Surface Plasmon Resonance Sensor Based on Polymer Liquid-Core Fiber for Refractive Index Detection

Abstract

1. Introduction

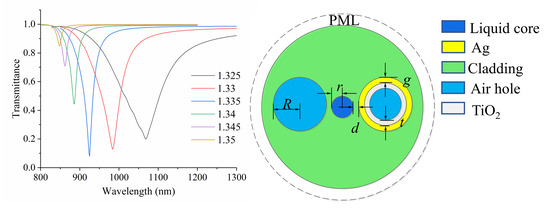

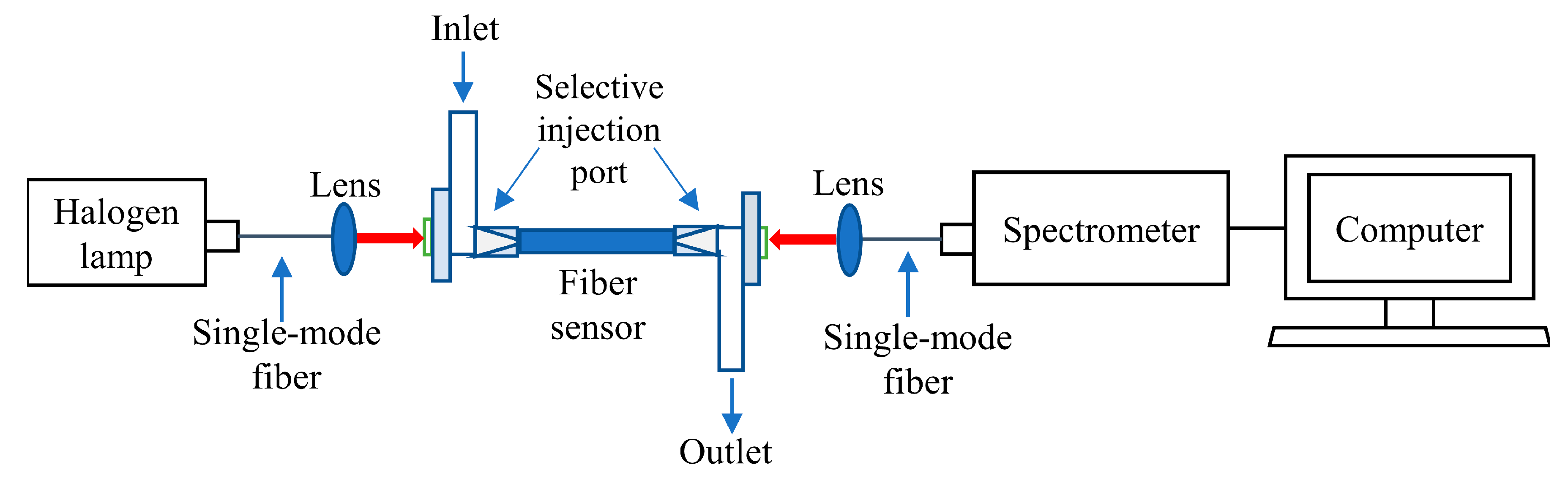

2. Materials and Methods

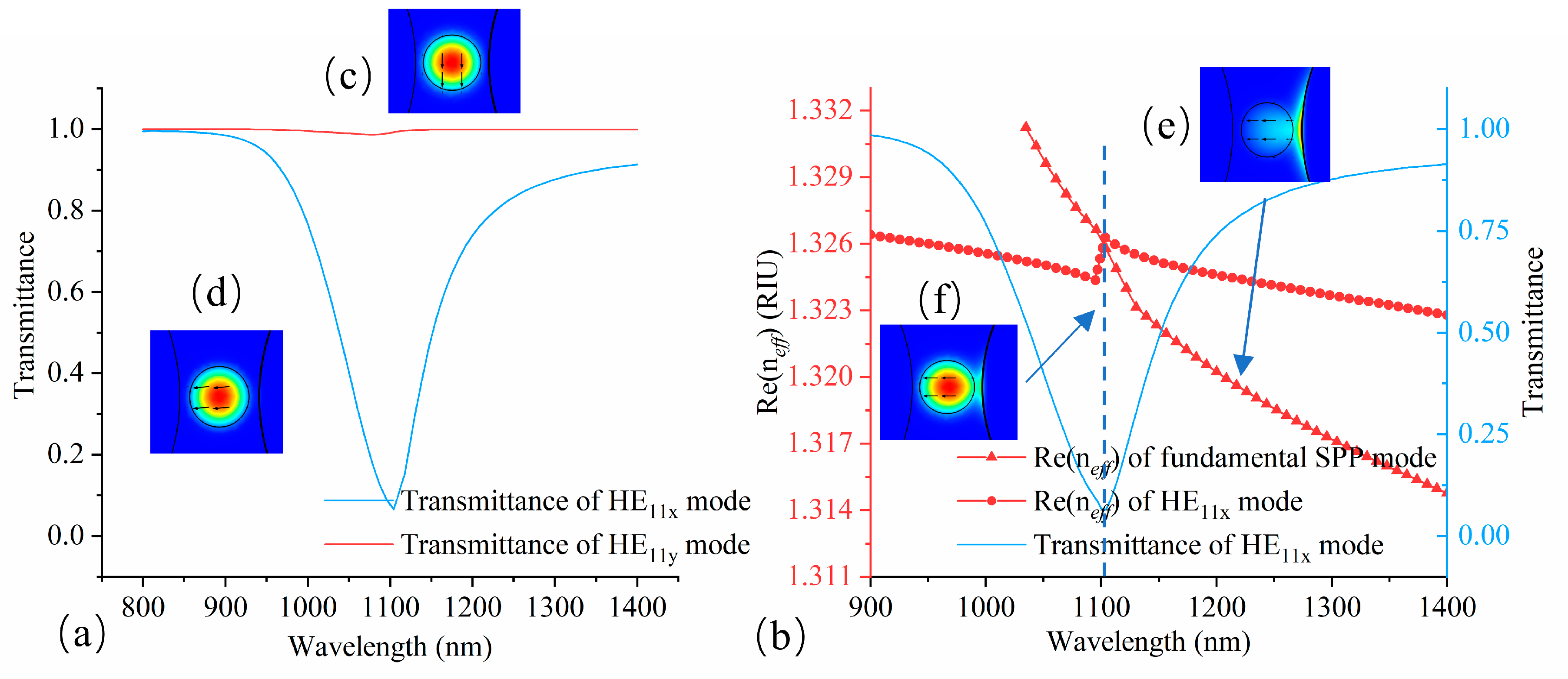

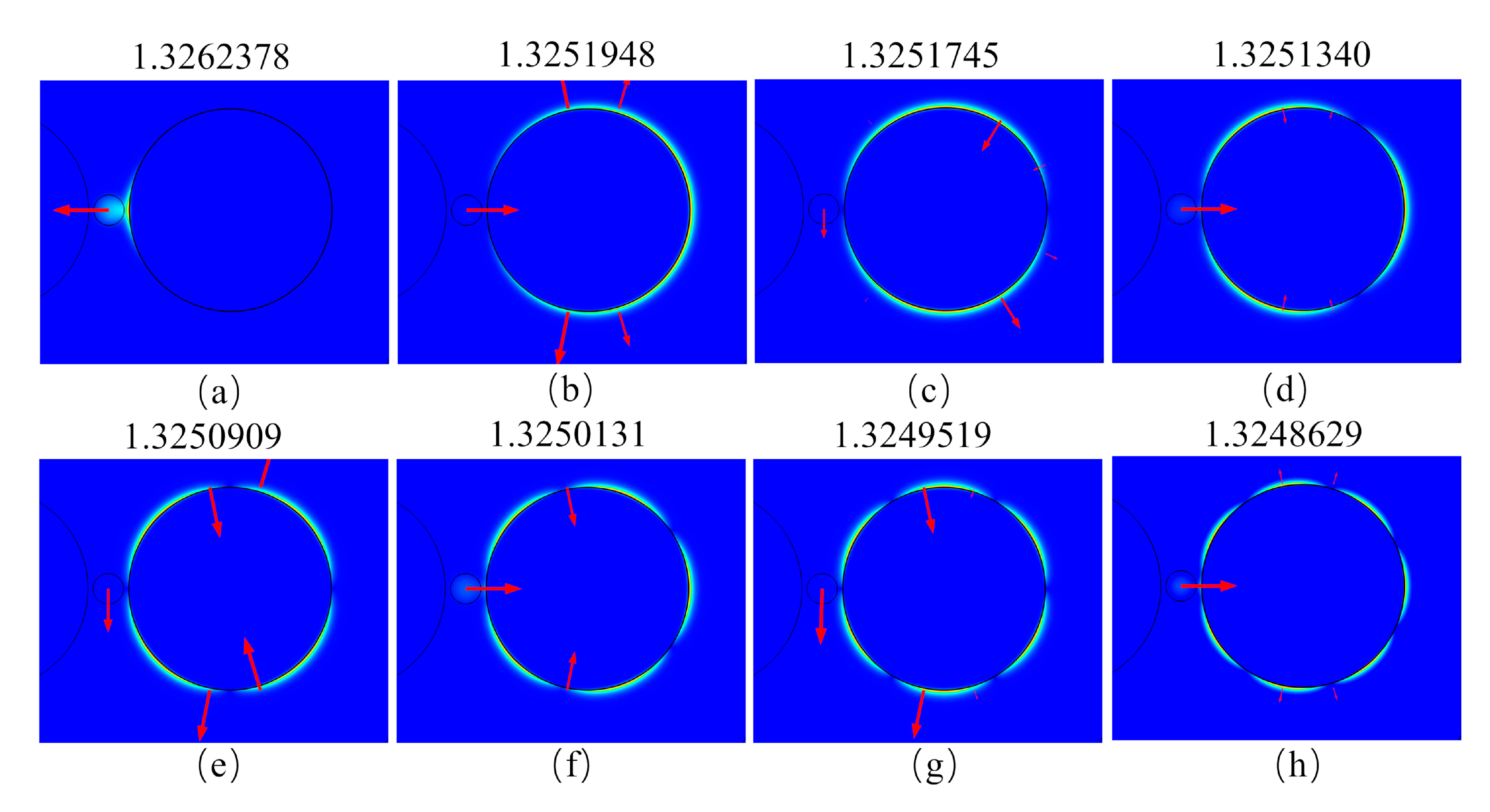

3. Results

4. Discussion

