Abstract

Structural health monitoring (SHM) plays a vital role in ensuring the safety, durability, and performance of civil infrastructure. This review delves into the significant advancements in optical fiber sensor (OFS) technologies such as Fiber Bragg Gratings, Distributed Temperature Sensing, and Brillouin-based systems, which have emerged as powerful tools for enhancing SHM capabilities. Offering high sensitivity, resistance to electromagnetic interference, and real-time distributed monitoring, these sensors present a superior alternative to conventional methods. This paper also explores the integration of OFSs with Artificial Intelligence (AI), which enables automated damage detection, intelligent data analysis, and predictive maintenance. Through case studies across key infrastructure domains, including bridges, tunnels, high-rise buildings, pipelines, and offshore structures, the review demonstrates the adaptability and scalability of these sensor systems. Moreover, the role of SHM is examined within the broader context of civil and urban infrastructure, where IoT connectivity, AI-driven analytics, and big data platforms converge to create intelligent and responsive infrastructure. While challenges remain, such as installation complexity, calibration issues, and cost, ongoing innovation in hybrid sensor networks, low-power systems, and edge computing points to a promising future. This paper offers a comprehensive amalgamation of current progress and future directions, outlining a strategic path for next-generation SHM in resilient urban environments.

1. Introduction

Civil infrastructure such as bridges, tunnels, dams, and skyscrapers play a vital role in supporting modern society [1,2]. These structures are essential not only for daily functioning but also for ensuring public safety, economic stability, and sustainable development [3]. Over time, however, they are exposed to environmental conditions, varying loads, and material aging [4]. Without timely and effective monitoring, these factors can lead to gradual deterioration, reduced performance, or, in some cases, sudden structural failure [5]. In response to this challenge, structural health monitoring (SHM) has emerged as a key approach for assessing the condition of infrastructure [6,7]. SHM systems enable either continuous or periodic monitoring of structural performance, helping engineers detect early signs of damage, plan maintenance proactively, and ultimately extend the lifespan of critical assets [1,8].

Among the various sensing technologies used in SHM [5,9,10], OFSs have gained significant attention due to their distinctive advantages [11,12,13]. These sensors are lightweight, immune to electromagnetic interference (EMI), and capable of measuring multiple parameters across long distances [14]. Technologies such as fiber Bragg gratings (FBGs) [15], distributed temperature and strain (DTS) sensors [16], and Brillouin-based distributed sensing systems [17] have shown strong potential in both experimental studies and real-world deployments. Their ability to function in harsh environments and their suitability for large-scale applications make them especially valuable in modern SHM systems [18,19,20].

At the same time, advances in artificial intelligence (AI) and machine learning (ML) are transforming how SHM data is analyzed [21,22]. These technologies can process large volumes of data, recognize complex patterns, and predict structural issues before they become critical. When combined with OFSs, AI enables automated damage detection, real-time condition assessment, and predictive maintenance strategies, significantly enhancing the overall efficiency and reliability of SHM systems [23]. The integration of AI into SHM has attracted considerable attention in recent years, leading to several comprehensive reviews that examine its role in enhancing infrastructure safety and reliability. One such study presented an in-depth analysis of the progress made in AI applications for SHM [24]. The evolution of intelligent systems in structural inspection was discussed, with particular emphasis on the growing incorporation of unmanned aerial vehicles (UAVs) and Internet of Things (IoT) platforms [24]. Advancements in image-based diagnostics and predictive models were also explored, while addressing the emerging significance of transparent and physically grounded AI algorithms. This work offered a structured outlook for future innovations in automated monitoring systems [24].

Furthermore, the development of smart cities adds another important dimension to this field [25]. As urban areas increasingly adopt digital technologies to improve sustainability, safety, and quality of life, intelligent infrastructure monitoring becomes a core component. In this context, fiber-optic SHM systems integrated with AI and connected through the Internet of Things (IoT) offer powerful capabilities for real-time monitoring, emergency response, and informed urban planning [26,27]. While numerous reviews have explored SHM using either fiber-optic sensors or AI independently, few have provided an integrated perspective that connects both domains [28]. Prior works often focused on specific modalities such as distributed acoustic sensing (DAS) or on AI methods applied to structural monitoring in isolation, without fully examining their combined potential [2,20,29,30]. In addition, traffic sensing and infrastructure diagnostics using other technologies like wireless or vision-based systems have received broader coverage, while comprehensive assessments of optical fiber sensing technologies remain relatively scarce. This review addresses these gaps by presenting a unified synthesis of recent advancements in optical fiber-based SHM, with a particular emphasis on their integration with AI. It also situates this technological convergence within the broader framework of smart cities, highlighting how intelligent sensor networks support resilient, data-driven infrastructure. Through this approach, the paper aims to offer a timely and distinctive contribution to the field.

In this review, the term key infrastructure domains refers to critical built structures that play an essential role in civil and urban systems by supporting transportation, energy generation, water distribution, and large-scale human habitation. These domains were selected based on their structural complexity, load-bearing significance, vulnerability to environmental stressors, and documented adoption of OFS-based SHM solutions. The six key infrastructure domains examined in this paper are bridges, tunnels, high-rise buildings, dams, pipelines, and offshore platforms including wind turbines. Although offshore platforms and wind turbines are geographically distant from urban centers, they are included due to their strategic relevance to national infrastructure and their demanding monitoring requirements in harsh environments. This classification provides a coherent framework for analyzing the diverse applications and advantages of OFSs across different structural settings.

The paper is organized as follows. Section 2 introduces the fundamentals of OFSs. Section 3 reviews applications across various types of infrastructure. Section 4 outlines key challenges and limitations. Section 5 examines how AI contributes to smarter SHM systems. Section 6 discusses the implications for civil and urban infrastructure development. Section 7 and Section 8 address future directions and provide concluding remarks, respectively.

2. Fundamentals of OFSs

OFSs operate based on the fundamental principle of total internal reflection (TIR) [31]. An optical fiber typically consists of a core surrounded by a cladding, where the core has a higher refractive index. When light enters the fiber at an appropriate angle, it is confined within the core through repeated reflections at the core–cladding boundary. This mechanism allows the light to travel long distances with minimal loss [32]. In the realm of SHM, a variety of OFSs are employed to detect parameters such as strain, temperature, and pressure [13,30,33]. Among the most prominent are FBG sensors [15,34]. These sensors are produced by creating periodic changes in the refractive index along the fiber core. When light travels through the fiber FBGs reflect specific wavelengths, known as Bragg wavelengths, while allowing others to pass through. Any strain or temperature variation alters the spacing of the grating, causing a measurable shift in the reflected wavelength. This makes FBGs highly effective for precise and localized sensing, and their compact form factor allows for easy embedding into structural materials [34].

DOFSs represent another powerful class of sensing technologies [35,36]. They differ from point sensors like FBGs by enabling continuous monitoring along the entire length of an optical fiber. Techniques such as distributed temperature sensing (DTS) [37,38], distributed acoustic sensing (DAS) [39,40], and Brillouin optical time-domain analysis (BOTDA) [41,42] are used to detect thermal, acoustic, and mechanical changes along long stretches of fiber. These systems rely on naturally occurring scattering effects within the fiber, Raman, Rayleigh, and Brillouin scattering, respectively, to extract spatially resolved data. Their ability to provide real-time, kilometer-scale monitoring makes them highly suitable for infrastructure such as pipelines, tunnels, bridges, and large industrial complexes.

In a study conducted by Minardo et al. the application of a distributed optical fiber strain sensing system, utilizing stimulated Brillouin scattering, was examined for its effectiveness in tracking tunnel deformation [43]. The subject of the study was a railway tunnel crossing the Varco d’Izzo earthflow, an active landslide region within the southern Apennines of Italy. Following damage caused by ground instability, the tunnel underwent reconstruction in 1992, incorporating a reinforced concrete box structure flanked by deep sheet pile walls. To detect and monitor structural stress, an optical fiber-based internal strain monitoring system was installed in 2016. Findings from this system indicated that strain levels were highest around the tunnel’s joints, with fiber elongation patterns corresponding to measurements obtained from supplementary monitoring technologies.

