Characteristics of Fused Silica Exit Surface Damage by Low-Temporal Coherence Light Irradiation

Abstract

1. Introduction

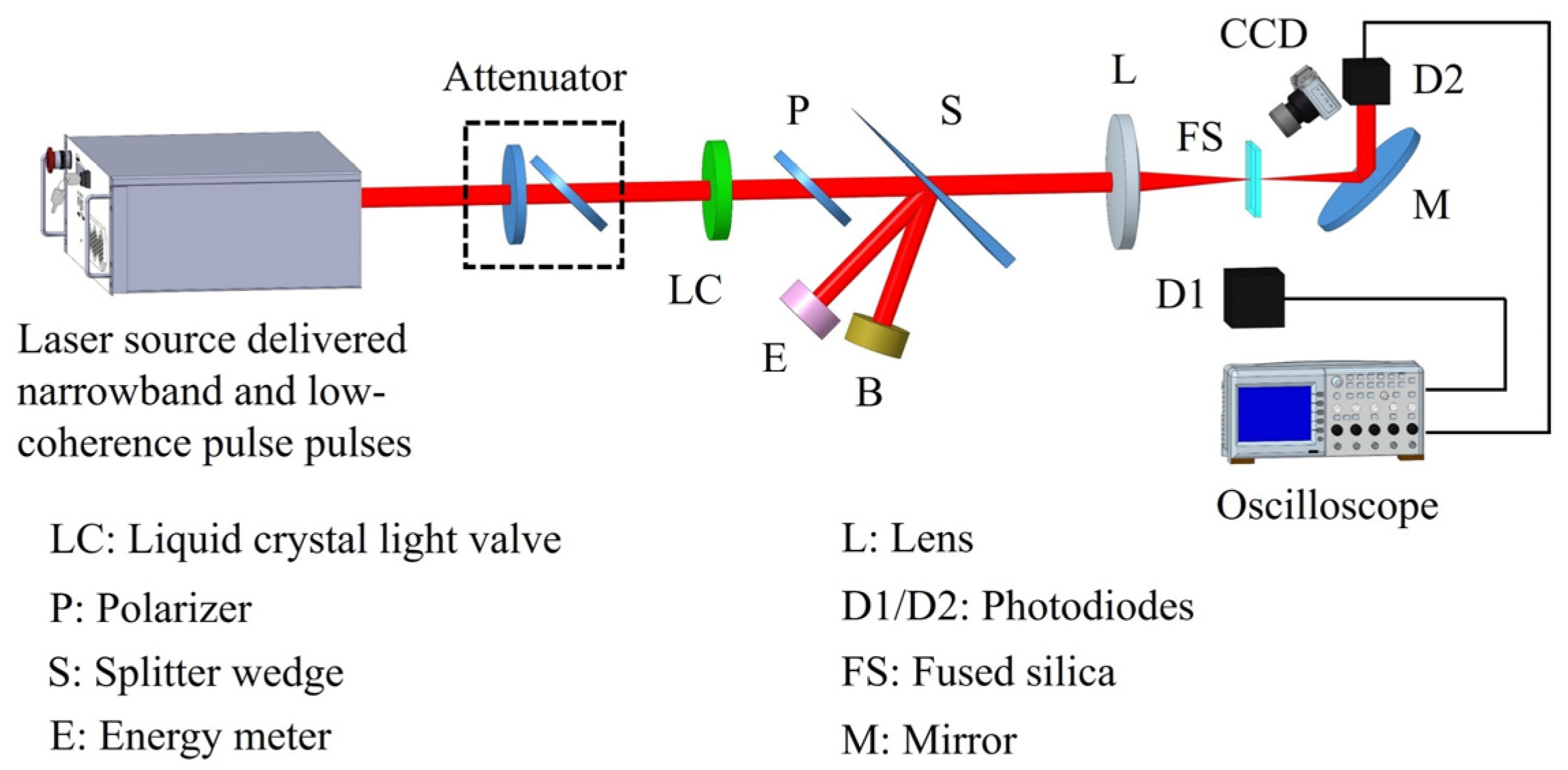

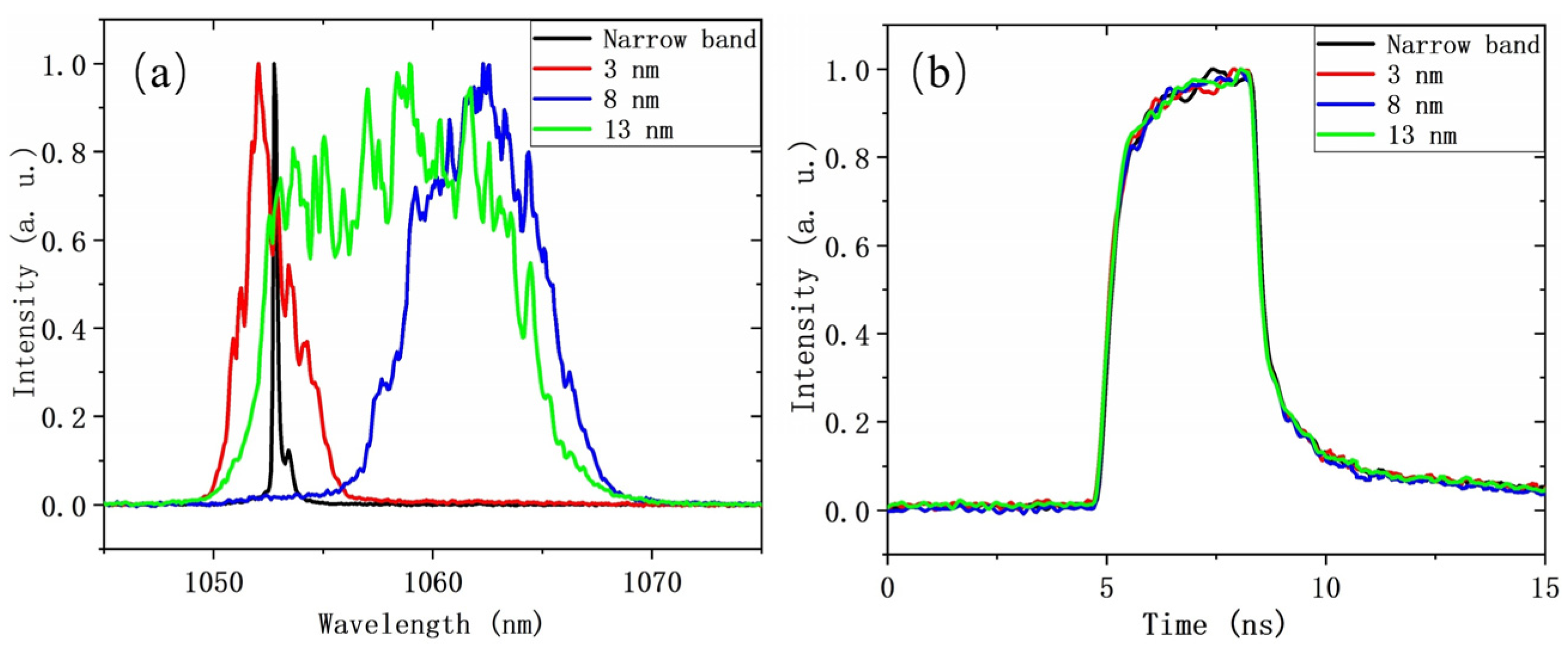

2. Experimental Details

Experimental Setup

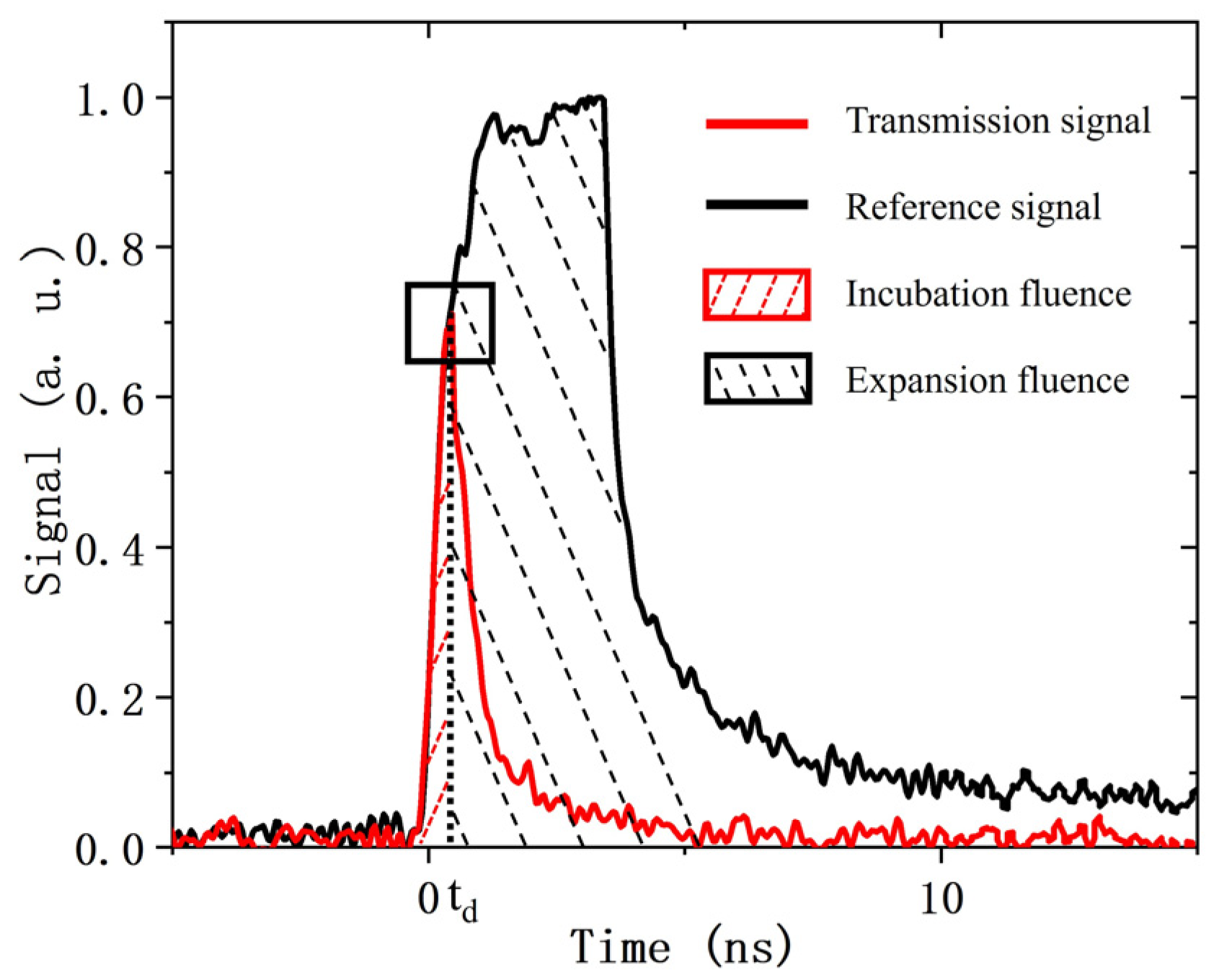

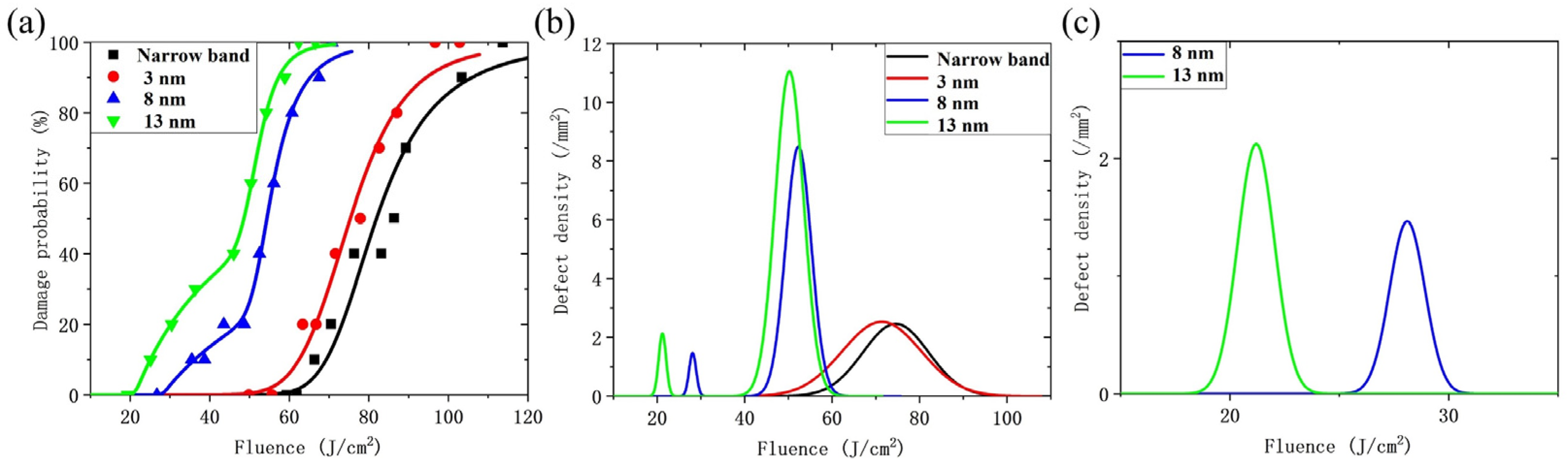

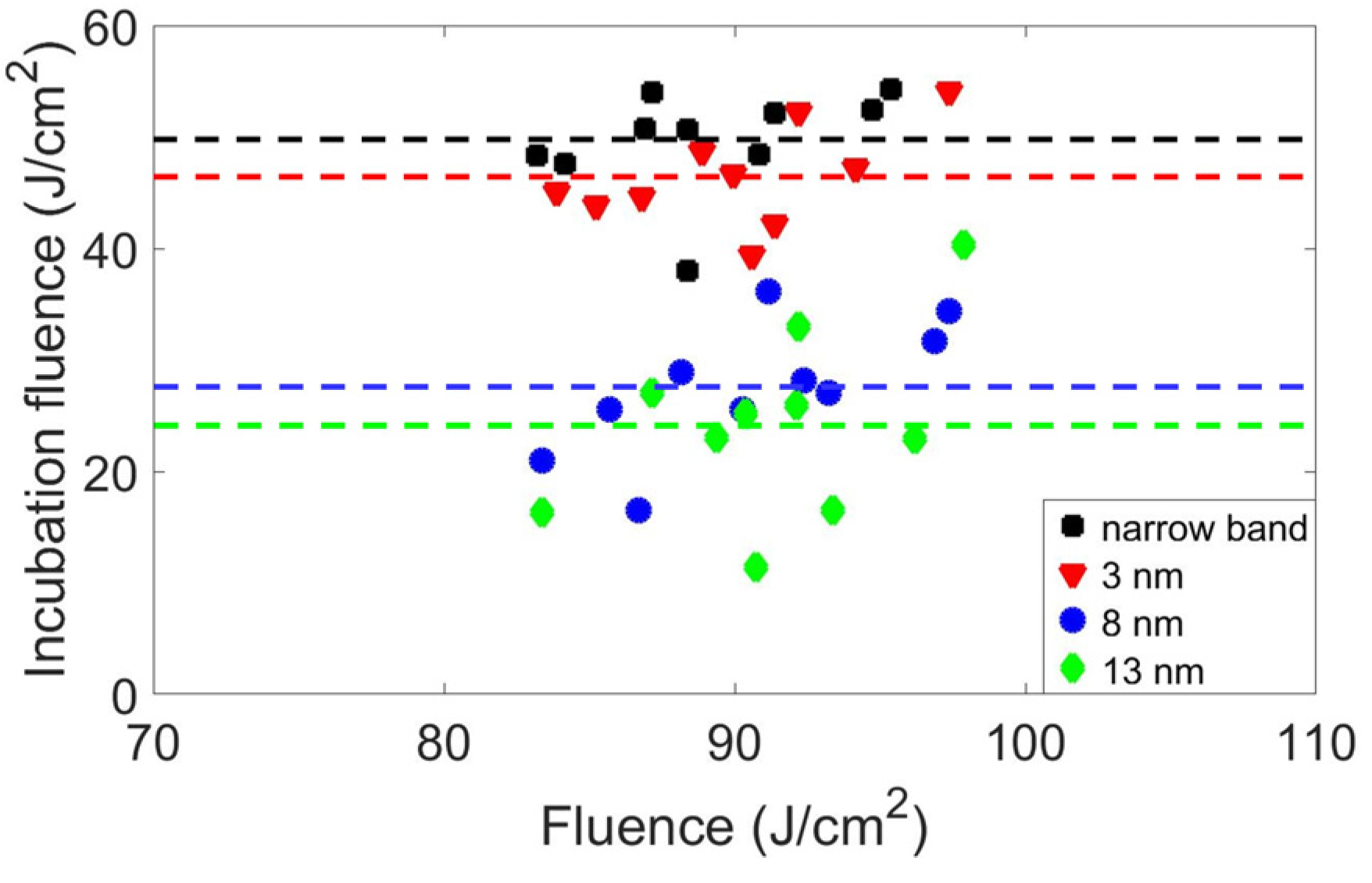

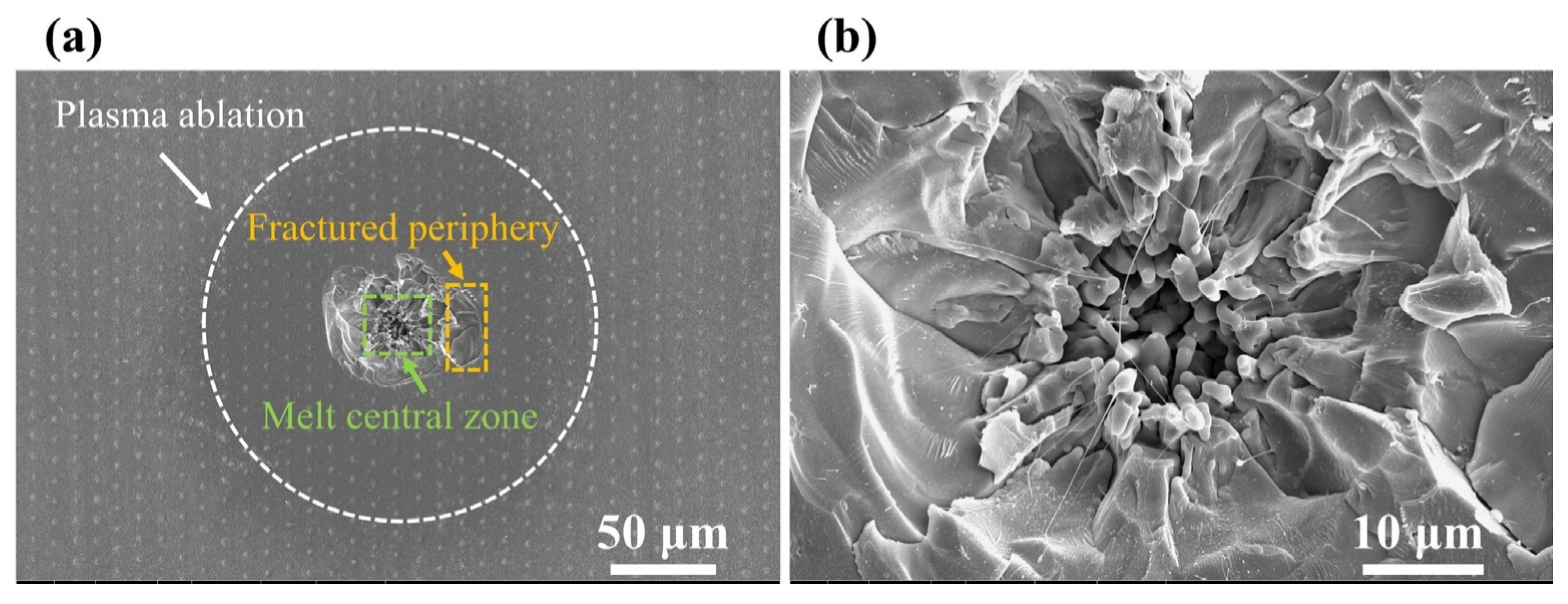

