Damage Characteristics of Silicon Solar Cells Induced by Nanosecond Pulsed Laser

Abstract

1. Introduction

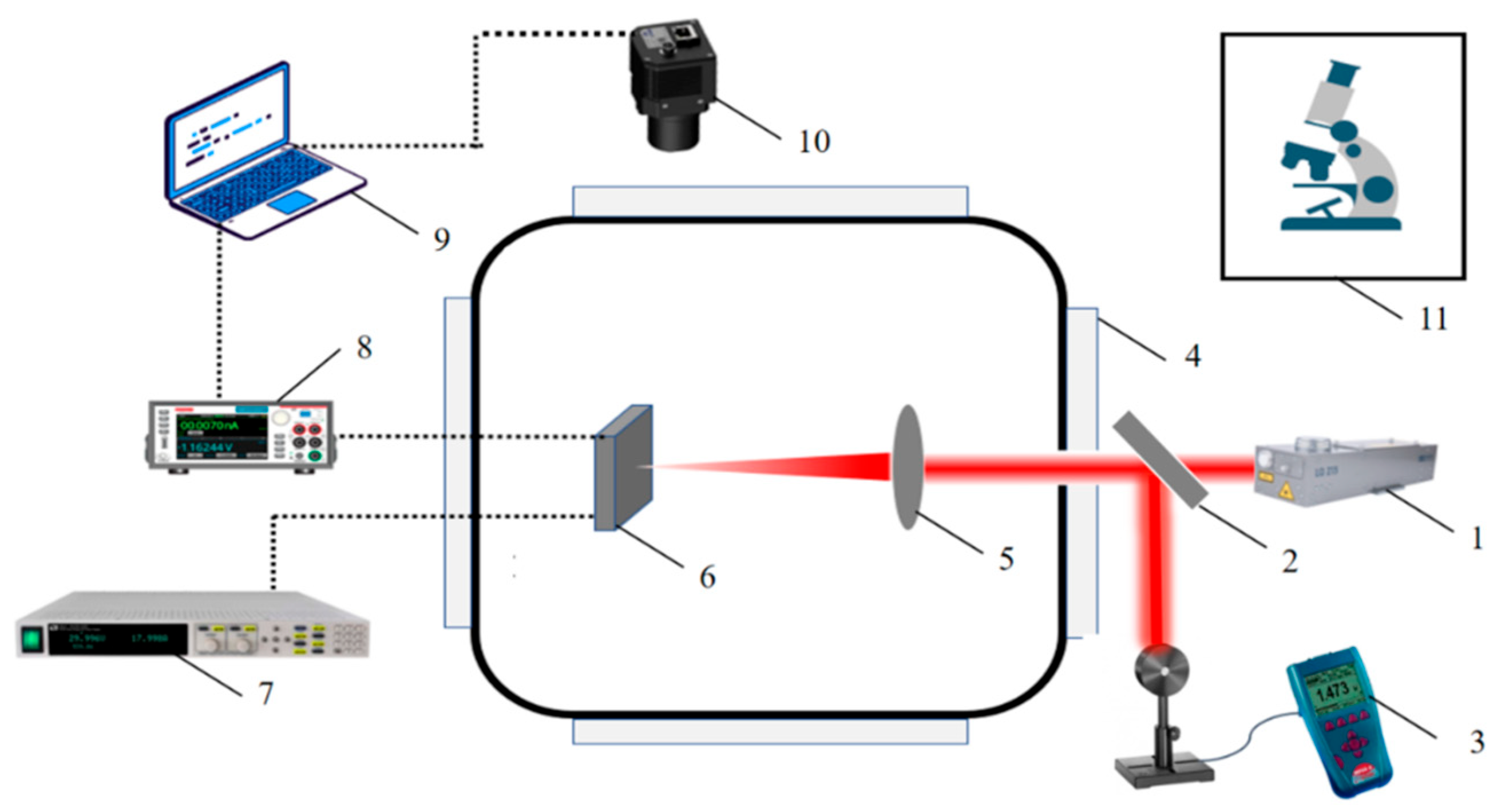

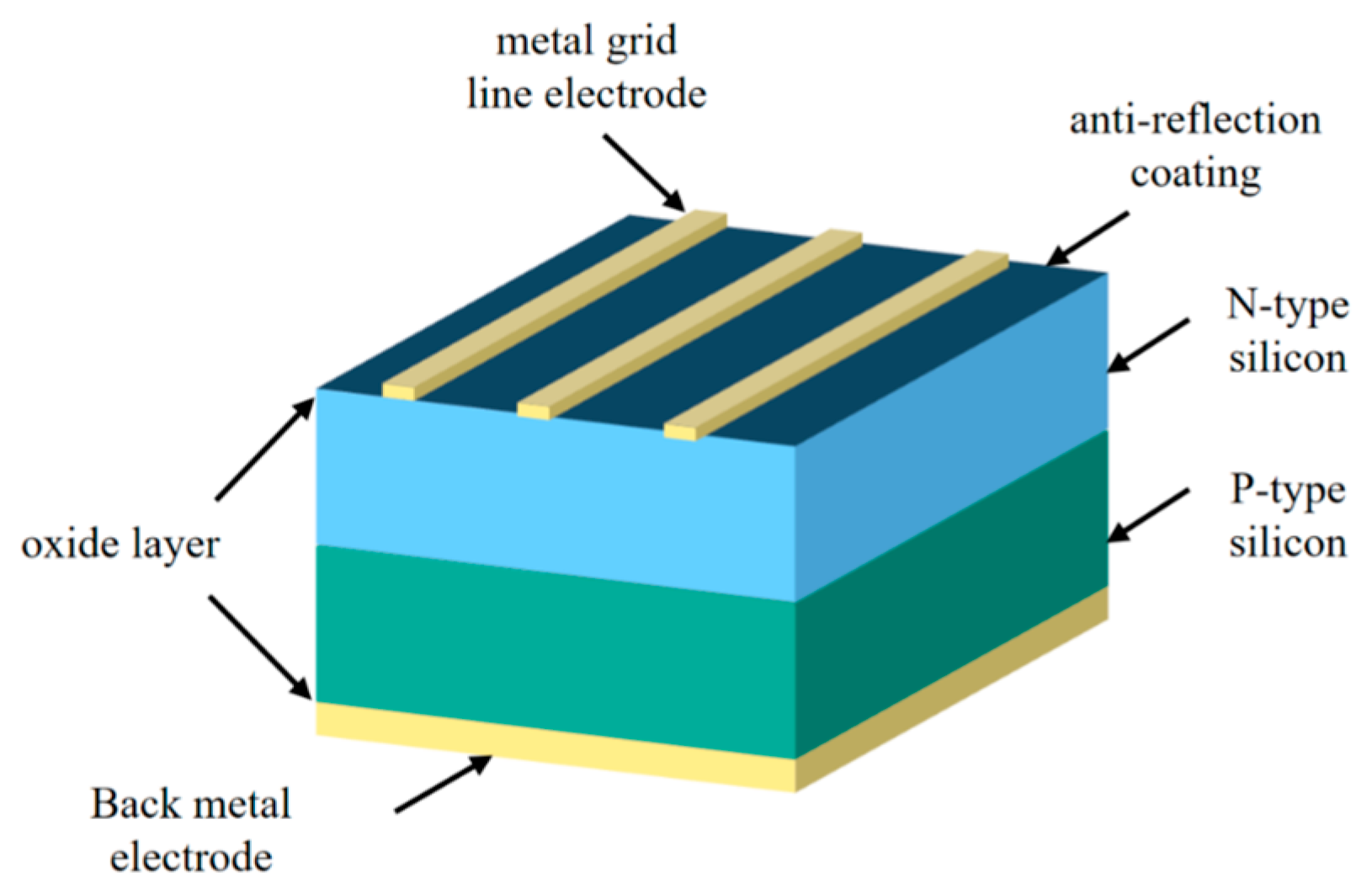

2. Experimental Setup

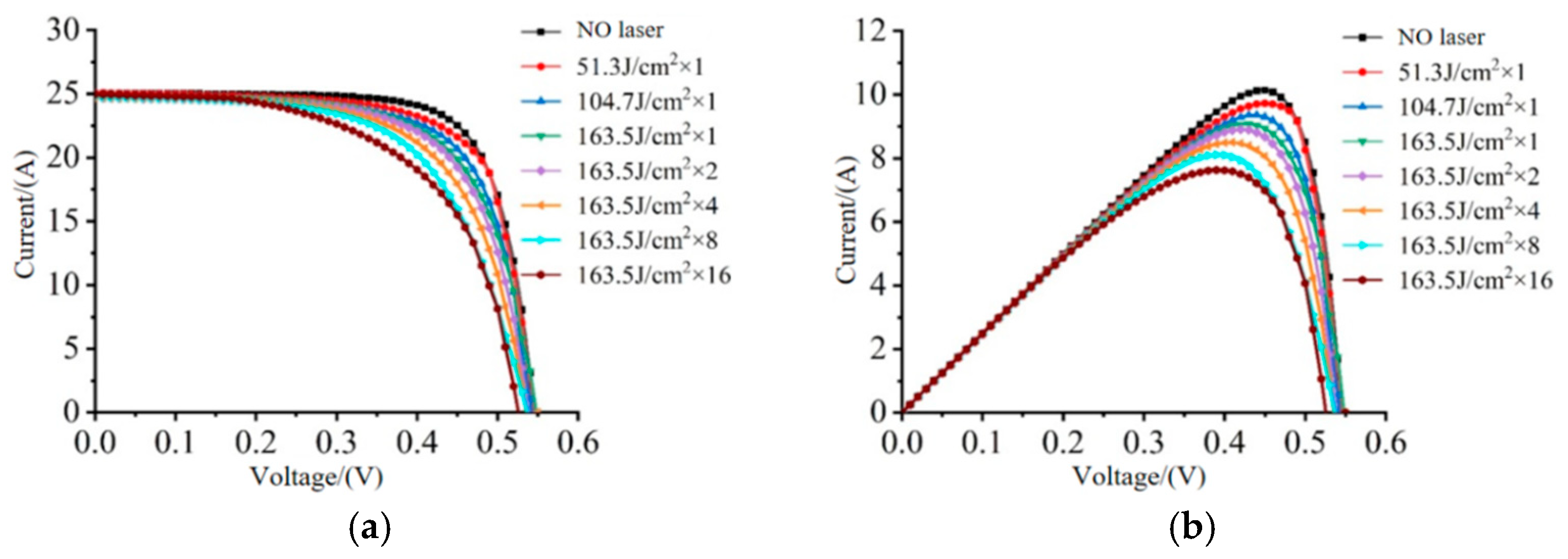

3. Results

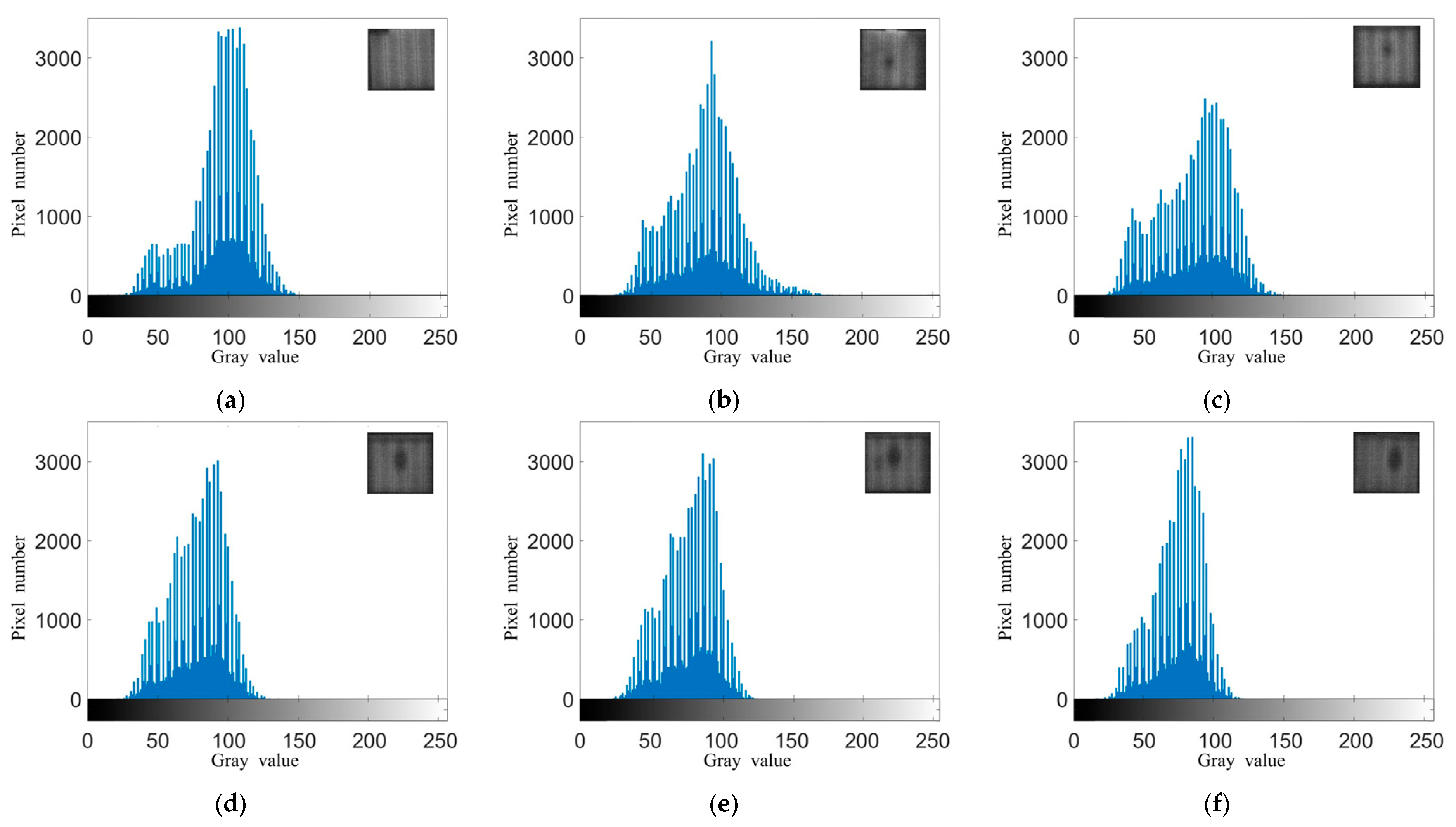

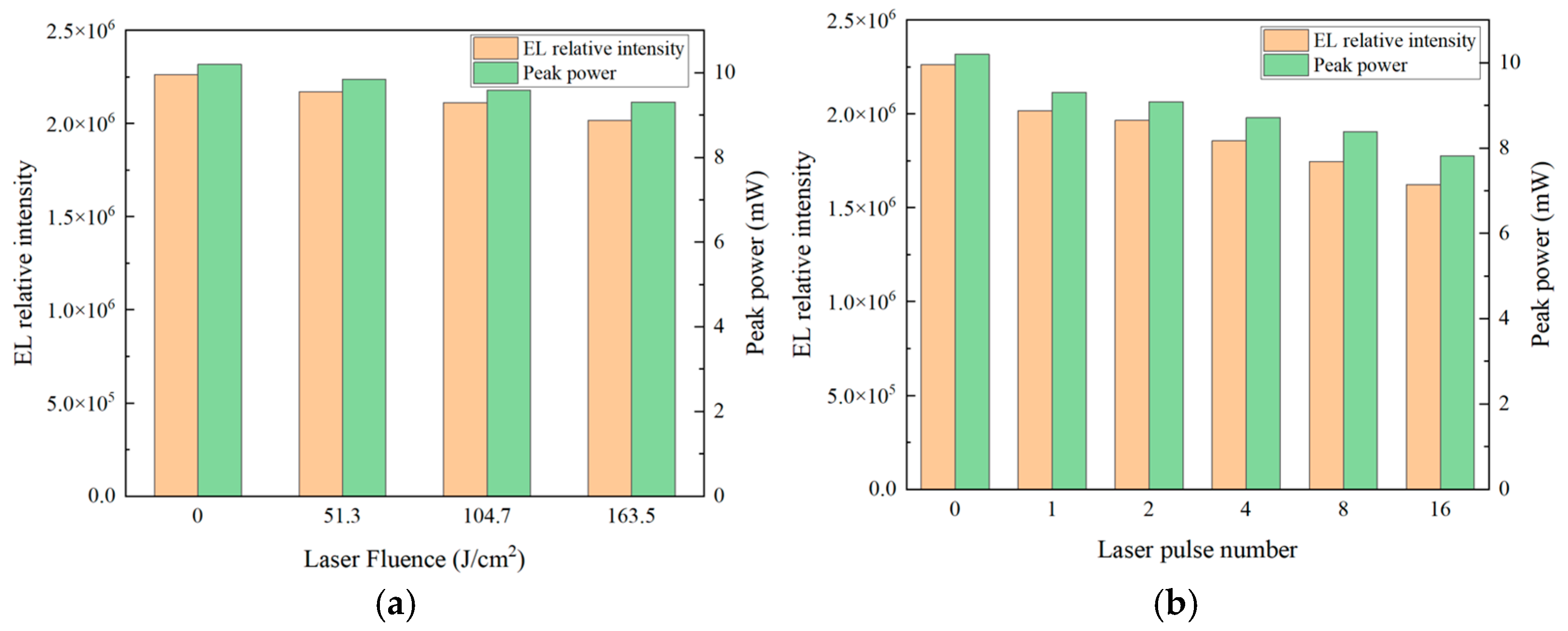

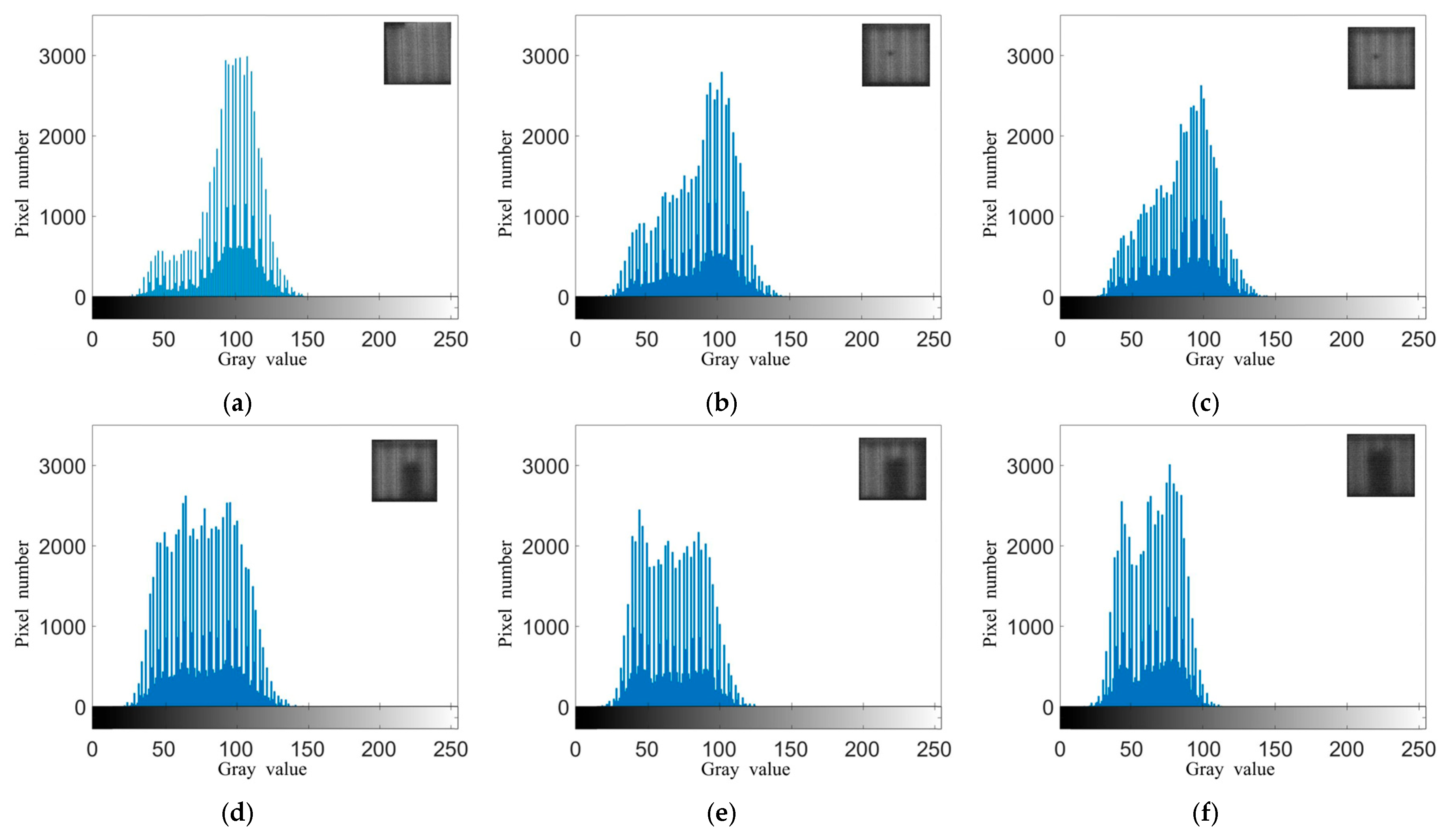

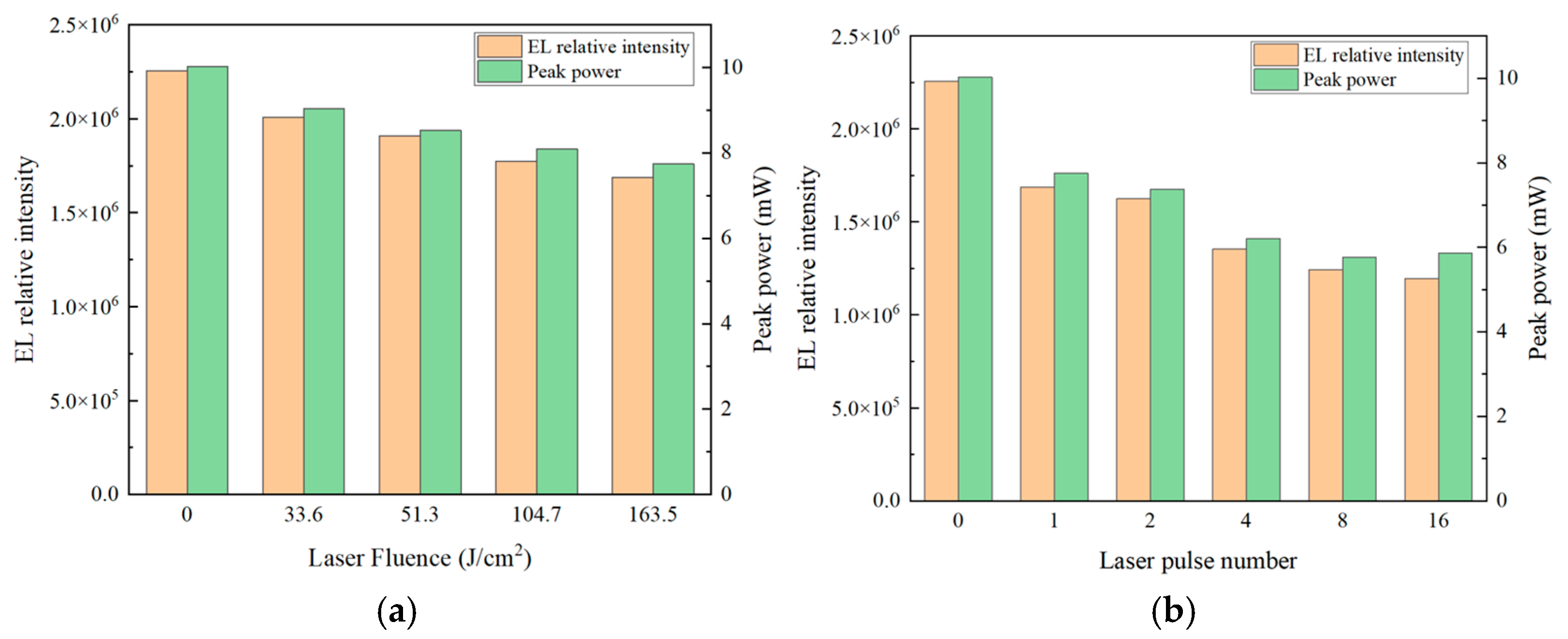

3.1. Laser-Induced Damage at Non-Gridded Areas