Strain distribution along the tunnel’s sidewalls was evaluated using single-mode optical fibers and the principle of stimulated Brillouin scattering (SBS). This technique involved transmitting two laser beams with slightly offset frequencies from either end of the fiber. As these beams interacted, they formed a traveling interference pattern that triggered the generation of an acoustic wave, provided that the frequency offset aligned with the fiber’s Brillouin gain spectrum (BGS). This wave, in turn, scattered a portion of the pump beam’s energy, leading to amplification of the counter-propagating probe beam. The level of this amplification depended on the Brillouin frequency shift (BFS), which for fibers operating at a 1.55 µm wavelength typically falls within the 10 to 11 GHz range [43].

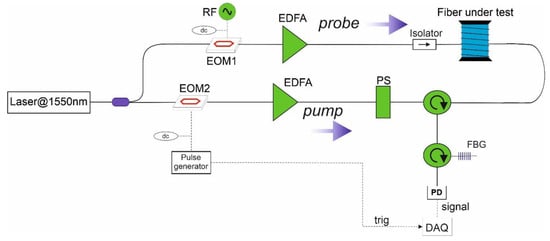

Since BFS was linearly related to strain and temperature, these parameters can be determined. In Brillouin optical time-domain analysis (BOTDA) the pump beam was pulsed, enabling sequential SBS interactions along the fiber which can be temporally resolved. By recording the probe wave’s intensity over time, the spatial Brillouin gain distribution was obtained. By adjusting the pump–probe frequency shift and repeating measurements, the BGS can be acquired with high spectral resolution. Spatial resolution was determined by the pump pulse duration, with a 10 ns pulse yielding a 1 μm resolution. The field trials were conducted using a prototype BOTDA analyzer, as shown in Figure 1. Moreover, the experiments showed an increased rate of fiber deformation at both the beginning and end of the monitoring period, which coincides with an acceleration in the landslide’s movement as indicated by nearby inclinometers [43].

Figure 1.

The experimental setup for Brillouin optical time-domain analysis (BOTDA) measurements consists of several critical components, including an electro-optic modulator (EOM), a polarization switch (PS), an erbium-doped fiber amplifier (EDFA), a photodetector (PD), a fiber Bragg grating (FBG), and a data acquisition (DAQ) system [43].

Interferometric OFSs offer another advanced approach to precision measurement [44]. These sensors function by analyzing changes in the phase of light due to external perturbations [45]. Fabry–Perot interferometers use the interference of light reflected between two parallel surfaces inside a cavity. Variations in cavity length caused by strain or pressure change the interference pattern, providing a measure of the physical deformation. The Mach–Zehnder interferometer splits a beam of light into two paths—one exposed to the measured environment and the other serving as a reference. Changes in the optical path length due to external conditions cause phase shifts when the beams are recombined, allowing for extremely sensitive detection of environmental changes such as vibration or displacement [46].

The advantages of OFSs extend beyond their robustness and flexibility. They are lightweight, compact, and resistant to corrosion, making them ideal for harsh environments and embedded applications [47]. Their ability to perform real-time monitoring over long distances, sometimes spanning tens of kilometers, makes them a critical tool for ensuring the safety and longevity of infrastructure. Furthermore, their high sensitivity and compatibility with smart monitoring systems support the development of intelligent infrastructure capable of autonomous assessment and early warning for structural failures. These features collectively make OFSs a superior alternative to many conventional sensing technologies in modern SHM systems. The characteristics of OFSs are presented in Table 1.

Table 1.

Characteristics of OFSs.

3. Applications of OFSs in SHM

SHM is a critical discipline that ensures the safety, functionality, and longevity of infrastructure by continuously assessing its condition and detecting early signs of damage or degradation. Among the various technologies used for SHM, OFSs have emerged as a powerful solution due to their high sensitivity, immunity to EMI, durability, and ability to function in harsh environments [52]. These sensors can measure a wide range of physical parameters such as strain, temperature, pressure, and vibration with remarkable accuracy. Their small size and flexibility allow them to be embedded within structural elements or surface-mounted, making them ideal for real-time, long-term monitoring of large-scale civil infrastructure.

While optical fiber sensing has been increasingly applied to a wide range of civil infrastructure, including slopes [53,54], foundation ditches [55,56], roadbeds [57], roadways [58,59], and railway tracks [60,61,62], this review specifically focuses on built structures such as high-rise buildings, bridges, tunnels, dams, offshore platforms, and wind turbines. The exclusion of geotechnical and transportation infrastructure is intentional to maintain a clear focus on structural systems with primary load-bearing functions. Readers seeking insights into fiber-optic applications in those domains are encouraged to consult dedicated reviews and case studies in the relevant geotechnical and transportation engineering literature [53,54,55,56,57,58,59,60,61,62,63,64,65]. Figure 2 illustrates the various applications of OFSs in SHM as discussed in this paper. Table 2 demonstrates the advantages of OFSs in SHM compared to traditional sensor systems. Below are the key applications of OFSs in SHM across various sectors.

Figure 2.

The applications of OFSs in SHM discussed in this section.

Table 2.

Key advantages of OFSs versus electrical sensors in SHM.

3.1. Bridges

Bridges are continually exposed to dynamic loads, temperature fluctuations, and environmental degradation, making them ideal candidates for SHM using OFSs [75]. OFSs, particularly FBG sensors, are embedded in or attached to bridge components like decks, piers, cables, and expansion joints to measure strain, vibration, and thermal effects. These sensors offer continuous, distributed monitoring, enabling the detection of stress concentration, fatigue damage, or crack initiation before they become critical [76]. For instance, suspension and cable-stay bridges benefit greatly from the use of distributed strain sensing to assess the health of tension cables over long distances. By providing actionable data in real time, OFS systems significantly enhance bridge safety and extend service life while reducing inspection costs.

A Rayleigh scattering-based distributed optical fiber-optic sensing (DOFS) system was implemented as the primary SHM solution for Poland’s inaugural fiber-reinforced polymer (FRP) composite bridge [76]. Given the novel use of FRP materials in bridge construction, it was essential to thoroughly validate the DOFS approach to ensure it could deliver precise, high-resolution data suited to the unique structural behavior of composite materials. Validation efforts included a combination of proof load tests and finite element analysis (FEA), aimed at verifying the accuracy and reliability of the DFOS readings. To support this validation, two conventional techniques—foil strain gauges and vibrating wire strain gauges—were employed to provide reference strain data. DOFS-based strain distributions were initially compared against the discrete measurements captured by these traditional sensors. These strain results were then used to derive deflection profiles, which were cross-validated using linear variable differential transducers (LVDTs).

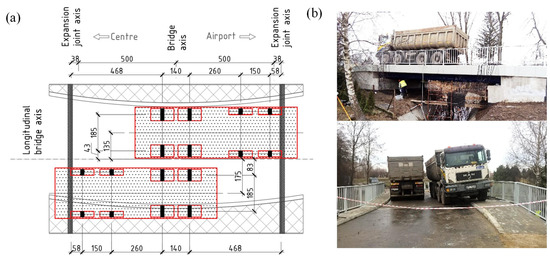

Furthermore, the experimentally derived measurement profiles were evaluated against simulated responses generated from the FEA model. Two proof load tests were conducted on the FRP bridge superstructure to evaluate its structural performance and validate the monitoring system. The first test took place shortly after construction was completed and before the bridge was opened to traffic. This test was essential not only for obtaining the official service permit but also for comparing the DOFS system with traditional measurement techniques. Approximately eight months later, a second test was performed during the bridge’s operational phase. This test focused on assessing the long-term functionality of the DOFS system and analyzing the bridge’s structural behavior under service conditions. In both tests, two four-axle heavy vehicles were used to apply the proof load, providing a total mass of 64,220 kg. The positioning of these vehicles on the bridge deck during loading is depicted in Figure 3. The outcomes from both experimental and numerical comparisons confirmed that the DOFS technique is a dependable and precise tool for monitoring FRP bridge structures, making it well-suited for long-term SHM applications in advanced composite infrastructure [76].

Figure 3.

(a) Position of the applied proof load on the bridge (measured in centimeters); and (b) a visual representation of the bridge under load during testing [76].

