Machine Learning-Assisted Optimization of Femtosecond Laser-Induced Superhydrophobic Microstructure Processing

Abstract

1. Introduction

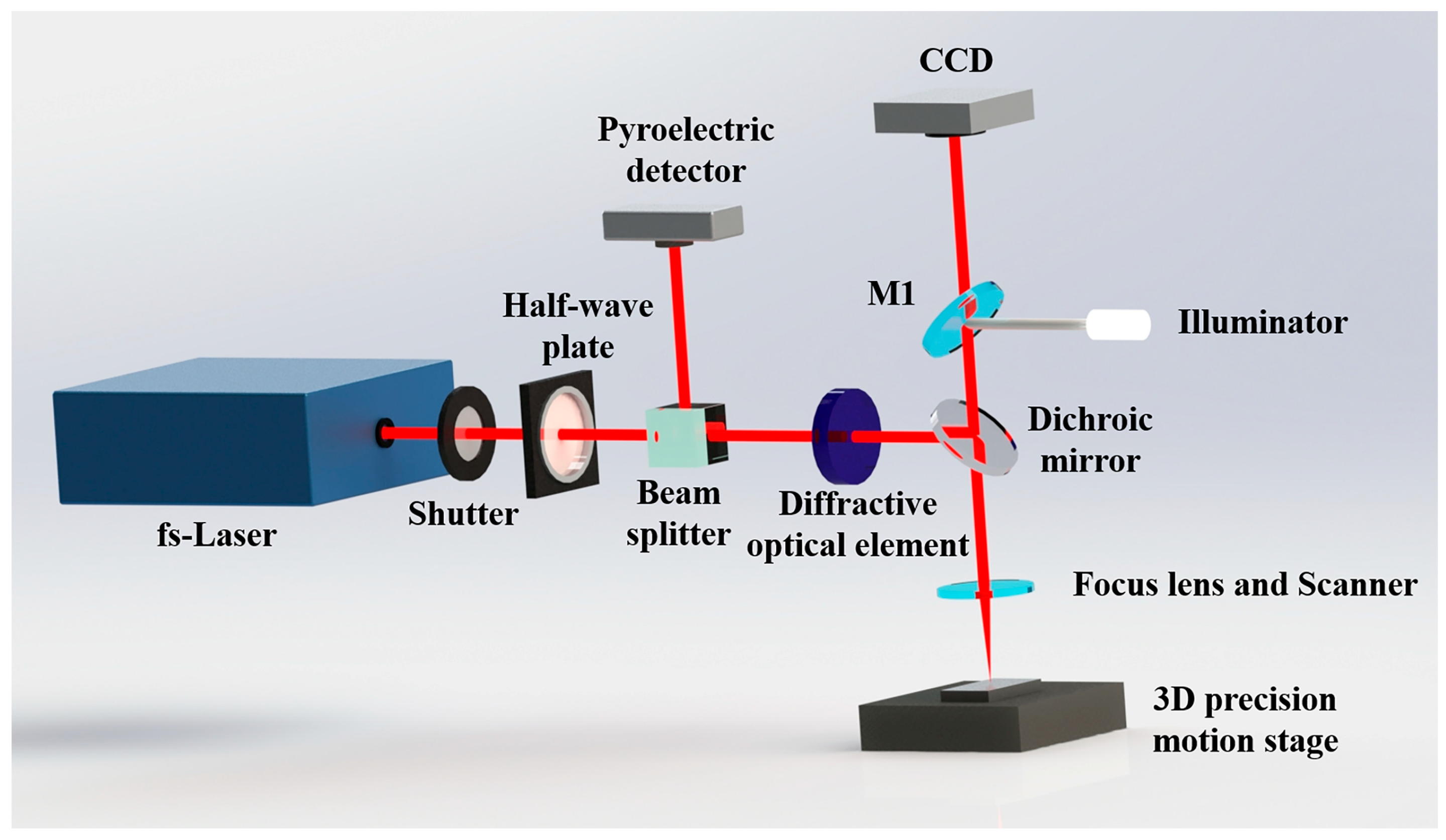

2. Experimental and Simulation Methods