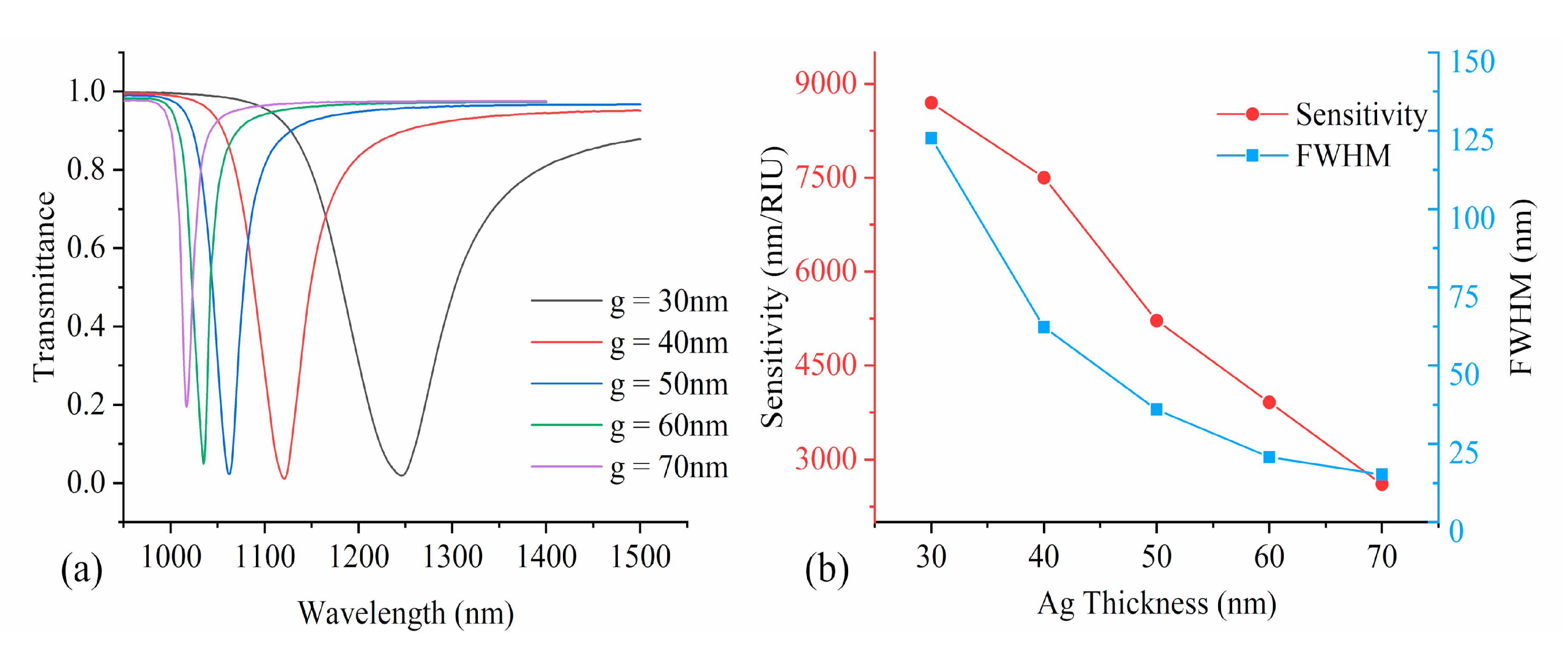

4.1. Evaluation of Ag Thickness on Sensing Performance

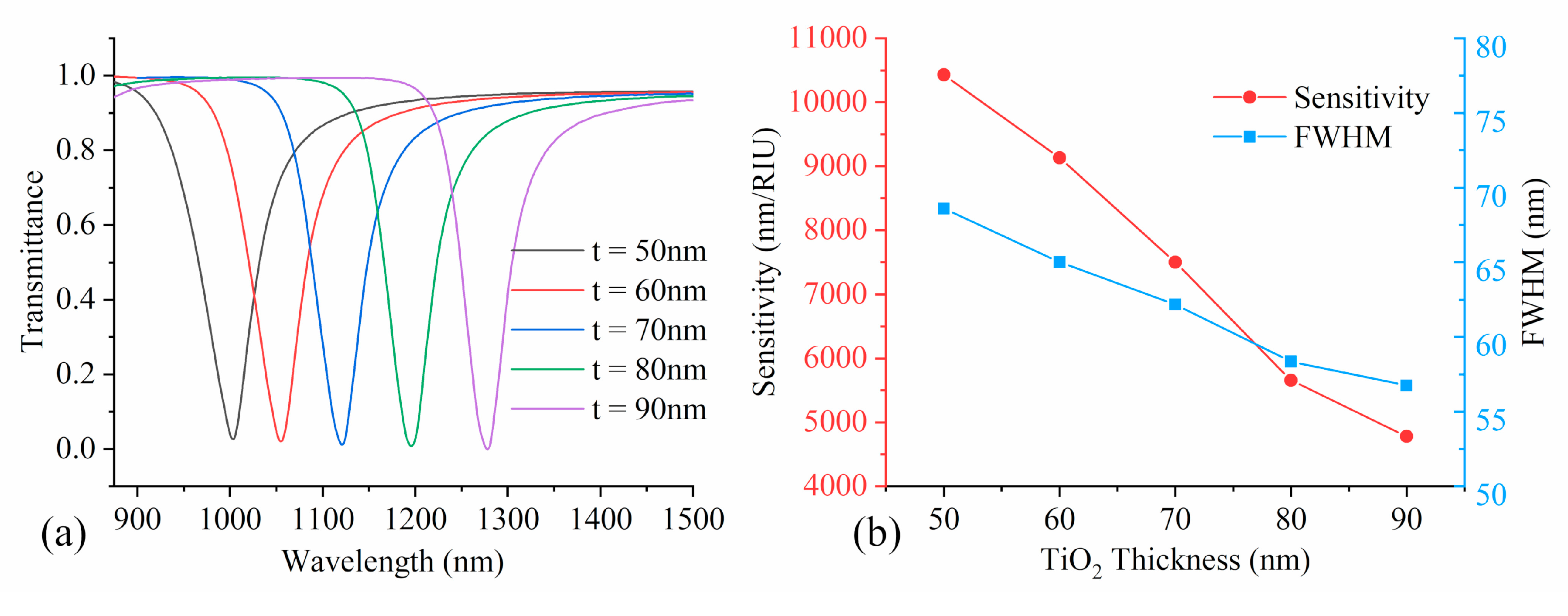

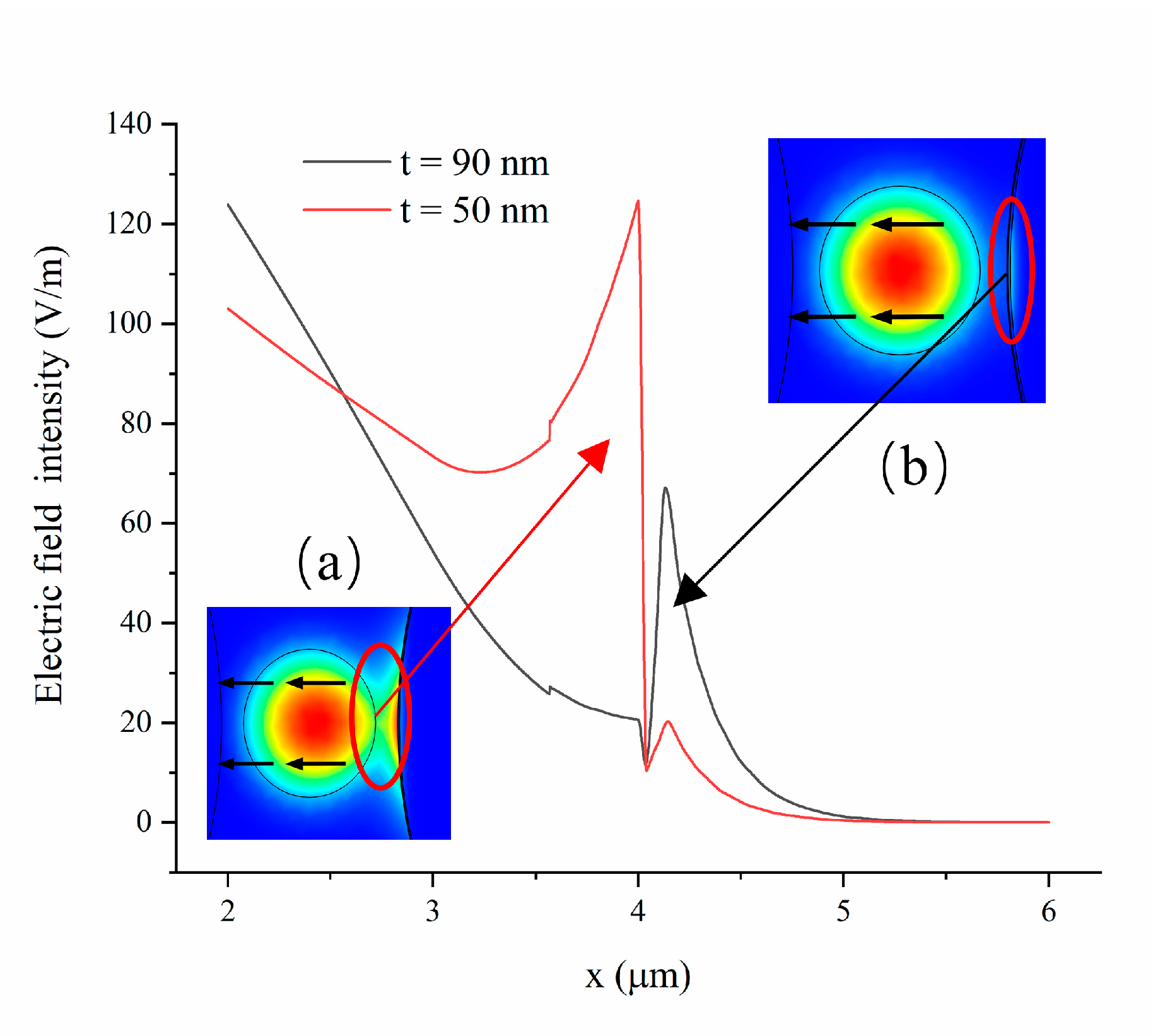

4.2. Evaluation of Effect of TiO2 Thickness on Sensing Performance

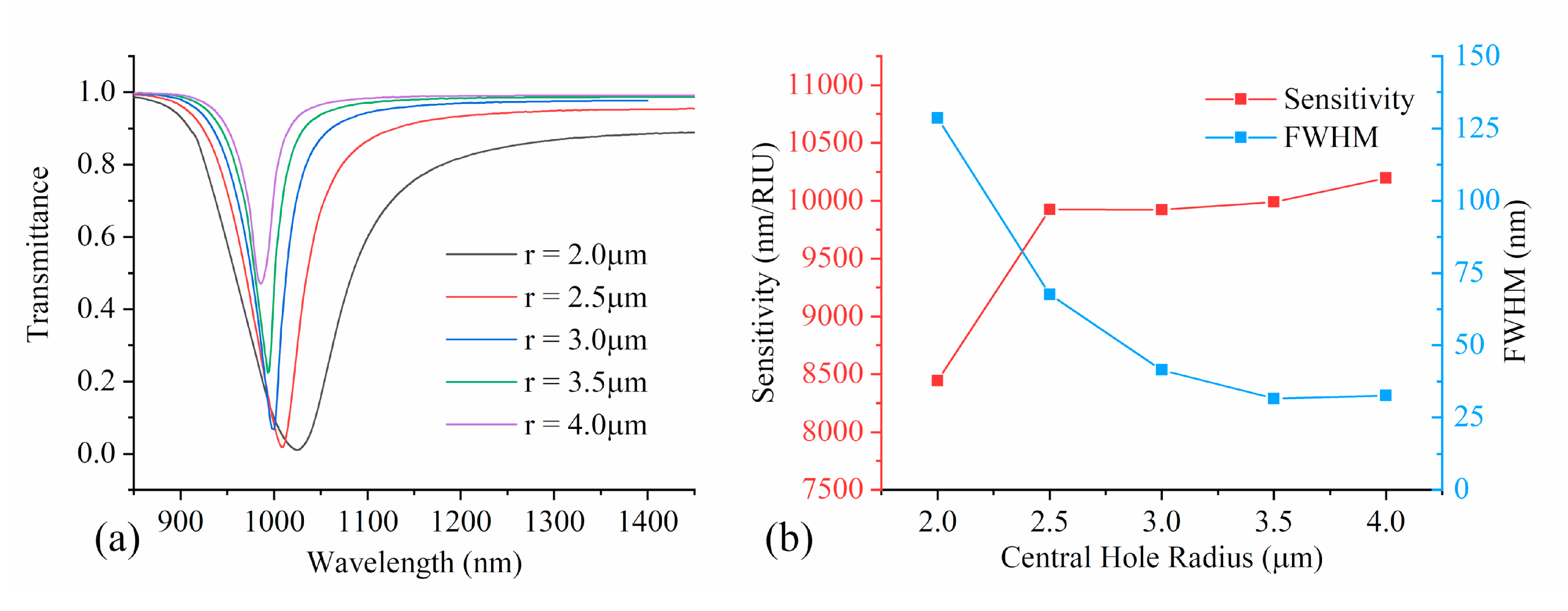

4.3. Evaluation of Effect of Central Hole Radius on Sensing Performance

