Magnetic Field and Temperature Dual-Parameter Optical Fiber Sensor Based on Fe3O4 Magnetic Film

Abstract

1. Introduction

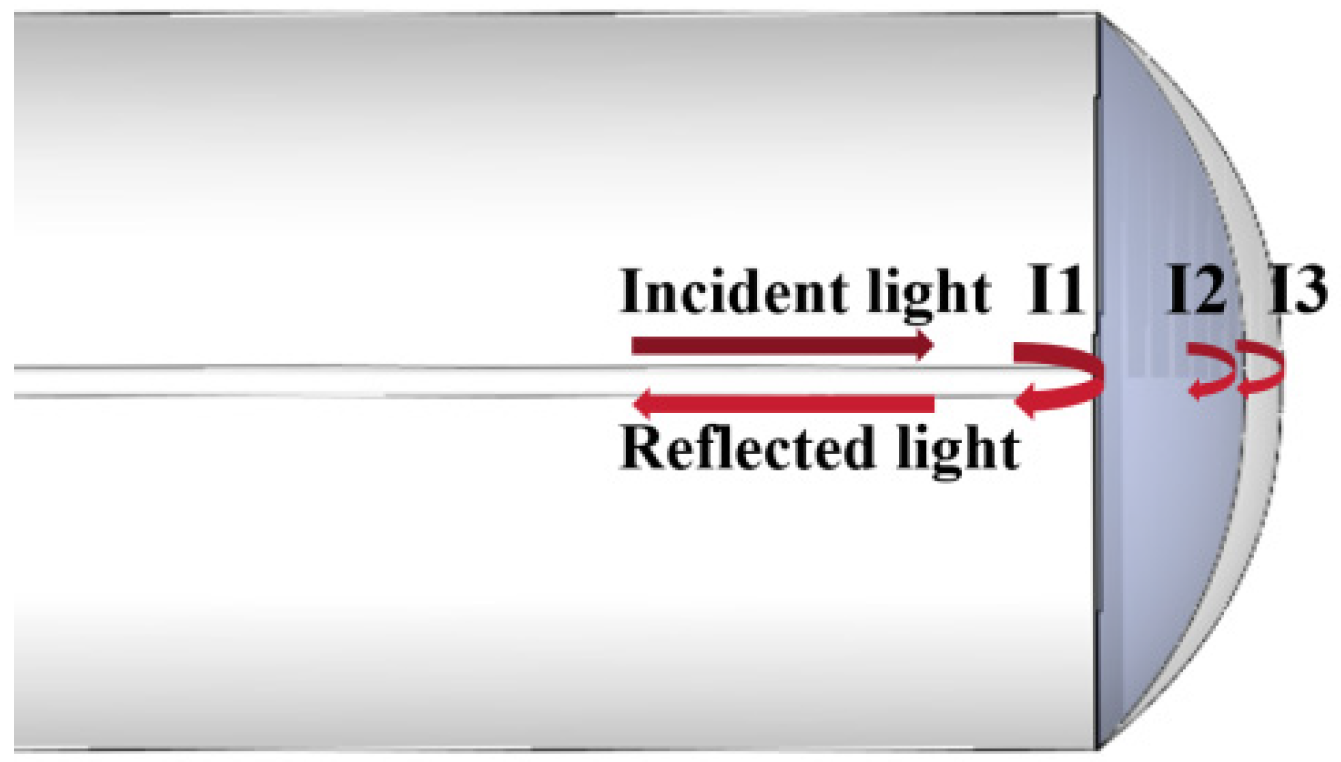

