Abstract

Although lasers are widely used in various industries, including aviation, healthcare, and communication engineering, there has been little research concentrated on the field of horticulture. In this paper, five semiconductor pumped fiber-coupled lasers emitting laser pulses of different wavelengths (450 nm, 532 nm, 808 nm, 915 nm, and 1064 nm) were used in the experimental drilling and cutting of hedge branches. A drilling effect on the hedge branches as a function of the laser power density, incident angle, and defocus condition was demonstrated, and it was found that a laser with a central wavelength of 450 nm had the lowest drilling power density and the shortest drilling-through time. It also enables the maximum tolerance of changes to the incident angle. The reason is closely related to the different absorption coefficients of lasers of various wavelengths on the hedge branches. In the cutting experiment, a laser at a wavelength of 450 nm was used, and the scanning speed of the laser was optimized. Good cutting effects were found at laser scanning speeds ranging from 18 mm/s to 23 mm/s. The layer of carbide formed by cutting the hedge branches can effectively block the invasion of bacteria, which is the advantage of using laser cutting in the field of horticulture.

1. Introduction

Since their advent, lasers have attracted attention for their unique operating principles. Laser-manufacturing technology is widely used in various fields, including in industrial production and the medical, aerospace, military, and archeological fields, and so on [1,2,3,4,5,6]. Among these applications, cutting wood materials was one of the earliest uses [7]. The primary effect of lasers on organic plant tissues is thermal, where biological tissues absorb the laser’s energy and convert it into heat, leading to processes such as vaporization and carbonization [8].

Malachowski [9] explored the CO2 laser (10.6 μm) cutting of green branches for possible laser tree pruning applications (1984). These results confirm the feasibility of cutting green branches with a CO2 laser. After this, many scholars used CO2 lasers to carry out relevant experimental research on cutting wood. The effects of beam power and feed rate on the water contact angle of the cutting surface of fresh wood with a CO2 laser (2000 nm) were studied by Adam Maciak et al. [10]. The surface irregularity of a cross-section of wood after CO2 laser cutting was studied by Lukas Adamcik et al. [11]. The results were that surface irregularity increased with an increase in laser power and decrease in feed rate.

In 2007, Juan Carlos Hernandez conducted experiments on the laser-cutting performance of wood using a high-power ytterbium (Yb) fiber laser (1070–1080 nm) and confirmed the feasibility of cutting dried wood with this type of laser [12]. In the following years, he further investigated the influence of laser power, focusing on the plane position, transverse speed, and cutting direction, as well as the wood’s shape and moisture content, on the cutting results. A comparison showed that the results of cutting wood with an ytterbium fiber laser were more precise than those obtained with a CO2 laser (10.6 μm). From an energy perspective, the ytterbium fiber laser consumed less electrical energy, on average, than the CO2 laser [13,14,15].

Satoshi Fukuta discovered that the laser-machining of wood has traditionally used pulse durations longer than one millisecond and long-wavelength CO2 lasers. For the first time, he tested wood drilling and laser cutting using short-pulse ultraviolet lasers (349 and 355 nm) [16]. The results confirm the feasibility and superiority of UV laser technology for wood drilling and cutting processes. He analyzed that the difference in processing performance between different wavelengths was due to the different light absorption rates of wood [7,17,18]. In the same year, he carried out extended experiments. In this study, we used lasers (266, 355, 532, and 1064 nm) to perform wood cutting and investigated wavelength dependence, as well as post-processing appearance, in relation to machining performance [19]. That is, we tested the optimal wavelength for the machining of wood. The optimal wavelength for machining wood is 355 nm of UV light.

In 2020, Monika Aniszewska [10] used a fiber laser (800 nm) and a CO2 laser (2000 nm) to cut fresh branches of wood at different laser powers and beam speeds. The cell structure of the cutting surfaces was examined, and it was found that some of the surfaces were covered with a layer of charred cells. Cutting branches in nurseries, plantation, and orchards with a laser beam could prevent wound invasion caused by pathogens. Azaman also mentioned this view in [7,20]. These studies provide ideas for the application of lasers in agriculture and horticulture.

With improvements in agricultural modernization and environmental awareness, laser-weeding technology has great potential as an innovative solution [21]. In 1991, Heisel et al. used a CO2 laser to cut weeds, indicating that the use of lasers could effectively inhibit the regrowth of weeds and even have a fatal effect on weeds without causing any pollution. They compared the ability of UV (355 nm), IR (1064 nm), and CO2 (10.6 μm) lasers to cut weeds [22]. Their investigation indicated that all laser types were able to cut weed stems with doses above 6 J/mm. They found that the CO2 laser was most easily absorbed by the weeds. Later scholars found that the efficiency of laser weeding was related to the wavelength, exposure time, spot size, and laser power. The weed species also has a great influence on the efficiency of laser weeding [17,23].

Given the numerous applications of laser technology in cutting wood and in weeding, it is evident that the application of laser technology in horticulture and agriculture holds significant development potential. Recently, there have been some studies conducted in this direction. Cutting tomato peduncles with a 30 W fiber-coupled semiconductor laser (980 nm) was first verified by the tests and calculations of Liu J. Z. et al. (2011) [24]. A. Carlos O. Ferraz explored a method of laser cutting on tissue-cultured potato seedlings [25]. The laser-cutting technology achieved non-contact cuttings of potato tissue-cultured seedlings, thereby reducing the probability of virus transmission among the seedlings. Later, Xu Tao validated this experiment [26].

In this experiment, we used hedge branches as samples, a common plant in urban landscapes. Considering that CO2 lasers are relatively large and heavy [27], making them less portable and difficult to integrate, a fiber laser will be utilized in this study. Fiber lasers offer high efficiency, compact size, excellent beam quality, and low maintenance costs [28,29]. Since plants exhibit different absorption coefficients for lasers [19,30] at different wavelengths, comparative experiments will be conducted at different wavelengths—450 nm, 532 nm, 808 nm, 915 nm, and 1064 nm. This study will focus on analyzing the effects of wavelength, energy density, defocus distance, incident angle, and cutting speed on hedges.

2. Materials and Methods

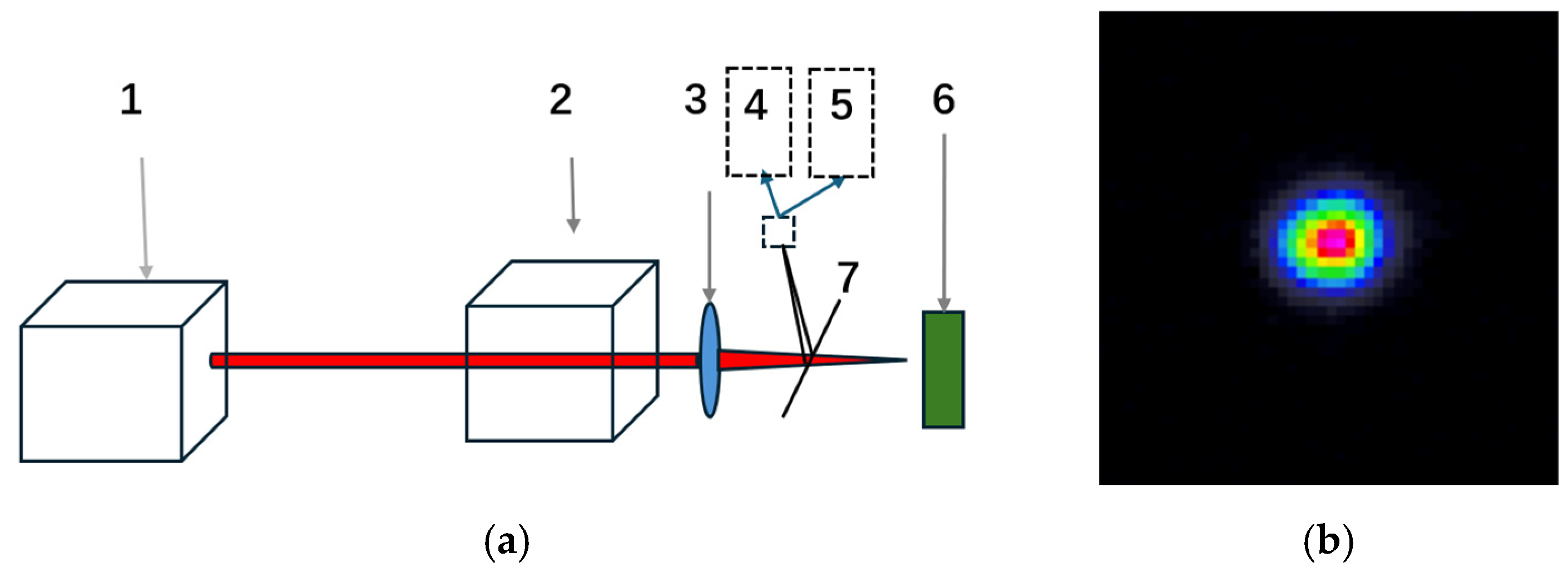

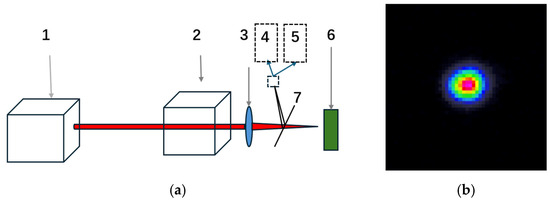

The experimental setup is shown in Figure 1, which consists of laser sources, a two-dimensional scanning galvanometer, a focusing lens, and a rotating table mounted on a three-dimensional translation platform. The laser sources used in the experiments are fiber-coupled diode lasers, emitting laser pulses with central wavelengths of 450 nm, 532 nm, 808 nm, 915 nm, and 1064 nm, respectively. A beam sampler (7) is added to the laser optical path diagram, so that a sampled beam can be measured by a CCD (4) and a laser power meter (5). In the experiment, the position of the CCD is aligned with the position of the laser focal plane, and the size of the focused spot can be accurately measured. Meanwhile, the laser power can be calibrated, measured, and monitored in real time. The diameters of the focal spots for the above-mentioned laser sources after passing through the lens are 0.838 mm, 0.322 mm, 1.833 mm, 0.962 mm, and 1.840 mm, respectively. Figure 1 shows the focal spot of the 1064 nm laser beam measured by a CCD (Cam-HR) from COHERENT (Saxonburg, PA, USA). Detailed parameters of the interacting laser pulses on hedge branches are listed in Table 1.