The use of DOFS technology in monitoring civil infrastructure was also explored by Kishida et al. with a field application conducted on an elevated railway bridge in Taiwan [77]. Multiple strain-sensing fibers were installed along a 1 km span of a bullet train railway bridge, and the collected data were combined to calculate the three-dimensional deformation of the structure. The sensing system, once installed, enabled continuous measurements that allowed for rapid safety assessments following earthquakes of magnitudes 6.4 and 6.8 on the Richter scale. Additionally, the dynamic monitoring of a passing bullet train using DAS was demonstrated, highlighting the capability of OFSs for both static and dynamic structural evaluations. The empirical data obtained from this field test were used to assess the effectiveness of DFOS technology for structural health monitoring applications [77].

Recently, a novel optical fiber cable integrated with weak fiber Bragg grating (wFBG) arrays was designed to enhance strain monitoring capabilities across large-scale structures [78]. The study presented a hybrid modulation and demodulation approach that combines wavelength division multiplexing (WDM) and time division multiplexing (TDM). This method took advantage of the cable’s periodic wavelength shifting under strain, enabling simultaneous and efficient acquisition of multiple sensing signals along a single fiber line. A comprehensive strain transfer model was then formulated, grounded in elasticity theory. The model distinguished between the strain behavior in the bonded (glued) regions and the suspended (overhanging) regions of the optical cable. By integrating the transfer characteristics of both sections, a complete sensitivity model was derived to accurately quantify the cable’s response to structural deformation [78].

To further refine the system, FEA was utilized to optimize key structural parameters of the optical cable, ensuring adaptability for either high-sensitivity detection or broad measurement range, depending on application needs. This advanced wFBG-based optical sensing cable was implemented in a steel–concrete composite bridge as a case study. Through a series of static and dynamic load tests the system demonstrated its ability to track strain variations effectively. In addition to structural monitoring, the system supports intelligent traffic features such as lane recognition, vehicle load estimation, and speed monitoring, illustrating its potential as a multifunctional component in smart transportation networks [78]. In another study, FBGs were utilized to measure static and dynamic loads on bridge decks and columns, including applications involving composite repairs for rehabilitation [79]. A new long-gauge concept enabling the measurement of overall average strains was developed, with gauge lengths ranging from 1 to 20 m. These gauges were either bonded to the concrete structures or embedded within composite repair patches. Six projects undertaken by ISIS Canada, aimed at incorporating fiber-optic sensing for the SHM of Canadian bridges, were presented. Data collected from several bridges over multiple years in hostile environments were provided to demonstrate system reliability [79].

3.2. Tunnels

Tunnel infrastructure, whether used for transportation, water conveyance, or mining, must withstand ground pressure, seismic activity, and environmental stress [80,81,82]. OFSs are ideal for such confined and challenging environments. They can be embedded in tunnel linings or installed along walls to monitor deformation, convergence, and temperature fluctuations [83]. Technologies like distributed temperature sensing (DTS) and distributed strain sensing (DSS) are commonly used to detect structural anomalies, ground movement, and even water ingress [69]. OFSs are also vital for fire detection, offering rapid response through temperature change monitoring [2]. The durability and precision of optical fibers make them indispensable for ensuring tunnel safety and minimizing maintenance disruptions [82,84].

Bremer et al. explored the use of OFSs for monitoring the structural health of civil infrastructure [13]. An OFS designed for crack detection was introduced along with two distinct moisture sensors aimed at identifying water infiltration in concrete-based structures. The research also addressed the potential deterioration in the performance of optical glass fibers when exposed to the mechanical and chemical effects present in concrete environments, which may affect their long-term durability. Furthermore, the study showcased the effectiveness of OFS systems for assessing the condition of sewer tunnels, emphasizing their suitability for reliable monitoring in demanding settings [13]. Distributed optic fiber sensing (DOFS) is a proven technology used in civil engineering for monitoring temperature, strain, and acoustic signals across large structures. Kishida et al. outlined the following two recent advances: improved accuracy by adopting Rayleigh scattering instead of Brillouin-based methods, and enhanced data acquisition speed for real-time monitoring during construction [85]. These upgrades allowed engineers to make quicker safety assessments and support the permanent integration of fiber-optic cables for long-term SHM.

Piccolo et al. presented an innovative method for measuring tunnel convergence using distributed optical fiber strain sensors based on Rayleigh backscattering [86]. By applying different fiber anchoring techniques around the tunnel circumference, the system enabled accurate strain monitoring without obstructing the usable tunnel section. Designed for durability in harsh environments, the approach provided fully distributed measurements, offering richer data compared to conventional methods. An inverse analysis technique, supported by finite element modeling, was employed to estimate convergence from orthoradial strain measurements. The performance of this method was assessed by identifying key influencing parameters and evaluating how their uncertainties affect the analysis outcomes. Laboratory testing confirmed the method’s effectiveness, demonstrating its ability to detect tunnel convergence with a resolution of 1 mm, aligning with anticipated performance criteria [86].

Zhang et al. presented the development of a DOFS-based distributed sensing network aimed at assessing the structural integrity of concrete immersed tunnels [87]. A key contribution of this research was the establishment of a generalized framework for implementing DOFS systems in the field, covering sensor network design, installation, and data acquisition, along with a detailed validation through a real-world case study. Special emphasis was placed on detecting joint deformations, a critical indicator of structural behavior in immersed tunnels, which DOFS is especially well-equipped to monitor. The study also addressed essential elements of field deployment, including the selection of appropriate optical fibers or cables, optimization of interrogator system parameters, sensor installation techniques, and strategies for reliable data collection and post-processing. The effectiveness of this approach was demonstrated through a case study involving an operational immersed tunnel, where the sensing network successfully captured cyclic structural deformations induced by daily tidal movements and seasonal temperature variations. The data obtained not only validated the proposed monitoring system but also provided valuable insights for ongoing structural condition assessments. Overall, the findings underscore the potential of DOFS technology to enhance the monitoring and maintenance of large-scale tunnel infrastructure [87].

Gomez et al. presented the implementation of a DOFS system for SHM in the TMB L-9 metro tunnel in Barcelona [69]. The tunnel’s structural integrity is of particular concern due to the potential impacts of a nearby residential building’s construction. To evaluate the performance of this innovative monitoring technology, a detailed analysis of the strain data collected from the DOFS system was conducted. Based on this analysis, new data post-processing techniques were developed. Furthermore, the study assessed the reliability of the DOFS system by comparing its measurements with predictions from a theoretical model representing the site’s structural conditions [69]. Monsberger et al. presented a large-scale DOFS system installed in the tunnel lining of a highway tunnel under construction in Austria, which faced challenging geological conditions, including loose rock excavation with minimal overburden [81]. Fiber-optic cables were placed along both tunnel tubes to monitor 13 cross-sections of the primary shotcrete lining, covering 220 m, and 10 cross-sections of the secondary inner lining. Data was continuously evaluated and sent to the on-site geotechnical engineer for analysis, with automatic alerts if safety thresholds were exceeded. The results showed that the DOFS system responds quickly to structural changes, improving safety at the construction site [81].

While recent studies confirm the feasibility and effectiveness of DOFS in tunnel monitoring, most results reported in the literature remain qualitative [80,83]. Establishing quantitative correlations between distributed strain measurements and specific structural behaviors poses significant challenges due to the inherent complexity of tunnel environments. One major obstacle is the presence of multiple interacting physical processes. These include thermal, mechanical, and hydraulic influences, which affect sensor readings in ways that are difficult to decouple [81]. Additionally, the materials used in tunnel construction and the surrounding geology are often highly variable, resulting in non-uniform strain distributions that complicate interpretation and modeling [87]. The dynamic nature of tunnel loading, including the effects of passing vehicles and soil–structure interactions, introduces further variability [88]. Sensor responses can also be influenced by differences in installation depth and positioning [80]. Moreover, environmental noise from factors such as ground moisture changes, seismic activity, and temperature fluctuations can obscure meaningful patterns in the data. Together, these issues make it difficult to develop reliable, quantitative models. Addressing these challenges will require a combination of high-resolution simulations, advanced signal processing, and larger, more diverse datasets from field implementations [89].