3. Experimental Results

4. Discussion

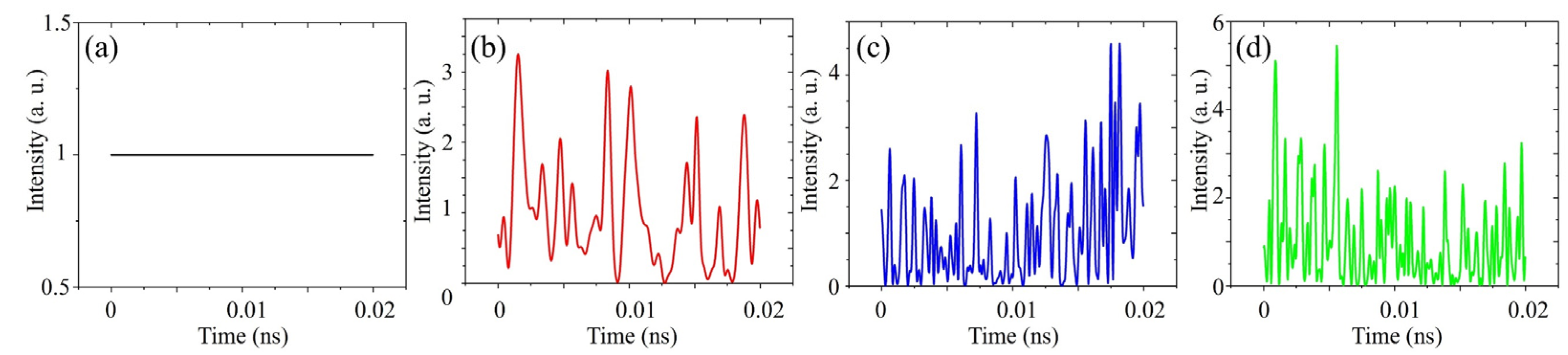

4.1. Temporal Spike Structure

4.2. Defect Precursor Information

4.3. Artificially Prepared Defect Precursor

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Clery, D. Explosion marks laser fusion breakthrough. Science 2022, 378, 1154–1155. [Google Scholar] [CrossRef] [PubMed]

- Tollefson, J.; Gibney, E. Nuclear-Fusion Lab Achieves ‘Ignition’: What Does