Performance Evaluation of Solid-State Laser Gain Module by Measurement of Thermal Effect and Energy Storage

Abstract

:1. Introduction

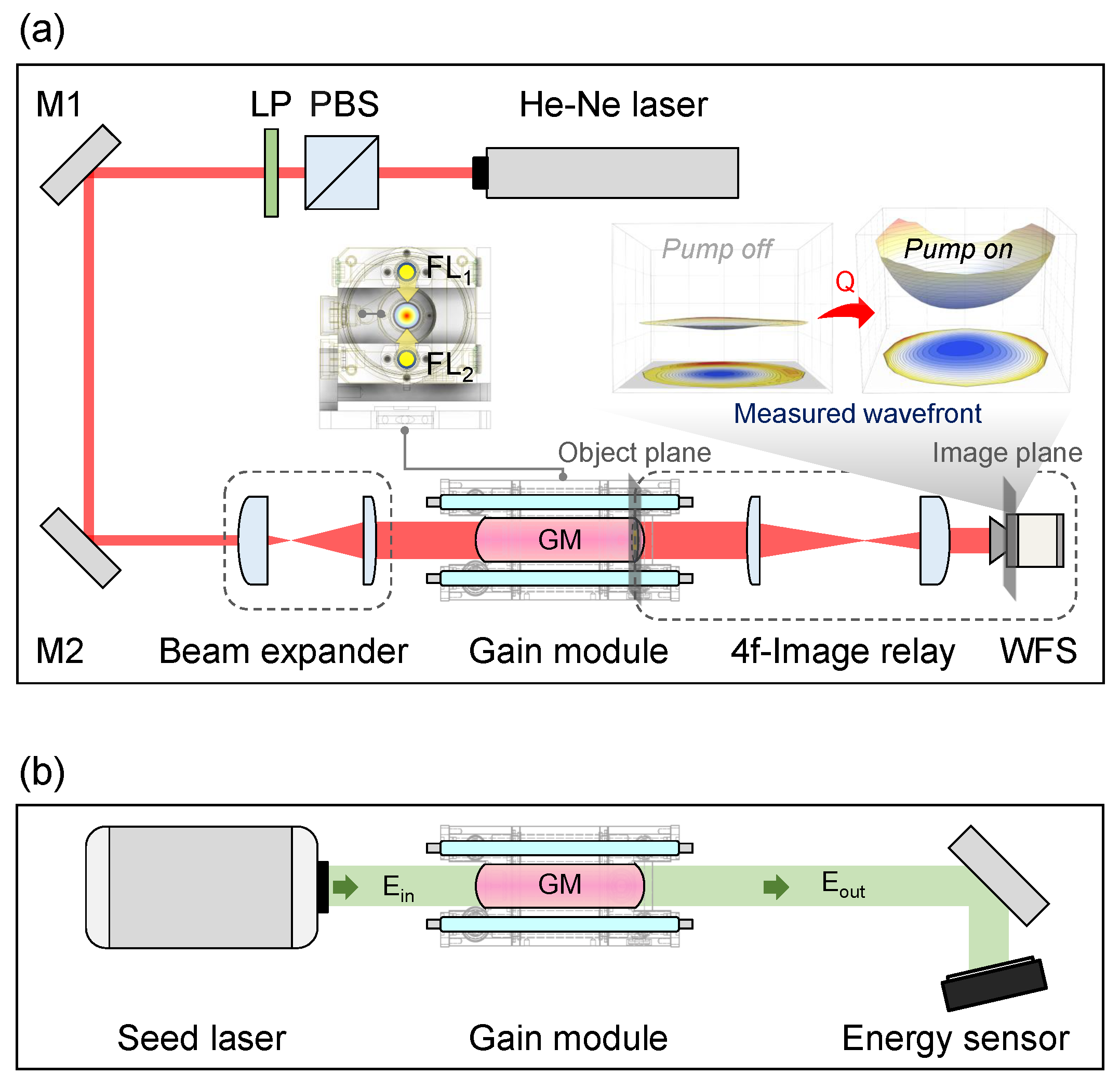

