Imaging Feature Analysis-Based Intelligent Laser Cleaning Using Metal Color Difference and Dynamic Weight Dispatch Corrosion Texture

Abstract

1. Introduction

2. Proposed Method

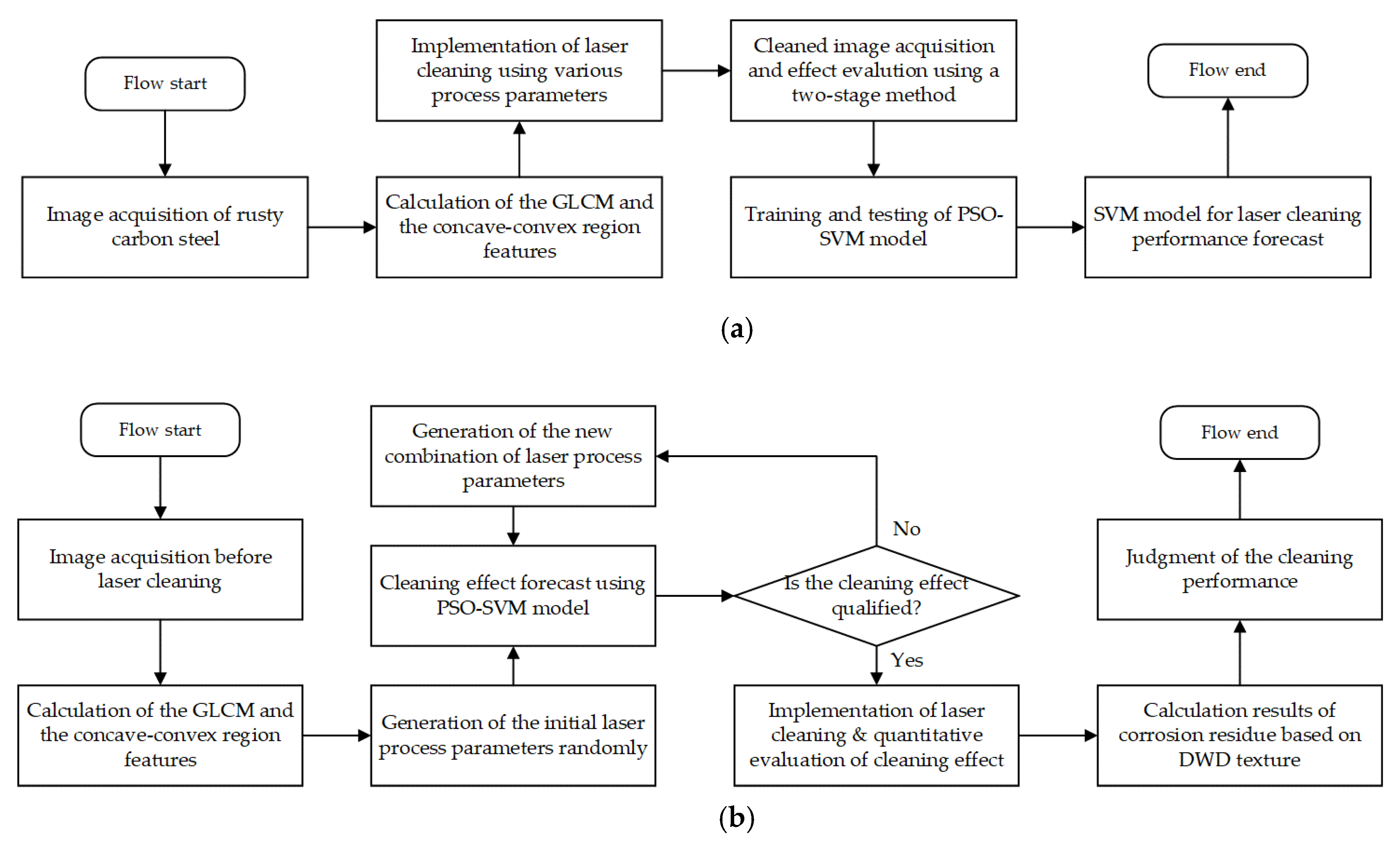

2.1. Algorithm Flowchart

2.2. Cleaning Performance Evaluation Using a Two-Stage Method

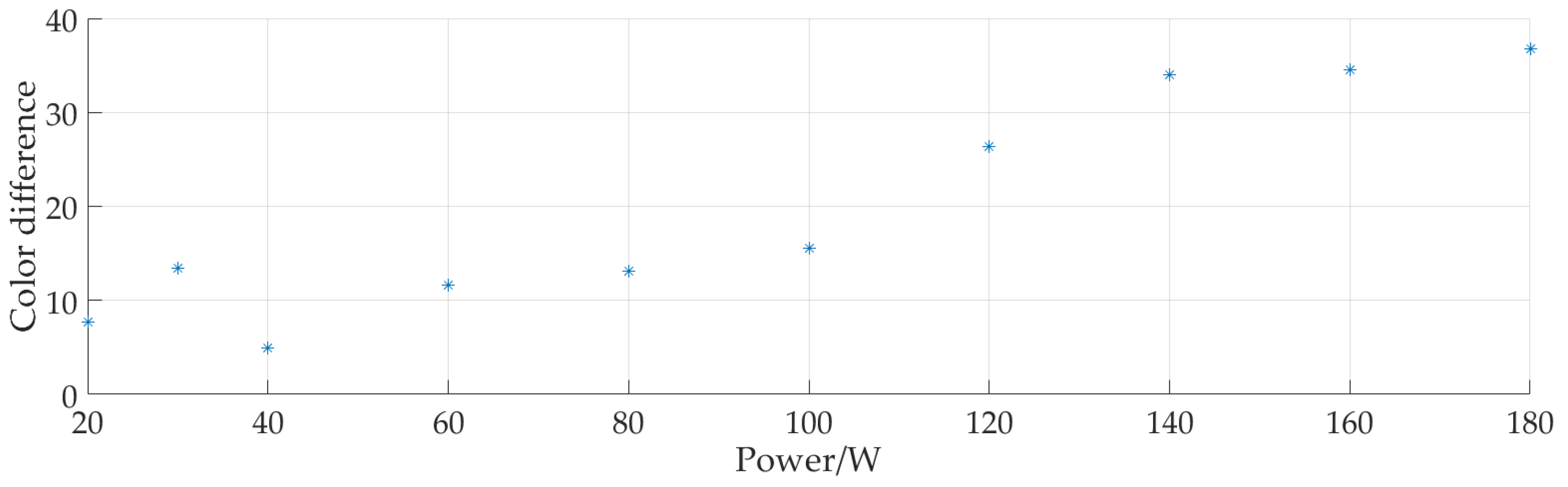

2.2.1. Color Difference Feature

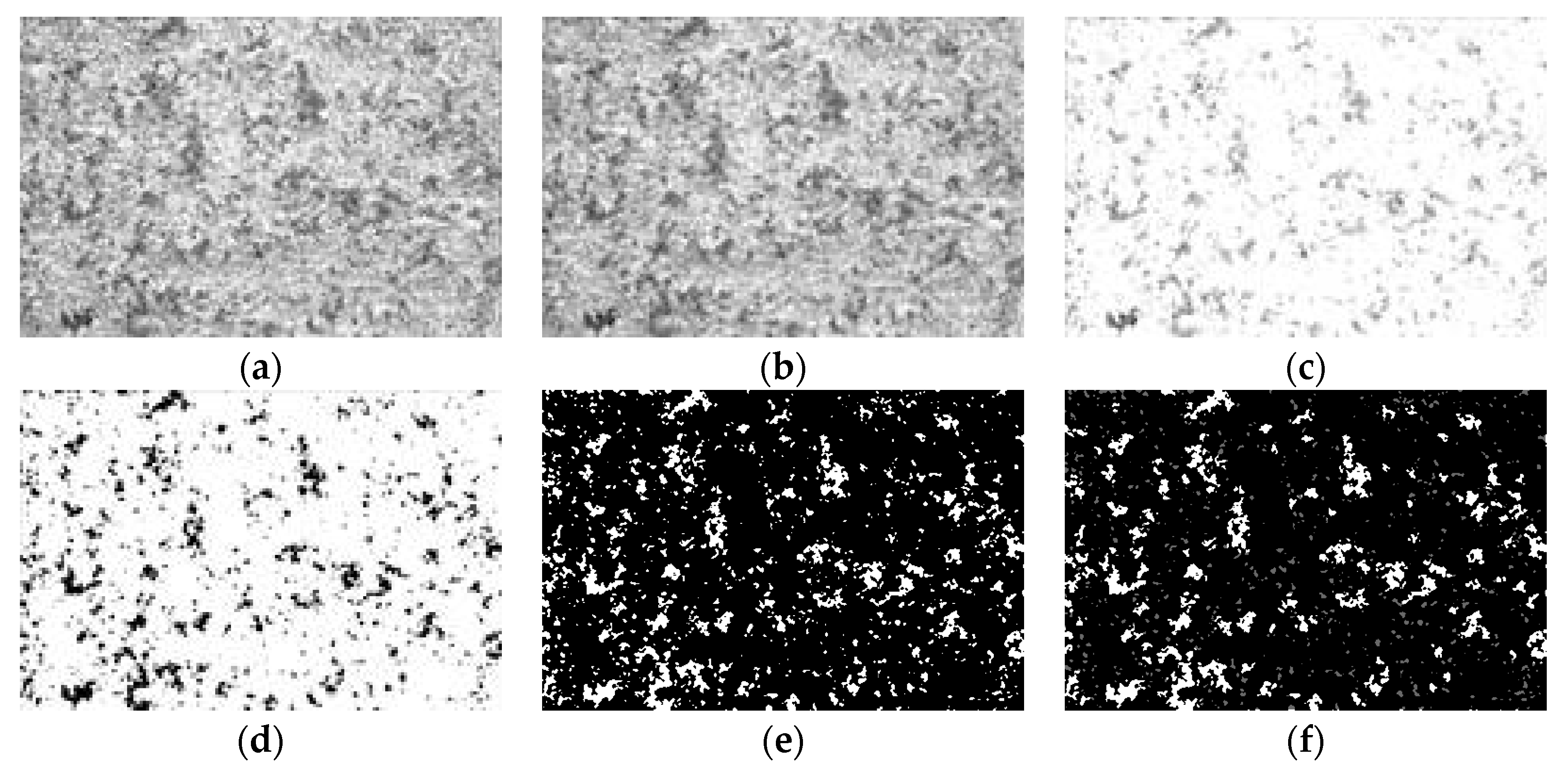

2.2.2. Dynamic Weight Dispatch (DWD) Corrosion Texture Feature

2.3. Cleaning Performance Prediction Using Particle Swarm Optimization-Support Vector Machine (PSO-SVM)

3. Experiments and Discussion

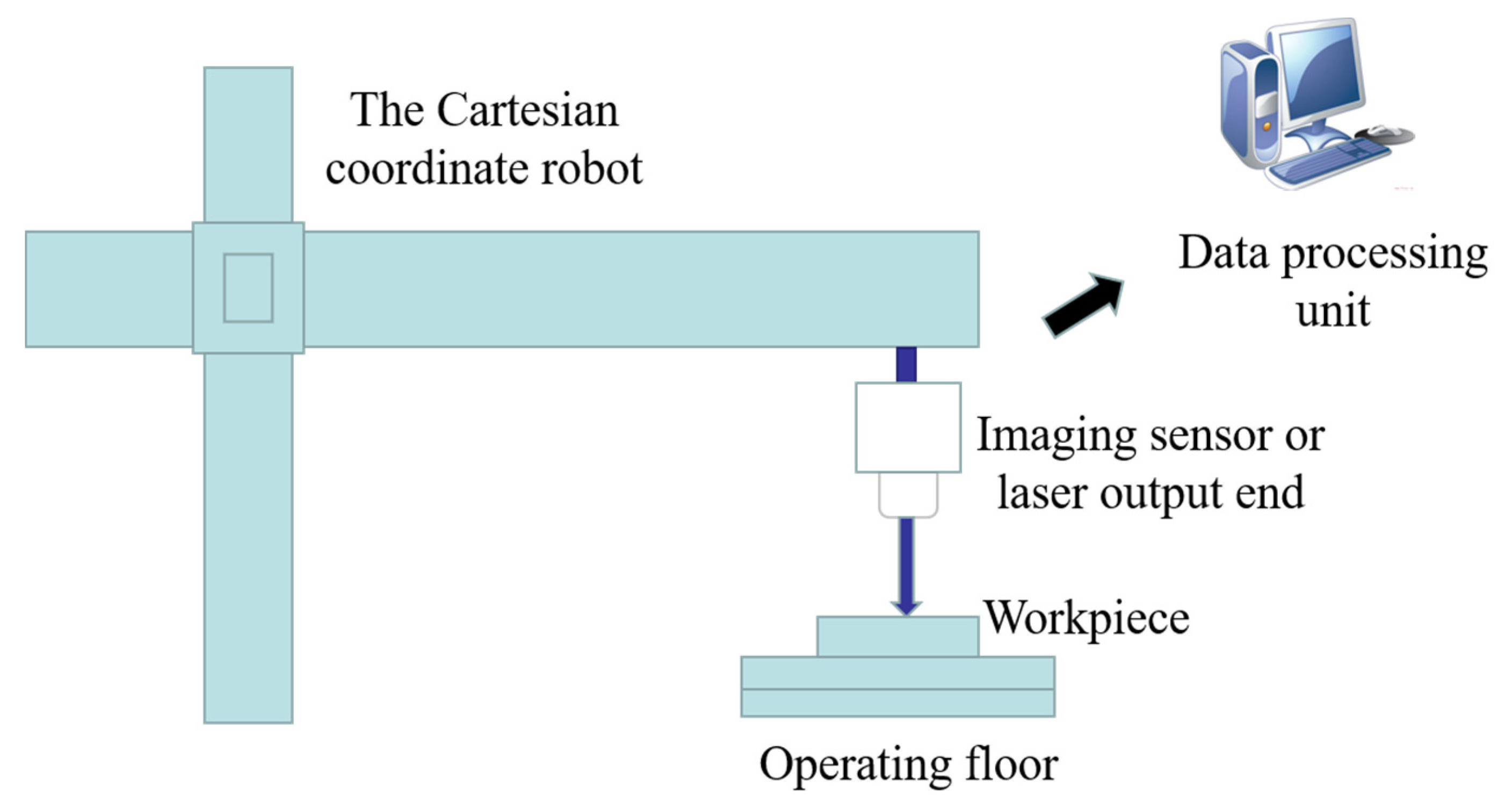