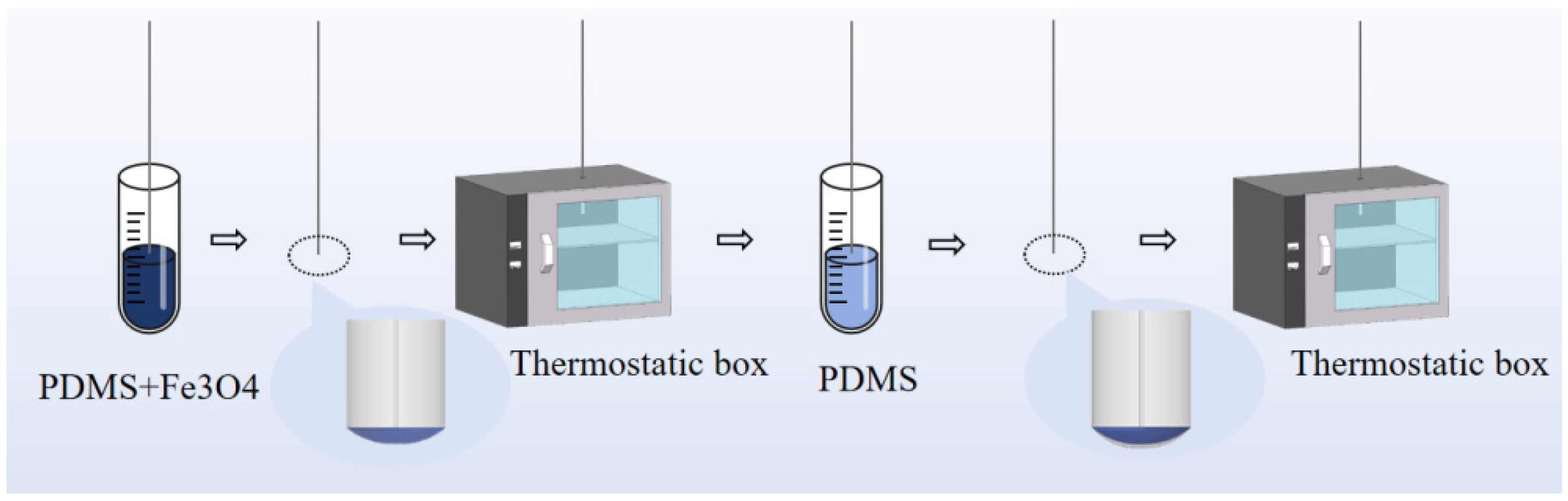

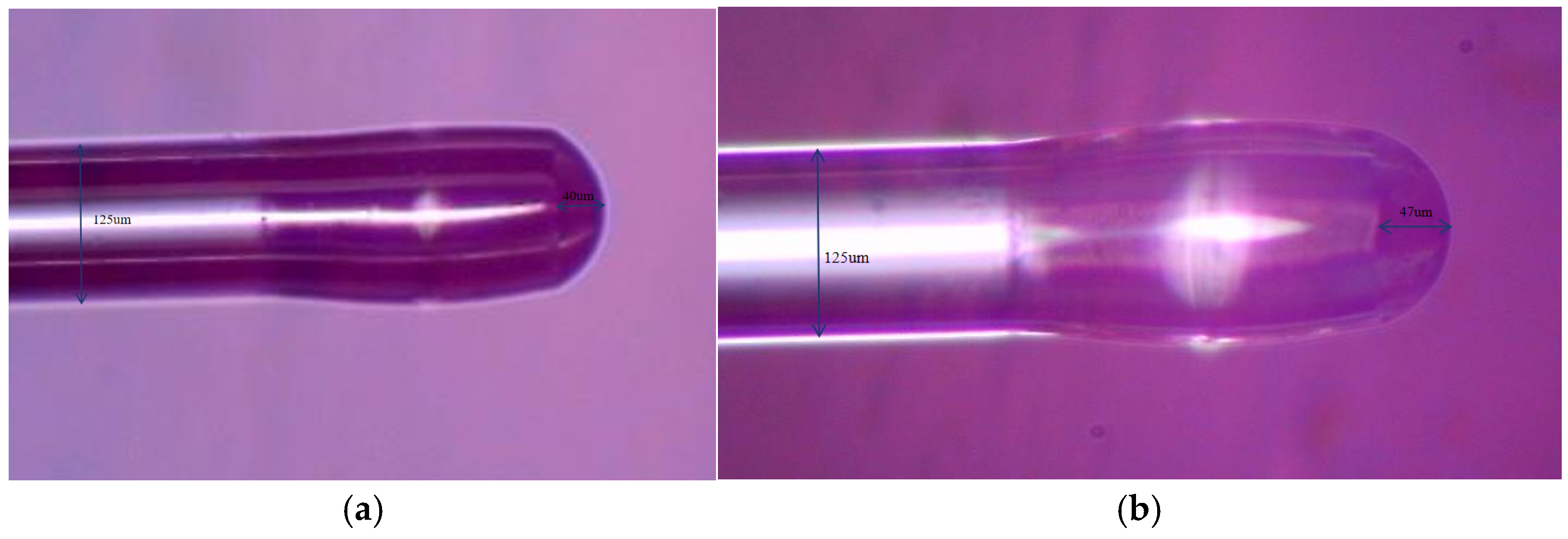

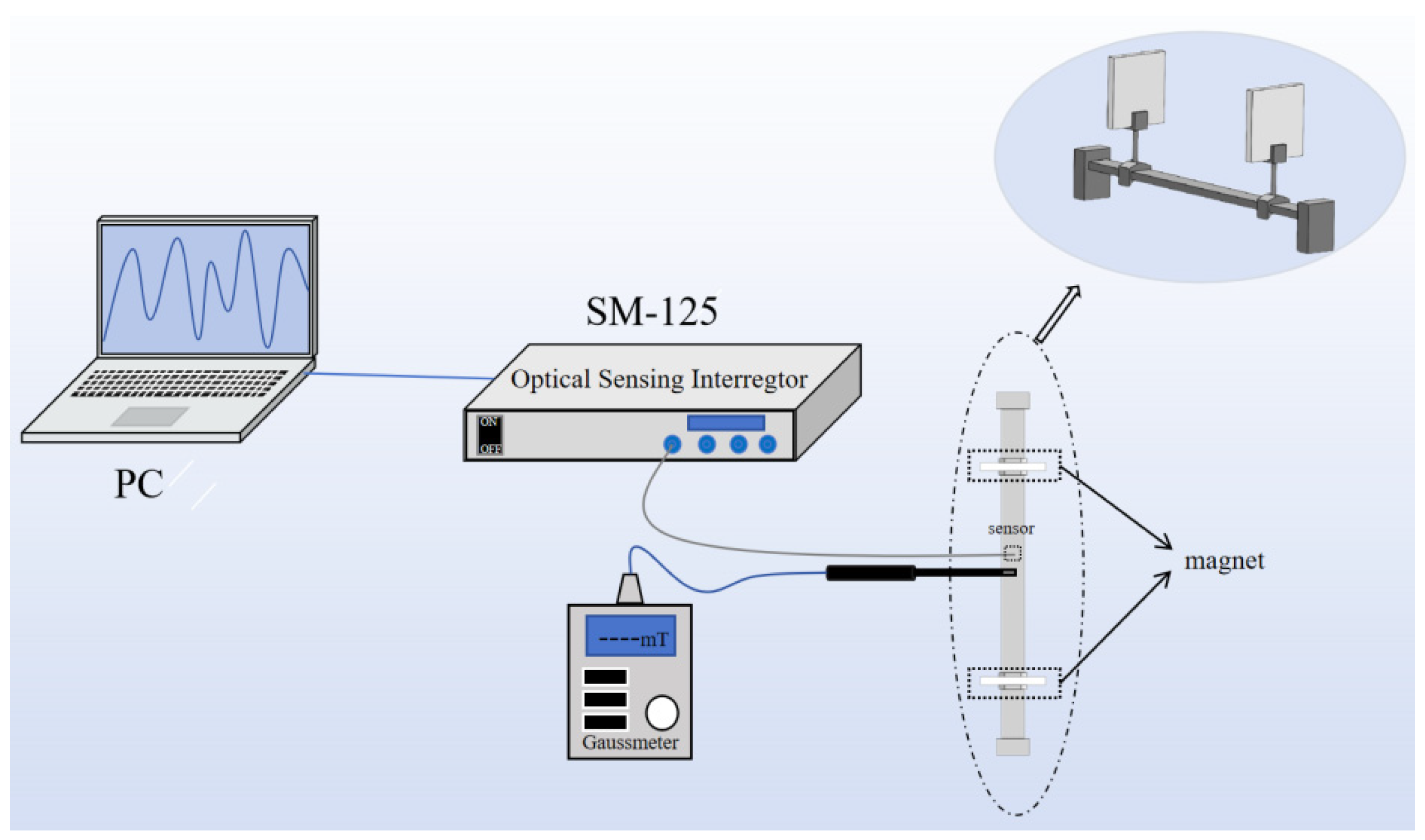

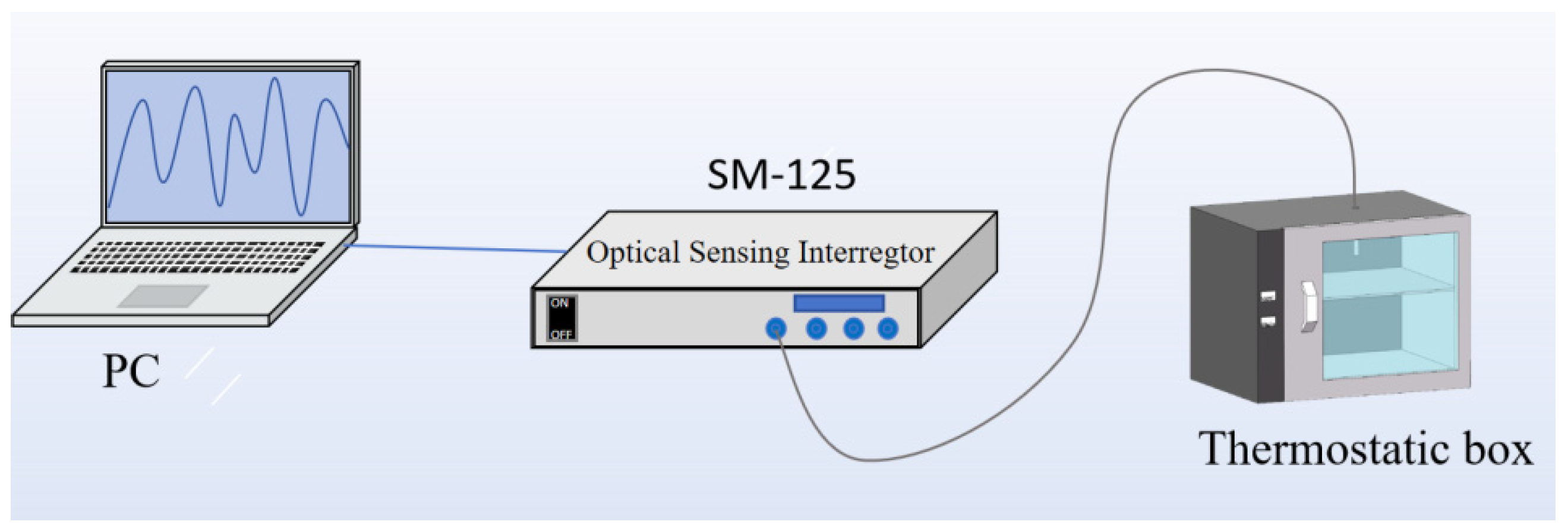