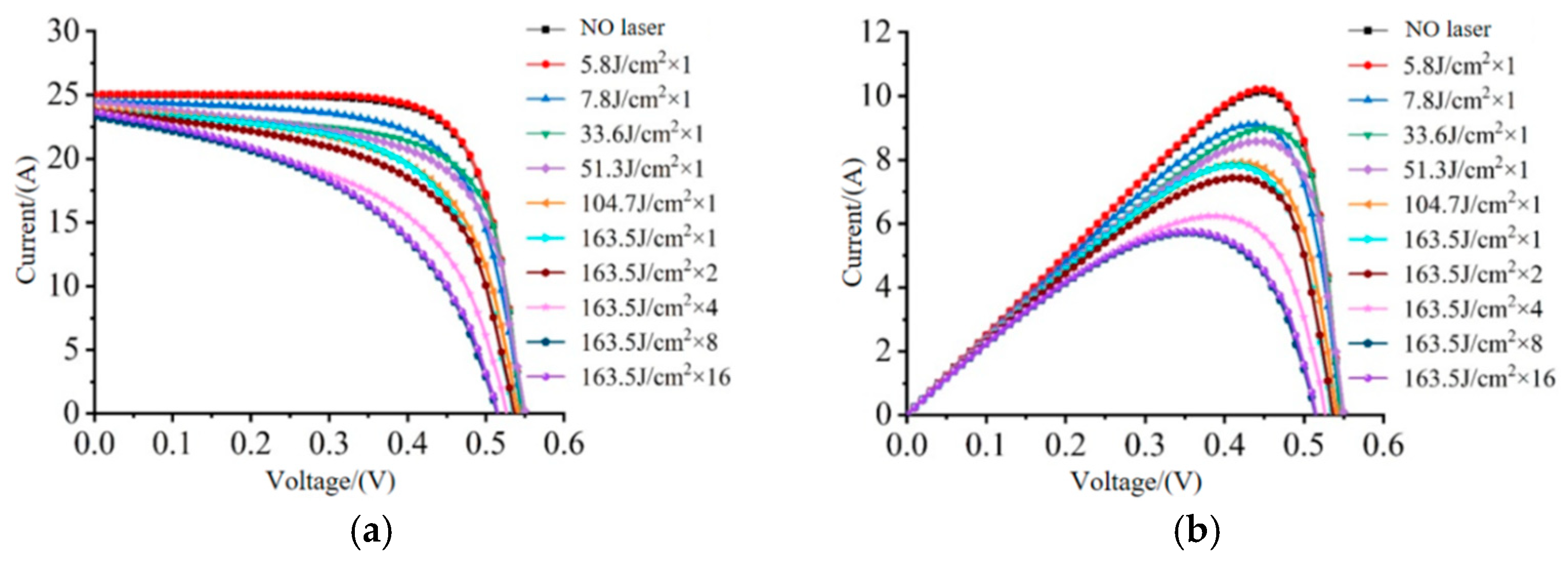

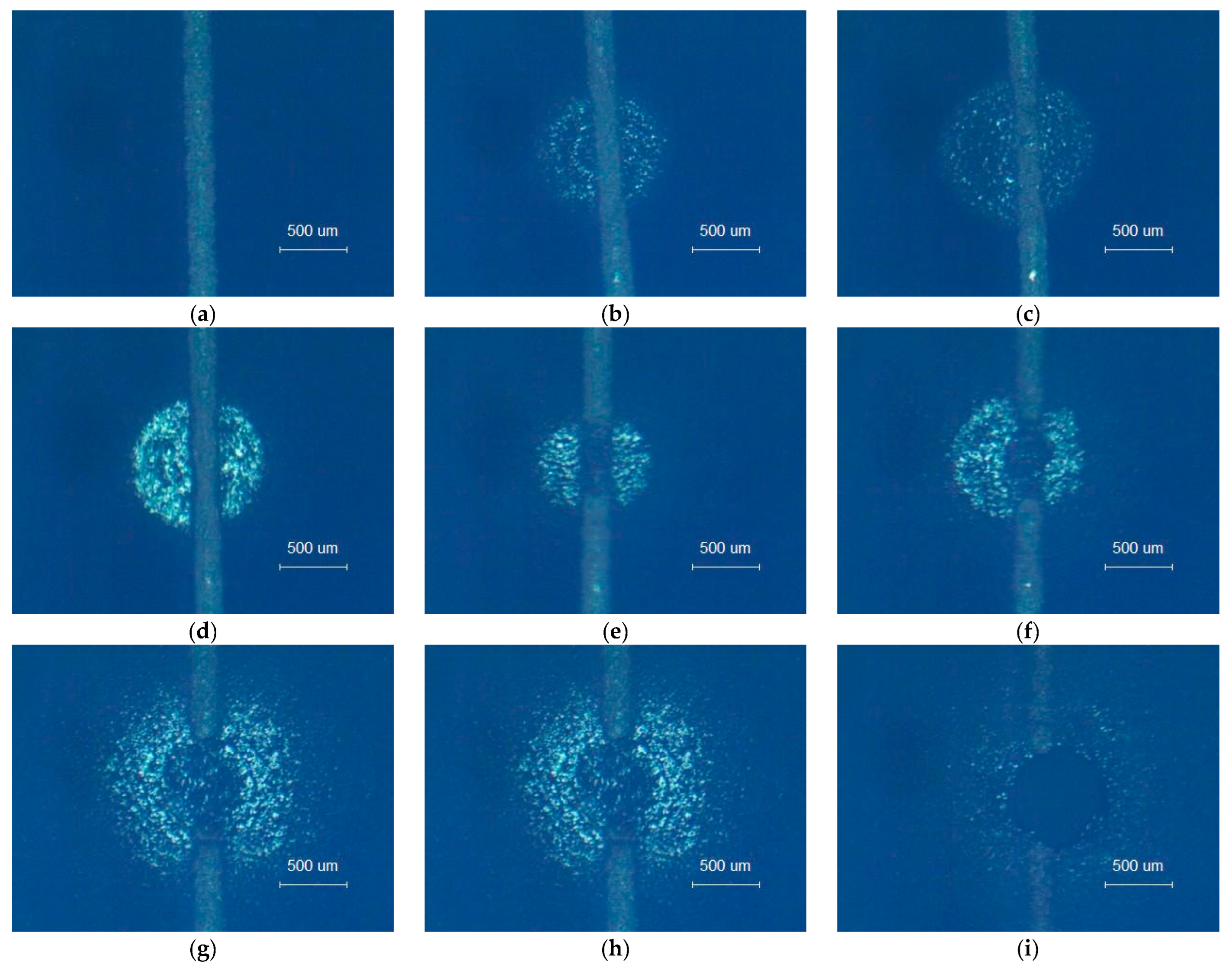

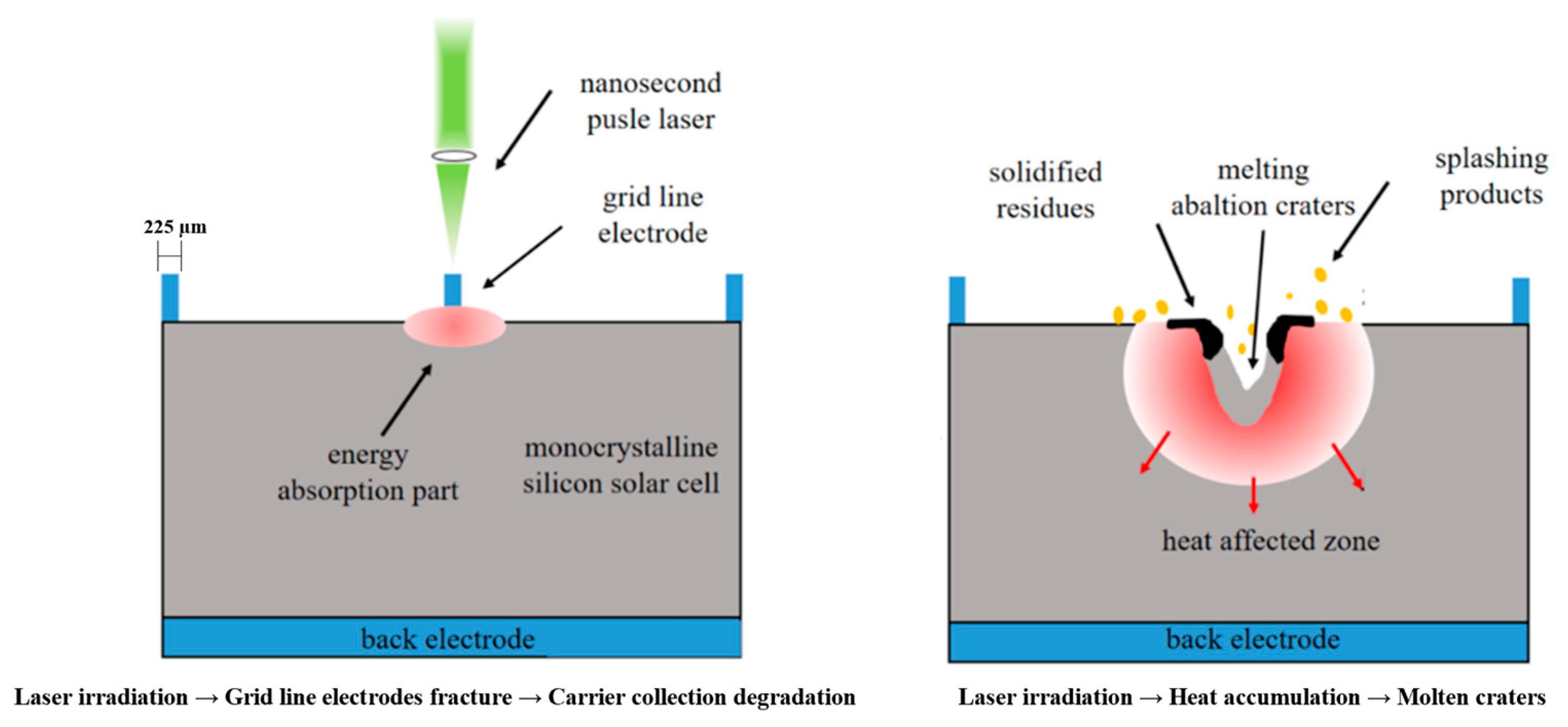

3.2. Laser-Induced Damage at Metal Grid Line Electrodes

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PV | Photovoltaic |

| EL | Electroluminescence |

| VAR | Volt ampere relation |

References

- Xiang, X.B.; Du, W.H.; Chang, X.L.; Yuan, H.R. The study on high efficient AlxGa1−xAs/GaAs solar cells. Sol. Energy Mater. Sol. Cells 2001, 68, 97–103. [Google Scholar] [CrossRef]

