Superlattice Structure for High Performance AlGaN Deep Ultraviolet LEDs

Abstract

1. Introduction

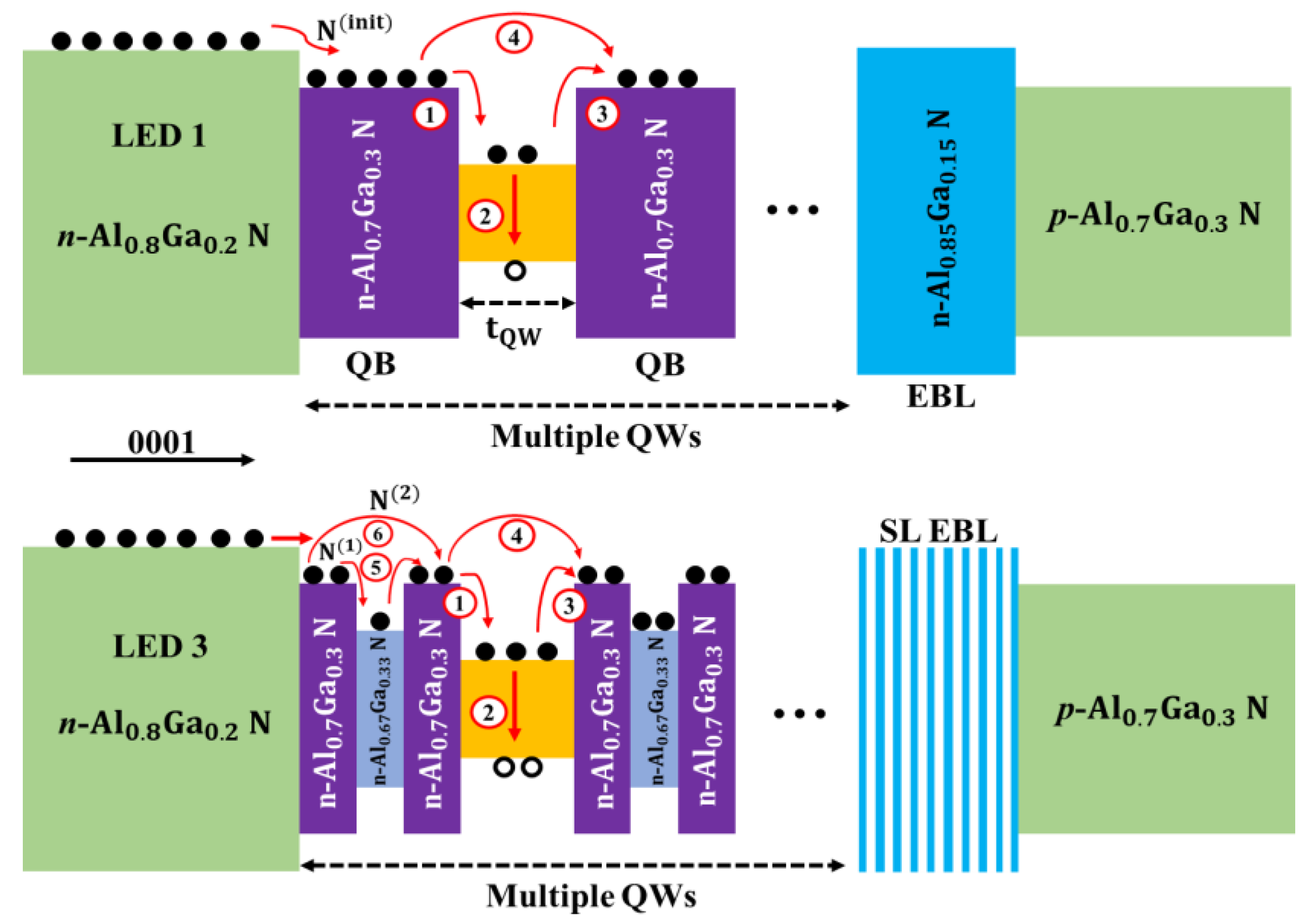