2. Sensor Fabrication and Principle

3. Experimental Results and Discussion

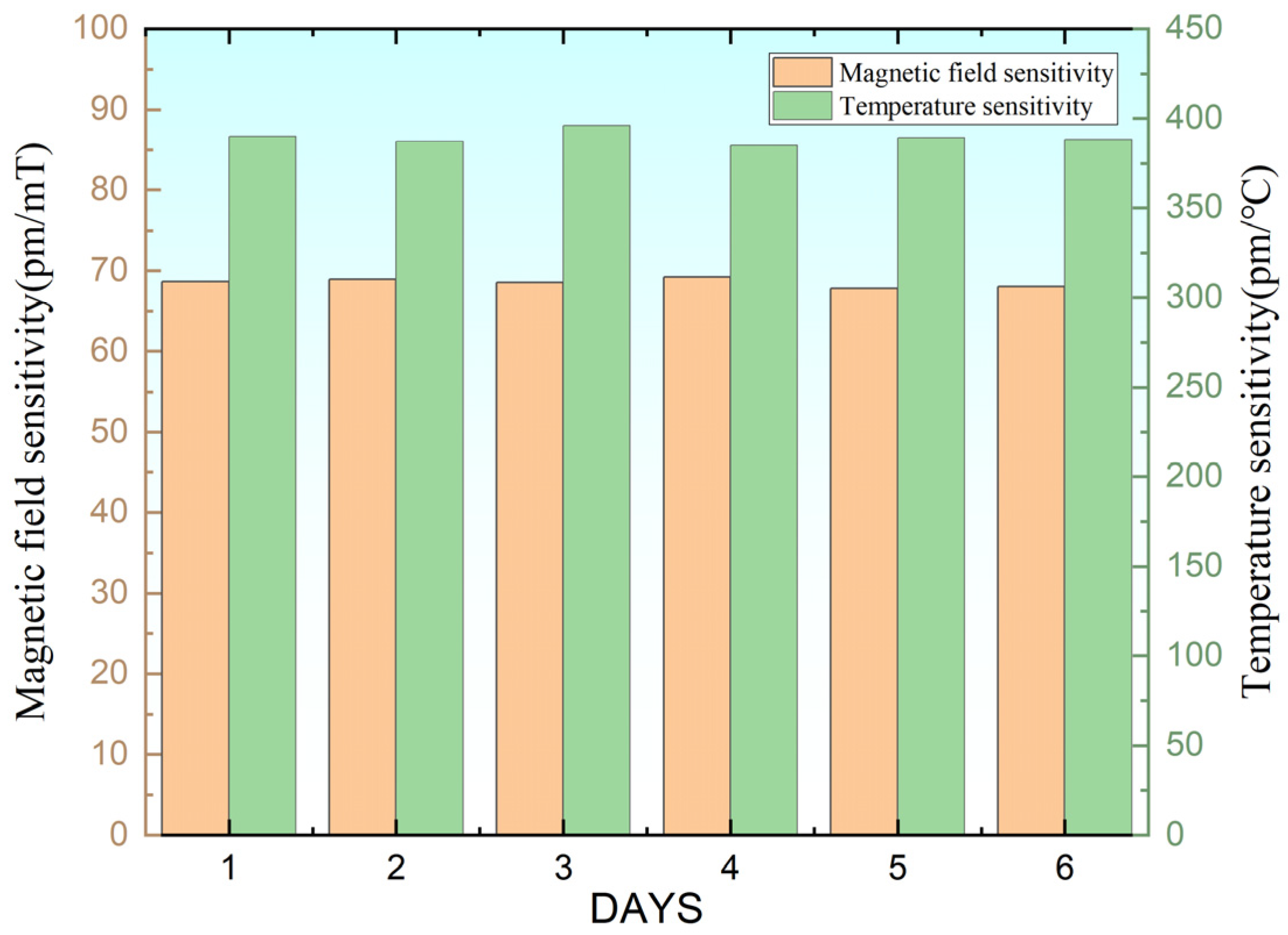

3.1. Magnetic Field Sensitivity Experiment

3.2. Temperature Sensing Experiment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, C.; Shen, T.; Wu, H.B.; Feng, Y.; Chen, J.-J. Applications of magneto-strictive, magneto-optical, magnetic fluid materials in optical fiber current sensors and optical fiber magnetic field sensors: A review. Opt. Fiber Technol. 2021, 65, 102634. [Google Scholar] [CrossRef]

