Highly Sensitive Light Guide Sensor for Multilocation and Multimodal Deformation Decoupling Using Flexible OLED

Abstract

1. Introduction

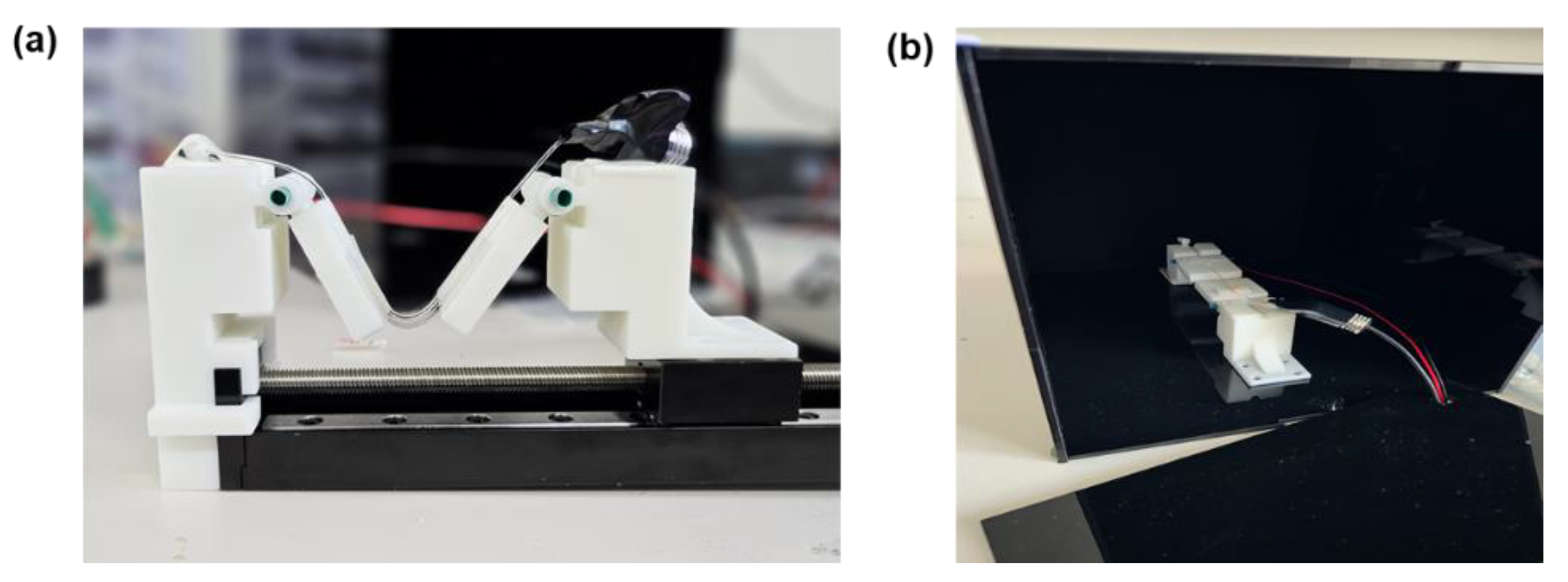

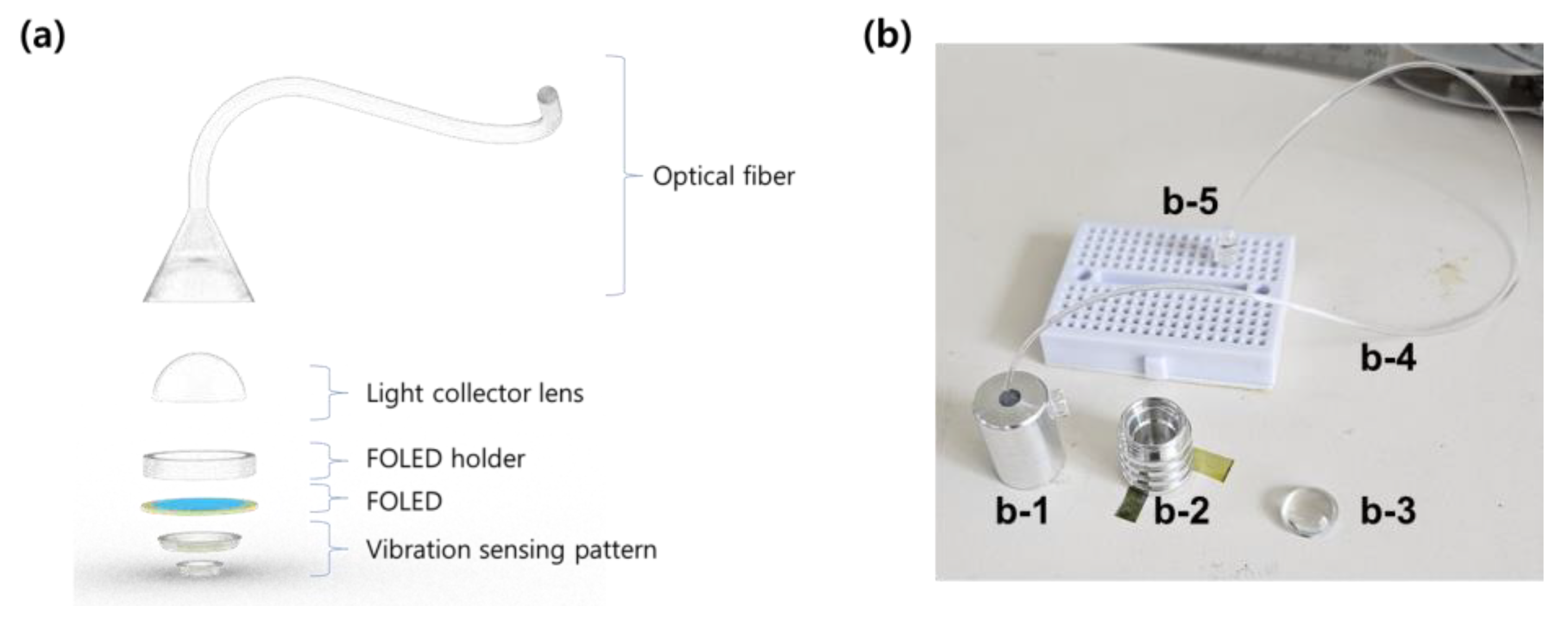

2. Materials and Methods

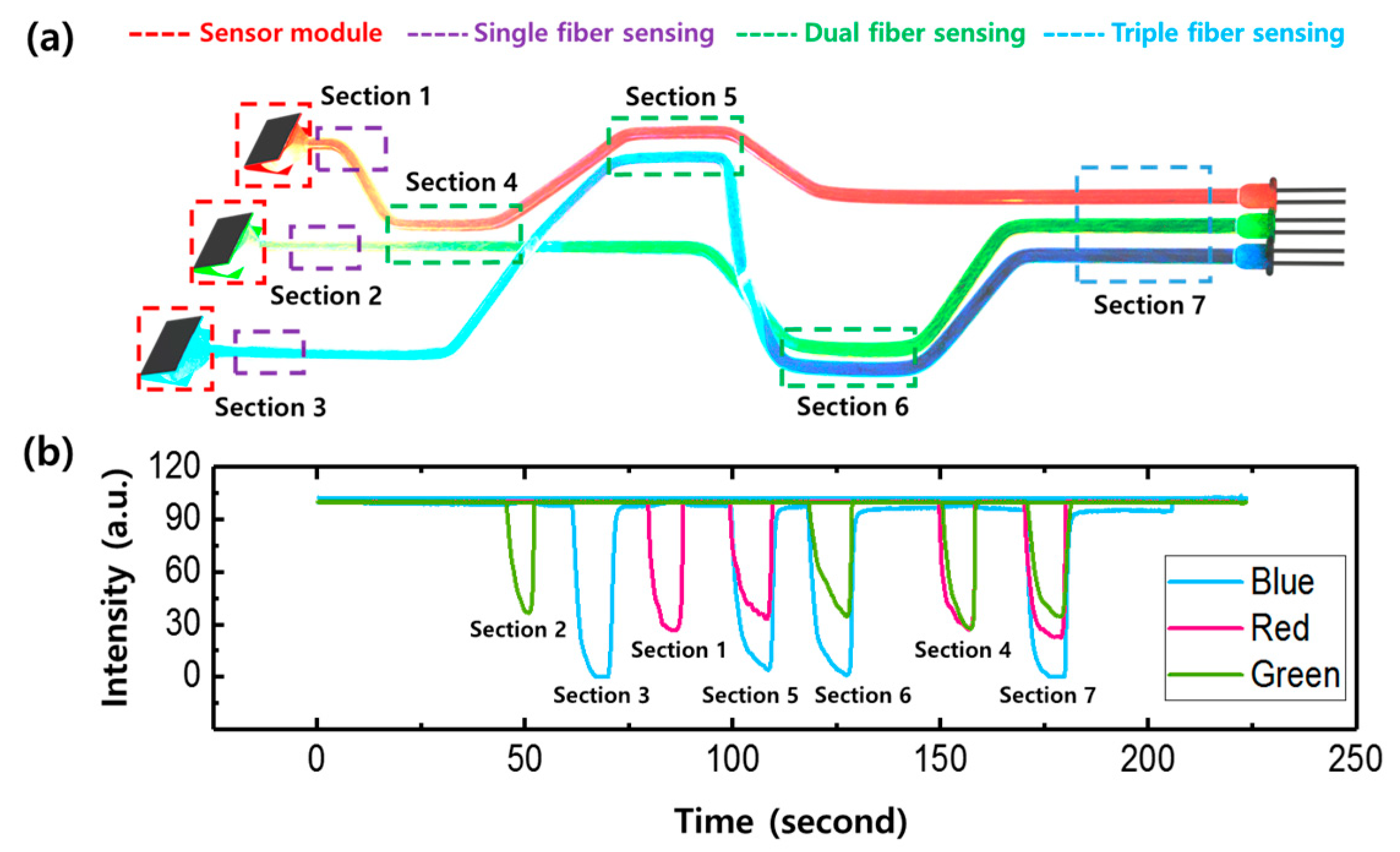

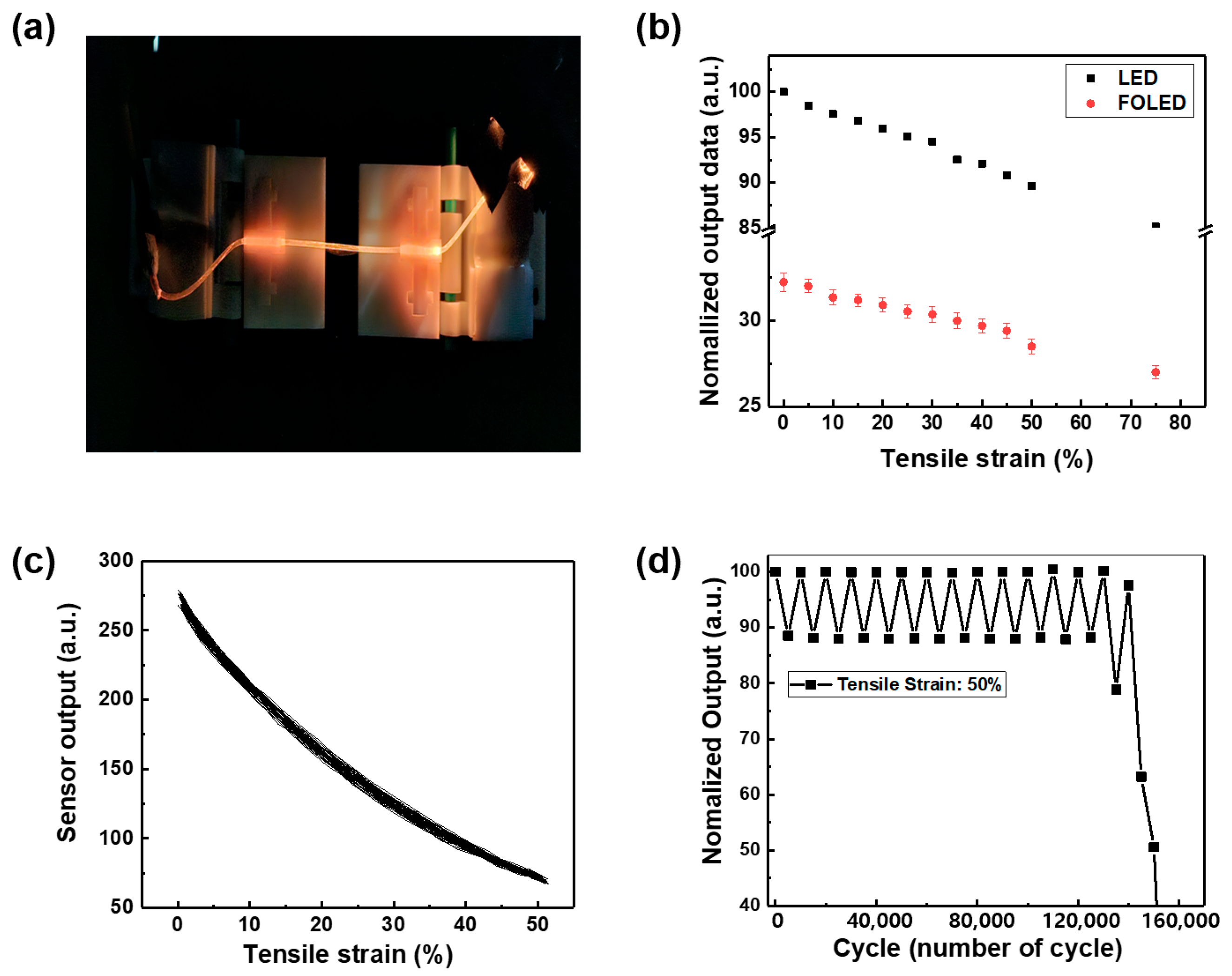

3. Results and Discussion

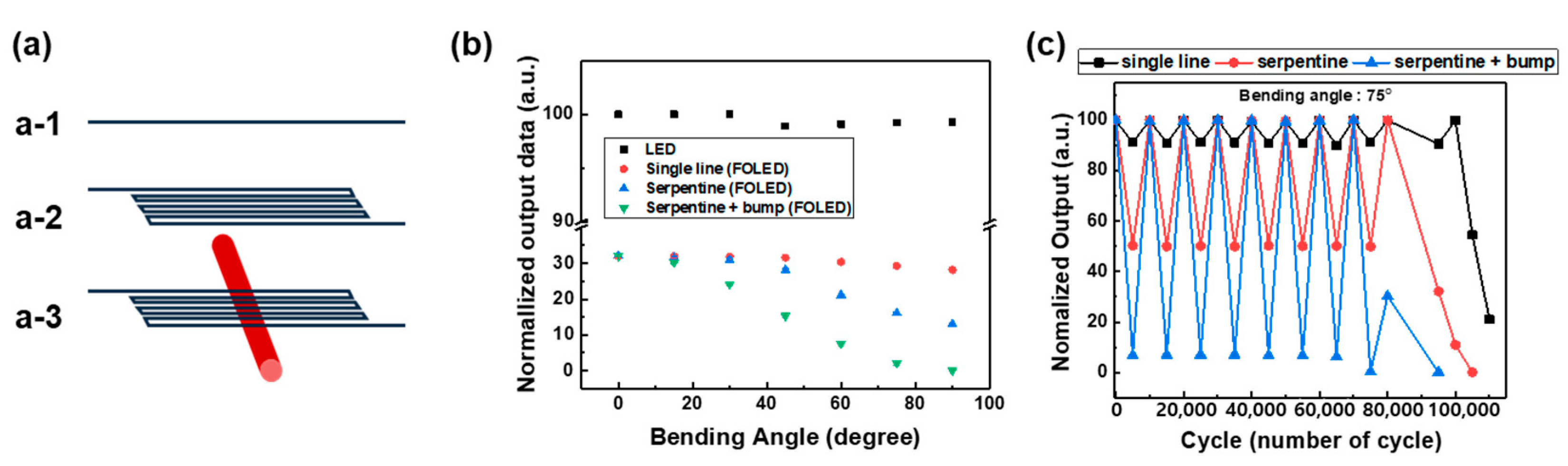

3.1. Structure of the FOLEDs and Optical Fiber Sensor System

3.2. Physical Deformation Sensing with Stretchable Optical Fiber

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- O’Rahilly, R.; Müller, F.; Carpenter, S.; Swenson, R.S. Chapter 3: The nervous system. In Basic Human Anatomy; Swenson, R., Ed.; Dartmouth Medical School: Hanover, NH, USA, 2008. [Google Scholar]