It Mean? Nature 2022, 612, 597–598. [Google Scholar] [CrossRef] [PubMed]

- Manes, K.R.; Spaeth, M.L.; Adams, J.J.; Bowers, M.W.; Bude, J.D.; Carr, C.W.; Conder, A.D.; Cross, D.A.; Demos, S.G.; Di Nicola, J.M.G.; et al. Damage Mechanisms Avoided or Managed for NIF Large Optics. Fusion Sci. Technol. 2016, 1, 146–249. [Google Scholar] [CrossRef]

- Miquel, J.-L.; Lion, C.; Vivini, P. The laser mega-Joule: LMJ & PETAL status and program overview. J. Phys. Conf. Ser. 2016, 688, 012067. [Google Scholar]

- Zheng, W.; Wei, X.; Zhu, Q.; Jing, F.; Hu, D.; Yuan, X.; Dai, W.; Zhou, W.; Wang, F.; Xu, D.; et al. Laser performance upgrade for precise ICF experiment in SG-III laser facility. Matter Radiat. Extrem. 2017, 2, 243–255. [Google Scholar] [CrossRef]

- Aikens, D.M.; Bissinger, H.D. Overview of small optics for the National Ignition Facility. In Optical Manufacturing and Testing III; SPIE: Bellingham, WA, USA, 1999; Volume 3782, pp. 476–487. [Google Scholar]

- Camp, D.W.; Kozlowski, M.R.; Sheehan, L.M.; Nichols, M.A.; Dovik, M.; Raether, R.G.; Thomas, I.M. Subsurface damage and polishing compound affect the 355-nm laser damage threshold of fused silica surfaces. In Laser-Induced Damage in Optical Materials; SPIE: Bellingham, WA, USA, 1998; Volume 3244, pp. 356–364. [Google Scholar]

