Complete Suppression of Color Dispersion in Quantum-Dot Backlights by Optimizing Optical Configuration of Films

Abstract

1. Introduction

2. Experiments

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Kybayashi, S.; Mikoshiba, S.; Lim, S. (Eds.) LCD Backlights; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- Schubert, E.F.; Kim, J.K.; Luo, H.; Xi, J.-Q. Solid-state lighting—A benevolent technology. Rep. Prog. Phys. 2006, 69, 3069. [Google Scholar] [CrossRef]

- Pust, P.; Schmidt, P.J.; Schnick, W. A revolution in lighting. Nat. Mater. 2015, 14, 454. [Google Scholar] [CrossRef]

- Lin, C.C.; Liu, R.-S. Advances in phosphors for light-emitting diodes. J. Phys. Chem. Lett. 2011, 2, 1268. [Google Scholar] [CrossRef]

- McKittrick, J.; Shea-Rohwer, L.E. Down conversion materials for solid-state lighting. J. Am. Ceram. Soc. 2014, 97, 1327. [Google Scholar] [CrossRef]

- Choi, H.-W.; Choi, M.H.; Ko, J.-H. Effect of Temperature on the Luminous Properties of White-light-emitting Diodes with Red and Green Phosphors. New Phys. Sae Mulli 2013, 63, 1149. [Google Scholar] [CrossRef]

- Erdem, T.; Demir, H.V. Color science of nanocrystal quantum dots for lighting and displays. Nanophotonics 2013, 2, 57. [Google Scholar] [CrossRef]

- Bae, W.K.; Lim, J.; Lee, D.; Park, M.; Lee, H.; Kwak, J.; Char, K.; Lee, C.; Lee, S. R/G/B/natural white light thin colloidal quantum dot-based light-emitting devices. Adv. Mater. 2014, 26, 6387. [Google Scholar] [CrossRef] [PubMed]

- Lim, S.J.; Zahid, M.U.; Le, P.; Ma, L.; Entenberg, D.; Harney, A.S.; Condeelis, J.; Smith, A.M. Brightness-equalized quantum dots. Nat. Commun. 2015, 6, 8210. [Google Scholar] [CrossRef]

- Lim, J.; Park, Y.S.; Wu, K.; Yun, H.J.; Klimov, V.I. Droop-free colloidal quantum dot light-emitting diodes. Nano Lett. 2018, 18, 6645. [Google Scholar] [CrossRef]

- Denault, K.A.; Mikhailovsky, A.A.; Brinkley, S.; DenBaars, S.P.; Seshadri, R. Improving color rendition in solid state white lighting through the use of quantum dots. J. Mater. Chem. C 2013, 1, 1461. [Google Scholar] [CrossRef]

- Chung, S.-R.; Chen, S.-S.; Wang, K.-W.; Siao, C.-B. Promotion of solid-state lighting for ZnCdSe quantum dot modified-YAG-based white light-emitting diodes. RSC Adv. 2016, 6, 51989. [Google Scholar] [CrossRef]

- Li, C.; Murase, N. Synthesis of Highly Luminescent Glasses Incorporating CdTe Nanocrystals through Sol-Gel Processing. Langmuir 2004, 20, 1. [Google Scholar] [CrossRef]

- Bullen, C.; Mulvaney, P.; Sada, C.; Ferrari, M.; Chiasera, A.; Martucci, A. Incorporation of a highly luminescent semiconductor quantum dot in ZrO2–SiO2 hybrid sol–gel glass film. J. Mater. Chem. 2004, 14, 1112. [Google Scholar] [CrossRef]

- Tetsuya, H.; Ebina, T.; Mizukami, F. Highly luminescent flexible quantum dot-clay films. Adv. Mater. 2008, 20, 3039. [Google Scholar] [CrossRef]

- Mutlugun, E.; Hernandez-Martinez, P.L.; Eroglu, C.; Coskun, Y.; Erdem, T.; Sharma, V.K.; Unal, E.; Panda, S.K.; Hicky, S.G.; Gaponik, N.; et al. Large-Area (over 50 cm × 50 cm) Freestanding Films of Colloidal InP/ZnS Quantum Dots. Nano Lett. 2012, 12, 3986. [Google Scholar] [CrossRef]

- Kim, J.-H.; Yang, H. White lighting device from composite films embedded with hydrophilic Cu(In, Ga)S2/ZnS and hydrophobic InP/ZnS quantum dots. Nanotechnology 2014, 25, 225601. [Google Scholar] [CrossRef]

- Lien, J.-Y.; Chen, C.-J.; Chiang, R.-K.; Wang, S.-L. High color-rendering warm-white lamps using quantum-dot color conversion films. Opt. Express 2016, 24, A1021. [Google Scholar] [CrossRef] [PubMed]

- Jang, E.; Jun, S.; Jang, H.; Lim, J.; Kim, B.; Kim, Y. White-light-emitting diodes with quantum dot color converters for display backlights. Adv. Mater. 2010, 22, 3076. [Google Scholar] [CrossRef] [PubMed]

- Jun, S.; Lee, J.; Jang, E. Highly luminescent and photostable quantum dot–silica monolith and its application to light-emitting diodes. ACS Nano 2013, 7, 1472. [Google Scholar] [CrossRef]

- Altintas, Y.; Genc, S.; Talpur, M.Y.; Mutlugun, E. CdSe/ZnS quantum dot films for high performance flexible lighting and display applications. Nanotechnology 2016, 27, 295604. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.-W.; Zhu, R.-D.; He, J.; Duan, W.; Hu, W.; Lu, Y.-Q.; Li, M.-C.; Lee, S.-L.; Dong, Y.-J.; Wu, S.-T. Going beyond the limit of an LCD’s color gamut. Light Sci. Appl. 2017, 6, e17043. [Google Scholar] [CrossRef]