Figure 1.

(a) Experimental setup: (1) fiber-coupled diode lasers, (2) scanning galvanometer, (3) focusing lens, (4) CCD camera, (5) power meter, (6) sample and platform, and (7) light-splitting sampling glass. (b) Focal spot of 1064 nm laser beams.

Table 1.

Parameters of the laser pulses.

The scanning galvanometer can accurately control the parameters, including the deflection, direction, and action time. The hurrySCAN20 galvanometer, the German company SCANLAB (Puchheim, Germany), is used in the experiment. The response time is extremely fast, and the maximum scanning speed is 8000 mm/s. The typical scanning angle of the X and Y axes ranges from −0.35 rad to 0.35 rad. The dynamic tracking error ranges from 0.11 to 0.14 ms. The focusing lens is an F-THETA flat-field scanning lens with a focal length of 163 mm, a scanning range of 112 mm × 112 mm, and an incident pupil diameter of about 10 mm. This lens is manufactured by Wavelength OE, a company located in Nanjing, China.

The Axio CSM700 laser confocal microscope, manufactured by Carl Zeiss AG (Oberkochen, Germany), is used to observe the surface morphology of the sample before and after laser treatment. It allows the clear observation of the sample’s microstructure and the precise measurement of the relevant dimensions. The ZWSP-2KCH industrial camera is manufactured by ZW Technology, Shenzhen, China. This camera features 2 million effective pixels, a resolution of 1920 × 1080, and a pixel size of 3.75 μm × 3.75 μm. A vernier caliper is also used in the experiment.

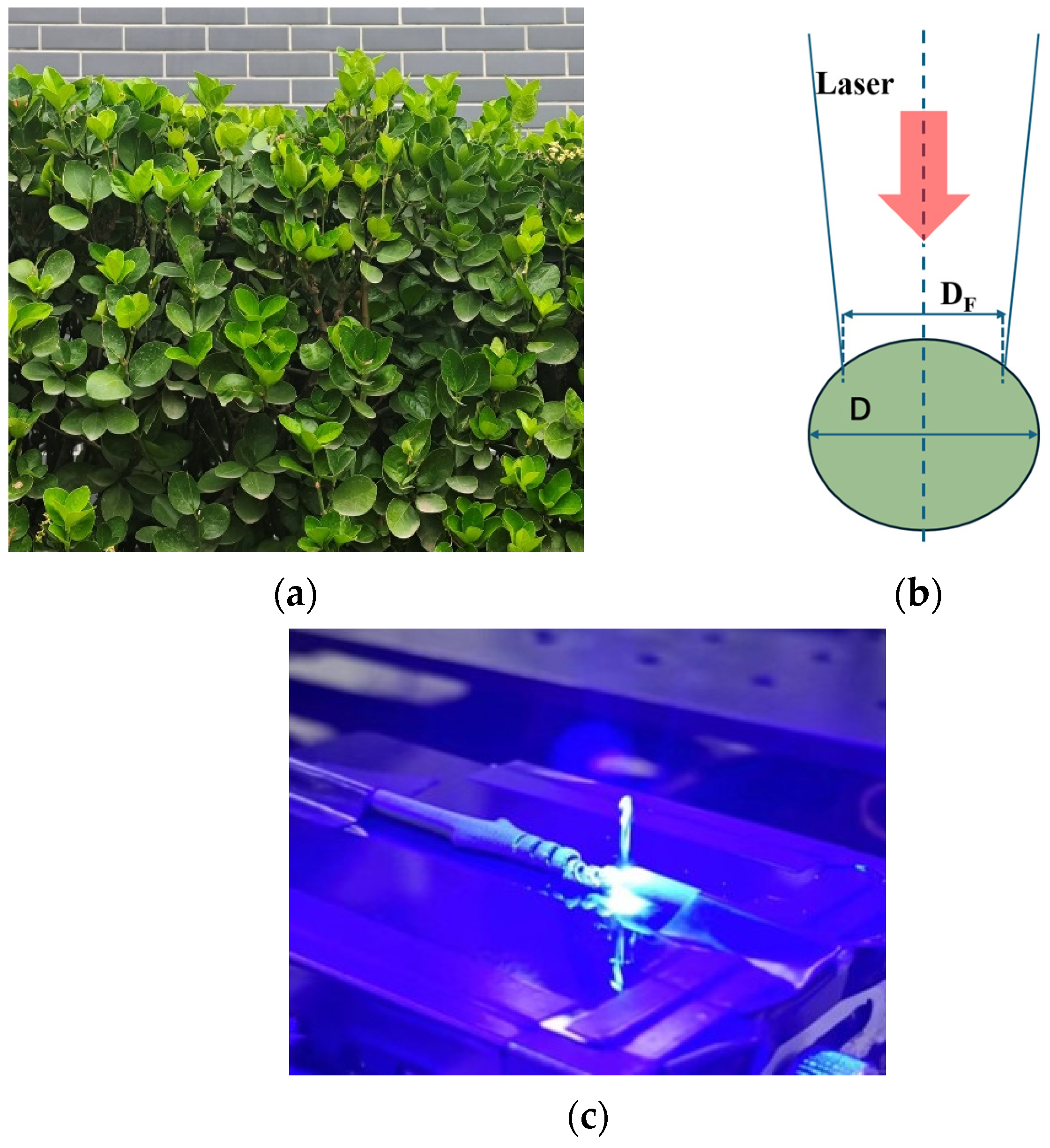

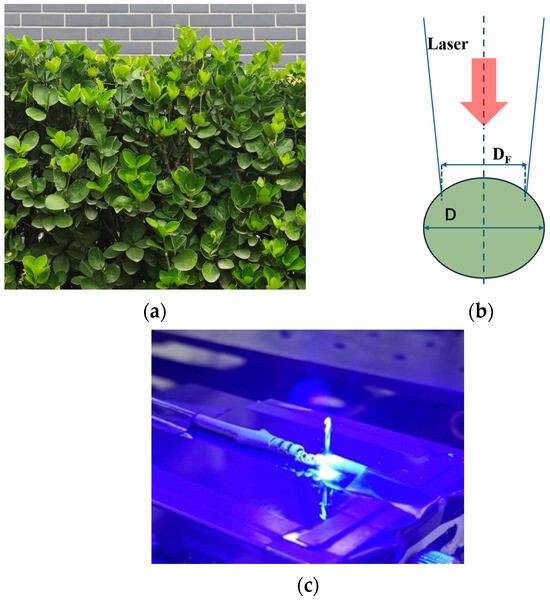

As shown in Figure 2a, the samples used in this experiment are from hedge branches (Magnoliopsida) collected from April to June. Hedge branches with a diameter of approximately 3–5 mm and a length of 8 cm, measured by a vernier caliper, are selected to ensure the consistency of the experimental samples. The samples are freshly cut from the living hedges about 0.5 h before the experiments. They are then fixed on a three-dimensional translation platform and a rotating table. The focusing lens is aligned to remain parallel to the rotating table.

Figure 2.

(a) field-grown hedge branches as the samples; (b) Laser beam drilling through the samples; (c) Laser cutting of the samples.

In the laser drilling experiment, laser pulses are incident perpendicularly on the surface of hedge branches, as shown in Figure 2b. The drilling time is defined as the period during which the laser pulses ablate the surface until they exit the other end of the hedge branches. The drilling time is measured simultaneously by using the control computer of the scanning galvanometer, which provides the electronic timing, while a stopwatch is used for manual timing. The drilling time is recorded in the experiment as a function of the laser power density, central wavelength, interacting beam diameters, and angle of incidence to determine the suitable wavelength for the laser treatment of hedge branches. The ablated area is also photographed using a CCD camera (ZWSP-2KCH) and subsequently analyzed.