- Chortos, A.; Liu, J.; Bao, Z. Pursuing prosthetic electronic skin. Nat. Mater. 2016, 15, 937–950. [Google Scholar] [CrossRef]

- Dahiya, R.S.; Metta, G.; Valle, M.; Sandini, G. Tactile sensing—From humans to humanoids. IEEE Trans. Robot. 2010, 26, 1–20. [Google Scholar] [CrossRef]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Mengüç, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D printing of strain sensors within highly stretchable elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef] [PubMed]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef]

- White, E.L.; Yuen, M.C.; Kramer, R.K. Distributed sensing in capacitive conductive composites. In Proceedings of the IEEE Sensors, Glasgow, UK, 29 October–1 November 2017; IEEE: New York, NY, USA, 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Anderson, I.A.; Gisby, T.A.; McKay, T.G.; O’Brien, B.M.; Calius, E.P. Multifunctional dielectric elastomer artificial muscles for soft and smart machines. J. Appl. Phys. 2012, 112, 041101. [Google Scholar] [CrossRef]

- Case, J.C.; White, E.L.; Kramer, R.K. Sensor enabled closed-loop bending control of soft beams. Smart Mater. Struct. 2016, 25, 045018. [Google Scholar] [CrossRef]

- Ozel, S.; Skorina, E.H.; Luo, M.; Tao, W.; Chen, F.; Pan, Y.; Onal, C.D. A composite soft bending actuation module with integrated curvature sensing. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; IEEE: New York, NY, USA, 2016; pp. 4963–4968. [Google Scholar] [CrossRef]

- Truby, R.L.; Wehner, M.; Grosskopf, A.K.; Vogt, D.M.; Uzel, S.G.M.; Wood, R.J.; Lewis, J.A. Soft somatosensitive actuators via embedded 3D printing. Adv. Mater. 2018, 30, 1706383. [Google Scholar] [CrossRef] [PubMed]

- Farrow, N.; Correll, N. A soft pneumatic actuator that can sense grasp and touch. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; IEEE: New York, NY, USA, 2015; pp. 2317–2323. [Google Scholar] [CrossRef]

- Park, Y.L.; Majidi, C.; Kramer, R.; Bérard, P.; Wood, R.J. Hyperelastic pressure sensing with a liquid-embedded elastomer. J. Micromech. Microeng. 2010, 20, 125029. [Google Scholar] [CrossRef]

- O’Brien, B.; Gisby, T.; Anderson, I.A. Stretch sensors for human body motion. In Proceedings of the SPIE Electroactive Polymer Actuators and Devices, San Diego, CA, USA, 30 April 2014; SPIE: Bellingham, WA, USA, 2014; Volume 9056, p. 905618. [Google Scholar] [CrossRef]

- Tairych, A.; Anderson, I.A. Distributed sensing: Multiple capacitive stretch sensors on a single channel. In Proceedings of the SPIE Electroactive Polymer Actuators and Devices, Portland, OR, USA, 26–29 March 2017; SPIE: Bellingham, WA, USA, 2017; Volume 10163, p. 1016306. [Google Scholar] [CrossRef]