While OFS technologies such as FBGs, BOTDA, and DAS are universal in principle, their application is often customized based on the unique structural, environmental, and operational conditions of each infrastructure type. Tunnels benefit from BOTDA’s ability to capture distributed strain under geological stress, while bridges leverage FBG arrays for real-time load monitoring. Buildings often rely on localized FBGs for tilt and vibration sensing, and pipelines use DAS for acoustic-based leak detection. This versatility underscores the need for application-specific deployment strategies even when using common OFS technologies.

3.3. Buildings and Skyscrapers

In modern high-rise buildings and smart structures, OFSs provide valuable data on load distribution, structural movement, and environmental conditions [20]. Sensors can be strategically placed in load-bearing columns, floors, and façades to monitor stress, detect settlement, and measure vibrations caused by wind or seismic activity. This information is critical not only for ensuring structural integrity but also for integrating building management systems that optimize energy use and maintenance schedules. During seismic events, OFSs deliver real-time data that helps assess the building’s structural response, guiding emergency responses and post-event evaluations [13,90]. Their ability to function without signal degradation across large areas makes them ideal for multi-story monitoring systems.

Early detection of hidden defects in reinforced concrete structures requires reliable monitoring tools, and OFSs offer a promising solution. Aimagambetova et al. reviewed prior research and presented experimental results on using OFSs to assess the structural condition of buildings. Tests showed that mechanical stress alters the reflected light spectrum in an OFS, enabling accurate strain measurement. The use of G652 optical fiber allows for continuous monitoring of stress, load, and deformation. The experiments also revealed that fatigue in optical fibers under cyclic loading was influenced by stress amplitude, deformation levels, and load duration. Quasi-distributed OFS systems can pinpoint damaged areas, and with optical reflectometry failure locations can be identified with up to one-meter precision, making OFSs an effective tool for long-term structural health monitoring.

Bremer and colleagues investigated the use of fiber-optic technology for SHM in civil engineering applications. Their research emphasized the creation of a fiber-optic sensor for crack detection, along with two types of moisture sensors tailored to identify water infiltration in concrete. Beyond the sensor development, the study also evaluated how well optical-glass fiber sensors could withstand the demanding mechanical and chemical conditions commonly present in concrete structures. The results highlighted the effectiveness of fiber-optic systems for continuous inspection, particularly in sewer tunnels, where timely identification of structural deterioration is essential [13].

Huang et al. proposed a distributed optical fiber acoustic sensing system using phase-sensitive time-domain reflectometry to enhance safety monitoring around building glass windows [91]. The system processed vibration signals through Wigner bispectrum analysis to capture their time–frequency energy distribution. To extract relevant features, an axially integrated bispectrum algorithm was applied, followed by sub-band division to minimize information loss and lower computational load. For event classification, the system used the Extreme Gradient Boosting (XGBoost) algorithm to recognize the unique signal patterns of various acoustic events. The following eight environmental scenarios were selected for testing: wind, knocking, window opening, water spraying, hammering, dog barking, aircraft noise, and ambient silence. Experimental results showed the system effectively distinguishes between these events, achieving an average recognition accuracy of 93.3%, demonstrating its reliability for real-time vibration monitoring in building environments [91].

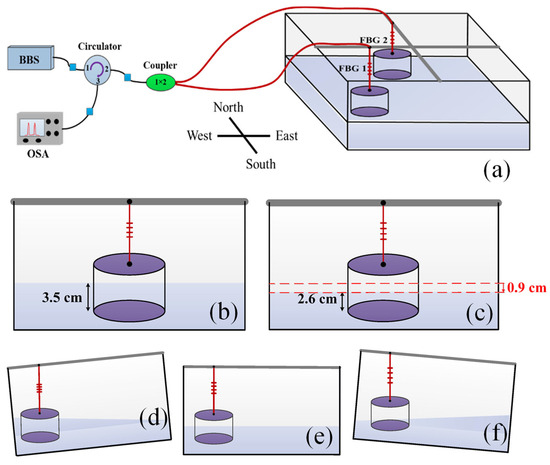

Chao et al. presented a novel dual-axis optical fiber tilt sensor designed using FBG technology for two-dimensional angle detection [92]. The sensor consisted of two cylindrical floats immersed in water, each connected to an FBG element (Figure 4a). As shown in Figure 4b, the FBG experiences no load when initially connected to the cylindrical float. Introducing pre-tension, the liquid level was lowered by 0.9 cm, reducing buoyancy by 52 g, which increased tension on the FBG (Figure 4c). This pre-stretching enables one-dimension tilt sensing with a single FBG, reducing complexity and cost. Unlike conventional setups that require four gratings, only two FBGs are needed for two-dimension tilt detection, while maintaining good sensitivity. When the sensor was tilted due to external forces, the liquid inside the container was redistributed to form a new equilibrium surface (Figure 4d–f). This change altered the depth at different points, affecting the buoyancy acting on the floats. The resulting variation in buoyant force causes strain on the FBGs, leading to a shift in the reflected wavelength which was measured using an optical spectrum analyzer (OSA). These wavelength changes directly correlated with tilt angles along two axes. Capable of detecting tilt within a ±5° range, the sensor offered a sensitivity of 0.1° given an OSA resolution of 0.01 nm. With its high linearity and precision, the sensor was particularly suitable for monitoring building tilts and other structural applications [92].

Figure 4.

(a) Diagram illustrating the design of the proposed FBG tilt sensor; schematic of the FBG pre-tension: (b) with no sustained weight (0 g), and (c) with a sustained weight of 52 g. Schematic of the tilt sensor: (d) tilted at a negative angle, (e) in a neutral position, and (f) tilted at a positive angle [92].

3.4. Dams and Pipelines

Dams and pipelines represent vital infrastructure whose failure can lead to catastrophic consequences. OFSs are employed in dams to monitor internal stresses, seepages, uplift pressures, and temperature variations [93,94]. These sensors are embedded in the concrete structure or placed along foundation galleries to provide real-time insights into the dam’s behavior under operational and environmental loads. In pipelines, OFSs are used for leak detection, corrosion monitoring, and strain measurement over long distances [95]. Technologies like distributed acoustic sensing (DAS) allow operators to pinpoint anomalies such as leaks, impacts, or unauthorized access, enabling fast response and reducing environmental risks [95,96]. The longevity and reliability of optical fibers make them a cost-effective choice for such critical infrastructure [97]. Its potential application in industrial environments was explored in a research project conducted at BAM, with the goal of enabling spatially continuous condition monitoring and the early detection of structural damage before the release of any material [95]. In initial experiments, a short section of pipe was used and optical fibers were applied directly to the surface. Artificial signals were introduced to determine optimal system parameters and to assess different methods of fiber attachment [95].

Water loss remains a significant global challenge, highlighting the need for more effective monitoring of water distribution systems. In 2020, Italy reported that over a third (36.2%) of its freshwater supply was lost before reaching end users, emphasizing the urgency for improved infrastructure management. Maintaining such systems requires consistent investment, both in terms of maintenance and innovation. Bertulessi et al. investigated the potential of DOFS, utilizing stimulated Brillouin scattering (SBS) as a solution for real-time monitoring of water pipelines [98]. High-density polyethylene (HDPE), the most used material for water pipes, was selected for this research. Optical fiber cables were externally mounted on the pipe surface to evaluate their ability to detect strain patterns associated with abnormal pressure variations, such as those caused by leaks. The study was divided into two main experimental phases. In the first, the sensor configuration was tested under static pressure to examine its sensitivity and to analyze the viscoelastic properties of HDPE. A Burger model, incorporating both Maxwell and Kelvin–Voigt elements, was calibrated and validated to describe the pipe’s mechanical response. The second phase involved simulating leakage events within a water-circulating system driven by a pump to assess the sensors’ capability to identify pressure irregularities under dynamic conditions. The results confirmed that DOFS can effectively detect structural changes in HDPE pipelines, supporting its suitability for pipeline monitoring [98].

A novel fiber-optic sensing approach was introduced for monitoring embankment dams, utilizing the principles of bending loss in optical fibers combined with optical time domain reflectometry (OTDR) [99]. The system was engineered to detect changes in water pressure within the dam structure, thereby providing an indirect method for assessing water infiltration levels. The sensor’s response was examined under varying conditions, including different numbers of fiber loops, pump wavelengths, and pulse durations. The architecture of the sensing network featured a modular design with at least six independent sensing units, allowing each unit to be tailored for specific monitoring requirements or environmental conditions. To enhance durability and ensure compatibility between the mechanical characteristics of the optical fiber and the surrounding water, each sensor unit was encased in a custom-designed silicone rubber housing. This protective layer also safeguards the sensors against potential environmental damage, supporting reliable long-term operation in field conditions [99].