As shown in Figure 2c, the laser pulses are directed by a scanning galvanometer to scan along the hedge branches for cutting experiments. The effect of the cutting speed, laser energy density, and laser defocusing conditions on the laser cutting of the hedge branches are investigated. The cross-section of the cut stem is examined using a confocal microscope (ZEISS AXIO CSM 700) to analyze the morphology changes after the cutting experiments.

3. Results and Discussion

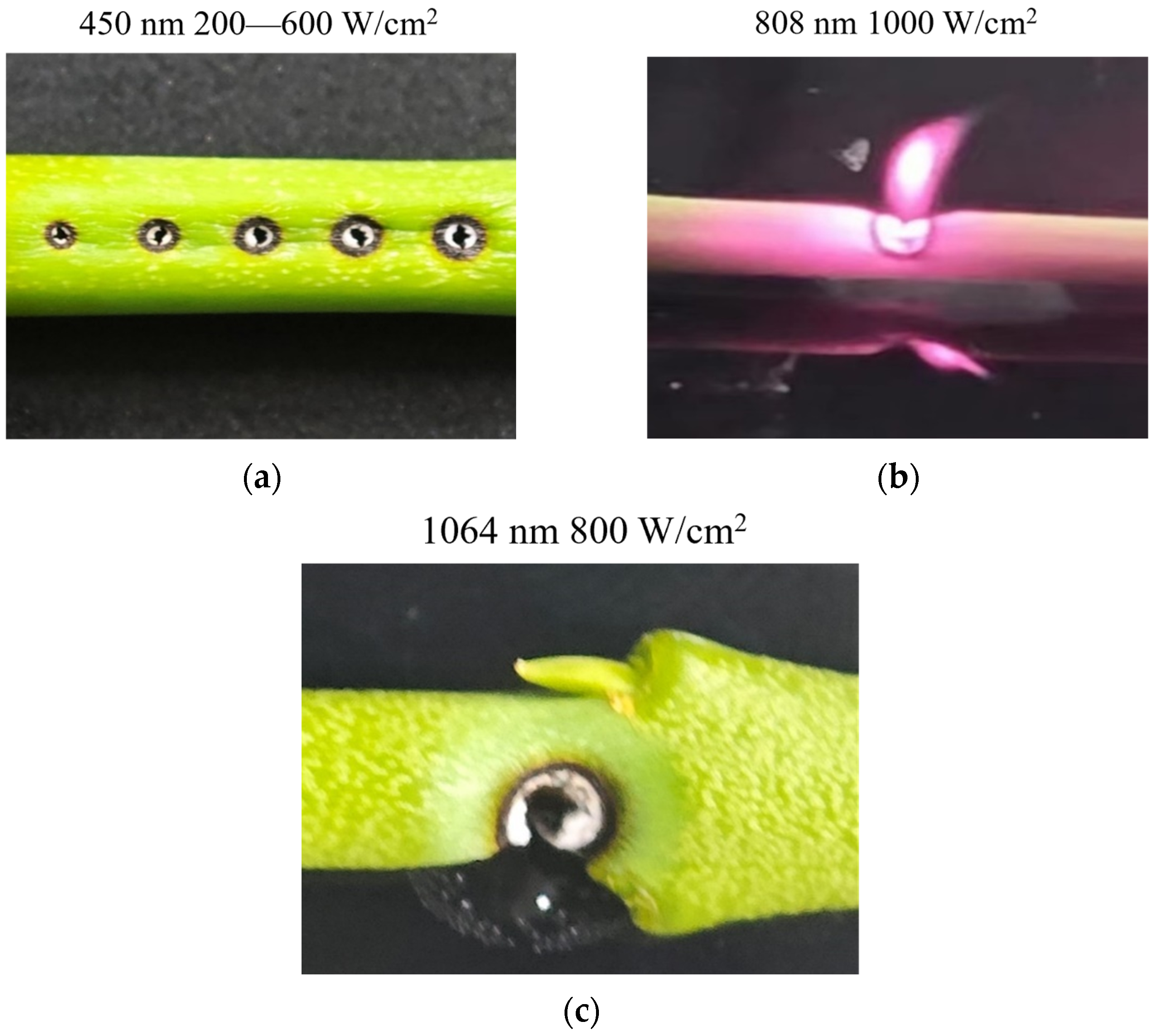

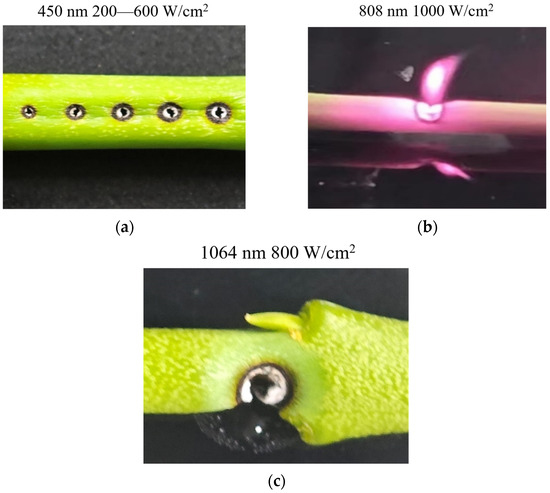

During the interaction between the laser and the hedges, the ablation aperture increases with higher energy. This process is accompanied by the presence of flames and smoke and the evaporation of water droplets. For example, during the ablating of the hedge with a 450 nm laser, as the energy density increases from 200 W/cm2 to 600 W/cm2, the diameter of the ablation hole gradually enlarges, as shown in Figure 3a. Figure 3b depicts the irradiation of hedges with an 808 nm laser at a power density of 1000 W/cm2, causing the hedges to ignite. We observe water on the experimental platform beneath the branches, as shown in Figure 3c. This can be attributed to the strong absorption of laser energy by water molecules within the plant tissue, which leads to intense heating and the explosive boiling of the stem tissue.

Figure 3.

(a) The ablation aperture increases with the rise in energy; (b) drilling with flames and dust; (c) liquid appears on the experimental platform.

