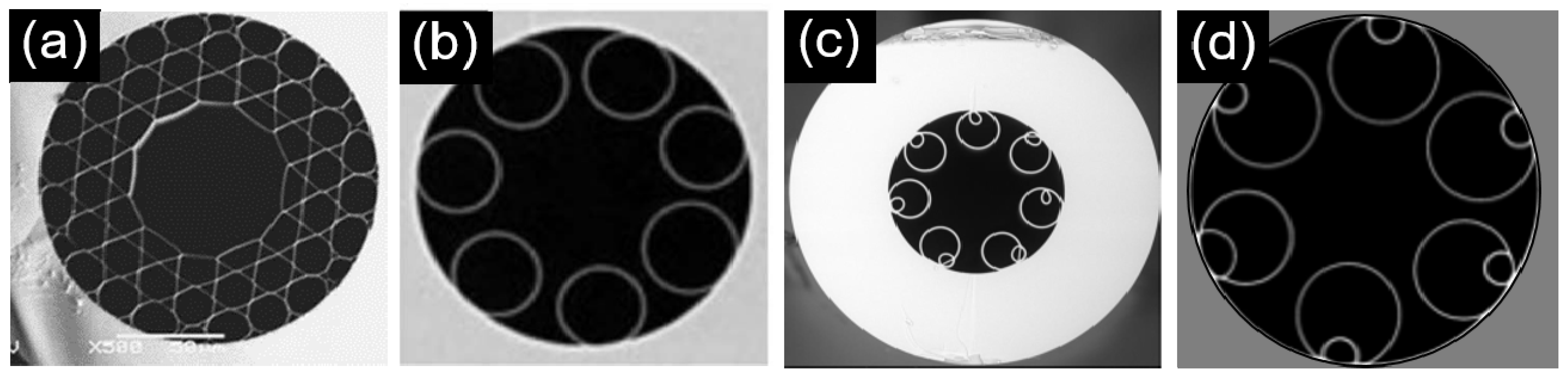

2.2. Various Structures of AR-HCFs

3. AR-HCF-Based Sensing Applications

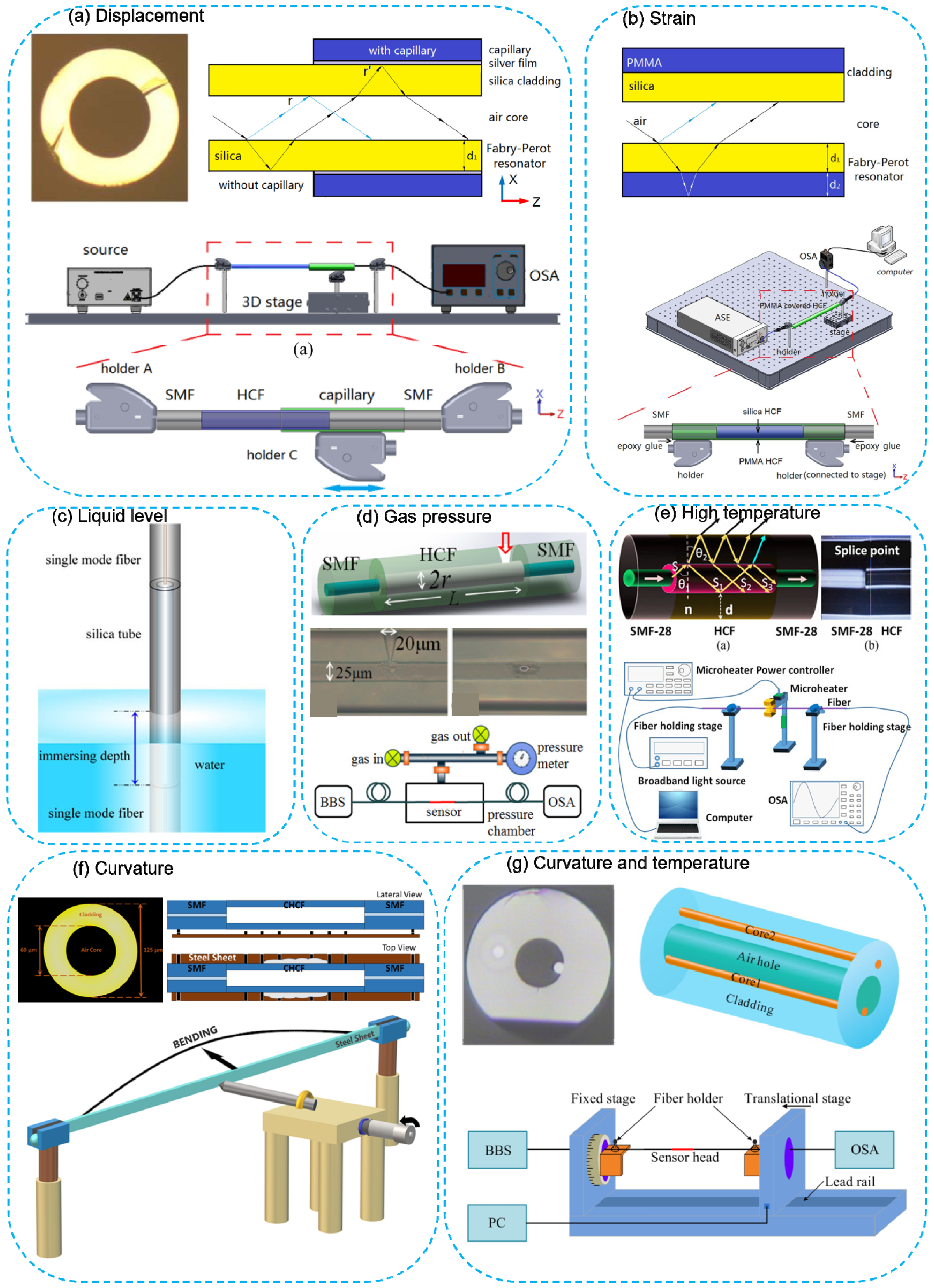

3.1. Special Device-Based Sensing Applications

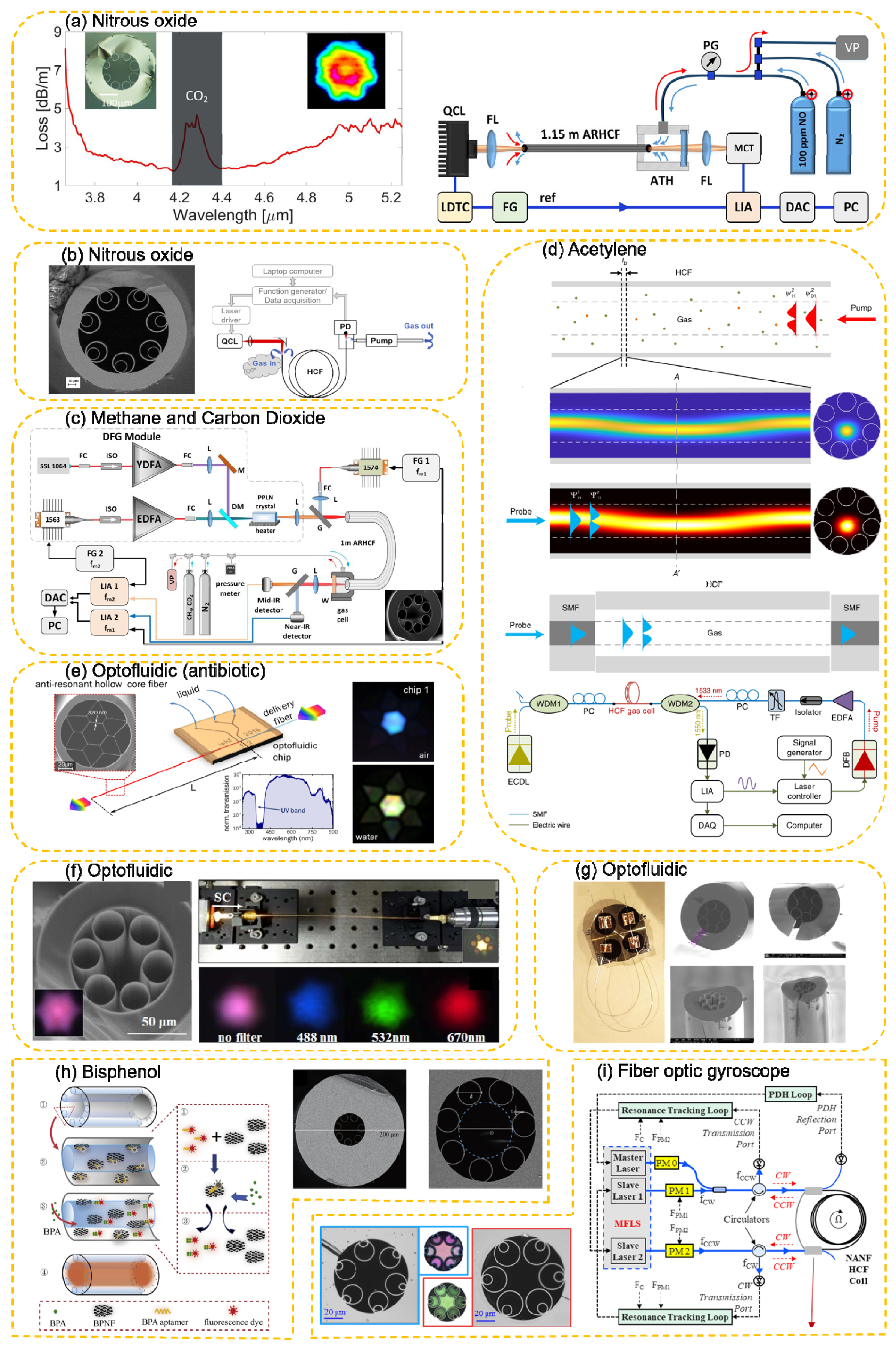

3.2. Versatile Platform Based Sensing Applications

4. Prospects and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sagae, Y.; Matsui, T.; Sakamoto, T.; Nakajima, K. Ultra-Low Crosstalk Multi-Core Fiber with Standard 125-μm Cladding Diameter for 10,000km-Class Long-Haul Transmission. IEICE Trans. Commun. 2020, E103.B, 1199–1205. [Google Scholar] [CrossRef]

- Habib, M.S.; Bang, O.; Bache, M. Low-loss single-mode hollow-core fiber with anisotropic anti-resonant elements. Opt. Express 2016, 24, 8429–8436. [Google Scholar] [CrossRef]

- Francesco, P. Nested antiresonant nodeless hollow core fiber. Opt. Express 2014, 22, 23807–23828. [Google Scholar]