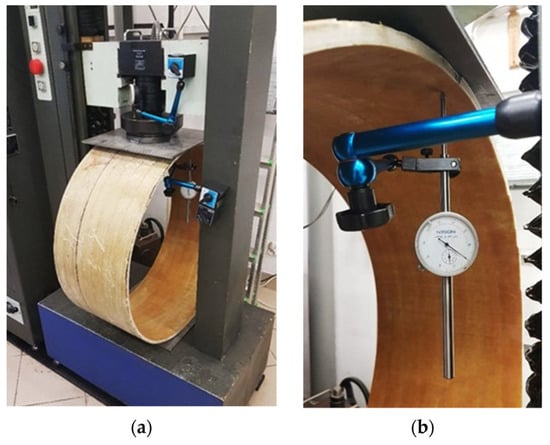

Construction projects often face difficulties in accurately replicating ground conditions during various phases, which makes dependable measurement methods crucial for validating theoretical models and enhancing design accuracy. Addressing this, Bernarz et al. proposed a novel monitoring strategy employing distributed optical fiber sensors (DOFS) to evaluate strain and displacement in glass fiber-reinforced polymer (GFRP) pipelines and collectors [100]. In the study, composite pipes were instrumented with optical fibers placed along both internal and external surfaces. These pipes were then exposed to external forces, and the resulting strain distributions were used to determine actual deformation patterns across the pipe’s cross-section. The shape reconstruction was performed using the trapezoidal numerical method. Mechanical testing was conducted using the Heckert FPZ-100, a precision testing machine capable of applying up to 100 kN of force with controlled, unidirectional piston motion (Figure 5a). During the tests, the machine automatically captured force and displacement data. Additionally, a spot displacement sensor was positioned beneath the upper internal surface of the pipe to provide reference measurements (Figure 5b). To verify the accuracy of the DOFS-based system, the results were cross-checked with data from the reference sensor and outcomes from finite element method (FEM) simulations. The approach proved effective in capturing both strain and deformation responses, offering a reliable tool for comprehensive structural assessment. These findings contribute to the ongoing development and maintenance strategies for aging collector systems [100].

Figure 5.

Test setup: (a) overview of the setup; and (b) detailed view of the reference displacement sensor [100].

3.5. Offshore Platforms and Wind Turbines

Offshore structures are exposed to extreme weather, corrosion, and dynamic oceanic forces [101]. OFSs are well-suited for this harsh environment, offering long-term durability and precise monitoring capabilities [29]. In offshore oil platforms, they monitor structural loading, fatigue, and tilt due to wave and wind forces. Wind turbines, particularly their blades and towers, benefit from FBG sensors that measure strain, deflection, and vibration [102,103]. This data is essential for optimizing performance, predicting maintenance needs, and extending equipment lifespan. By enabling condition-based maintenance and performance optimization, OFSs help reduce downtime and operational costs in renewable energy and oil extraction sectors [104,105].

Xu et al. introduced and validated a pioneering approach to SHM for offshore wind turbines using fiber-optic strain sensing [104]. A full-scale wind turbine underwent testing on the shaking table at the University of California, Berkeley, to simulate realistic offshore dynamic loading. The following two advanced DOFS techniques based on Rayleigh scattering were utilized to monitor strain: OFDR, capable of capturing precise strain data over shorter ranges (up to several tens of meters), and phase-sensitive optical time-domain reflectometry (ϕ-OTDR), often used in DAS and suited for long-distance measurements spanning kilometers. To define the expected strain patterns, simulations were conducted using OpenFAST software v4.0.5, modeling a floating offshore wind turbine system. Fiber-optic cables were strategically applied to the turbine tower in multiple configurations to capture both overall structural responses and localized strain behaviors. Initial tests involved bending the tower under quasi-static loads to validate sensor accuracy. The main experiment used a six-degree-of-freedom shake table to simulate offshore conditions with complex multi-directional motion. Loosened bolt scenarios at flange joints were also introduced to evaluate the system’s ability to detect structural issues. Both OFDR and ϕ-OTDR provided consistent results, successfully capturing global and local strain patterns, including the effects of bolt looseness. The study also highlighted key installation practices and noted that while ϕ-OTDR is effective for long-range monitoring, vibration noise must be controlled to detect small strains accurately [104].

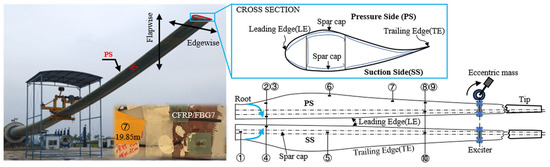

A compact strain sensing solution was developed for wind turbine blades, consisting of an FBG sensor housed within a carbon fiber-reinforced polymer (CFRP) enclosure [106]. This design aimed to enhance strain transmission from the blade to the sensor by leveraging the mechanical compatibility of the CFRP packaging. The system’s performance was validated through rigorous fatigue and aging tests to assess its durability and accuracy under long-term operational conditions. Subsequently, multiple units of these CFRP-encased FBG sensors were installed on a 56.85 m-long wind turbine blade to monitor strain during high-cycle fatigue loading in both flapwise and edgewise directions. Figure 6 illustrates the experimental setup designed for fatigue testing of a full-scale wind turbine blade, focusing on both flapwise (spanwise) and edgewise (chordwise) bending modes.

Figure 6.

Fatigue testing of a full-scale wind turbine blade under both flapwise and edgewise bending conditions. The diagram on the right illustrates the sensor layout, highlighting the placement of CFRP-encased FBG sensors along the blade [106].

While numerous CFRP-packaged FBG sensors were installed along the blade, only a subset is shown for performance evaluation. These sensors were strategically placed at critical locations commonly used for strain gauge installation, as these points are key to monitoring structural behavior during fatigue loading. To assess the accuracy of the fiber-optic sensors, each one was paired with a nearby conventional strain gauge, serving as a benchmark for comparing sensor output and validating the effectiveness of the CFRP/FBG sensing modules. Throughout millions of loading cycles, the sensors demonstrated consistent and precise strain detection. Compared to conventional electrical strain gauges, the proposed sensing units showed improved measurement stability and a longer operational lifespan, confirming their effectiveness for long-term structural monitoring applications [106].

4. Challenges and Limitations

OFSs have emerged as a promising technology for SHM due to their high sensitivity, immunity to EMI, and their ability to provide distributed and continuous sensing [107]. Despite these advantages, their practical implementation in real-world infrastructure continues to face several notable challenges and limitations [90].

One of the most significant issues is the complexity involved in installation. Optical fibers are fragile and require careful handling during deployment [97]. In new constructions, particularly those involving reinforced concrete, the sensors must be precisely embedded during the building process to ensure accurate data collection. When it comes to retrofitting existing structures, the installation becomes even more challenging. Mounting the sensors on materials such as steel or composite surfaces often requires extensive surface preparation and the use of specialized adhesives to achieve proper bonding. Additionally, for large or geometrically complex structures such as tunnels or bridges, determining the optimal routing of the fiber cables can be logistically demanding. Protective casings may be needed to guard the fibers against mechanical stress or environmental exposure, which adds another layer of complexity to the process [108].

Another barrier to widespread use is the cost associated with these systems. Although the price of optical components has decreased over the years, the overall cost of a fiber-optic sensing system remains relatively high [109]. This includes not only the sensors themselves but also the necessary interrogation units, specialized tools for installation, and the involvement of trained personnel. For large-scale projects, these expenses can accumulate quickly. Furthermore, the long-term maintenance, occasional recalibration, and potential need for system upgrades contribute to the total cost of ownership. These financial requirements can be a major limitation for infrastructure projects with restricted budgets or for assets that are considered lower priority [110].