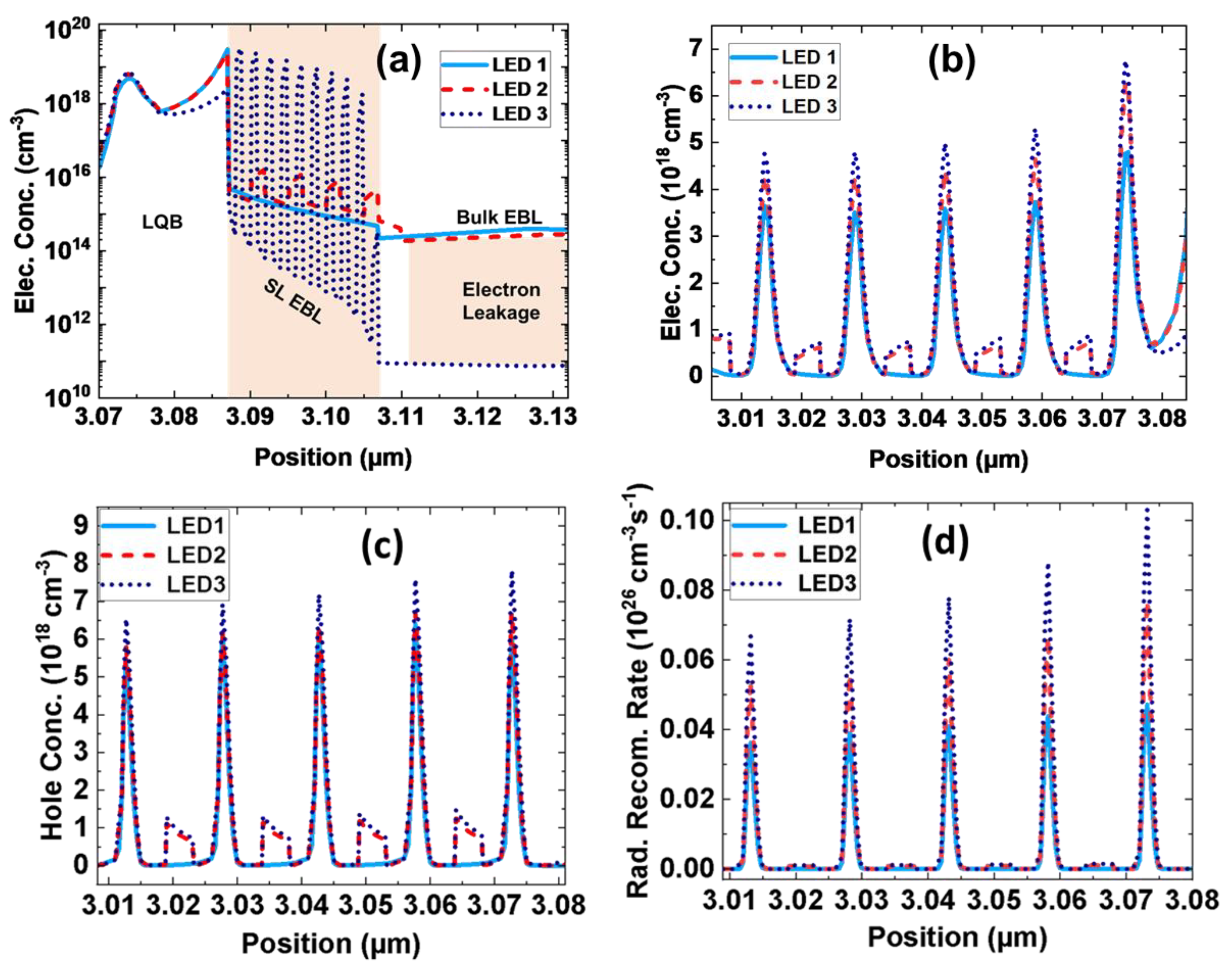

2. Device Structure and Parameters

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CBBH | Conduction Band Barrier Height |

