Abstract

Calcium fluoride (CaF2) crystals are widely utilized in deep-ultraviolet (DUV) lithography due to their excellent optical properties. The laser-induced degradation and damage of CaF2 crystals is a critical concern that restricts its extended application. Impurities of CaF2 crystal are considered a key factor affecting its laser resistance. Establishing the quantitative relationship and mechanism of impurity content impacting the degradation and damage characteristics of CaF2 crystal is essential. This study investigated the characteristics of different impurity contents affecting the degradation and laser-induced damage thresholds (LIDTs) of CaF2 crystals under X-ray and 193 nm pulsed laser irradiations, and quantitatively analyzed the degradation process and mechanism. Our findings demonstrate that impurities at ppm levels significantly diminish the transmittance of CaF2 crystals across various wavelengths following X-ray irradiation. In contrast, these impurities have a negligible effect on the LIDT test results, suggesting distinct damage mechanisms between X-ray and laser irradiation. This study provides valuable insights for optimizing the CaF2 crystal fabrication process and enhancing irradiation resistance.

1. Introduction

Based on the advantages of calcium fluoride (CaF2) crystal with high transmittance in deep-ultraviolet (DUV) and high laser-induced damage thresholds, it has numerous applications in light sources, illumination, and objective lenses of DUV lithography systems [1,2,3,4,5]. With the development of DUV lithography, the repetition frequency and irradiation power have been continuously improved [6,7,8,9]. However, under extreme operating conditions of high fluence and long-term irradiation, the laser-induced degradation and damage of CaF2 crystals have become bottleneck issues restricting the stability and reliability of entire DUV lithography systems.

The fluorite structure of CaF2 crystals makes it easy to introduce impurity ions, and these impurities play a crucial role in affecting its optical properties [10,11,12,13,14,15,16,17,18,19,20,21]. Nicoara et al. found that Pb2+ impurities induce two broad absorption peaks at 410 nm and 730 nm in CaF2 crystals, causing a significant decrease in transmittance through γ-ray irradiation experiments [16]. Mühlig et al. quantitatively investigated that Na impurities significantly increase the absorption coefficients of CaF2 crystals by stabilizing the and centers through simulations and experiments [21]. In addition, laser-induced damage threshold (LIDT) and high-energy ray tests, such as X-ray, are widely used to evaluate the irradiation resistance of optical components [22,23,24,25]. Shao et al. determined the LIDT of CaF2 crystals by 193 nm ArF excimer laser irradiation with a 1-on-1 test method and analyzed how the periodic structure on the damaged surface might be related to the interference of the plasma wave on the material surface [23]. Wang et al. demonstrated that X-ray irradiation has the same principle as 193 nm laser-induced color centers, and the irradiation resistance property of CaF2 crystals at 193 nm could be equivalently evaluated [24,25]. Previous research has mainly focused on the impurities of CaF2 crystals affecting their overall irradiation resistance. However, the quantitative relationship between the impurities of CaF2 crystals and the degradation and damage properties of X-ray and 193 nm irradiations, as well as the corresponding mechanism, has not been reported.

This paper investigated the influence of impurity content in CaF2 crystal on its laser-induced damage threshold (LIDT) at 193 nm and X-ray induced degradation characteristics. The degradations of CaF2 crystal were quantitatively evaluated by recording the decrease in transmittance of the color center’s absorption after X-ray irradiation, and the corresponding degradation process and mechanism were analyzed. Meanwhile, the relationship between the impurity content of CaF2 crystal and the LIDT under 193 nm pulsed laser irradiation was also investigated. It was concluded that under the condition of extremely low impurity contents in CaF2 crystal (<25 ppm), the impurity contents would not directly affect their LIDTs, but these impurities could also influence the degradation properties of CaF2 crystal after X-ray irradiation. This study provides reliable information for improving the quality of CaF2 crystals.

