Advanced Research and Engineering Application of Tunnel Structural Health Monitoring Leveraging Spatiotemporally Continuous Fiber Optic Sensing Information

Abstract

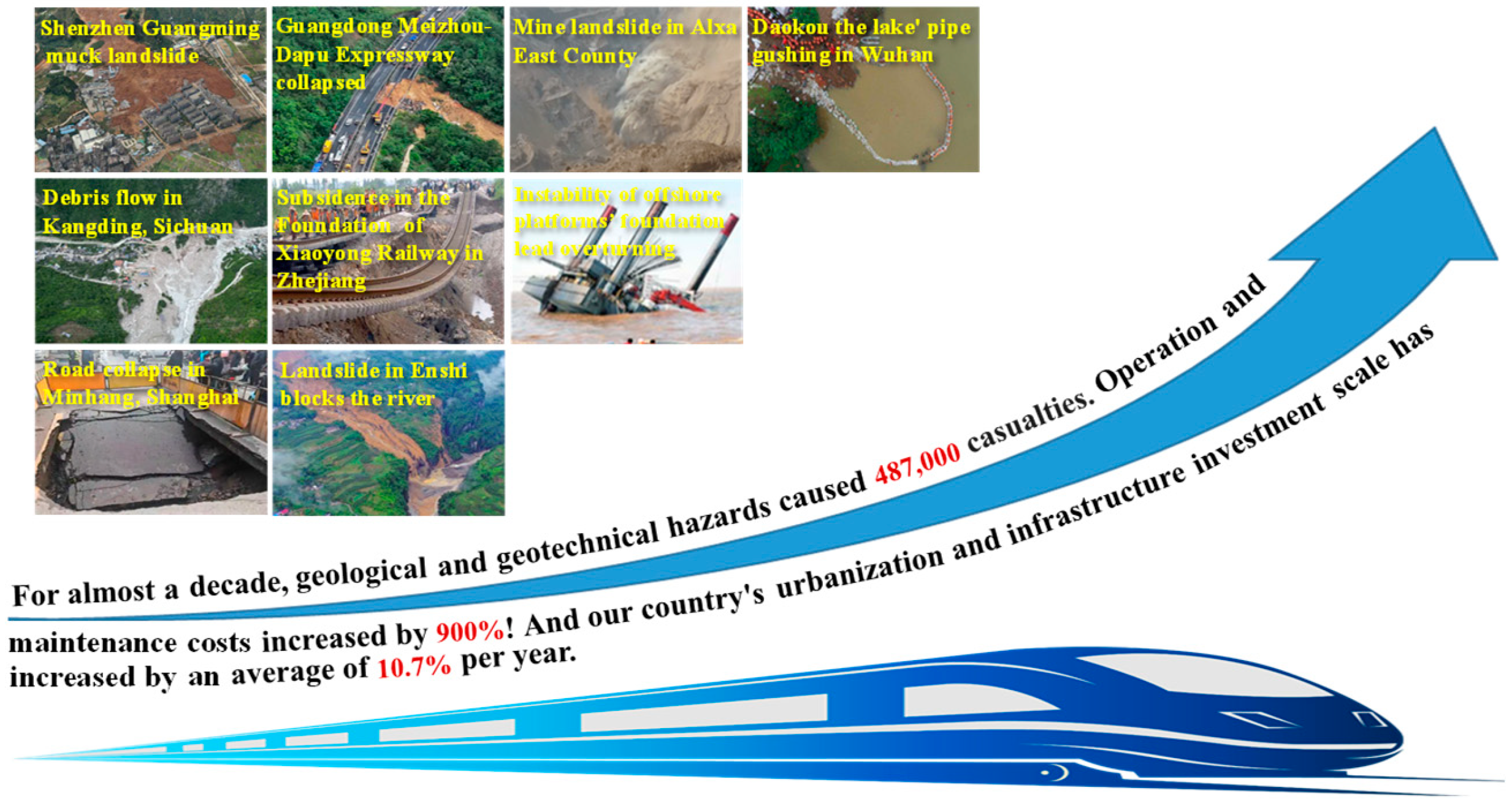

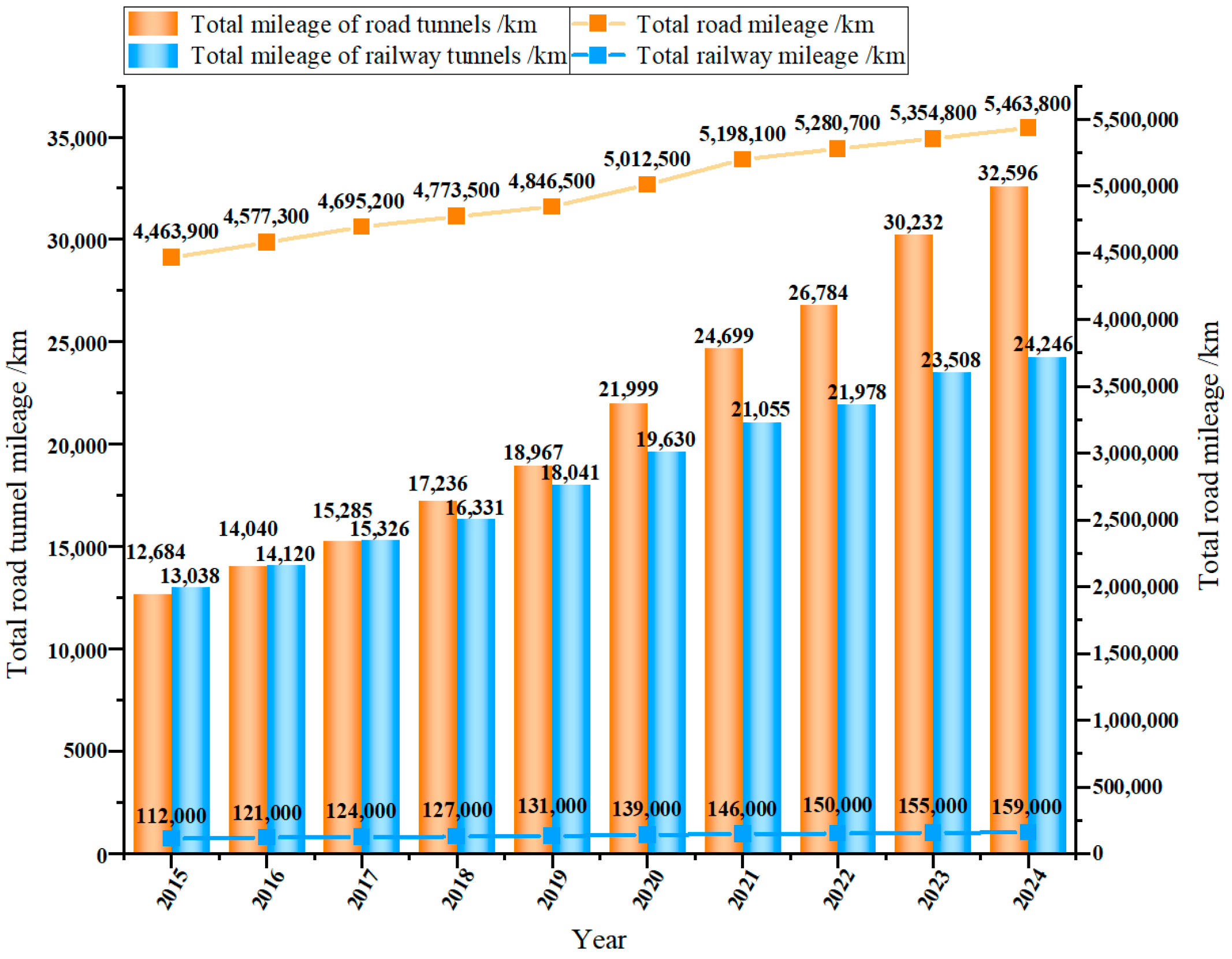

1. Introduction

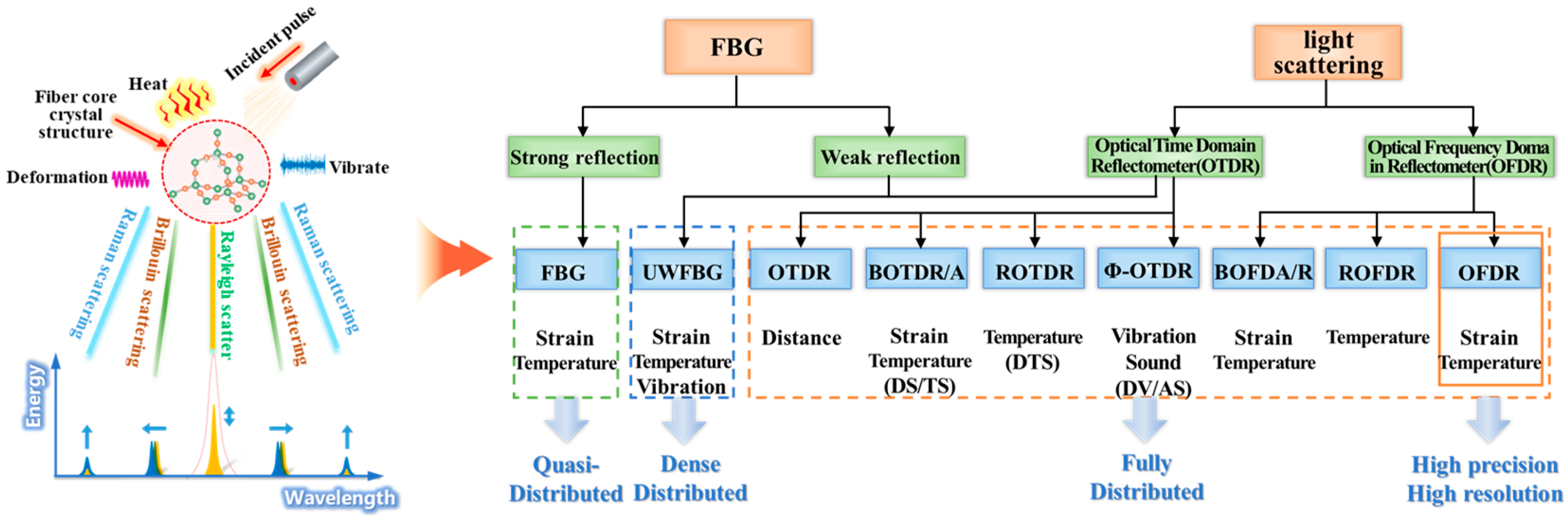

2. Theoretical and Technical Research on Structural Health Monitoring of Tunnel Engineering

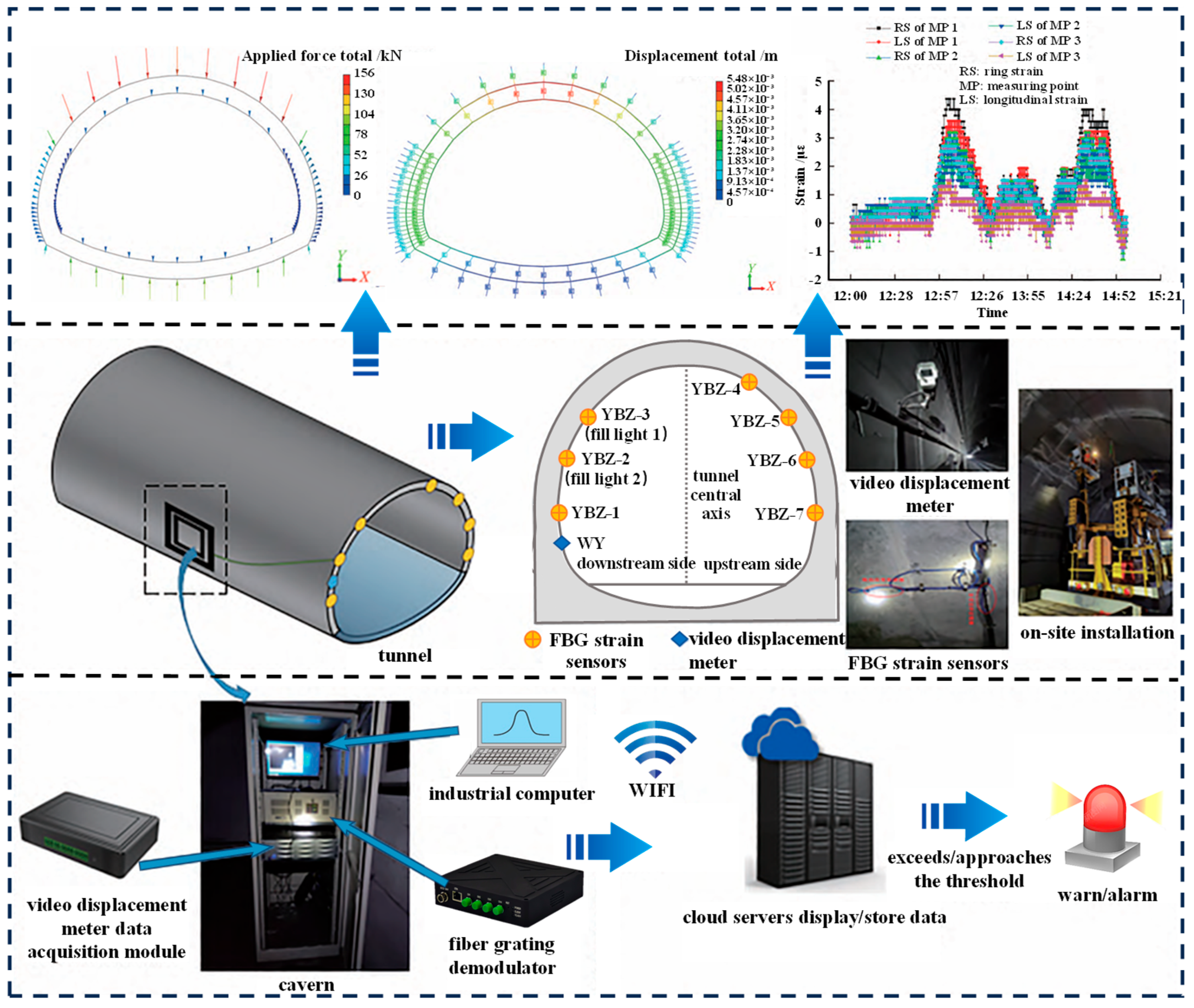

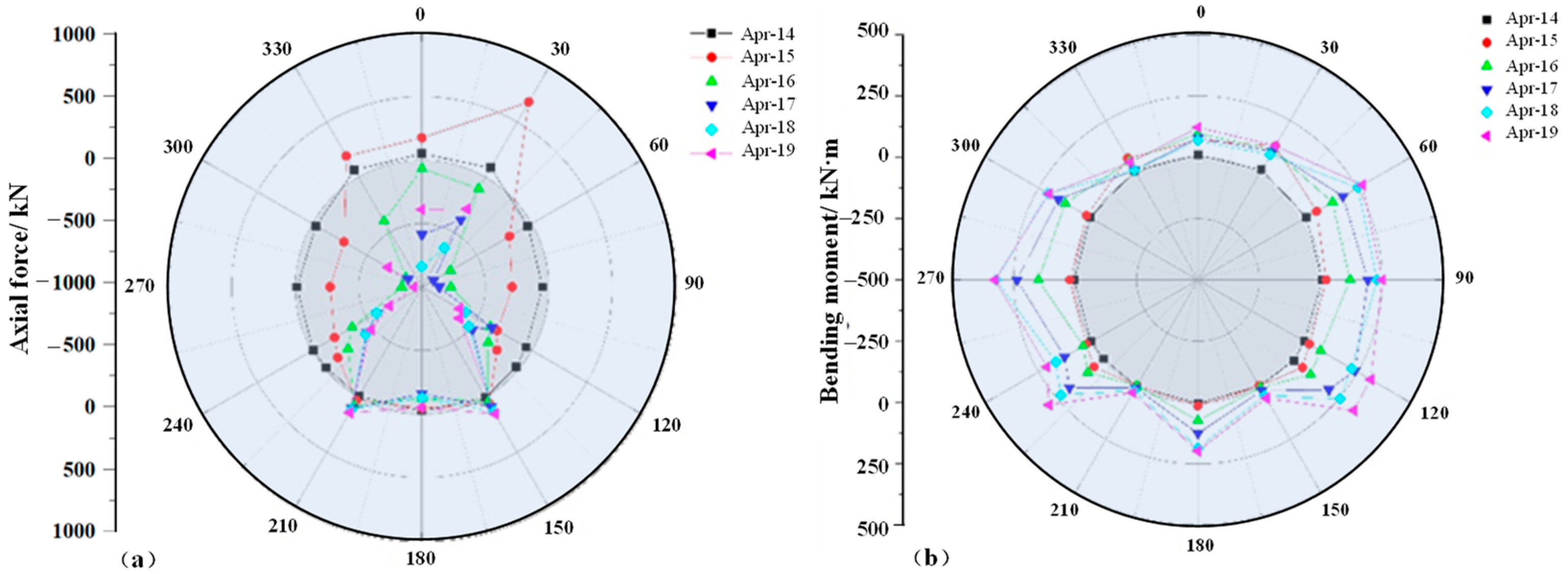

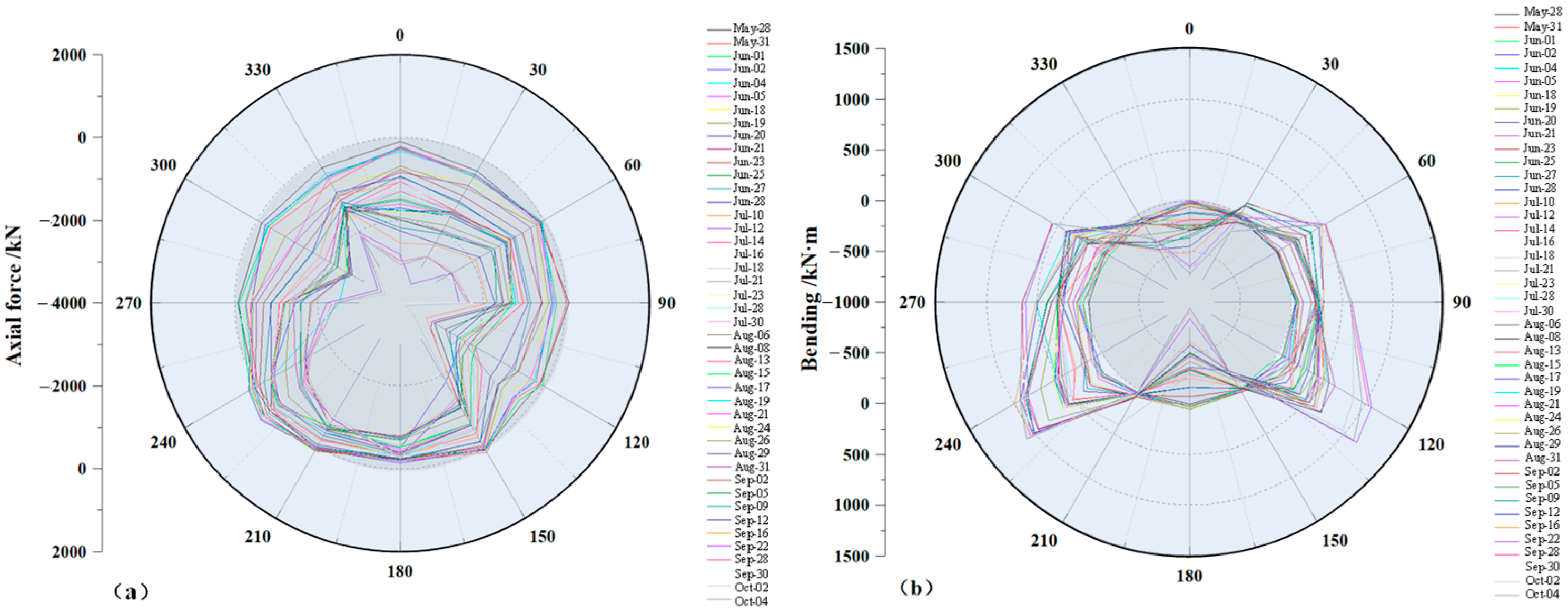

3. Application of DFOS in the Safety Monitoring of Tunnel Engineering

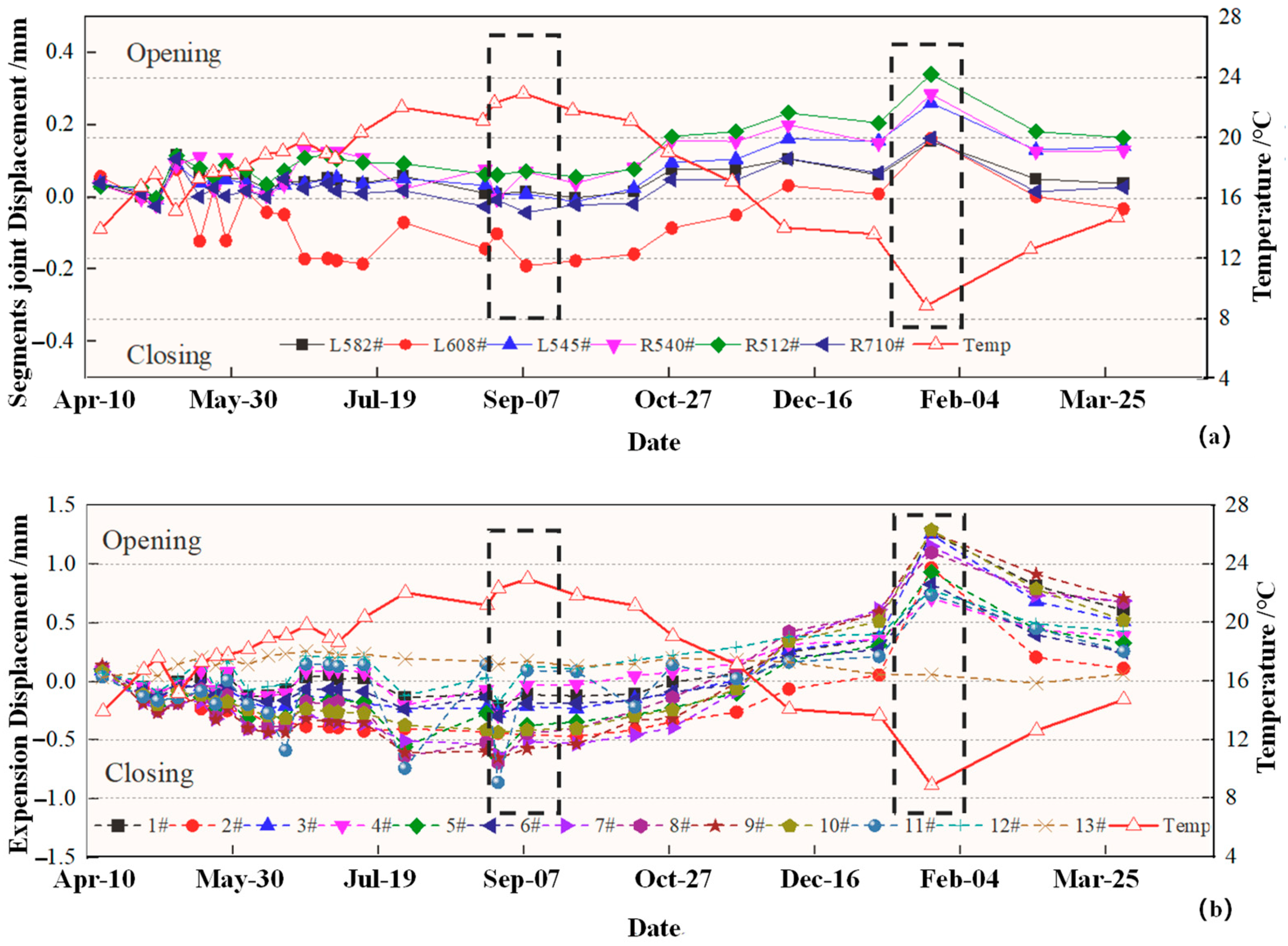

3.1. Deformation Monitoring of Tunnel Engineering Based on FBG

3.2. Temperature Monitoring of Tunnel Engineering Based on BOFDA

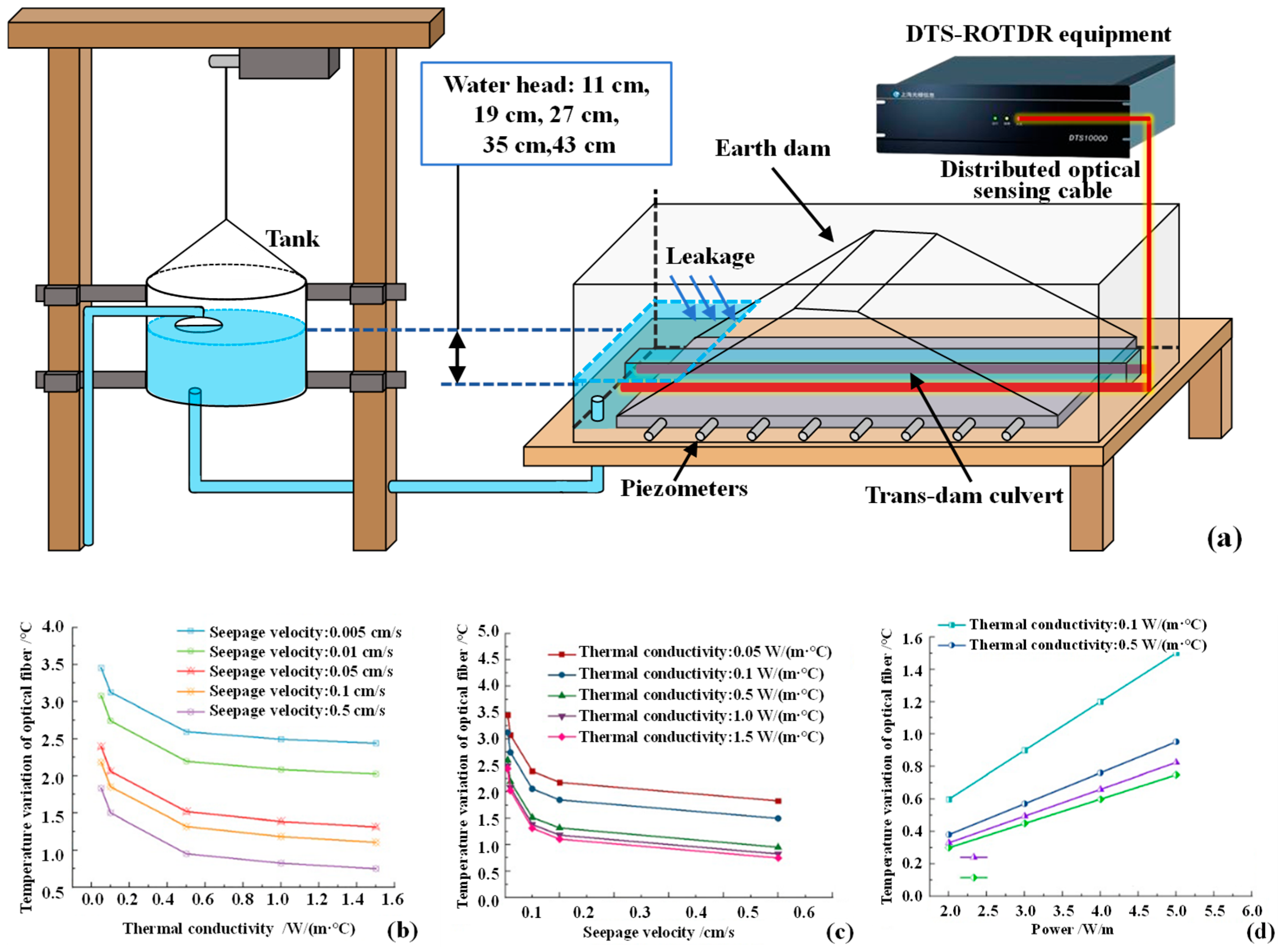

3.3. Seepage Monitoring of Tunnel Engineering Based on DTS