- Abe, S.; Joos, J.J.; Martin, L.I.D.; Hens, Z.; Smet, P.F. Hybrid remote quantum dot/powder phosphor designs for display backlights. Light Sci. Appl. 2017, 6, e16271. [Google Scholar] [CrossRef]

- Chen, E.; Xie, H.; Huang, J.; Miu, H.; Shao, G.; Li, Y.; Guo, T.; Xu, S.; Ye, Y. Flexible/curved backlight module with quantum-dots microstructure array for liquid crystal displays. Opt. Express 2018, 26, 3466. [Google Scholar] [CrossRef]

- Yang, X.; Lan, X.-Y.; Liu, Y.-S.; Yang, H.-Y.; Li, Y.; Zheng, S.-W. Highly Stable White Light-Emitting Diodes Based on Quantum-Dots Dispersed Into the Backlight Lens for Display Backlight. IEEE Photonics J. 2019, 11, 8200707. [Google Scholar] [CrossRef]

- Kim, S.J.; Jang, H.W.; Lee, J.-G.; Ko, J.-H.; Ko, Y.W.; Kim, Y. Substantial Improvement of Color-Rendering Properties of Conventional White LEDs Using Remote-Type Red Quantum-Dot Caps. New Phys. Sae Mulli 2019, 69, 861. [Google Scholar] [CrossRef]

- Lee, J.-G.; Ko, J.-H. Simulation Study on the Improvement of the Luminance and the Color Uniformities of Integrated Quantum-Dot Backlights for LCD Applications. J. Korean Phys. Soc. 2020, 77, 264. [Google Scholar] [CrossRef]

- Halder, S.; Shin, Y.; Zhou, Z.; Zhang, X.; Hu, L.; Yang, D.-K. Aligned polymer dispersed liquid crystal film for light enhancement of quantum dot backlight. Opt. Express 2021, 29, 43241. [Google Scholar] [CrossRef]

- Lee, G.J.; Lee, J.-G.; Kim, Y.; Park, T.; Ko, Y.W.; Ko, J.-H. The effect of the reflective property of a reflection film on the performance of backlight units with quantum-dot films for LCD applications. J. Inf. Disp. 2021, 22, 55. [Google Scholar] [CrossRef]

- Chen, Y.L.; Ye, Z.T.; Lai, W.; Chiu, C.C.; Lin, K.W.; Han, P. Application of mini-LEDs with microlens arrays and quantum dot film as extra-thin, large-area, and high-luminance backlight. Nanomaterials 2022, 12, 1032. [Google Scholar] [CrossRef]

- Huang, B.; Chen, E.; Sun, L.; Guo, T. Quantum-dot color conversion film patterned by screen printing and overprinting process for display backlights. Opt. Laser Technol. 2022, 145, 107486. [Google Scholar] [CrossRef]

- Lee, T.-Y.; Huang, W.-T.; Chen, J.-H.; Liu, W.-B.; Chang, S.-W.; Chen, F.-C.; Kuo, H.-C. Optimized design with artificial intelligence quantum dot white mini LED backlight module development. Crystals 2023, 13, 1411. [Google Scholar] [CrossRef]

- Luo, Z.; Chen, Y.; Wu, S.-T. Wide color gamut LCD with a quantum dot backlight. Opt. Express 2023, 21, 26269. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, Y.; Cai, J.; Deng, L.; Xu, S.; Ye, Y.; Yan, Q.; Guo, T.; Chen, E. Uniformity improvement of a mini-LED backlight by a quantum-dot color conversion film with nonuniform thickness. Opt. Lett. 2023, 48, 5643. [Google Scholar] [CrossRef]

- Lee, S.-M.; Choo, H.-H.; Jang, J.-H.; Kwak, M.-J.; Baek, E.; Kim, S.; Ko, J.-H. Correlation between the gain factor of a reflective polarizer and the optical structure of quantum dot-based backlights for LCD applications. J. Korean Phys. Soc. 2024, 85, 915. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Q.; Yu, B.; Lemmer, U. A Review on Quantum Dot-Based Color Conversion Layers for Mini/Micro-LED Displays: Packaging, Light Management, and Pixelation. Adv. Opt. Mater. 2024, 12, 2300873. [Google Scholar] [CrossRef]

- Xu, B.; Zhou, J.; Zhang, C.; Chang, Y.; Deng, Z. Research Progress on Quantum Dot-Embedded Polymer Films and Plates for LCD Backlight Display. Polymers 2025, 17, 233. [Google Scholar] [CrossRef]

- Baek, E.; Kim, B.; Kim, S.; Song, J.; Yoo, J.; Park, S.M.; Lee, J.-M.; Ko, J.-H. Color Rendering Index over 95 Achieved by Using Light Recycling Process Based on Hybrid Remote-Type Red Quantum-Dot Components Applied to Conventional LED Lighting Devices. Nanomaterials 2023, 13, 2560. [Google Scholar] [CrossRef]

- Lee, G.; Lee, H.; Cho, J.; Choi, I.; Park, S.M.; Ko, J.-H. Study on High-Efficiency White Light-Emitting Diodes Using a Remote Phosphor with Cadmium-Free Quantum Dots. New Phys. Sae Mulli 2023, 73, 703. [Google Scholar] [CrossRef]

- Yoo, J.; Baek, E.; Kim, S.; Lee, H.; Park, S.M.; Ko, J.-H. Tunable viewing angle characteristics of QD-enhanced LED lighting through combinations of holographic diffuser and prism film. J. Korean Phys. Soc. 2025, 86, 1101. [Google Scholar] [CrossRef]

