A Bio-Compatible Fiber Optic pH Sensor Based on a Thin Core Interferometric Technique

Abstract

:1. Introduction

2. Theory and Simulations

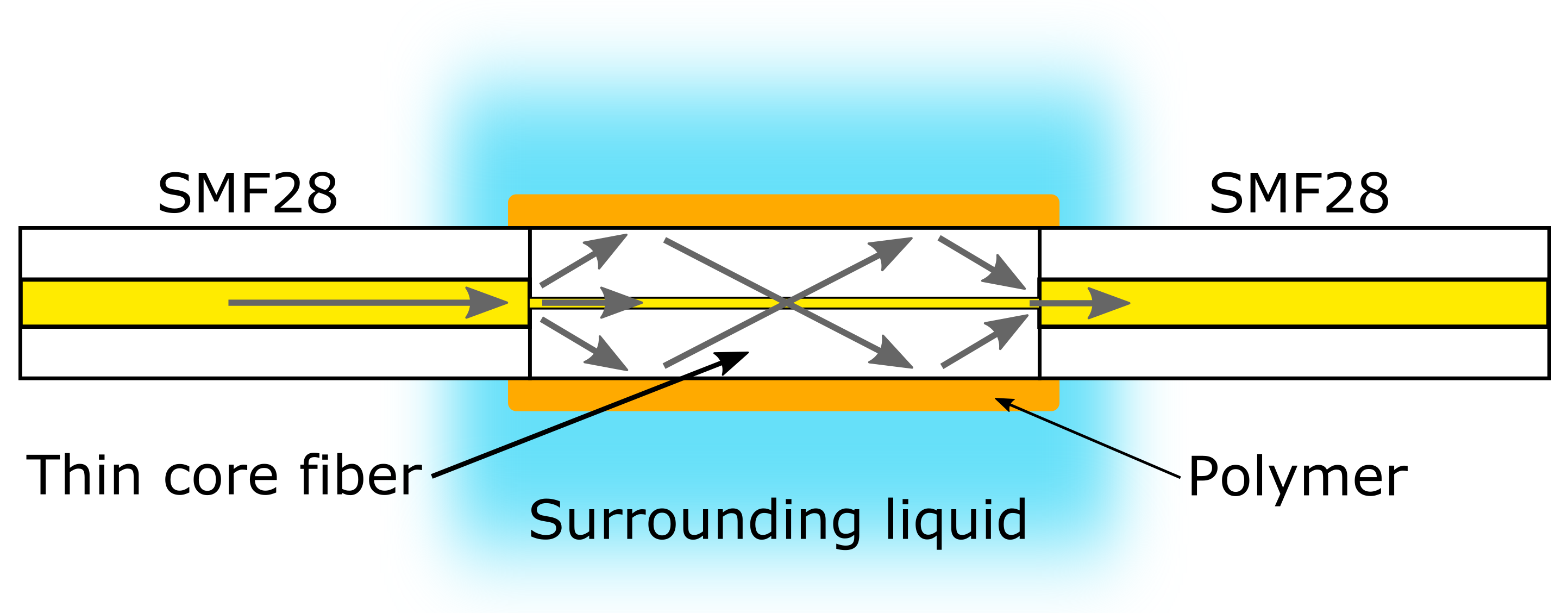

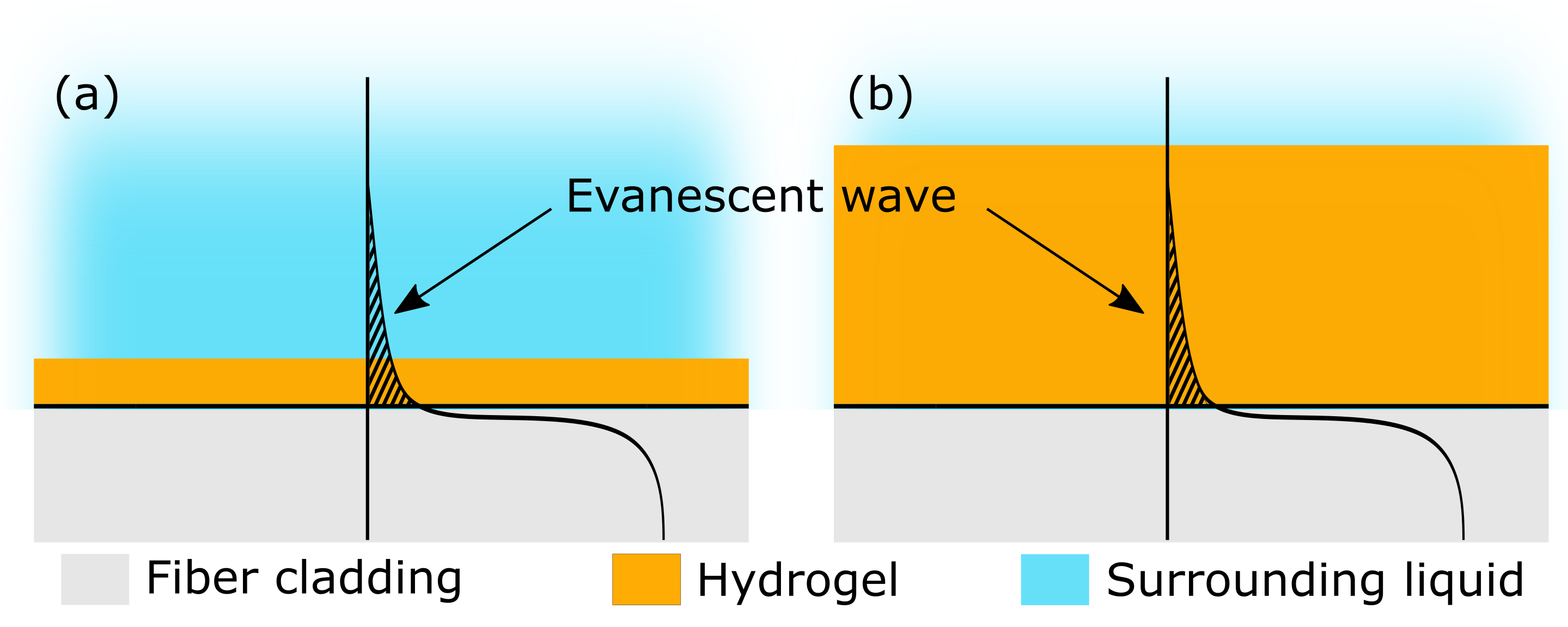

2.1. Sensor Concept

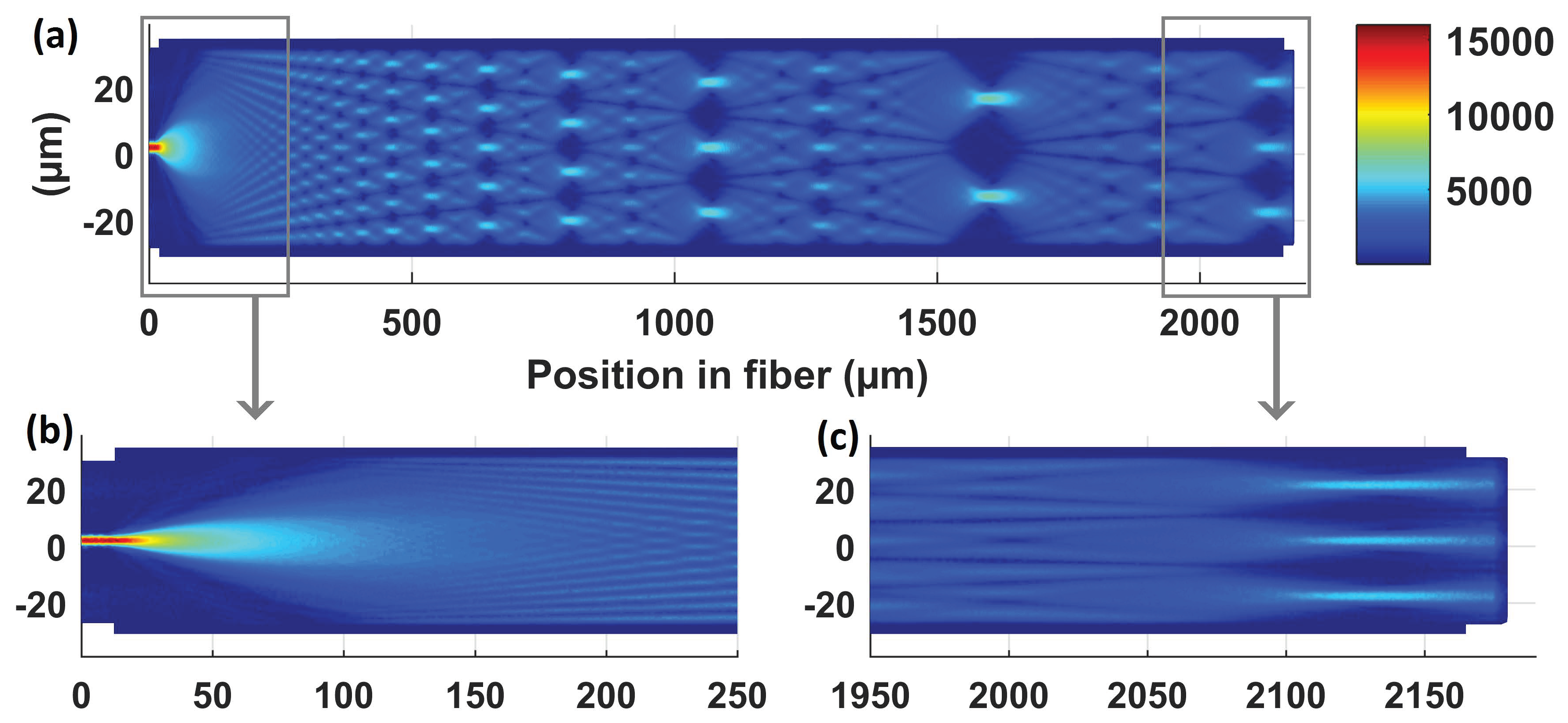

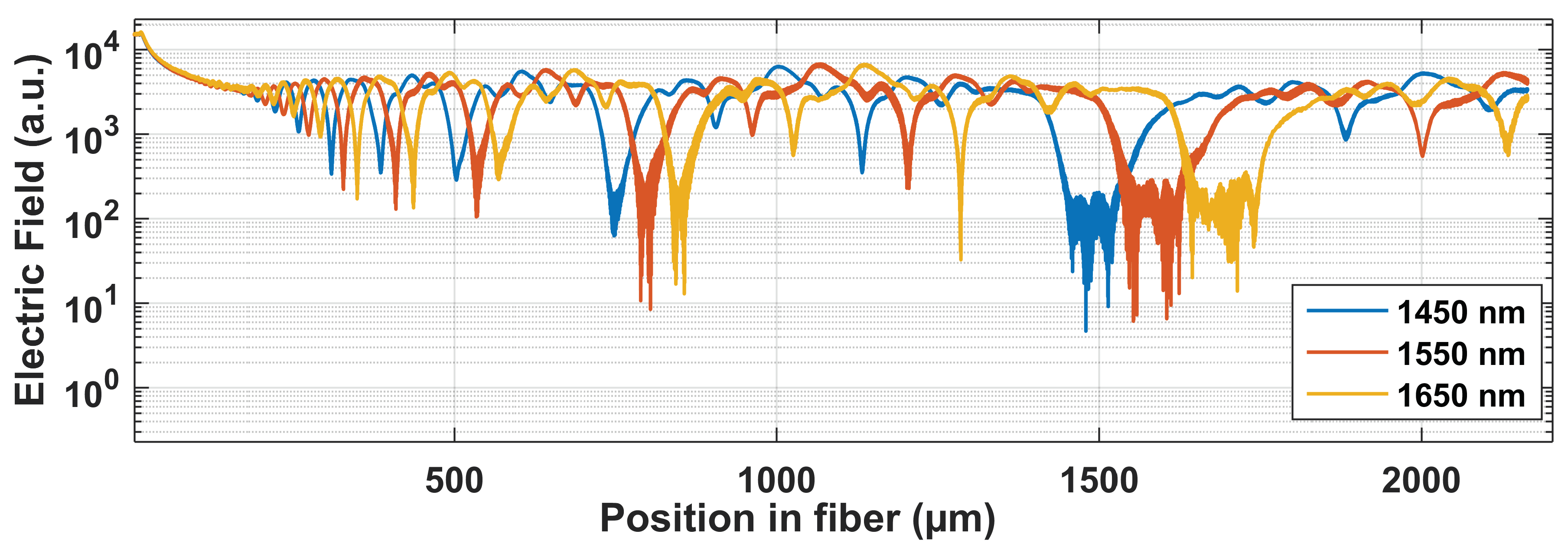

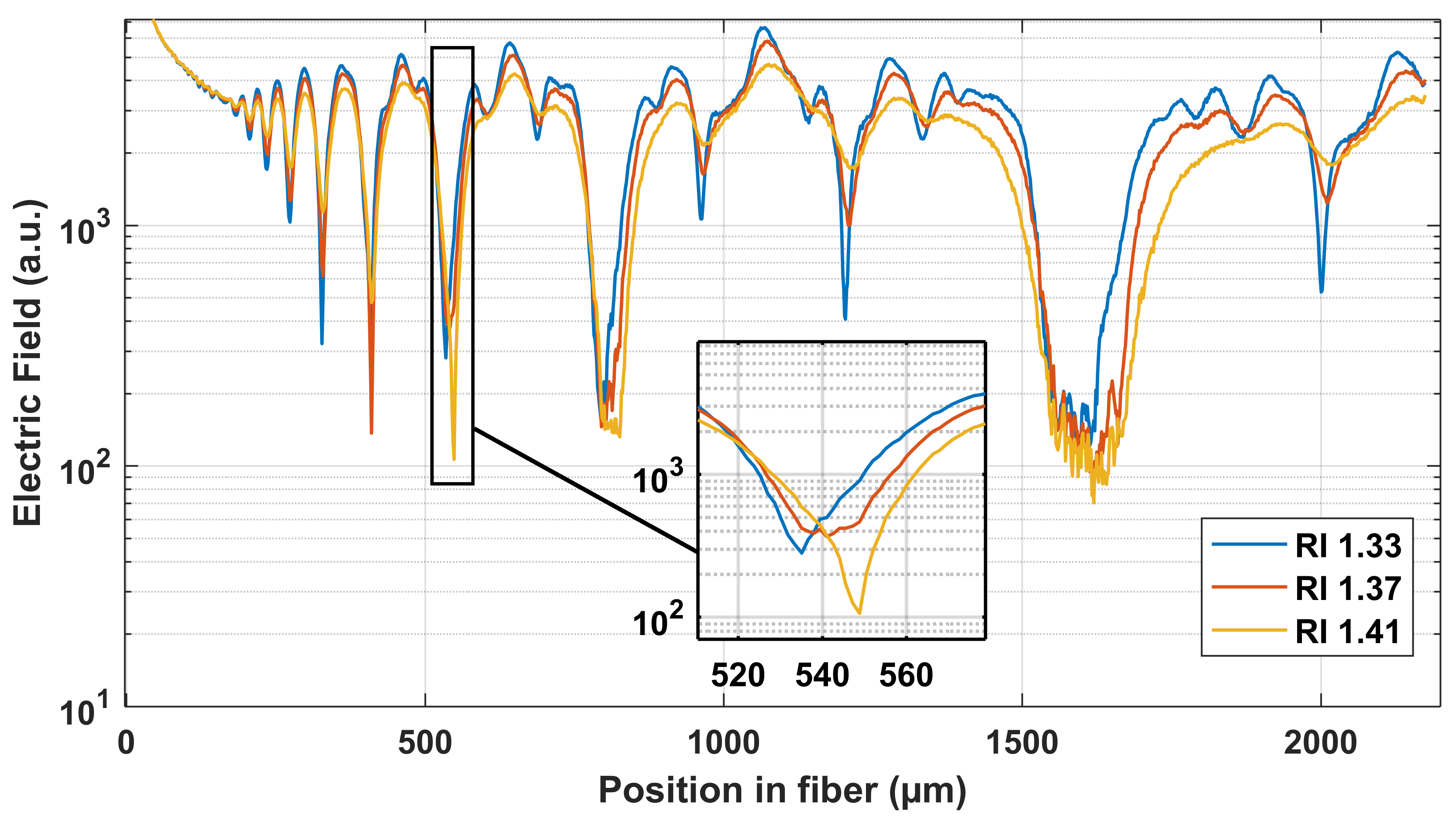

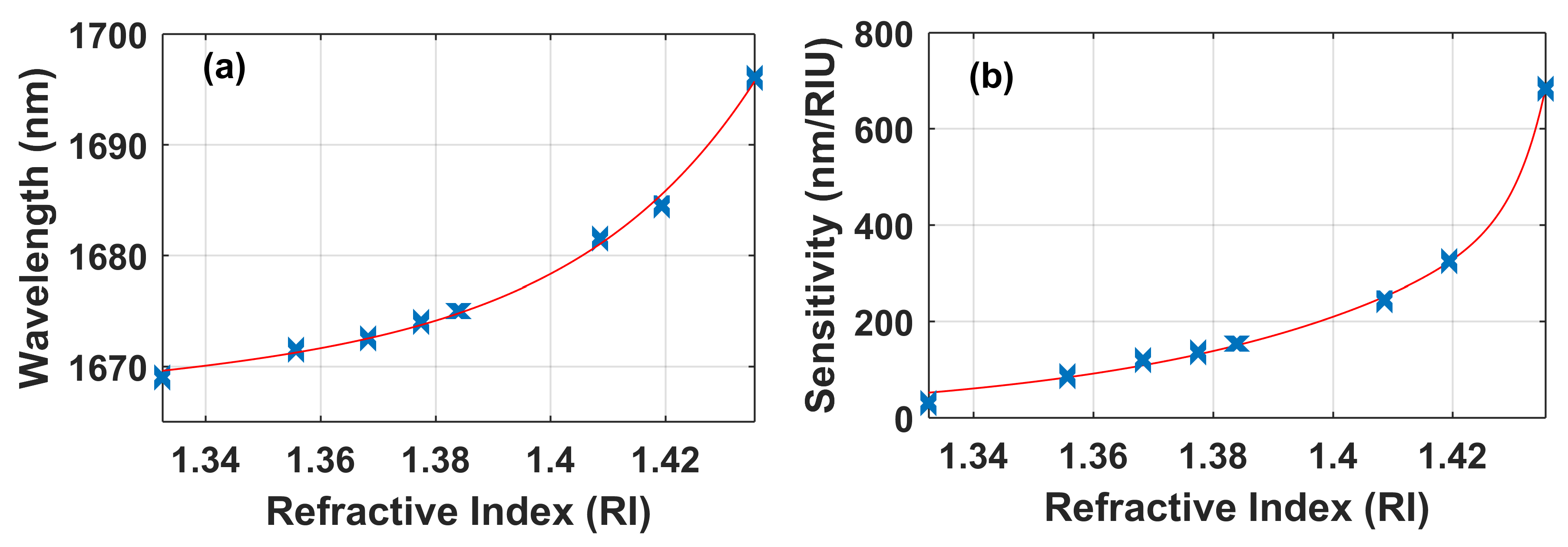

2.2. Simulation of the Inline Sensor

2.3. Simulation Results

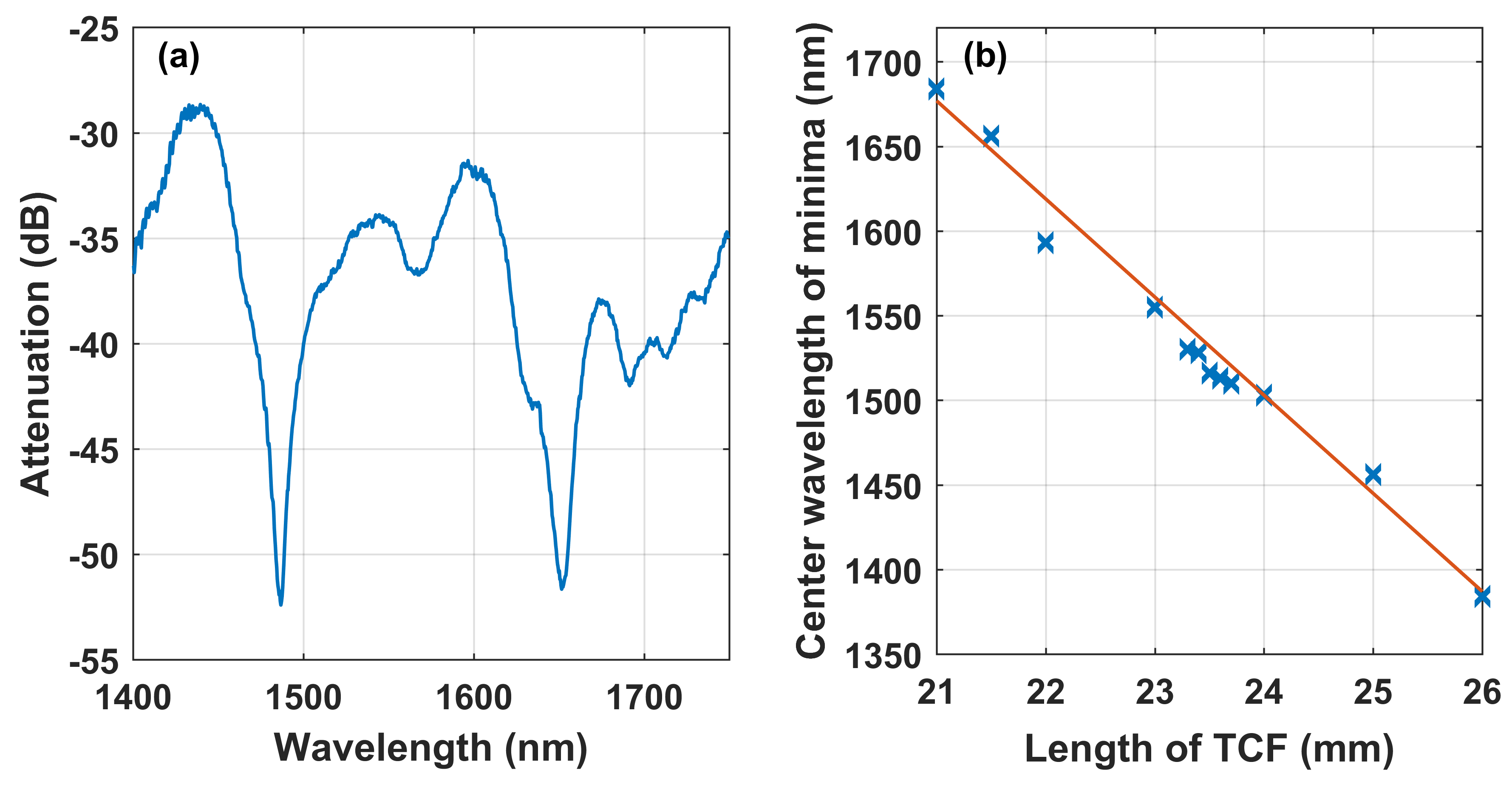