2.1. Experimental Procedures

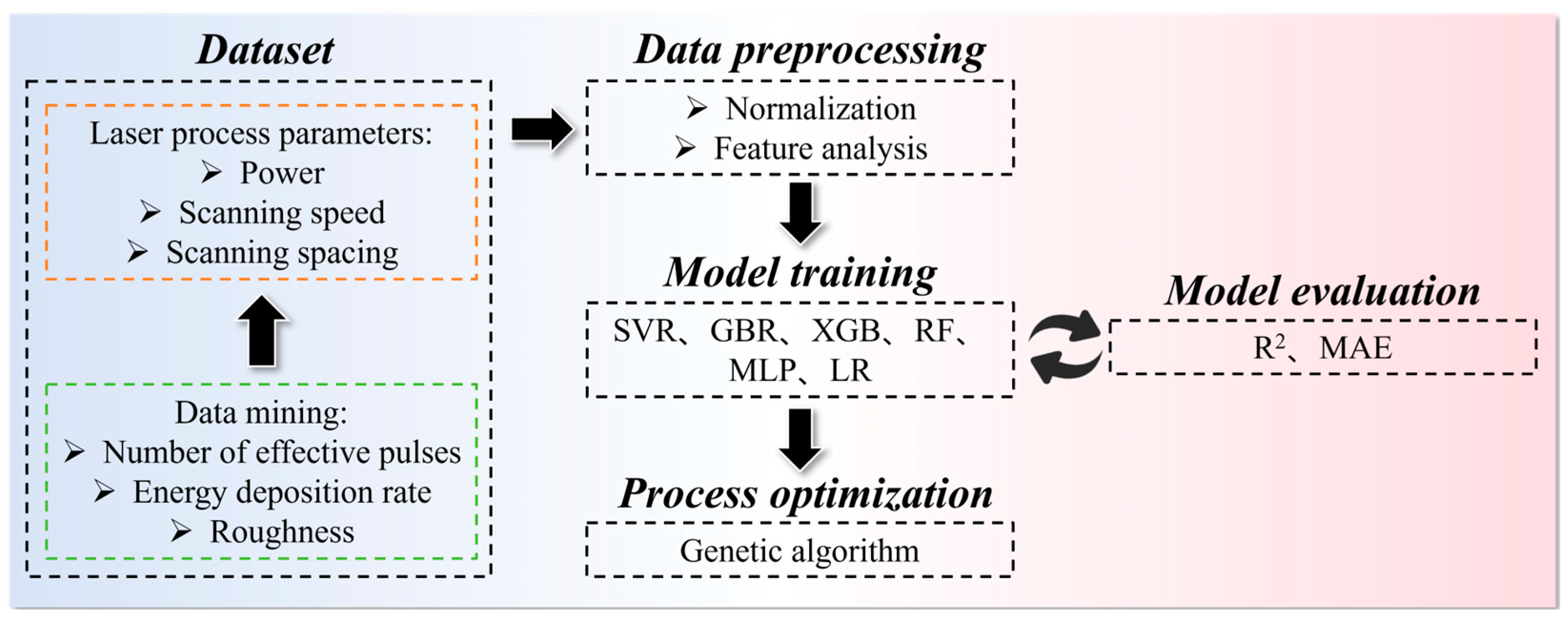

2.2. Modeling the Femtosecond Laser Process Using Machine Learning

3. Results and Discussion

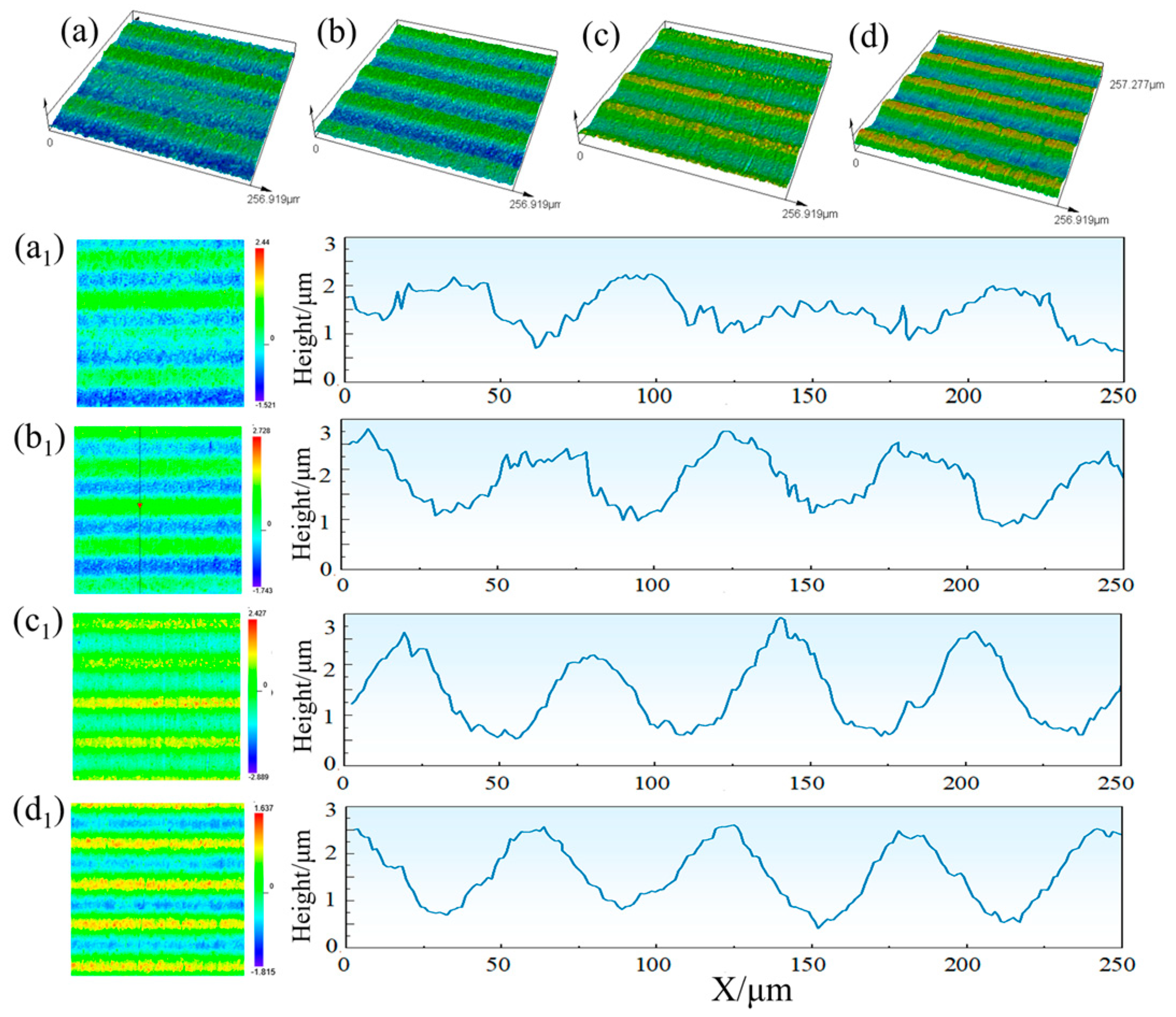

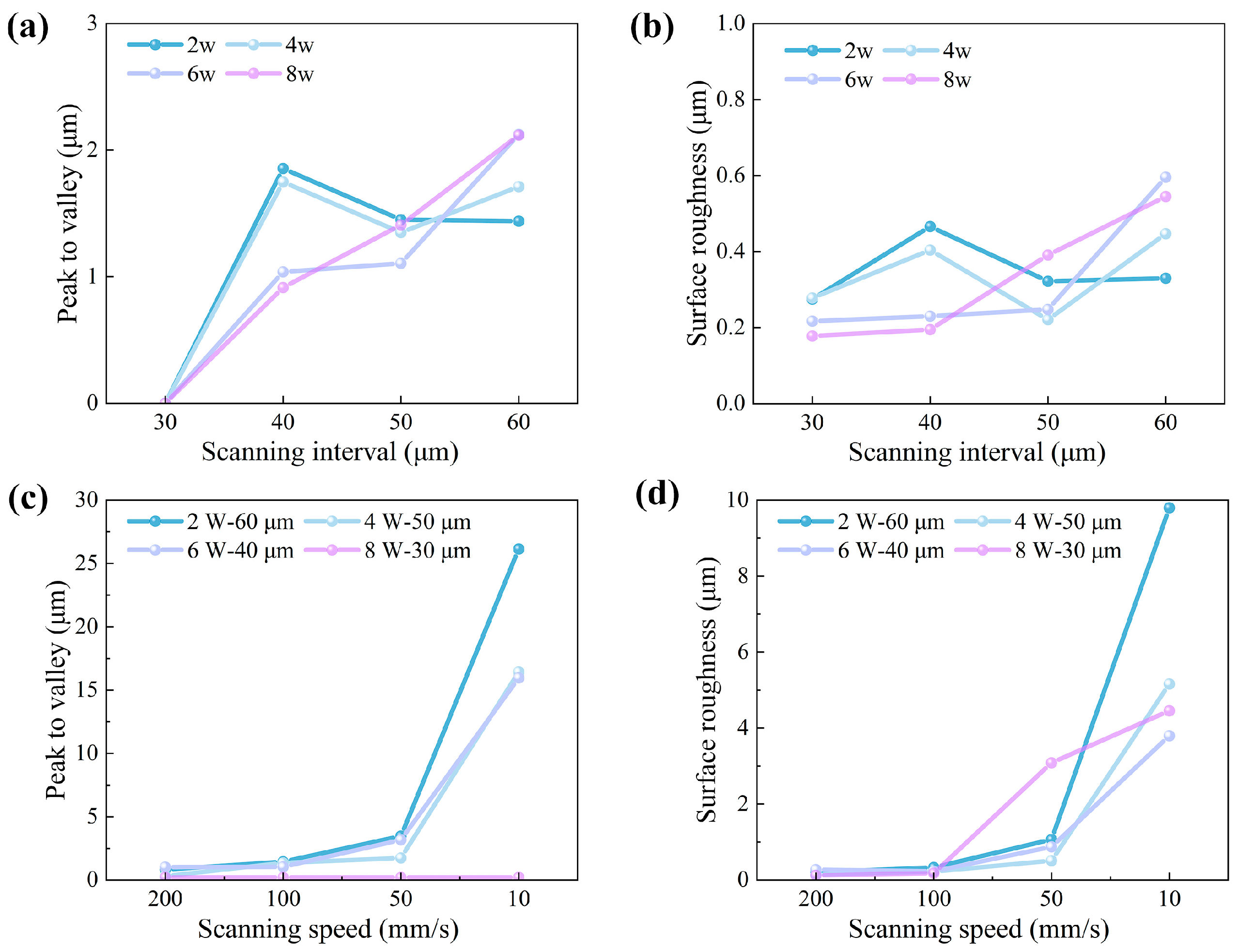

3.1. Effect of Laser Process Parameters on Microstructures

3.2. Selection of the Machine Learning Algorithm and the Prediction Results

3.3. Femtosecond Laser Process Optimization by Coupling SVR Model and GA

4. Conclusions

- (1)