- Shahinpoor, M.; Bar-Cohen, Y.; Simpson, J.O.; Smith, J. Ionic polymer-metal composites (IPMCs) as biomimetic sensors, actuators and artificial muscles—A review. Smart Mater. Struct. 1998, 7, R15–R30. [Google Scholar] [CrossRef]

- Ramadan, K.S.; Sameoto, D.; Evoy, S. A review of piezoelectric polymers as functional materials for electromechanical transducers. Smart Mater. Struct. 2014, 23, 033001. [Google Scholar] [CrossRef]

- Ju, W.-E.; Moon, Y.-J.; Park, C.-H.; Choi, S.T. A flexible tactile-feedback touch screen using transparent ferroelectric polymer film vibrators. Smart Mater. Struct. 2014, 23, 074004. [Google Scholar] [CrossRef]

- Pendão, C.; Silva, I. Optical fiber sensors and sensing networks: Overview of the main principles and applications. Sensors 2022, 22, 7554. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; O’Brien, K.; Li, S.; Shepherd, R.F. Optoelectronically innervated soft prosthetic hand via stretchable optical waveguides. Sci. Robot. 2016, 1, eaai7529. [Google Scholar] [CrossRef]

- Harnett, C.K.; Zhao, H.; Shepherd, R.F. Stretchable optical fibers: Threads for strain-sensitive textiles. Adv. Mater. Technol. 2017, 2, 1700087. [Google Scholar] [CrossRef]

- Guo, J.; Liu, X.; Jiang, N.; Yetisen, A.K.; Yuk, H.; Yang, C.; Khademhosseini, A.; Zhao, X.; Yun, S.-H. Highly stretchable, strain sensing hydrogel optical fibers. Adv. Mater. 2016, 28, 10244–10249. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.; Bae, K.S.; Kim, G.; Lee, D.-Y.; Moon, G.; Yang, D.; Lee, H.; An, J.; Park, J.; Yoon, S.; et al. Sensor organic light-emitting diode display, combining fingerprint and biomarker capturing. Commun. Eng. 2024, 3, 92. [Google Scholar] [CrossRef]

- Lee, S.; Kim, M.K.; Kwon, S.; Leong, J.C.; Noh, B.; Sim, J.; Jeong, E.G.; Lee, H.J.; Choi, K.C. Advanced Micro-OLED Integration on Thin and Flexible Polymer Neural Probes for Targeted Optogenetic Stimulation. Adv. Funct. Mat. 2025, 35, 2420758. [Google Scholar] [CrossRef]

- Missinne, J.; Kalathimekkad, S.; Van Hoe, B.; Bosman, E.; Vanfleteren, J.; Van Steenberge, G. Stretchable optical waveguides. Opt. Exp. 2014, 22, 4168–4179. [Google Scholar] [CrossRef]

- Song, J.; Kim, K.H.; Kim, E.; Moon, C.K.; Kim, Y.H.; Kim, J.J.; Yoo, S. Lensfree OLEDs with over 50% external quantum efficiency via external scattering and horizontally oriented emitters. Nat. Commun. 2018, 9, 3207. [Google Scholar] [CrossRef]

- Bi, H.; Chen, D.; Li, D.; Yuan, Y.; Xia, D.; Zhang, Z.; Zhang, H.; Wang, Y. A green emissive amorphous fac-Alq3 solid generated by grinding crystalline blue fac-Alq3 powder. Chem. Commun. 2011, 47, 4135–4137. [Google Scholar] [CrossRef]

- Hung, S.-Y.; Kao, R.-L.; Lin, K.-Y.; Yang, C.-C.; Lin, K.-S.; Chao, Y.-C.; Wang, J.-S.; Shen, J.-L.; Chiu, K.-C. Characterization of facial and meridional Alq3 thin films fabricated from physical vapor transport at high substrate temperatures. Mater. Chem. Phys. 2015, 154, 100–106. [Google Scholar] [CrossRef]