| EBL | Electron Blocking Layer |

| IQE | Internal Quantum Efficiency |

| LEDs | Light Emitting Diodes |

| MFP | Mean Free Path |

| MQWs | Multiple Quantum Wells |

| QBs | Quantum Barriers |

| SL | Superlattice |

| UV | Ultraviolet |

| VBBH | Valence Band Barrier Height |

References

- Feng, F.; Liu, Y.; Zhang, K.; Yang, H.; Hyun, B.R.; Xu, K.; Kwok, H.S.; Liu, Z. High-power AlGaN deep-ultraviolet micro-light-emitting diode displays for mask less photolithography. Nat. Photonics 2024, 19, 101–108. [Google Scholar] [CrossRef]

- Liu, X.; Lv, Z.; Liao, Z.; Sun, Y.; Zhang, Z.; Sun, K.; Zhou, Q.; Tang, B.; Geng, H.; Qi, S.; et al. Highly efficient AlGaN-based deep-ultraviolet light-emitting diodes: From bandgap engineering to device craft. Microsyst. Nanoeng. 2024, 10, 110. [Google Scholar] [CrossRef]

- Xu, R.; Kang, Q.; Zhang, Y.; Zhang, X.; Zhang, Z. Research progress of AlGaN-based deep ultraviolet light-emitting diodes. Micromachines 2023, 14, 844. [Google Scholar] [CrossRef]

- Li, D.; Jiang, K.; Sun, X.; Guo, C. AlGaN photonics: Recent advances in materials and ultraviolet devices. Adv. Opt. Photon. 2018, 10, 43–110. [Google Scholar] [CrossRef]

- Khan, M.A.; Maeda, N.; Itokazu, Y.; Jo, M.; Iimura, K.; Hirayama, H. Milliwatt-Power AlGaN Deep-UV Light-Emitting Diodes at 254 nm Emission as a Clean Alternative to Mercury Deep-UV Lamps. Phys. Status Solidi A 2023, 220, 2200621. [Google Scholar] [CrossRef]

- Muramoto, Y.; Kimura, M.; Nouda, S. Development and future of ultraviolet light-emitting diodes: UV-LED will replace the UV lamp. Semicond. Sci. Technol. 2014, 29, 084004. [Google Scholar] [CrossRef]

- Malik, S.; Usman, M.; Khan, M.A.; Hirayama, H. Polarization-dependent hole generation in 222 nm-band AlGaN-based Far-UVC LED: A way forward to the epi-growers of MBE and MOCVD. J. Mater. Chem. C 2021, 9, 16545–16557. [Google Scholar] [CrossRef]

- Song, K.; Mohseni, M.; Taghipour, F. Application of ultraviolet light-emitting diodes (UV-LEDs) for water disinfection: A review. Water Res. 2016, 94, 341–349. [Google Scholar] [CrossRef]

- Yeh, N.G.; Wu, C.-H.; Cheng, T.C. Light-emitting diodes—Their potential in biomedical applications. Renew. Sust. Energ. Rev. 2010, 14, 2161–2166. [Google Scholar] [CrossRef]

- Heilingloh, C.S.; Aufderhorst, U.W.; Schipper, L.; Dittmer, U.; Witzke, O.; Yang, D.; Zheng, X.; Sutter, K.; Trilling, M.; Alt, M.; et al. Susceptibility of SARS-CoV-2 to UV irradiation. Am. J. Infect. Control 2020, 48, 1273–1275. [Google Scholar] [CrossRef]