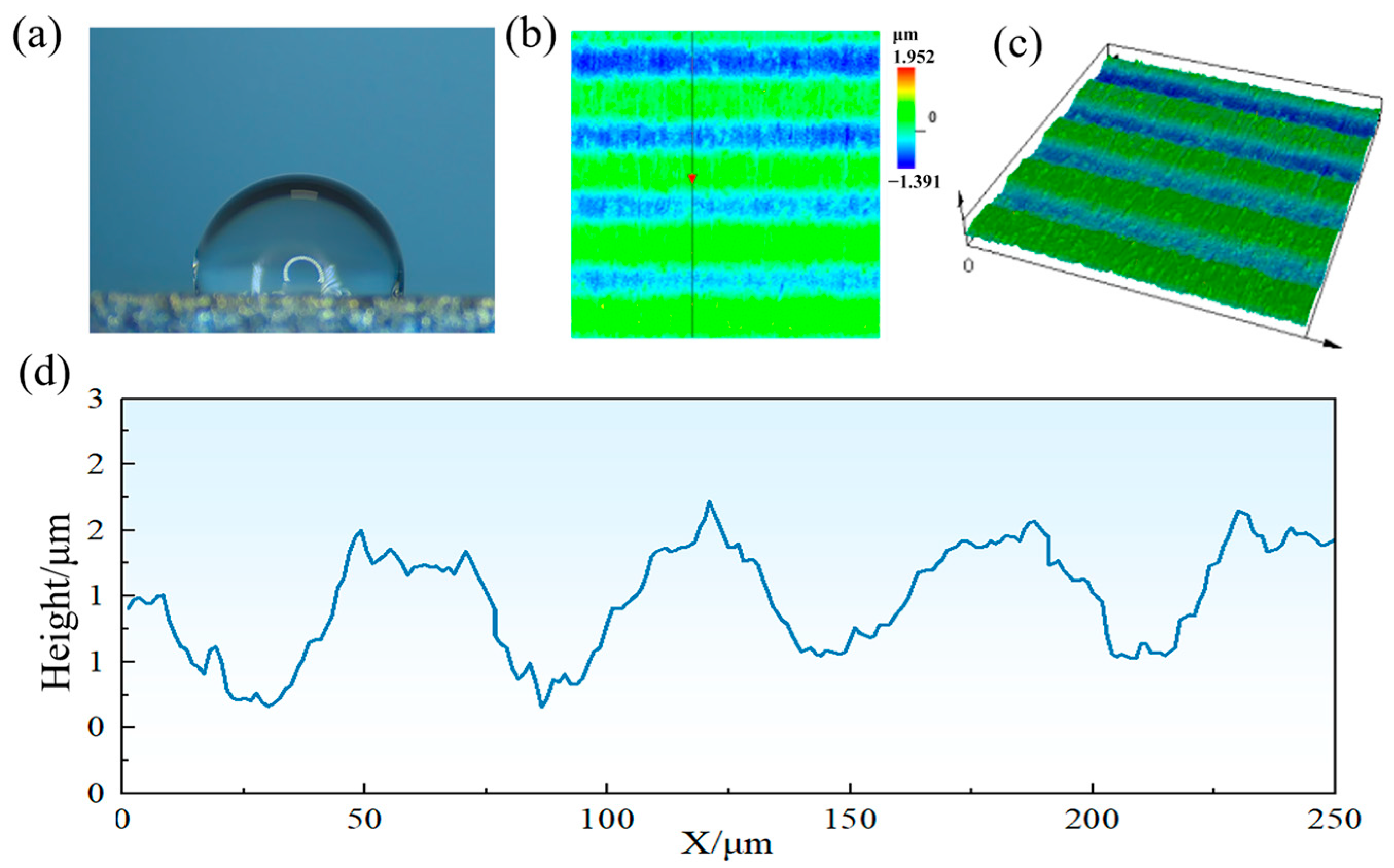

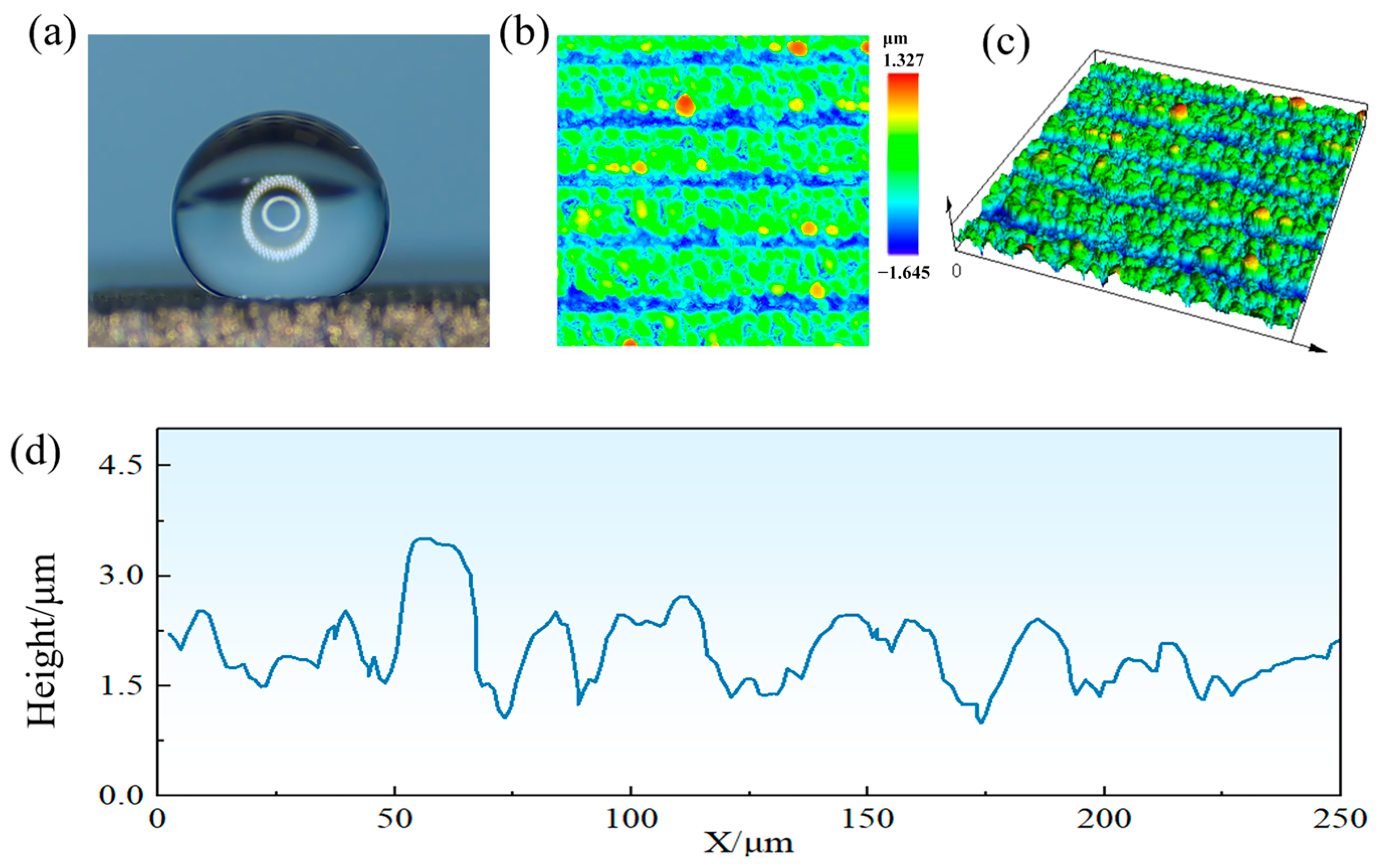

- Femtosecond laser linear scanning produced regular micro-groove structures on the TC4 surface. The power, scanning speed, and scanning spacing exhibited complex coupling influence patterns on the geometric dimensions and roughness of these structures. At high scanning speeds, a high power led to larger PV values and a greater roughness on the surface, while the opposite pattern occurred at low scanning speeds. The PV value and roughness of the micro-groove structures increased as the scanning speed decreased.

- (2)

- Based on the characteristics of laser-induced micro-groove structures, the shallow layer mechanisms of hydrophilicity and hydrophobicity can be qualitatively summarized. For micro-groove structures with a low aspect ratio, an excessively large spacing prevents the surface from effectively supporting the liquid droplets, which then penetrate into the gaps of the micro-structures, resulting in a small CA. In contrast, micro-grooves with a large aspect ratio couple with the nanoscale particles attached to the surface to form a porous structure, which supports the liquid droplets and reduces their contact with the surface, thus exhibiting an excellent hydrophobic performance.

- (3)

