Recent Progress in Liquid Crystal-Based Smart Windows with Low Driving Voltage and High Contrast

Abstract

1. Introduction

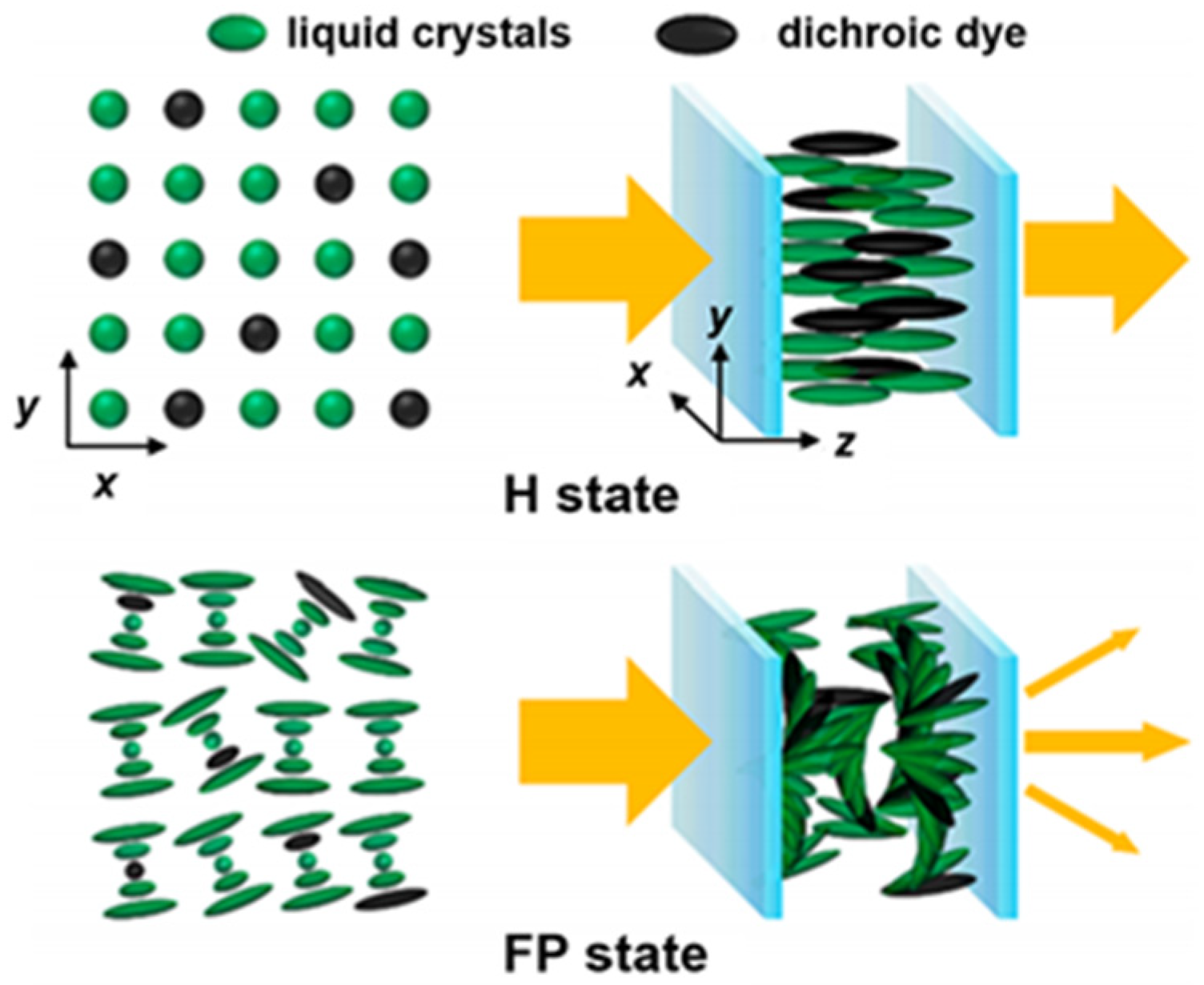

2. Transparency-Changing LC-Based Smart Windows

3. Enhanced Electrical and Optical Performance: Low Driving Voltage and High Contrast

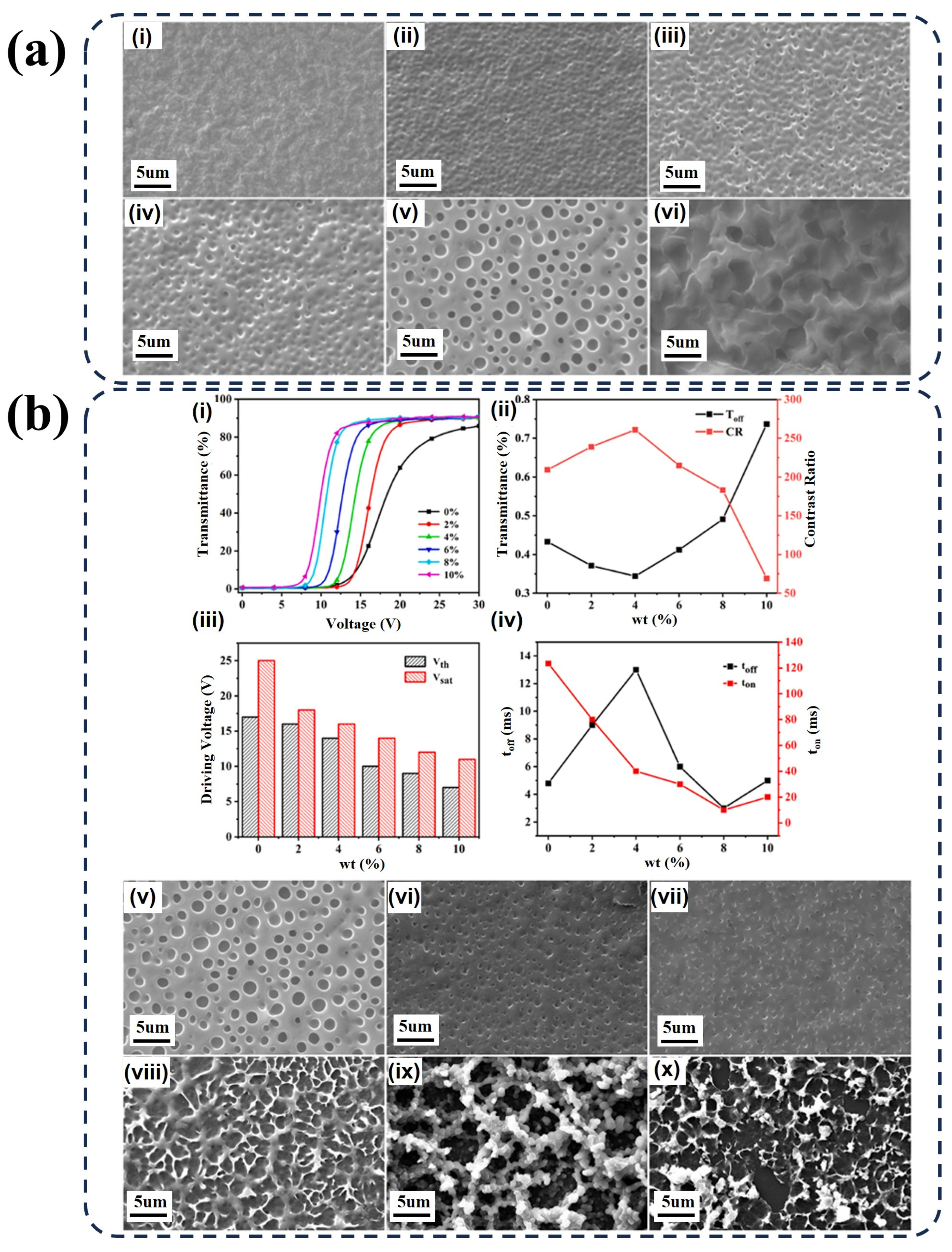

3.1. Doping with General Organic/Inorganic Compounds

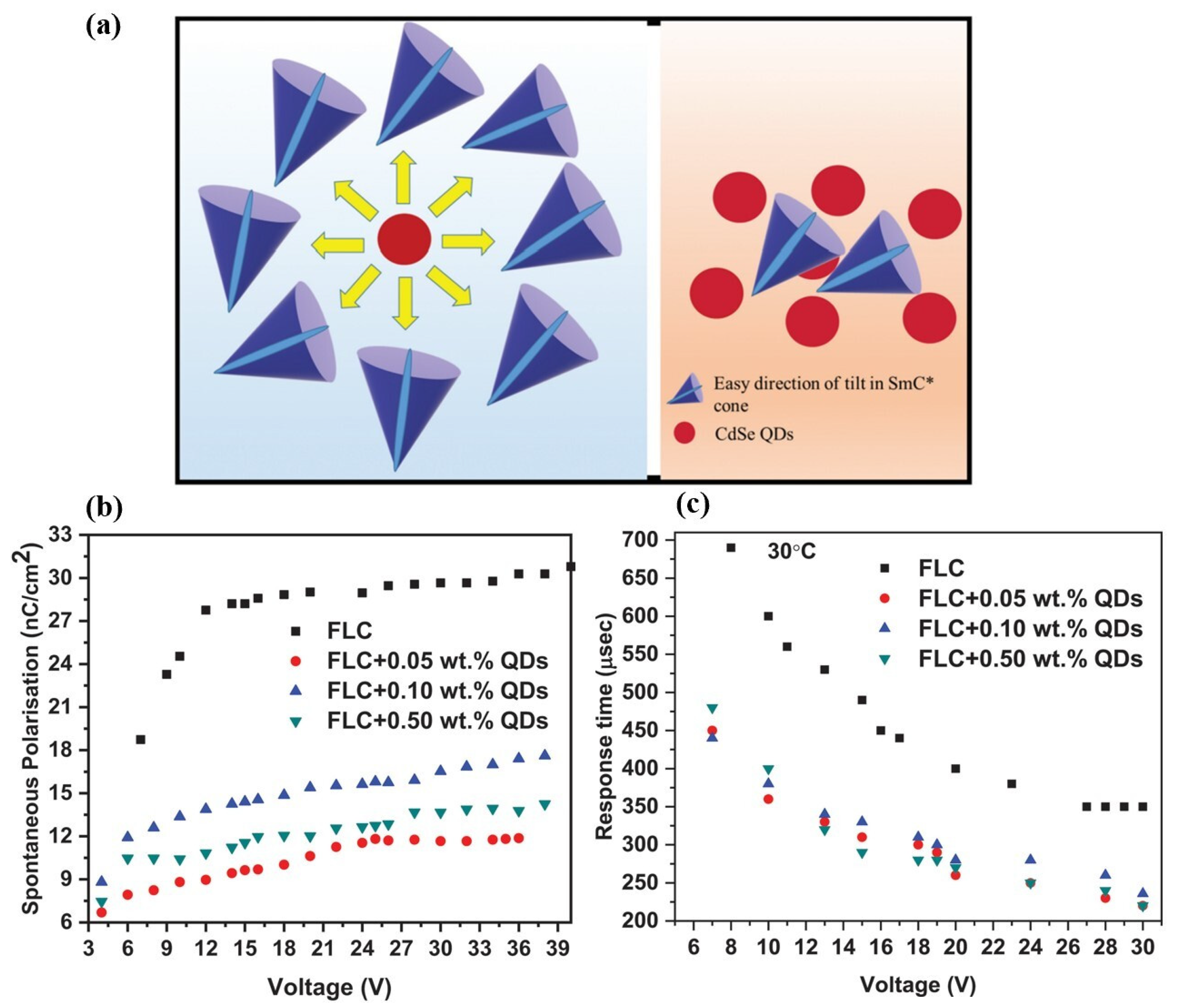

3.2. Doping with Nanoparticles

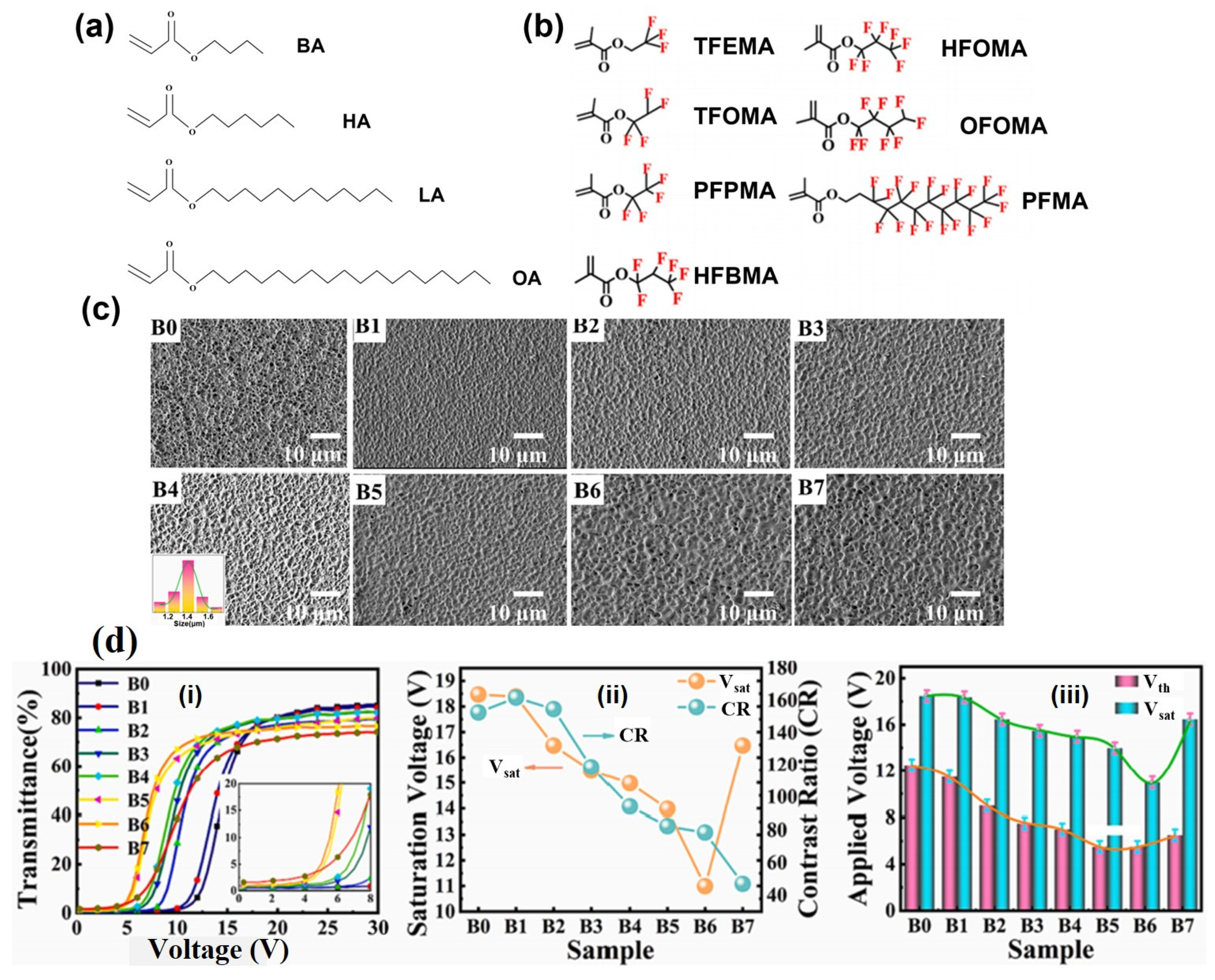

3.3. Optimization of Doping Material Structures

3.4. Selecting Appropriate Polymerization Temperature and UV Intensity

3.5. Adjusting the Driving Frequency

4. Conclusions and Perspective

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Geng, Y.; Ji, W.; Wang, Z.; Lin, B.; Zhu, Y. A review of operating performance in green buildings: Energy use, indoor environmental quality and occupant satisfaction. Energy Build. 2019, 183, 500–514. [Google Scholar] [CrossRef]

- Yang, L.; Yan, H.; Lam, J.C. Thermal comfort and building energy consumption implications—A review. Appl. Energy 2014, 115, 164–173. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; Xu, J.; He, X.; Yuan, B.; Chen, C.; Zou, C.; Wang, Q.; Gao, Y.; Yu, M.; et al. A novel dual-functional flexible dimming film for smart window applications: Energy saving and self-cleaning performance. Chem. Eng. J. 2024, 488, 150601. [Google Scholar] [CrossRef]

- Ke, Y.; Zhou, C.; Zhou, Y.; Wang, S.; Chan, S.H.; Long, Y. Emerging Thermal-Responsive Materials and Integrated Techniques Targeting the Energy-Efficient Smart Window Application. Adv. Funct. Mater. 2018, 28, 1800113. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, B.; Zhu, N.; Huang, Y.; Wang, F.; Li, R.; Zhao, Y.; Jiang, Q.; Wu, X.; Zhang, R. Dual-band electrochromic materials for energy-saving smart windows. Carbon Neutralization 2023, 2, 4–27. [Google Scholar] [CrossRef]