- Shi, L.; Chen, S. Over 32.5% Efficient Top-Emitting Quantum-Dot LEDs with Angular-Independent Emission. ACS Appl. Mater. Interfaces 2022, 14, 30039. [Google Scholar] [CrossRef] [PubMed]

- Dai, B.-L.; Ji, J.-W.; Wu, B.-H.; Chen, K.-A.; Kuroda, H.; Kou, H.-C.; Akada, T.; Li, C.-Y. Investigation and comparison of the influence of modified DBR and yellow color filters for quantum dot color conversion-based micro LED applications. Heliyon 2024, 10, e35492. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Li, R.; Wu, L.; Lin, X.; Xia, X.; Ao, Z.; Sun, X.; Chen, X.; Chen, S. Ultrabright and stable top-emitting quantum-dot light-emitting diodes with negligible angular color shift. Nat. Commun. 2024, 15, 5161. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.G.; Jeong, J.H.; Lee, J.-Y.; Nahm, K.-B.; Ko, J.-H.; Kim, J.H. Light output characteristics of rounded prism films in the backlight unit for liquid crystal display. J. Inf. Disp. 2006, 7, 1. [Google Scholar] [CrossRef]

- Watson, P.; Boyd, G.T. Mobile Displays; Bhowmik, A.K., Li, Z., Bos, P.J., Eds.; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar]

- Won, Y.-H.; Cho, O.; Kim, T.; Chung, D.-Y.; Kim, T.; Chung, H.; Jang, H.; Lee, J.; Kim, D.; Jang, E. Highly efficient and stable InP/ZnSe/ZnS quantum dot light-emitting diodes. Nature 2019, 575, 634. [Google Scholar] [CrossRef] [PubMed]

| Haze | Total Transmittance | Parallel Transmittance | Diffuse Transmittance | |