- Belard, W. Design and Properties of Hollow Antiresonant Fibers for the Visible and Near Infrared Spectral Range. J. Lightwave Technol. 2015, 33, 4497–4503. [Google Scholar] [CrossRef]

- Kosolapov, A.F.; Alagashev, G.K.; Kolyadin, A.N.; Pryamikov, A.D.; Biryukov, A.S.; Bufetov, I.A.; Dianov, E.M. Hollow-core revolver fibre with a double-capillary reflective cladding. Quantum Electron. 2016, 46, 267–270. [Google Scholar] [CrossRef]

- Gao, S.; Wang, Y.; Ding, W.; Jiang, D.; Gu, S.; Zhang, X.; Wang, P. Hollow-core conjoined-tube negative-curvature fibre with ultralow loss. Nat. Commun. 2018, 9, 1–6. [Google Scholar] [CrossRef]

- Bradley, T.D.; Hayes, J.R.; Chen, Y.; Jasion, G.T.; Sandoghchi, S.R.; Slavik, R.; Fokoua, E.N.; Bawn, S.; Sakr, H.; Davidson, I.A.; et al. Record low-loss 1.3 dB/km data transmitting antiresonant hollow core fibre. In Proceedings of the 2018 European Conference on Optical Communication (ECOC), Rome, Italy, 23–27 September 2018. [Google Scholar]