- Ghosh, A.; Hafnaoui, R.; Mesloub, A.; Elkhayat, K.; Albaqawy, G.; Alnaim, M.M.; Mayhoub, M. Active smart switchable glazing for smart city: A review. J. Build. Eng. 2024, 84, 108644. [Google Scholar] [CrossRef]

- Shen, W.; Li, G. Recent Progress in Liquid Crystal-Based Smart Windows: Materials, Structures, and Design. Laser Photon. Rev. 2023, 17, 2200207. [Google Scholar] [CrossRef]

- Hemaida, A.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Simulation study for a switchable adaptive polymer dispersed liquid crystal smart window for two climate zones (Riyadh and London). Energy Build. 2021, 251, 111381. [Google Scholar] [CrossRef]

- Iluyemi, D.C.; Nundy, S.; Shaik, S.; Tahir, A.; Ghosh, A. Building energy analysis using EC and PDLC based smart switchable window in Oman. Sol. Energy 2022, 237, 301–312. [Google Scholar] [CrossRef]

- Chen, C.; Chen, Y.; Yao, H.; Song, Q.; Jia, C.; Zhang, Y. A dual-mode laser-textured ice-phobic slippery surface: Low-voltage-powered switching transmissivity and wettability for thermal management. Nanoscale 2022, 14, 4474–4483. [Google Scholar] [CrossRef]

- Kamal, W.; Li, M.; Lin, J.; Parry, E.; Jin, Y.; Elston, S.J.; Castrejón-Pita, A.A.; Morris, S.M. Spatially Patterned Polymer Dispersed Liquid Crystals for Image-Integrated Smart Windows. Adv. Opt. Mater. 2022, 10, 2101748. [Google Scholar] [CrossRef]

- Mateen, F.; Ali, M.; Oh, H.; Hong, S.-K. Nitrogen-doped carbon quantum dot based luminescent solar concentrator coupled with polymer dispersed liquid crystal device for smart management of solar spectrum. Sol. Energy 2019, 178, 48–55. [Google Scholar] [CrossRef]

- Wang, J.; Meng, C.; Gu, Q.; Tseng, M.C.; Tang, S.T.; Kwok, H.S.; Cheng, J.; Zi, Y. Normally Transparent Tribo-Induced Smart Window. ACS Nano 2020, 14, 3630–3639. [Google Scholar] [CrossRef]

- Xia, Y.; Liang, X.; Jiang, Y.; Wang, S.; Qi, Y.; Liu, Y.; Yu, L.; Yang, H.; Zhao, X. High-Efficiency and Reliable Smart Photovoltaic Windows Enabled by Multiresponsive Liquid Crystal Composite Films and Semi-Transparent Perovskite Solar Cells. Adv. Energy Mater. 2019, 9, 1900720. [Google Scholar] [CrossRef]

- Sen, C.; Alkan, B.; Mohammadmoradi, O.; Taralp, A. Polymer Dispersed Liquid Crystal Smart Film Technologies: Overview. In Revolutionizing Energy Conversion—Photoelectrochemical Technologies and Their Role in Sustainability; Zendehdel, M., Nia, N.Y., Samer, M., Eds.; IntechOpen: Rijeka, Croatia, 2024. [Google Scholar]

- Casini, M. Active dynamic windows for buildings: A review. Renew. Energy 2018, 119, 923–934. [Google Scholar] [CrossRef]

- Lei, P.; Wang, J.; Gao, Y.; Hu, C.; Zhang, S.; Tong, X.; Wang, Z.; Gao, Y.; Cai, G. An Electrochromic Nickel Phosphate Film for Large-Area Smart Window with Ultra-Large Optical Modulation. Nano-Micro Lett. 2023, 15, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Guo, Z.H.; Xu, F.; Jia, L.; Pan, C.; Wang, Z.L.; Pu, X. Triboelectric-optical responsive cholesteric liquid crystals for self-powered smart window, E-paper display and optical switch. Sci. Bull. 2021, 66, 1986–1993. [Google Scholar] [CrossRef] [PubMed]

- Ren, R.; Liu, S.; Gao, Y.; Lei, P.; Wang, J.; Tong, X.; Zhang, P.; Wang, Z.; Cai, G. Tunable Interaction between Zn2+ and Superstructured Nb18W16O93 Bimetallic Oxide for Multistep Tinted Electrochromic Device. ACS Energy Lett. 2023, 8, 2300–2307. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, R.; Gao, Y.; Jia, Y.; Cai, G. Unveiling the Multistep Electrochemical Desorption Mechanism of Cubic NiO Films for Transmissive-to-Black Electrochromic Energy Storage Devices. J. Phys. Chem. Lett. 2023, 14, 2284–2291. [Google Scholar] [CrossRef]

- Wang, J.-L.; Sheng, S.-Z.; He, Z.; Wang, R.; Pan, Z.; Zhao, H.-Y.; Liu, J.-W.; Yu, S.-H. Self-Powered Flexible Electrochromic Smart Window. Nano Lett. 2021, 21, 9976–9982. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Feng, Z.; Zhao, J.; Yang, Z.; Wang, X.; Wang, W. Self-accelerating photocharge separation in BiOBr ultrathin nanosheets for boosting photoreversible color switching. Chem. Eng. J. 2022, 428, 131235. [Google Scholar] [CrossRef]

- Kim, J.E.; Han, T.H.; Lee, S.H.; Kim, J.Y.; Ahn, C.W.; Yun, J.M.; Kim, S.O. Graphene Oxide Liquid Crystals. Angew. Chem. Int. Ed. Engl. 2011, 50, 3043–3047. [Google Scholar] [CrossRef]

- Lagerwall, J.P.; Scalia, G. A new era for liquid crystal research: Applications of liquid crystals in soft matter nano-, bio- and microtechnology. Curr. Appl. Phys. 2012, 12, 1387–1412. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, S.-T. Electric field-induced monodomain blue phase liquid crystals. Appl. Phys. Lett. 2013, 102, 171110. [Google Scholar] [CrossRef]

- Guillamat, P.; Ignés-Mullol, J.; Sagués, F. Control of active liquid crystals with a magnetic field. Proc. Natl. Acad. Sci. USA 2016, 113, 5498–5502. [Google Scholar] [CrossRef]

- Schwartz, J.J.; Mendoza, A.M.; Wattanatorn, N.; Zhao, Y.; Nguyen, V.T.; Spokoyny, A.M.; Mirkin, C.A.; Baše, T.; Weiss, P.S. Surface Dipole Control of Liquid Crystal Alignment. J. Am. Chem. Soc. 2016, 138, 5957–5967. [Google Scholar] [CrossRef]

- Wei, W.-S.; Xia, Y.; Ettinger, S.; Yang, S.; Yodh, A.G. Molecular heterogeneity drives reconfigurable nematic liquid crystal drops. Nature 2019, 576, 433–436. [Google Scholar] [CrossRef]

- Chen, J.-W.; Huang, C.-C.; Chao, C.-Y. Supramolecular Liquid-Crystal Gels Formed by Polyfluorene-Based π-Conjugated Polymer for Switchable Anisotropic Scattering Device. ACS Appl. Mater. Interfaces 2014, 6, 6757–6764. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, H.; Chen, Y.; Yu, H. Progress in Fabrication and Applications of Cholesteric Liquid Crystal Microcapsules. Chem.—A Eur. J. 2024, 30, e202303198. [Google Scholar] [CrossRef]

- Chauhan, G.; Malik, P.; Deep, A. Morphological, dielectric, electro-optic and photoluminescence properties of titanium oxide nanoparticles enriched polymer stabilized cholesteric liquid crystal composites. J. Mol. Liq. 2023, 376, 121406. [Google Scholar] [CrossRef]

- Gan, P.; Zhang, X.; Zhao, L.; Shi, W.; Cao, H.; Wang, H.; Yang, Z.; Wang, D.; He, W. Broadband reflection in polymer-stabilized cholesteric liquid crystal film with zinc oxide nanoparticles film thermal diffusion method. Liq. Cryst. 2021, 48, 1959–1968. [Google Scholar] [CrossRef]

- Sadigh, M.K.; Naziri, P.; Ranjkesh, A.; Zakerhamidi, M. Relationship of pitch length of cholesteric liquid crystals with order parameter and normalized polarizability. Opt. Mater. 2021, 119, 111373. [Google Scholar] [CrossRef]

- Du, X.; Li, Y.; Liu, Y.; Wang, F.; Luo, D. Electrically switchable bistable dual frequency liquid crystal light shutter with hyper-reflection in near infrared. Liq. Cryst. 2019, 46, 1727–1733. [Google Scholar] [CrossRef]