2. Theory and Method

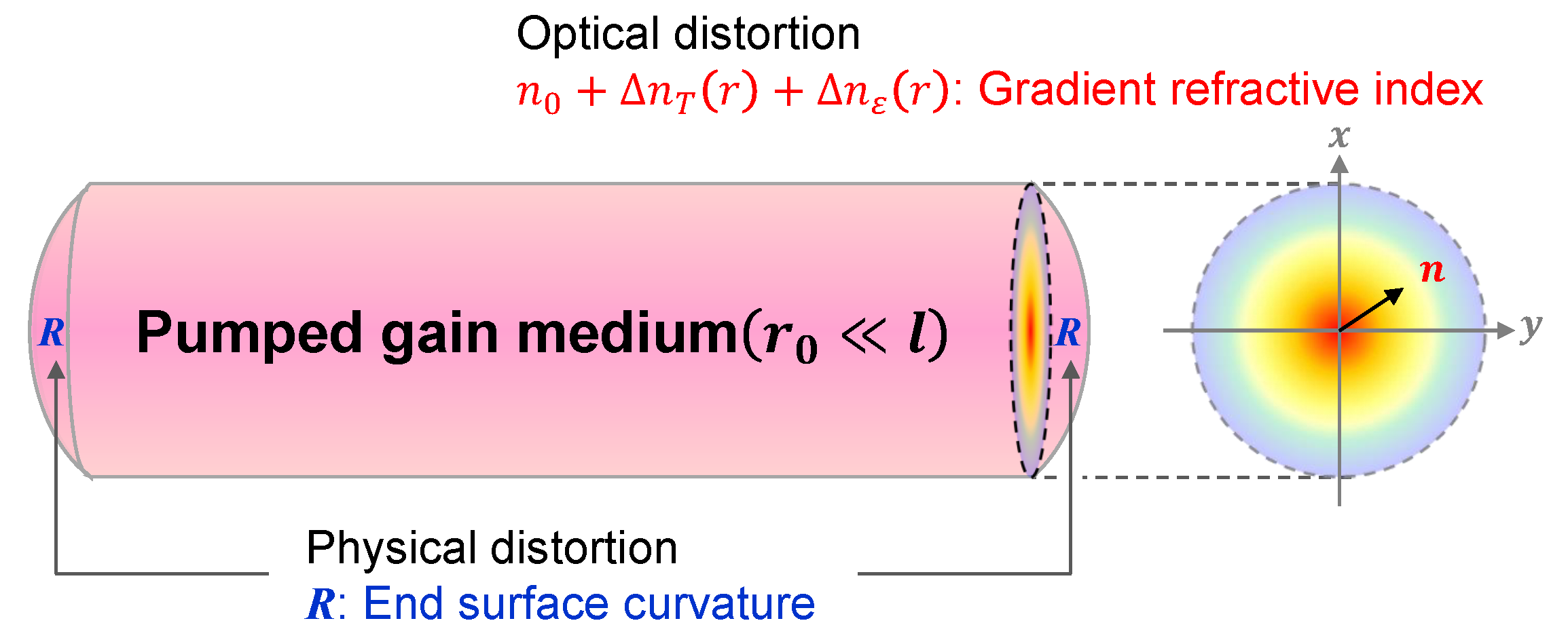

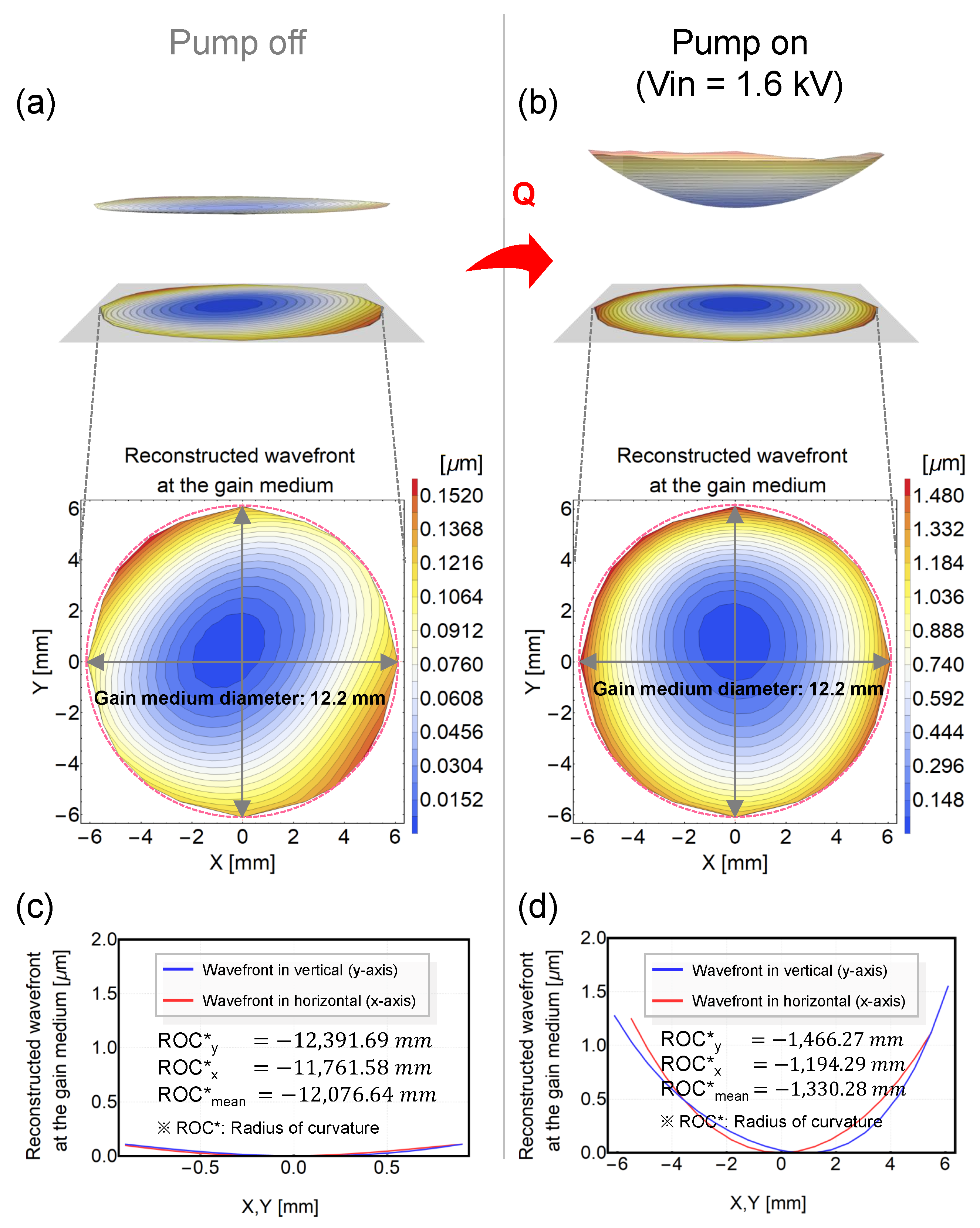

2.1. Optical and Physical Distortion in Cylindrical Laser Rod

- (1)