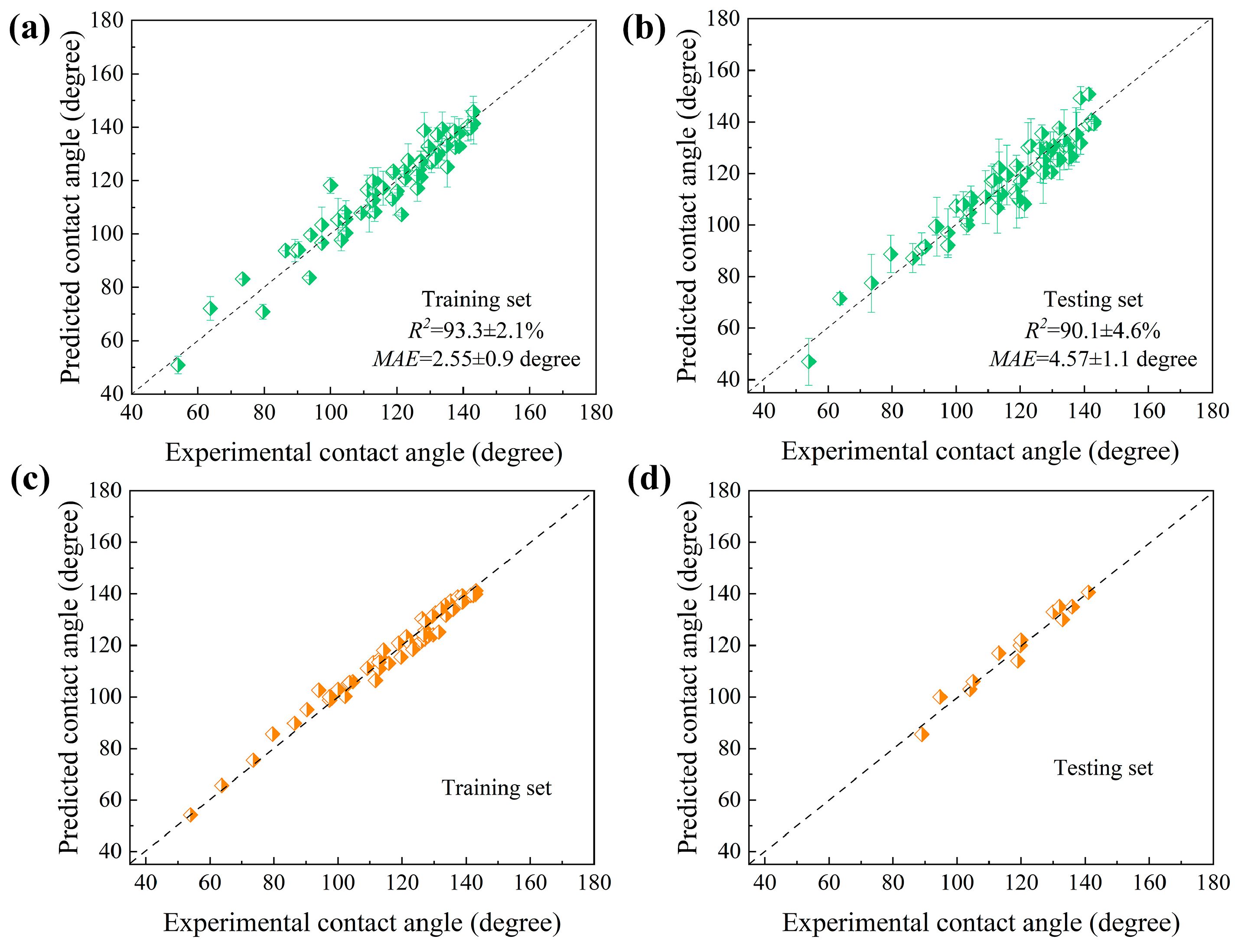

- Prediction models for the relationship between femtosecond laser process parameters and the contact angle were successfully established using various machine learning algorithms. The SVR algorithm exhibited the optimal prediction accuracy. For the training set and the testing set, the R2 and MAE were 90.1 ± 4.6%, 3.3 ± 2.1%, 2.55 ± 0.89 degrees, and 4.57 ± 1.11 degrees, respectively. Compared with using only pure process parameters, the introduction of additional variables such as the number of effective pulses, energy deposition rate, and roughness enriches the dataset available for training, improves the model accuracy, and provides a solution for constructing a reliable prediction model with a small sample size.

- (4)

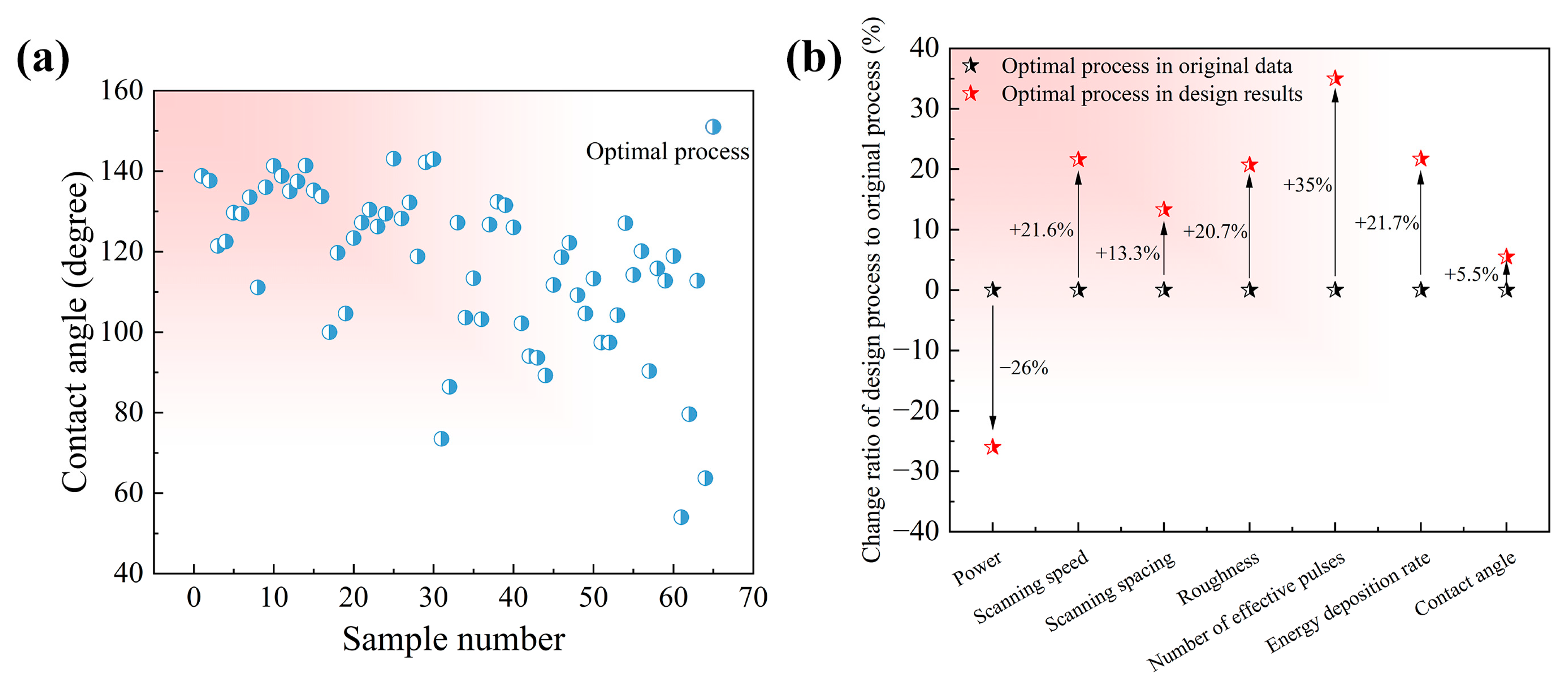

- The combination of the machine learning model and the GA efficiently achieved the optimization of multi-dimensional laser processes, effectively improving the hydrophobic performance. Compared with the optimal performance in the original dataset, the CA of the designed process increased by 5.5%, reaching 151 degrees. Moreover, the designed process was significantly different from the optimal process in the original dataset, and the complex parameter combination made it difficult to obtain this process scheme by experimental exploration. The framework combining machine learning and the GA provides a feasible method for process optimization in the complex problem of femtosecond laser-induced superhydrophobic structures, and can be extended to other laser material processing fields.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qi, Y.; Yang, Z.; Huang, W.; Zhang, J. Robust superhydrophobic surface for anti-icing and cooling performance: Application of fluorine-modified TiO2 and fumed SiO2. Appl. Surf. Sci. 2021, 538, 148131. [Google Scholar] [CrossRef]