3. Results and Experimental Verification of Sensor Concept

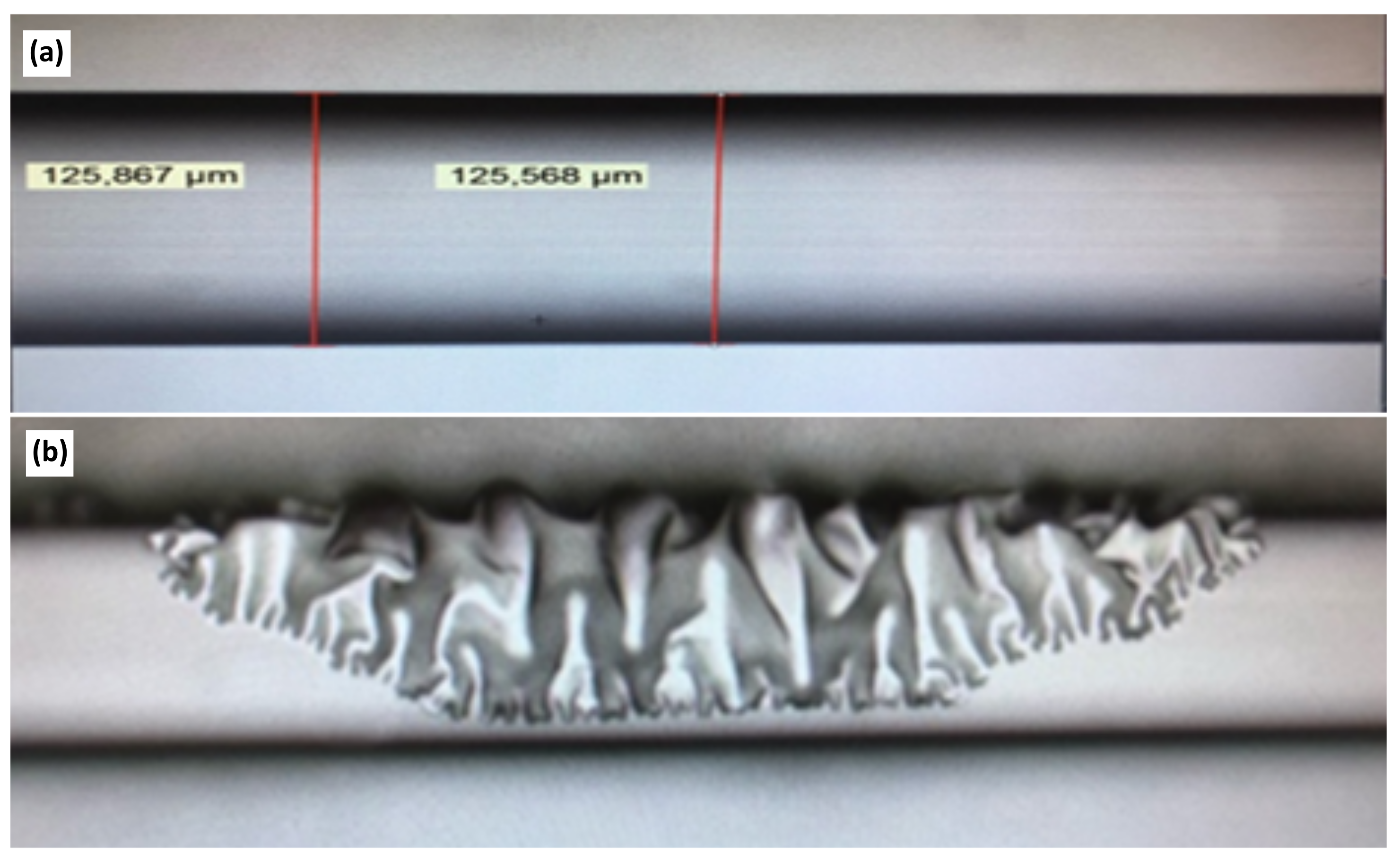

3.1. Sensor Design and Construction

3.2. Polymer Preparation and Coating Procedure

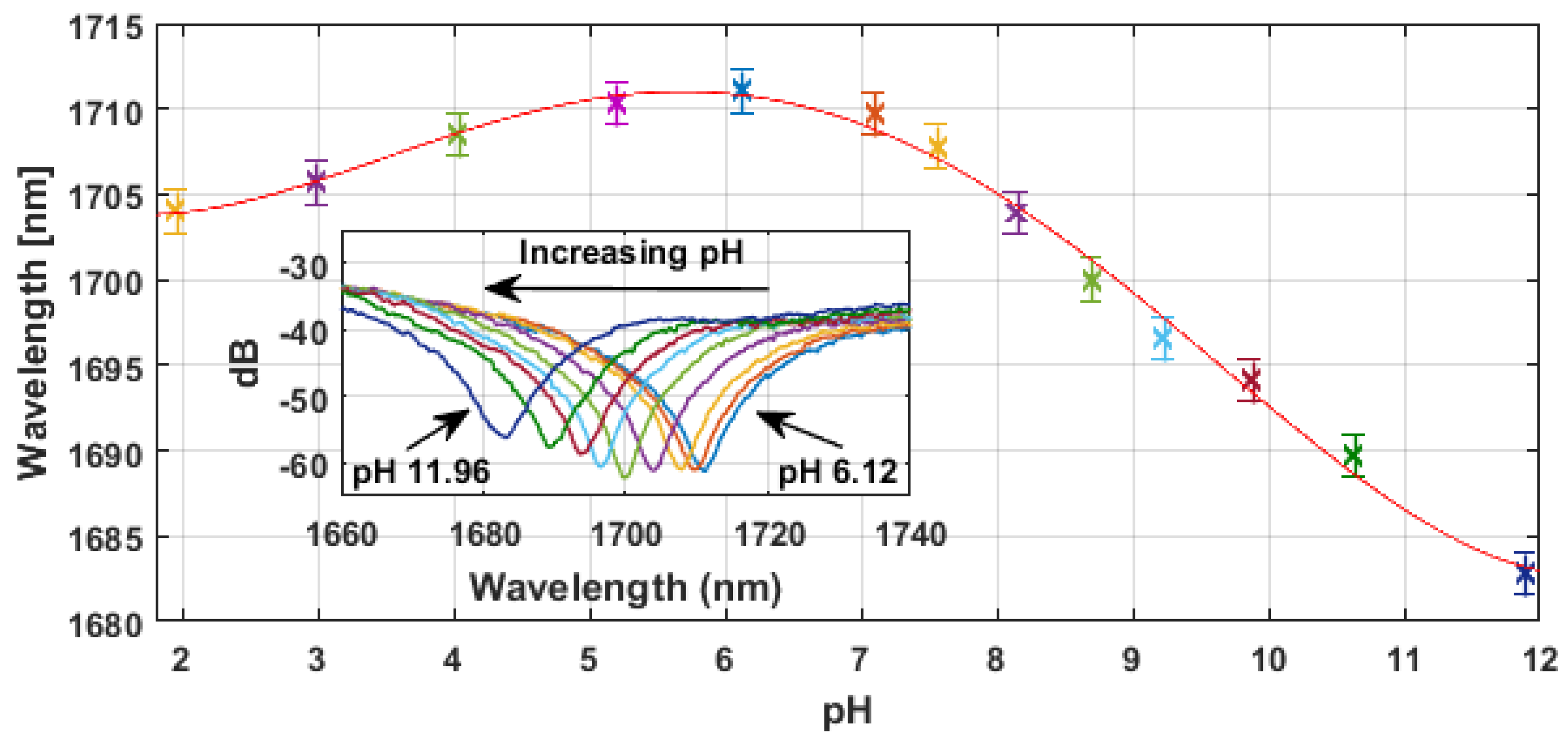

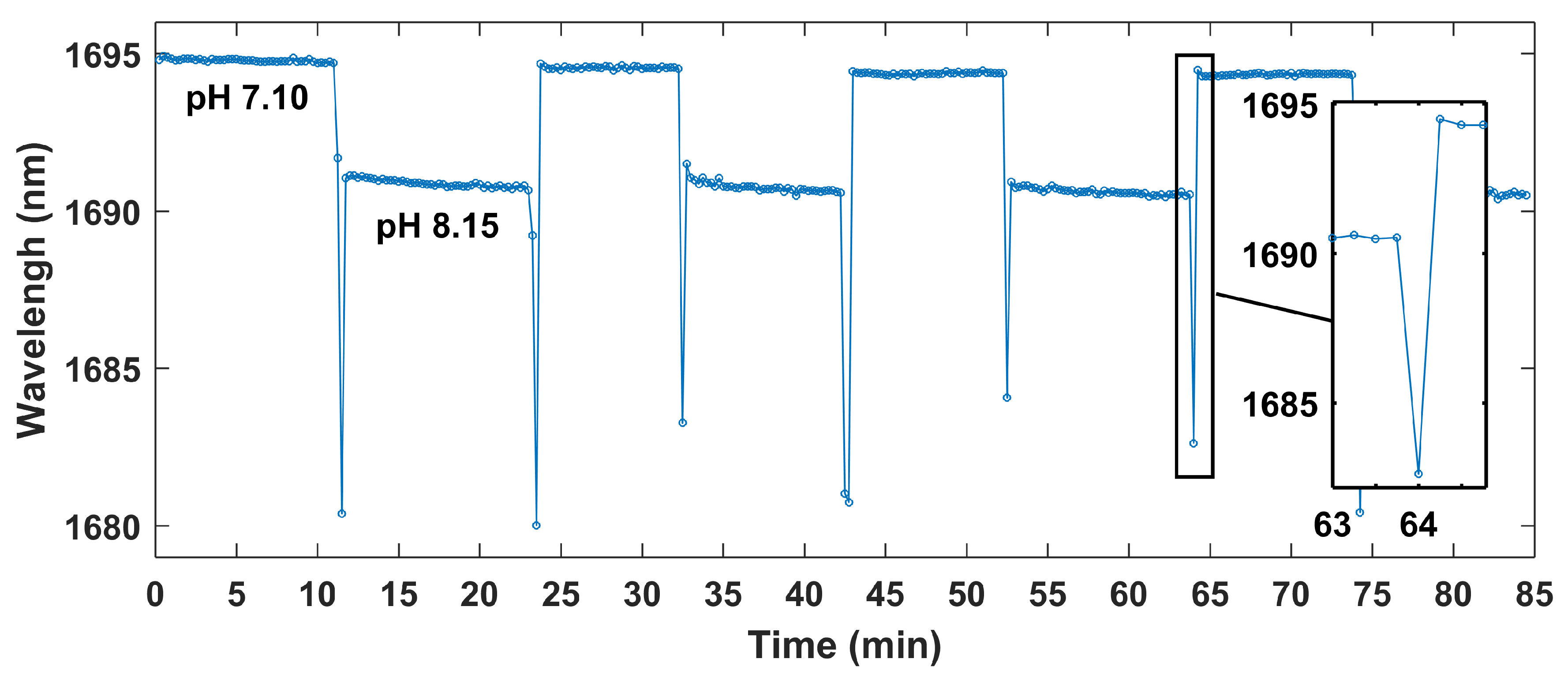

3.3. Experimental Evaluation of the pH Sensors

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gu, B.; Yin, M.; Zhang, A.P.; Qian, J.; He, S. Biocompatible fiber-optic pH sensor based on optical fiber modal interferometer self-assembled