- Sharma, S.; Jain, K.K.; Sharma, A. Solar cells: In research and applications—A review. Mater. Sci. Appl. 2015, 6, 1145–1155. [Google Scholar] [CrossRef]

- Yamaguchi, M. High-efficiency GaAs-based solar cells. In Post-Transition Metals; IntechOpen: London, UK, 2020; pp. 107–128. [Google Scholar] [CrossRef]

- Battaglia, C.; Cuevas, A.; De Wolf, S. High-efficiency crystalline silicon solar cells: Status and perspectives. Energy Environ. Sci. 2016, 9, 1552–1576. [Google Scholar] [CrossRef]

- Jin, K.; Zhou, W. Wireless laser power transmission: A review of recent progress. IEEE Trans. Power Electron. 2018, 34, 3842–3859. [Google Scholar] [CrossRef]

- Dang, C.; Labie, R.; Tous, L.; Russell, R.; Recaman, M.; Deckers, J.; Uruena, A.; Duerinckx, F.; Poortmans, J. Investigation of laser ablation induced defects in crystalline silicon solar cells. Energy Procedia 2014, 55, 649–655. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Zhou, Y.; Zhang, X.; Jin, G. Experimental study of the damage morphology induced by the millisecond–nanosecond combined-pulse laser with different pulse delay on silicon. Optik 2021, 226, 165904. [Google Scholar] [CrossRef]

- Sun, Z.; Gupta, M.C. A study of laser-induced surface defects in silicon and impact on electrical properties. J. Appl. Phys. 2018, 124, 223103. [Google Scholar] [CrossRef]

- Li, S.; Huang, L.; Ye, J.; Hong, Y.; Wang, Y.; Gao, H.; Cui, Q. Study on Radiation Damage of Silicon Solar Cell Electrical Parameters by Nanosecond Pulse Laser. Electronics 2024, 13, 1795. [Google Scholar] [CrossRef]

- Qiu, D.; Jin, H.; Liu, S. Damage contrast of solar cells induced by short-pulse laser and CW Laser. Optoelectron. Technol. 2011, 31, 112–116. [Google Scholar] [CrossRef]

- Qiu, D.; Jin, H.; Sun, Y. Damage effects research of solar cells under the irradiation of 1064nm CW laser. Laser J. 2013, 34, 23–24. [Google Scholar] [CrossRef]

- Höhn, O.; Walker, A.W.; Bett, A.W.; Helmers, H. Optimal laser wavelength for efficient laser power converter operation over temperature. Appl. Phys. Lett. 2016, 108, 971–974. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Dou, P.; Shi, Y.; Feng, G. Thermal damage mechanism of single junction GaAs solar cells irradiated by con-tinuous wave laser. Infrared Laser Eng. 2018, 47, 97–102. [Google Scholar] [CrossRef]