2. Test Sample Preparation and Experimental Methodology

2.1. CaF2 Crystals Preparations

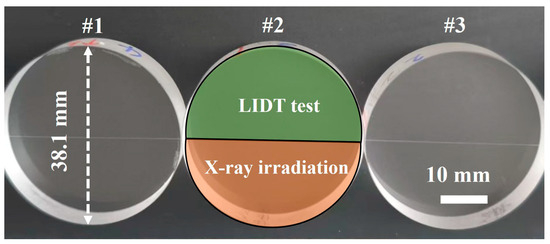

In this paper, three single CaF2 (111) crystals ( mm) prepared by Bridgman’s method with different growth conditions were selected as test samples, as shown in Figure 1. All samples in this study were prepared using the Bridgman method [26,27]. First, high-purity CaF2 raw material was accurately weighed, and several grams of lead fluoride (PbF2) was added as a deoxidizer to effectively eliminate moisture and oxide impurities (e.g., calcium oxide, CaO) adsorbed at high temperatures. Next, the weighed raw materials were thoroughly ground and mixed in a mixer to ensure a uniform distribution of components. The resulting homogeneous powder was then carefully loaded into a specially designed graphite crucible. The crystal growth process was conducted in a precisely controlled chamber, where the vacuum level and the meticulously regulated heating and cooling rates served as key process parameters determining the final crystal purity and crystallization quality (e.g., defect density and uniformity). Samples 1–3 are single CaF2 (111) crystals produced from distinct batches under varying growth conditions while being subjected to uniform processing conditions. Consequently, the surface roughness of the crystals is generally consistent, although variations in impurity content are observed, and we will describe the details below. A femtosecond pulsed laser (duration: 340 fs, fluence: 0.53 J/cm2) was utilized to mark the surface of each CaF2 crystal, and the test sample was divided into two regions for LIDT testing and X-ray irradiation experiments, respectively.

Figure 1.

Three test samples.

During the crystal growth process, CaF2 crystals would introduce various metal impurities such as Na, Fe, Mg, Sr, etc. These impurities are mainly caused by the purity of raw materials, the growth method, the growth conditions, and the crucible materials [28]. The impurity contents of each test sample would be quantitatively analyzed subsequently.

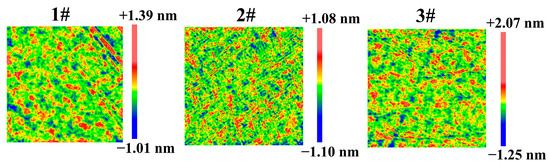

2.1.1. The Surface Roughness

For the deep-ultraviolet (DUV) laser-induced damage threshold test, the surface roughness of the test material significantly influences the experimental outcomes. To objectively evaluate the influence mechanism of impurities on laser resistance properties, each CaF2 crystal underwent the same precision mechanical polishing process. The surface roughness of three test samples was characterized using a surface profiler with an accuracy of 0.2 nm (New View 8050), as shown in Figure 2. The surface roughness of each test sample was observed to be essentially identical, with RMS values all controlled under 0.3 nm (as shown in Table 1).

Figure 2.

Surface roughness maps of each CaF2 test sample.

Table 1.

Surface roughness test results.

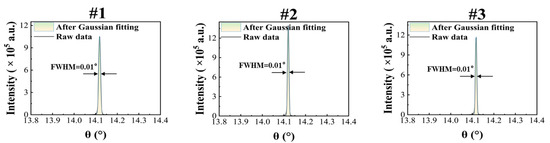

2.1.2. Crystallinity of Crystals

The double-crystal rocking test of the CaF2 crystal was performed using a high-resolution X-ray diffractometer (Bruker D8-Discover), as shown in Figure 3. Each tested sample exhibited diffraction peaks at the 14.12° position, corresponding to the θ angle of the Bragg diffraction equation for the crystal plane (111) of CaF2. The half-peak widths, obtained via Gaussian fitting, were all 0.01°. Additionally, the diffraction peaks did not show obvious splitting or broadening, indicating excellent crystalline properties for the three test samples.

Figure 3.

The double-crystal rocking curve of each CaF2 crystal test sample.