with sodium alginate/polyethylenimine coating. IEEE Sens. J. 2012, 12, 1477–1482. [Google Scholar] [CrossRef]

- Lee, D.; Yang, M.; Qi, C.; Dai, J.; Wen, X.; Xie, W. An in-line optical fiber refractometer with porous thin film coating. Sens. Actuat. B Chem. 2015, 209, 602–605. [Google Scholar] [CrossRef]

- Lei, M.; Zhang, Y.N.; Han, B.; Zhao, Q.; Zhanga, A.; Fu, D. In-line Mach-Zehnder interferometer and FBG with smart hydrogel for simultaneous pH and temperature detection. IEEE Sens. J. 2018, 18, 7499–7504. [Google Scholar] [CrossRef]

- Gu, B.; Yin, M.J.; Zhang, A.P.; Qian, J.W.; He, S. Low-cost high-performance fiber-optic pH sensor based on thin-core fiber modal interferometer. Opt. Express 2009, 17, 22296–22302. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Chen, L.H.; Dong, X.; Yang, J.; Long, H.Y.; So, P.L.; Chan, C.C. Miniature pH optical fiber sensor based on Fabry–Perot interferometer. IEEE J. Sel. Top. Quantum Electron. 2016, 22, 331–335. [Google Scholar] [CrossRef]