- Bradley, T.D.; Jasion, G.T.; Hayes, J.R.; Chen, Y.; Hooper, L.; Sakr, H.; Gouveia, M.A.; Taranta, A.; Saljoghei, A.; Mulvad, H.C.; et al. Antiresonant hollow core fibre with 0.65 dB/km attenuation across the C and L telecommunication bands. In Proceedings of the 45th European Conference on Optical Communication (ECOC 2019), Dublin, Ireland, 22–26 September 2019. [Google Scholar]

- Jasion, G.T.; Bradley, T.D.; Harrington, K.; Sakr, H.; Chen, Y.; Fokoua, E.N.; Davidson, I.A.; Taranta, A.; Hayes, J.R.; Richardson, D.J.; et al. Hollow core NANF with 0.28 dB/km attenuation in the C and L bands. In Proceedings of the Optical Fiber Communication Conference, San Diego, CA, USA, 10–12 March 2020; Optical Society of America: Washington, DC, USA, 2020. [Google Scholar]

- Laser Focus World Reported on 01 Oct, 2020, and Sources from Lumenisty Company. Available online: https://www.laserfocusworld.com/fiber-optics/article/14184480/lumenisity-unveils-hollowcore-fiberoptic-cable-for-10-gbit-dwdm-transmission-over-10-km-links (accessed on 14 April 2021).