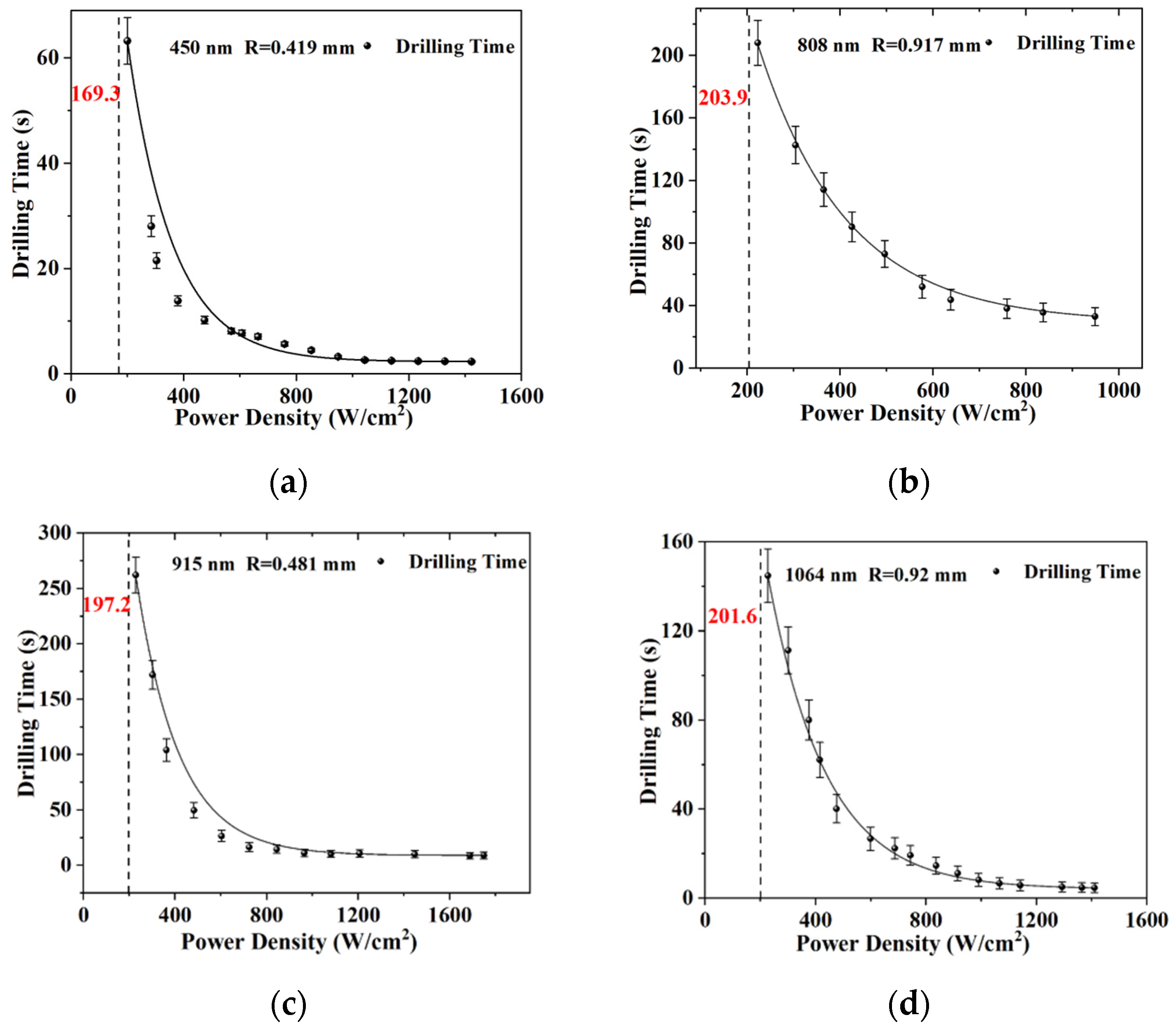

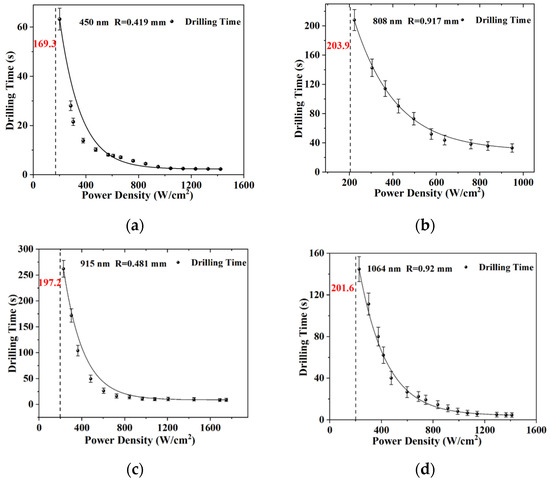

Figure 4 illustrates the correlation between the drilling time and laser power density using laser pulses with different wavelengths. When the laser power density increases, the drilling time decreases. Once the laser power density exceeds 600 W/cm2, the reduction in drilling time becomes less pronounced. The 532 nm laser is unable to effectively penetrate the branches.

Figure 4.

Variation in drilling phenomenon as a function of laser power density: (a) 450 nm, (b) 808 nm, (c) 915 nm, and (d) 1064 nm.

The ablation thresholds for lasers with wavelengths of 450 nm, 808 nm, 915 nm, and 1064 nm are 163.9 W/cm2, 203.9 W/cm2, 197.2 W/cm2, and 201.6 W/cm2, respectively. The 450 nm wavelength laser has the lowest ablation threshold. When the laser power density is the same, the drilling time for different wavelengths follows the order T450 < T1064 < T808 < T915. The difference in drilling time is mainly reflected in the process of drilling the surface of the green hedge branches (Ts); for example, Ts450 = 5.06 s, Ts808 = 45.17 s, Ts915 = 10.08 s, and Ts1064 = 16.23 s. The time it takes for the lasers to drill the surface of the hedge branches and reach the other side is almost the same, ranging from 2 to 3 s. This phenomenon is due to the varying absorption of different wavelengths of laser by hedges. This view is also mentioned by Satoshi Fukuta in [16,19] and Yu-Pin Lan in [17].

For the five lasers used, the laser absorption rate is inversely proportional to the drilling time, meaning that the higher the absorption rate, the less time is required for drilling. The absorption rate of 450 nm laser pulses is about 85%; therefore, the efficiency of laser energy conversion is the highest and the drilling time is the shortest, which is in good agreement with the experimental results. However, laser pulses with a wavelength of 532 nm are at a reflection peak and little laser energy has been absorbed by the hedges. The hedges can not be drilled using 532 nm laser pulses in the experiments. Experimental results from the utilization of 532 nm laser pulses are excluded from the following comparison.

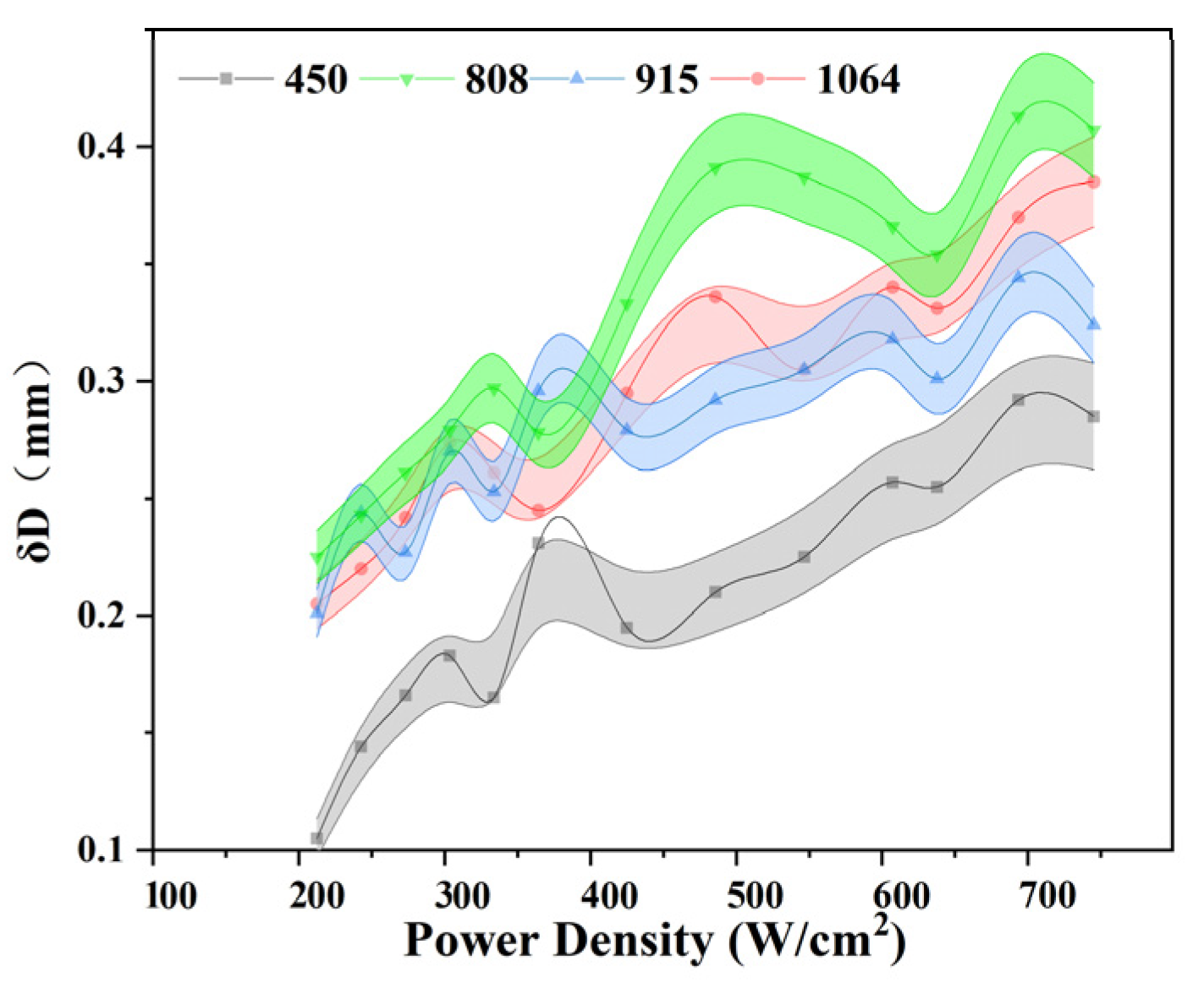

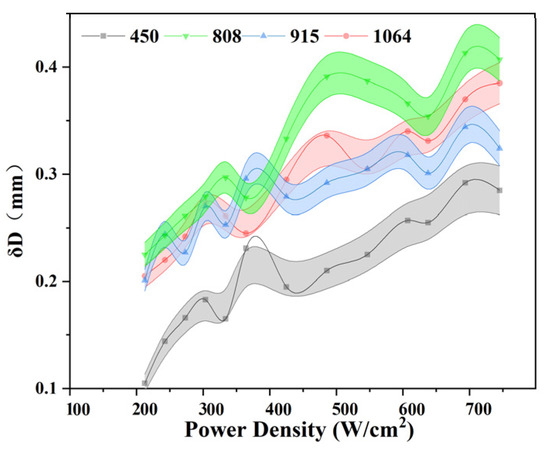

The difference (δD) between the diameter of the drilling hole and the laser focus as a function of the laser power density is shown in Figure 5. δD is the difference between the diameter of the drilling hole and the laser spot, which is affected by the laser power density and sample material used in the experiment. Its formula is δD = D (drilling hole diameter)-D (laser focus diameter). With the increase in laser power density, δD increases. When the energy is the same, δD produced by 808 nm laser pulses is the largest and that of 450 nm laser pulses is the smallest. δD can be considered an indication of the efficiency of the sample in utilizing the laser energy. A larger δD suggests a more extensive thermal diffusion. The laser with a wavelength of 450 nm demonstrate superior performance compared to others. This is because they produce the smallest δD, implying a more focused and efficient conversion of laser energy into the cutting process, thereby resulting in minimum energy wastage.

Figure 5.

The diameters of the ablated holes versus laser power density.