3.4. Vibration Monitoring of Tunnel Engineering Based on DAS

4. High–Speed Railway Tunnel Engineering Application

4.1. Project Overview

4.2. Monitoring Program

4.3. Analysis of Monitoring Results

5. Discussion

5.1. Aspects of Theoretical and Technological Innovation

5.2. Aspects of Monitoring Technology Verification

5.3. Aspects of On–Site Engineering Tests

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- National Bureau of Statistics of China. Statistical Communiqué of the People’s Republic of China on the 2024 National Economic and Social Development [EB/OL]. Available online: https://www.gov.cn/lianbo/bumen/202502/content_7008605.htm (accessed on 28 February 2025).

- Zhang, X.H.; Zhu, H.H.; Jiang, X.; Broere, W. Distributed fiber optic sensors for tunnel monitoring: A state–of–the–art review. J. Rock. Mech. Geotech. Eng. 2024, 16, 3841–3863. [Google Scholar] [CrossRef]

- Zhang, T.; Gan, Q.; Zhao, Y.X.; Zhu, G.P.; Nie, X.D.; Yang, K.; Li, J.Z. Investigations into mining–induced stress–fracture–seepage field coupling effect considering the response of key stratum and composite aquifer. Rock. Mech. Rock. Eng. 2019, 52, 4017–4031. [Google Scholar] [CrossRef]

- Zheng, J.T.; Zheng, L.G.; Liu, H.H.; Ju, Y. Relationships between permeability, porosity and effective stress for low–permeability sedimentary rock. Int. J. Rock. Mech. Min. Sci. 2015, 78, 304–318. [Google Scholar] [CrossRef]

- Sun, Y.J.; Zhao, X.M.; Xu, Z.M.; Zhang, L.; Chen, G.; Feng, L.; Li, X.; Chen, T.C.; Yuan, H.Q.; Liu, Q.; et al. Hydrodynamic field driving effect and mathematical model construction of water quality formation and evolution in coal mine. J. China Coal Soc. 2023, 48, 4157–4170. [Google Scholar] [CrossRef]