- Litchinitser, N.M.; Abeeluck, A.K.; Headley, C.; Eggleton, B.J. Antiresonant reflecting photonic crystal optical waveguides. Opt. Lett. 2002, 27, 1592–1594. [Google Scholar] [CrossRef]

- Xiaobei, Z.; Haiyang, P.; Huawen, B.; Ming, Y.; Jiawei, W.; Chuanlu, D.; Tianxing, W. Transition of Fabry–Perot and antiresonant mechanisms via a SMF-capillary-SMF structure. Opt. Lett. 2018, 43, 2268–2271. [Google Scholar]

- Cai, N.; Xia, L.; Wu, Y. Multiplexing of anti-resonant reflecting optical waveguides for temperature sensing based on quartz capillary. Opt. Express 2018, 26, 33501–33509. [Google Scholar] [CrossRef]

- Wei, C.; Weiblen, R.J.; Menyuk, C.R.; Hu, J. Negative curvature fibers. Adv. Opt. Photonics 2017, 9, 504–561. [Google Scholar] [CrossRef]

- Couny, F.; Benabid, P.S. Light. Large-pitch kagome-structured hollow-core photonic crystal fiber. Opt. Lett. 2006, 31, 3574–3576. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.Y.; Wheeler, N.V.; Couny, F.; Roberts, P.J.; Benabid, F. Low loss broadband transmission in hypocycloid-core Kagome hollow-core photonic crystal fiber. Opt. Lett. 2011, 36, 669–671. [Google Scholar] [CrossRef] [PubMed]

- Wheeler, N.V.; Heidt, A.M.; Baddela, N.K.; Fokoua, E.N.; Hayes, J.R.; Sandoghchi, S.R.; Poletti, F.; Petrovich, M.N.; Richardson, D.J. Low-loss and low-bend-sensitivity mid-infrared guidance in a hollow-core–photonic-bandgap fiber. Opt. Lett. 2014, 39, 295–298. [Google Scholar] [CrossRef]

- Debord, B.; Alharbi, M.; Bradley, T.; Fourcade-Dutin, C.; Wang, Y.Y.; Vincetti, L.; Gérôme, F.; Benabid, F. Hypocycloid-shaped hollow-core photonic crystal fiber Part I: Arc curvature effect on confinement loss. Opt. Express 2013, 21, 28597–28608. [Google Scholar] [CrossRef]

- Uebel, P.; Günendi, M.C.; Frosz, M.H.; Ahmed, G.; Edavalath, N.N.; Ménard, J.M.; Russell P. St., J. Broadband robustly single-mode hollow-core PCF by resonant filtering of higher-order modes. Opt. Lett. 2016, 41, 1961–1964. [Google Scholar] [CrossRef]

- Provino, L.; Haboucha, A.; Havranek, M.; Monteville, A.; Landais, D.; Goffic, O.; Insou, X.; Barbier, M.; Chartier, T.; Thual, M.; et al. Large-Core Hollow-Core Antiresonant Fiber with Low-Loss and Truly Single-Mode Guidance for N-IR Wavelengths. In Proceedings of the OSA Laser Congress, Boston, MA, USA, 4–8 November 2018; Optical Society of America: Washington, DC, USA, 2018. [Google Scholar]

- Michieletto, M.; Jens, K.; Lyngsø, C.J.; Lægsgaard, J.; Bang, O.; Alkeskjold, T.T. Hollow-core fibers for high power pulse delivery. Opt. Express 2016, 24, 7103–7119. [Google Scholar] [CrossRef]

- Hayes, J.R.; Sandoghchi, S.R.; Bradley, T.D.; Liu, Z.; Slavík, R.; Gouveia, M.A.; Wheeler, N.V.; Jasion, G.; Chen, Y.; Fokoua, E.N.; et al. Antiresonant Hollow Core Fiber with an Octave Spanning Bandwidth for Short Haul Data Communications. J. Lightwave Technol. 2017, 35, 437–442. [Google Scholar] [CrossRef]

- Pryamikov, A.D.; Biriukov, A.S.; Kosolapov, A.F.; Plotnichenko, V.G.; Semjonov, S.L.; Dianov, E.M. Demonstration of a waveguide regime for a silica hollow—core microstructured optical fiber with a negative curvature of the core boundary in the spectral region > 3.5 μm. Opt. Express 2011, 19, 1441–1448. [Google Scholar] [CrossRef] [PubMed]

- Kolyadin, A.N.; Kosolapov, A.F.; Pryamikov, A.D.; Biriukov, A.S.; Plotnichenko, V.G.; Dianov, E.M. Light transmission in negative curvature hollow core fiber in extremely high material loss region. Opt. Express 2013, 21, 9514–9519. [Google Scholar] [CrossRef]

- Newkirk, A.V.; Antonio-Lopez, J.E.; Anderson, J.; Aguirre, R.A.; Eznaveh, Z.S.; Galmiche, G.L.; Correa, R.A.; Schülzgen, A. Modal analysis of antiresonant hollow core fibers using S2 imaging. Opt. Lett. 2016, 41, 3277–3280. [Google Scholar] [CrossRef]