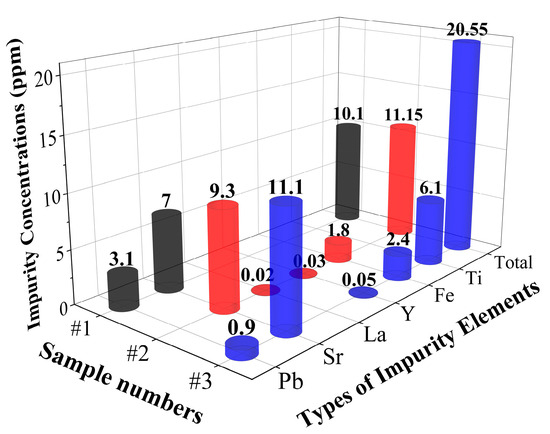

2.1.3. Metal Impurity Content

To investigate the effect of trace metal impurities on the irradiation resistance of CaF2 crystal, the trace impurities in the crystals were quantitatively analyzed using inductively coupled plasma–mass spectrometry (ICAP RQ) with a minimum resolution up to 0.08 ppt, and the test results of each test sample are shown in Figure 4. A full-element impurity content test was conducted for each sample, and the test results below the detection limit are not marked in Figure 4. The detection limit of inductively coupled plasma–mass spectrometry (ICP-MS) can typically reach extremely low levels, although the specific threshold varies depending on the element and instrument conditions. For instance, the detection limit for rare earth elements is 0.01 ppm, while that for metal impurities is 0.2 ppm, thereby ensuring an accurate characterization of the impurity content in each test sample. For the experimental test results, sample #1 exhibited a relatively high concentration of palladium impurities, primarily due to the excessive use of deoxidizer (PdF2) during the crystal preparation process. Conversely, sample #3 showed elevated levels of other impurity elements, which can be ascribed to the suboptimal purity of the raw materials.

Figure 4.

Metal impurity concentrations of three CaF2 crystal test samples.

It could be observed that sample #1 has the lowest total impurity content, which contains 10.1 ppm of Sr impurities and Pb impurities. These impurities would reduce the optical absorption and luminescence efficiency of CaF2 crystals and cause the absorption and emission peaks to be red-shifted [29]. Test samples #2 and #3 both contained different quantities of impurities such as Ti, Fe, Y, and La, but the impurity content of sample #3 was greater than that of sample #2. The presence of Pb impurities may have been caused by residual PdF2 deoxidizer, while Ti, Y, and La impurities may have originated from residual CaF2 feedstock. Fe impurities could have been released from iron- or ferro-alloyed materials in the growth equipment under high-temperature conditions. It is worth noting that the rare earth elements Y and La, which have a greater impact on the transmittance of CaF2 crystal, were controlled to below 1 ppm by improving the growth process.

2.2. X-Ray Irradiation and LIDT Test at 193 nm

Since the LIDT test and the X-ray irradiation tests were performed on the same test sample, to avoid material property variation in the test samples during X-ray irradiation and affecting LIDT test results, this paper first carried out LIDT tests on each test sample by 193 nm pulsed laser irradiation, followed by X-ray irradiation tests.

For the X-ray irradiation experiment, an XRad160 device was utilized at an operating voltage of 160 kV and a current of 18.7 mA. The samples were exposed to a dose rate of 23 Gy/min, accumulating a total dose of 2000 Gy over 87 min. To ensure uniform dose delivery, the crystal samples were precisely centered on the rotating sample stage, with each positioned 10 cm vertically from the irradiation center. Following irradiation, all samples were stored under identical conditions.

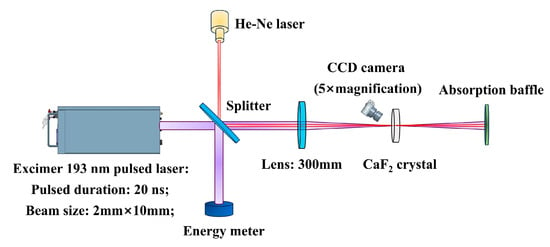

The LIDTs tests at 193 nm were strictly controlled in the LIDT test area for each test sample (as shown in Figure 1), and the corresponding LIDTs of each CaF2 crystal were obtained using the 1-on-1 test method with the same pulse number [30]. The incident laser duration was 20 ns, a lens with a focal length of 300 mm was used for focusing, and the focal spot area was 0.45 mm2. A beam-splitting energy meter was utilized to measure the incident energy during the LIDT tests, and the laser-induced damage characteristics were recorded using a CCD camera (1920 1078 pixels, 5 magnification), as shown in Figure 5. According to the 1-on-1 test method described in [30], CaF2 crystals that exhibit irreversible structural variations upon laser irradiation are considered damaged. A CCD camera with 5× magnification was used to observe whether damage occurred after laser exposure. To determine the LIDTs, different incident fluence levels were applied to separate positions on the CaF2 crystals using a single pulsed laser. By determining the damage probability (damage probability: laser-induced damage number/total irradiation amount) at each fluence level, and applying linear fitting, the laser fluence corresponding to a zero-damage probability was defined as the LIDT for each CaF2 crystal. Additionally, the LIDT was defined as the fluence at which maximum damage was observed in the CaF2 crystals.