- Yu, P.; Liu, H.H.; Wang, Z.S.; Fu, J.N.; Zhang, H.; Wang, J.; Yang, Q. Development of urban underground space in coastal cities in China: A review. Deep. Undergr. Sci. Eng. 2023, 2, 148–172. [Google Scholar] [CrossRef]

- Sun, Q.; Yan, C.H.; Qiu, J.F.; Xu, B.; Sha, J.Q. Numerical Simulation of a Deep Excavation near a Shield Tunnel. Technol. Gaz. 2018, 25, 670–678. [Google Scholar]

- Wang, S.Y.; Sloan, S.W.; Tang, C.A.; Zhu, W.C. Numerical simulation of the failure mechanism of circular tunnels in transversely isotropic rock masses. Tunn. Undergr. Space Technol. 2012, 32, 231–244. [Google Scholar] [CrossRef]

- Mao, M.M.; Yang, X.W.; Liu, C.; Zhao, T.; Liu, H. Deformation monitoring at shield tunnel joints: Laboratory test and discrete element simulation. Deep. Undergr. Sci. Eng. 2025, 4, 149–157. [Google Scholar] [CrossRef]

- Zhong, S.H.; Li, S.C.; Sun, H.Z.; Li, X. Tunnel construction of exploratory forecasting faults, fracture zones and groundwater technology. Superv. Test. Cost. Constr. 2009, 2, 69–73. [Google Scholar]

- Li, S.C.; Liu, B.; Sun, H.F.; Nie, L.C.; Zhong, S.H.; Su, M.X.; Li, X.; Xu, Z.H. State of art and trends of advanced geological prediction in tunnel construction. Chin. J. Rock. Mech. Eng. 2014, 33, 1090–1113. [Google Scholar] [CrossRef]

- Chambon, P.; Corte, J.F. Shallow tunnels in cohesionless soil: Stability of tunnel face. J. Geotech. Eng. 1994, 120, 1148–1165. [Google Scholar] [CrossRef]

- Zhu, W.S.; He, M.C. Stability of Surrounding Rock and Dynamic Construction Mechanics of Rock Mass Under Complex Conditions; China Science Publishing & Media Ltd. (CSPM): Beijing, China, 1995. [Google Scholar]

- Zhu, H.H.; Jiang, Y.; Xia, C.C.; Yang, L.D.; Cui, M.Y. Study on Tunnel Construction Informational Technology in Complicated Geological Condition. Chin. J. Rock. Mech. Eng. 2002, 2, 2548–2553. [Google Scholar]