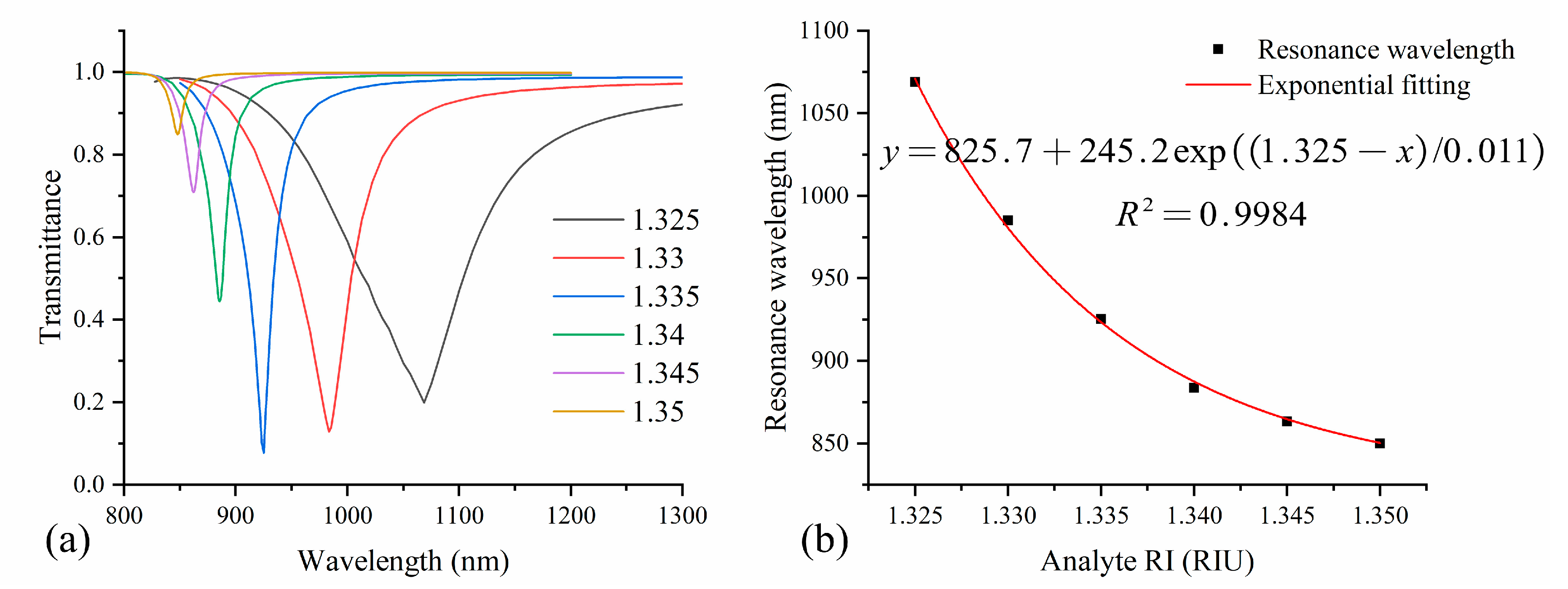

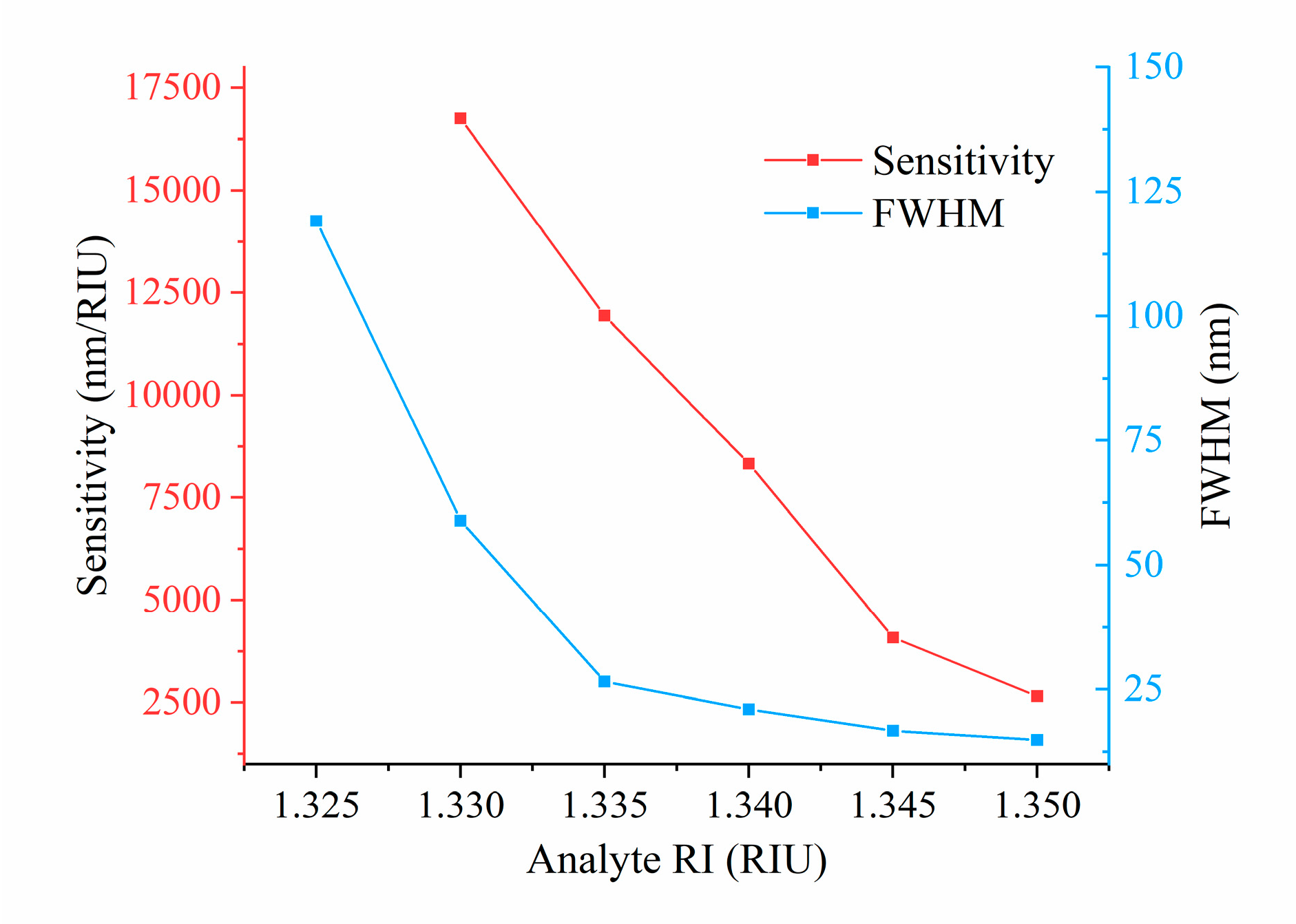

4.4. Sensing Performance with Optimal Parameters

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jorgenson, R.C.; Yee, S.S. A fiber-optic chemical sensor based on surface plasmon resonance. Sens. Actuators B Chem. 1993, 12, 213–220. [Google Scholar] [CrossRef]