Long-term durability and environmental exposure represent additional concerns. While optical fibers are generally reliable in controlled environments, they may degrade when exposed to real-world conditions such as ultraviolet radiation, extreme temperatures, moisture, and chemical agents. Civil structures located outdoors, such as bridges or wind turbines, are particularly susceptible to these environmental stressors [12,104]. Repeated mechanical loading can also cause fatigue in the sensors or compromise the bond between the fiber and the structure. Although protective coatings and encapsulation methods are commonly used, they do not always provide indefinite protection. Over time, these materials can deteriorate, potentially leading to data quality issues or complete sensor failure. Additionally, the interrogation devices used to collect data from the sensors may become outdated, posing further challenges to the long-term reliability of the system [111].

The interpretation and calibration of signals present further difficulties [112]. OFSs, particularly distributed systems such as those based on Brillouin or Rayleigh scattering, generate large volumes of data [113]. Extracting meaningful insights from this data requires sophisticated processing algorithms and technical expertise. Differentiating between structural strain and temperature-induced changes can be complex and often require additional sensing mechanisms. Moreover, calibration is highly dependent on the specific structure, material properties, and loading conditions [114]. There is currently no universal standard for calibration, which means that each installation must be individually adjusted. Without accurate calibration, there is a risk of misinterpreting sensor outputs, leading to either false alarms or missed indicators of structural damage.

5. Integration with AI

Environmental variations, particularly those related to temperature and humidity, have a considerable effect on the structural performance of civil infrastructure such as buildings and bridges. Both sudden and gradual climatic changes can accelerate material degradation and contribute to structural distress over time [2]. Considering these challenges, risk assessment and disaster management have become essential components of modern infrastructure safety strategies. Integrating sensor technologies into smart structures allows for real-time monitoring, enabling prompt and informed responses during adverse environmental events. To enhance the accuracy and reliability of such monitoring systems, AI and ML algorithms are increasingly being adopted [115]. These tools help to identify patterns between environmental factors and structural behavior, offering the potential to predict deterioration before it becomes critical. Linear regression, among other ML techniques, has shown promise in evaluating structural health trends based on sensor data. Shibu et al. focused on leveraging AI and ML approaches to assess and forecast structural health conditions to provide early warnings to relevant authorities in the event of impending failure [22]. As part of the analysis, datasets collected from embedded sensors were used to examine crack formation, which served as a key indicator of structural damage. Experimental observations revealed that the average width of the detected cracks was 2.38 cm, while the mean length measured approximately 63.36 cm. These insights contributed to the development of predictive models for proactive infrastructure management [22].

In a related investigation, Altabey and Noori analyzed how ML and deep learning (DL) techniques are being employed across various SHM processes [116]. Their review covered system modeling, feature selection, fault identification, and damage localization. A key contribution of their study was the emphasis on integrating AI with sensor networks to support continuous monitoring and real-time analysis. They highlighted AI’s capacity to process extensive datasets, enabling precise detection of structural anomalies and contributing to more accurate lifecycle assessments. Their work also explored the intersection of AI and smart infrastructure, providing insights into its role in the development of intelligent cities [116]. Azimi and colleagues focused specifically on DL-based methods for SHM, assessing both vibration analysis and image-based monitoring systems [117]. They identified several obstacles to wider adoption, such as the scarcity of high-quality field data, the variability of environmental conditions, and the challenges involved in creating multi-level damage interpretation frameworks. The study underscored the need for real-time, scalable data processing solutions and called for further refinement of DL algorithms to improve their ability to approximate human-level judgment in complex structural environments [117].

Zinno et al. directed their attention toward bridge structures, exploring how AI is reshaping traditional monitoring methodologies across various stages of the asset lifecycle [118]. Their work emphasizes the use of big data analytics and IoT systems to enhance data interpretation and forecasting accuracy. By applying AI models to tasks such as performance assessment and maintenance planning, the study illustrated the potential of these technologies to facilitate smarter, more responsive infrastructure management [118]. Similarly, Zhang et al. examined recent developments in DL applications tailored to bridge health monitoring [119]. Their review addressed the use of both sensor-based and vision-based approaches, highlighting successful case studies in real-world deployments. The authors also discussed the limitations of current tools, such as data quality and model generalizability, and outlined potential improvements in monitoring precision and operational scalability [119]. Another recent analysis surveyed the following three core applications of AI in bridge SHM: computer vision for automated flaw detection, sensor-driven analytics for structural assessment, and AI-assisted forecasting for deterioration and risk analysis [120]. While the integration of vision systems and sensor networks has progressed significantly, the study notes that predictive modeling for long-term performance remains an area in need of deeper exploration. The authors advocate for continued research to refine AI applications in infrastructure risk evaluation and long-term management [120].

Yan et al. introduced a novel method for developing distributed structural health and control systems powered by AI [121]. The method involved breaking down the structure into regional and local zones, then analyzing each one separately to extract and describe key features. By looking at how the structure responded to stress and how those responses were distributed across different areas, the researchers were able to propose a new way to detect abnormal conditions and calculate associated risk levels. The testing phase showed that the system could accurately detect both widespread and localized damage across the structure. Building on this, the study also developed a safety evaluation method for very large structures spanning several kilometers using data from distributed fiber-optic sensors that measure strain along the entire length of the structure. Several load tests were performed on a real long-span structure to validate the approach. At the same time, a detailed finite element model was created using ABAQUS software v6.6 to simulate how the structure would behave under different loading conditions. A series of parametric studies helped explore how those load scenarios influenced the structural response. Finally, the study compared the results from the physical load tests, the safety assessment method, and the simulation to understand how closely they aligned. The findings showed that AI can make these systems more efficient by allowing faster deployment, more reliable analysis, and the ability to adapt to changing conditions, making it a powerful tool for the future of structural health monitoring and control [121].

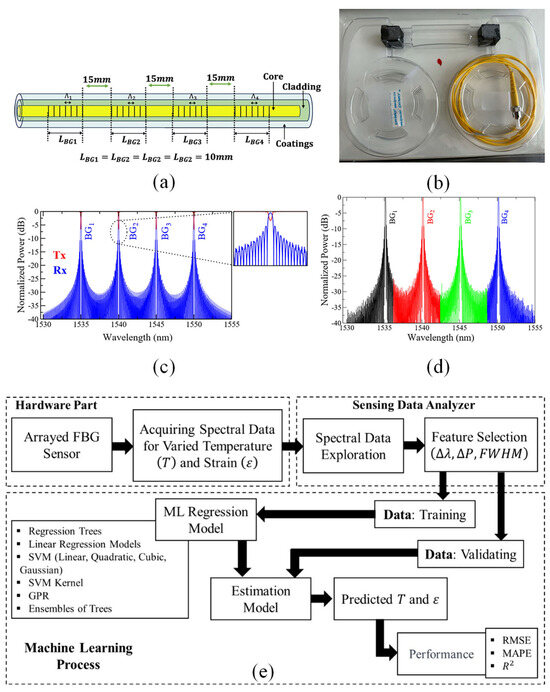

One of the main challenges with using OFSs for SHM is the influence of environmental temperature changes. Temperature variations can affect the sensor readings, making it difficult to determine whether the changes are caused by actual structural strain or simply by shifts in temperature. To overcome this issue, researchers developed an advanced sensing system that combined FBG technology with ML [122]. This approach made it possible to measure both strain and temperature at the same time using a single sensor. The project began with the design and laboratory testing of a new sensor that included four separate fiber Bragg gratings, each set to a different wavelength. This setup allowed for the collection of richer and more diverse data. Once the sensor had been developed, ML algorithms were introduced to help distinguish between the effects of temperature and mechanical strain. To train and test the system, researchers subjected the sensor to mechanical loading while also exposing it to different temperature conditions. This helped the model learn how to identify and separate the influence of each factor [122].

An SMF-28 fiber was used to inscribe four FBGs, each 10 mm long and spaced 15 mm apart, resulting in a total sensor length of 85 mm. The layout of the FBG array is illustrated in Figure 7a, while the fabricated sensor is shown in Figure 7b. For validation, the sensor was tested under varying mechanical loads and temperatures. It was connected to an ST/PC connector using a fusion splicer. Figure 7c displays the theoretical reflection spectrum under no-load conditions, and Figure 7d presents the corresponding experimental spectrum measured at room temperature [122].

Figure 7.