- Debord, B.; Amsanpally, A.; Chafer, M.; Baz, A.; Maurel, M.; Blondy, J.M.; Hugonnot, E.; Scol, F.; Vincetti, L.; Gérome, F.; et al. Ultralow transmission loss in inhibited-coupling guiding hollow fibers. Optica 2017, 4, 209–217. [Google Scholar] [CrossRef]

- Belardi, W.; Knight, J.C. Hollow antiresonant fibers with low bending loss. Opt. Express 2014, 22, 10091–10096. [Google Scholar] [CrossRef] [PubMed]

- Kosolapov, A.F.; Pryamikov, A.D.; Biriukov, A.S.; Shiryaev, V.S.; Astapovich, M.S.; Snopatin, G.E.; Plotnichenko, V.G.; Churbanov, M.F.; Dianov, E.M. Demonstration of CO2-laser power delivery through chalcogenide-glass fiber with negative-curvature hollow core. Opt. Express 2011, 19, 25723–25728. [Google Scholar] [CrossRef] [PubMed]

- Gattass, R.R.; Rhonehouse, D.; Gibson, D.; McClain, C.C.; Thapa, R.; Nguyen, V.Q.; Bayya, S.S.; Weiblen, R.J.; Menyuk, C.L.; Shaw, B.; et al. Infrared glass-based negative-curvature anti-resonant fibers fabricated through extrusion. Opt. Express 2016, 24, 25697–25703. [Google Scholar] [CrossRef] [PubMed]

- Setti, V.; Vincetti, L.; Argyros, A. Flexible tube lattice fibers for terahertz applications. Opt. Express 2013, 21, 3388–3399. [Google Scholar] [CrossRef]

- Antonio-Lopez, J.E.; Habib, M.S.; Newkirk, A.V.; Galmiche, G.L.; Eznaveh, Z.S.; Zacarisa, J.C.; Bang, O.; Bache, M.; Schülzgen, A.; Correa, R.A. Antiresonant hollow core fiber with seven nested capillaries. In Proceedings of the 2016 IEEE Photonics Conference (IPC), Waikoloa, HI, USA, 2–6 October 2016. [Google Scholar]

- Hong, Y.; Sakr, H.; Taengnoi, N.; Bottrill, K.R.; Bradley, T.D.; Hayes, J.R.; Jasion, G.T.; Kim, H.; Thipparapu, N.K.; Wang, Y.; et al. Multi-Band Direct-Detection Transmission Over an Ultrawide Bandwidth Hollow-Core NANF. J. Lightwave Technol. 2020, 38, 2849–2857. [Google Scholar] [CrossRef]

- Wang, S.; Shan, C.; Jiang, J.; Liu, K.; Zhang, X.; Han, Q.; Lei, J.; Xiao, H.; Liu, T. Temperature-insensitive curvature sensor based on anti-resonant reflection guidance and Mach–Zehnder interferometer hybrid mechanism. Appl. Phys. Express 2019, 12, 106503. [Google Scholar] [CrossRef]

- Liu, S.; Ji, Y.; Cui, L.; Sun, W.; Yang, J.; Li, H. Humidity-insensitive temperature sensor based on a quartz capillary anti-resonant reflection optical waveguide. Opt. Express 2017, 25, 18929–18939. [Google Scholar] [CrossRef]

- Gao, R.; Lu, D.; Cheng, J.; Qi, Z. Self-referenced antiresonant reflecting guidance mechanism for directional bending sensing with low temperature and strain crosstalk. Opt. Express 2017, 25, 18081–18091. [Google Scholar] [CrossRef]

- Wang, S.; Wang, S.; Zhang, S.; Feng, M.; Wu, S.; Jin, R.; Zhang, L.; Lu, P. An inline fiber curvature sensor based on anti-resonant reflecting guidance in silica tube. Opt. Laser Technol. 2019, 111, 407–410. [Google Scholar] [CrossRef]

- Gao, H.; Jiang, Y.; Zhang, L.; Cui, Y.; Jiang, Y.; Jia, J.; Jiang, L. Antiresonant mechanism based self-temperature-calibrated fiber optic Fabry–Perot gas pressure sensors. Opt. Express 2019, 27, 22181–22189. [Google Scholar] [CrossRef] [PubMed]

- Suo, X.; Yu, H.; Li, J.; Wu, X. Transmissive resonant fiber-optic gyroscope employing Kagome hollow-core photonic crystal fiber resonator. Opt. Lett. 2020, 45, 2227–2230. [Google Scholar] [CrossRef] [PubMed]