3.1. Experiment System and Data

3.2. Evaluations of the Proposed Algorithms

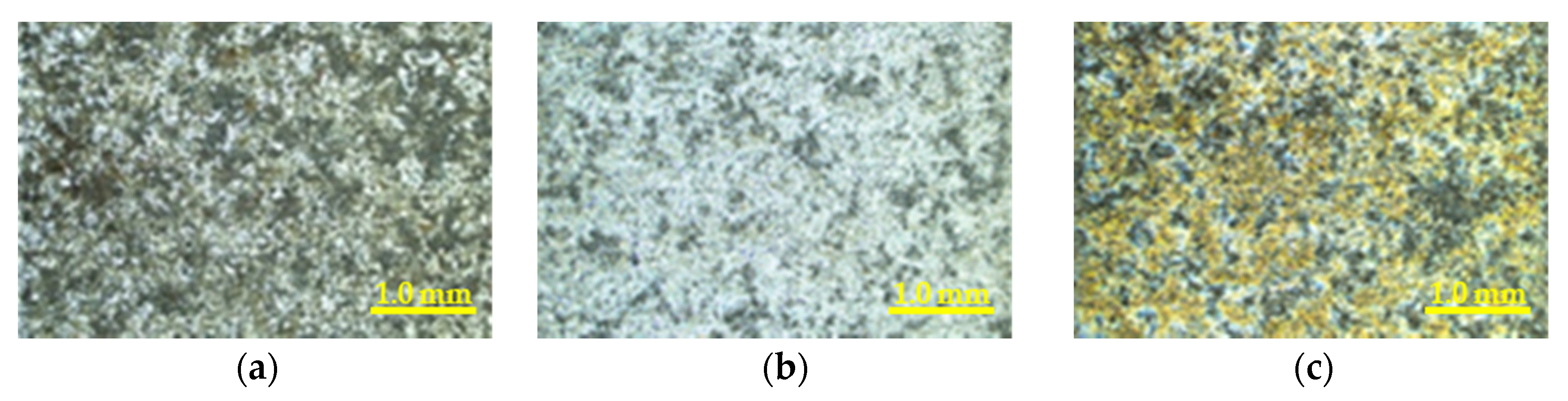

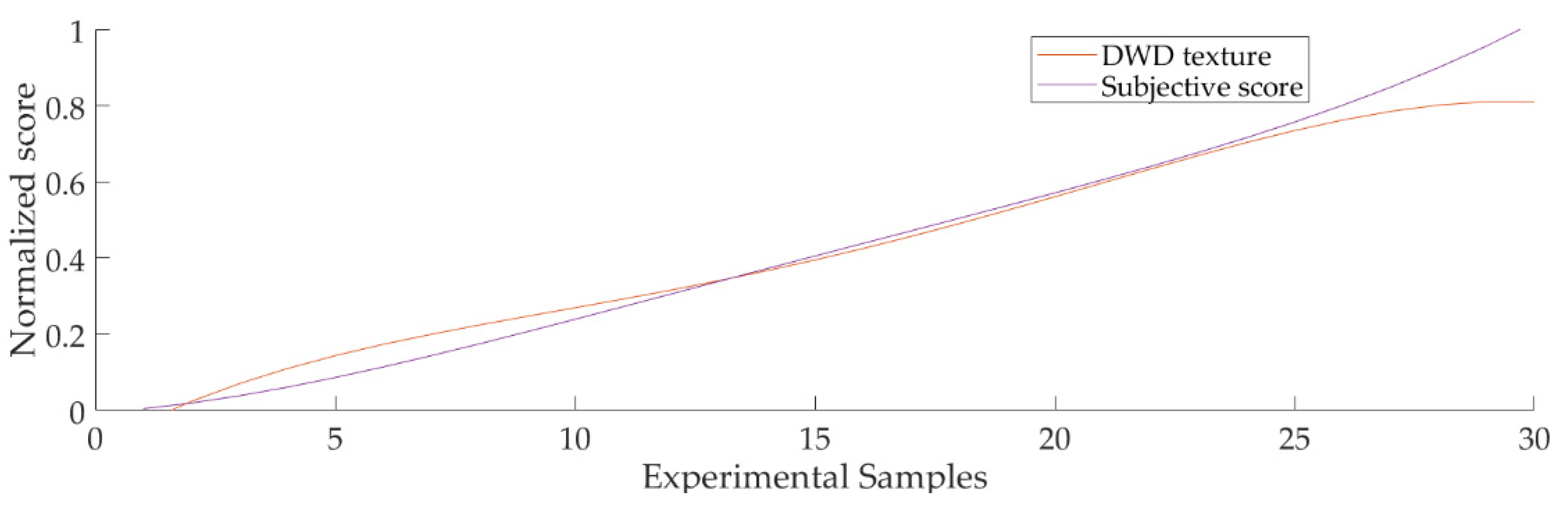

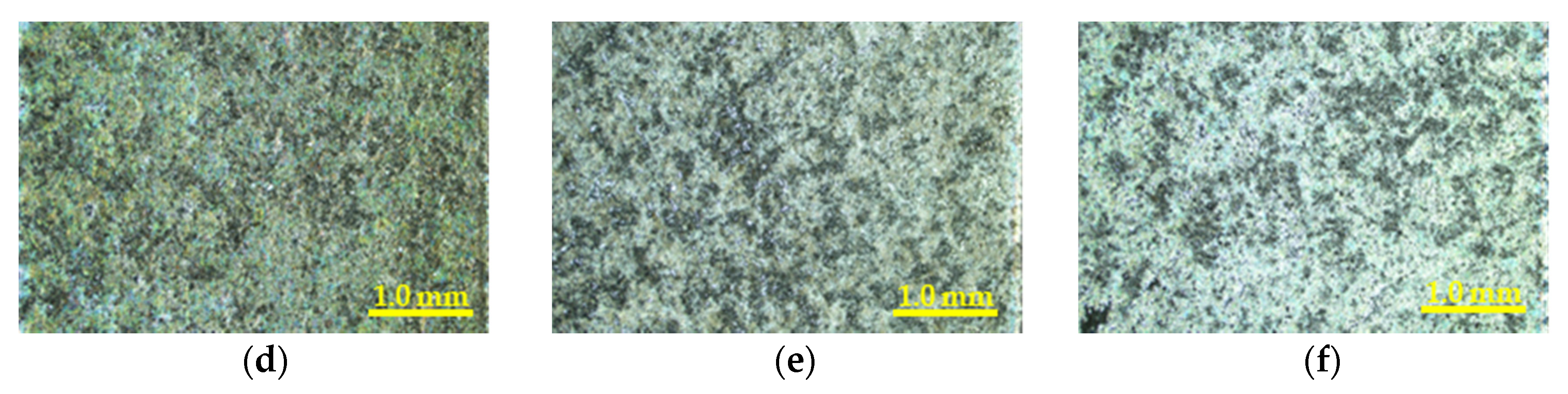

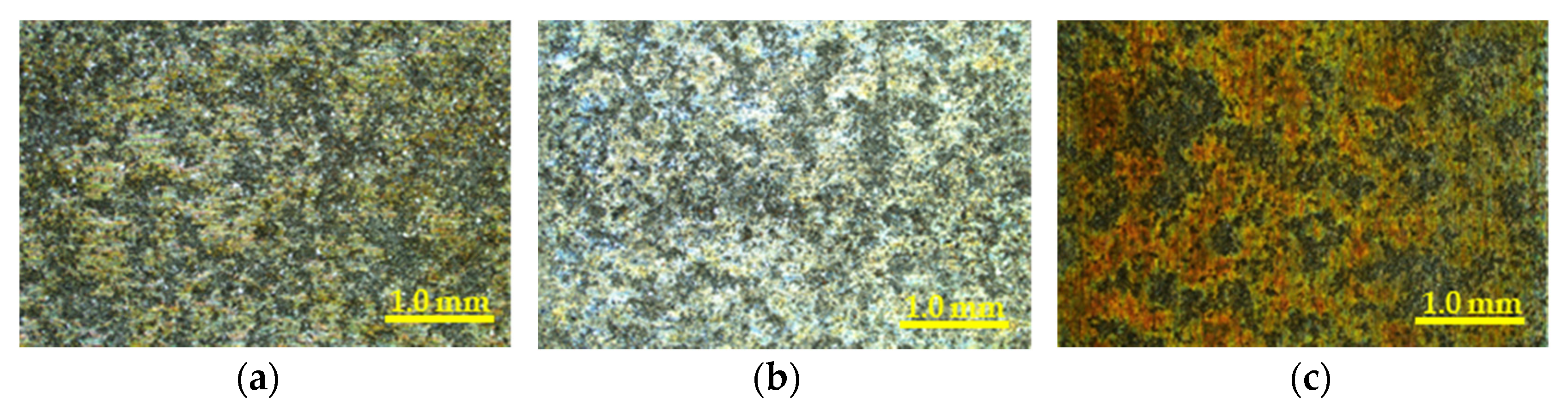

3.2.1. Evaluations of Cleaning Performance Using Color Differences and DWD Features

3.2.2. Evaluation of Laser Process Parameter Control Using PSO-SVM

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Raza, M.; Das, S.; Tudu, P.; Saha, P. Excimer laser cleaning of black sulphur encrustation from silver surface. Opt. Laser Technol. 2019, 113, 95–103. [Google Scholar] [CrossRef]