|---|---|---|---|---|

| DF(HighH) | 97.07 | 95.55 | 2.8 | 92.75 |

| DF(LowH) | 67.96 | 91.38 | 29.28 | 62.10 |

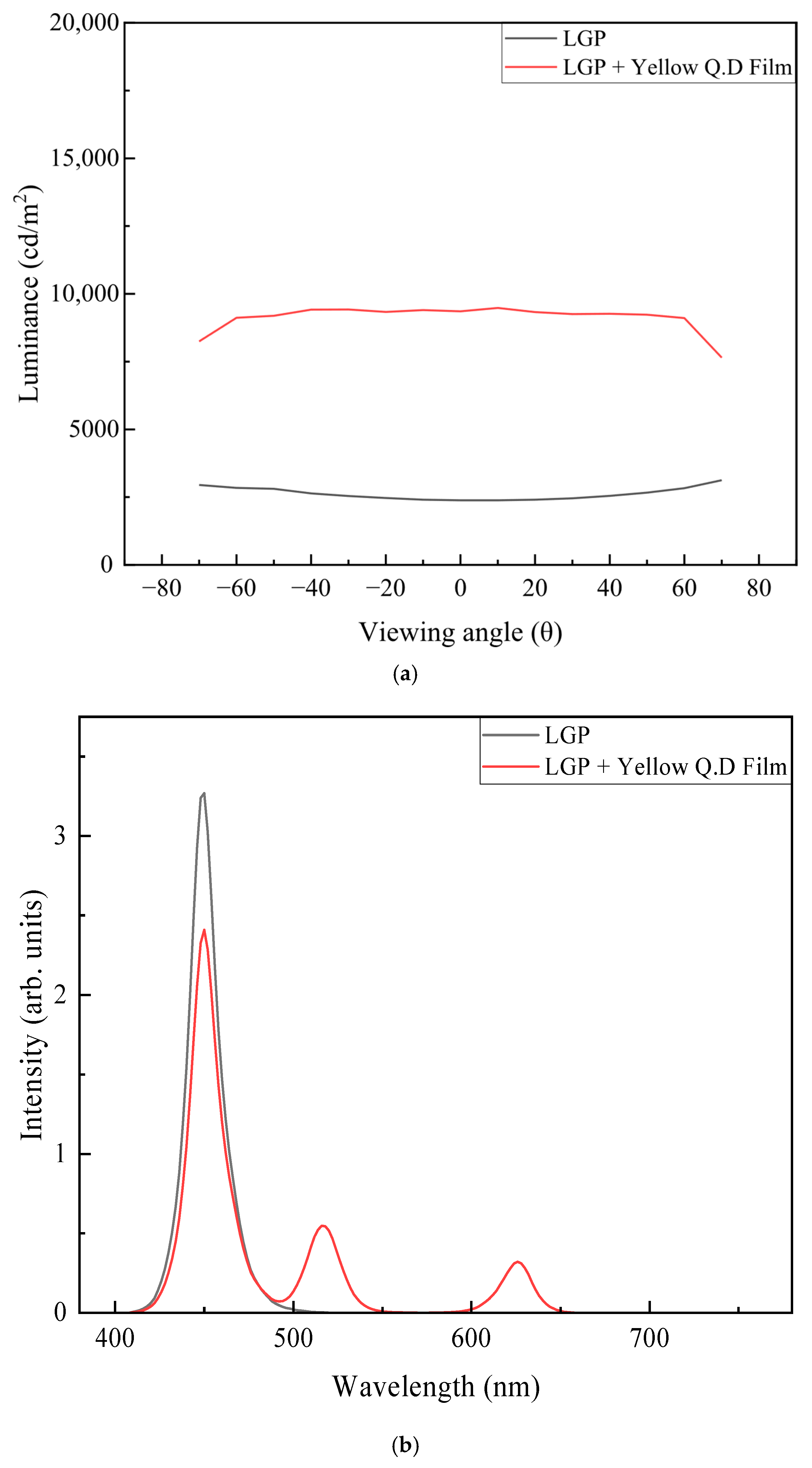

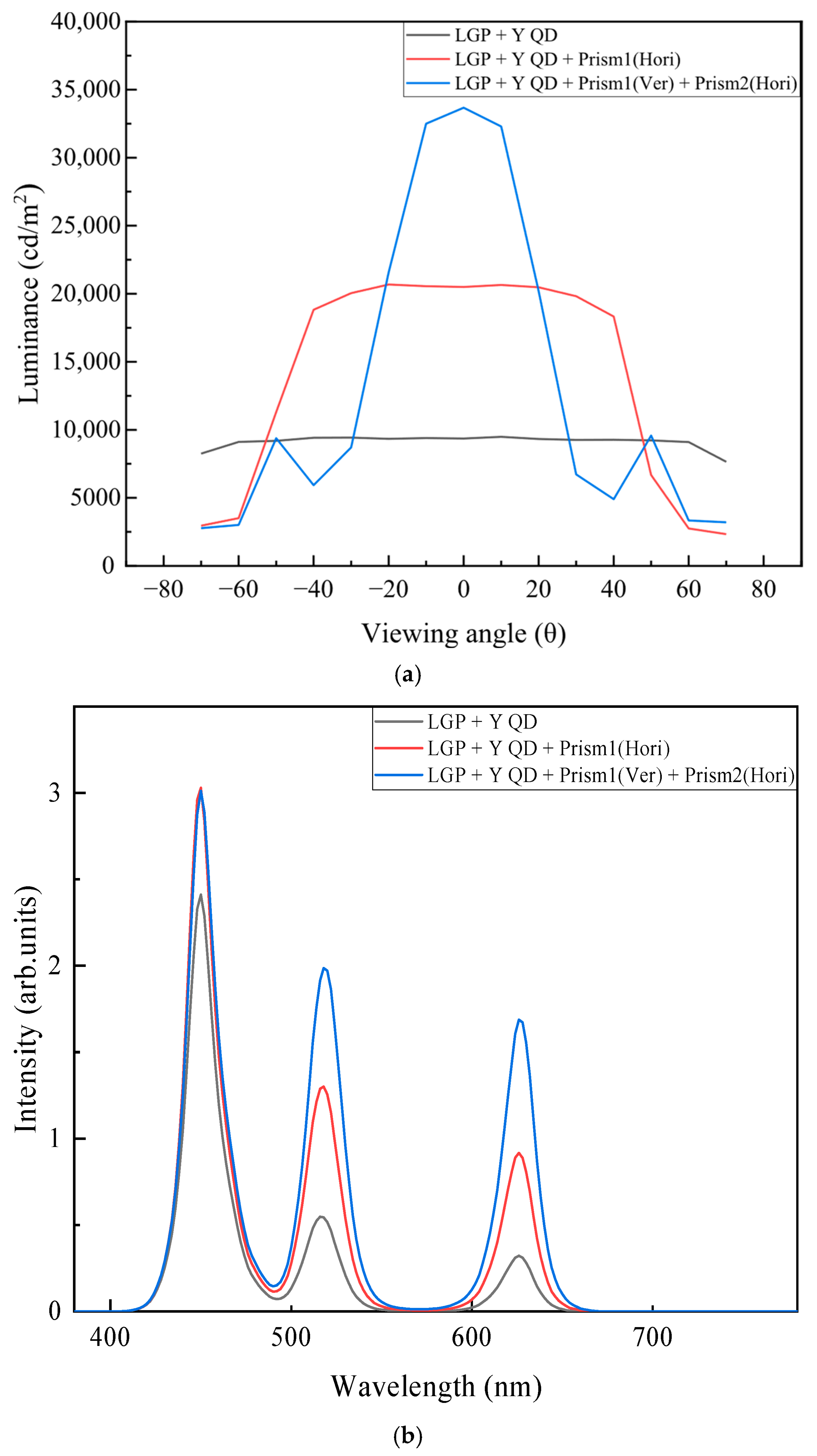

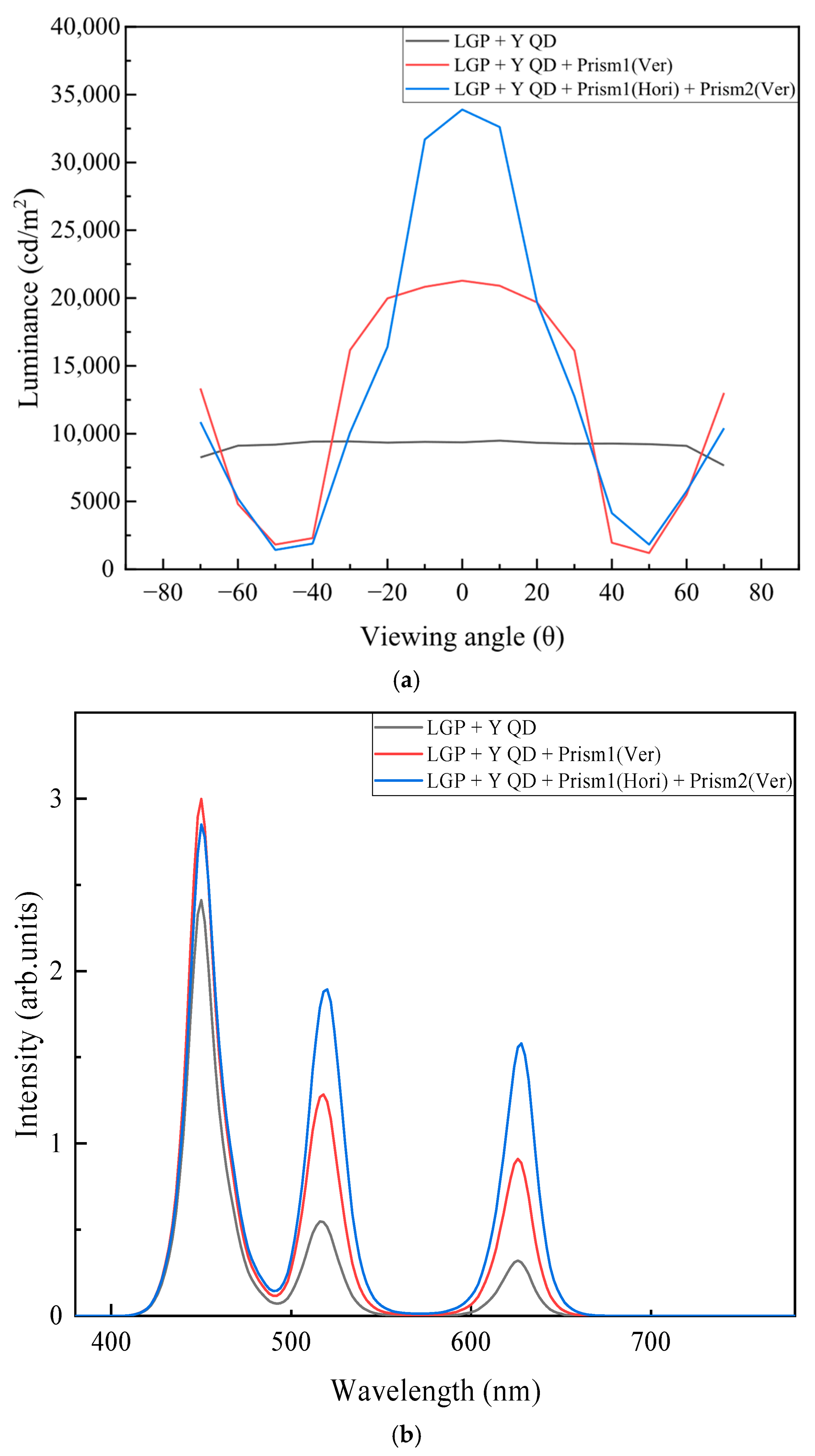

| Combination of Optical Films | Luminance (cd/m2) | x | y |

|---|---|---|---|

| LGP | 2380 | 0.1532 | 0.0232 |

| LGP + YQD | 9357 | 0.1787 | 0.1045 |

| LGP + YQD + P1(Hori) | 20,500 | 0.2076 | 0.1674 |

| LGP + YQD + P1(Ver) | 21,280 | 0.2081 | 0.1647 |

| LGP + YQD + P1(Ver) + P2(Hori) | 33,310 | 0.2422 | 0.2176 |

| LGP + YQD + P1(Hori) + P2(Ver) | 33,900 | 0.2433 | 0.2199 |

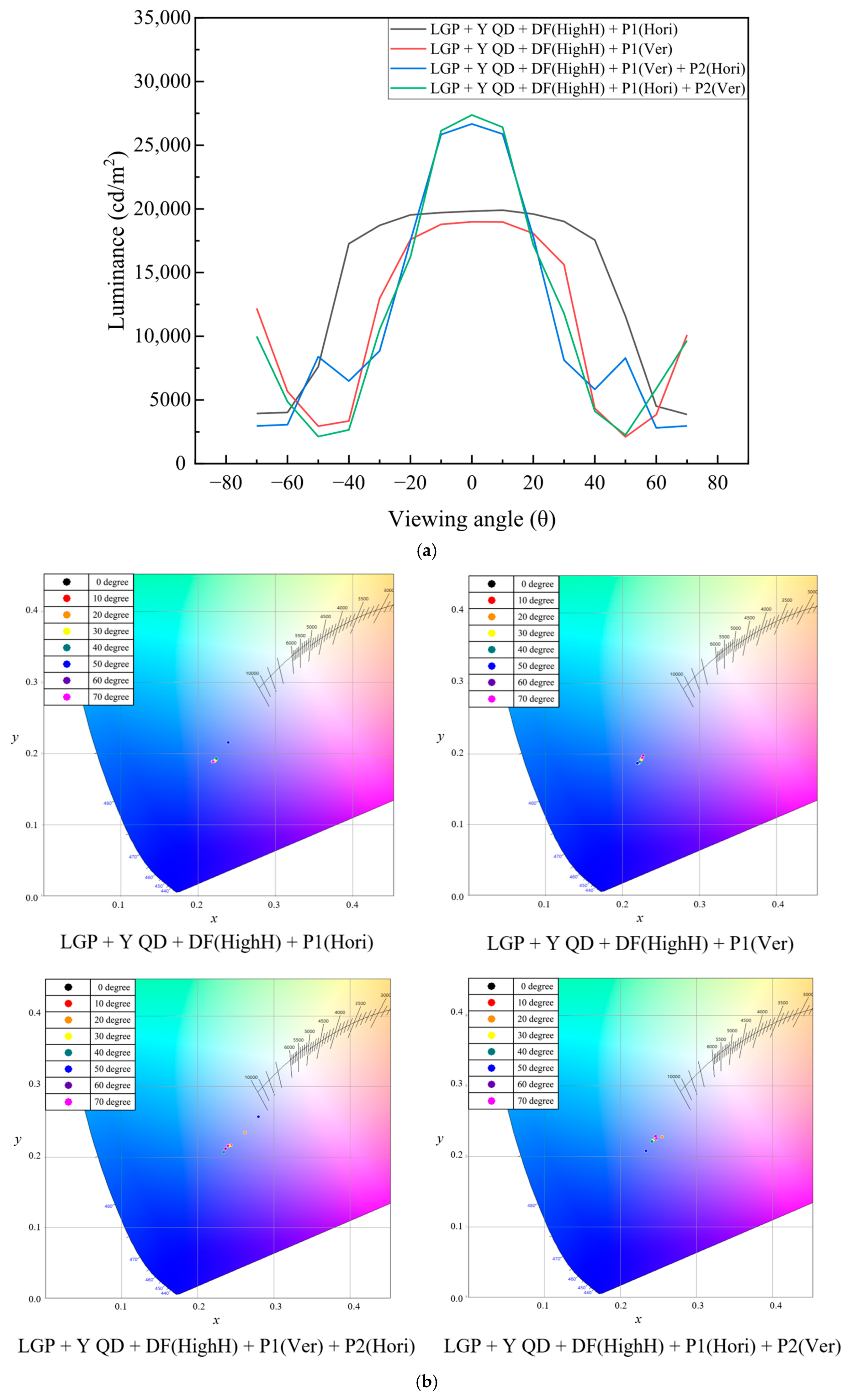

| LGP + YQD + DF(HighH) + P1(Hori) | 19,820 | 0.2216 | 0.189 |

| LGP + YQD + DF(HighH) + P1(Ver) | 18,990 | 0.2212 | 0.1867 |