Figure 5.

Schematic diagram of the LIDT test system.

3. Test Results and Discussion

3.1. Damage Characteristics of CaF2 Crystal

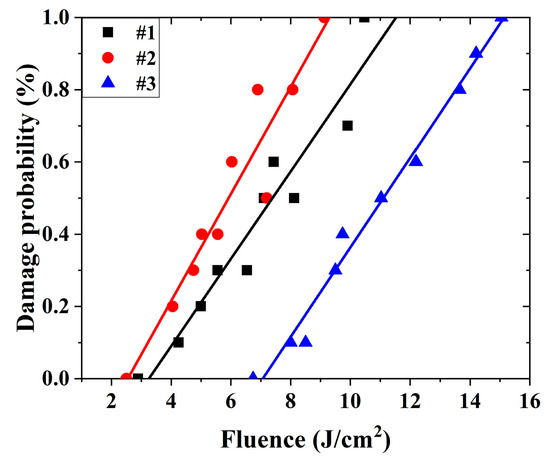

The influence of impurities on the LIDTs at 193 nm of CaF2 crystals was characterized, and the LIDT test results of each sample are shown in Figure 6. The LIDTs of samples #1, #2, and #3 were 3.25 J/cm2, 2.54 J/cm2, and 7.07 J/cm2, respectively, indicating significantly different LIDTs for CaF2 crystals prepared under different growth conditions but with the same processing method. Meanwhile, the relationship between the impurity content of each sample and its corresponding LIDT was established (Table 2). The impurity of sample #3 was higher than samples #1 and #2, yet its LIDT was much higher. This indicated that the impurities in CaF2 crystals are introduced during synthesis and constitute intrinsic defects in the material. Notably, during LIDT testing, the laser does not generate additional impurities. And under trace impurity conditions, the impurity content of CaF2 crystals is no longer the primary factor affecting the LIDT. That is, the intrinsic defects within the CaF2 crystal are not directly correlated with its LIDT. Instead, non-intrinsic defects introduced during surface processing—including both surface and subsurface imperfections—might serve as the primary determinants of the 193 nm LIDT of calcium fluoride crystals. This phenomenon was similarly observed in tests of the fused silica bulk damage threshold, where trace metal impurities exhibited only a weak correlation with the bulk damage threshold [31].

Figure 6.

The LIDT test results for each test sample.

Table 2.

The relationship between LIDTs and impurity concentrations.

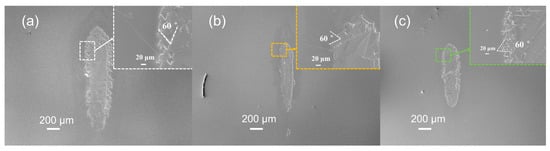

Although the impurity content and LIDTs of three CaF2 crystals were different, the damage morphology of each test sample remained identical, as shown in Figure 7. The damage morphologies of CaF2 crystals observed using Scanning Electron Microscopy (SEM) showed that the initial damage morphology was lamellar stripped cleavage damage, and the flake peeling damage area exhibited an equilateral triangle shape. This was caused by the cleavage plane (111) of CaF2 crystal being easily stripped under laser irradiation. The sliding direction was arranged at a 120° angle on the (111) cleavage plane of the CaF2 crystal. Therefore, equilateral triangular flakes peeled off along the disintegrated surface under the thermal stresses generated by laser irradiation [32]. The depth of the initial damage was approximately 1 μm.

Figure 7.

(a–c) Initial damage morphology of #1~#3 test samples under 193 nm pulsed laser irradiation with a fluence of 9.83 J/cm2.

3.2. Characteristics and Mechanisms of Crystal Optical Property Degradation

As mentioned above, ppm-level impurity in CaF2 crystal would not affect its LIDT test result. In this chapter, we will investigate the characteristics and mechanism of how trace impurities influence the crystals’ optical degradation properties. During X-ray-induced modifications of calcium fluoride crystals, significant changes occur in the crystal’s optical properties, including its transmittance. This study utilizes the analysis of transmittance across various wavelengths (200–1000 nm)—a well-established method documented in the literature—to examine these X-ray-induced modifications. By focusing on the variations in transmittance at different wavelengths, the research aims to elucidate the mechanisms through which impurity content influences degradation effects.