- Zhang, G.; Hua, X.; Li, F.; Zhang, Y.; Cheng, J. Effect of laser cleaning process parameters on the surface roughness of 5754-grade aluminum alloy. Int. J. Adv. Manuf. Technol. 2019, 105, 2481–2490. [Google Scholar] [CrossRef]

- Zhou, X.; Imasaki, K.; Furukawa, H.; Umino, H.; Sakagishi, K.; Nakai, S.; Yamanaka, C. A study of the surface products on zinc-coated steel during laser ablation cleaning. Surf. Coat. Technol. 2001, 137, 170–174. [Google Scholar] [CrossRef]

- Nevin, A.; Pouli, P.; Georgiou, S.; Georgiou, S.; Fotakis, C. Laser conservation of art. Nat. Mater 2007, 6, 320–322. [Google Scholar] [CrossRef]

- Maffini, A.; Uccello, A.; Dellasega, D.; Passoni, M. Laser cleaning of diagnostic mirrors from tungsten–oxygen tokamak-like contaminants. Nucl. Fusion 2016, 56, 086008. [Google Scholar] [CrossRef]

- Stefan, G.W.; Norbert, S.E.; Josef, A.P.; Hubert, S.T.; Johannes, D.P. Chemical imaging with Laser Ablation–Spark Discharge–Optical Emission Spectroscopy (LA-SD-OES) and Laser-Induced Breakdown Spectroscopy (LIBS). Opt. Laser Technol. 2020, 123, 105944. [Google Scholar]

- Stefan, K.; Jens, H.; Klaus, D.; Stratoudaki, T.; Vassilis, Z. LIBS-spectroscopy for monitoring and control of the laser cleaning process of stone and medieval glass. J. Cult. Herit. 2000, 1, S287–S292. [Google Scholar]

- Lim, H.; Kim, D. Laser-assisted chemical cleaning for oxide-scale removal from carbon steel surfaces. J. Laser Appl. 2004, 16, 25–30. [Google Scholar] [CrossRef]