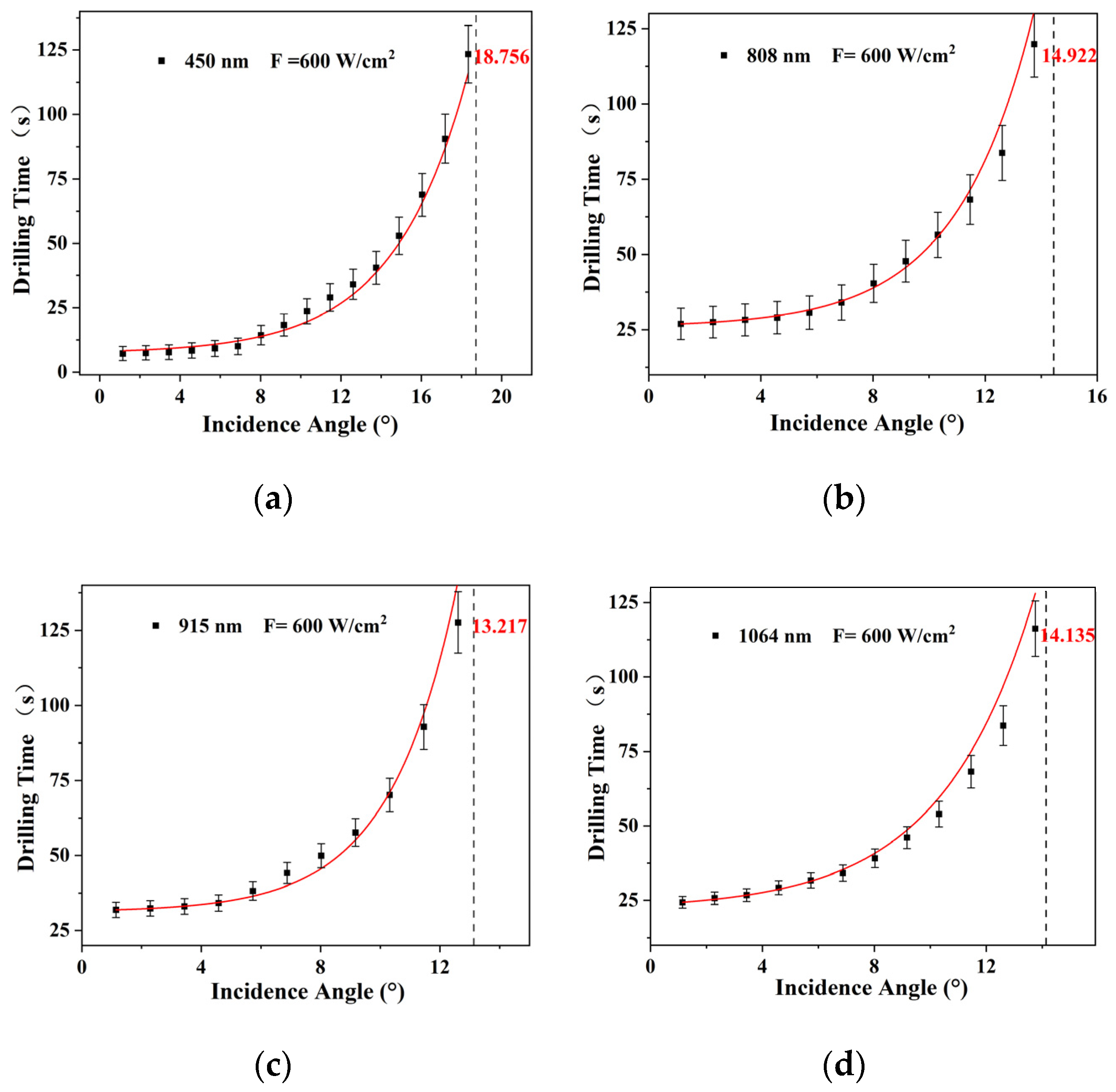

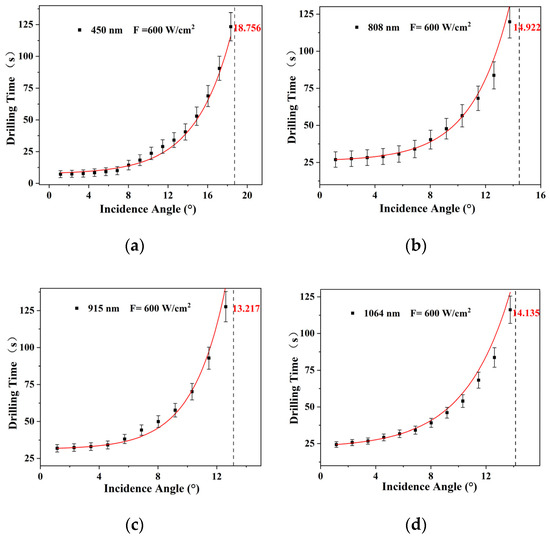

In practical applications of the laser treatment of hedge branches, it is almost impossible to achieve an ideal perpendicular condition due to the limited space among the branches. Therefore, it is crucial to study the influence of incident angles on the drilling experiments. Figure 6 shows the relationship between the drilling time and the angle of laser incidence at a power density of 600 W/cm2.

Figure 6.

The relationship between the drilling-through time and the laser incidence angle: (a) 450 nm, (b) 808 nm, (c) 915 nm, and (d) 1064 nm.

It is obvious that the shortest drilling time is achieved when the laser beam is incident perpendicularly on the branch for all the wavelengths used. As the angle of incidence increases, the drilling time is significantly prolonged. The change in drilling time is within 2.36% as the incident angle changes from 0° to 6°. However, as the incidence angle increases to more than 6°, the drilling time increases markedly, and eventually, it fails to drill through the hedges. The maximum incident angles allowed by the four wavelengths are 18.756°, 14.922°, 13.217°, and 14.135°, respectively.

This is because a decrease in laser power density at the interaction zone occurs with the increase in the incident angle, leading to the prolongation of drilling time. This general rule is consistent with the results reported by Liu [24]. Furthermore, it has been found that with the same laser interaction parameters, the laser with a wavelength of 450 nm tolerates the maximum incident angle, at about 18.76°, which is significantly higher than those of laser with other wavelengths.