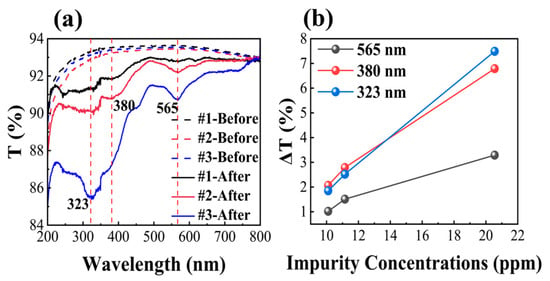

In this study, a UV-VIS-IR spectrophotometer (Cary 5000, Agilent Technologies, Santa Clara, CA, USA) was utilized to characterize the transmission spectra of each test sample before and after 2000 Gy X-ray irradiation. The results, as shown in Figure 8a, reveal that the transmittance of CaF2 crystal across different wavelengths significantly decreased after X-ray irradiation, and three prominent absorption peaks appeared at 323 nm, 380 nm, and 565 nm, respectively. These phenomena were primarily attributed to the formation of color centers during X-ray irradiation [33]. It is worth noticing that due to measurement limitations in the vacuum ultraviolet (VUV) region (190–200 nm), which approaches the lower detection limit of spectrophotometric instruments, significant fluctuations were observed in test results. Moreover, previous studies have demonstrated that X-ray irradiation-induced color centers primarily manifest in the ultraviolet and visible bands. Consequently, this study selected a spectral range of 200–800 nm to analyze the degradation characteristics of CaF2 crystals induced by X-ray irradiation.

Figure 8.

(a) Transmittance variation spectra of CaF2 samples with different impurity contents under the same X-ray irradiation dose of 2000 Gy; (b) relationship between impurity concentrations and decreasing value of transmittance of CaF2 crystals in different bands.

The absorption peak at 323 nm is primarily attributed to X-ray-induced H and Vk centers within CaF2 crystals [34,35,36]. These centers represent distinct hole-related defects in CaF2. The Vk center is a transient defect that forms through the rapid localization of holes at two adjacent fluoride ions following irradiation. Due to its extreme instability, Vk centers could rapidly transform into H centers or recombinations, thereby contributing minimally to permanent damage. In contrast, the H center—a stable defect resulting from the holes localized at interstitial fluoride dimers—directly contributes to long-term irradiation damage. Consequently, the H center plays a dominant role in reducing transmittance in the 323 nm band. The absorption peak at 380 nm is ascribed to F centers [35,37], which are primarily formed by the capture of electrons by anionic vacancies (typically F ionic vacancies) in the crystal. Additionally, the absorption peak at 565 nm is attributed to calcium colloids. This peak exhibits a red shift relative to the previously reported position of 550 nm [38,39,40], a shift that is mainly caused by the formation of larger metallic calcium colloids following irradiation [41].

It was observed that under 2000 Gy X-ray irradiation, CaF2 crystals with an impurity content in the 25 ppm range did not exhibit a direct impact on their LIDTs; however, the impurity content did affect their optical degradation characteristics, as illustrated in Figure 8b. Moreover, the optical degradation associated with calcium colloids (565 nm) was less pronounced than that caused by H centers (323 nm) and F centers (380 nm). Consequently, under an equivalent high-energy photon dose, the optical degradation of CaF2 crystals increases with higher impurity content. Therefore, controlling the impurity levels during the preparation of CaF2 crystals remains crucial for enhancing their operational lifetime in deep-ultraviolet lithography applications.

4. Conclusions

This paper focused on the characteristics and mechanism of impurity content affecting X-ray-induced optical degradation properties and LIDT at 193 nm of CaF2 crystals. Test results show that trace impurity elements significantly affect the X-ray irradiation resistance of CaF2 crystal. Transmittance of CaF2 crystal in different wavelengths after X-ray irradiation is significantly reduced, mainly caused by different color centers. Different properties and dynamics of color centers lead to different optical degradation in different central wavelengths, and the transmittance-decreasing characteristics of each color center were quantitatively analyzed. Meanwhile, when impurity content is controlled at the ppm level, especially for impurities such as rare earth ions, oxygen ions, and lead ions, which strongly influence CaF2 crystal properties, their influence on the LIDTs of CaF2 crystals is relatively insignificant. Instead, subsurface structural defects or other absorptive precursors during surface processing might become dominant factors. This research provides reliable information to enhance our understanding of CaF2 crystal degradation, damage progress, and mechanisms.