- Stasiewicz, K.A.; Jakubowska, I.; Moś, J.E.; Marć, P.; Paczesny, J.; Zbonikowski, R.; Jaroszewicz, L.R. Optical properties of a tapered optical fiber coated with alkanes doped with Fe3O4 nanoparticles. Sensors 2022, 22, 7801. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.F.; Chiang, C.C. A Micro Rectangular-Shaped Long-Period Fiber Grating Coated with Fe3O4 Nanoparticle Thin Overlay for Magnetic Sensing. Materials 2015, 8, 7074–7083. [Google Scholar] [CrossRef]

- Li, L.; Wang, X.; Jiang, C.; Zhou, L.; Cong, Z.; Sun, Y.; Dong, T.; Liu, X.; Chen, P. A novel flexible optical fiber magnetic field sensor based on integrated Fe3O4 nanoparticles. Opt. Fiber Technol. 2024, 87, 103904. [Google Scholar] [CrossRef]

- Song, J.; Sun, S.; Jiang, C.; Chen, H.; Zhu, X.; Ren, J.; Wang, S. A tapered multicore fiber sensor for measuring temperature and magnetic field. Opt. Fiber Technol. 2023, 80, 103384. [Google Scholar] [CrossRef]

- Li, Y.; Xie, F.; Jia, L.; Li, G.; Liang, L. A microfiber interferometer magnetic sensor with magnetostrictive polymer composite. J. Mod. Opt. 2025, 72, 201–206. [Google Scholar] [CrossRef]

- Wu, B.; Chen, H.; Xiao, S.; Yin, B.; Wang, M.; Zhao, X.; Yan, F. Sensitivity Enhancement for magnetic field sensor using an optoelectronic oscillator based on fiber Bragg grating Fabry-Perot Cavity with acrylate-adhesive. IEEE Sens. J. 2024, 24, 19117–19124. [Google Scholar] [CrossRef]

- Deng, L.; Jiang, C.; Gao, J.; Hu, C.; Li, L.; Cao, T.; Li, H.; Sun, S.; Huang, H. Ultrasensitive magnetic field sensor based on Fabry–Perot interferometer and magnetostrictive material. IEEE Sens. J. 2023, 23, 30444–30450. [Google Scholar] [CrossRef]

- Chen, X.; Wu, S.; Li, N.; Liu, L.; He, S. Passive temperature-compensated fiber Fabry-Perot magnetic field sensor. Opt. Express 2025, 33, 449–461. [Google Scholar] [CrossRef]

- Peng, J.; Zhang, S.; Jia, S.; Kang, X.; Yu, H.; Yang, S.; Wang, S.; Yang, Y. A highly sensitive magnetic field sensor based on FBG and magnetostrictive composite with oriented magnetic domains. Measurement 2022, 189, 110667. [Google Scholar] [CrossRef]

- Zhu, M.; Gao, P.; Cai, S.; Zhang, N.; Wu, B.; Liu, Y.; Yin, B.; Wang, M. High-Sensitivity Magnetic Field Sensor Based on an Optoelectronic Oscillator with a Mach-Zehnder Interferometer. Sensors 2025, 25, 1621. [Google Scholar] [CrossRef] [PubMed]

- Xu, R.; Niu, G.; Xue, Y.; Ke, C.; Deng, H.; Deng, S.; Chen, M.; Yuan, L. An all-optical vector magnetic field sensor based on magnetic fluid and side-polished hollow-core optical fiber. IEEE Sens. J. 2021, 21, 21410–21416. [Google Scholar] [CrossRef]

- Xia, J.; Wang, F.; Luo, H.; Wang, Q.; Xiong, S. A magnetic field sensor based on a magnetic fluid-filled FP-FBG structure. Sensors 2016, 16, 620. [Google Scholar] [CrossRef] [PubMed]

- Shi, F.; Bai, X.; Wang, F.; Pang, F.; Pu, S.; Zeng, X. All-fiber magnetic field sensor based on hollow optical fiber and magnetic fluid. IEEE Sens. J. 2016, 17, 619–622. [Google Scholar] [CrossRef]