- Danyliv, Y.; Ivaniuk, K.; Danyliv, I.; Bezvikonnyi, O.; Volyniuk, D.; Galyna, S.; Lazauskas, A.; Skhirtladze, L.; Ågren, H.; Stakhira, P.; et al. Carbazole-σ-sulfobenzimide derivative exhibiting mechanochromic thermally activated delayed fluorescence as emitter for flexible OLEDs: Theoretical and experimental insights. Dyes Pigm. 2023, 208, 110841. [Google Scholar] [CrossRef]

- Zhan, Z.; Sun, Q.; Tang, C.; Wu, H.; Lu, Y. Ultra-highly sensitive and self-healing flexible strain sensor with a wide measuring range based on a bilayer structure. Sens. Actuators A Phys. 2023, 360, 114510. [Google Scholar] [CrossRef]

- Cui, X.; Jiang, Y.; Xu, Z.; Xi, M.; Jiang, Y.; Song, P.; Zhao, Y.; Wang, H. Stretchable strain sensors with dentate groove structure for enhanced sensing recoverability. Compos. Part B Eng. 2021, 211, 108641. [Google Scholar] [CrossRef]

- Drissi-Habti, M.; Raman, V. Fatigue behavior of smart composites with distributed fiber optic sensors for offshore applications. J. Compos. Sci. 2021, 6, 2. [Google Scholar] [CrossRef]

- Zahri, N.N.A.H.; Nordin, A.N.; Azlan, N.Z.; Hassan, I.H.; Tung, L.H.; Lim, L.M.; Samsudin, Z. Wearable strain sensors: Design shapes, fabrication, encapsulation and performance evaluation methods. Sens. Diagn. 2024, 3, 1635–1650. [Google Scholar] [CrossRef]

- Zou, Y.; Zhong, M.; Li, S.; Qing, Z.; Xing, X.; Gong, G.; Yan, R.; Qin, W.; Shen, J.; Zhang, H.; et al. Flexible wearable strain sensors based on laser-induced graphene for monitoring human physiological signals. Polymers 2023, 15, 3553. [Google Scholar] [CrossRef]

- Mou, Y.; Wang, C.; Liu, S.; Liu, L.; Duan, J.A. Flexible Vibration Sensors with Omnidirectional Sensing Enabled by Femtosecond Laser-Assisted Fabrication. Polymers 2025, 17, 211. [Google Scholar] [CrossRef] [PubMed]

- Homayounfar, S.Z.; Andrew, T.L. Wearable sensors for monitoring human motion: A review on mechanisms, materials, and challenges. SLAS Technol. 2020, 25, 9–24. [Google Scholar] [CrossRef]

- Park, J.W.; Kim, T.; Kim, D.; Hong, Y.; Gong, H.S. Measurement of finger joint angle using stretchable carbon nanotube strain sensor. PLoS ONE 2019, 14, e0225164. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; An, H.S.; Park, J. Highly Sensitive Light Guide Sensor for Multilocation and Multimodal Deformation Decoupling Using Flexible OLED. Photonics 2025, 12, 909. https://doi.org/10.3390/photonics12090909

Lee H, An HS, Park J. Highly Sensitive Light Guide Sensor for Multilocation and Multimodal Deformation Decoupling Using Flexible OLED. Photonics. 2025; 12(9):909. https://doi.org/10.3390/photonics12090909

Chicago/Turabian StyleLee, Hayoon, Hyeon Seok An, and Jongwook Park. 2025. "Highly Sensitive Light Guide Sensor for Multilocation and Multimodal Deformation Decoupling Using Flexible OLED" Photonics 12, no. 9: 909. https://doi.org/10.3390/photonics12090909

APA StyleLee, H., An, H. S., & Park, J. (2025). Highly Sensitive Light Guide Sensor for Multilocation and Multimodal Deformation Decoupling Using Flexible OLED. Photonics, 12(9), 909. https://doi.org/10.3390/photonics12090909