- Scarano, S.; Mariani, S.; Minunni, M. SPR-Based Affinity Biosensors as Innovative Analytical Devices. J. Light. Technol. 2015, 33, 3374–3384. [Google Scholar] [CrossRef]

- Mishra, S.K.; Gupta, B.D. Surface Plasmon Resonance-Based Fiber Optic Chlorine Gas Sensor Utilizing Indium-Oxide-Doped Tin Oxide Film. J. Light. Technol. 2015, 33, 2770–2776. [Google Scholar] [CrossRef]

- Tripathi, S.M.; Bock, W.J.; Mikulic, P.; Chinnappan, R.; Ng, A.; Tolba, M.; Zourob, M. Long period grating based biosensor for the detection of Escherichia coli bacteria. Biosens. Bioelectron. 2012, 35, 308–312. [Google Scholar] [CrossRef]

- Kumar, R.; Kushwaha, A.S.; Srivastava, M.; Mishra, H.; Srivastava, S.K. Enhancement in sensitivity of graphene-based zinc oxide assisted bimetallic surface plasmon resonance (SPR) biosensor. Appl. Phys. A 2018, 124, 235. [Google Scholar] [CrossRef]

- Wu, L.; Jia, Y.; Jiang, L.; Guo, J.; Dai, X.; Xiang, Y.; Fan, D. Sensitivity Improved SPR Biosensor Based on the MoS2/Graphene–Aluminum Hybrid Structure. J. Light. Technol. 2017, 35, 82–87. [Google Scholar] [CrossRef]