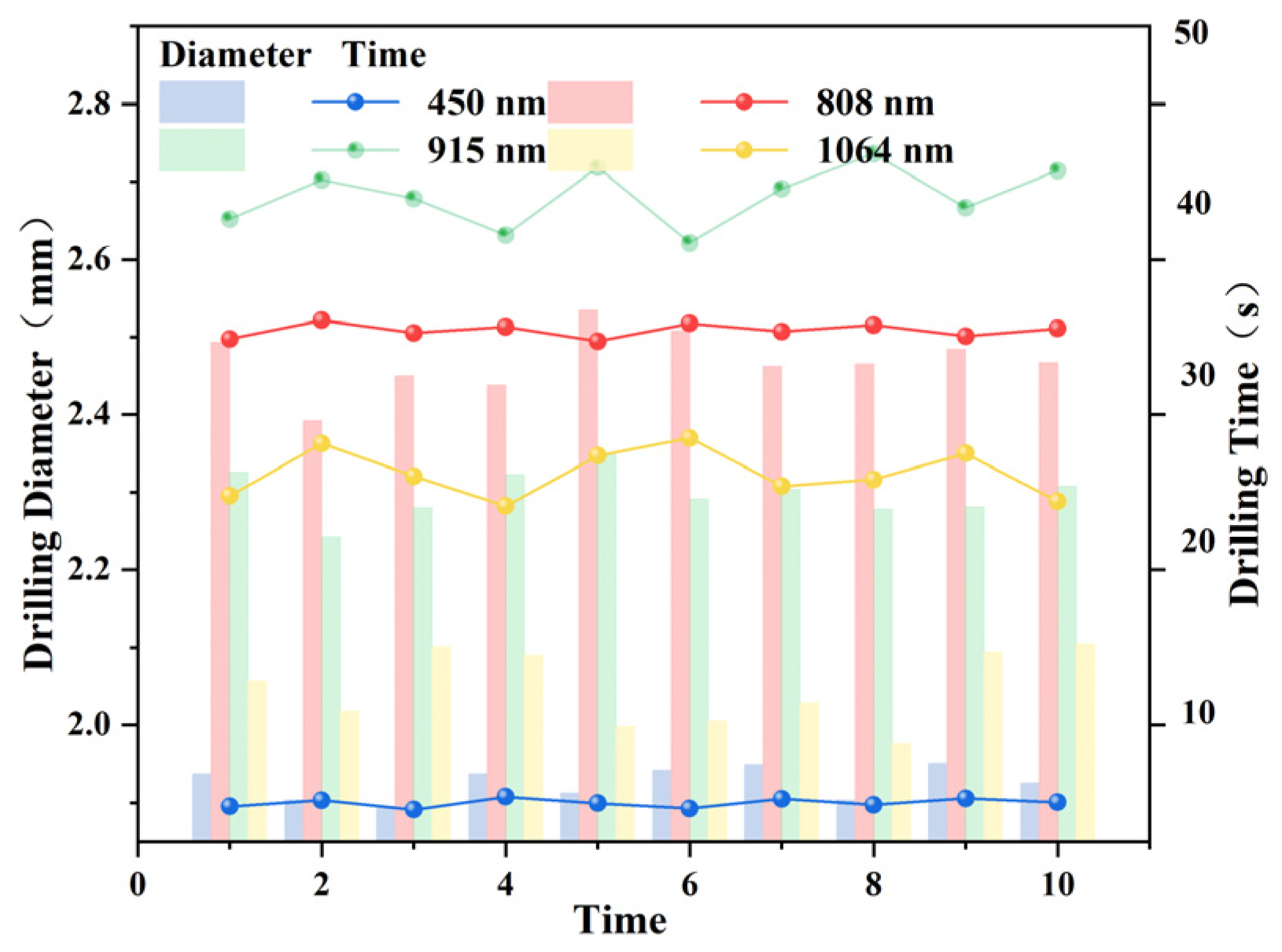

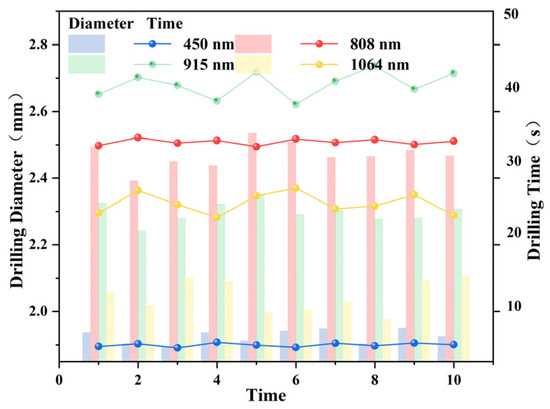

To minimize the impact of varying spot diameters and laser power on the experimental results, these factors are standardized. A laser spot diameter of 1.83 mm is selected. This ensures a more even distribution of the laser across the branch surface, allowing for the efficient use of the laser energy while minimizing the effects of local power density fluctuations. Furthermore, the spot size is optimally chosen to prevent excessive energy dispersion. Due to the output of the four lasers, a laser power density of 600 W/cm2 is set. As shown in Figure 7, the results are consistent with previous findings. The drilling time with 450 nm laser pulses is the shortest, at 5.23 s, while the diameter of the hole is also the smallest, measuring 1.942 mm. The drilling times for 808 nm, 915 nm, and 1064 nm lasers all exceed 30 s. The 450 nm laser shows an advantage in drilling efficiency, demonstrating its potential applications for cutting precision and efficiency.

Figure 7.

Comparison of the drilling diameters and time with laser pulses of different wavelengths using laser power density of 600 W/cm2.