Author Contributions

Methodology, P.H., Z.Z. (Zhen Zhang) and C.S. (Chongyun Shao); Software, X.P.; Formal analysis, D.J. and Z.Z. (Zhonghan Zhang); Investigation, Q.W. and Y.L.; Resources, H.K.; Data curation, R.L. and Z.Z. (Zhen Zhang); Writing—original draft, P.H.; Writing—review & editing, C.S. (Chong Shan) and Y.Z.; Supervision, L.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (52450255, 12074353) and the CAS Project for Young Scientists in Basic Research (YSBR-024).

Data Availability Statement

The data underlying the results presented in this paper are not publicly available at this time but may be obtained from the authors upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Chen, Z.; Sun, H.; Ma, S.; Lu, Y.; Wu, Z.; Chen, B.; Zhang, J.; Xiao, J.; Xu, J. Investigation on the microscopic mechanism of low-energy argon ion irradiation on calcium fluoride. Appl. Surf. Sci. 2025, 684, 161860. [Google Scholar] [CrossRef]

- Exarhos, G.J.; Sakuragi, S.; Guenther, A.H.; Taguchi, Y.; Sato, H.; Kaiser, N.; Lewis, K.L.; Kasai, A.; Nanba, H.; Soileau, M.J.; et al. Evaluation of high quality CaF2 single crystals for ultra-violet laser applications. In Laser-Induced Damage in Optical Materials: 2004; SPIE: Bellingham, WA, USA, 2005; Volume 5647, pp. 314–321. [Google Scholar]

- Guesmi, M.; Thoř, T.; Procháska, F.; Hlubučková, M.; Kanclíř, V.; Taboubi, O.; Šeděnková, I.; Žídek, K. Sub-bandgap laser-induced fluorescence in the CaF2 via a linear process. J. Lumin. 2025, 278, 121023. [Google Scholar] [CrossRef]

- He, X.; Yang, L.; Zhang, K.; Li, R.; Peng, Y. Research on the shear thickening polishing CaF2 with textured hollow polishing tool. J. Manuf. Process. 2024, 119, 193–203. [Google Scholar] [CrossRef]

- Mouchovski, J.T.; Temelkov, K.A.; Vuchkov, N.K.; Sabotinov, N.V. Laser grade CaF2 with controllable properties: Growing conditions and structural imperfection. J. Phys. D Appl. Phys. 2007, 40, 7682–7686. [Google Scholar] [CrossRef]

- Chkhalo, N.I.; Durov, K.V.; Nechay, A.N.; Perekalov, A.A.; Polkovnikov, V.N.; Salashchenko, N.N. On the prospects of lithography in the region of wavelengths shorter than 13.5 nm. J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 2024, 17, S226–S232. [Google Scholar] [CrossRef]

- Chkhalo, N.I.; Salashchenko, N.N. Current state and prospects for the development of X-Ray lithography. J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 2023, 17, 307–331. [Google Scholar] [CrossRef]

- He, R.; Cheng, J.; Wang, F. Lithography Equipment. In Handbook of Integrated Circuit Industry; Springer: Berlin/Heidelberg, Germany, 2024; pp. 1327–1359. [Google Scholar]

- Zhang, Y.; Yu, H.; Wang, L.; Wu, X.; He, J.; Huang, W.; Ouyang, C.; Chen, D.; Keshta, B.E. Advanced lithography materials: From fundamentals to applications. Adv. Colloid Interface Sci. 2024, 329, 10319. [Google Scholar] [CrossRef]

- Görlich, P.; Karras, H.; Lüdke, W.; Mothes, H.; Reimann, R. Coloration of yttrium-doped CaF2 and SrF2 crystals by X-Ray irradiation. Phys. Status Solidi (B) 2006, 3, 478–484. [Google Scholar] [CrossRef]

- Hu, H.; Zhou, J.; Ye, Y.; Li, H.; Tu, C.; Wen, H.; Ke, Y.; Sun, Y. Preparation of REE-doped CaF2 single crystals for accurate determination of REE concentrations in CaF2 crystals via UV-LA-ICP-MS. Talanta 2025, 285, 12739. [Google Scholar] [CrossRef]