- Fan, S.-W.; Srivastava, A.K.; Dravid, V.P. UV-activated room temperature gas sensing mechanism of polycrystalline ZnO. Appl. Phys. Lett. 2009, 95, 142106. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, X.; Lunev, A.; Deng, J.; Bilenko, Y.; Katona, T.M.; Shur, M.S.; Gaska, R.; Khan, M.A. AlGaN deep-ultraviolet light-emitting diodes. Jpn. J. Appl. Phys. 2005, 44, 7250. [Google Scholar] [CrossRef]

- Kneissl, M.; Seong, T.-Y.; Han, J.; Amano, H. The emergence and prospects of deep-ultraviolet light-emitting diode technologies. Nat. Photonics 2019, 13, 233–244. [Google Scholar] [CrossRef]

- Simon, J.; Protasenko, V.; Lian, C.; Xing, H.; Jena, D. Polarization induced hole doping in wide–band-gap uniaxial semiconductor heterostructures. Science 2010, 327, 60–64. [Google Scholar] [CrossRef]

- Nguyen, H.P.T.; Cui, K.; Zhang, S.; Djavid, M.; Korinek, A.; Botton, G.A.; Mi, Z. Controlling electron overflow in phosphor-free InGaN/GaN nanowire white light-emitting diodes. Nano Lett. 2012, 12, 1317–1323. [Google Scholar] [CrossRef]

- Ding, K.; Avrutin, V.; Özgür, Ü.; Morkoç, H. Status of growth of group III-nitride heterostructures for deep ultraviolet light-emitting diodes. Crystals 2017, 7, 300. [Google Scholar] [CrossRef]

- Zhang, M.; Li, Y.; Chen, S.; Tian, W.; Xu, J.; Li, X.; Wu, Z.; Fang, Y.; Dai, J.; Chen, C. Performance improvement of AlGaN-based deep ultraviolet light-emitting diodes by using staggered quantum wells. Superlattices Microstruct. 2014, 75, 63–71. [Google Scholar] [CrossRef]

- Velpula, R.T.; Jain, B.; Bui, H.Q.T.; Shakiba, F.M.; Jude, J.; Tumuna, M.; Nguyen, H.D.; Lenka, T.R.; Nguyen, H.P.T. Improving carrier transport in AlGaN deep-ultraviolet light-emitting diodes using a strip-in-a-barrier structure. Appl. Opt. 2020, 59, 5276–5281. [Google Scholar] [CrossRef]

- Jain, B.; Muthu, M.B.S.; Velpula, R.T.; Nguyen, N.T.A.; Nguyen, H.P.T. Advantages of concave quantum barriers in AlGaN deep ultraviolet light-emitting diodes. In Proceedings of the Gallium Nitride Materials and Devices XVIII 2023, San Francisco, CA, USA, 30 January–2 February 2023; SPIE: Bellingham, WA, USA, 2023; Volume 12421, pp. 143–148. [Google Scholar] [CrossRef]

- Jain, B.; Velpula, R.T.; Bui, H.Q.T.; Tumuna, M.; Jude, J.; Nguyen, H.P.T. Electron blocking layer free AlGaN deep-ultraviolet light emitting diodes. In Proceedings of the 2020 Conference on Lasers and Electro-Optics (CLEO), San Jose, CA, USA, 10–15 May 2020. AF1I-3. [Google Scholar] [CrossRef]

- Nguyen, H.P.T.; Djavid, M.; Woo, S.Y.; Liu, X.; Connie, A.T.; Sadaf, S.; Wang, Q.; Botton, G.A.; Shih, I.; Mi, Z. Engineering the carrier dynamics of InGaN nanowire white light-emitting diodes by distributed p-AlGaN electron blocking layers. Sci. Rep. 2015, 5, 7744. [Google Scholar] [CrossRef]

- Jain, B.; Velpula, R.T.; Velpula, S.; Nguyen, H.D.; Nguyen, H.P.T. Enhanced hole transport in AlGaN deep ultraviolet light-emitting diodes using a double-sided step graded superlattice electron blocking layer. J. Opt. Soc. Am. B 2020, 37, 2564–2569. [Google Scholar] [CrossRef]