- Li, C.-C.; Tseng, H.-Y.; Chen, C.-W.; Wang, C.-T.; Jau, H.-C.; Wu, Y.-C.; Hsu, W.-H.; Lin, T.-H. Versatile Energy-Saving Smart Glass Based on Tristable Cholesteric Liquid Crystals. ACS Appl. Energy Mater. 2020, 3, 7601–7609. [Google Scholar] [CrossRef]

- Moheghi, A.; Nemati, H.; Li, Y.; Li, Q.; Yang, D.-K. Bistable salt doped cholesteric liquid crystals light shutter. Opt. Mater. 2016, 52, 219–223. [Google Scholar] [CrossRef]

- Ke, Y.; Chen, J.; Lin, G.; Wang, S.; Zhou, Y.; Yin, J.; Lee, P.S.; Long, Y. Smart Windows: Electro-, Thermo-, Mechano-, Photochromics, and Beyond. Adv. Energy Mater. 2019, 9, 1902066. [Google Scholar] [CrossRef]

- Geng, C.; Dou, S.; Zhao, J.; Ren, F.; Gu, J.; Wei, H.; Guan, H.; Liang, S.; Li, L.; Li, Y.; et al. Self-templated method to fabricate VO2 nanoparticles with ultrahigh luminous transmittance for energy-efficient thermochromic windows. Appl. Surf. Sci. 2022, 592, 153267. [Google Scholar] [CrossRef]

- Qu, Z.; Yao, L.; Li, J.; He, J.; Mi, J.; Ma, S.; Tang, S.; Feng, L. Bifunctional Template-Induced VO2@SiO2 Dual-Shelled Hollow Nanosphere-Based Coatings for Smart Windows. ACS Appl. Mater. Interfaces 2019, 11, 15960–15968. [Google Scholar] [CrossRef]

- Fan, X.; Pan, M.; Li, X.; Kong, L.; Kuchmizha, A.; Xu, H. Research progress of MOF electrochromic materials. Resour. Chem. Mater. 2024, 3, 230–245. [Google Scholar] [CrossRef]

- Wen, R.-T.; Granqvist, C.G.; Niklasson, G.A. Eliminating degradation and uncovering ion-trapping dynamics in electrochromic WO3 thin films. Nat. Mater. 2015, 14, 996–1001. [Google Scholar] [CrossRef]

- Madasamy, K.; Velayutham, D.; Suryanarayanan, V.; Kathiresan, M.; Ho, K.-C. Viologen-based electrochromic materials and devices. J. Mater. Chem. C 2019, 7, 4622–4637. [Google Scholar] [CrossRef]

- Pande, G.K.; Heo, J.S.; Choi, J.H.; Eom, Y.S.; Kim, J.; Park, S.K.; Park, J.S. RGB-to-black multicolor electrochromic devices enabled with viologen functionalized polyhedral oligomeric silsesquioxanes. Chem. Eng. J. 2021, 420, 130446. [Google Scholar] [CrossRef]

- Wang, J.; Liu, J.; Hu, M.; Zeng, J.; Mu, Y.; Guo, Y.; Yu, J.; Ma, X.; Qiu, Y.; Huang, Y. A flexible, electrochromic, rechargeable Zn//PPy battery with a short circuit chromatic warning function. J. Mater. Chem. A 2018, 6, 11113–11118. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, J.; Tong, Z.; Ji, H.; Qu, H. Bioinspired Dynamically Switchable PANI/PS-b-P2VP Thin Films for Multicolored Electrochromic Displays with Long-Term Durability. Adv. Funct. Mater. 2021, 31, 2106577. [Google Scholar] [CrossRef]

- Jamdegni, M.; Kaur, A. Review—Polymeric/Small Organic Molecules-Based Electrochromic Devices: How Far Toward Realization. J. Electrochem. Soc. 2022, 169, 030541. [Google Scholar] [CrossRef]

- Chen, J.; Song, G.; Cong, S.; Zhao, Z. Resonant-Cavity-Enhanced Electrochromic Materials and Devices. Adv. Mater. 2023, 35, e2300179. [Google Scholar] [CrossRef]

- Ko, I.J.; Park, J.H.; Kim, G.W.; Lampande, R.; Kwon, J.H. An optically efficient full-color reflective display with an electrochromic device and color production units. J. Inf. Disp. 2019, 20, 155–160. [Google Scholar] [CrossRef]

- Neubrech, F.; Duan, X.; Liu, N. Dynamic plasmonic color generation enabled by functional materials. Sci. Adv. 2020, 6, eabc2709. [Google Scholar] [CrossRef] [PubMed]

- Xiong, K.; Olsson, O.; Svirelis, J.; Palasingh, C.; Baumberg, J.; Dahlin, A. Video Speed Switching of Plasmonic Structural Colors with High Contrast and Superior Lifetime. Adv. Mater. 2021, 33, 2103217. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Gong, W.; Wang, X.; Chen, Z.; Chen, X.; Chen, J.; Sun, H.; Song, G.; Cong, S.; Geng, F.; et al. Remarkable Near-Infrared Electrochromism in Tungsten Oxide Driven by Interlayer Water-Induced Battery-to-Pseudocapacitor Transition. ACS Appl. Mater. Interfaces 2020, 12, 33917–33925. [Google Scholar] [CrossRef]

- Azam, A.; Kim, J.; Park, J.; Novak, T.G.; Tiwari, A.P.; Song, S.H.; Kim, B.; Jeon, S. Two-Dimensional WO3 Nanosheets Chemically Converted from Layered WS2 for High-Performance Electrochromic Devices. Nano Lett. 2018, 18, 5646–5651. [Google Scholar] [CrossRef]

- Ma, D.; Eh, A.L.-S.; Cao, S.; Lee, P.S.; Wang, J. Wide-Spectrum Modulated Electrochromic Smart Windows Based on MnO2/PB Films. ACS Appl. Mater. Interfaces 2022, 14, 1443–1451. [Google Scholar] [CrossRef] [PubMed]

- Sajitha, S.; Aparna, U.; Deb, B. Ultra-Thin Manganese Dioxide-Encrusted Vanadium Pentoxide Nanowire Mats for Electrochromic Energy Storage Applications. Adv. Mater. Interfaces 2019, 6, 1901038. [Google Scholar] [CrossRef]

- Mjejri, I.; Gaudon, M.; Song, G.; Labrugère, C.; Rougier, A. Crystallized V2O5 as Oxidized Phase for Unexpected Multicolor Electrochromism in V2O3 Thick Film. ACS Appl. Energy Mater. 2018, 1, 2721–2729. [Google Scholar] [CrossRef]

- Zhang, W.; Li, H.; Al-Hussein, M.; Elezzabi, A.Y. Electrochromic Battery Displays with Energy Retrieval Functions Using Solution-Processable Colloidal Vanadium Oxide Nanoparticles. Adv. Opt. Mater. 2020, 8, 1901224. [Google Scholar] [CrossRef]

- Cao, S.; Zhang, S.; Zhang, T.; Yao, Q.; Lee, J.Y. A Visible Light-Near-Infrared Dual-Band Smart Window with Internal Energy Storage. Joule 2019, 3, 1152–1162. [Google Scholar] [CrossRef]

- Liang, Y.; Cao, S.; Wei, Q.; Zeng, R.; Zhao, J.; Li, H.; Yu, W.W.; Zou, B. Reversible Zn2+ Insertion in Tungsten Ion-Activated Titanium Dioxide Nanocrystals for Electrochromic Windows. Nano-Micro Lett. 2021, 13, 1–12. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Q.; Cong, S.; Chen, Z.; Zhao, J.; Yang, M.; Zheng, Z.; Zeng, S.; Yang, X.; Geng, F.; et al. Using Intrinsic Intracrystalline Tunnels for Near-Infrared and Visible-Light Selective Electrochromic Modulation. Adv. Opt. Mater. 2017, 5, 1700194. [Google Scholar] [CrossRef]

- Zhang, W.; Li, H.; Hopmann, E.; Elezzabi, A.Y. Nanostructured inorganic electrochromic materials for light applications. Nanophotonics 2021, 10, 825–850. [Google Scholar] [CrossRef]

- Jiang, J.; Qin, L.; Halim, J.; Persson, P.O.Å.; Hou, L.; Rosen, J. Colorless-to-colorful switching of electrochromic MXene by reversible ion insertion. Nano Res. 2022, 15, 3587–3593. [Google Scholar] [CrossRef]

