Cladding–Thickness–Dependent Performance of SMS Optical Fiber Sensors

Abstract

1. Introduction

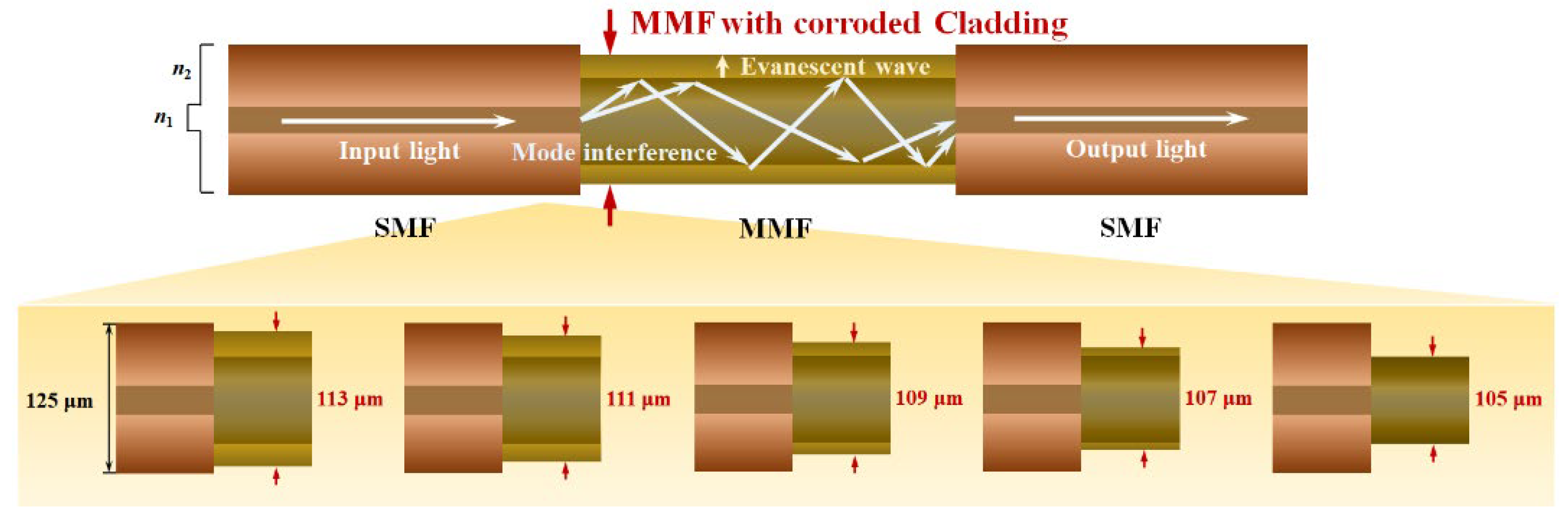

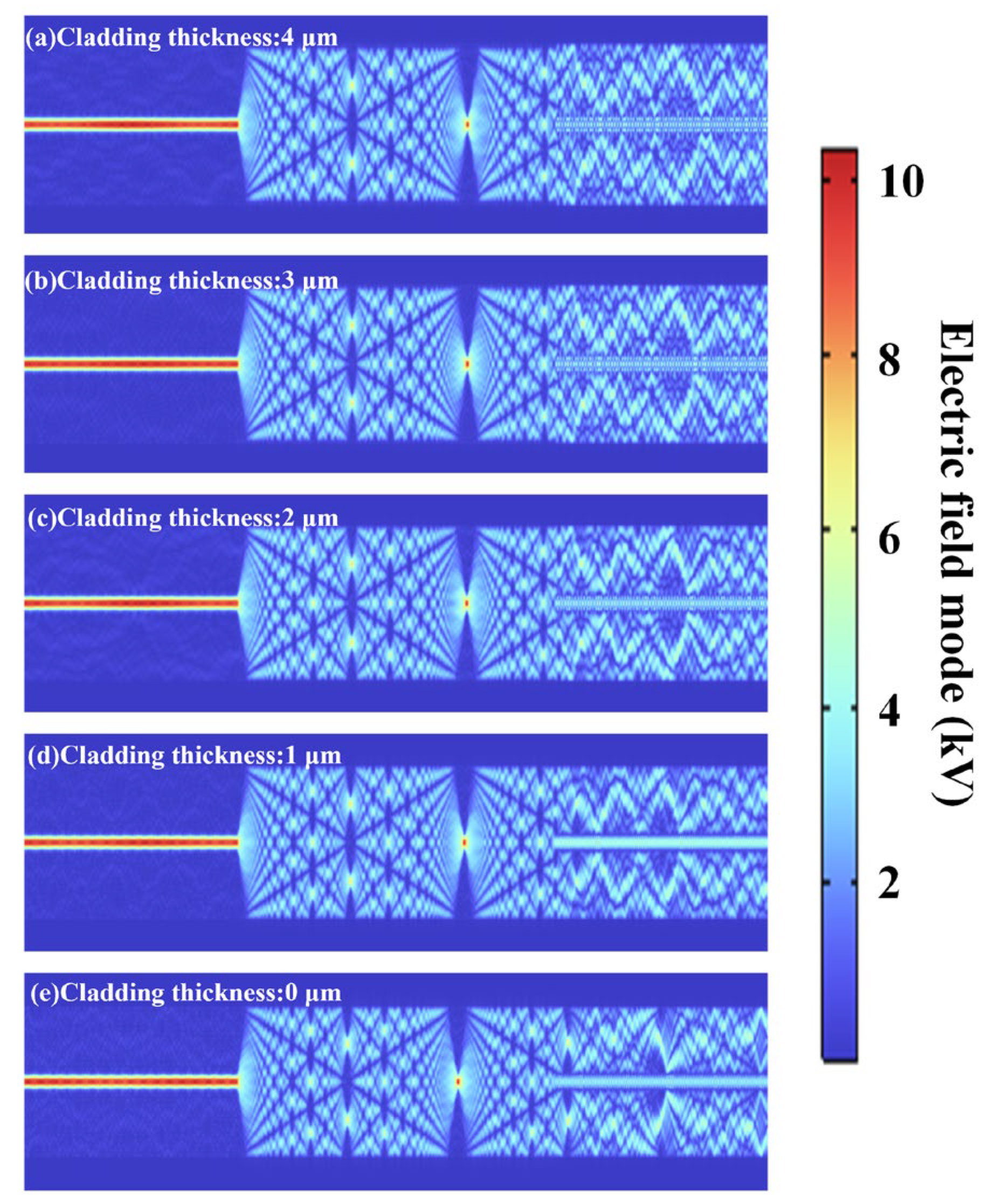

2. Sensor Fabrication and Principle

3. Results and Comprehensive Evaluation

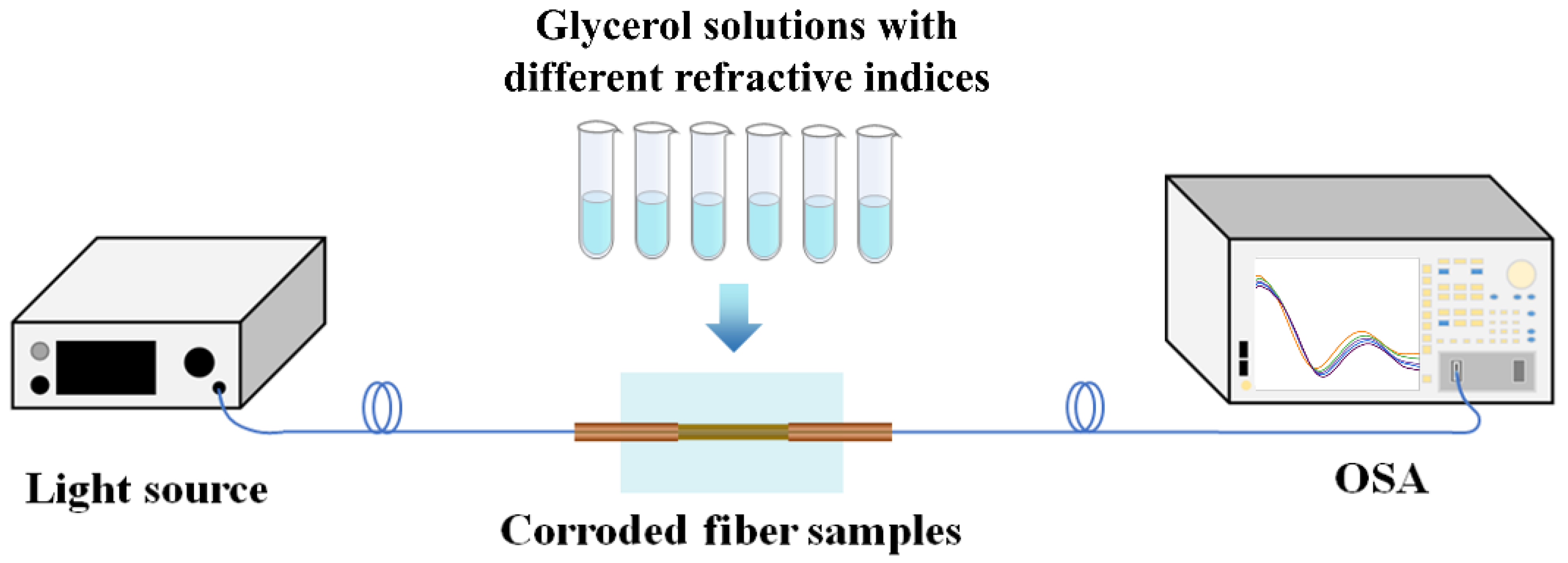

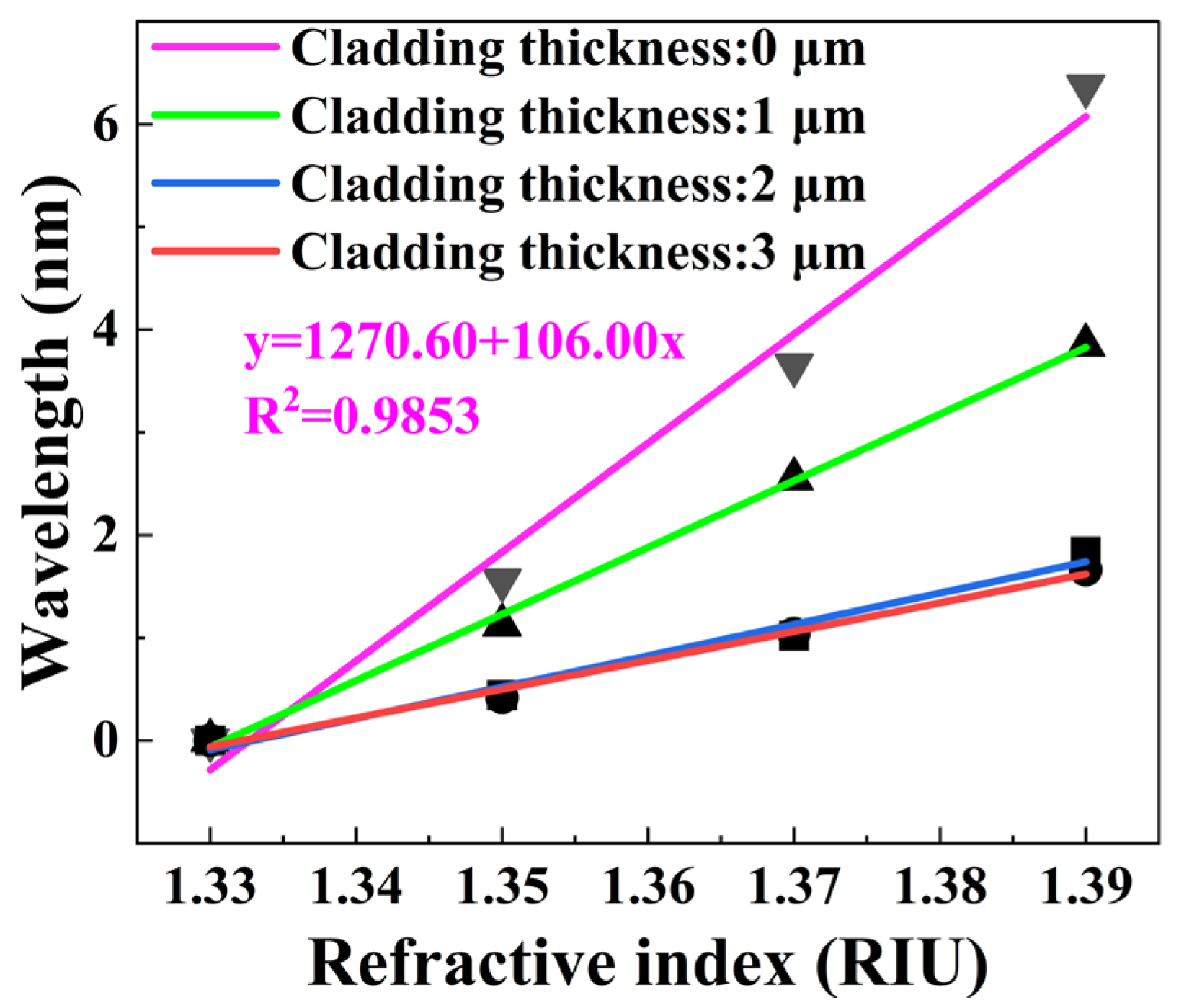

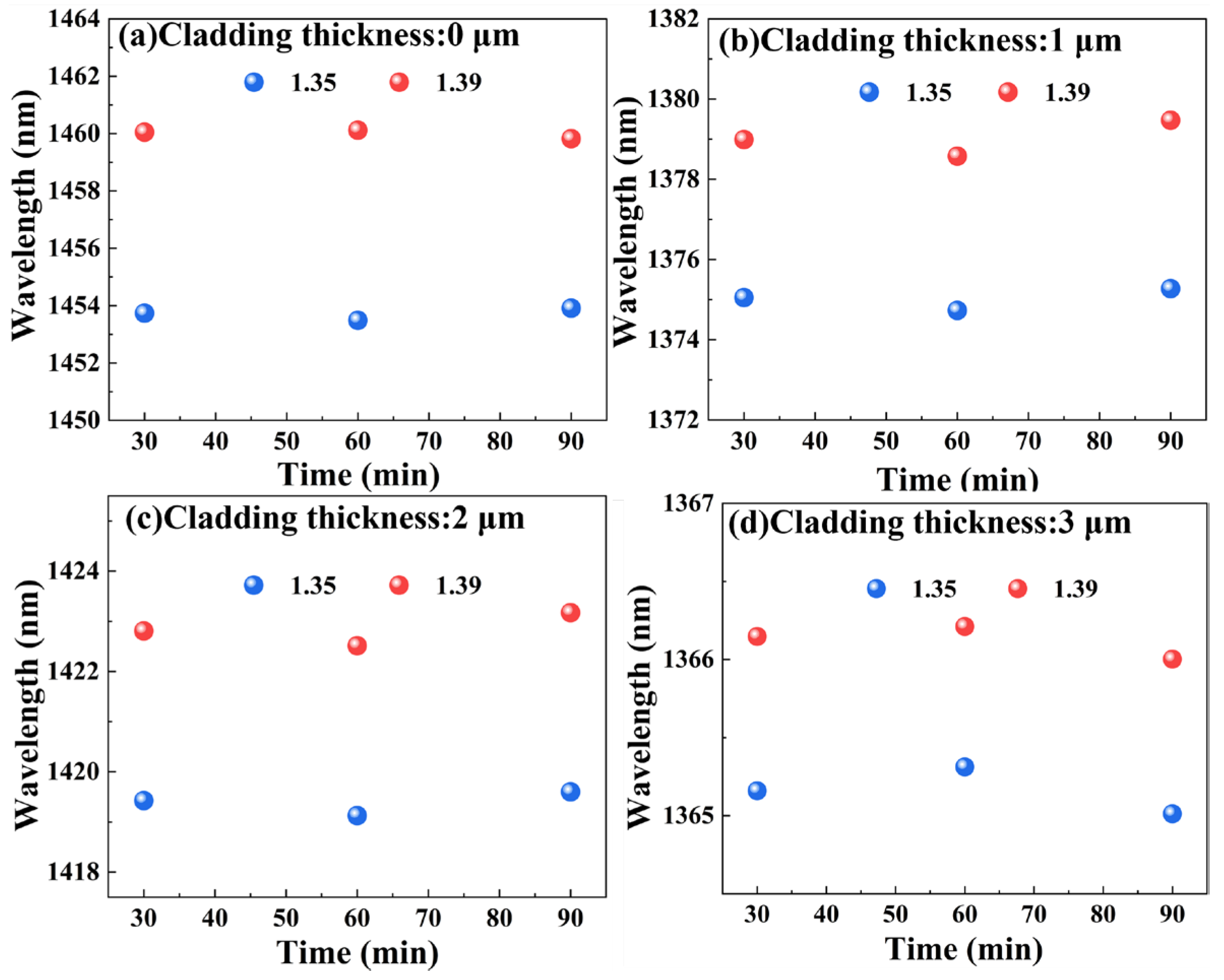

3.1. Experiments and Results

3.2. Comprehensive Evaluation

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, X.; Ge, K.; Tong, J.-H.; Zhai, T. Low-cost biosensors based on a plasmonic random laser on fiber facet. Opt. Express 2020, 28, 12233–12242. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Li, C.; Cai, J.; Wu, S.; Dai, M.; Geng, Y.; Yi, D.; Li, X. Fabry–Perot interference optical fiber biosensor based on the ECF for label-free DNA detection. Appl. Opt. 2025, 64, 2255–2260. [Google Scholar] [CrossRef] [PubMed]

- Gu, C.; Liu, X.; Lang, X.; Zhang, W.; Singh, R.; Li, G.; Xie, Y.; Zhang, B.; Kumar, S. Development of a core-offset-based SMS fiber structure for detection of various biomolecules. Appl. Opt. 2023, 62, 1992–1998. [Google Scholar] [CrossRef] [PubMed]

- Jena, J.; Swanepoel, F.; Mahed, G.; Waswa, D. Simultaneous vibration and soil moisture sensing using a single mode fiber for structural health monitoring applications. Appl. Opt. 2025, 64, C74–C78. [Google Scholar] [CrossRef]

- Shum, P.; Zhang, L.; Li, J. Specialty optical fibers for advanced sensing applications. Opto-Electron. Sci. 2023, 12, 220025. [Google Scholar]

- Wen, Z.; Guan, Z.; Dong, J.; Li, H.; Cai, Y.; Gao, S. A review of sensitivity enhancement in interferometer-based fiber sensors. Sensors 2022, 22, 2506. [Google Scholar] [CrossRef]

- Borjikhani, P.; Granpayeh, N.; Zibaii, M.I. High sensitivity tapered fiber refractive index biosensor using hollow gold nanoparticles. Sci. Rep. 2025, 15, 1458. [Google Scholar] [CrossRef]

- Feng, Y.; Li, H.; Li, S.; Liu, Y.; Meng, X. A high-sensitivity SPR refractive index sensor based on no-core fiber with Ag–Cu composite films. Sensors 2021, 21, 7000. [Google Scholar] [CrossRef]

- Jin, Y.; Gao, L.; Xue, Y.; Yang, J.; Liu, Y.; Zhu, Z.; Shi, J.; Grattan, K.T.V.; Guan, C. Refractive index and temperature dual-parameter sensors based on loss mode resonance and directional coupler in side-polished hole-assisted dual-core fiber. Opt. Express 2025, 33, 573–582. [Google Scholar] [CrossRef]