- : optical distortion by temperature and stress;

- (2)

- R: physical distortion by end surface curvature.

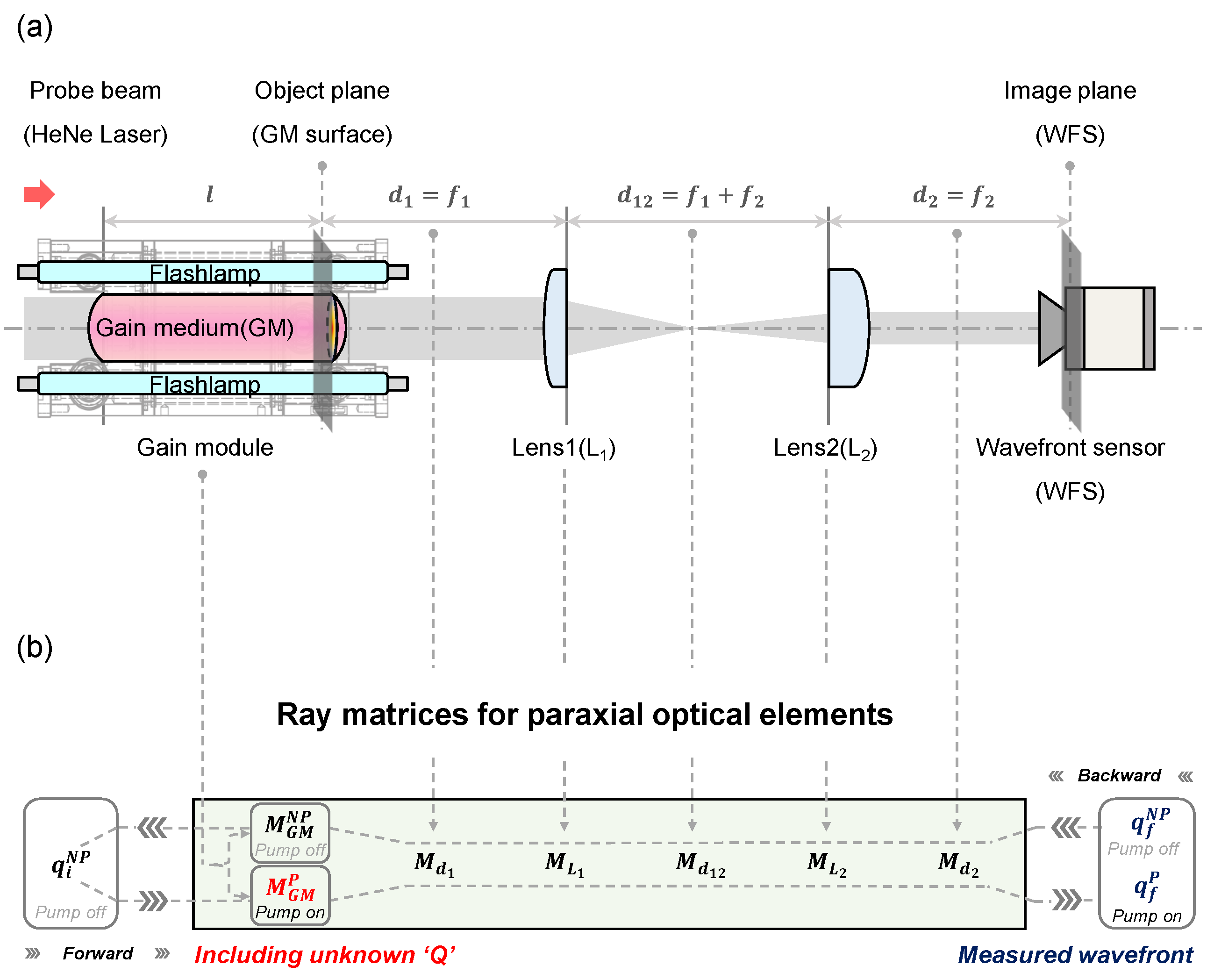

2.2. Gain Medium Surface Image Relay and Wavefront Reconstruction

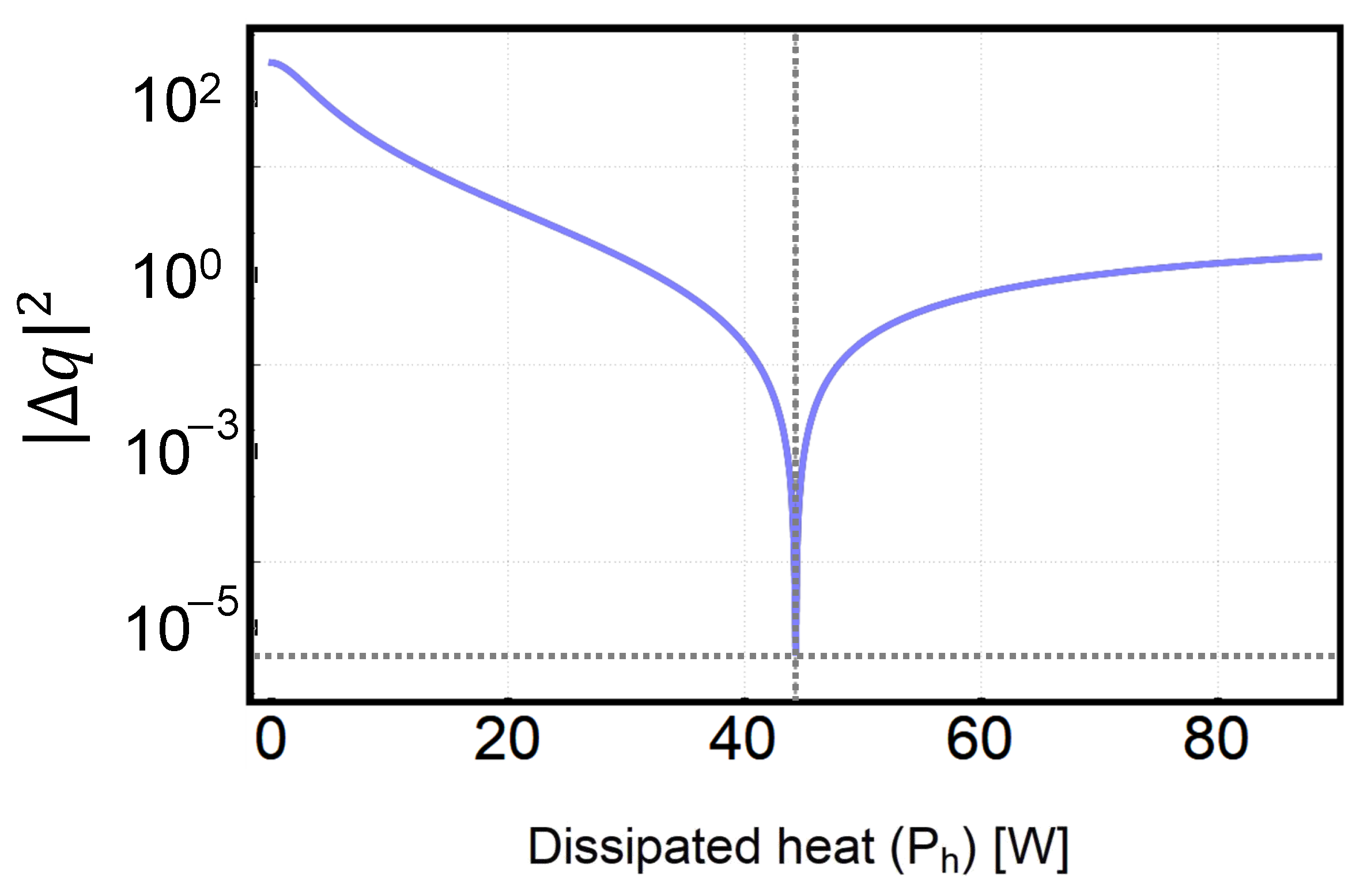

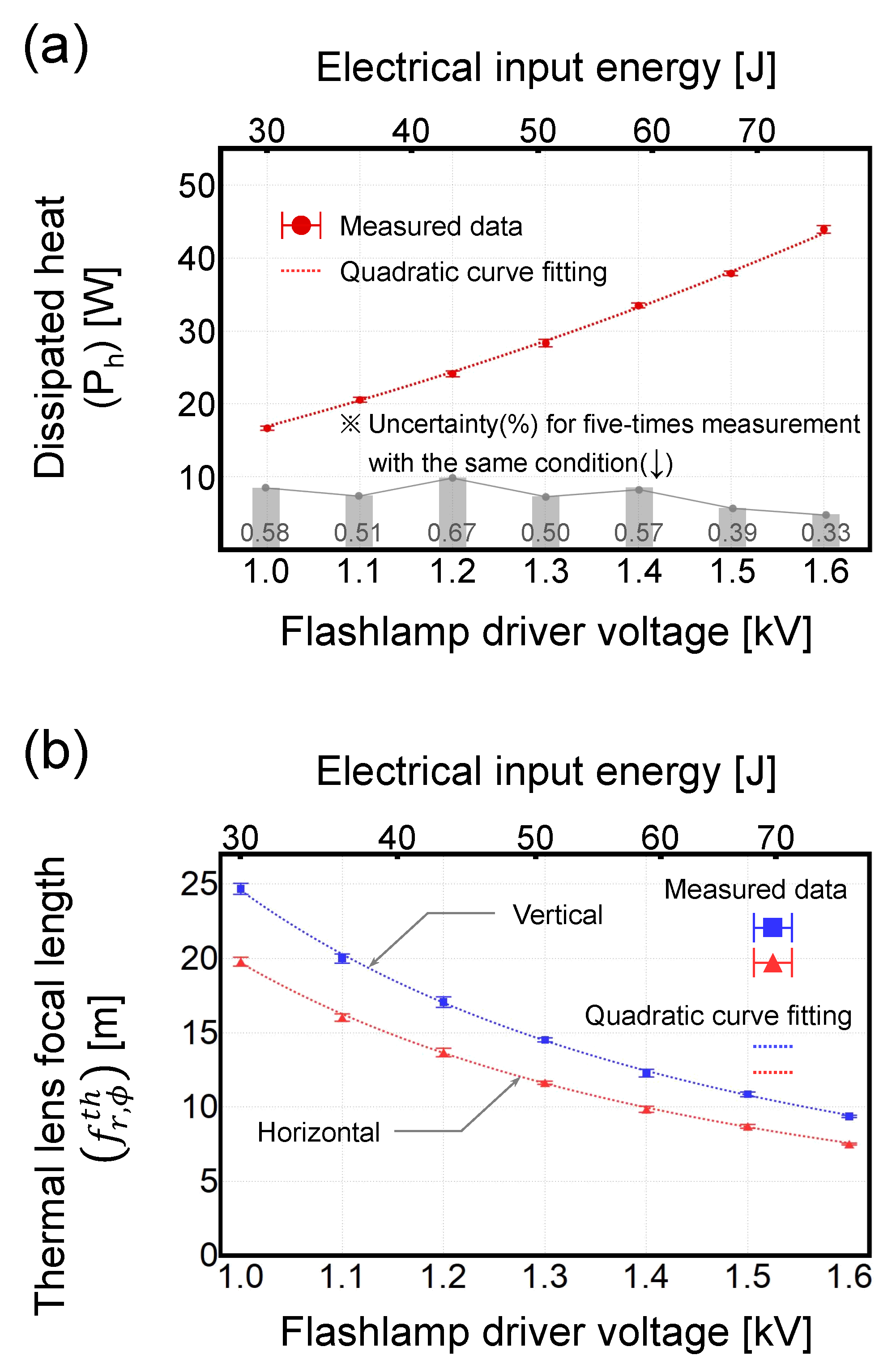

2.3. Ray Transfer Matrix to Obtain Heat Dissipated into Gain Medium

2.4. Small-Signal Gain Measurement and Gain Module Efficiency

3. Experiment Setup

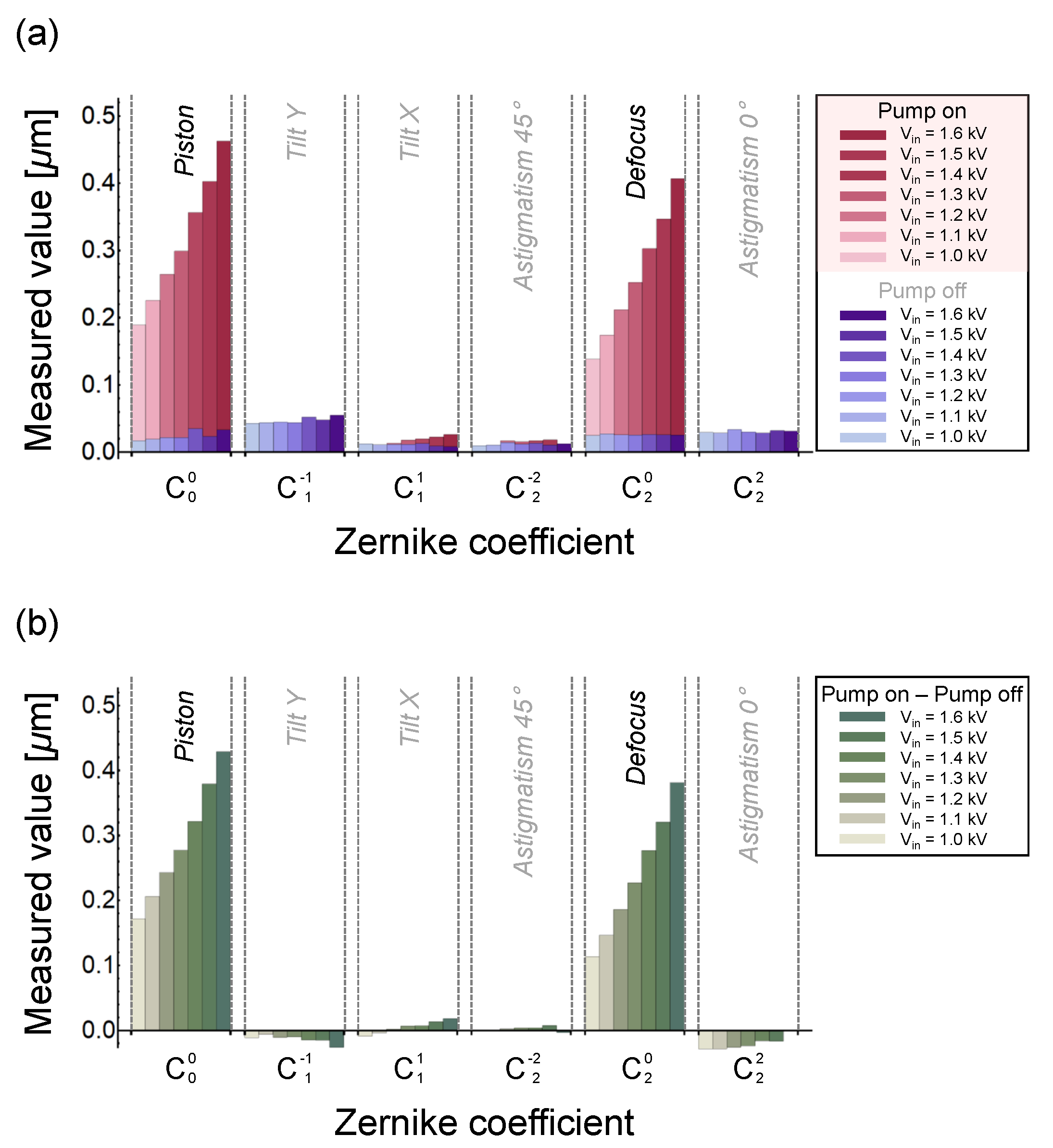

4. Results and Discussion

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| OPD | Optical path difference |

| GRIN | Gradient index |

| GM | Gain medium |

| M | Mirror |

| LP | Linear polarizer |

| PBS | Polarizing beamsplitter |

| WFS | Wavefront sensor |

| FL | Flashlamp |

References

- Cao, J.; Jiang, Y.; Qiu, R.; Lü, T. Filamentary damage of fused silica irradiated by a 532 nm nanosecond laser. Opt. Mater. Express 2021, 11, 936–942. [Google Scholar] [CrossRef]