- Shao, Z.; Huang, A.; Ming, C.; Bell, J.; Yu, P.; Sun, Y.-Y.; Jin, L.; Ma, L.; Luo, H.; Jin, P.; et al. All-solid-state proton-based tandem structures for fast-switching electrochromic devices. Nat. Electron. 2022, 5, 45–52. [Google Scholar] [CrossRef]

- Li, H.; Firby, C.J.; Elezzabi, A.Y. Rechargeable Aqueous Hybrid Zn2+/Al3+ Electrochromic Batteries. Joule 2019, 3, 2268–2278. [Google Scholar] [CrossRef]

- Tamaoki, N. Cholesteric Liquid Crystals for Color Information Technology. Adv. Mater. 2001, 13, 1135–1147. [Google Scholar] [CrossRef]

- Fung, Y.K.; Yang, D.-K.; Ying, S.; Chien, L.-C.; Zumer, S.; Doane, J.W. Polymer networks formed in liquid crystals. Liq. Cryst. 1995, 19, 797–801. [Google Scholar] [CrossRef]

- West, J.L. Polymer-Dispersed Liquid Crystals; ACS Publications: Washington, DC, USA, 1990. [Google Scholar]

- Whitehead, J.J.B.; Zumer, S.; Doane, W.; Doane, J.W.; Yaniv, Z. Light Transmission And Scattering of Polymer Dispersed Liquid Crystals. In Proceedings of the OE/LASE ’89, Los Angeles, CA, USA, 15–20 January 1989; pp. 250–257. [Google Scholar]

- Ren, Y.; Hu, W.; Sun, C.; Huang, J.; Hu, J.; Shen, J.; He, W.; Zhang, L.; Yuan, X.; Yu, M.; et al. Study on electro-optical and adhesion properties of polymer dispersed liquid crystal films from thiol-ene click reaction. Liq. Cryst. 2021, 48, 2188–2199. [Google Scholar] [CrossRef]

- Shen, W.; Wang, L.; Zhong, T.; Chen, G.; Li, C.; Chen, M.; Zhang, C.; Zhang, L.; Li, K.; Yang, Z.; et al. Electrically switchable light transmittance of epoxy-mercaptan polymer/nematic liquid crystal composites with controllable microstructures. Polymer 2019, 160, 53–64. [Google Scholar] [CrossRef]

- Hikmet, R.A.M. Electrically induced light scattering from anisotropic gels. J. Appl. Phys. 1990, 68, 4406–4412. [Google Scholar] [CrossRef]

- Ma, Y.D.; Wu, B.G.; Xu, G. Reverse-Mode Microdroplet Liquid Crystal Display. In Electronic Imaging: Advanced Devices and Systems; SPIE: Washington, DC, USA, 1990; Volume 1257. [Google Scholar]

- Gotoh, T.; Murai, H. Preparation and characteristics of new reverse mode film of polymer dispersed liquid crystal type. Appl. Phys. Lett. 1992, 60, 392–394. [Google Scholar] [CrossRef]

- Nicoletta, F.P.; De Filpo, G.; Lanzo, J.; Chidichimo, G. A method to produce reverse-mode polymer-dispersed liquid-crystal shutters. Appl. Phys. Lett. 1999, 74, 3945–3947. [Google Scholar] [CrossRef]

- Macchione, M.; Cupelli, D.; De Filpo, G.; Nicoletta, F.P.; Chidichimo, G. Rough surfaces for orientation control in reverse mode polymer dispersed liquid crystal films. Liq. Cryst. 2000, 27, 917–920. [Google Scholar] [CrossRef]

- Yamaguchi, R.; Waki, Y.; Sato, S. Reverse Mode and Wide Viewing Angle Properties in Polymer Dispersed Liquid Crystal Cells Prepared Using a UV Curable Liquid Crystal. Jpn. J. Appl. Phys. 1997, 36, 2771–2774. [Google Scholar] [CrossRef]

- Ma, C.; Wu, Y.; Yu, M.; Gao, Y.; Xiao, J.; Zou, C.; Yang, H. Effect of Liquid Crystalline Acrylates on the Electro-Optical Properties and Micro-Structures of Polymer-Dispersed Liquid Crystal Films. Crystals 2023, 13, 1294. [Google Scholar] [CrossRef]

- Doane, J.W.; Yang, D.K.; Chien, L.C. Polymer Stabilized Liquid Crystalline Light Modulating Device and Material. U.S. Patent 5,691,795, 25 November 1997. [Google Scholar]

- Epure, E.-L.; Stoica, I.; Albu, R.M.; Hulubei, C.; Barzic, A.I. New Strategy for Inducing Surface Anisotropy in Polyimide Films for Nematics Orientation in Display Applications. Nanomaterials 2021, 11, 3107. [Google Scholar] [CrossRef]

- Yang, D.K.; Li, Q. Polymer Stabilized Cholesteric Liquid Crystal for Switchable Windows. Liq. Cryst. Beyond Disp. 2012, 1, 505–523. [Google Scholar]

- Yang, D.K.; Chien, L.C.; Fung, Y.K. Polymer-Stabilized Cholesteric Textures: Materials and Applications. In Liquid Crystals in Complex Geometries; CRC Press: Boca Raton, FL, USA, 1996; pp. 103–142. [Google Scholar]

- He, Z.; Chu, Y.; Luo, S.; Yang, H.; Yu, P.; Wang, L.; Miao, Z. Reverse mode LCPG films with self-assembly support of gel networks. Liq. Cryst. 2024, 51, 1708–1718. [Google Scholar] [CrossRef]

- Yin, W.; Zhao, Y.; Gao, H.; Du, Z.; Wang, D.; Li, C.; Luan, Y.; Cao, H.; Yang, Z.; He, W. A recyclable, interchangeable optical switch with a PDLC-PVA-PSCLC structure and a low-voltage drive system. Liq. Cryst. 2024, 51, 1942–1955. [Google Scholar] [CrossRef]

- Amundson, K. Electro-optic properties of a polymer-dispersed liquid-crystal film: Temperature dependence and phase behavior. Phys. Rev. E 1996, 53, 2412–2422. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.-G.; Erdmann, J.H.; Doane, J.W. Response times and voltages for PDLC light shutters. Liq. Cryst. 1989, 5, 1453–1465. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, C.; Zhao, W.; Li, M.; Wang, X.; Yang, X.; Hu, X.; Yuan, D.; Yang, W.; Zhang, Y.; et al. Polymer Stabilized Liquid Crystal Smart Window with Flexible Substrates Based on Low-Temperature Treatment of Polyamide Acid Technology. Polymers 2019, 11, 1869. [Google Scholar] [CrossRef]

- Yun, C.; Saeed, M.H.; Kim, D.; Kim, K.; Choi, M.; Park, S.-C.; Na, J.-H. Reverse Mode Polymer-Stabilized Liquid Crystal Films via Thiol and Acrylic Azobenzene. ACS Appl. Polym. Mater. 2023, 5, 3919–3927. [Google Scholar] [CrossRef]

- Yin, S.; Li, X.; Ge, S.; Zhao, Y.; Ma, H.; Sun, Y. Low driving voltage reverse-mode polymer-stabilised cholesteric liquid crystal devices using small phenylacetylene molecule. Liq. Cryst. 2024, 51, 442–451. [Google Scholar] [CrossRef]

- Zhang, Z.; He, X.; Zhang, L.; Xu, J.; Yuan, B.; Chen, C.; Zou, C.; Wang, Q.; Gao, Y.; Yu, M.; et al. A novel low-voltage fast-response electrically controlled dimming film based on fluorinated PDLC for smart window applications. Chem. Eng. J. 2024, 479, 147668. [Google Scholar] [CrossRef]

- Yu, M.; Zhou, F.; Zhang, L.; He, X.; Chen, C.; Zhang, Z.; Gao, Y.; Wang, Q.; Xiao, J.; Wei, H.; et al. Effects of hydroxylated acrylates on electro-optical performance and adhesion strength of polymer dispersed liquid crystal films. J. Mol. Liq. 2024, 397, 124180. [Google Scholar] [CrossRef]

- Yu, M.; He, X.; Qin, J.; Hu, Y.; Wang, Q.; Zou, C.; Wei, H.; Wang, X.; Gao, Y.; Yang, H. Impact of crosslinking agents with steric cyclic groups on the properties of polymer-dispersed liquid crystals. Phys. Chem. Chem. Phys. 2024, 26, 7388–7397. [Google Scholar] [CrossRef]