- Wang, K.; Yu, S.; Li, W.; Song, Y.; Gong, P.; Zhang, M.; Li, H.; Sun, D.; Yang, X.; Wang, X. Superhydrophobic and photocatalytic synergistic Self-Cleaning ZnS coating. Appl. Surf. Sci. 2022, 595, 153565. [Google Scholar] [CrossRef]

- Wu, C.; Liu, Q.; Chen, R.; Liu, J.; Zhang, H.; Li, R.; Takahashi, K.; Liu, P.; Wang, J. Fabrication of ZIF-8@ SiO2 micro/nano hierarchical superhydrophobic surface on AZ31 magnesium alloy with impressive corrosion resistance and abrasion resistance. ACS Appl. Mater. Interfaces 2017, 9, 11106–11115. [Google Scholar] [CrossRef] [PubMed]

- Zhou, R.; Lin, S.; Shen, F.; Khew, S.Y.; Hong, M. A universal copper mesh with on-demand wettability fabricated by pulsed laser ablation for oil/water separation. Surf. Coat. Tech. 2018, 348, 73–80. [Google Scholar] [CrossRef]

- He, Y.; Yin, K.; Wang, L.; Wu, T.; Chen, Y.; Arnusch, C.J. Femtosecond laser structured black superhydrophobic cork for efficient solar-driven cleanup of crude oil. Appl. Phys. Lett. 2024, 124, 171601. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X.; Huang, H.; Wang, S.; Li, B.; Wang, X.; Deng, H.; Shen, G. FEM-ANN coupling dynamic prediction of residual stresses induced by laser shock peening of TC4 titanium alloy. Opt. Laser Technol. 2024, 179, 111395. [Google Scholar] [CrossRef]

- Zha, S.; Zhang, H.; Yang, J.; Zhang, Z.; Qi, X.; Zu, Q. Fatigue Threshold and Microstructure Characteristic of TC4 Titanium Alloy Processed by Laser Shock. Metals 2025, 15, 453. [Google Scholar] [CrossRef]

- Das, S.; Kumar, S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. A review on superhydrophobic polymer nanocoatings: Recent development and applications. Ind. Eng. Chem. Res. 2018, 57, 2727–2745. [Google Scholar] [CrossRef]

- Kamal, S.A.A.; Ritikos, R.; Rahman, S.A. Wetting behaviour of carbon nitride nanostructures grown by plasma enhanced chemical vapour deposition technique. Appl. Surf. Sci. 2015, 328, 146–153. [Google Scholar] [CrossRef]

- Wang, L.; Yin, K.; Deng, Q.; Huang, Q.; Arnusch, C.J. Multiscale hybrid-structured femtosecond laser-induced graphene with outstanding photo-electro-thermal effects for all-day anti-icing/deicing. Carbon 2024, 219, 118824. [Google Scholar] [CrossRef]

- Myronyuk, O.; Baklan, D.; Rodin, A.M. UV resistance of super-hydrophobic stainless steel surfaces textured by femtosecond laser pulses. Photonics 2023, 10, 1005. [Google Scholar] [CrossRef]

- Yang, Q.; Yu, M.; Chen, Z.; Ai, S.; Kentsch, U.; Zhou, S.; Jia, Y.; Chen, F.; Liu, H. A novel approach towards robust construction of physical colors on lithium niobate crystal. Opto-Electron. Adv. 2025, 8, 240193. [Google Scholar] [CrossRef]

- Yin, S.-Y.; Guo, Q.; Liu, S.-R.; He, J.-W.; Yu, Y.-S.; Tian, Z.-N.; Chen, Q.-D. Three-dimensional multichannel waveguide grating filters. Opto-Electron. Sci. 2024, 3, 240003. [Google Scholar] [CrossRef]

- Miao, B.; Wang, L.; Zhang, T.; Zhang, Z.; Wang, C. Fabrication of micro-nano gradient wettability surface by nanosecond laser and thermal oxidation. Appl. Phys. A 2025, 131, 202. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Z.; Zhao, Z.; Liu, Y.; Wang, C.; Xu, W. Multimodal deep-learning framework for accurate prediction of wettability evolution of laser-textured surfaces. ACS Appl. Mater. Interfaces 2023, 15, 10261–10272. [Google Scholar] [CrossRef]

- Tang, Y.; Yang, R.; Feng, B.; Lin, D.; Guo, W.; Cai, Y. Fabricating superhydrophobic surfaces of silicone rubber with laser abalation. Appl. Surf. Sci. 2025, 701, 163286. [Google Scholar] [CrossRef]

- Sun, X.; Pan, R.; Xu, J.; Zhang, S.; Zhou, T.; Shi, Y.; Liu, W.; Chen, P.; Chen, S. Enhanced superhydrophobicity of acrylic polyurethane coatings by femtosecond laser ablation. Prog. Org. Coat. 2024, 197, 108874. [Google Scholar] [CrossRef]

- Zhang, Z.; Jia, M.; Zhang, T.; Yu, Y.; Yang, Z.; Wang, Y.; Wang, C.; Lv, Z.; Xu, W. Efficient prediction of long-term wettability evolution in laser-textured surfaces using short-term data and cyclic deep learning. Opt. Laser Technol. 2025, 184, 112558. [Google Scholar] [CrossRef]