- Lee, C.J.; Wu, B.R.; Chen, H.T.; Chiang, K.H. Tunnel stability and arching effects during tunneling in soft clayey soil. Tunn. Undergr. Space Technol. 2006, 21, 119–132. [Google Scholar] [CrossRef]

- Gu, S.L.; Wang, F.M.; Dong, X.P. Evaluation of the effect of ESO algorithm for tunnel section shape optimization. Yellow River 2010, 32, 109–110. [Google Scholar]

- Li, S.C.; He, P.; Li, L.P.; Zhang, Q.Q.; Shi, S.S.; Xu, F.; Liu, H.L. Reliability analysis method of sub–classification of tunnel rock mass and its engineering application. Rock. Soil. Mech. 2018, 39, 967–976. [Google Scholar]

- Xu, C.B.; Zheng, Z.T.; Xin, H.S.; Miu, Y.B.; Du, J. Classification and prospect for large deformation of tunnel surrounding rock. Tunn. Constr. 2023, 43, 27–40. [Google Scholar]

- Wang, F.M.; Guo, C.C.; Sun, B.; Wang, H.R.; Guan, H.; Liu, J.Y.; Huo, J.X.; Da, Z.Q. Research on Key Technologies for Integrated Waterproofing, Seismic Reduction, and Thermal Insulation in Tunnels. Railw. Stand. Des. 2024, 68, 1–10. [Google Scholar]

- Bao, Y.B.; Sun, J.Q.; Huang, Q. Distributed Fiber Sensor Based on Brillouin Optical Time Domain Reflection Technique. Laser Optoelectron. Prog. 2020, 57, 21–39. [Google Scholar] [CrossRef]

- Mohamad, H.; Soga, K.; Bennett, P.J.; Mair, R.J.; Lim, C.S. Monitoring twin tunnel interaction using distributed optical fiber strain measurements. J. Geotech. Geoenviron. Eng. 2012, 138, 957–967. [Google Scholar] [CrossRef]

- Wang, J.; Garg, A.; Satyam, N.; Zhussupbekov, A.; Sushkova, S. DFOS Technology in Geoengineering Monitoring in the Past 35 Years: A Bibliometric Analysis. Sensors 2024, 24, 5051. [Google Scholar] [CrossRef]

- Su, H.Z.; Ou, B.; Yang, L.F.; Wen, Z.P. Distributed optical fiber–based monitoring approach of spatial seepage behavior in dike engineering. Opt. Laser Techno. 2018, 103, 346–353. [Google Scholar] [CrossRef]

- Sun, Y.J.; Shi, B.; Chen, S.E.; Zhu, H.H.; Zhang, D.; Lu, Y. Feasibility study on corrosion monitoring of a concrete column with central rebar using BOTDR. Smart Struct. Syst. 2014, 13, 41–53. [Google Scholar] [CrossRef]

- Fajkus, M.; Nedoma, J.; Mec, P.; Hrubešová, E.; Martinek, R.; Vasinek, V. Analysis of the highway tunnels monitoring using an optical fiber implemented into primary lining. J. Electr. Eng. 2017, 68, 364–370. [Google Scholar] [CrossRef]

- Hoes, O.A.C.; Schilperoort, R.P.S.; Luxemburg, W.M.J.; Clemens, F.H.L.R.; van de Giesen, N.C. Locating illicit connections in storm water sewers using fiber–optic distributed temperature sensing. Water Res. 2009, 43, 5187–5197. [Google Scholar] [CrossRef]

- Monsberger, C.M.; Bauer, P.; Buchmayer, F.; Lienhart, W. Large–scale distributed fiber optic sensing network for short and long–term integrity monitoring of tunnel linings. J. Civ. Struct. Health Monit. 2022, 12, 1317–1327. [Google Scholar] [CrossRef]

- Guo, J.Y.; Fang, J.H.; Shi, B.; Zhang, C.C.; Liu, L. High–sensitivity water leakage detection and localization in tunnels using novel ultra–weak fiber Bragg grating sensing technology. Tunn. Undergr. Space Technol. 2024, 144, 105574. [Google Scholar] [CrossRef]

- Zhang, X.H.; Zhu, H.H.; Jiang, X.; Broere, W.; Long, L.Y. Designing a Distributed Sensing Network for Structural Health Monitoring of Concrete Tunnels: A Case Study. Struct. Control Health Monit. 2024, 2024, 6087901. [Google Scholar] [CrossRef]

- Klar, A.; Dromy, I.; Linker, R. Monitoring tunneling induced ground displacements using distributed fiber–optic sensing. Tunn. Undergr. Space Technol. 2014, 40, 141–150. [Google Scholar] [CrossRef]

- Shi, B. On the ground sensing system and ground sensing engineering. J. Eng. Geol. 2017, 25, 582–591. [Google Scholar] [CrossRef]

- Wang, H.P.; Dai, J.G.; Wang, X.Z. Improved temperature compensation of fiber Bragg grating–based sensors applied to structures under different loading conditions. Opt. Fiber Technol. 2021, 63, 102506. [Google Scholar] [CrossRef]

- Ren, C.; Sun, X.M.; He, M.C.; Tao, Z.G. Application of FBG Sensing Technology for Real–Time Monitoring in High–Stress Tunnel Environments. Appl. Sci. 2024, 14, 8202. [Google Scholar] [CrossRef]

- Song, H.B.; Pei, H.F.; Zhu, H.H. Monitoring of tunnel excavation based on the fiber Bragg grating sensing technology. Measurement 2021, 169, 108334. [Google Scholar] [CrossRef]

- Li, J.; Zhang, D.B.; Zhang, X.W.; Zhang, J.R.; Yao, R.X.; Fan, B.B. Safety Monitoring of Railway Tunnel Structure During Operation Period Based on Fiber Grating Sensing and Video Displacement Meter Technology. Laser Optoelectron. Prog. 2023, 60, 177–185. [Google Scholar]

- Jiao, H.R.; Shi, B.; Wei, G.Q.; Wang, X.; Jia, L.X. Study on influence factors of temperature coefficient of sensing optical fiber based on BOFDA. J. Electron. Meas. Instrum. 2018, 32, 73–80. [Google Scholar] [CrossRef]

- Wang, X.; Shi, B.; Wei, G.Q.; Chen, S.E.; Zhu, H.H.; Wang, T. Monitoring the behavior of segment joints in a shield tunnel using distributed fiber optic sensors. Struct. Control Health Monit. 2018, 25, e2056. [Google Scholar] [CrossRef]