- Li, Y.; Chen, S.; Tian, W.; Wu, Z.; Fang, Y.; Dai, J.; Chen, C. Advantages of AlGaN-based 310-nm UV light-emitting diodes with Al content graded AlGaN electron blocking layers. IEEE Photonics J. 2013, 5, 8200309. [Google Scholar] [CrossRef]

- Schubert, E.; Grieshaber, W.; Goepfert, I. Enhancement of deep acceptor activation in semiconductors by superlattice doping. Appl. Phys. Lett. 1996, 69, 3737–3739. [Google Scholar] [CrossRef]

- Kozodoy, P.; Hansen, M.; DenBaars, S.P.; Mishra, U.K. Enhanced Mg doping efficiency in Al0.2 Ga0.8N/ GaN superlattices. Appl. Phys. Lett. 1999, 74, 3681–3683. [Google Scholar] [CrossRef]

- Saxler, A.; Mitchel, W.; Kung, P.; Razeghi, M. Aluminum gallium nitride short-period superlattices doped with magnesium. Appl. Phys. Lett. 1999, 74, 2023–2025. [Google Scholar] [CrossRef]

- Goepfert, I.; Schubert, E.; Osinsky, A.; Norris, P. Demonstration of efficient p-type doping in AlxGa1–xN/ GaN superlattice structures. Electron. Lett. 1999, 35, 1109–1111. [Google Scholar] [CrossRef]

- Yan, J.; Wang, J.; Zhang, Y.; Cong, P.; Sun, L.; Tian, Y.; Zhao, C.; Li, J. AlGaN-based deep-ultraviolet light-emitting diodes grown on high quality AlN template using MOVPE. J. Cryst. Growth 2015, 414, 254–257. [Google Scholar] [CrossRef]

- Fiorentini, V.; Bernardini, F.; Ambacher, O. Evidence for nonlinear macroscopic polarization in III–V nitride alloy heterostructures. Appl. Phys. Lett. 2002, 80, 1204–1206. [Google Scholar] [CrossRef]

- Piprek, J. (Ed.) Nitride Semiconductor Devices: Principles and Simulation; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar] [CrossRef]

- Nam, K.B.; Nakarmi, M.L.; Li, J.; Lin, J.Y.; Jiang, H.X. Mg acceptor level in AlN probed by deep ultraviolet photoluminescence. Appl. Phys. Lett. 2003, 83, 878–880. [Google Scholar] [CrossRef]

- Yun, J.; Shim, J.I.; Hirayama, H. Analysis of efficiency droop in 280-nm AlGaN multiple-quantum-well light-emitting diodes based on carrier rate equation. Appl. Phys. Express 2015, 8, 022104. [Google Scholar] [CrossRef]

- Collazo, R.; Mita, S.; Xie, J.; Rice, A.; Tweedie, J.; Dalmau, R.; Sitar, Z. Progress on n-type doping of AlGaN alloys on AlN single crystal substrates for UV optoelectronic applications. Phys. Status Solidi C 2011, 8, 2031–2033. [Google Scholar] [CrossRef]

- Coughlan, C.; Schulz, S.; Caro, M.A.; O’Reilly, E.P. Band gap bowing and optical polarization switching in Al Ga N alloys. Phys. Status Solidi B 2015, 252, 879–884. [Google Scholar] [CrossRef]

- Velpula, R.T.; Jain, B.; Velpula, S.; Nguyen, H.D.; Nguyen, H.P.T. High-performance electron-blocking-layer-free deep ultraviolet light-emitting diodes implementing a strip-in-a-barrier structure. Opt. Lett. 2020, 45, 5125–5128. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Liu, W.; Tan, S.T.; Ju, Z.; Ji, Y.; Kyaw, Z.; Zhang, X.; Hasanov, N.; Zhu, B.; Lu, S. On the mechanisms of InGaN electron cooler in InGaN/GaN light-emitting diodes. Opt. Express 2014, 22, A779–A789. [Google Scholar] [CrossRef]