- Pathak, A.; Bhardwaj, V.; Gangwar, R.; De, M.; Singh, V. Fabrication and characterization of TiO2 coated cone shaped nano-fiber pH sensor. Opt. Commun. 2017, 386, 43–48. [Google Scholar] [CrossRef]

- Pathak, A.K.; Singh, V.K. A wide range and highly sensitive optical fiber pH sensor using polyacrylamide hydrogel. Opt. Fiber Technol. 2017, 39, 43–48. [Google Scholar] [CrossRef]

- Hammarling, K.; Hilborn, J.; Nilsson, H.E.; Manuilskiy, A. Blood pH optrode based on evanescent waves and refractive index change. In Proceedings of the Optical Fibers and Sensors for Medical Diagnostics and Treatment Applications XIV, San Francisco, CA, USA, 1–6 February 2014; Volume 8938, p. 89381F. [Google Scholar]

- Gotor, R.; Ashokkumar, P.; Hecht, M.; Keil, K.; Rurack, K. Optical pH sensor covering the range from pH 0–14 compatible with mobile-device readout and based on a set of rationally designed indicator dyes. Anal. Chem. 2017, 89, 8437–8444. [Google Scholar] [CrossRef]

- Wang, X.; Boschetti, C.; Ruedas-Rama, M.J.; Tunnacliffe, A.; Hall, E.A. Ratiometric pH-dot ANSors. Analyst 2010, 135, 1585–1591. [Google Scholar] [CrossRef]

- Hibino, Y. Cladding-mode-recoupling-based tilted fiber Bragg grating sensor with a core-diameter-mismatched fiber section. IEEE Photonics J. 2010, 2, 152–157. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, G.; Zhou, B.; Lee, E.H.; He, S. Reflective Optical Fiber Refractometer Based on Long-Period Grating Tailored Active Bragg Grating. IEEE Photonics Technol. Lett. 2015, 27, 1173–1176. [Google Scholar] [CrossRef]