- Shibayama, J.; Takeuchi, T.; Goto, N.; Yamauchi, J.; Nakano, H. Numerical Investigation of a Kretschmann-Type Surface Plasmon Resonance Waveguide Sensor. J. Light. Technol. 2007, 25, 2605–2611. [Google Scholar] [CrossRef][Green Version]

- Jing, J.-Y.; Li, S.-Y.; Wang, X.-Z.; Zhu, Q.; Meng, F.-L.; Wang, Q. A D-type fiber based symmetrical long-range surface plasmon resonance sensor with high quality factor. Measurement 2019, 140, 395–406. [Google Scholar] [CrossRef]

- Haque, E.; Hossain, M.A.; Ahmed, F.; Namihira, Y. Surface Plasmon Resonance Sensor Based on Modified D -Shaped Photonic Crystal Fiber for Wider Range of Refractive Index Detection. IEEE Sens. J. 2018, 18, 8287–8293. [Google Scholar] [CrossRef]

- Zhao, L.; Han, H.; Lian, Y.; Luan, N.; Liu, J. Theoretical analysis of all-solid D-type photonic crystal fiber based plasmonic sensor for refractive index and temperature sensing. Opt. Fiber Technol. 2019, 50, 165–171. [Google Scholar] [CrossRef]

- Lam, W.W.; Chu, L.H.; Wong, C.L.; Zhang, Y.T. A surface plasmon resonance system for the measurement of glucose in aqueous solution. Sens. Actuators B Chem. 2005, 105, 138–143. [Google Scholar] [CrossRef]

- Aray, A.; Saghafifar, H.; Soltanolkotabi, M. Calculation of Dispersion Relation and Single Mode Operation in Surface Plasmon Resonance Based Fiber Optic Refractive Index Sensors. J. Light. Technol. 2016, 34, 2782–2788. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, C.; Wang, Y.; Shen, C.; Dong, X. A Highly Sensitive Fibre-Optic Nano-Displacement Sensor Based on Surface Plasmon Resonance. J. Light. Technol. 2016, 34, 2324–2330. [Google Scholar] [CrossRef]

- Duan, L.; Yang, X.; Lu, Y.; Yao, J. Hollow-fiber-based surface plasmon resonance sensor with large refractive index detection range and high linearity. Appl. Opt. 2017, 56, 9907–9912. [Google Scholar] [CrossRef]

- Mahfuz, M.A.; Mollah, M.A.; Momota, M.R.; Paul, A.K.; Masud, A.; Akter, S.; Hasan, M.R. Highly sensitive photonic crystal fiber plasmonic biosensor: Design and analysis. Opt. Mater. Amst. 2019, 90, 315–321. [Google Scholar] [CrossRef]

- Gao, D.; Guan, C.; Wen, Y.; Zhong, X.; Yuan, L. Multi-hole fiber based surface plasmon resonance sensor operated at near-infrared wavelengths. Opt. Commun. 2014, 313, 94–98. [Google Scholar] [CrossRef]

- Biswas, T.; Chattopadhyay, R.; Bhadra, S.K. Plasmonic hollow-core photonic band gap fiber for efficient sensing of biofluids. J. Opt. 2014, 16, 45001. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, X.; Zhang, Y.; Zhang, Y.; Zhu, Z.; Yang, X.; Zhang, J.; Yang, J.; Yuan, L. Hollow fiber SPR sensor available for microfluidic chip. Sens. Actuators B Chem. 2018, 265, 211–216. [Google Scholar] [CrossRef]

- De, M.; Singh, V.K. Analysis of a highly sensitive flat fiber plasmonic refractive index sensor. Appl. Opt. 2020, 59, 380–388. [Google Scholar] [CrossRef]

- Yang, M.K.; French, R.H.; Tokarsky, E.W. Optical properties of Teflon® AF amorphous fluoropolymers. J. Micro/Nanolithogr. MEMS MOEMS 2008, 7, 1–9. [Google Scholar] [CrossRef]

- Goto, M.; Quema, A.; Takahashi, H.; Ono, S.; Sarukura, N. Teflon Photonic Crystal Fiber as Terahertz Waveguide. Jpn. J. Appl. Phys. 2004, 43, L317–L319. [Google Scholar] [CrossRef]

- Arrospide, E.; Durana, G.; Azkune, M.; Aldabaldetreku, G.; Bikandi, I.; Ruiz-Rubio, L.; Zubia, J. Polymers beyond standard optical fibres—Fabrication of microstructured polymer optical fibres. Polym. Int. 2018, 67, 1155–1163. [Google Scholar] [CrossRef]

- Wang, Y.; Liao, C.R.; Wang, D.N. Femtosecond laser-assisted selective infiltration of microstructured optical fibers. Opt. Express 2010, 18, 18056–18060. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.-H.; Jiang, Y.-X.; Zhu, X.-S.; Tang, X.-L.; Shi, Y.-W. Hollow fiber surface plasmon resonance sensor for the detection of liquid with high refractive index. Opt. Express 2013, 21, 32349–32357. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Lu, Y.; Liu, B.; Yao, J. Design of a Tunable Single-Polarization Photonic Crystal Fiber Filter With Silver-Coated and Liquid-Filled Air Holes. IEEE Photonics J. 2017, 9, 1–8. [Google Scholar] [CrossRef]

- Johnson, R.W.; Hultqvist, A.; Bent, S.F. A brief review of atomic layer deposition: From fundamentals to applications. Mater. Today 2014, 17, 236–246. [Google Scholar] [CrossRef]