- Kaserer, L.; Braun, J.; Stajkovic, J.; Leitz, K.H.; Singer, P.; Letofsky-Papst, I.; Kestler, H.; Leichtfried, G. Microstructure and mechanical properties of molybdenum-titanium-zirconium-carbon alloy TZM processed via laser powder-bed fusion. Int. J. Refract. Met. Hard Mater. 2020, 93, 105369. [Google Scholar] [CrossRef]

- Awadala, A.S.; Elfaky, A.E.; Marouf, A.A. Impact of High Power Nd:YAG Laser on Surface Morphology of Zirconium Silicate. Int. J. Sci. Res. Chem. 2020, 5, 34–40. [Google Scholar]

- Jiang, P.; Ni, J.; Zhang, H.; Qi, H.; Wang, W.; Song, Z.; Guo, J.; Peng, G.; Wang, C. High-power and high-energy Nd:YAG-Nd:YVO4 hybrid gain Raman yellow laser. Opt. Express 2020, 28, 24088–24094. [Google Scholar] [CrossRef] [PubMed]

- Verma, N.; Anoop, K.K.; Dominic, P.; Philip, R. Fabrication of durable superhydrophilic silicon surfaces using nanosecond laser pulses. J. Appl. Phys. 2020, 128, 135304. [Google Scholar] [CrossRef]

- Jeong, J.; Cho, S.; Hwang, S.; Lee, B.; Yu, T.J. Modeling and Analysis of High-Power Ti:sapphire Laser Amplifiers—A Review. Appl. Sci. 2019, 9, 2396. [Google Scholar] [CrossRef] [Green Version]

- Jeong, J.; Cho, S.; Hwang, S.; Yu, T.J. Amplified spontaneous emission suppression of a saturable absorber in a nanosecond double-pass laser amplifier. Jpn. J. Appl. Phys. 2019, 58, 020901. [Google Scholar] [CrossRef]

- Park, D.; Jeong, J.; Yu, T.J. Optimization of the pulse width and injection time in a double-pass laser amplifier. High Power Laser Sci. Eng. 2018, 6, e60. [Google Scholar] [CrossRef] [Green Version]

- Ji, S.; Huang, W.; Feng, T.; Pan, L.; Wang, J.; Lu, X.; Jiang, B.; Fan, W.; Li, X. Modeling and Measurement of Thermal Effect in a Flashlamp-Pumped Direct-Liquid-Cooled Split-Disk Nd:LuAG Ceramic Laser Amplifier. Photonics 2021, 8, 97. [Google Scholar] [CrossRef]

- Liu, H.; Sun, S.; Zheng, L.; Wang, G.; Tian, W.; Zhang, D.; Han, H.; Zhu, J.; Wei, Z. Review of laser-diode pumped Ti:sapphire laser. Microw. Opt. Technol. Lett. 2021, 63, 2135–2144. [Google Scholar] [CrossRef]

- Lureau, F.; Matras, G.; Chalus, O.; Derycke, C.; Morbieu, T.; Radier, C.; Casagrande, O.; Laux, S.; Ricaud, S.; Rey, G.; et al. High-energy hybrid femtosecond laser system demonstrating 2 × 10 PW capability. High Power Laser Sci. Eng. 2020, 8, e43. [Google Scholar] [CrossRef]

- Abdelhakim, M.M.; Shokry, S.; Alshershby, M.; Badr, Y.; Mokhtar, A.M. Design and implementation of a flash lamp pumped Nd-YAG pulsed laser for electro-optical sensors soft damage. In Proceedings of the 2020 12th International Conference on Electrical Engineering (ICEENG), Cairo, Egypt, 7–9 July 2020. [Google Scholar]