- Zheng, Z.-G.; Wang, C.; Shen, D. Dichroic-dye-doped polymer stabilized optically isotropic chiral liquid crystals. J. Mater. Chem. C 2013, 1, 6471–6478. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Li, H.; Li, Y.; Zheng, W.; Quan, Y.; Cheng, Y. Dynamic Circularly Polarized Luminescence with Tunable Handedness and Intensity Enabled by Achiral Dichroic Dyes in Cholesteric Liquid Crystal Medium. Adv. Mater. 2022, 34, e2202309. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.-Y.; Ma, W.-Y.; Zhang, Y.-M.; Xu, C.-T.; Ren, H.; Han, W.-M.; Chen, C.-Y.; Hu, W. Broadband spatial polarization processing of light via a photopatterned dichroic medium. Appl. Phys. Lett. 2022, 120, 041103. [Google Scholar] [CrossRef]

- Gahrotra, R.; Sharma, V.; Dogra, A.R.; Malik, P.; Kumar, P. Performance augmentation of bistable cholesteric liquid crystal light shutter- effect of dichroic dye on morphological and electro-optical characteristics. Opt. Mater. 2022, 127, 112243. [Google Scholar] [CrossRef]

- Zhan, T.; Xiong, J.; Tan, G.; Wu, S.-T. Absorption-based polarization gratings. Opt. Express 2020, 28, 13907–13912. [Google Scholar] [CrossRef]

- Lee, J.; Nam, S.; Choi, S.S. Design of chiral guest-host liquid crystals for a transmittance-tunable smart window. Opt. Mater. Express 2022, 12, 2568–2583. [Google Scholar] [CrossRef]

- Li, G.; Zhou, Y. Recent Advances in High-Performance Polarization-Independent Tunable Broadband Modulators for Optometry. Investig. Ophthalmol. Vis. Sci. 2024, 65, 6360. [Google Scholar]

- Li, G.; Zhou, Y.; Huo, D. Low-Voltage, High-Contrast Ratio, Broadband Tunable Attenuator Based on Liquid Crystal Materials. Investig. Ophthalmol. Vis. Sci. 2023, 64, 1489. [Google Scholar]

- Chang, Y.-C.; Yang, S.-H.; Zyryanov, V.Y.; Lee, W. Electrically tunable thermoresponsive optic switch for smart window application based on dye-doped cholesteric liquid crystal. J. Mol. Liq. 2023, 388, 122752. [Google Scholar] [CrossRef]

- Lin, H.; Zhao, Y.; Jiao, X.; Gao, H.; Guo, Z.; Wang, D.; Luan, Y.; Wang, L. Preparation and Application of Polymer-Dispersed Liquid Crystal Film with Step-Driven Display Capability. Molecules 2024, 29, 1109. [Google Scholar] [CrossRef]

- Singh, B.P.; Agarwal, S.; Hatshan, M.R.; Singh, K.K.; Kumar, K.D.; Manohar, R.; Tripathi, P.K.; Singh, D.P. Examining Energy Storage Potential in Weakly Polar Nematic Liquid Crystals Infused with Anthraquinone Dye: A Comprehensive Approach. J. Compos. Sci. 2023, 7, 470. [Google Scholar] [CrossRef]

- Chinky; Malik, P.; Kumar, P. Influence of orange azo dichroic dye on morphological, electro-optical, phase transition and absorption behaviour of ZnO nanoparticles-induced homeotropically aligned liquid crystal display cell. J. Mater. Sci. Mater. Electron. 2023, 34, 1–13. [Google Scholar] [CrossRef]

- Kocakülah, G. Comparison of electro-optical and dielectric properties of cobalt (II) phthalocyanine doped cholesteric liquid crystals. Opt. Mater. 2023, 141, 113949. [Google Scholar] [CrossRef]

- Peng, C.; Xu, C.; Hu, W. Smart beam via electrically addressing the dye-doped and polymer-stabilized cholesteric liquid crystals. Chin. Opt. Lett. 2024, 22, 053301. [Google Scholar] [CrossRef]

- Chinky; Malik, P.; Kumar, P. Effect of varying concentration of dichroic dye on textural, electro-optical, phase transition and band gap studies of zinc oxide nanoparticles induced vertically aligned liquid crystals. J. Mol. Struct. 2024, 1311, 138375. [Google Scholar] [CrossRef]

- Mhatre, M.M.; Katariya-Jain, A.; Deshmukh, R.R. Improved electro-optical and dielectric properties of polymer dispersed liquid crystal doped with disperse dye red 1 and carbon nanoparticles. Liq. Cryst. 2023, 50, 957–976. [Google Scholar] [CrossRef]

- Bisoyi, H.K.; Kumar, S. Liquid-crystal nanoscience: An emerging avenue of soft self-assembly. Chem. Soc. Rev. 2011, 40, 306–319. [Google Scholar] [CrossRef]

- Hegmann, T.; Qi, H.; Marx, V.M. Nanoparticles in liquid crystals:synthesis, self-assembly, defect formation and potential applications. J. Inorg. Organomet. Polym. 2007, 17, 483–508. [Google Scholar] [CrossRef]

- Marzal, V.; Caño-García, M.; Torres, J.C.; Quintana, X.; Pérez, I.; Garcia-Camara, B. Electrical Behavior of Liquid Crystal Devices with Dielectric Nanoparticles. J. Nanomater. 2020, 2020, 1–7. [Google Scholar] [CrossRef]

- Mirzaei, J.; Reznikov, M.; Hegmann, T. Quantum dots as liquid crystal dopants. J. Mater. Chem. 2012, 22, 22350–22365. [Google Scholar] [CrossRef]

- Budaszewski, D.; Siarkowska, A.; Chychłowski, M.; Jankiewicz, B.; Bartosewicz, B.; Dąbrowski, R.; Woliński, T.R. Nanoparticles-enhanced photonic liquid crystal fibers. J. Mol. Liq. 2018, 267, 271–278. [Google Scholar] [CrossRef]

- Rodarte, A.L.; Nuno, Z.S.; Cao, B.H.; Pandolfi, R.J.; Quint, M.T.; Ghosh, S.; Hein, J.E.; Hirst, L.S. Tuning Quantum-Dot Organization in Liquid Crystals for Robust Photonic Applications. Chemphyschem 2014, 15, 1413–1421. [Google Scholar] [CrossRef]

- Siarkowska, A.; Chychłowski, M.; Budaszewski, D.; Jankiewicz, B.; Bartosewicz, B.; Woliński, T.R. Thermo- and electro-optical properties of photonic liquid crystal fibers doped with gold nanoparticles. Beilstein J. Nanotechnol. 2017, 8, 2790–2801. [Google Scholar] [CrossRef]

- Rastogi, A. Polymer Dispersed Liquid Crystals (PDLCs): A Mini Review. J. Electr. Power Energy Syst. 2022, 6, 71–75. [Google Scholar] [CrossRef]

- Saeed, M.H.; Zhang, S.; Cao, Y.; Zhou, L.; Hu, J.; Muhammad, I.; Xiao, J.; Zhang, L.; Yang, H. Recent Advances in The Polymer Dispersed Liquid Crystal Composite and Its Applications. Molecules 2020, 25, 5510. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Yu, P.; Zhang, H.; Zhao, Y.; Zhu, Y.; Guo, Z.; Ma, C.; Zhang, H.; Miao, Z.; Shen, W. Silicon nanostructure-doped polymer/nematic liquid crystal composites for low voltage-driven smart windows. Nanotechnology 2022, 33, 085205. [Google Scholar] [CrossRef]

- He, Z.; Yu, P.; Zhao, Y.; Yang, Q.; Zhao, Y.; Zhang, H.; Zi, S.; Miao, Z.; Zhang, H.; Shen, W. The regulation of electric-optical properties of polymer-dispersed liquid crystals via implantation of polyhedral oligomeric silsesquioxane (POSS) microstructure. Liq. Cryst. 2022, 49, 240–247. [Google Scholar] [CrossRef]

- Yu, P.; Zhao, Y.; He, Z.; Zhang, H.; Zhao, Y.; Zhang, Y.; Guo, Z.; Ma, C.; Gao, J.; Zhang, H. Effect of preparation conditions on the electro-optical performance and the polymer morphology of polymer-dispersed liquid crystals with polyhedral oligomeric silsesquioxane (POSS) microstructure. Mol. Cryst. Liq. Cryst. 2022, 737, 41–51. [Google Scholar] [CrossRef]

- He, Z.; Yu, P.; Gao, J.; Ma, C.; Xu, J.; Duan, W.; Zhao, Y.; Miao, Z. An energy-efficient and low-driving-voltage flexible smart window enhanced by POSS and CsxWO3. Sol. Energy Mater. Sol. Cells 2023, 250, 112096. [Google Scholar] [CrossRef]