- Zhang, X.; Taliercio, T.; Kolliakos, S.; Lefebvre, P. Influence of electron-phonon interaction on the optical properties of III nitride semiconductors. J. Phys. Condens. Matter 2001, 13, 7053–7074. [Google Scholar] [CrossRef]

- Kuball, M. Raman spectroscopy of GaN, AlGaN and AlN for process and growth monitoring/control. Surf. Interface Anal. 2001, 31, 987–999. [Google Scholar] [CrossRef]

- Mora-Ramos, M.; Gaggero-Sager, L. Electron-optical-phonon scattering rates in AlGaN/GaN-based single heterostructures. Phys. Status Solidi C 2005, 2, 3002–3005. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Liu, W.; Ju, Z.; Tan, S.T.; Ji, Y.; Kyaw, Z.; Zhang, X.; Wang, L.; Sun, X.W.; Demir, H.V. Self-screening of the quantum confined Stark effect by the polarization induced bulk charges in the quantum barriers. Appl. Phys. Lett. 2014, 104, 243501. [Google Scholar] [CrossRef]

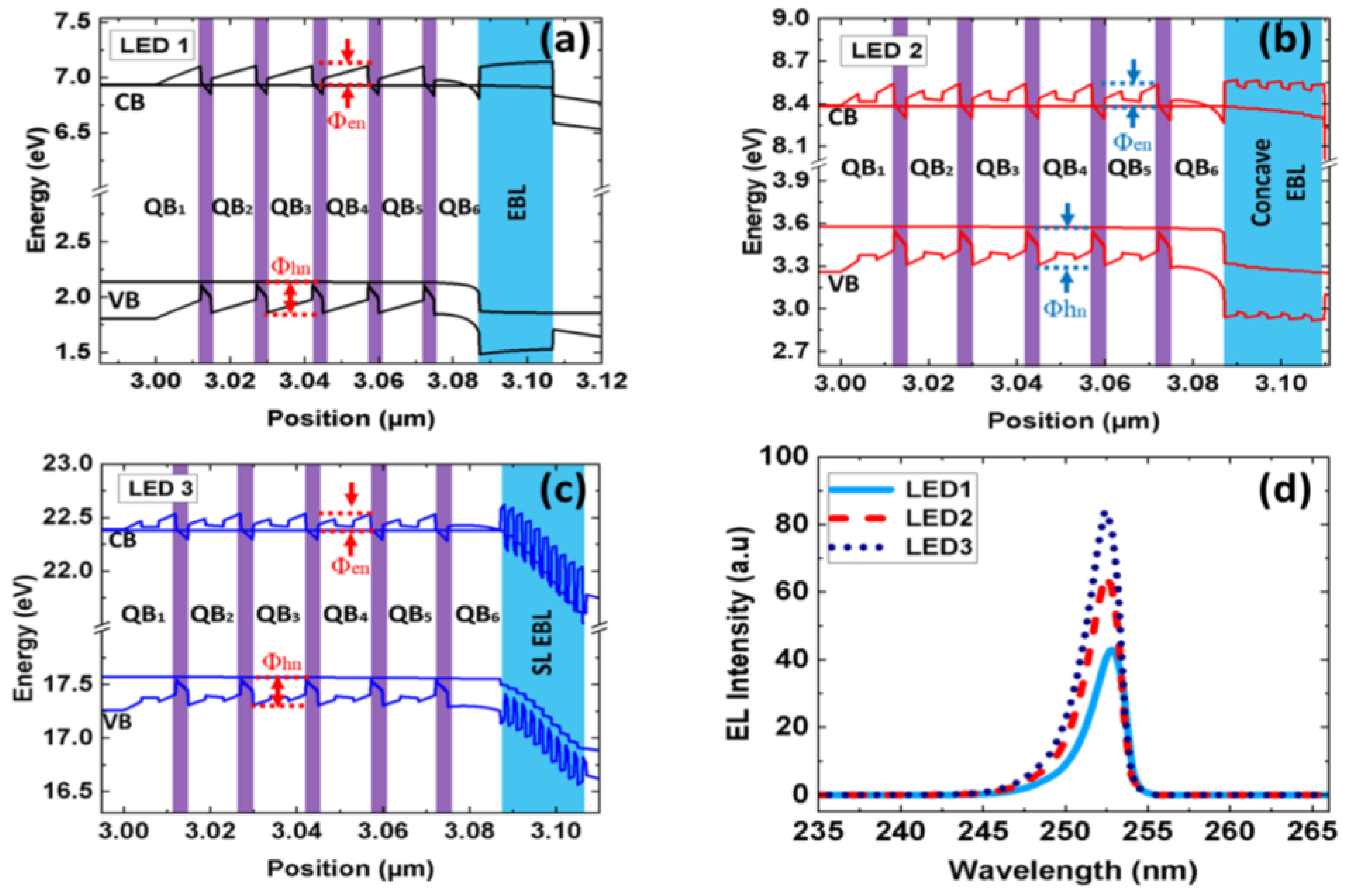

| CBBH | LED 1 | LED 2 | LED 3 |

|---|---|---|---|

| Φe1 | 173.7 meV | 160.6 meV | 154.8 meV |

| Φe2 | 177.6 meV | 160.8 meV | 156.1 meV |