(a) Schematic layout of the designed multi-array sensor and (b) the actual fabricated version. The sensor’s response was examined under no mechanical load and at a room temperature of 25.2 degrees Celsius, (c) theoretical transmission and reflection spectra are in red and blue, respectively, (d) reflection spectra obtained from experimental measurements, and (e) strain and temperature prediction achieved through a combination of data collection techniques and ML models [122].

In the final stage, the sensing system was tested on a real bridge made from post-tensioned concrete. Data were collected from sensors embedded within the structure, and the ML models were applied to analyze the results (Figure 7e). Even though the FBG sensors produced a limited amount of spectral information, the models were still able to address the challenge of temperature interference effectively. This approach represented an important step forward in the use of smart technologies for infrastructure monitoring. By making it easier to track the condition of structures accurately over time, fiber-optic sensors supported by intelligent algorithms can help extend the lifespan of critical infrastructure. This not only improves safety and reliability but also supports efforts to reduce the environmental impact of construction by cutting down on unnecessary repairs and replacements, moving the industry closer to achieving sustainability and climate goals such as net-zero emissions [122].

The fusion of OFS data with AI algorithms marks a significant advancement in SHM. However, the true impact of this integration extends beyond individual structures. As urban environments become increasingly interconnected and reliant on real-time data, these intelligent SHM systems play a pivotal role in shaping the infrastructure backbone of smart cities. The ability to continuously monitor, analyze, and predict infrastructure performance not only enhances safety but also enables data-driven governance and sustainable urban planning. Building on this, the next section explores how optical fiber-based SHM contributes directly to the development and operation of smart cities, serving as a foundational component of intelligent infrastructure systems.

6. Role of SHM in Civil and Urban Infrastructures

Civil and urban infrastructures rely on real-time data, intelligent analytics, and resilient infrastructure to ensure safety, efficiency, and sustainability. At the heart of this transformation is SHM, which enables civil infrastructure to self-report conditions, detect anomalies, and support proactive maintenance [123]. OFSs have emerged as a key technology within this framework, providing the high-resolution, long-range, and distributed sensing capabilities essential for the data-driven management of urban assets [69]. The integration of OFS-based SHM systems with Internet of Things (IoT) networks and AI platforms is a major enabler of intelligent infrastructure. Data collected from OFSs, whether measuring strain, vibration, temperature, or displacement, can be transmitted to centralized or edge computing systems, where AI algorithms analyze it in real time. This combination enables cities to transition from reactive to predictive maintenance strategies. Table 3 presents the integration of OFS and DL methods applied to SHM in civil infrastructure.

Table 3.

Integrated applications of OFSs and DL in SHM.

As mentioned earlier, in tunnel systems like the Barcelona Metro L9 [69] and in long-span bridges in Taiwan [77] DOFS has been deployed to continuously monitor structural deformation and detect early signs of stress. These implementations demonstrate how OFS technology forms the sensory backbone of infrastructure that not only monitors itself but also integrates into broader urban decision-making systems. Tam et al. presented a railway health monitoring system that utilized an OFS network to support predictive maintenance strategies [132]. ML techniques were employed to build models capable of detecting and classifying various track anomalies, including rail corrugation, uneven weld joints, and track crossings.

OFS-based SHM systems also contribute to environmental and operational sustainability in civil and urban infrastructures. By enabling early detection of defects, these systems help extend the lifespan of infrastructure, reduce downtime, and lower the environmental impact associated with repairs or failures. When deployed across water pipelines, bridges, and high-rise buildings, OFSs provide essential data for digital twins and smart asset management platforms. This is particularly significant in civil and urban infrastructures aiming to achieve carbon neutrality and optimize urban resource use. While Section 5 discusses the role of AI in enhancing SHM performance, the full potential of these advancements is realized within the smart city context, where integrated sensor networks inform traffic control, public safety, disaster resilience, and infrastructure sustainability. The synergy between OFSs, AI, and the IoT creates an infrastructure that is not only intelligent but also adaptive and resilient. Therefore, optical fiber sensor technologies are not peripheral to smart city SHM strategies, they are foundational to their success.

Morshed et al. explored the viability of a multimode OFS, specifically a single-mode–multi-mode–single-mode (SMS) fiber configuration, for measuring strain and vibrations within structural components [123]. To evaluate its performance, the SMS sensor was tested on a pressurized pipe, and its strain measurement capability was compared against that of a conventional FBG sensor. Experimental results revealed a strong linear relationship (R2 ≈ 0.95) between the sensor’s spectral response and the applied pressure, indicating dependable strain sensitivity. Additionally, the SMS sensor exhibited higher sensitivity than the FBG sensor, suggesting its potential as a robust alternative for SHM applications.

An automated vehicle classification method was developed using an experimental setup based on FBG sensor arrays. As the volume of data generated by sensor networks continues to grow, the need for advanced analytical approaches has become increasingly important. To address this, techniques involving AI have been explored. An experimental platform was constructed, where two distinct sets of FBG sensor arrays, one horizontally and one vertically embedded, were integrated into the upper pavement layers. These arrays were connected to interrogators, allowing the measurement of surface deformations caused by passing vehicles. A neural network-based visual classification system, supported by closed-circuit television (CCTV), was employed to categorize the vehicles. This classification output was used to validate the data collected from the sensor arrays. A new neural network model was trained using sensor data to perform vehicle classification. From the experimental results, it was observed that trucks could be accurately distinguished from other vehicles with a success rate of 94.9%. Additionally, classification into three general vehicle categories was achieved with an accuracy of 70.8%. Based on the findings, it was recommended that the sensor array system be extended to improve classification accuracy further [133].

Wang et al. developed a distributed optical fiber sensing system for temperature monitoring in large-scale infrastructure [134]. To meet the requirements for accuracy, spatial resolution, and near real-time performance, a quaternion wavelet transform image denoising algorithm was introduced for processing edge-node data. The system used Brillouin optical time domain analysis with a sensing fiber up to forty kilometers in length. The Brillouin gain spectrum image was decomposed into one magnitude and three phase components. While noise appeared randomly in the phase images, it had a greater effect on the magnitude image where meaningful signal data were concentrated in high-amplitude coefficients. A Bayesian shrinkage method was applied to reduce noise in the magnitude image. The denoising process significantly improved signal-to-noise ratio and frequency precision, enabling Brillouin frequency shift detection with an accuracy of 0.2 megahertz, equivalent to a temperature error of ±0.1 degrees Celsius. The system processed high-resolution images in under four seconds and reduced data volume from 40 megabytes to approximately 0.08 megabytes per measurement. These results demonstrate strong potential for real-time structural health monitoring in IoT-based infrastructure systems [134].

Tragic incidents have occasionally resulted from crowd behavior in densely populated pedestrian environments, particularly when sudden disturbances escalate the situation and lead to trampling or crashing. To address these risks, it is crucial to continuously monitor crowd movement for early warning and preventive intervention. Mustapha et al. introduced a recently developed system designed for the combined monitoring of crowd dynamics and structural responses through an innovative integration of sensing technologies [127]. The system employed fixed structural sensors using FBG OFSs along with wearable devices that include inertial measurement units (IMUs). The proposed methodology focuses on accurately estimating crowd flow and the load exerted on pedestrian bridges by applying advanced machine learning techniques to sensor data collected from both structural and wearable sources. A key contribution of this work was the incorporation of sensor fusion at both the input data and feature extraction levels within the ML framework. The models used in this study included convolutional neural networks (CNNs) and support vector machines (SVMs), which were initially trained on each sensor type independently and later extended to process combined data through multi-modal fusion [127].

Integrating data from multiple sensors enhanced the learning models by improving accuracy and robustness, particularly in scenarios affected by signal noise or temporal inconsistencies. The system was evaluated using experimental data obtained from a controlled crowd simulation conducted on a scaled pedestrian bridge. The results demonstrated high effectiveness, with classification accuracy reaching 98% for single-speed motion detection, 91% for multi-class motion speed and load categorization, and a minimum error rate of 9% for load estimation through regression. These findings confirmed the potential of the proposed monitoring approach for real-world applications in crowd safety and SHM [127].