- Singh, A.K.; Malik, P.; Chauhan, G.; Hegde, G.; Malik, P. Synthesis and characterization of biowaste-based porous carbon nanoparticle-polymer dispersed ferroelectric liquid crystal composites. J. Mol. Liq. 2023, 390, 123024. [Google Scholar] [CrossRef]

- Jiang, Y.; Meng, J.; Xu, B.; Wang, W.; Wang, G.; Chen, Z. A hybrid ionic liquid crystal comprising imidazolium surfactant-graphene oxide. Liq. Cryst. 2023, 50, 2510–2520. [Google Scholar] [CrossRef]

- Mrukiewicz, M.; Kowiorski, K.; Perkowski, P.; Mazur, R.; Djas, M. Threshold voltage decrease in a thermotropic nematic liquid crystal doped with graphene oxide flakes. Beilstein J. Nanotechnol. 2019, 10, 71–78. [Google Scholar] [CrossRef] [PubMed]

- Yadav, S.; Malik, P.; Khushboo; Jayoti, D. Electro-optical, dielectric and optical properties of graphene oxide dispersed nematic liquid crystal composites. Liq. Cryst. 2020, 47, 984–993. [Google Scholar] [CrossRef]

- Dalir, N.; Javadian, S.; Kakemam, J.; Yousefi, A. Evolution of electro-chemical and electro-optical properties of nematic liquid crystal doped with graphene oxide. J. Mol. Liq. 2018, 265, 398–407. [Google Scholar] [CrossRef]

- Kaur, M.; Malik, P. New graphene oxide doped polymer dispersed liquid crystal nanocomposites targeted to eco-friendly and energy-efficient smart windows. J. Mol. Liq. 2024, 410, 125565. [Google Scholar] [CrossRef]

- Zhao, Y.; Ji, H.; Lu, M.; Tao, J.; Ou, Y.; Wang, Y.; Chen, Y.; Huang, Y.; Wang, J.; Mao, Y. Thermochromic Smart Windows Assisted by Photothermal Nanomaterials. Nanomaterials 2022, 12, 3865. [Google Scholar] [CrossRef]

- Dierking, I.; Scalia, G.; Morales, P.; LeClere, D. Aligning and Reorienting Carbon Nanotubes with Nematic Liquid Crystals. Adv. Mater. 2004, 16, 865–869. [Google Scholar] [CrossRef]

- Russell, J.M.; Oh, S.; LaRue, I.; Zhou, O.; Samulski, E.T. Alignment of nematic liquid crystals using carbon nanotube films. Thin Solid Films 2006, 509, 53–57. [Google Scholar] [CrossRef]

- Shivaraja, S.; Gupta, R.; Manjuladevi, V. Faster switching polymer dispersed liquid crystal devices incorporated with functionalized SWCNTs. J. Mol. Liq. 2022, 354, 118905. [Google Scholar] [CrossRef]

- Wu, Y.; Cao, H.; Duan, M.; Li, E.; Wang, H.; Yang, Z.; Wang, D.; He, W. Effects of a chemically modified multiwall carbon nanotubes on electro-optical properties of PDLC films. Liq. Cryst. 2018, 45, 1023–1031. [Google Scholar] [CrossRef]

- Li, J.; Ji, D.; Zhang, Z.; Yang, Y.; Zhang, R.; Wang, T.; Zhang, Y.; Cao, W.; Zhu, J. MWCNT Doped Reverse-Mode Polymer Network Liquid Crystals with Frequency Response Property. Chin. Phys. Lett. 2024, 41, 038501. [Google Scholar] [CrossRef]

- Zhong, Z.; Zhao, Y.; He, Z.; Gao, H.; Du, Z.; Zhang, H.; Wang, D.; Li, C.; Luan, Y. ATO and Cs0·33WO3 loaded bilayer nanofiber membrane doped polymer dispersed liquid crystals for infrared shielding. Sol. Energy Mater. Sol. Cells 2024, 275, 113039. [Google Scholar] [CrossRef]

- Kumar, J.; Gupta, R.K.; Kumar, S.; Manjuladevi, V. Electro-Optic and Dielectric Studies on Quantum Dot Doped Nematic Liquid Crystal. Macromol. Symp. 2015, 357, 47–51. [Google Scholar] [CrossRef]

- Kumar, S.; Sagar, L.K. CdSe quantum dots in a columnar matrix. Chem. Commun. 2011, 47, 12182–12184. [Google Scholar] [CrossRef] [PubMed]

- Kurochkina, M.A.; Shcherbinin, D.P.; Konshina, E.A. Control of photoluminescence of CdSe/ZnS quantum dots in a nematic liquid crystal by an electric field. Opt. Spectrosc. 2015, 119, 812–815. [Google Scholar] [CrossRef]

- Kaur, G.; Malik, P.; Yadav, S.; Malik, P. Tailoring the physical parameters of ferroelectric liquid crystal mixture with cadmium selenide quantum dots. Liq. Cryst. 2023, 50, 1825–1838. [Google Scholar] [CrossRef]

- Prakash, J.; Choudhary, A.; Mehta, D.S.; Biradar, A.M. Effect of carbon nanotubes on response time of ferroelectric liquid crystals. Phys. Rev. E 2009, 80, 012701. [Google Scholar] [CrossRef]

- He, Z.; Yu, P.; Kang, X.; Ma, H.; Gao, J.; Ge, Y.; Song, W.; Miao, Z. Regulation of the properties of polymer-dispersed liquid crystals via the introduction of silicon-based materials. Liq. Cryst. 2023, 50, 2144–2153. [Google Scholar] [CrossRef]

- Lu, Y.; Yang, D.; Gao, H.; Du, X.; Zhao, Y.; Wang, D.; He, Z.; Miao, Z.; Cao, H.; Yang, Z.; et al. Enhanced electro-optical properties of polymer-dispersed liquid crystals co-doped with fluorescent molecules and nanoparticles for multifunctional applications. Chem. Eng. J. 2024, 485, 149654. [Google Scholar] [CrossRef]

- Malik, P.; Singh, A.K. Metal oxide alumina nanowire-induced polymer-dispersed liquid crystal composites for low power consumption smart windows. J. Mol. Liq. 2023, 378, 121573. [Google Scholar] [CrossRef]

- Katariya-Jain, A.; Mhatre, M.; Dierking, I.; Deshmukh, R. Enhanced thermo-electro-optical and dielectric properties of carbon nanoparticle-doped polymer dispersed liquid crystal based switchable windows. J. Mol. Liq. 2024, 393, 123575. [Google Scholar] [CrossRef]

- Xu, J.; Yu, M.; Zou, C.; Zhang, Z.; Gao, Y.; Zhu, S.; Yang, H. Effect of different types of mesogenic compounds with fluorine and cyano-group on the working temperature of polymer dispersed liquid crystal films. J. Mol. Liq. 2023, 387, 122629. [Google Scholar] [CrossRef]

- Kashima, M.; Cao, H.; Liu, H.; Meng, Q.; Wang, D.; Li, F.; Yang, H. Effects of the chain length of crosslinking agents on the electro-optical properties of polymer-dispersed liquid crystal films. Liq. Cryst. 2010, 37, 339–343. [Google Scholar] [CrossRef]

- Liu, F.; Cao, H.; Mao, Q.; Song, P.; Yang, H. Effects of monomer structure on the morphology of polymer networks and the electro-optical properties of polymer-dispersed liquid crystal films. Liq. Cryst. 2012, 39, 419–424. [Google Scholar] [CrossRef]

- Shen, W.; Wang, L.; Chen, G.; Li, C.; Zhang, L.; Yang, Z.; Yang, H. A facile route towards controllable electric-optical performance of polymer-dispersed liquid crystal via the implantation of liquid crystalline epoxy network in conventional resin. Polymer 2019, 167, 67–77. [Google Scholar] [CrossRef]

- Zhong, T.; Mandle, R.J.; Goodby, J.W.; Zhang, C.; Zhang, L. Thiol-ene reaction based polymer dispersed liquid crystal composite films with low driving voltage and high contrast ratio. Liq. Cryst. 2020, 47, 2171–2183. [Google Scholar] [CrossRef]

- Lu, H.; Wang, H.; Bai, H.; Wang, Y.; Qiu, L.; Zhu, J.; Xu, M. Polymer-dispersed liquid crystal with low driving voltage utilising reaction selectivity of two-stage polymerisation. Liq. Cryst. 2024, 51, 761–772. [Google Scholar] [CrossRef]