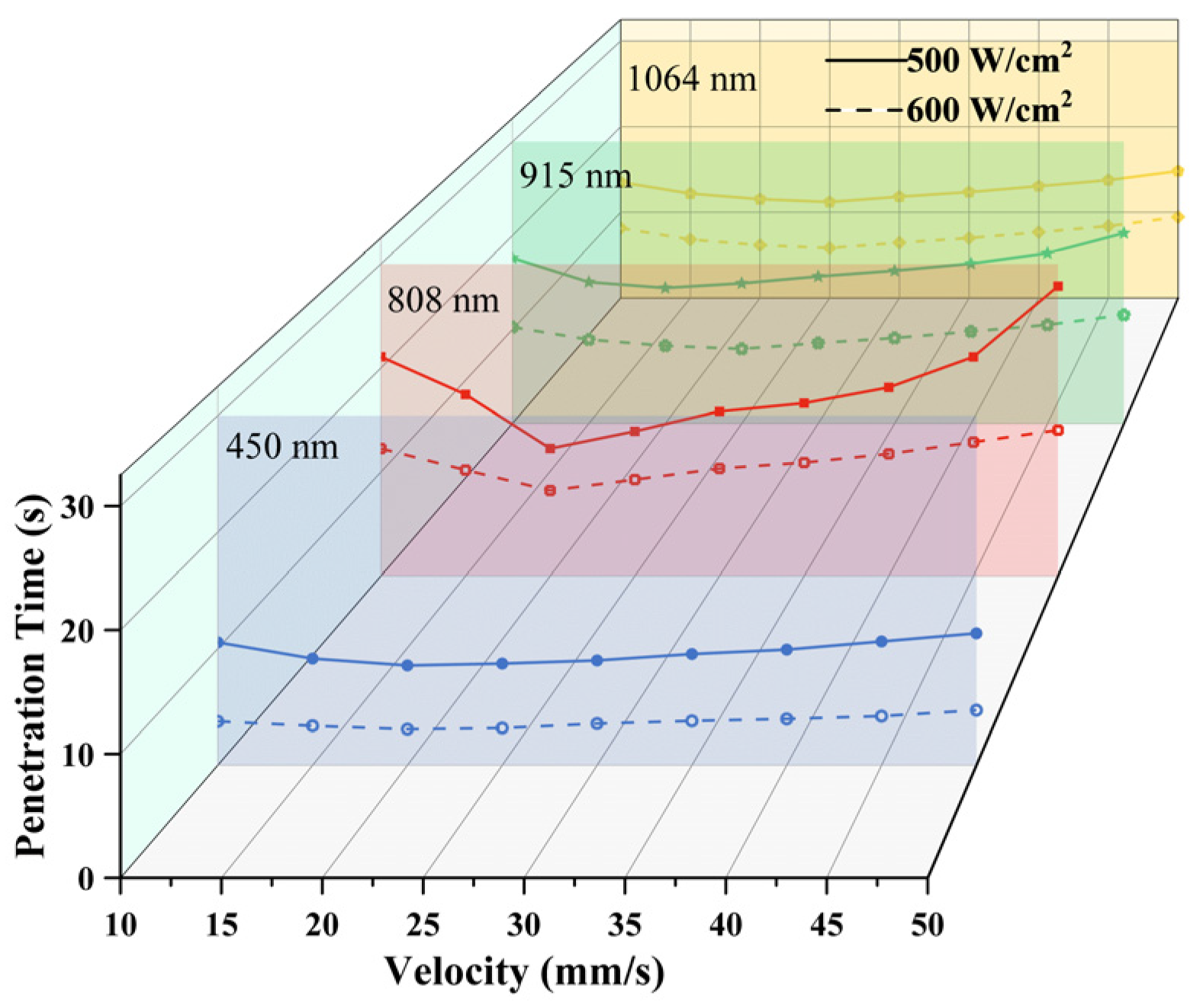

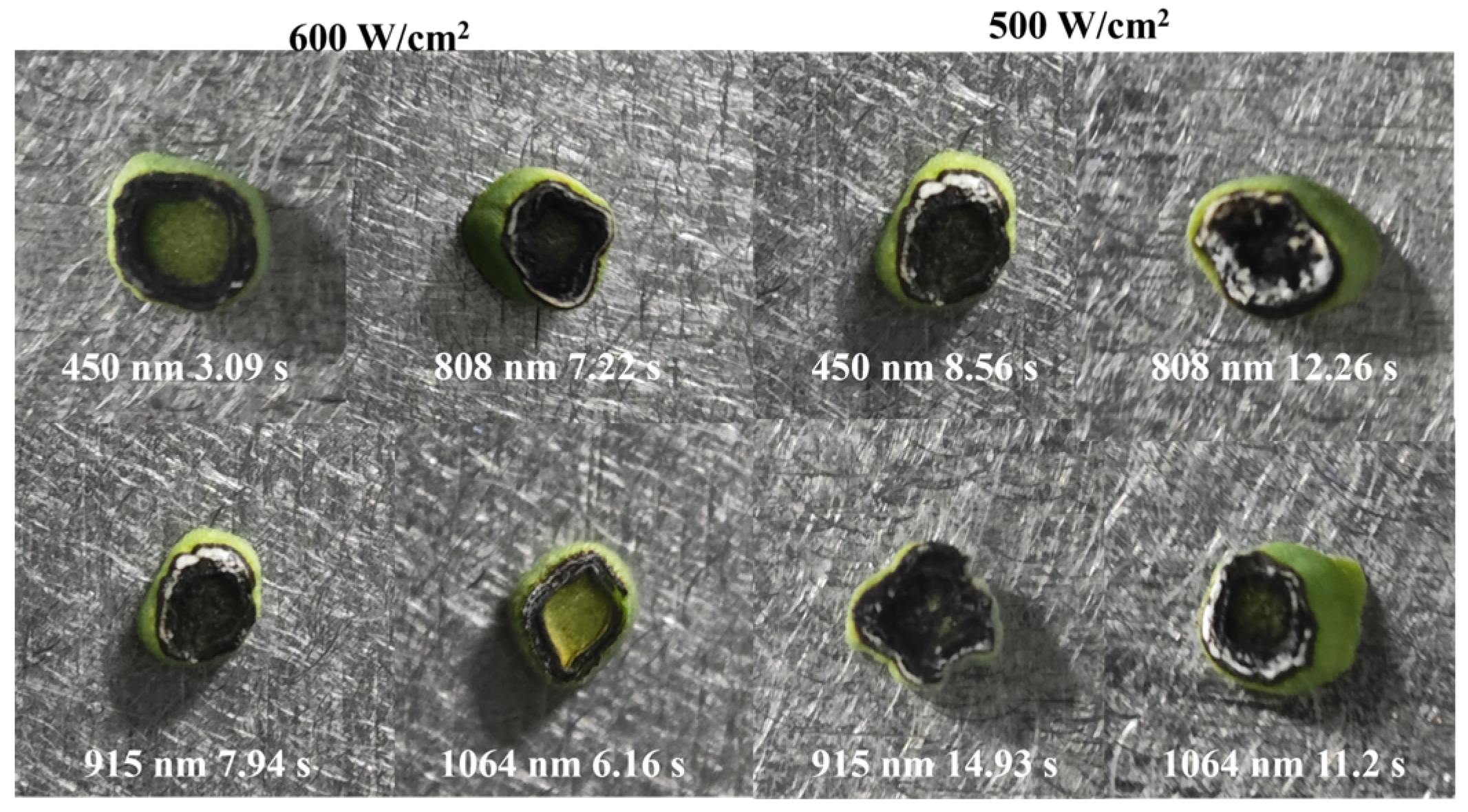

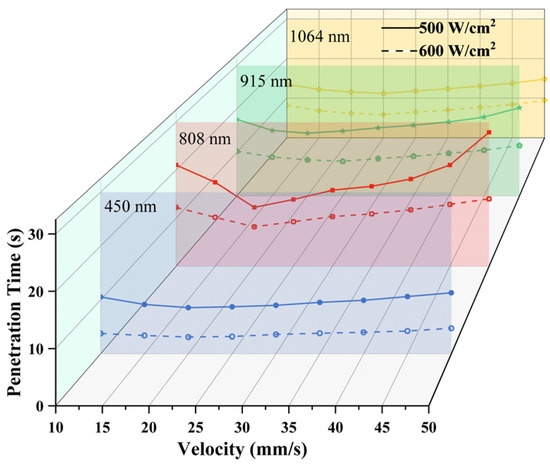

Following the laser drilling experiments on hedge branches, we found that laser pulses with a wavelength of 450 nm achieve faster and more efficient drilling. It is expected that laser pulses with this wavelength also yield the best cutting results. This hypothesis is supported by the laser cutting experiment regarding hedge branches with four different laser wavelengths, as shown in Figure 8. Under two power densities, the time consumed by the 450 nm laser cutting process is significantly the shortest.

Figure 8.

Laser cutting experiments with laser power densities of 500 W/cm2 and 600 W/cm2.

In the cutting experiment, it was observed that the cutting time is longer than the drilling time under the same conditions. There is a mathematical relationship between the cutting time, the drilling time, the cutting speed, and the cutting distance. The drilling experiment can be considered a special case of cutting, where the cutting speed is 0. The cutting time is determined by the cutting speed and laser power. The cutting time first decreases and then increases as the speed increases, and the cutting time is the shortest when the speed is around 20 mm/s. The laser operating at a wavelength of 450 nm proved to be the most efficient in cutting experiments. Our findings are consistent with those of Lan, Y [17]. In her research, she found that plants had the highest absorption of 455 nm light, and a 455 nm laser showed the best effect on plants.

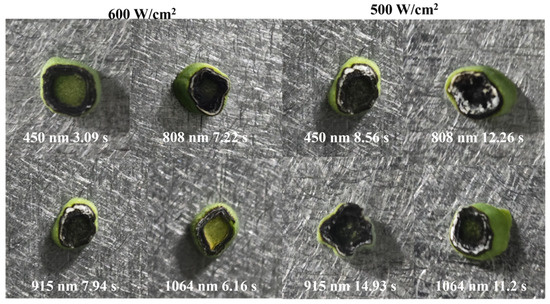

Figure 9 shows the cross-section of the hedge branches. The shape of the hedge branches has changed after laser cutting, making them more irregular due to the loss of tissue moisture. Under the same power density, the degree of carbonization of the section after 450 nm laser cutting is the lowest, while that of lasers with other wavelength is higher to varying degrees. This is consistent with Kortsalioudakis ’s research [18], which concluded that the degree of carbonization is also related to the optical absorption coefficient.

Figure 9.

Deformation of the samples after laser cutting.

Generally speaking, high power leads to a greater degree of carbonization [7]. However, our results show that the degree of carbonization at 500 W/cm2 is greater than that at 600 W/cm2. We believe that the ablation time is also one of the most important factors influencing laser carbonization. With the laser power density used in our experiments, the degree of carbonization mainly depends on the exposure time of the workpiece rather than the power of the laser beam, which is consistent with the experimental results reported in reference [10].

This carbonized layer provides a certain degree of protection and helps seal the cross-section, thereby reducing water loss. The carbonized layer prevents the external environment from directly contacting the healthy part of the branch by acting as a physical barrier, effectively reducing the chance of bacteria invasion through the incision and reducing the risk of infection. This is beneficial to our research.

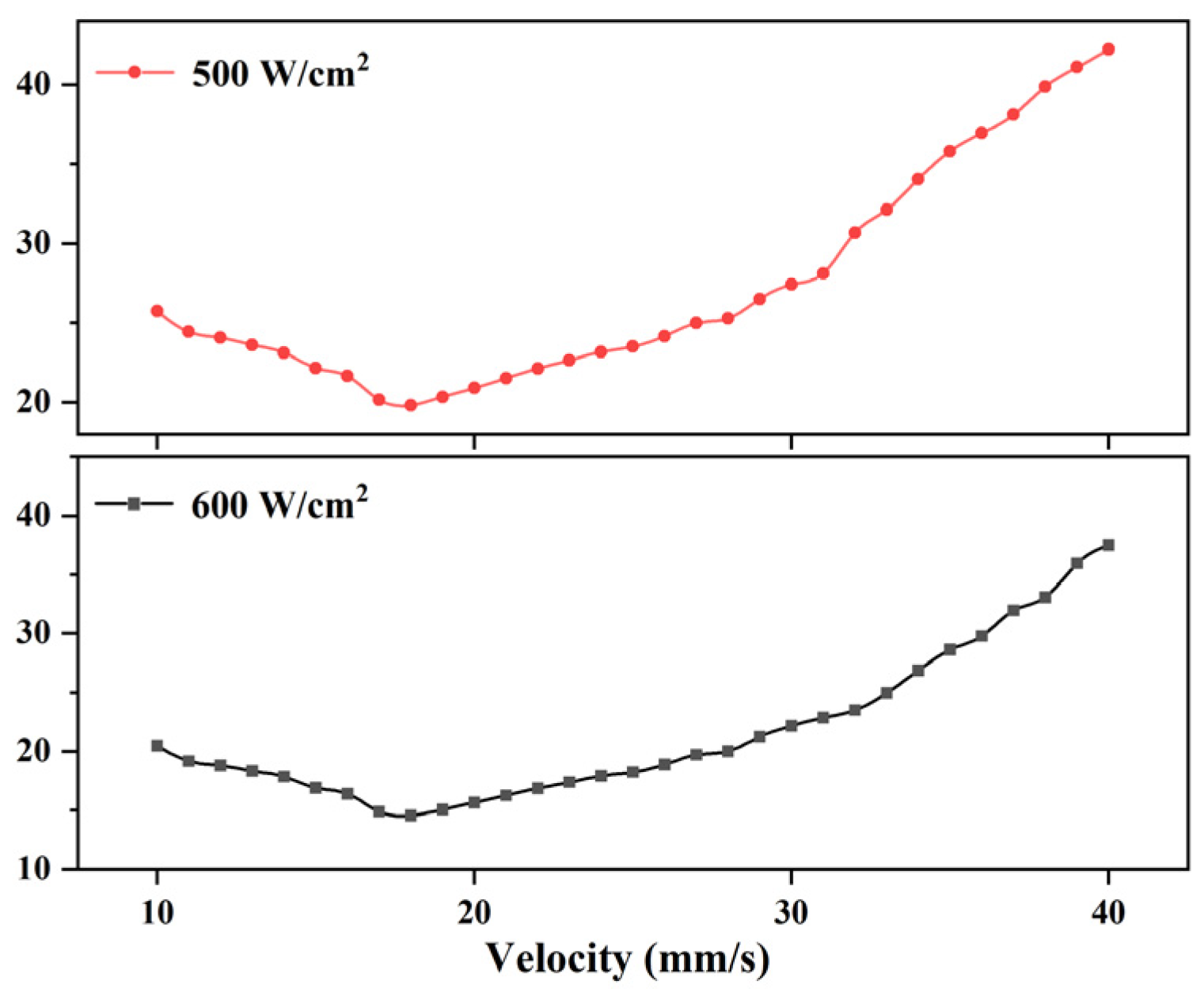

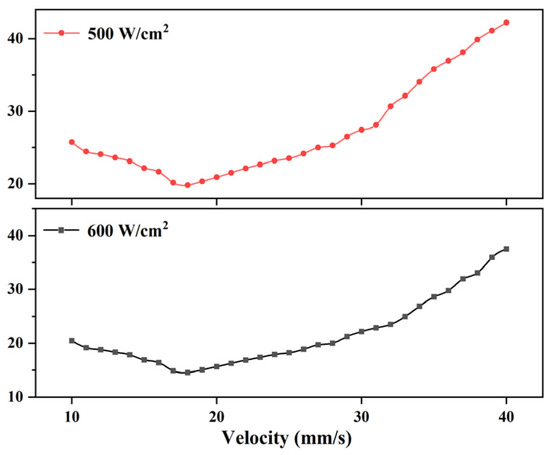

It might be expected that a slower laser cutting speed would result in greater energy per unit width, thereby reducing the total cutting time. However, our experiments show this is not always true. Changes in cutting speed affect the interaction time and area between the laser and the hedge branches, thereby affecting the cutting outcome, as shown in Figure 10. At a laser power density of 500 W/cm2, an optimal cutting speed of 18 mm/s results in a cutting time of 14.55 s, the shortest time achieved. At a higher power density of 600 W/cm2, the optimal cutting speed increases to 21 mm/s, and the shortest cutting time is reduced to 3.09 s.