- Lu, P.; Men, L.; Sooley, K.; Chen, Q. Tapered fiber Mach-Zehnder interferometer for simultaneous measurement of refractive index and temperature. Appl. Phys. Lett. 2009, 94, 131110. [Google Scholar] [CrossRef]

- Wu, Q.; Semenova, Y.; Wang, P.; Farrell, G. High sensitivity SMS fiber structure based refractometer— Analysis and experiment. Opt. Express 2011, 19, 7937–7944. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Qiao, X.; Guo, T.; Wang, R.; Zhang, J.; Weng, Y.; Rong, Q.; Hu, M.; Feng, Z. Mach-Zehnder interferometer based on a sandwich fiber structure for refractive index measurement. IEEE Sens. J. 2012, 12, 2081–2085. [Google Scholar] [CrossRef]

- Jung, Y.; Kim, S.; Lee, D.; Oh, K. Compact three segmented multimode fibre modal interferometer for high sensitivity refractive-index measurement. Meas. Sci. Technol. 2006, 17, 1129. [Google Scholar] [CrossRef]

- Lee, B.H.; Kim, Y.H.; Park, K.S.; Eom, J.B.; Kim, M.J.; Rho, B.S.; Choi, H.Y. Interferometric fiber optic sensors. Sensors 2012, 12, 2467–2486. [Google Scholar] [CrossRef] [PubMed]

- Hammarling, K.; Sandberg, M.; Engholm, M.; Andersson, H.; Nilsson, H.E. Synthesis, Curing Behavior and Swell Tests of pH-Responsive Coatings from Acryl-Terminated Oligo (β-Amino Esters). Chemosensors 2018, 6, 10. [Google Scholar] [CrossRef]

- Comsol, A.B. RF Module User’s Guide, 2012. Available online: https://is.muni.cz/el/1431/podzim2013/F7061/um/RFMod\uleUsersGuide.pdf (accessed on 24 October 2018).

- Huang, G.; Zhou, B.; Chen, Z.; Jiang, H.; Xing, X. Magnetic-field sensor utilizing the ferrofluid and thin-core fiber modal interferometer. IEEE Sens. J. 2015, 15, 333–336. [Google Scholar] [CrossRef]

- Wu, J.; Miao, Y.; Song, B.; Lin, W.; Zhang, K.; Zhang, H.; Liu, B.; Yao, J. Simultaneous measurement of displacement and temperature based on thin-core fiber modal interferometer. Opt. Commun. 2015, 340, 136–140. [Google Scholar] [CrossRef]

- Haiwei, F.; Na, Z.; Min, S.; Huidong, L.; Hong, G.; Qinpeng, L.; Zhen, Y.; Yinggang, L.; Xueguang, Q. High-sensitivity Mach-Zehnder interferometric curvature fiber sensor based on thin-core fiber. IEEE Sens. J. 2015, 15, 520–525. [Google Scholar] [CrossRef]

- Wu, Q.; Semenova, Y.; Wang, P.; Farrell, G. A comprehensive analysis verified by experiment of a refractometer based on an SMF28—Small-core singlemode fiber (SCSMF)—SMF28 fiber structure. J. Opt. 2011, 13, 125401. [Google Scholar] [CrossRef]

- Ahmad, M.; Hench, L.L. Effect of taper geometries and launch angle on evanescent wave penetration depth in optical fibers. Biosens. Bioelectron. 2005, 20, 1312–1319. [Google Scholar] [CrossRef] [PubMed]

- Fiorini, B. Sensore di pH Basato su Interferometro Modale in Fibra Thin-Core. Master’s Thesis, UNIMORE University, Modena, Italy, 2016. [Google Scholar]

- Hammarling, K.; Beatrice, F.; Magnus, E. Fiber Optic pH-Sensor with Fast Response Time, Broad Operating Range and Simple Readout System. Optical Fibers and Sensors for Medical Diagnostics and Treatment Applications XVI. 2016, Volume 9702. Available online: https://spie.org/PW16B/conferencedetails/opticalfibers-and-sensors-medical-diagnostics (accessed on 24 October 2018).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Engholm, M.; Hammarling, K.; Andersson, H.; Sandberg, M.; Nilsson, H.-E. A Bio-Compatible Fiber Optic pH Sensor Based on a Thin Core Interferometric Technique. Photonics 2019, 6, 11. https://doi.org/10.3390/photonics6010011

Engholm M, Hammarling K, Andersson H, Sandberg M, Nilsson H-E. A Bio-Compatible Fiber Optic pH Sensor Based on a Thin Core Interferometric Technique. Photonics. 2019; 6(1):11. https://doi.org/10.3390/photonics6010011

Chicago/Turabian StyleEngholm, Magnus, Krister Hammarling, Henrik Andersson, Mats Sandberg, and Hans-Erik Nilsson. 2019. "A Bio-Compatible Fiber Optic pH Sensor Based on a Thin Core Interferometric Technique" Photonics 6, no. 1: 11. https://doi.org/10.3390/photonics6010011

APA StyleEngholm, M., Hammarling, K., Andersson, H., Sandberg, M., & Nilsson, H.-E. (2019). A Bio-Compatible Fiber Optic pH Sensor Based on a Thin Core Interferometric Technique. Photonics, 6(1), 11. https://doi.org/10.3390/photonics6010011