- Shayeganrad, G.; Cante, S.; Mosquera, J.P.; Bailey, W.O.S.; Mackenzie, J.I. Highly efficient 110-W closed-cycle cryogenically cooled Nd:YAG laser operating at 946 nm. Opt. Lett. 2020, 45, 5368–5371. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.; Yu, G.; Zheng, R.; Zhou, J.; Zhu, X.; Duan, W.; Fang, C.; Wei, W. A compact, high-power single-frequency laser based on Nd:YAG slab amplifier. Opt. Commun. 2020, 464, 125534. [Google Scholar] [CrossRef]

- Javed, F.; Zhang, H.; Gao, Q.; Li, X.; Imran, A.; Jiang, Y. A high average power, compact 100 kHz, 11.6-ns Nd:YAG Innoslab amplifier. Results Phys. 2020, 16, 102926. [Google Scholar] [CrossRef]

- Lebedev, V.F.; Pavlov, K.V.; Fedina, M.A.; Fedin, A.V. Concept and Design of a Compact Laser System for Remote Measurements Using Laser-Induced Breakdown Spectroscopy. Bull. Russ. Acad. Sci. Phys. 2020, 84, 336–338. [Google Scholar] [CrossRef]

- Chen, Y.F.; Pan, Y.Y.; Liu, Y.C.; Cheng, H.P.; Tsou, C.H.; Liang, H.C. Efficient high-power continuous-wave lasers at green-lime-yellow wavelengths by using a Nd:YVO 4 self-Raman crystal. Opt. Express 2019, 27, 2029–2035. [Google Scholar] [CrossRef] [PubMed]

- Danson, C.N.; Haefner, C.; Bromage, J.; Butcher, T.; Chanteloup, J.C.; Chowdhury, E.A.; Galvanauskas, A.; Gizzi, L.A.; Hein, J.; Hillier, D.I.; et al. Petawatt and exawatt class lasers worldwide. High Power Laser Sci. Eng. 2019, 7, e54. [Google Scholar] [CrossRef]

- Koechner, W. Solid-State Laser Engineering, 6th ed.; Springer: New York, NY, USA, 2006. [Google Scholar]

- Mangir, M.; Rockwell, D. Measurements of heating and energy storage in flashlamp-pumped Nd:YAG and Nd-doped phosphate laser glasses. IEEE J. Quantum Electron. 1986, 22, 574–580. [Google Scholar] [CrossRef]

- Kim, D.L.; Ok, C.M.; Jung, B.H.; Kim, B.T. Optimization of pumping conditions with consideration of the thermal effects at ceramic Nd:YAG laser. Optik 2019, 181, 1085–1090. [Google Scholar] [CrossRef]

- Qi, Y.; Zhao, Z.; Liu, C.; Xiang, Z. Beam quality management in multi-stage side-pumped Nd:YAG MOPA laser systems. IEEE J. Sel. Top. Quantum Electron. 2014, 21, 220–225. [Google Scholar]

- Zhang, X.; Zhang, X.; Xiang, A. Analysis of thermal effect and beam wavefront properties for LD-pumped Q-switch Nd:YAG laser. Opt. Laser Technol. 2013, 49, 268–273. [Google Scholar] [CrossRef]

- Yang, H.; Feng, G.; Zhou, S. Thermal effects in high-power Nd:YAG disk-type solid state laser. Opt. Laser Technol. 2011, 43, 1006–1015. [Google Scholar] [CrossRef]

- Xu, Y.-T.; Xu, J.-L.; Cui, Q.-J.; Xie, S.-Y.; Lu, Y.-F.; Bo, Y.; Peng, Q.-J.; Cui, D.-F.; Xu, Z.-Y. High efficiency multi-kW diode-side-pumped Nd:YAG laser with reduced thermal effect. Chin. Phys. Lett. 2010, 27, 024201. [Google Scholar]

- Shibib, K.S.; Minshid, M.A.; Alattar, N.E. Thermal and stress analysis in Nd:YAG laser rod with different double end pumping methods. Therm. Sci. 2011, 15, 399–407. [Google Scholar] [CrossRef]

- Tünnermann, H.; Puncken, O.; Weßels, P.; Frede, M.; Neumann, J.; Kracht, D. Linearly polarized single-mode Nd:YAG oscillators using [100]-and [110]-cut crystals. Opt. Express 2011, 19, 12992–12999. [Google Scholar] [CrossRef]

- Puncken, O.; Tünnermann, H.; Morehead, J.J.; Weßels, P.; Frede, M.; Neumann, J.; Kracht, D. Intrinsic reduction of the depolarization in Nd:YAG crystals. Opt. Express 2010, 18, 20461–20474. [Google Scholar] [CrossRef]

- Shin, J.S.; Park, S.; Kong, H.J. Compensation of the thermally induced depolarization in a double-pass Nd:YAG rod amplifier with a stimulated Brillouin scattering phase conjugate mirror. Opt. Commun. 2010, 283, 2402–2405. [Google Scholar] [CrossRef]

- Khazanov, E.; Potemkin, A.; Katin, E. Compensating for birefringence in active elements of solid-state lasers: Novel method. J. Opt. Soc. Am. B 2002, 19, 667–671. [Google Scholar] [CrossRef]

- Hodgson, N.; Weber, H. High-power solid-state lasers with unstable resonators. Opt. Quantum Electron. 1990, 22, S39–S55. [Google Scholar] [CrossRef]