| LGP + YQD + DF(HighH) + P1(Ver) + P2(Hori) | 27,240 | 0.2426 | 0.2151 |

| LGP + YQD + DF(HighH) + P1(Hori) + P2(Ver) | 27,370 | 0.2465 | 0.2243 |

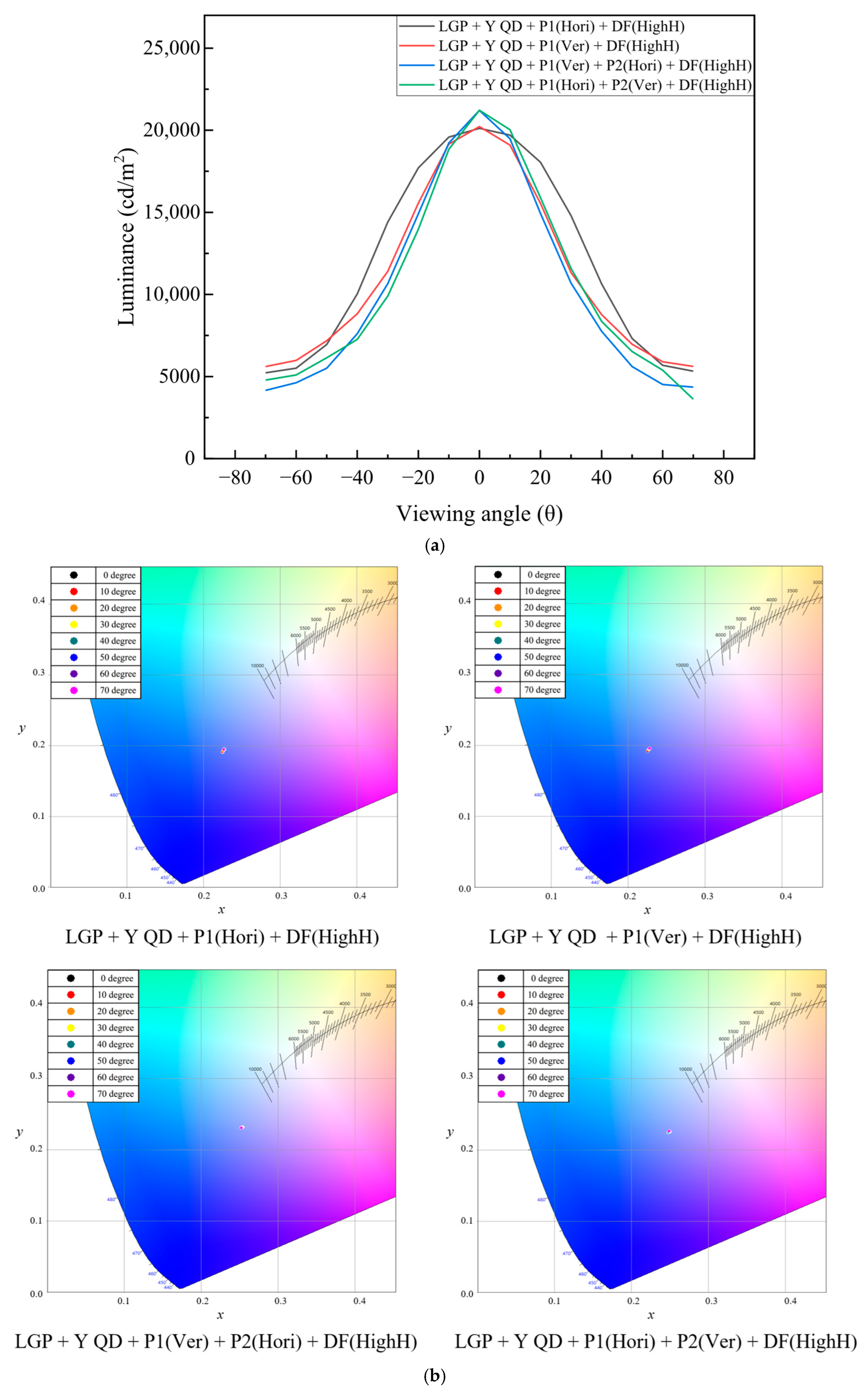

| LGP + YQD + P1(Hori) + DF(HighH) | 20,120 | 0.2247 | 0.1907 |

| LGP + YQD + P1(Hori) + DF(LowH) | 19,660 | 0.2149 | 0.181 |

| LGP + YQD + P1(Ver) + DF(HighH) | 20,220 | 0.2255 | 0.1915 |

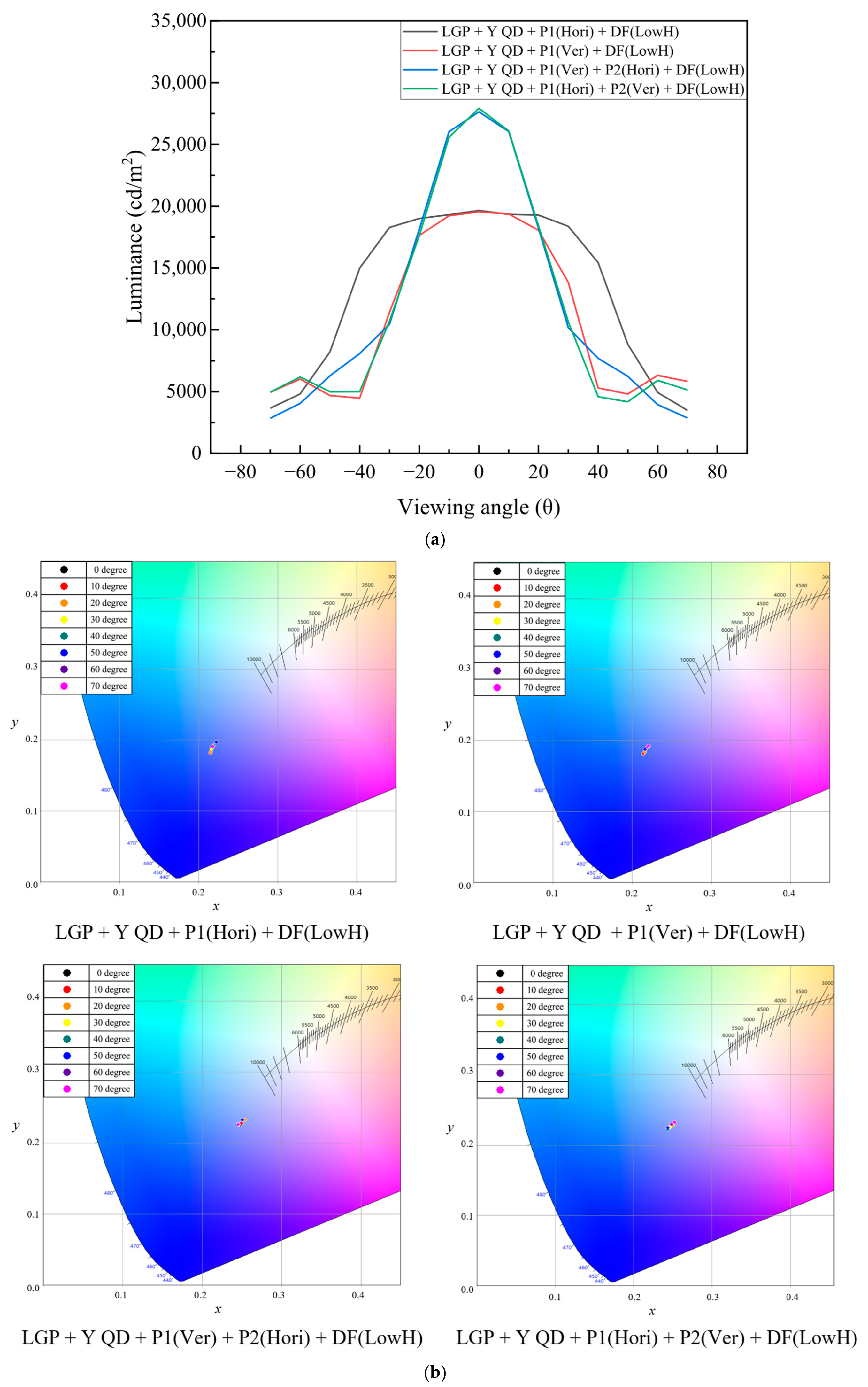

| LGP + YQD + P1(Ver) + DF(LowH) | 19,560 | 0.2145 | 0.1808 |

| LGP + YQD + P1(Ver) + P2(Hori) + DF(HighH) | 21,210 | 0.2544 | 0.2319 |

| LGP + YQD + P1(Ver) + P2(Hori) + DF(LowH) | 27,640 | 0.2482 | 0.2257 |

| LGP + YQD + P1(Hori) + P2(Ver) + DF(HighH) | 16,080 | 0.2498 | 0.2256 |