- Tesar, A.A.; Brown, N.J.; Taylor, J.R.; Stolz, C.J. Subsurface polishing damage of fused silica: Nature and effect on laser damage of coated surfaces. In Laser-Induced Damage in Optical Materials; SPIE: Bellingham, WA, USA, 1991; Volume 1441, pp. 154–172. [Google Scholar]

- Bude, J.; Miller, P.; Baxamusa, S.; Shen, N.; Laurence, T.; Steele, W.; Suratwala, T.; Wong, L.; Carr, W.; Cross, D.; et al. High fluence laser damage precursors and their mitigation in fused silica. Opt. Express 2014, 22, 5839–5851. [Google Scholar] [CrossRef]

- Bates, J.W.; Myatt, J.F.; Shaw, J.G.; Follett, R.K.; Weaver, J.L.; Lehmberg, R.H.; Obenschain, S.P. Mitigation of cross-beam energy transfer in inertial-confinement-fusion plasmas with enhanced laser bandwidth. Phys. Rev. E 2018, 97, 061202. [Google Scholar] [CrossRef]

- Cui, Y.; Gao, Y.; Rao, D.; Liu, D.; Li, F.; Ji, L.; Shi, H.; Liu, J.; Zhao, X.; Feng, W.; et al. High-energy low-temporal-coherence instantaneous broadband pulse system. Opt. Lett. 2019, 44, 2859. [Google Scholar] [CrossRef]

- Gao, Y.-Q.; Ji, L.; Zhao, X.; Cui, Y.; Rao, D.; Feng, W.; Xia, L.; Liu, D.; Wang, T.; Shi, H.; et al. High-power, low-coherence laser driver facility. Opt. Lett. 2020, 45, 6839–6842. [Google Scholar] [CrossRef]

- Ji, L.; Zhao, X.; Liu, D.; Gao, Y.; Cui, Y.; Rao, D.; Feng, W.; Li, F.; Shi, H.; Liu, J.; et al. High-efficiency second-harmonic generation of low-temporal-coherent light pulse. Opt. Lett. 2019, 44, 4359–4362. [Google Scholar] [CrossRef]

- Zhao, X.; Ji, L.; Liu, D.; Gao, Y.; Rao, D.; Cui, Y.; Feng, W.; Li, F.; Shi, H.; Shan, C.; et al. Second-harmonic generation of temporally low-coherence light. APL Photonics 2020, 5, 091301. [Google Scholar] [CrossRef]

- Dorrer, C.; Hill, E.M.; Zuegel, J.D. High-energy parametric amplification of spectrally incoherent broadband pulses. Opt. Express 2020, 28, 451–471. [Google Scholar] [CrossRef]

- Lei, A.; Kang, N.; Zhao, Y.; Liu, H.; An, H.; Xiong, J.; Wang, R.; Xie, Z.; Tu, Y.; Xu, G.; et al. Reduction of Backward Scatterings at the Low-Coherence Kunwu Laser Facility. Phy. Rev. Lett. 2024, 132, 035102. [Google Scholar] [CrossRef]

- Wang, P.P.; An, H.H.; Fang, Z.H.; Xiong, J.; Xie, Z.Y.; Wang, C.; He, Z.Y.; Jia, G.; Wang, R.R.; Zheng, S. Backward scattering of laser plasma interactions from hundreds-of-joules broadband laser on thick target. Matter Radiat. Extrem. 2024, 9, 015602. [Google Scholar] [CrossRef]

- Crisp, M.D.; Boling, N.L.; Dube, G. Importance of Fresnel reflections in laser surface damage of transparent dielectrics. Appl. Phys. Lett. 1972, 21, 364–366. [Google Scholar] [CrossRef]

- Laurence, T.A.; Bude, J.D.; Ly, S.; Shen, N.; Feit, M.D. Extracting the distribution of laser damage precursors on fused silica surfaces for 351 nm, 3 ns laser pulses at high fluences (20–150 J/cm2). Opt. Express 2012, 20, 11561–11573. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Liu, H.; Huang, J.; Ye, X.; Xia, H.; Li, Q.; Jiang, X.; Wu, W.; Yang, L.; Zheng, W. Reaction ion etching process for improving laser damage resistance of fused silica optical surface. Opt. Express 2016, 24, 199–211. [Google Scholar] [CrossRef] [PubMed]

- Lia, B.; Hou, C.; Tian, C.; Guo, J.; Xiang, X.; Jiang, X.; Wang, H.; Liao, W.; Yuan, X.; Jiang, X.; et al. Layer by layer exposure of subsurface defects and laser-induced damage mechanism of fused silica. Appl. Surf. Sci 2020, 508, 145186. [Google Scholar] [CrossRef]

- Carr, C.W.; Trenholme, J.B.; Spaeth, M.L. Effect of temporal pulse shape on optical damage. Appl. Phys. Lett. 2007, 90, 041110. [Google Scholar] [CrossRef]