- Kawaguchi, N.; Kimura, H.; Akatsuka, M.; Okada, G.; Kawano, N.; Fukuda, K.; Yanagida, T. Scintillation Characteristics of Pr:CaF2 Crystals for Charged-particle Detection. Sens. Mater. 2018, 30, 1585–1590. [Google Scholar] [CrossRef]

- Ke, Y.; Hu, H.; Zhou, J.; Li, H.; Zhang, Y.; Tu, C.; Wen, H.; Sun, Y. Study on ablation behavior and mechanism for accurate determination of rare earth elements in CaF2 crystals by UV-LA-ICP-MS. Spectrochim. Acta Part B At. Spectrosc. 2025, 224, 10709. [Google Scholar] [CrossRef]

- Kumar, R.; Joseph, D. Spectroscopic studies of Tm-doped CaF2 single-crystal. Eur. Phys. J. Plus 2024, 139, 961. [Google Scholar] [CrossRef]

- Mouhovski, J.T. Control of oxygen contamination during the growth of optical calcium fluoride and calcium strontium fluoride crystals. In Progress in Crystal Growth and Characterization of Materials; Elsevier: Amsterdam, The Netherlands, 2007; Volume 53, pp. 79–116. [Google Scholar]

- Nicoara, I.; Stef, M.; Vizman, D.; Negut, C.D. Gamma-rays induced color centers in Pb2+ doped CaF2 crystals. Radiat. Phys. Chem. 2018, 153, 70–78. [Google Scholar] [CrossRef]

- Pandurangappa, C.; Lakshminarasappa, B.N. Optical studies on lanthanum-doped calcium fluoride. J. Mater. Sci. 2011, 47, 892–897. [Google Scholar] [CrossRef]

- Sils, J.; Hausfeld, S.; Clauß, W.; Pahl, U.; Lindner, R.; Reichling, M. Impurities in synthetic fluorite for deep ultraviolet optical applications. J. Appl. Phys. 2009, 106, 063109. [Google Scholar] [CrossRef]

- Sils, J.; Radzhabov, E.; Reichling, M. Characterisation of oxygen defects in calciumdifluoride. J. Phys. Chem. Solids 2007, 68, 420–425. [Google Scholar] [CrossRef]

- Yanagida, T.; Kim, K.J.; Kamada, K.; Yokota, Y.; Maeo, S.; Yoshikawa, A.; Kawaguchi, N.; Fukuda, K.; Sarukura, N.; Chani, V. Growth, optical properties, and scintillation light yield of CaF2:Ce crystals with different Ce concentration. Jpn. J. Appl. Phys. 2010, 49, 032601. [Google Scholar] [CrossRef]

- Mühlig, C.; Triebel, W.; Stafast, H.; Letz, M. Influence of Na-related defects on ArF laser absorption in CaF2. Appl. Phys. B 2010, 99, 525–533. [Google Scholar] [CrossRef]

- Li, C.; Kang, X.; Han, W.; Zheng, W.; Su, L. Nanosecond laser-induced surface damage and material failure mechanism of single crystal CaF2 (111) at 355 nm. Appl. Surf. Sci. 2019, 480, 1070–1077. [Google Scholar] [CrossRef]

- Shao, J.; Liang, X.; You, L.; Pan, N.; Lin, Y.; Wang, S.; Deng, Z.; Fang, X.; Wang, X. Laser-induced damage and periodic stripe structures of a CaF2 single crystal by an ArF excimer laser. Chin. Opt. Lett. 2020, 18, 021403. [Google Scholar] [CrossRef]

- Wang, J.; Cox, G.P.; Donohue, K.J.; Davis, R.W.; Shi, Y.; Cushman, C.V.; Rezikyan, A.; Moore, G.G.; Tingley, J.E.; Becken, K.J.; et al. Laser-induced damage of CaF2 optics at 193 nm. In Laser-Induced Damage in Optical Materials 2023; SPIE: Bellingham, WA, USA, 2023; Volume 12726, pp. 127260G-1–127260G-10. [Google Scholar]

- Wang, J.; Piché, F.; Fanning, E.M.; Glebov, A.L.; Leisher, P.O. Surface and bulk damage resistance of calcium fluoride optics assessed by X-ray induced color centers. In Components and Packaging for Laser Systems IX; SPIE: Bellingham, WA, USA, 2023; Volume 12402, pp. 1240208-1–1240208-8. [Google Scholar]