- Hodgson, N.; Bostanjoglo, G.; Weber, H. Multirod unstable resonators for high-power solid-state lasers. Appl. Opt. 1993, 32, 5902–5917. [Google Scholar] [CrossRef] [PubMed]

- Morin, M.; Poirier, M. Graded reflectivity mirror unstable laser resonator design. In Laser Resonators; International Society for Optics and Photonics: Bellingham, WA, USA, 1998. [Google Scholar]

- Frantz, L.M.; Nodvik, J.S. Theory of pulse propagation in a laser amplifier. J. Appl. Phys. 1963, 34, 2346–2349. [Google Scholar] [CrossRef]

- Albrodt, P.; Delen, X.; Besbes, M.; Lesparre, F.; Georges, P. Simulation and experimental investigation of beam distortions in end-pumped laser rod amplifiers. J. Opt. Soc. Am. B 2018, 35, 3004–3013. [Google Scholar] [CrossRef]

- Kuznetsov, I.I.; Mukhin, I.B.; Silin, D.E.; Vyatkin, A.G.; Vadimova, O.L.; Palashov, O.V. Thermal effects in end-pumped Yb:YAG thin-disk and Yb:YAG/YAG composite active element. IEEE J. Quantum Electron. 2014, 50, 133–140. [Google Scholar] [CrossRef]

- Slezak, O.; Lucianetti, A.; Divoky, M.; Sawicka, M.; Mocek, T. Optimization of wavefront distortions and thermal-stress induced birefringence in a cryogenically-cooled multislab laser amplifier. IEEE J. Quantum Electron. 2013, 49, 960–966. [Google Scholar] [CrossRef]

- Nagisetty, S.S.; Severova, P.; Miura, T.; Smrž, M.; Kon, H.; Uomoto, M.; Shimatsu, T.; Kawasaki, M.; Higashiguchi, T.; Endo, A.; et al. Lasing and thermal characteristics of Yb:YAG/YAG composite with atomic diffusion bonding. Laser Phys. Lett. 2016, 14, 015001. [Google Scholar] [CrossRef]

- Pyhtila, J.W.; Wax, A. Improved interferometric detection of scattered light with a 4f imaging system. Appl. Opt. 2005, 44, 1785–1791. [Google Scholar] [CrossRef]

- Han, W.; Cheng, W.; Zhan, Q. Design and alignment strategies of 4f systems used in the vectorial optical field generator. Appl. Opt. 2015, 54, 2275–2278. [Google Scholar] [CrossRef]

- Schwiegerling, J. Review of Zernike polynomials and their use in describing the impact of misalignment in optical systems. In Proceedings of the Optical System Alignment, Tolerancing, and Verification XI, San Diego, CA, USA, 22 August 2017; International Society for Optics and Photonics: Bellingham, WA, USA, 2017; Volume 10377. [Google Scholar]

- Siegman, A.E. Lasers; University Science Books: Sausalito, CA, USA, 1986. [Google Scholar]

- WFS150-5C-Manual. Available online: https://www.thorlabs.com/catalogpages/Obsolete/2018/WFS150-5C.pdf (accessed on 20 March 2021).

- ISO/IEC Guide 98-3: 2008-09: Uncertainty of Measurement—Part 3: Guide to the Expression of Uncertainty in Measurement (GUM: 1995); International Standardization Organization: Geneva, Switzerland, 2008.

- Choubey, A.; Mondal, S.; Singh, R.; Upadhyaya, B.N.; Datta, P.K.; Oak, S.M. Enhancement of p-polarized output power in long pulse single rod Nd:YAG laser using a tilted 90° quartz rotator. Opt. Commun. 2014, 330, 61–70. [Google Scholar] [CrossRef]

| Refractive index, (at 633 nm) | |

| Thermal conductivity, K (W/cm K) | |

| Thermal coefficient of refractive index, (K) | |

| Thermal expansion coefficient, (K) | |

| Radial photoelastic coefficient, | |

| Tangential photoelastic coefficient, |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, D.; Jeong, J.; Hwang, S.; Lee, S.; Cho, S.; Yu, T.J. Performance Evaluation of Solid-State Laser Gain Module by Measurement of Thermal Effect and Energy Storage. Photonics 2021, 8, 418. https://doi.org/10.3390/photonics8100418

Park D, Jeong J, Hwang S, Lee S, Cho S, Yu TJ. Performance Evaluation of Solid-State Laser Gain Module by Measurement of Thermal Effect and Energy Storage. Photonics. 2021; 8(10):418. https://doi.org/10.3390/photonics8100418

Chicago/Turabian StylePark, Daewoong, Jihoon Jeong, Seungjin Hwang, Sungyoon Lee, Seryeyohan Cho, and Tae Jun Yu. 2021. "Performance Evaluation of Solid-State Laser Gain Module by Measurement of Thermal Effect and Energy Storage" Photonics 8, no. 10: 418. https://doi.org/10.3390/photonics8100418

APA StylePark, D., Jeong, J., Hwang, S., Lee, S., Cho, S., & Yu, T. J. (2021). Performance Evaluation of Solid-State Laser Gain Module by Measurement of Thermal Effect and Energy Storage. Photonics, 8(10), 418. https://doi.org/10.3390/photonics8100418