- Ma, L.; Huang, Y.; Hou, M.; Xie, Z.; Zhang, Z. Ag Nanorods Coated with Ultrathin TiO2 Shells as Stable and Recyclable SERS Substrates. Sci. Rep. 2015, 5, 15442. [Google Scholar] [CrossRef]

- Zuo, Y.; Yu, W.; Liu, C.; Cheng, X.; Qiao, R.; Liang, J.; Zhou, X.; Wang, J.; Wu, M.; Zhao, Y.; et al. Optical fibres with embedded two-dimensional materials for ultrahigh nonlinearity. Nat. Nanotechnol. 2020. [Google Scholar] [CrossRef]

- Zheng, D.; Li, Y.; Chen, E.; Li, B.; Kong, D.; Li, W.; Wu, J. Free-space to few-mode-fiber coupling under atmospheric turbulence. Opt. Express 2016, 24, 18739–18744. [Google Scholar] [CrossRef]

- Babar, S.; Weaver, J.H. Optical constants of Cu, Ag, and Au revisited. Appl. Opt. 2015, 54, 477–481. [Google Scholar] [CrossRef]

- Siefke, T.; Kroker, S.; Pfeiffer, K.; Puffky, O.; Dietrich, K.; Franta, D.; Ohlídal, I.; Szeghalmi, A.; Kley, E.-B.; Tünnermann, A. Materials Pushing the Application Limits of Wire Grid Polarizers further into the Deep Ultraviolet Spectral Range. Adv. Opt. Mater. 2016, 4, 1780–1786. [Google Scholar] [CrossRef]

- Dong, J.; Zhang, Y.; Wang, Y.; Yang, F.; Hu, S.; Chen, Y.; Zhu, W.; Qiu, W.; Guan, H.; Lu, H.; et al. Side-polished few-mode fiber based surface plasmon resonance biosensor. Opt. Express 2019, 27, 11348–11360. [Google Scholar] [CrossRef] [PubMed]

- Momota, M.R.; Hasan, M.R. Hollow-core silver coated photonic crystal fiber plasmonic sensor. Opt. Mater. Amst. 2018, 76, 287–294. [Google Scholar] [CrossRef]

- Hassani, A.; Skorobogatiy, M. Design criteria for microstructured-optical-fiber-based surface-plasmon-resonance sensors. J. Opt. Soc. Am. B 2007, 24, 1423–1429. [Google Scholar] [CrossRef]

- Zha, F.; Li, J.; Sun, P.; Ma, H. Highly sensitive selectively coated D-shape photonic crystal fibers for surface plasmon resonance sensing. Phys. Lett. A 2019, 383, 1825–1830. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, X.; Zhu, X.-S.; Shi, Y.-W. Long-range surface plasmon resonance sensor based on the GK570/Ag coated hollow fiber with an asymmetric layer structure. Opt. Express 2019, 27, 9550–9560. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.; Li, S. Design and numerical analysis of a novel dual-polarized refractive index sensor based on D-shaped photonic crystal fiber. Metrologia 2018, 55, 828–839. [Google Scholar] [CrossRef]

- Luan, N.; Yao, J. High Refractive Index Surface Plasmon Resonance Sensor Based on a Silver Wire Filled Hollow Fiber. IEEE Photonics J. 2016, 8, 1–9. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| g | 60 nm | R | 20 μm |

| t | 50 nm | d | 1 μm |

| r | 3.5 μm | L | 5 mm |

| Ref. | Configuration | RI Range | Sensitivity (nm/RIU) | Figure of Merit (FOM) (RIU−1) |

|---|---|---|---|---|

| [32] | Side-polished multi-mode fiber | 1.394–1.404 | Up to 4796 | Up to 46.1 |

| [24] | Inner Ag-coated hollow fiber | 1.509–1.763 | 2185–6607 | - |

| [36] | GK570/Ag-coated hollow fiber | 1.4772–1.5116 | 3470–12511 | 105.9–113.9 |

| [37] | Au-coated D-shaped PCF 1 | 1.26–1.36 | Up to 11039 | - |

| [38] | Silver-wire-filled hollow fiber | 1.47–1.52 | 4200–16200 | - |

| [8] | Symmetrical long-range SPR 2 | 1.33–1.38 | 3500.6 | Up to 107.5 |

| This work | Liquid-core PTFE-based POF 3 | 1.325–1.35 | 2653–16750 | 178.3–450.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shui, X.; Gu, Q.; Jiang, X.; Si, G. Surface Plasmon Resonance Sensor Based on Polymer Liquid-Core Fiber for Refractive Index Detection. Photonics 2020, 7, 123. https://doi.org/10.3390/photonics7040123

Shui X, Gu Q, Jiang X, Si G. Surface Plasmon Resonance Sensor Based on Polymer Liquid-Core Fiber for Refractive Index Detection. Photonics. 2020; 7(4):123. https://doi.org/10.3390/photonics7040123

Chicago/Turabian StyleShui, Xuqing, Qiongchan Gu, Xiaoxiao Jiang, and Guangyuan Si. 2020. "Surface Plasmon Resonance Sensor Based on Polymer Liquid-Core Fiber for Refractive Index Detection" Photonics 7, no. 4: 123. https://doi.org/10.3390/photonics7040123

APA StyleShui, X., Gu, Q., Jiang, X., & Si, G. (2020). Surface Plasmon Resonance Sensor Based on Polymer Liquid-Core Fiber for Refractive Index Detection. Photonics, 7(4), 123. https://doi.org/10.3390/photonics7040123