- Gong, X.N.; Guo, P.P. Prevention and Mitigation Methods for Water Leakage in Tunnels and Underground Structures. China J. Highw. Transp. 2021, 34, 1–30. [Google Scholar] [CrossRef]

- Wu, X.G.; Liu, P.C.; Wang, L.; Chen, H.Y.; Zhang, L.M. Monitoring and Warning of Seepage in Subway Operation Tunnel Based on 3D Laser Scanning. J. Civ. Eng. Manag. 2020, 37, 1–7+15. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, L.Z.; Zhang, X.S.; Sun, H.L.; Miao, M.; Qu, S.G.; Xie, Q.Y.; Han, B.; Wang, K. Monitoring contact seepage between earth–fill dam and trans–dam culvert based on temperature variation regularity of optical fiber. J. Civ. Struct. Health Monit. 2023, 13, 767–780. [Google Scholar] [CrossRef]

- Fu, S.C.; Zhang, D.; Peng, Y.; Shi, B.; Yedili, N.; Ma, Z. A simulation of gas pipeline leakage monitoring based on distributed acoustic sensing. Meas. Sci. Technol. 2022, 33, 095108. [Google Scholar] [CrossRef]

- Jousset, P.; Reinsch, T.; Ryberg, T.; Blanck, H.; Clarke, A.; Aghayev, R.; Hersir, G.P.; Henninges, J.; Weber, M.; Krawczyk, C.M. Dynamic strain determination using fibre–optic cables allows imaging of seismological and structural features. Nat. Commun. 2018, 9, 2509. [Google Scholar] [CrossRef]

- Williams, E.F.; Fernández-Ruiz, M.R.; Magalhaes, R.; Vanthillo, R.; Zhan, Z.W.; González-Herráez, M.; Martins, H.F. Distributed sensing of microseisms and teleseisms with submarine dark fibers. Nat. Commun. 2019, 10, 5778. [Google Scholar] [CrossRef]

- Spica, Z.J.; Perton, M.; Martin, E.R.; Beroza, G.C.; Biondi, B. Urban Seismic Site Characterization by Fiber–Optic Seismology. J. Geophys. Res. Solid. Earth 2020, 125, e2019JB018656. [Google Scholar] [CrossRef]

- Zhang, T.Y.; Zhang, C.C.; Xie, T.; Xu, X.M.; Shi, B. Automatic Identification of Diverse Tunnel Threats with Machine Learning–Based Distributed Acoustic Sensing. Struct. Control Health Monit. 2025, 2025, 9780866. [Google Scholar] [CrossRef]

- Yang, H.; Xu, X.Y. Structure monitoring and deformation analysis of tunnel structure. Compos. Struct. 2021, 276, 114565. [Google Scholar] [CrossRef]

- Xu, X.; Yang, H. Vision Measurement of Tunnel Structures with Robust Modelling and Deep Learning Algorithms. Sensors 2020, 20, 4945. [Google Scholar] [CrossRef] [PubMed]

- Cheng, G.; Wang, Z.X.; Shi, B.; Zhu, W.; Li, T.B. Research on a Space–Time Continuous Sensing System for Overburden Deformation and Failure during Coal Mining Overburden Deformation and Failure during Coal Mining. Sensors 2023, 23, 5947. [Google Scholar] [CrossRef]

- Wang, D.Y.; Zhu, H.H.; Huang, J.W.; Yan, Z.R.; Zheng, X.; Shi, B. Fiber optic sensing and performance evaluation of water conveyance tunnel with composite linings under super high internal pressures. J. Rock. Mech. Geotech. Eng. 2023, 15, 1997–2012. [Google Scholar] [CrossRef]

- Afrazi, M.; Armaghani, D.J.; Afrazi, H.; Fattahi, H.; Samui, P. Real–time monitoring of tunnel structures using digital twin and artificial intelligence: A short overview. Deep. Undergr. Sci. Eng. 2025. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Zhang, T.T.; Li, X.Z.; Dias, D. Bayesian ensemble methods for predicting ground deformation due to tunnelling with sparse monitoring data. Undergr. Space 2024, 16, 79–93. [Google Scholar] [CrossRef]

- Wang, X.; Wang, M.; Jiang, R.; Xu, J.; Li, B.; Wang, X.; Yu, J.; Su, P.; Liu, C.; Yang, Q.; et al. Structural deformation monitoring during tunnel construction: A review. J. Civ. Struct. Health Monit. 2024, 14, 591–613. [Google Scholar] [CrossRef]

- Gue, C.Y.; Wilcock, M.; Alhaddad, M.M.; Elshafie, M.Z.E.B.; Soga, K.; Mair, R.J. The monitoring of an existing cast iron tunnel with distributed fibre optic sensing (DFOS). J. Civ. Struct. Health Monit. 2015, 5, 573–586. [Google Scholar] [CrossRef]

| Classification | Name | Basic Performance Metrics | Scope of Application | Advantages and Disadvantages |

|---|---|---|---|---|

| Equipment | Vibrating Wire Displacement Meter | Measurement range: 25~200 mm Resolution: ≤0.05%F·S Non–repetition: ≤0.5%F·S | Monitor the displacement changes in multiple measurement points of the tunnel structure concurrently. | High accuracy; multi–point monitoring; real–time monitoring. High cost; low environmental adaptability; complex data processing. |

| MEMS Inclinometer | Measurement range: ±30° (dual axis) or ±90° (single axis) Measurement accuracy: ±0.02°~±0.1° Resolution: 0.001°~0.005° | Monitor the joint of shield tunnel segments and the inner surface of the tunnel lining. | Low cost; low power consumption; high reliability; easy to integrate; achieve intelligence. short lifespan; difficult to adapt to the harsh working environment. | |

| Tunnel Clearance Convergence Meter | Measurement range: ±0.06 mm Measurement accuracy: ±0.06~±2 mm Resolution: 0.01 mm | Monitor the relative displacement between the tunnel vault, arch feet and side walls. | High precision; easy to operate; real–time monitoring. Susceptibility to environmental influences; measurement point layout restrictions; data processing is complex. | |

| Rock–Bolt Dynamometer | Measurement range: Tensile stress, 0~200 MPa; Compressive stress: 0~100 MPa Resolution: ≤0.05%F·S Operating temperature range: −20 °C~+80 °C | Monitor key support sections such as tunnel vaults, arches, and side walls. | Real–time monitoring; high precision; good stability. Higher cost; complex installation and maintenance. | |