7. Future Trends and Research Opportunities

Future trends and research opportunities in OFSs for SHM are increasingly centered around enhancing performance, adaptability, and sustainability [135,136,137]. One of the most promising directions is the development of hybrid sensing systems that combine OFSs with wireless communication technologies [138]. To enhance the capabilities of DAS, integration with other sensing modalities offers substantial potential. For visual classification tasks such as vehicle type recognition or anomaly detection (e.g., debris or stationary vehicles), camera systems including both thermal and visible-light imaging are particularly valuable [139]. For applications requiring precise measurements of speed, vehicle length, or axle count, inductive loop detectors and Doppler radar provide high temporal resolution and accurate point-based data [140]. DAS, with its ability to passively monitor distributed vibrations over long distances, can be effectively complemented by LiDAR or infrared sensors in scenarios demanding detailed spatial mapping or object contour tracking [141]. The combination of these modalities allows for complementary strengths as DAS offers continuous, long-range coverage and early event detection, while point sensors and vision-based systems enable discretion, verifiable event confirmation, and classification. Together, they support more robust, multi-layered systems for traffic sensing, structural monitoring, and intelligent transportation networks [142,143].This integration leverages the high sensitivity and immunity to EMI of fiber sensors with the flexibility and scalability of wireless networks [144]. It enables real-time data transmission from inaccessible or large-scale infrastructures without the need for extensive physical cabling [145]. As these hybrid systems evolve, research is focusing on synchronizing data streams, ensuring energy efficiency, and maintaining data integrity across the network [146]. A parallel and equally transformative area of exploration is the design of self-powered or energy-harvesting fiber-optic sensors [147,148]. These systems address the logistical challenges of powering sensors in remote or hard-to-reach locations. By harvesting ambient energy such as vibrations, heat, or solar radiation, fiber-optic sensors can operate autonomously over extended periods. Incorporating piezoelectric, thermoelectric, or photovoltaic elements into the sensor systems is a major focus of ongoing research, along with reducing the power demands of sensor interrogation units. These advancements are crucial for sustainable, maintenance-free deployment across a variety of infrastructure types [149].

In addition to physical innovations, the integration of edge AI and fog computing is transforming the way sensor data is processed and utilized [150]. Fiber-optic sensors generate large volumes of data, and traditional centralized processing can be slow or inefficient. Edge computing allows data to be analyzed near its source, significantly reducing latency and improving responsiveness. By embedding machine learning models directly into edge devices, these systems can detect anomalies, trigger alerts, and even initiate predictive maintenance routines without needing constant connectivity to a central server. This approach supports more intelligent, autonomous monitoring systems capable of adapting in real time to evolving structural conditions [151,152].

Future research in SHM must move beyond the use of isolated sensing parameters. In many real-world scenarios, it is difficult to accurately determine the type, location, or severity of structural damage based on a single variable such as strain or temperature [153,154]. Multi-parameter monitoring, which combines data from various physical indicators including strain, vibration, acoustic signals, and thermal responses offers a more robust and reliable basis for damage identification [155]. The intelligent fusion of these parameters using ML or data-driven inference models can improve the classification of unknown or evolving damage patterns [156]. This approach is essential for developing adaptive and resilient monitoring systems capable of detecting subtle or complex structural changes in real time.

As these technologies advance, the need for standardization and regulatory frameworks becomes increasingly critical [157]. Standardized protocols for installation, calibration, data interpretation, and system interoperability will be essential to ensure consistent performance across different applications and vendors. Regulatory bodies are beginning to address certification processes for optical fiber SHM technologies, especially for use in safety-critical environments such as transportation networks, energy infrastructure, and public buildings. Establishing clear standards will not only accelerate adoption but also boost confidence among engineers, policymakers, and investors [110].

Finally, OFSs are expected to play a key role in supporting climate-resilient infrastructure [158]. With the growing frequency of extreme weather events and environmental stressors, continuous and accurate monitoring of structural integrity is essential for early detection of damage and deterioration [159]. Fiber-optic systems, capable of detecting subtle shifts in temperature, strain, and vibration, are ideally suited to track the impacts of climate change on infrastructure over time. Future research will likely focus on integrating these sensors with climate forecasting models and deploying them in environmentally vulnerable areas to enhance adaptive capacity, inform maintenance planning, and support resilient infrastructure design [160].

8. Concluding Remarks

In this review, we highlighted the transformative potential of OFSs in SHM, particularly when integrated with cutting-edge AI and civil and urban infrastructure. As civil structures continue to age and face environmental, operational, and climate-induced stressors, the need for reliable, real-time, and scalable monitoring systems becomes increasingly vital. OFSs, due to their high sensitivity, immunity to EMI, and suitability for distributed and long-range applications, have proven themselves as indispensable tools for assessing structural integrity across a wide range of applications, including bridges, tunnels, skyscrapers, pipelines, dams, and offshore platforms.

We also discussed different sensing technologies, such as fiber Bragg gratings (FBGs), distributed acoustic sensing (DAS), and Brillouin optical time-domain analysis (BOTDA), which have evolved to offer precise and continuous data collection. These systems not only enhance safety but also support predictive maintenance, ultimately reducing long-term costs and downtime. Moreover, the integration of AI and ML with optical fiber sensing significantly improves the interpretation of complex datasets. This combination allows for automated damage detection, anomaly recognition, and forecasting capabilities, aligning with the goals of proactive infrastructure management.

Despite their advantages, the implementation of optical fiber-based SHM systems is not without challenges. High initial costs, installation complexity, calibration difficulties, and the impact of environmental conditions on long-term performance remain notable barriers. However, ongoing research into hybrid sensing networks, energy-harvesting solutions, and edge computing is paving the way for more autonomous, efficient, and sustainable monitoring ecosystems. In the broader context of smart cities, optical fiber SHM systems serve as foundational components for data-driven urban planning and resilience. They enable infrastructure to become “aware”, continuously reporting its health status and anticipating failures before they occur. When embedded within IoT frameworks and enhanced with big data analytics, these systems offer a compelling solution to the growing need for safer, smarter, and more sustainable urban environments.

Looking ahead, the standardization of installation protocols and data interpretation methods will be essential for wider adoption and cross-system compatibility. Furthermore, it calls for deeper interdisciplinary collaboration among engineers, data scientists, policymakers, and urban planners to fully leverage the potential of SHM in shaping the cities of tomorrow. With continued innovation, fiber-optic SHM technologies are poised to redefine how we build, monitor, and maintain the built environment in an increasingly connected world.

Author Contributions

Conceptualization, S.N.K. and N.V.G.; methodology, N.V.G. and S.N.K.; software, S.N.K.; validation, S.N.K., N.L.K. and N.V.G.; formal analysis, N.V.G. and S.N.K.; investigation, N.V.G. and S.N.K.; resources, S.N.K. and N.L.K.; data curation, S.N.K. and N.L.K.; writing—original draft preparation, S.N.K., N.V.G. and N.L.K.; writing—review and editing, S.N.K. and N.V.G.; visualization, N.V.G.; supervision, S.N.K. and N.L.K.; project administration, S.N.K. and N.V.G.; funding acquisition, N.V.G. All authors have read and agreed to the published version of the manuscript.

Funding

This work was performed within the State assignment for scientific research to Samara University (project FSSS-2024-0016) in part of perspectives of IoT and smart cities and within the scientific program of the National Center for Physics and Mathematics, section #1 “National Center for Supercomputer Architecture Research. Stage 2023–2025” in part of the integration of optical fiber sensors with Artificial Intelligence.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created.

Acknowledgments

The authors acknowledge equal contribution of all the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

Structural health monitoring = SHM; optical fiber sensors = OFS; artificial intelligence = AI; machine learning = ML; deep learning = DL; electromagnetic interference = EMI; distributed acoustic sensing = DAS; fiber Bragg grating = FBG; Brillouin optical time-domain analysis = BOTDA.

References

- Wang, G.; Ke, J. Literature Review on the Structural Health Monitoring (SHM) of Sustainable Civil Infrastructure: An Analysis of Influencing Factors in the Implementation. Buildings 2024, 14, 402. [Google Scholar] [CrossRef]

- Ye, X.W.; Su, Y.H.; Han, J.P. Structural Health Monitoring of Civil Infrastructure Using Optical Fiber Sensing Technology: A Comprehensive Review. Sci. World J. 2014, 2014, 652329. [Google Scholar] [CrossRef]