- Elswie, I.; Lazarevic, Z.; Radojevic, V.; Gilic, M.; Rabasovic, M.; Sevic, D.; Romcevic, N. The Bridgman method growth and spectroscopic characterization of calcium fluoride single crystals. Sci. Sinter. 2016, 48, 333–341. [Google Scholar] [CrossRef]

- Xu, J.; Shi, M.; Lu, B.; Li, X.; Wu, A. Bridgman growth and characterization of calcium fluoride crystals. J. Cryst. Growth 2006, 292, 391–394. [Google Scholar] [CrossRef]

- Yonezawa, T.; Matsuo, K.; Nakayama, J.; Kawamoto, Y. Behaviors of metal-oxide impurities in CaF2 and BaF2 single-crystals grown with PbF2 scavenger by Stockbarger’s method. J. Cryst. Growth 2003, 258, 385–393. [Google Scholar] [CrossRef]

- Pandurangappa, C.; Lakshminarasappa, B.N. Spectroscopic studies of γ-rayed CaF2:Sr. J. Lumin. 2013, 138, 61–64. [Google Scholar] [CrossRef][Green Version]

- ISO 21254–1; Lasers and Laser-Related Equipment—Test Methods for Laser-Induced Damage Threshold. ISO Standard: Geneva, Switzerland, 2011.

- Huang, J.; Liu, H.; Wang, F.; Ye, X.; Sun, L.; Zhou, X.; Wu, Z.; Jiang, X.; Zheng, W.; Sun, D. Influence of bulk defects on bulk damage performance of fused silica optics at 355 nm nanosecond pulse laser. Opt. Express 2017, 25, 33416–33428. [Google Scholar] [CrossRef]

- Shao, J.; Liang, X.; Lin, Y.; Wang, S.; Deng, Z.; Meng, G.; Fang, X. KrF excimer laser induced damage and its mechanism of CaF2 single crystal with (1 1 1), (1 1 0) and (1 0 0) planes. Appl. Surf. Sci. 2022, 586, 152716. [Google Scholar] [CrossRef]

- Williams, R.T. Optically generated lattice defects in halide crystals. Opt. Eng. 1989, 28, 1024–1033. [Google Scholar]

- Beaumont, J.H.; Hayes, W.; Kirk, D.L.; Summers, G.P. An investigation of trapped holes and trapped excitons in alkaline earth fluorides. In Proceedings of the Royal Society of London. A. Mathematical and Physical Sciences; Royal Society: London, UK, 1997; Volume 315, pp. 69–97. [Google Scholar]

- Cooke, D.W.; Bennett, B.L. Optical absorption and luminescence of 14-MeV neutron-irradiated CaF2 single crystals. J. Nucl. Mater. 2003, 321, 158–164. [Google Scholar] [CrossRef]

- Parker, S.; Song, K.; Catlow, C.; Stoneham, A. Geometry and charge distribution of H centres in the fluorite structure. J. Phys. C Solid State Phys. 1981, 14, 4009–4015. [Google Scholar] [CrossRef]

- Scouler, W.J.; Smakula, A. Coloration of pure and doped calcium fluoride crystals at 20 °C and −190 °C. Phys. Rev. 1960, 120, 1154–1161. [Google Scholar] [CrossRef]

- Orera, V.M.; Alcalá, R. Formation and size evolution of Ca colloids in additively colored CaF2. Phys. Status Solidi (A) 1976, 38, 621–627. [Google Scholar] [CrossRef]

- Izerrouken, M.; Guerbous, L.; Meftah, A. Colour centres formation in CaF2 single crystals by γ-rays and reactor neutrons. In Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment; Elsevier: Amsterdam, The Netherlands, 2010; Volume 621, pp. 68–70. [Google Scholar]

- Cramer, L.P.; Schubert, B.E.; Petite, P.S.; Langford, S.C.; Dickinson, J.T. Laser interactions with embedded Ca metal nanoparticles in single crystal CaF2. J. Appl. Phys. 2005, 76, 074307. [Google Scholar] [CrossRef]

- Hazem, R.; Izerrouken, M. Proton irradiation-induced defect aggregation and metallic nanoparticles in CaF2 single-crystal. Radiat. Phys. Chem. 2023, 204, 110643. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).