- Ni, W.; Lu, P.; Fu, X.; Sun, H.; Shum, P.; Liao, H.; Jiang, X.; Liu, D.; Yang, C.; Zhang, J.; et al. Simultaneous implementation of enhanced resolution and large dynamic range for fiber temperature sensing based on different optical transmission mechanisms. Opt. Lett. 2018, 26, 18341–18350. [Google Scholar] [CrossRef]

- Ankan, I.M.; Mollah, M.A.; Sultana, J.; Islam, M. Negative Curvature Hollow-core Anti-resonant Fiber for Terahertz Sensing. Appl. Opt. 2020, 59, 8519–8525. [Google Scholar] [CrossRef]

- Gao, R.; Lu, D.; Cheng, J.; Jiang, Y.; Jiang, L.; Ye, J.; Qi, Z. Magnetic Fluid-Infiltrated Anti-Resonant Reflecting Optical Waveguide for Magnetic Field Sensing Based on Leaky Modes. J. Lightwave Technol. 2016, 34, 3490–3495. [Google Scholar] [CrossRef]

- Newkirk, A.V.; Lopez, J.E.A.; Correa, R.A.; Schülzgen, A.; Mazurowski, J. Anti-resonant hollow core fiber for precision timing applications. In Astronomical Optics: Design, Manufacture, & Test of Space & Ground Systems; Astronomical Optics: San Diego, CA, USA, 2017; Volume 10401, p. 104010F-1. [Google Scholar]

- Jaworski, P.; Yu, F.; Boj, P.; Wu, D.; Koziol, P.E.; Dudzik, G.; Abramski, K.M.; Liao, M.; Krzempek, K. Antiresonant Hollow-Core Fiber for Multiple Gas Detection in the Mid-IR. In CLEO: QELSFundamental Science; Optical Society of America: Washington, DC, USA, 2020; p. JTu2G.33. [Google Scholar]

- Liu, S.; Wang, Y.; Hou, M.; Guo, J.; Li, Z.; Lu, P. Anti-resonant reflecting guidance in alcohol-filled hollow core photonic crystal fiber for sensing applications. Opt. Lett. 2013, 21, 31690–31697. [Google Scholar] [CrossRef]

- Gao, R.; Lu, D.; Zhang, M.; Qi, Z. Optofluidic Immunosensor Based on Resonant Wavelength Shift of a Hollow Core Fiber for Ultratrace Detection of Carcinogenic Benzo[a]pyrene. ACS Photonics 2018, 5, 1273–1280. [Google Scholar] [CrossRef]

- Zheng, D.; Cai, Z.; Floris, I.; Madrigal, J.; Pan, W.; Zou, X.; Sales, S. Temperature-insensitive optical tilt sensor based on a single eccentric-core fiber Bragg grating. Opt. Lett. 2019, 44, 5570–5573. [Google Scholar] [CrossRef] [PubMed]

- Guo, K.; He, J.; Shao, L.; Xu, G.; Wang, Y. Simultaneous Measurement of Strain and Temperature by a Sawtooth Stressor-Assisted Highly Birefringent Fiber Bragg Grating. J. Lightwave Technol. 2020, 38, 2060–2066. [Google Scholar] [CrossRef]

- Zuowei, X.; Huang, B.; Shu, X. Dual interference effects in a line-by-line inscribed fiber Bragg grating. Opt. Lett. 2020, 45, 2950–2953. [Google Scholar]

- Zhang, S.; Li, X.; Niu, H.; Yan, Q.; Sun, C.; Peng, F.; Ma, Y.; Zhang, K.; Geng, T.; Yang, W.; et al. Few-mode fiber-embedded long-period fiber grating for simultaneous measurement of refractive index and temperature. Appl. Opt. 2020, 59, 9248–9253. [Google Scholar] [CrossRef] [PubMed]

- Ni, W.; Lu, P.; Luo, C.; Fu, X.; Liu, L.; Jiang, X.; Liao, H.; Liu, D.; Zhang, J. Bending direction detective fiber sensor for dual-parameter sensing based on an asymmetrical thin-core long-period fiber grating. IEEE Photonics J. 2016, 8, 6803811. [Google Scholar] [CrossRef]

- Gao, R.; Lu, D.; Cheng, J.; Jiang, Y.; Jiang, L.; Qi, Z. Optical displacement sensor in a capillary covered hollow core fiber based on anti-resonant reflecting guidance. IEEE J. Sel. Top. Quantum Electron. 2016, 23, 5600106. [Google Scholar] [CrossRef]

- Gao, R.; Lu, D.; Cheng, J.; Qi, Z. In-Fiber Double-Layered Resonator for High-Sensitive Strain Sensing. IEEE Photonics Technol. Lett. 2017, 29, 857–860. [Google Scholar] [CrossRef]