- Mutin, T.; Smirnov, V.; Veiko, V.; Volkov, S. Cleaning laser spark spectroscopy for online cleaning quality control method development. Proc. SPIE-Int. Soc. Opt. Eng. 2010, 7996, 1056–1062. [Google Scholar]

- Tserevelakis, G.J.; Pozo-Antonio, J.S.; Siozos, P.; Rivas, T.; Pouli, P.; Zacharakis, G. On-line photoacoustic monitoring of laser cleaning on stone: Evaluation of cleaning performanceiveness and detection of potential damage to the substrate. J. Cult. Herit. 2019, 35, 108–115. [Google Scholar] [CrossRef]

- Chu, H.; Xie, Z.; Liu, Q.; Shao, Y.; Mi, Z. Surface-cleanliness inspection apparatus for optical component based on machine vision. Image Signal Process. Int. Congr. 2010, 4, 1694–1698. [Google Scholar]

- Shi, T.; Zhou, L.; Wang, C.; Mi, G.; Jiang, P. Machine Vision-Based Real-Time Monitor System for Laser Cleaning Aluminum Alloy. Chin. J. Lasers 2019, 46, 83–89. [Google Scholar]

- Liu, H.; Li, J.; Yang, Y.; Lan, J.; Xue, Y. Automatic Process Parameters Tuning and Surface Roughness Estimation for Laser Cleaning. IEEE Access 2020, 8, 20904–20919. [Google Scholar] [CrossRef]

- Sun, Z.; Xu, J.; Zhou, W. Parameters and mechanism of laser cleaning rust deposit on the steel surface. Proc. SPIE-Int. Soc. Opt. Eng. 2002, 4915. [Google Scholar] [CrossRef]