- Li, Y.; Pu, S.; Zhao, Y.; Yao, T. Fiber-optic magnetic field sensing based on microfiber knot resonator with magnetic fluid cladding. Sensors 2018, 18, 4358. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, N.; Gao, P.; Zhao, Y. Magnetic field sensor based on ring WGM resonator infiltrated with magnetic fluid. J. Magn. Magn. Mater. 2020, 493, 165701. [Google Scholar] [CrossRef]

- Zu, P.; Chan, C.C.; Lew, W.S.; Hu, L.; Jin, Y.; Liew, H.F.; Chen, L.H.; Wong, W.C.; Dong, X. Temperature-insensitive magnetic field sensor based on nanoparticle magnetic fluid and photonic crystal fiber. IEEE Photonics J. 2012, 4, 491–498. [Google Scholar]

- Yan, L.; Wang, Q.; Yin, B.; Xiao, S.; Li, H.; Wang, M.; Liu, X.; Wu, S. Research on simultaneous measurement of magnetic field and temperature based on petaloid photonic crystal fiber sensor. Sensors 2023, 23, 7940. [Google Scholar] [CrossRef]

- Zhang, J.; Qiao, X.; Yang, H.; Wang, R.; Rong, Q.; Lim, K.S.; Ahmad, H. All-fiber magnetic field sensor based on tapered thin-core fiber and magnetic fluid. Appl. Opt. 2017, 56, 200–204. [Google Scholar] [CrossRef]

- Song, B.; Miao, Y.; Lin, W.; Zhang, H.; Liu, B.; Wu, J.; Liu, H.; Yan, D. Loss-based magnetic field sensor employing hollow core fiber and magnetic fluid. IEEE Photonics Technol. Lett. 2014, 26, 2283–2286. [Google Scholar] [CrossRef]

- Guo, J.; Wang, W.; Dong, L.; Li, X.; Guo, Z.; Du, X.; Zhang, J. Highly sensitive magnetic field sensor based on few mode fiber interferometry. IEEE Sens. J. 2024, 24, 16179–16187. [Google Scholar] [CrossRef]

- Gao, R.; Lu, D.F.; Cheng, J.; Jiang, Y.; Jiang, L.; Ye, J.S.; Qi, Z.M. Magnetic fluid-infiltrated anti-resonant reflecting optical waveguide for magnetic field sensing based on leaky modes. J. Light. Technol. 2016, 34, 3490–3495. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, H.; Fu, R.; Li, B.; Yan, X.; Zhang, X.; Wang, F.; Cheng, T. High sensitivity surface plasmon resonance magnetic field sensor based on Au/gold nanoparticles/magnetic fluid in the hollow core fiber. IEEE Sens. J. 2023, 23, 12899–12905. [Google Scholar] [CrossRef]

- Tian, P.; Guan, C.; Ye, P.; Cheng, T.; Yang, J.; Zhu, Z.; Shi, J.; Yang, J.; Yuan, L. Dual mode interference magnetic-field sensor based on hollow suspended-core fiber. IEEE Photonics Technol. Lett. 2021, 34, 43–46. [Google Scholar] [CrossRef]

- Zheng, Y.; Dong, X.; Chan, C.C.; Shum, P.P.; Su, H. Optical fiber magnetic field sensor based on magnetic fluid and microfiber mode interferometer. Opt. Commun. 2015, 336, 5–8. [Google Scholar] [CrossRef]

- Yin, J.; Ruan, S.; Liu, T.; Jiang, J.; Wang, S.; Wei, H.; Yan, P. All-fiber-optic vector magnetometer based on nano-magnetic fluids filled double-clad photonic crystal fiber. Sens. Actuators B Chem. 2017, 238, 518–524. [Google Scholar] [CrossRef]

- Duan, S.; Pu, S.; Lin, X.; Liu, W.; Hao, Z.; Zhang, C.; Fu, J.; Han, S. Enhanced sensitivity of temperature and magnetic field sensor based on FPIs with Vernier effect. Opt. Express 2023, 32, 275–286. [Google Scholar] [CrossRef]