- Liu, S.; Tian, J.; Liu, N.; Xia, J.; Lu, P. Temperature Insensitive Liquid Level Sensor Based on Antiresonant Reflecting Guidance in Silica Tube. J. Lightwave Technol. 2016, 34, 5239–5243. [Google Scholar] [CrossRef]

- Hou, M.; Zhu, F.; Wang, Y.; Wang, Y.; Liao, C.; Liu, S.; Lu, P. Antiresonant reflecting guidance mechanism in hollow-core fiber for gas pressure sensing. Opt. Lett. 2016, 24, 27890–27898. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Wu, Q.; Mei, C.; Yuan, J.; Xin, X.; Mallik, A.K.; Wei, F.; Han, W.; Kumar, R.; Yu, C.; et al. Hollow Core Fiber Based Interferometer for High-Temperature (1000 °C) Measurement. J. Lightwave Technol. 2018, 36, 1583–1590. [Google Scholar] [CrossRef]

- Herrera-Piad, L.A.; Hernández-Romano, I.; May-Arrioja, D.A.; Minkovich, V.P.; Cisneros, M.T. Sensitivity Enhancement of Curvature Fiber Sensor Based on Polymer-Coated Capillary Hollow-Core Fiber. Sensors 2020, 20, 3763. [Google Scholar] [CrossRef]

- Ni, W.; Lu, P.; Zhang, J.; Yang, C.; Fu, X.; Sun, Y.; Liao, H.; Liu, D. Single hole twin eccentric core fiber sensor based on anti-resonant effect combined with inline Mach-Zehnder interferometer. Opt. Lett. 2017, 25, 12372–12380. [Google Scholar] [CrossRef] [PubMed]

- Jaworski, P.; Krzempek, K.; Dudzik, G.; Sazio, P.J.; Belardi, W. Nitrous oxide detection at 5.26 µm with a compound glass antiresonant hollow-core optical fiber. Opt. Lett. 2020, 45, 1326–1329. [Google Scholar] [CrossRef] [PubMed]

- Nikodem, M.; Gomółka, G.; Klimczak, M.; Pysz, D.; Buczyński, R. Demonstration of mid-infrared gas sensing using an anti-resonant hollow core fiber and a quantum cascade laser. Opt. Lett. 2019, 27, 36350–36357. [Google Scholar] [CrossRef] [PubMed]

- Jaworski, P.; Koziol, P.E.; Krzempek, K.; Wu, D.; Yu, F.; Boj, P.; Dudzik, G.; Liao, M.; Abramski, K.M.; Knight, J.C. Antiresonant Hollow-Core Fiber-Based Dual Gas Sensor for Detection of Methane and Carbon Dioxide in the Near-and Mid-Infrared Regions. Sensors 2020, 20, 3813. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Zhao, Y.; Bao, H.; Ho, H.; Jin, W.; Fan, S.; Gao, S.; Wang, Y.; Wang, P. Mode-phase-difference photothermal spectroscopy for gas detection with an anti-resonant hollow-core optical fiber. Nat. Commun. 2020, 11, 847. [Google Scholar] [CrossRef]

- Mona, N.; Brenda, D.; Jonas, H.; Jens, K.; Karina, W.; Thomas, H.; Maekus, A.S. UV Absorption Spectroscopy in Water-Filled Antiresonant Hollow Core Fibers for Pharmaceutical Detection. Sensors 2018, 18, 478. [Google Scholar]

- Liu, X.; Ding, W.; Wang, Y.; Gao, S.; Cao, L.; Feng, X.; Wang, P. Characterization of a liquid-filled nodeless anti-resonant fiber for biochemical sensing. Opt. Lett. 2017, 42, 863–866. [Google Scholar] [CrossRef]

- Adamu, A.I.; Wang, Y.; Correa, R.A.; Bang, O.; Markos, C. Low-loss micro-machining of anti-resonant hollow-core fiber with focused ion beam for optofluidic application. Opt. Mater. Express 2021, 11, 338–344. [Google Scholar] [CrossRef]

- Qiao, P.; Wang, X.; Gao, S.; Yin, X.; Wang, Y.; Wang, P. Integration of black phosphorus and hollow-core anti-resonant fiber enables two-order magnitude enhancement of sensitivity for bisphenol A detection. Biosens. Bioelectron. 2019, 149, 111821. [Google Scholar] [CrossRef]