- Zhu, R.; Wang, R.; Cheng, X.; Xu, Z. Study of concentric iridescent ring around the laser-induced pits on the solar cell surface. Appl. Surf. Sci. 2015, 336, 375–379. [Google Scholar] [CrossRef]

- Wang, X.; Shen, Z.H.; Lu, J.; Ni, X.W. Laser-induced damage threshold of silicon in millisecond, nanosecond, and picosec-ond regimes. J. Appl. Phys. 2010, 108, 033103. [Google Scholar] [CrossRef]

- Yang, Y.; Lyu, T.; Zhang, R. Effect of repetition frequency laser on the response characteristics of silicon solar cell. Laser J. 2024, 1, 70–74. [Google Scholar] [CrossRef]

- Xue, Q.; Wu, W.; Ye, Y.; Liu, H.; Chen, R.; Hua, Y. Property degradation of GaAs/Ge solar cells after femtosecond laser irradiation. Laser Optoelectron. Prog 2015, 52, 122–128. [Google Scholar] [CrossRef]

- Guo, W.; Chang, H.; Yu, C.H.; Li, M.Y. Damage characteristics of continuous-wave laser ablation triple-junction solar cells. J. Laser Appl. 2022, 34, 042038. [Google Scholar] [CrossRef]

- Iwata, H.; Asakawa, K. Accumulative damage of GaAs and InP surfaces induced by Multiple-Laser-Pulse irradiation. Jpn. J. Appl. Phys. 2008, 47, 2161–2167. [Google Scholar] [CrossRef]

- Zhou, W.; Wen, M.; Chang, H.; Chen, Y.; Ji, G.; Ma, Y.; Jian, Z.; Liao, Y. Damage characteristics of solar cells irradiated by picosecond pulsed lasers. Infrared Laser Eng. 2023, 52, 20210870-1. [Google Scholar] [CrossRef]

- Matsuoka, Y.; Usami, A. Laser damage of silicon solar cells with different surface states. Opto-Electron. 1974, 6, 217–223. [Google Scholar] [CrossRef]

- Matsuoka, Y. Normal laser damage of silicon solar cells without phase change. Appl. Phys. Lett. 1974, 25, 574. [Google Scholar] [CrossRef]

- Matsuoka, Y.; Usami, A. Laser Damage of Silicon Solar Cells. J. Nucl. Sci. Technol. 1973, 10, 61–62. [Google Scholar] [CrossRef][Green Version]

- Jia, Z.; Wang, W.; Li, X.; Hao, L. Millisecond laser-induced damage process of (001) silicon wafer. Opt. Eng. 2021, 60, 097101. [Google Scholar] [CrossRef]

- Schinke, C.; Christian Peest, P.; Schmidt, J.; Brendel, R.; Bothe, K.; Vogt, M.R.; Kröger, I.; Winter, S.; Schirmacher, A.; Lim, S.; et al. Uncertainty analysis for the coefficient of band-to-band absorption of crystalline silicon. AIP Adv. 2016, 5, 067168. [Google Scholar] [CrossRef]

- Fuyuki, T.; Kitiyanan, A. Photographic diagnosis of crystalline silicon solar cells utilizing electroluminescence. Appl. Phys. A 2009, 96, 189–196. [Google Scholar] [CrossRef]

| Laser Fluence × Pulse Number | Grid Line Electrode | Non-Gridded Line Area | Performance Gap |

|---|---|---|---|

| 5.8 J/cm2 × 1 | 1.0% | 0.0% | 1.0% |

| 7.8 J/cm2 × 1 | 9.9% | 0.0% | 9.9% |

| 33.6 J/cm2 × 1 | 10.9% | 0.0% | 10.9% |

| 51.3 J/cm2 × 1 | 14.9% | 4.0% | 10.9% |

| 104.7 J/cm2 × 1 | 21.8% | 6.9% | 14.9% |

| 163.5 J/cm2 × 1 | 22.8% | 9.9% | 12.9% |

| 163.5 J/cm2 × 2 | 26.7% | 11.9% | 14.8% |

| 163.5 J/cm2 × 4 | 38.6% | 15.8% | 22.8% |

| 163.5 J/cm2 × 8 | 43.6% | 19.8% | 23.8% |

| 163.5 J/cm2 × 16 | 42.6% | 24.8% | 17.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, H.; Zhou, W.; Ma, Y.; Jian, Z.; Quan, X.; Xiao, C. Damage Characteristics of Silicon Solar Cells Induced by Nanosecond Pulsed Laser. Photonics 2025, 12, 804. https://doi.org/10.3390/photonics12080804

Chang H, Zhou W, Ma Y, Jian Z, Quan X, Xiao C. Damage Characteristics of Silicon Solar Cells Induced by Nanosecond Pulsed Laser. Photonics. 2025; 12(8):804. https://doi.org/10.3390/photonics12080804

Chicago/Turabian StyleChang, Hao, Weijing Zhou, Yingjie Ma, Zhilong Jian, Xiaoyuan Quan, and Chenyu Xiao. 2025. "Damage Characteristics of Silicon Solar Cells Induced by Nanosecond Pulsed Laser" Photonics 12, no. 8: 804. https://doi.org/10.3390/photonics12080804

APA StyleChang, H., Zhou, W., Ma, Y., Jian, Z., Quan, X., & Xiao, C. (2025). Damage Characteristics of Silicon Solar Cells Induced by Nanosecond Pulsed Laser. Photonics, 12(8), 804. https://doi.org/10.3390/photonics12080804