- Zeng, Z.; Liu, H.; Zhang, H.; Cheng, S.; Yi, Y.; Yi, Z.; Wang, J.; Zhang, J. Tunable ultra-sensitive four-band terahertz sensors based on Dirac semimetals. Photonics Nanostruct.-Fundam. Appl. 2025, 63, 101347. [Google Scholar] [CrossRef]

- Zeng, L.; Li, B.; Wen, R.; Zhang, X. Plasmonic sensor based on multi fano resonance in inverse T shape structure for detection of CO2 concentration. IEEE Photonics J. 2023, 15, 2201805. [Google Scholar] [CrossRef]

- Li, Z.; Tian, J.; Jiao, Y.; Sun, Y.; Yao, Y. Simultaneous measurement of air pressure and temperature using fiber-optic cascaded Fabry-Perot interferometer. IEEE Photonics J. 2018, 11, 7100410. [Google Scholar] [CrossRef]

- Luo, L.; Pu, S.; Dong, S.; Tang, J. Fiber-optic magnetic field sensor using magnetic fluid as the cladding. Sens. Actuators A Phys. 2015, 236, 67–72. [Google Scholar] [CrossRef]

- Su, G.H.; Shi, J.; Xu, D.G.; Zhang, H.W.; Xu, W.; Wang, Y.Y.; Feng, J.C.; Yao, J.Q. Simultaneous magnetic field and temperature measurement based on no-core fiber coated with magnetic fluid. IEEE Sens. J. 2016, 16, 8489–8493. [Google Scholar] [CrossRef]

- Wei, L.; Li, H.; Hu, T.; Fu, R.; Zhao, Y.; Cheng, T.; Yan, X. Magnetic field and temperature two-parameter sensor based on Mach-Zehnder interferometer and faraday rotation effect. IEEE Sens. J. 2023, 23, 14041–14048. [Google Scholar] [CrossRef]

- Ying, Y.; Hu, N.; Si, G.Y.; Xu, K.; Liu, N.; Zhao, J.Z. Magnetic field and temperature sensor based on D-shaped photonic crystal fiber. Optik 2019, 176, 309–314. [Google Scholar] [CrossRef]

| Structures | Detecting Range | Magnetic Field Sensitivity | Temperature Sensitivity | Reference |

|---|---|---|---|---|

| SMS | 0–13 mT | 659 pm/mT | −42 pm/K | [31] |

| No-core Fiber | 2–14 mT | 74 pm/mT | −247 pm/K | [32] |

| FP-MZI | 0–15 mT | 19 pm/mT | −846 pm/K | [33] |

| Microfiber interferometer | 0–200 mT | 49 pm/mT | \ | [6] |

| D-shaped PCF | 0–27 mT | 2100 pm/mT | −1250 pm/K | [34] |

| SMS-FP | 0–50 mT | 69 pm/mT | 390 pm/K | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, S.; Zhang, H.; Cao, Z.; Lu, Y.; Zhou, R.; Zhang, Z. Magnetic Field and Temperature Dual-Parameter Optical Fiber Sensor Based on Fe3O4 Magnetic Film. Photonics 2025, 12, 633. https://doi.org/10.3390/photonics12070633

Xiong S, Zhang H, Cao Z, Lu Y, Zhou R, Zhang Z. Magnetic Field and Temperature Dual-Parameter Optical Fiber Sensor Based on Fe3O4 Magnetic Film. Photonics. 2025; 12(7):633. https://doi.org/10.3390/photonics12070633

Chicago/Turabian StyleXiong, Shichun, Haojie Zhang, Zhongwei Cao, Yipeng Lu, Rui Zhou, and Zhiguo Zhang. 2025. "Magnetic Field and Temperature Dual-Parameter Optical Fiber Sensor Based on Fe3O4 Magnetic Film" Photonics 12, no. 7: 633. https://doi.org/10.3390/photonics12070633

APA StyleXiong, S., Zhang, H., Cao, Z., Lu, Y., Zhou, R., & Zhang, Z. (2025). Magnetic Field and Temperature Dual-Parameter Optical Fiber Sensor Based on Fe3O4 Magnetic Film. Photonics, 12(7), 633. https://doi.org/10.3390/photonics12070633