- Kusumaatmaja, H.; Yeomans, J. Modeling contact angle hysteresis on chemically patterned and superhydrophobic surfaces. Langmuir 2007, 23, 6019–6032. [Google Scholar] [CrossRef]

- Li, W.; Amirfazli, A. Microtextured superhydrophobic surfaces: A thermodynamic analysis. Adv. Colloid. Interface Sci. 2007, 132, 51–68. [Google Scholar] [CrossRef]

- Moradi, S.; Englezos, P.; Hatzikiriakos, S.G. Contact Angle Hysteresis of Non-Flattened-Top Micro/Nanostructures. Langmuir 2014, 30, 3274–3284. [Google Scholar] [CrossRef]

- Wang, C.; Xu, W. Overview: Integration and Development of Physical Models and Artificial Intelligence in Alloy Design. Acta Met. Sin. 2025, 61, 541–560. [Google Scholar]

- Murzin, S.P. Digital Engineering in Diffractive Optics for Precision Laser Processing. Photonics 2025, 12, 306. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, S.; Zhang, Y.; Wang, C.; Zhang, S.; Yang, Z.; Xu, W. Optimization of low-power femtosecond laser trepan drilling by machine learning and a high-throughput multi-objective genetic algorithm. Opt. Laser Technol. 2022, 148, 107688. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Z.; Yang, Z.; Wang, C. Femtosecond laser-induced evolution of surface micro-structure in depth direction of nickel-based alloy. Appl. Sci. 2022, 12, 8464. [Google Scholar] [CrossRef]

- Shen, C.; Wang, C.; Wei, X.; Li, Y.; van der Zwaag, S.; Xu, W. Physical metallurgy-guided machine learning and artificial intelligent design of ultrahigh-strength stainless steel. Acta Mater. 2019, 179, 201–214. [Google Scholar] [CrossRef]

- Khan, S.A.; Boltaev, G.S.; Iqbal, M.; Kim, V.; Ganeev, R.A.; Alnaser, A.S. Ultrafast fiber laser-induced fabrication of superhydrophobic and self-cleaning metal surfaces. Appl. Surf. Sci. 2021, 542, 148560. [Google Scholar] [CrossRef]

- Vasiliev, M.M.; Shukhov, Y.G.; Rodionov, A.A.; Sulyaeva, V.S.; Markovich, D.M.; Starinskiy, S.V. Why do metals become superhydrophilic during nanosecond laser processing? Design of superhydrophilic, anisotropic and biphilic surfaces. Appl. Surf. Sci. 2024, 653, 159392. [Google Scholar] [CrossRef]

- Sen, B.; Hussain, S.A.I.; Mia, M.; Mandal, U.K.; Mondal, S.P. Selection of an ideal MQL-assisted milling condition: An NSGA-II-coupled TOPSIS approach for improving machinability of Inconel 690. Int. J. Adv. Manuf. Technol. 2019, 103, 1811–1829. [Google Scholar] [CrossRef]

- Han, H.; Yu, R.; Li, B.; Zhang, Y. Multi-objective optimization of corrugated tube inserted with multi-channel twisted tape using RSM and NSGA-II. Appl. Therm. Eng. 2019, 159, 113731. [Google Scholar] [CrossRef]

- Cassie, A.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

| Variables | Maximum | Minimum | Average | Standard Deviation | |

|---|---|---|---|---|---|

| Inputs | Laser power (W) | 8 | 2 | / | / |

| Scanning speed (mm/s) | 200 | 10 | / | / | |

| Scanning spacing (μm) | 60 | 30 | / | / | |

| Effective number of pulses | 5 | 0.25 | / | / | |

| Energy deposition rate (μJ/μm2·s) | 4076 | 1019 | / | / | |

| Roughness (μm) | 9.9 | 0.1 | / | / | |

| Outputs | Contact angle (degree) | 143 | 54 | 116.9 | 19.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Gu, Y.; Tian, X.; Wang, J.; Jia, Y.; Xu, J.; Zhang, Z.; Liu, S.; Liu, S. Machine Learning-Assisted Optimization of Femtosecond Laser-Induced Superhydrophobic Microstructure Processing. Photonics 2025, 12, 530. https://doi.org/10.3390/photonics12060530

Wang L, Gu Y, Tian X, Wang J, Jia Y, Xu J, Zhang Z, Liu S, Liu S. Machine Learning-Assisted Optimization of Femtosecond Laser-Induced Superhydrophobic Microstructure Processing. Photonics. 2025; 12(6):530. https://doi.org/10.3390/photonics12060530

Chicago/Turabian StyleWang, Lifei, Yucheng Gu, Xiaoqing Tian, Jun Wang, Yan Jia, Junjie Xu, Zhen Zhang, Shiying Liu, and Shuo Liu. 2025. "Machine Learning-Assisted Optimization of Femtosecond Laser-Induced Superhydrophobic Microstructure Processing" Photonics 12, no. 6: 530. https://doi.org/10.3390/photonics12060530

APA StyleWang, L., Gu, Y., Tian, X., Wang, J., Jia, Y., Xu, J., Zhang, Z., Liu, S., & Liu, S. (2025). Machine Learning-Assisted Optimization of Femtosecond Laser-Induced Superhydrophobic Microstructure Processing. Photonics, 12(6), 530. https://doi.org/10.3390/photonics12060530