- Srivastava, A.; Esposito, F.; Campopiano, S.; Iadicicco, A. Mode transition phenomena into an in-fiber Mach–Zehnder interferometer. Opt. Fiber Technol. 2023, 80, 103481. [Google Scholar] [CrossRef]

- Wu, Q.; Qu, Y.; Liu, J.; Yuan, J.-H. Singlemode–multimode–singlemode fiber structures for sensing applications—A review. IEEE Sens. J. 2020, 21, 12734–12751. [Google Scholar] [CrossRef]

- Mohammed, W.S.; Smith, P.W.E. All-fiber multimode interference bandpass filter. Opt. Lett. 2006, 31, 2547–2549. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Wang, Y. Compact bandpass filter based on multimode interference in a tapered fiber structure. Appl. Opt. 2008, 47, 3778–3781. [Google Scholar]

- Zhang, X.; Yang, B.; Jiang, J.; Liu, K.; Fan, X.; Liu, Z.; Peng, M.; Chen, G.; Liu, T. Side-polished SMS based RI sensor employing macro-bending perfluorinated POF. Opto-Electron. Adv. 2021, 4, 200041. [Google Scholar] [CrossRef]

- Liu, F.; Lin, H.F.; Liu, Y.; Zhou, A.; Dai, Y.T. Femtosecond-induced spiral micro-structured SMS fiber structure for refractive index measurement. Opt. Express 2018, 26, 17388–17396. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, S.; Wang, R.; Farrell, G.; Zhang, M.; Geng, T.; Lewis, E.; Tian, K. Temperature-insensitive refractometer based on an RI-modulated singlemode-multimode-singlemode fiber structure. Opt. Express 2019, 27, 13754–13764. [Google Scholar] [CrossRef]

- Del Villar, I.; Goñi, J.; Vicente, A.; Arregui, F.J.; Matias, I.R. Etched and nanocoated single-mode multimode single-mode (SMS) fibers for detection of wind turbine gearbox oil degradation. J. Light. Technol. 2019, 37, 4665–4673. [Google Scholar] [CrossRef]

- Song, Q.; Nie, G.; Xie, Y.; Wu, X.; Yang, K.; Pu, S. Comparative study and comprehensive evaluation of refractive index sensor based on hetero-core fusion-spliced fiber structures. Infrared Phys. Technol. 2025, 149, 105922. [Google Scholar] [CrossRef]

- Huang, S.; Pu, S.; Ji, Y.; Zhang, C.; Liu, W.; Xu, T.; Han, S. Refractive index and magnetic field sensing based on bent microfiber functionalized with graphene oxide. Opt. Express 2025, 33, 5355–5368. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, B.; Zhu, J.; Liu, J.; Wan, S.; Wu, T.; Sun, J. Asymmetrical tapered SMS fiber coupler for simultaneous measurement of temperature and refractive index and its application for biosensing. Chin. Opt. Lett. 2020, 18, 061201. [Google Scholar] [CrossRef]

- Tian, K.; Zhang, M.; Farrell, G.; Wang, R.; Lewis, E.; Wang, P. Highly sensitive strain sensor based on composite interference established within S-tapered multimode fiber structure. Opt. Express 2018, 26, 33982–33992. [Google Scholar] [CrossRef]

- Wang, K.; Mizuno, Y.; Lee, H.; Dong, X.; Kurz, W.; Fink, M.; Jakobi, M.; Koch, A.W. Experimental demonstration of offset-induced sensitivity enhancement in SMS-based temperature and strain sensing. Appl. Phys. Express 2023, 16, 052003. [Google Scholar] [CrossRef]

- Dey, K.; Pavan, V.D.R.; Roy, S.; Shankar, S.; Ramesh, B. Interrogation of SMS for measuring of temperature and strain using half-etched FBG with enhanced sensitivity. Proc. SPIE 2020, 11355, 113550Z. [Google Scholar]

- Zhang, S.; Deng, S.; Geng, T.; Sun, C.; Niu, H.; Li, X.; Wang, Z.; Li, X.; Ma, Y.; Yang, W.; et al. A miniature ultra long period fiber grating for simultaneous measurement of axial strain and temperature. Opt. Laser Technol. 2020, 126, 106121. [Google Scholar] [CrossRef]

- Liang, H.; Wang, X.; Tian, K.; Yang, W.; Lewis, E.; Wang, P. Multimode-interference-effect-based all-fiber displacement sensing system for an orthopedic Ilizarov apparatus device. Appl. Opt. 2019, 58, 3209–3213. [Google Scholar] [CrossRef]

- Liang, H.; Jiang, Y.; Wang, X.; Lewis, E.; Wang, P. All-fiber optic displacement sensing system for an Ilizarov transverse tibial bone transport device. Appl. Opt. 2020, 59, 2077–2084. [Google Scholar] [CrossRef]