| LGP + YQD + P1(Hori) + P2(Ver) + DF(LowH) | 27,930 | 0.2477 | 0.2262 |

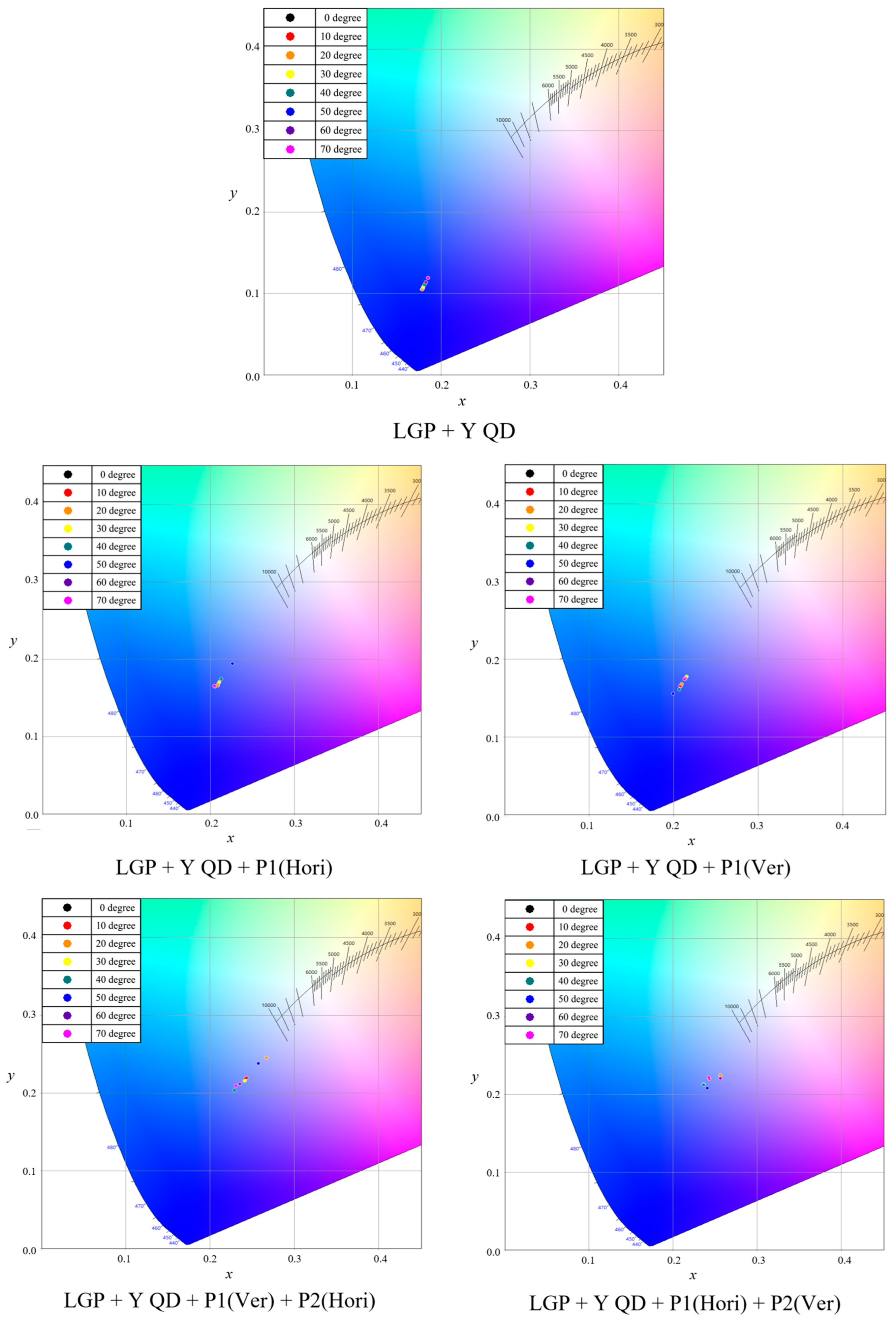

| Combination of Optical Films | Reference (0°) | Angle | Δx | Δy | Δxy |

|---|---|---|---|---|---|

| LGP + Y QD + P1(Hori) + P2(Ver) | (0.2433, 0.2199) | 10° | 0.0001 | 0.0001 | 0.0001 |

| 30° | −0.0066 | −0.0074 | 0.0099 | ||

| 50° | −0.0023 | −0.0123 | 0.0125 | ||

| 70° | −0.0005 | 0.0012 | 0.0013 | ||

| LGP + Y QD + DF(HighH) + P1(Ver) + P2(Hori) | (0.2426, 0.2151) | 10° | 0.0009 | 0.0015 | 0.0017 |

| 30° | −0.0003 | 0.0007 | 0.0008 | ||

| 50° | 0.0372 | 0.0422 | 0.0563 | ||

| 70° | −0.0028 | 0.0007 | 0.0029 | ||

| LGP + Y QD + P1(Hori) + P2(Ver) + DF(HighH) | (0.2498, 0.2256) | 10° | −0.0002 | −0.0001 | 0.0002 |

| 30° | −0.0016 | −0.0012 | 0.002 | ||