| LiDAR Laser Scanner | Vertical scanning range: ≥270° Horizontal scanning range: mostly 360° Maximum scanning distance: ≥100 m | Monitor tunnel sections, cracks and damage, and tunnel settlement. | Rich measurement data; high precision; working around the clock; non–contact measurement. There are errors in the monitoring data; the monitoring accuracy is limited; high cost. | |

| Technology | Fiber Bragg Grating (FBG) | Strain accuracy: ±1 με Temperature accuracy: ±0.1 °C Distance: ≤3.00 km Spatial resolution: >0.20 m Sampling resolution: 0.5 cm | Monitor tunnel linings, supporting structures, cracks and other parts, and carry out large–scale networked integrated monitoring. | High sensitivity; anti–electromagnetic interference; quasi–distributed; the measured data are stable; easy to implement multiplexing. High maintenance costs; there is a missed detection; it is difficult to demodulate. |

| Ultra–Weak Fiber Bragg Grating (UWFBG) | Strain accuracy: ±1 με Temperature accuracy: ±0.1 °C Distance: ≥10 km Spatial resolution: 1.0 m Sampling resolution: 1.0 m | Monitor key structural parts such as tunnel lining structures and surrounding rock convergence. | Quasi–distributed; high precision; real–time monitoring; strong anti–interference ability; low operating costs. High hardware costs; high requirements for technical personnel; data processing is complex. | |

| Brillouin Optical Time Domain Reflectometer (BOTDR) | Strain accuracy: ±10 με Temperature accuracy: ±1.0 °C Distance: <80 km Spatial resolution: 1.00 m Sampling resolution: 0.05 m | Monitor the deformation of key positions such as the surface layer of the structure, lining structure, arch circle, and surrounding geological body in the tunnel. | Distributed; long distance; high precision; anti–electromagnetic interference; light, fine and flexible. High cost; long measurement time; large amount of data processing. | |

| Distributed Sensor System (DSS) | Strain accuracy: ±2~10 με Temperature accuracy: ±0.35~1°C Distance: 10~50 km Spatial resolution: 0.50~1.00 m Sampling resolution: 0.50 m | Monitor the strain of tunnel engineering: tunnel headroom convergence, vault deformation, surrounding rock settlement, and horizontal/vertical displacement of soil. | High precision; long distance; anti–electromagnetic interference; real–time monitoring; non–intrusive installation. High cost; high requirements for technical personnel. | |

| Distributed Temperature Sensing (DTS) | Distance: 2 km~30 km Temperature measurement range: −200 °C~+600 °C Spatial sampling resolution: 0.50 m~4.00 m Temperature resolution: 0.01 °C~1.00 °C | Monitor the seepage locations that are prone to occur, such as the contact surface between the tunnel lining and the surrounding rock, the vault and side walls, and the construction joints. | Distributed; long distance; high precision; real–time monitoring. High cost; complex data processing; there is a bias in the data. | |

| Distributed Acoustic Sensing (DAS) | Distance: >50 km Sound response frequency: 0~50 kHz Spatial sampling resolution: 0.25 m | Real–time vibration monitoring can be carried out on the tunnel vault, side wall, along the line, road surface and other positions. | Long distance; continuous monitoring; high precision; multi–parameter; high temperature resistance; small size; strong networking ability; low cost. Affected by the environment; high technical requirements for operators. |

| Measurement Point | Measurement Point | ||||||

|---|---|---|---|---|---|---|---|

| Max | Ave | Min | Max | Ave | Min | ||

| 1 | 8.7 | −13.8 | −29.1 | / | / | / | / |

| 2 | 23.3 | −10.1 | −27.8 | 14 | 6.5 | −34.2 | 51.8 |

| 3 | −0.6 | −30.2 | −40.4 | 13 | −0.5 | −29.2 | −41.7 |

| 4 | −0.9 | −26.9 | −34.6 | 12 | 0.0 | −29.0 | −38.2 |

| 5 | −0.2 | −6.5 | −9.9 | 11 | −0.1 | −7.1 | −10.1 |

| 6 | −0.2 | −6.0 | −9.0 | 10 | −0.1 | −5.0 | −6.9 |

| 7 | 5.2 | 3.2 | 0.1 | 9 | 4.8 | 3.2 | −0.2 |

| 8 | 2.2 | −3.3 | −6.2 | / | / | / | / |

| Measurement Point | Measurement Point | ||||||

|---|---|---|---|---|---|---|---|

| Max | Ave | Min | Max | Ave | Min | ||

| 1 | −7.3 | −40.8 | −68.8 | / | / | / | / |

| 2 | −13.7 | −42.4 | −68.8 | 14 | −13.6 | −39.2 | −51.2 |

| 3 | −1.5 | −27.8 | −49.8 | 13 | −7.7 | −59.9 | −90.8 |

| 4 | 0.7 | −29.9 | −48.6 | 12 | −3.5 | −28.9 | −48.9 |

| 5 | −0.5 | −23.1 | −43.5 | 11 | 3.1 | −5.6 | −24.3 |

| 6 | −4.2 | −21.7 | −42.5 | 10 | 5.5 | −1.2 | −12.6 |

| 7 | 5.4 | −12.4 | −37.7 | 9 | 4.7 | −7.4 | −21.7 |

| 8 | −4.8 | −12.9 | −27.1 | / | / | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, G.; Wang, Z.; Li, G.; Shi, B.; Wu, J.; Cao, D.; Nie, Y. Advanced Research and Engineering Application of Tunnel Structural Health Monitoring Leveraging Spatiotemporally Continuous Fiber Optic Sensing Information. Photonics 2025, 12, 855. https://doi.org/10.3390/photonics12090855

Cheng G, Wang Z, Li G, Shi B, Wu J, Cao D, Nie Y. Advanced Research and Engineering Application of Tunnel Structural Health Monitoring Leveraging Spatiotemporally Continuous Fiber Optic Sensing Information. Photonics. 2025; 12(9):855. https://doi.org/10.3390/photonics12090855

Chicago/Turabian StyleCheng, Gang, Ziyi Wang, Gangqiang Li, Bin Shi, Jinghong Wu, Dingfeng Cao, and Yujie Nie. 2025. "Advanced Research and Engineering Application of Tunnel Structural Health Monitoring Leveraging Spatiotemporally Continuous Fiber Optic Sensing Information" Photonics 12, no. 9: 855. https://doi.org/10.3390/photonics12090855

APA StyleCheng, G., Wang, Z., Li, G., Shi, B., Wu, J., Cao, D., & Nie, Y. (2025). Advanced Research and Engineering Application of Tunnel Structural Health Monitoring Leveraging Spatiotemporally Continuous Fiber Optic Sensing Information. Photonics, 12(9), 855. https://doi.org/10.3390/photonics12090855