- Palmier, S.; Gallais, L.; Commandre, M.; Cormont, P.; Courchinoux, R.; Lamaigne, L.; Rullier, J.L.; Legros, P. Optimization of a laser mitigation process in damaged fused silica. Appl. Surf. Sci. 2009, 255, 5532–5536. [Google Scholar] [CrossRef]

- Xu, Y.; Emmert, L.A.; Rudolph, W. Spatio-TEmporally REsolved Optical Laser Induced Damage (STEREO LID) technique for material characterization. Opt. Lett. 2015, 23, 21607–21614. [Google Scholar] [CrossRef]

- Miller, P.E.; Suratwala, T.I.; Bude, J.D.; Laurence, T.A.; Shen, N.; Steele, W.A.; Feit, M.D.; Menapace, J.A.; Wong, L.L. Laser damage precursors in fused silica. In Laser-Induced Damage in Optical Materials; SPIE: Bellingham, WA, USA, 2009; Volume 7504, pp. 318–331. [Google Scholar]

- Stuart, B.C.; Feit, M.D.; Rubenchik, A.M.; Shore, B.W.; Perry, M.D. Laser-induced damage in dielectrics with nanosecond to subpicosecond pulses. Phys. Rev. Lett. 1995, 74, 2248. [Google Scholar] [CrossRef] [PubMed]

- Stuart, B.C.; Feit, M.D.; Herman, S.; Rubenchik, A.M.; Shore, B.W.; Perry, M.D. Nanosecond-to-femtosecond laser-induced breakdown in dielectrics. Phys. Rev. B 1996, 53, 1749. [Google Scholar] [CrossRef] [PubMed]

- Smith, A.V.; Do, B.T. Bulk and surface laser damage of silica by picosecond and nanosecond pulses at 1064 nm. Appl. Opt. 2008, 47, 4812–4832. [Google Scholar] [CrossRef]

- Diaz, R.; Chambonneau, M.; Courchinoux, R.; Grua, P.; Luce, J.; Rullier, J.; Natoli, J.; Lamaignère, L. Influence of longitudinal mode beating on laser-induced damage in fused silica. Opt. Lett. 2014, 39, 674–677. [Google Scholar] [CrossRef] [PubMed]

- Diaz, R.; Chambonneau, M.; Grua, P.; Rullier, J.-L.; Natoli, J.-Y.; Lamaignèrea, L. Influence of vacuum on nanosecond laser-induced surface damage morphology in fused silica at 1064 nm. Appl. Surf. Sci. 2016, 362, 290–296. [Google Scholar] [CrossRef]

- Lamaignère, L.; Diaz, R.; Chambonneau, M.; Grua, P.; Natoli, J.-Y.; Rullier, J.-L. Correlation between laser-induced damage densities of fused silica and average incubation fluences at 1064 nm in the nanosecond regime. J. Appl. Phys. 2017, 121, 045306. [Google Scholar] [CrossRef]

- ISO 21254-1–21254-4; Lasers and Laser-Related Equipment—Test Methods for Laser-Induced Damage Threshold Part 4: Inspection, Detection and Measurement. International Organization for Standardization: Geneva, Switzerland, 2011.

- Mero, M.; Clapp, B.; Jasapara, J.; Rudolph, W.; Ristau, D.; Starke, K.; Krueger, J.; Martin, S.; Kautek, W. On the damage behavior of dielectric films when illuminated with multiple femtosecond laser pulses. Opt. Eng. 2005, 44, 051107. [Google Scholar] [CrossRef]

- Gao, E.; Xie, B.; Xu, Z. Two-dimensional silica: Structural, mechanical properties, and strain-induced band gap tuning. J. Appl. Phys. 2016, 119, 014301. [Google Scholar] [CrossRef]

- Natoli, J.Y.; Bertussi, B.; Commandre, M. Effect of multiple laser irradiations on silica at 1064 and 355 nm. Opt. Lett. 2005, 30, 1315–1317. [Google Scholar] [CrossRef]

- Nguyen, D.N.; Emmert, L.A.; Patel, D.; Menoni, C.S.; Rudolph, W. Transient phenomena in the dielectric breakdown of HfO2 optical films probed by ultrafast laser pulse pairs. Appl. Phys. Lett. 2010, 97, 191909. [Google Scholar] [CrossRef]

- Chmel, A.E. Fatigue laser-induced damage in transparent materials. Mat. Sci. Eng. B 1997, 49, 175–190. [Google Scholar] [CrossRef]

- Saito, K.; Ikushima, J. Absorption edge in silica glass. Phys. Rev. B 2000, 62, 8584–8587. [Google Scholar] [CrossRef]

- Laurence, T.A.; Bude, J.D.; Shen, N.; Feldman, T.; Miller, P.E.; Steele, W.A.; Suratwala, T. Metallic-like photoluminescence and absorption in fused silica surface flaws. Appl. Phys. Lett. 2009, 94, 151114. [Google Scholar] [CrossRef]