| 50° | −0.0004 | 0.0004 | 0.0006 | ||

| 70° | −0.0006 | 0.0007 | 0.0009 | ||

| LGP + Y QD + P1(Ver) + P2(Hori) + DF(LowH) | (0.2482, 0.2257) | 10° | 0.0015 | 0.0019 | 0.0024 |

| 30° | −0.002 | 0 | 0.002 | ||

| 50° | 0.0027 | 0.0065 | 0.007 | ||

| 70° | −0.0026 | 0.0001 | 0.0026 | ||

| 65-Inch QD-Mini LED TV | (0.2989, 0.2619) | 10° | −0.0002 | −0.0001 | 0.0002 |

| 30° | 0.0033 | 0.0037 | 0.005 | ||

| 50° | 0.0026 | 0.0028 | 0.0038 | ||

| 70° | 0.0044 | 0.0055 | 0.007 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.-H.; Kim, J.-Y.; Seo, M.-H.; Yang, J.-S.; Ko, J.-H. Complete Suppression of Color Dispersion in Quantum-Dot Backlights by Optimizing Optical Configuration of Films. Photonics 2025, 12, 864. https://doi.org/10.3390/photonics12090864

Kim D-H, Kim J-Y, Seo M-H, Yang J-S, Ko J-H. Complete Suppression of Color Dispersion in Quantum-Dot Backlights by Optimizing Optical Configuration of Films. Photonics. 2025; 12(9):864. https://doi.org/10.3390/photonics12090864

Chicago/Turabian StyleKim, Do-Hyeon, Jin-Young Kim, Mu-Hyeok Seo, Ju-Seok Yang, and Jae-Hyeon Ko. 2025. "Complete Suppression of Color Dispersion in Quantum-Dot Backlights by Optimizing Optical Configuration of Films" Photonics 12, no. 9: 864. https://doi.org/10.3390/photonics12090864

APA StyleKim, D.-H., Kim, J.-Y., Seo, M.-H., Yang, J.-S., & Ko, J.-H. (2025). Complete Suppression of Color Dispersion in Quantum-Dot Backlights by Optimizing Optical Configuration of Films. Photonics, 12(9), 864. https://doi.org/10.3390/photonics12090864