- Hu, J.; Hu, W.; Zhang, S.; Sun, C.; Lan, R.; Cao, Y.; Ren, Y.; Xu, J.; Wang, X.; Saeed, M.H.; et al. Combined effect of hydroxylated and fluorinated acrylate monomers on improving the electro-optical and mechanical performances of PDLC-films. Liq. Cryst. 2022, 49, 769–779. [Google Scholar] [CrossRef]

- Shim, H.; Lyu, H.-K.; Allabergenov, B.; Garbovskiy, Y.; Glushchenko, A.; Choi, B. Enhancement of frequency modulation response time for polymer-dispersed liquid crystal. Liq. Cryst. 2016, 43, 1390–1396. [Google Scholar] [CrossRef]

- Li, G.Q. Smart Eyeglass for Treatment of Amblyopia. CN Patent CN114099266B, 7 December 2021. [Google Scholar]

- Li, G.Q. An Optical Attenuator Based on Liquid Crystal Mixture and the Method for Fabrication. CN Patent CN116243525B, 30 December 2022. [Google Scholar]

| Materials | Methods | Features | Refs |

|---|---|---|---|

| 2 wt% PFPMA, BA, BDDA, LMA, NLC E8 | 20 μm thick PDLC, UV light (12.5 mW/cm2, 365 nm) | Vth: from 12 V to 7.5 V Vsat: from 18 V to 14 V, compared to that without PFPMA | [88] |

| 21.3 wt% CHMA, 10.7 wt% HPMA, 1.6 wt% BDDA, 6.4 wt% PEGDA600, 2 wt% Irg651, 60 wt% E8 | 20 μm thick PDLC, UV light (15 mW/cm2, 365 nm) | CR: reach to 262 | [89] |

| 2 wt% BDDA, 2 wt% TCDDA, IBOA, Irg651, NLC E8 | 20 μm thick PDLC, UV light (20 mW/cm2, 365 nm) | Vth: from 9 V to 8.2 V Vsat: from 23 V to 21.2 V CR: from 106 to 203, compared to TCDDA-only case | [90] |

| 1.25 wt% DEB, BPEFDA, RM257, S811, NLC E7 | 20 μm thick RPSLC, UV light (3.5 mW/cm2, 365 nm) | Vth: from 14.1 V to 7.6 V Vsat: 16.7 V to 10.4 V CR: from 40.9 to 49.2, compared to that without DEB | [87] |

| 0.3 wt% AABM, EDDET, NLC-HNG74100-100 | 25 μm thick RPSLC, UV light (10 mW/cm2, 365 nm) | Vth: from 18.2 V to 11.5 V CR: from 115.6 to 185.9, compared to that without AABM | [86] |

| Materials | Methods | Features (Compared to That Without Dye) | Refs |

|---|---|---|---|

| 0.2 wt% AMCA, 0.5 wt% IRG651, SLC-1717 | 20 μm thick PDLC | Vsat: from 39.7 V to 25.5 V CR: from 58.4 to 96.6 | [100] |

| 3 wt% Anthraquinone dye (26B3OH), NLC (D5AOB) | 20 μm thick | Vth: from 2.75 V to 2.45 V | [101] |

| 0.3 wt% ZnO, 0.0625 wt % orange azo dye-doped HALC | 10 μm thick | Vth: from 1.81 V to 1.79 V Vsat: from 2.05 V to 1.96 V CR: from 203 to 220 | [102] |

| 0.3 wt% dye CoPc, NLC E7, chiral dopant S811 | 7.7 μm thick | Reserve mode Operating voltage: from 9 V to 6.9 V | [103] |

| A few weight percent black dye, chiral dopant, E7 | 20 μm thick | The simplest structure and method Vsat: maintaining about 20 V CR: from about 100 to 400 | [97,98] |

| 1 wt% black dye (BD), chiral dopant R5011, polymer monomer LC242, E7 | 12 μm thick PDLC | Vth: maintaining 20 V Vsat: maintaining 26 V CR: from 100 to 286 | [104] |

| 0.248 wt% orange azo dye, 0.2983 wt% ZnO NPs, NLC (MC98468) | 10 μm thick | Vth: from 1.81 V to 1.71 V Vsat: from 2.05 V to 1.90 V CR: from 203 to 255 | [105] |

| 0.05 wt% azo dye DR1, NOA-65, NLC HPC21300-000 | 23 μm thick PDLC | Vth: from 34.87 V to 10.19 V Vsat: from 46.96 V to 25.54 V CR: from 132.29 to 253.5 | [106] |

| 0.5 wt% azo dye: orange 3, chiral dopant R1101, NLC-MDA003969 | 10 μm thick | Reserve mode Operating voltage: from 29 V to 27 V CR: from 13.7 to 16.4 | [94] |

| Materials | Methods | Features (Compared to Those Without NPs) | Refs |

|---|---|---|---|

| 0.6 wt% Zirconium oxide NPs, IRG651, CHMA, UV6301, SLC1717 | 20 μm thick PD&PSLC, UV light (365 nm) | Vth: from 13.73 V to 10.099 V Vsat: from 29.61 V to 20.83 V | [82] |

| 0.3 wt% AABM NPs, EDDET, LC HNG74100-000 | 25 μm thick RPSLC, UV light (10 mW/cm2, 365 nm) | Vth: from 18.2 V to 11.5 V CR: from 115.6 to 185.9 | [86] |

| 8 wt% SiO2-SH NPs, acrylate monomer, SLC1717 | 20 μm thick PDLC, UV light (5 mW/cm2, 365 nm) | Vth: from 72 V to 16 V Vsat: from 98 V to 28 V CR: from about 20 to 165 | [138] |

| 0.05 wt% CNP, NOA-65, NLC HPC21300-000 | 23 μm thick PDLC, UV light (15 W/cm2, 354 nm) | Vth: from 34.87 V to 9.26 V Vsat: from 46.96 V to 19.02 V CR: from 132.29 to 189.09 | [106] |

| 0.4 wt%/0.4 wt% Fe3O4/Cs0.33WO3 NPs, UV6301, CHMA, IRG651, SLC1717 | 20 μm thick PDLC, UV light (10 mW/cm2, 365 nm) | Vsat: from 30.14 V to 22.47 V CR: from 60.31 to 76.45 | [139] |

| 0.5 wt% TiO2 NPs, NOA65, NLC BL036, chiral dopant CB15 | 5 μm thick PSCLC, UV light (3 mW/cm2) | Vth: from 3.2 V to 1.4 V Vsat: from 10.5 V to 7.5 V | [31] |

| 1 wt% ANWs, NLC E7, NOA65 | 6 μm thick PDLC, UV light (3 mW/cm2) | Vth: from 4 V to 1.5 V Vsat: from 38 V to 19.5 V | [140] |

| 0.05 wt% CNPs, NLC E7, NOA-65 | 23 μm thick PDLC, UV light (8 mW/cm2, 354 nm) | Vth: from 37 V to 17 V Vsat: from 66 V to 43 V CR: from 464 to 822 | [141] |

| Sample | Composition | (wt%) |

|---|---|---|

| B0 | BDDA/BA/LMA | 6.0/12.0/12.0 |

| B1 | BDDA/BA/LMA/TFEMA | 6.0/10.0/12.0/2.0 |

| B2 | BDDA/BA/LMA/TFOMA | 6.0/10.0/12.0/2.0 |

| B3 | BDDA/BA/LMA/PFPMA | 6.0/10.0/12.0/2.0 |

| B4 | BDDA/BA/LMA/HFBMA | 6.0/10.0/12.0/2.0 |

| B5 | BDDA/BA/LMA/HFOMA | 6.0/10.0/12.0/2.0 |

| B6 | BDDA/BA/LMA/OFOMA | 6.0/10.0/12.0/2.0 |

| B7 | BDDA/BA/LMA/PFMA | 6.0/10.0/12.0/2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Li, G. Recent Progress in Liquid Crystal-Based Smart Windows with Low Driving Voltage and High Contrast. Photonics 2025, 12, 819. https://doi.org/10.3390/photonics12080819

Zhou Y, Li G. Recent Progress in Liquid Crystal-Based Smart Windows with Low Driving Voltage and High Contrast. Photonics. 2025; 12(8):819. https://doi.org/10.3390/photonics12080819

Chicago/Turabian StyleZhou, Yitong, and Guoqiang Li. 2025. "Recent Progress in Liquid Crystal-Based Smart Windows with Low Driving Voltage and High Contrast" Photonics 12, no. 8: 819. https://doi.org/10.3390/photonics12080819

APA StyleZhou, Y., & Li, G. (2025). Recent Progress in Liquid Crystal-Based Smart Windows with Low Driving Voltage and High Contrast. Photonics, 12(8), 819. https://doi.org/10.3390/photonics12080819