- Fournier, J.; Néauport, J.; Grua, P.; Fargin, E.; Jubera, V.; Talaga, D.; Jouannigot, S. Green luminescence in silica glass: A possible indicator of subsurface fracture. Appl. Phys. Lett. 2012, 100, 114103. [Google Scholar] [CrossRef]

- Natoli, J.Y.; Gallais, L.; Akhouayri, H.; Amra, C. Laser-induced damage of materials in bulk, thin-film, and liquid forms. Appl. Optic. 2002, 41, 3156–3166. [Google Scholar] [CrossRef] [PubMed]

- Krol, H.; Gallais, L.; Grezes-Besset, C.; Natoli, J.Y.; Commandre, M. Investigation of nanoprecursors threshold distribution in laser-damage testing. Opt. Commun. 2005, 256, 184–189. [Google Scholar] [CrossRef]

- Bataviciute, G.; Grigas, P.; Smalakys, L.; Melninkaitis, A. Revision of laser-induced damage threshold evaluation from damage probability data. Rev. Sci. Instrum. 2013, 84, 045108. [Google Scholar] [CrossRef]

- Liao, Z.M.; Roussell, R.; Adams, J.J.; Runkel, M.; Frenk, W.T.; Luken, J.; Carr, C.W. Defect population variability in deuterated potassium di-hydrogen phosphate crystals. Opt. Mater. Express 2012, 2, 1612–1623. [Google Scholar] [CrossRef]

- Makarov, S.V.; Tsypkin, A.N.; Voytova, T.A.; Milichko, V.A.; Mukhin, I.S.; Yulin, A.V.; Putilin, S.E.; Baranov, M.A.; Krasnok, A.E.; Morozov, I.A.; et al. Self-adjusted all-dielectric metasurfaces for deep ultraviolet femtosecond pulse generation. Nanoscale 2016, 8, 17809–17814. [Google Scholar] [CrossRef]

- Shcherbakov, M.R.; Liu, S.; Zubyuk, V.V.; Vaskin, A.; Vabishchevich, P.P.; Keeler, G.; Pertsch, T.; Dolgova, T.V.; Staude, I.; Brener, I.; et al. Ultrafast all-optical tuning of direct-gap semiconductor metasurfaces. Nat. Commun. 2017, 8, 17. [Google Scholar] [CrossRef] [PubMed]

| SLM (J/cm2) | LTCL-3 nm (J/cm2) | LTCL-8 nm (J/cm2) | LTCL-3 nm (J/cm2) | |

|---|---|---|---|---|

| LIDT | 59.93 | 53.61 | 32.83 | 21.79 |

| Sequence | (mm−3) | (J/cm2) | (J/cm2) |

|---|---|---|---|

| Narrow band | 46.26 | 74.58 | 14.99 |

| SLD (3 nm) | 57.06 | 71.36 | 17.96 |

| SLD (8 nm)-a | 2.97 | 28.10 | 1.61 |

| SLD (8 nm)-b | 62.59 | 52.30 | 5.88 |

| SLD (13 nm)-a | 4.49 | 21.19 | 1.68 |

| SLD (13 nm)-b | 89.80 | 50.24 | 6.48 |

| SLM (J/cm2) | LTCL-3 nm (J/cm2) | LTCL-8 nm (J/cm2) | LTCL-13 nm (J/cm2) | |

|---|---|---|---|---|

| LIDT | 4.07 | 3.28 | 2.63 | 1.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, C.; Han, P.; Wang, E.; Li, F.; Zhao, X.; Kou, H.; Jiang, D.; Wu, Q.; Peng, X.; Xu, P.; et al. Characteristics of Fused Silica Exit Surface Damage by Low-Temporal Coherence Light Irradiation. Photonics 2025, 12, 432. https://doi.org/10.3390/photonics12050432

Shan C, Han P, Wang E, Li F, Zhao X, Kou H, Jiang D, Wu Q, Peng X, Xu P, et al. Characteristics of Fused Silica Exit Surface Damage by Low-Temporal Coherence Light Irradiation. Photonics. 2025; 12(5):432. https://doi.org/10.3390/photonics12050432

Chicago/Turabian StyleShan, Chong, Ping Han, Erxi Wang, Fujian Li, Xiaohui Zhao, Huamin Kou, Dapeng Jiang, Qinghui Wu, Xing Peng, Penghao Xu, and et al. 2025. "Characteristics of Fused Silica Exit Surface Damage by Low-Temporal Coherence Light Irradiation" Photonics 12, no. 5: 432. https://doi.org/10.3390/photonics12050432

APA StyleShan, C., Han, P., Wang, E., Li, F., Zhao, X., Kou, H., Jiang, D., Wu, Q., Peng, X., Xu, P., Lian, Y., Zhao, Y., Su, L., Sui, Z., & Gao, Y. (2025). Characteristics of Fused Silica Exit Surface Damage by Low-Temporal Coherence Light Irradiation. Photonics, 12(5), 432. https://doi.org/10.3390/photonics12050432