| Φe3 | 177.8 meV | 160.0 meV | 154.8 meV |

| Φe4 | 176.7 meV | 158.5 meV | 153.2 meV |

| Φe5 | 173.3 meV | 155.6 meV | 149.7 meV |

| Φe6 | 44.3 meV | 43.9 meV | 38.7 meV |

| Φe-EBL | 226.7 meV | 233.1 meV | 244.3 meV |

| VBBH | LED 1 | LED 2 | LED 3 |

|---|---|---|---|

| Φh2 | 278.7 meV | 266.4 meV | 261.2 meV |

| Φh3 | 278.8 meV | 268.7 meV | 261.5 meV |

| Φh4 | 280.3 meV | 268.9 meV | 263.4 meV |

| Φh5 | 281.4 meV | 269.3 meV | 265.1 meV |

| Φh-EBL | 389.5 meV | 380.2 meV | 341.9 meV |

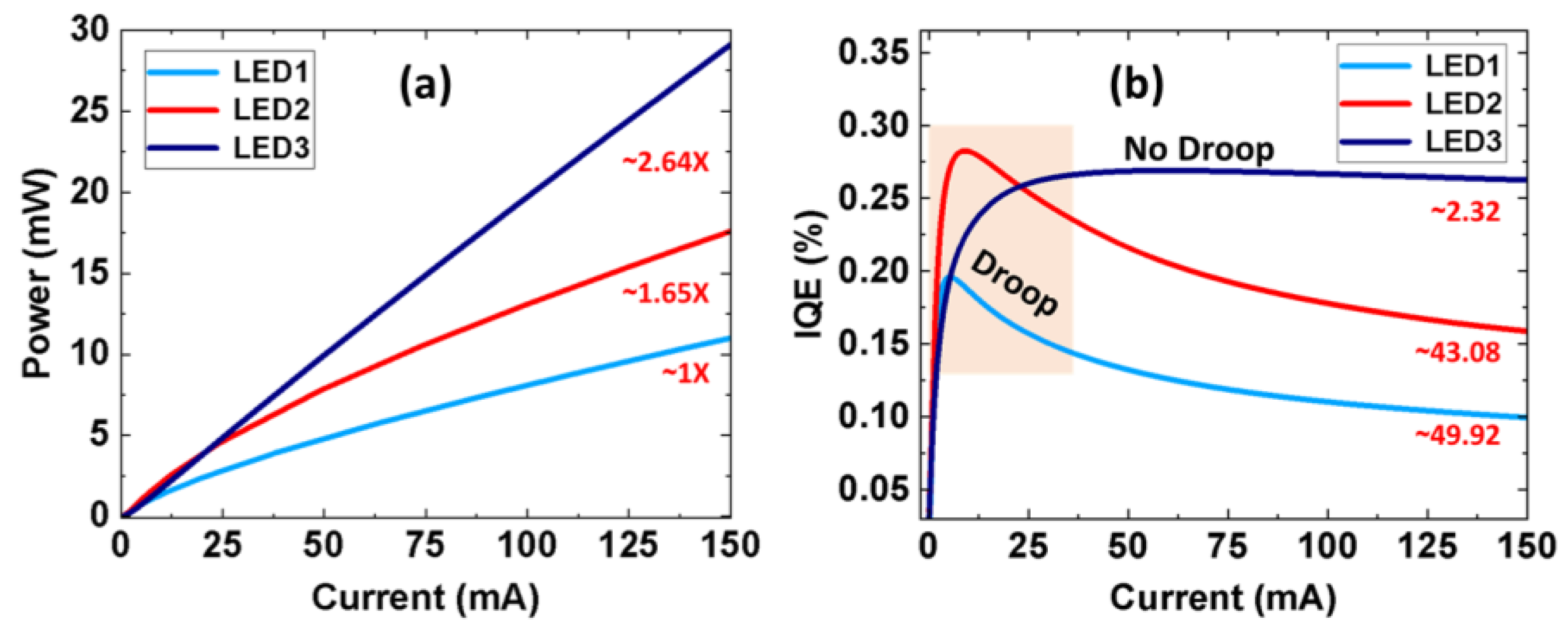

| LED Structures | Max. IQE (%) | IQE at 150 mA (%) | IQE Droop at 150 mA (%) | Power at 150 mA (mW) |

|---|---|---|---|---|

| LED1 | 19.8 | 9.8 | 49.92 | 11.01 |

| LED2 | 28.6 | 16.5 | 43.08 | 18.12 |

| LED3 | 26.8 | 26.2 | 2.32 | 29.04 |

| S.No | LED Design | IQE (%) | Output Power (mW) | Efficiency Droop (%) |

|---|---|---|---|---|

| 1 | Staggered QWs [17] | ~25 | ~15 | ~20 |

| 2 | Double-sided step graded SL EBL [22] | 24.2 | 15.68 | 9.1 |

| 3 | A strip-in-a-barrier structure [18,35] | 53.87 | 21.23 | 12.4 |