- Pant, P.; Chatterjee, D. Prediction of clad characteristics using ANN and combined PSO-ANN algorithms in laser metal deposition process. Surf. Interfaces 2020, 21, 100699. [Google Scholar] [CrossRef]

- Sun, B.; Xu, C.; He, J.; Yu, L.; Zhang, Y. Cleanliness prediction of rusty iron in laser cleaning using convolutional neural networks. Appl. Phys. A 2020, 126, 179. [Google Scholar] [CrossRef]

- López, A.J.; Lamas, J.; Pozo-Antonio, J.S.; Rivas, T.; Ramil, A. Development of processing strategies for 3D controlled laser ablation: Application to the cleaning of stonework surfaces. Opt. Lasers Eng. 2020, 126, 105897. [Google Scholar] [CrossRef]

- Nie, X.H.; Li, Y.L.; Li, J.K.; Zhang, H.B. Morphology, Products and Corrosion Mechanism Analysis of Q235 Carbon Steel in Sea-shore Salty Soil. J. Mater. Eng. 2010, 30, 24–28. [Google Scholar]

- Huang, C.L.; Dun, J.F. A distributed PSO-SVM hybrid system with feature selection and parameter optimization. Appl. Soft Comput. J. 2008, 8, 1381–1391. [Google Scholar] [CrossRef]

- Luo, M.R.; Cui, G.; Rigg, B. The development of the CIE 2000 colour-difference formula: CIEDE2000. Color Res. Appl. 2001, 26, 340–350. [Google Scholar] [CrossRef]

- Nordin, N.D.; Zan, M.S.D.; Abdullah, F. Comparative Analysis on the Deployment of Machine Learning Algorithms in the Distributed Brillouin Optical Time Domain Analysis (BOTDA) Fiber Sensor. Photonics 2020, 7, 79. [Google Scholar] [CrossRef]

- Fan, Y.; Zhang, L.; Guo, H.; Hao, H.; Qian, K. Image Processing for Laser Imaging Using Adaptive Homomorphic Filtering and Total Variation. Photonics 2020, 7, 30. [Google Scholar] [CrossRef]

- Hua, B.; Fu-Long, M.A.; Li-Cheng, J. Research on Computation of GLCM of Image Texture. Acta Electron. Sin. 2006, 1, 155–158. [Google Scholar]

- See, T.L.; Metsios, I.; Qian, D.; Antar, M.; Marimuthu, S. Feasibility study and demonstration of cleaning with laser adaptively by novel use of sensors. Procedia Cirp 2018, 74, 376–380. [Google Scholar] [CrossRef]

- Xu, X.H.; Zhang, R.Q.; Dong, X.Z.; Gehring, G.A. A study of the optimization of parameters for pulsed laser deposition using Monte Carlo simulation. Thin Solid Film. 2006, 515, 2754–2759. [Google Scholar] [CrossRef]

- Higashi, H.; Bui, M.V.; Aziz, A.; Nakauchi, S. Computational lighting for extracting optical features from RGB images. Measurement 2020, 151, 107183. [Google Scholar] [CrossRef]

- Lehmann, P. Surface-roughness measurement based on the intensity correlation function of scattered light under speckle-pattern illumination. Appl. Opt. 1999, 7, 1144–1152. [Google Scholar] [CrossRef]

- Peng, Y.; Yan, Z. Characterization of laser-induced local heating in a substrate. Int. J. Heat Mass Transf. 2017, 106, 989–996. [Google Scholar]

- Gorajek, L.; Gontar, P.; Jabczynski, J.; Firak, J.; Stefaniak, M.; Dabrowski, M.; Orzanowski, T.; Trzaskawka, P.; Sosnowski, T.; Firmanty, K.; et al. Characterization of Absorption Losses and Transient Thermo-Optic Effects in a High-Power Laser System. Photonics 2020, 7, 94. [Google Scholar] [CrossRef]

- Zhang, Y.; You, D.D.; Gao, X.; Wang, C.; Li, Y.; Gao, P.P. Real-time monitoring of high-power disk laser welding statuses based on deep learning framework. J. Intell. Manuf. 2020, 31, 799–814. [Google Scholar] [CrossRef]

- Zhang, L.C.; Zhao, J.; Zhao, P.; Wang, C. Preliminary study of cleaning out contaminants on the surface of glazed components of Yan Xi Tang in the Palace Museum. Sci. Conserv. Archaeol. 2020, 32, 98–104. [Google Scholar]

- Wang, H.; Fu, Y.H. Experimental study of laser cleaning of surface contaminants in marine stone sculptures cultural relic. Appl. Laser 2018, 38, 623–629. [Google Scholar]