- Mohammed, W.S.; Mehta, A.; Johnson, E.G. Wavelength tunable fiber lens based on multimode interference. J. Light. Technol. 2004, 22, 469–477. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Z.; Jian, S. Multimode interference refractive index sensor based on coreless fiber. Photonic Sens. 2014, 4, 21–27. [Google Scholar] [CrossRef]

- Ren, Z.-H.; Wang, Q.; Cong, X.-W.; Zhao, W.-M.; Tang, J.-R.; Wang, L.; Yan, X.; Zhu, A.-S.; Qiu, F.-M.; Chen, B.-H.; et al. A fiber SPR sensor with high comprehensive evaluation indicator based on core mismatched U-shaped and tapered arm. Measurement 2023, 206, 112248. [Google Scholar] [CrossRef]

- Wu, Q.; Semenova, Y.; Wang, P.; Farrell, G. High sensitivity SMS fiber structure-based refractometer—Analysis and experiment. Opt. Express 2011, 19, 7937–7944. [Google Scholar] [CrossRef]

- Socorro, A.B.; Posada-Roman, J.E.; Diaz-Herrera, N.; Mendez, A. Mode transition-based multimode interference refractometric sensor using high-index coatings. Opt. Express 2013, 21, 12668–12682. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Mizuno, Y.; Su, X.; Dong, X.; Kurz, W.; Fink, M.; Lee, H.; Jakobi, M.; Koch, A.W. Core diameter and numerical aperture dependences on the performance of fiber-optic multimode interference sensing. Appl. Phys. Express 2023, 16, 012003. [Google Scholar] [CrossRef]