| 4 | Concave QBs (no SL-EBL) [19] | 31 | 10.3 | 47.6 |

| 5 | Proposed LED Design (Concave QBs + SL-EBL) | 26.2 | 12.9 (at 60 mA) | <1 (at 60 mA) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muthu, M.B.S.; Velpula, R.T.; Jain, B.; Nguyen, H.P.T. Superlattice Structure for High Performance AlGaN Deep Ultraviolet LEDs. Photonics 2025, 12, 752. https://doi.org/10.3390/photonics12080752

Muthu MBS, Velpula RT, Jain B, Nguyen HPT. Superlattice Structure for High Performance AlGaN Deep Ultraviolet LEDs. Photonics. 2025; 12(8):752. https://doi.org/10.3390/photonics12080752

Chicago/Turabian StyleMuthu, Mano Bala Sankar, Ravi Teja Velpula, Barsha Jain, and Hieu Pham Trung Nguyen. 2025. "Superlattice Structure for High Performance AlGaN Deep Ultraviolet LEDs" Photonics 12, no. 8: 752. https://doi.org/10.3390/photonics12080752

APA StyleMuthu, M. B. S., Velpula, R. T., Jain, B., & Nguyen, H. P. T. (2025). Superlattice Structure for High Performance AlGaN Deep Ultraviolet LEDs. Photonics, 12(8), 752. https://doi.org/10.3390/photonics12080752