- Qi, Y.; Ye, Y.Y.; Wang, H.J.; Zhou, W.Q. Mechanisms of laser cleaning of contamination on surface of stonework. Chin. J. Lasers 2015, 42, 99–107. [Google Scholar]

| Number | Feature Name | Feature Dimension |

|---|---|---|

| 1 | Laser power, linear velocity, and line spacing | 3 |

| 2 | Energy, entropy, contrast, and correlation of GLCM in four directions 1 | 16 |

| 3 | Concave-convex feature of image | 1 |

| Laser Profile | Power/(W) | Linear Velocity/(mm/s) | Line Spacing/(mm) | Frequency/(kHz) | Pulse Width/(ns) | Focal Length/(mm) | Spot Size/() |

|---|---|---|---|---|---|---|---|

| Gaussian beam | 30–160 | 1000–5000 | 0.02–1.0 | 20 | 60 | 222 | 100 |

| Num. | Component L | Component A | Component B | Color Difference | Cleaning Performance | Result |

|---|---|---|---|---|---|---|

| 1 | 76.3272 | −7.99689 | 0.498998 | 0 |  | Standard image |

| 2 | 71.2207 | −7.83067 | 0.774683 | 3.79221 |  | Qualified |

| 3 | 71.9688 | −10.9803 | 2.105990 | 4.36297 |  | Qualified |

| 4 | 59.2680 | −7.11815 | 5.718440 | 14.2564 |  | Unqualified |

| 5 | 59.6419 | −8.06305 | 3.111690 | 13.3999 |  | Unqualified |

| 6 | 65.5585 | −9.46652 | 18.53510 | 14.7704 |  | Unqualified |

| 7 | 36.4584 | −1.66398 | 33.89080 | 42.4603 |  | Unqualified |

| Num | Power/(W) | Frequency/(kHz) | Linear Velocity/(mm/s) | Line Spacing/(mm) | Cleaning Performance | DWD Texture |

|---|---|---|---|---|---|---|

| 1 | 30 | 20 | 1000 | 0.05 |  | 0.3637 |

| 2 | 40 | 20 | 1000 | 0.05 |  | 0.1838 |

| 3 | 60 | 20 | 1000 | 0.05 |  | 0.2793 |

| 4 | 120 | 20 | 1000 | 0.05 |  | 0.4612 |

| 5 | 120 | 20 | 500 | 0.075 |  | 0.5087 |

| 6 | 120 | 20 | 1500 | 0.075 |  | 0.2790 |

| 7 | 120 | 20 | 2500 | 0.075 |  | 0.0726 |

| 8 | 120 | 20 | 5000 | 0.075 |  | 0.1798 |

| 9 | 120 | 25 | 2000 | 0.075 |  | 0.1192 |

| 10 | 120 | 35 | 2000 | 0.075 |  | 0.0956 |

| 11 | 120 | 45 | 2000 | 0.075 |  | 0.1553 |

| 12 | 120 | 50 | 2000 | 0.075 |  | 0.1746 |

| Kernel Function | Linear Kernel Function | Polynomial Kernel Function | RBF Kernel Function | Sigmoid Kernel Function |

|---|---|---|---|---|

| Accuracy (%) | 75 | 82.5 | 92.5 | 55 |

| Name | Power/(W) | Linear Velocity/(mm/s) | Line Spacing/(mm) |

|---|---|---|---|

| (a) | 120 | 500 | 0.075 |

| (b) | 120 | 1000 | 0.075 |

| (c) | 160 | 1000 | 0.075 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Liu, H.; Shi, L.; Lan, J. Imaging Feature Analysis-Based Intelligent Laser Cleaning Using Metal Color Difference and Dynamic Weight Dispatch Corrosion Texture. Photonics 2020, 7, 130. https://doi.org/10.3390/photonics7040130

Li J, Liu H, Shi L, Lan J. Imaging Feature Analysis-Based Intelligent Laser Cleaning Using Metal Color Difference and Dynamic Weight Dispatch Corrosion Texture. Photonics. 2020; 7(4):130. https://doi.org/10.3390/photonics7040130

Chicago/Turabian StyleLi, Jiacheng, Haoting Liu, Limin Shi, and Jinhui Lan. 2020. "Imaging Feature Analysis-Based Intelligent Laser Cleaning Using Metal Color Difference and Dynamic Weight Dispatch Corrosion Texture" Photonics 7, no. 4: 130. https://doi.org/10.3390/photonics7040130

APA StyleLi, J., Liu, H., Shi, L., & Lan, J. (2020). Imaging Feature Analysis-Based Intelligent Laser Cleaning Using Metal Color Difference and Dynamic Weight Dispatch Corrosion Texture. Photonics, 7(4), 130. https://doi.org/10.3390/photonics7040130