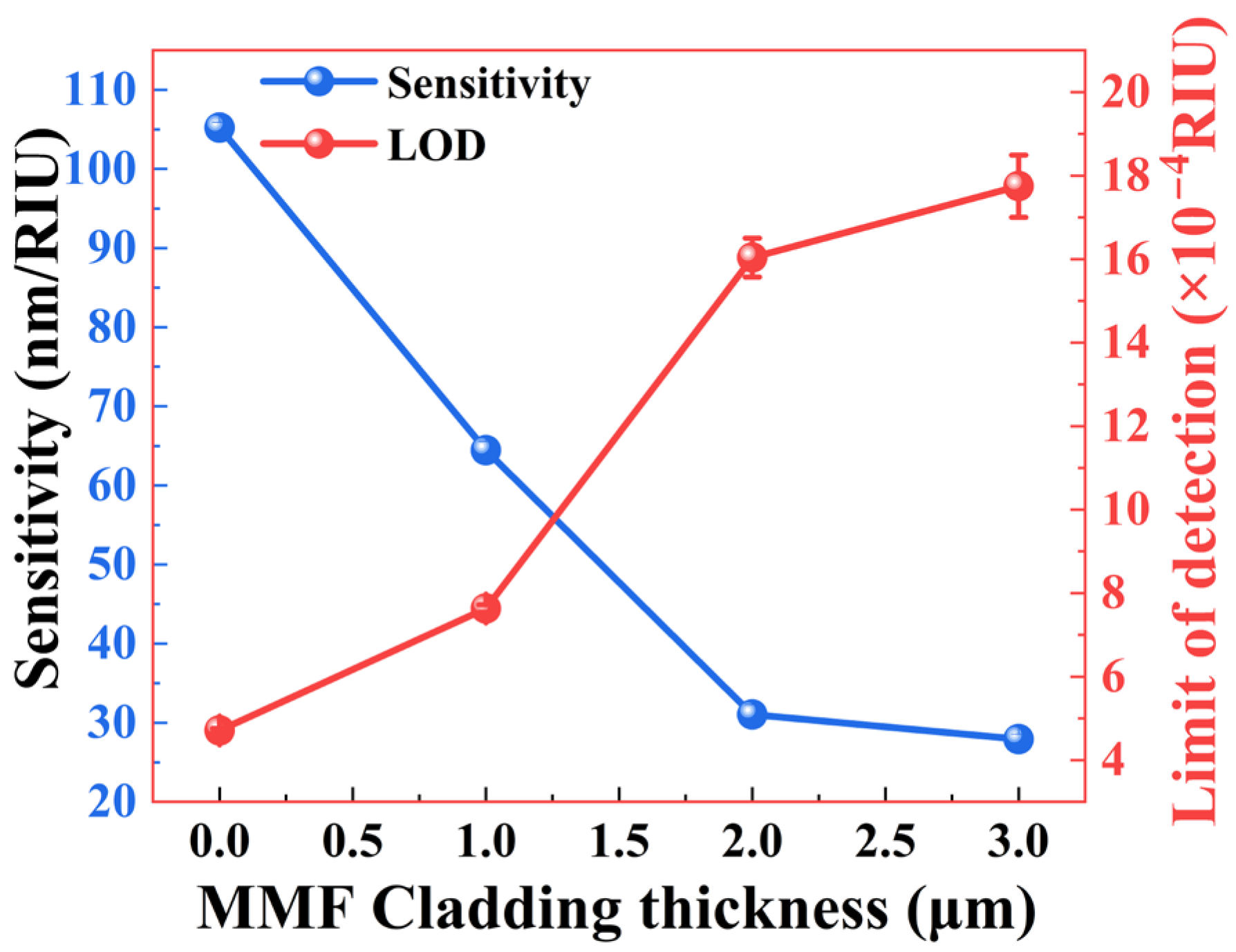

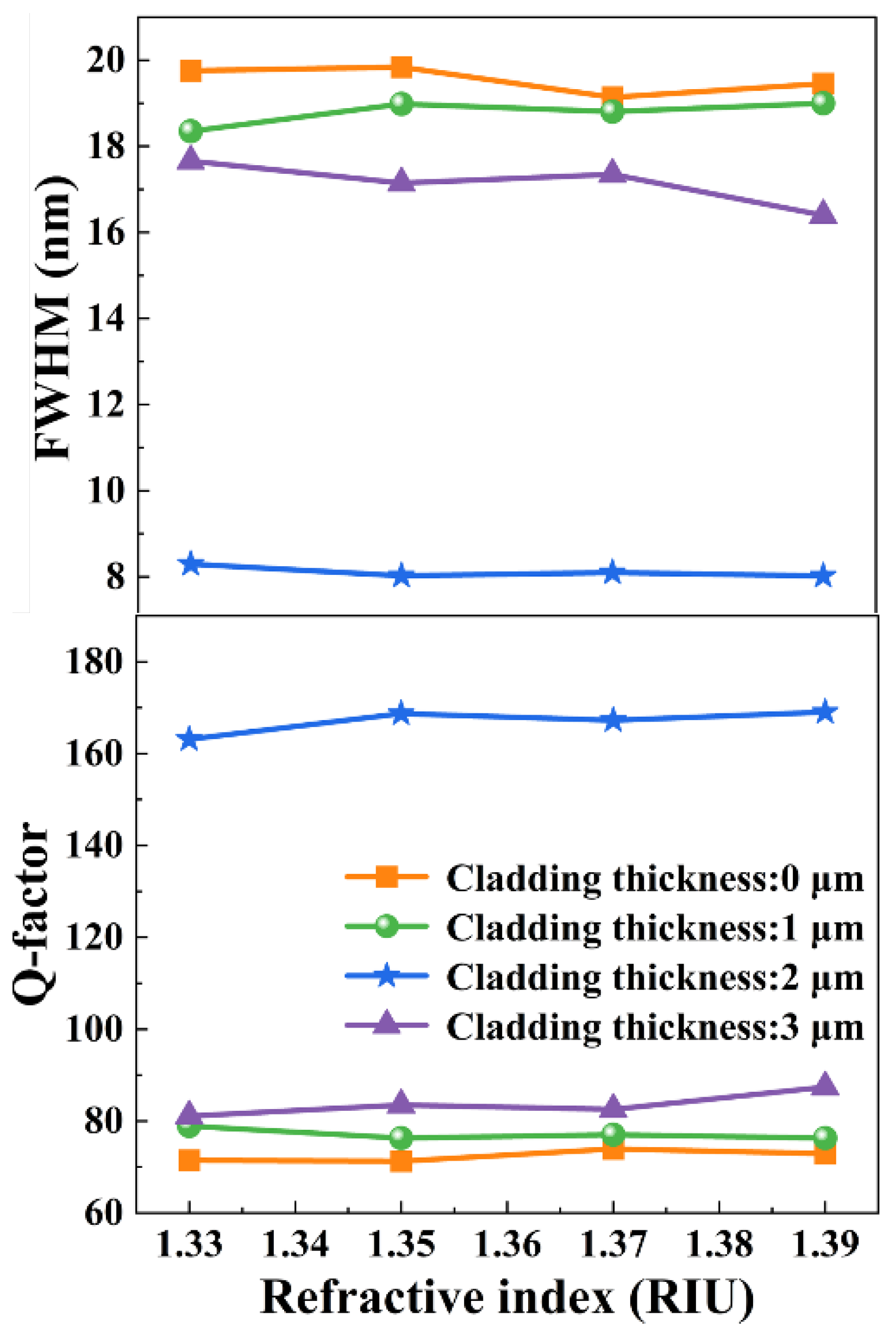

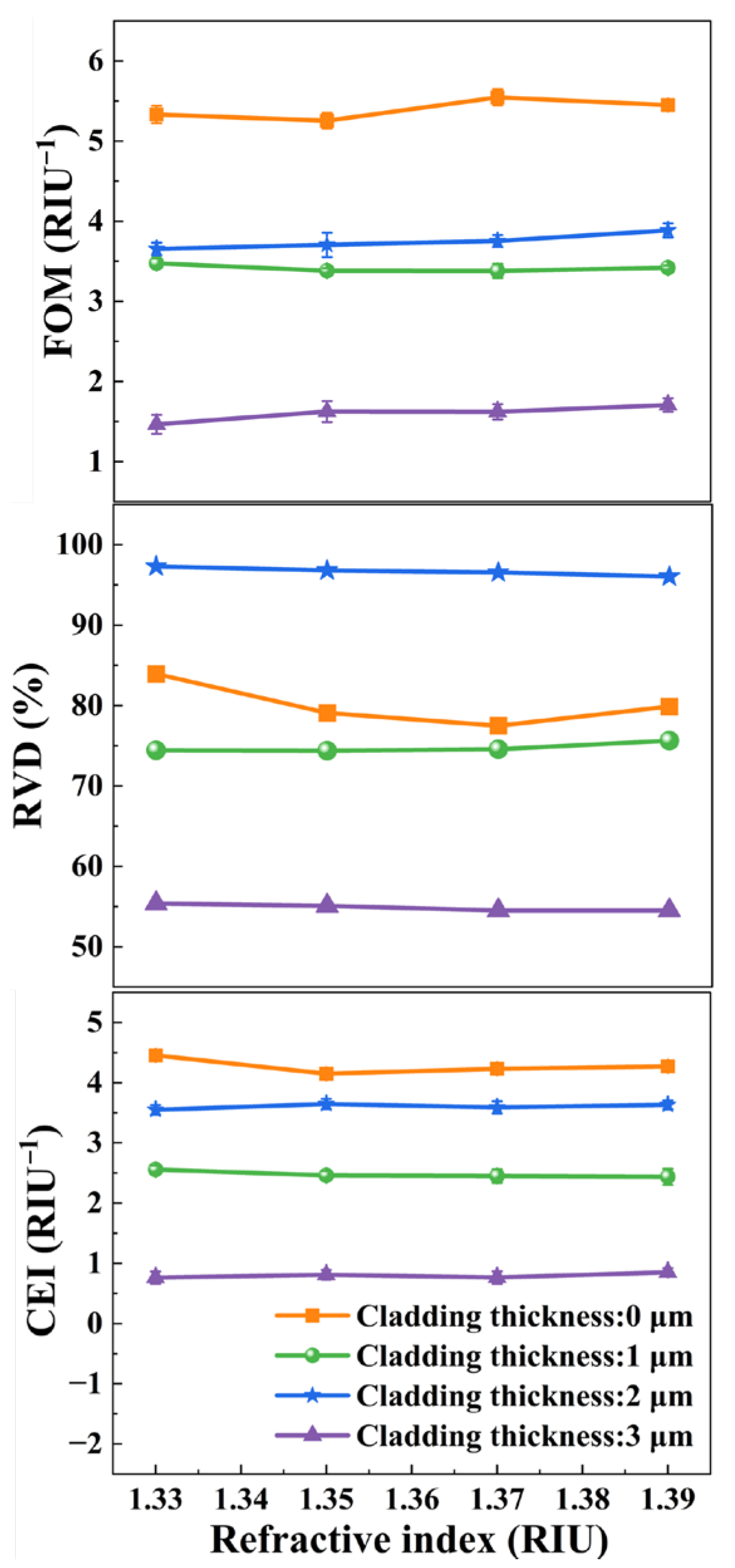

| Performance Index | MMF Cladding Thickness | |||

|---|---|---|---|---|

| 0 μm | 1 μm | 2 μm | 3 μm | |

| Sensitivity (nm/RIU) | 106.00 | 64.83 | 31 | 28.00 |

| LOD (×10−4 RIU) | 4.72 | 7.71 | 16.13 | 17.86 |

| FWHM (nm) | 19.14 | 18.35 | 8.02 | 16.40 |

| Q-factor | 73.94 | 78.89 | 169.02 | 87.39 |

| FOM (RIU−1) | 5.54 | 3.53 | 3.87 | 1.71 |

| RVD (%) | 83.93 | 75.63 | 97.30 | 55.38 |

| CEI (RIU−1) | 4.50 | 2.63 | 3.74 | 0.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nie, G.; Pu, S.; Wang, Y.; Song, Q. Cladding–Thickness–Dependent Performance of SMS Optical Fiber Sensors. Photonics 2025, 12, 863. https://doi.org/10.3390/photonics12090863

Nie G, Pu S, Wang Y, Song Q. Cladding–Thickness–Dependent Performance of SMS Optical Fiber Sensors. Photonics. 2025; 12(9):863. https://doi.org/10.3390/photonics12090863

Chicago/Turabian StyleNie, Guanzhong, Shengli Pu, Yuzhong Wang, and Qingxi Song. 2025. "Cladding–Thickness–Dependent Performance of SMS Optical Fiber Sensors" Photonics 12, no. 9: 863. https://doi.org/10.3390/photonics12090863

APA StyleNie, G., Pu, S., Wang, Y., & Song, Q. (2025). Cladding–Thickness–Dependent Performance of SMS Optical Fiber Sensors. Photonics, 12(9), 863. https://doi.org/10.3390/photonics12090863