- Sanders, G.A.; Taranta, A.A.; Narayanan, C.; Fokoua, E.N.; Mousavi, S.A.; Strandjord, L.K.; Smiciklas, M.; Bradley, T.D.; Hayes, J.; Jasion, G.T.; et al. Hollow-core resonator fiber optic gyroscope using nodeless anti-resonant fiber. Opt. Lett. 2021, 46, 46–49. [Google Scholar] [CrossRef]

- Zhang, N.; Humbert, G.; Gong, T.; Shum, P.; Li, K.; Auguste, J.R.; Wu, Z.; Hu, J.; Luan, F.; Dinh, Q.; et al. Side-channel photonic crystal fiber for surface enhanced Raman scattering sensing. Sens. Actuators B. Chem. 2016, 223, 195–201. [Google Scholar] [CrossRef]

- Zhang, M.; Li, K.; Shum, P.; Yu, X.; Zeng, S.; Wu, Z.; Wang, Q.; Yong, K.; Wei, L. Hybrid graphene/gold plasmonic fiber-optic biosensor. Adv. Mater. Technol. 2017, 2, 1600185. [Google Scholar] [CrossRef]

- Zhang, M.; Li, K.; Zhang, T.; Shum, P.; Wang, Z.; Wang, Z.; Zhang, N.; Zhang, J.; Wu, T.; Wei, L. Electron-rich two-dimensional molybdenum trioxides for highly integrated plasmonic biosensing. ACS Photonics 2018, 5, 347–352. [Google Scholar] [CrossRef]

- Zhang, N.; Humbert, G.; Wu, Z.; Li, K.; Shum, P.; Zhang, M.; Cui, Y.; Auguste, J.L.; Dinh, X.; Wei, L. In-line optofluidic refractive index sensing in a side-channel photonic crystal fiber. Opt. Lett. 2016, 24, 27674–27682. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Li, K.; Cui, Y.; Wu, Z.; Shum, P.; Auguste, J.L.; Dinh, X.; Humbert, G.; Wei, L. Ultra-sensitive chemical and biological analysis via specialty fibers with built-in microstructured optofluidic channels. Lab Chip 2018, 18, 655–661. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Qi, M.; Wang, Z.; Wang, Z.; Chen, M.; Li, K.; Shum, P.; Wei, L. One-step synthesis of cyclodextrin-capped gold nanoparticles for ultra-sensitive and highly-integrated plasmonic biosensors. Sens. Actuators B. Chem. 2019, 286, 429–436. [Google Scholar] [CrossRef]

| Type | Core Diameter | Silica Thickness | Transmission Loss | Reference |

|---|---|---|---|---|

| Densely arrangement | 45.8 μm | 0.51 μm | 300 dB/km | [15] |

| 50 μm | 0.28 μm | 180 dB/km | [16] | |

| 60 μm | 1.4 μm | 17 dB/km | [18] | |

| Suspended capillary tubes | 30 μm | 0.44 μm | 180 dB/km | [19] |

| 30 μm | 0.83 μm | 30 dB/km | [21] | |

| 41 μm | 0.545 μm | 7.7 dB/km | [26] | |

| Nested Suspended tubes | 25 μm | 2.3 μm | 75 dB/km | [5] |

| ~33 μm | ~0.78 μm | 2 dB/m | [31] | |

| ~35 μm | ~0.5 μm | 6.6 dB/km | [32] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, W.; Yang, C.; Luo, Y.; Xia, R.; Lu, P.; Hu, D.J.J.; Danto, S.; Shum, P.P.; Wei, L. Recent Advancement of Anti-Resonant Hollow-Core Fibers for Sensing Applications. Photonics 2021, 8, 128. https://doi.org/10.3390/photonics8040128

Ni W, Yang C, Luo Y, Xia R, Lu P, Hu DJJ, Danto S, Shum PP, Wei L. Recent Advancement of Anti-Resonant Hollow-Core Fibers for Sensing Applications. Photonics. 2021; 8(4):128. https://doi.org/10.3390/photonics8040128

Chicago/Turabian StyleNi, Wenjun, Chunyong Yang, Yiyang Luo, Ran Xia, Ping Lu, Dora Juan Juan Hu, Sylvain Danto, Perry Ping Shum, and Lei Wei. 2021. "Recent Advancement of Anti-Resonant Hollow-Core Fibers for Sensing Applications" Photonics 8, no. 4: 128. https://doi.org/10.3390/photonics8040128

APA StyleNi, W., Yang, C., Luo, Y., Xia, R., Lu, P., Hu, D. J. J., Danto, S., Shum, P. P., & Wei, L. (2021). Recent Advancement of Anti-Resonant Hollow-Core Fibers for Sensing Applications. Photonics, 8(4), 128. https://doi.org/10.3390/photonics8040128