Figure 10.

Laser cutting time as a function of the scanning speed with laser power densities of 500 W/cm2 and 600 W/cm2.

At a slower speed (10 mm/s to 15 mm/s), the laser remains in one spot long enough on the branch. Although there is enough time to melt and vaporize the material, the wide heat diffusion overheats the surrounding wood. This leads to carbonization at the cutting edge and even causes the material to catch fire. At a faster speed (greater than 30 mm/s), the laser’s interaction time of the laser on the surface of the branch is shortened, the heat is too slow to diffuse into the surrounding area, and the heat-affected zone is relatively small. The material is not completely vaporized or melted before the laser pulses move to other areas, resulting in incomplete cutting. As the speed increases, the cutting effect deteriorates. The best laser cutting speed for this kind of plant is about 18 mm/s to 23 mm/s.

4. Conclusions

This paper conducted experiments on green hedge branches using fiber lasers with five wavelengths: 450 nm, 532 nm, 808 nm, 915 nm, and 1064 nm. It analyzed the differences in the effects of lasers with five wavelengths in terms of power density, defocus amount, and incident angle. The preliminary results showed that a fiber-coupled diode laser at a central wavelength of 450 nm may be successfully applied to cut hedge branches. The different experimental effects with different wavelengths result from differences in the absorption and reflection of light by the green hedge.

The drilling time using different wavelength pulses is ranked as follows: T450 < T1064 < T808 < T915. The 532 nm laser did not cause any ablation on the sample, likely because of its low power. The ablation thresholds for lasers with wavelengths of 450 nm, 808 nm, 915 nm, and 1064 nm are 163.9 W/cm2, 203.9 W/cm2, 197.2 W/cm2, and 201.6 W/cm2, respectively. The 450 nm laser has the lowest ablation threshold.

The difference (δD) between the hole diameter and the focal spot diameter reflects the laser’s utilization. The smallest difference between the ablation hole diameter and the spot diameter was observed after irradiation with the 450 nm laser, while the largest difference was observed with the 808 nm laser. This indicates that the 450 nm laser has higher energy utilization efficiency during the process.

Within the range of 0° to 6°, the effect of the incident angle on the drilling time is small, as the focusing effect of the laser beam does not change significantly. However, as the incident angle increases further, the drilling time rises significantly. This phenomenon is particularly noticeable when the incident angle exceeds 10°, as the drilling time increases more rapidly. The maximum allowable incident angles for the four wavelengths are 18.756°, 14.922°, 13.217°, and 14.135°, respectively.

In the cutting experiment, the 450 nm laser still outperforms the other wavelengths. The cutting time for 450 nm is the shortest. The optimal cutting speed varies under different energy densities, with the best speed being around 18–25 mm/s. At 500 W/cm2, the optimal cutting speed of 18 mm/s results in the shortest cutting time of 14.55 s. At 600 W/cm2, the optimal cutting speed increases to 21 mm/s, and the shortest cutting time can be reduced to 3.09 s.

The cross-sections were covered with a layer of charred cells. This could prevent the wound invasion caused by the laser beam. The degree of carbonization increases with cutting time. When the power density is high, the cutting time is shorter. The carbonization of the cross-sections after using 450 nm laser is less than that of other wavelengths, which not only helps prevent pests and diseases but also avoids excessive carbonization.

Author Contributions

G.S. performed the experiment, analyzed the data, and wrote the original draft; X.L. provided the ideas, analyzed the data, reviewed and edited the draft, and provided the project and funding; S.N. provided helpful discussions on the results; and Y.L. helped the experiment. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Youth Innovation Promotion Association CAS (No. 2021123) and National Key Research and Development Program of China (No. 2020YFE0204600).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhou, B.H.; Mahdavian, S.M. Experimental and Theoretical Analyses of Cutting Nonmetallic Materials by Low Power CO2-Laser. J. Mater. Process. Technol. 2004, 146, 188–192. [Google Scholar] [CrossRef]

- Jelvani, S.; Maleki, M.H.; Khadir, S.; Darkhal, N.; Ebrahimi, A. Laser Cleaning on Bronze Artefacts by the XeCl Laser. Optik 2021, 242, 167316. [Google Scholar] [CrossRef]

- Powell, J. CO2 Laser Cutting; Springer: London, UK, 1998. [Google Scholar]

- Qian, W.; Cai, J.; Xin, Z.; Ye, Y.; Dai, F.; Hua, Y. Femtosecond laser polishing with high pulse frequency for improving performance of specialised aerospace material systems: MCrAlY coatings in thermal barrier coating system. Int. J. Mach. Tools Manuf. 2022, 182, 103954. [Google Scholar] [CrossRef]

- Park, S.-H.; Liu, P.; Yi, K.; Choi, G.; Jhang, K.-Y.; Sohn, H. Mechanical Properties Estimation of Additively Manufactured Metal Components Using Femtosecond Laser Ultrasonics and Laser Polishing. Int. J. Mach. Tools Manuf. 2021, 166, 103745. [Google Scholar] [CrossRef]

- Pan, X.; He, W.; Cai, Z.; Wang, X.; Liu, P.; Luo, S.; Zhou, L. Investigations on Femtosecond Laser-Induced Surface Modification and Periodic Micropatterning with Anti-Friction Properties on Ti6Al4V Titanium Alloy. Chin. J. Aeronaut. 2022, 35, 521–537. [Google Scholar] [CrossRef]

- Nath, S.; Waugh, D.G.; Ormondroyd, G.; Spear, M.; Pitman, A.; Curling, S.; Mason, P. Laser Incising of Wood: A Review. Lasers Eng. 2020, 45, 381–403. [Google Scholar]

- Majumdar, J.D.; Manna, I. Laser Processing of Materials. Sadhana 2003, 28, 495–562. [Google Scholar] [CrossRef]

- Malachowski, M.J. Trimming Trees Using a High Power CO2 Laser: Machining of Green and Dry Wood. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics; Laser Institute of America: Boston, MA, USA, 1984; pp. 185–192. [Google Scholar]

- Aniszewska, M.; Maciak, A.; Zychowicz, W.; Zowczak, W.; Mühlke, T.; Christoph, B.; Lamrini, S.; Sujecki, S. Infrared Laser Application to Wood Cutting. Materials 2020, 13, 5222. [Google Scholar] [CrossRef]

- Adamcik, L.; Igaz, R.; Stefancin, L.; Kubovský, I.; Kminiak, R. Evaluation of the Surface Irregularities of the Cross-Section of the Wood after CO2 Laser Cutting. Materials 2023, 16, 7175. [Google Scholar] [CrossRef]

- Hernandez-Castaneda, J.C.; Crouse, P.; Li, L. High-Power Yb-Doped Fibre Laser for Cutting Dry Pine Wood. World Congr. Eng. 2007, 2, 1129–1134. [Google Scholar]

- Hernandez-Castaneda, J.C.; Sezer, H.K.; Li, L. Statistical Analysis of Ytterbium-Doped Fibre Laser Cutting of Dry Pine Wood. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 775–789. [Google Scholar] [CrossRef]

- Hernandez-Castaneda, J.C.; Sezer, H.K.; Li, L. Dual Gas Jet-Assisted Fibre Laser Blind Cutting of Dry Pine Wood by Statistical Modelling. Int. J. Adv. Manuf. Technol. 2010, 50, 195–206. [Google Scholar] [CrossRef]

- Hernández-Castañeda, J.C.; Sezer, H.K.; Li, L. The Effect of Moisture Content in Fibre Laser Cutting of Pine Wood. Opt. Lasers Eng. 2011, 49, 1139–1152. [Google Scholar] [CrossRef]

- Fukuta, S.; Nomura, M.; Ikeda, T.; Yoshizawa, M.; Yamasaki, M.; Sasaki, Y. UV Laser Machining of Wood. Eur. J. Wood Prod. 2016, 74, 261–267. [Google Scholar] [CrossRef]

- Lan, Y.-P. Laser-Optics-Based Method to Suppress Mikania Micrantha Growth. Sci. Rep. 2022, 12, 19864. [Google Scholar] [CrossRef]

- Kortsalioudakis, N.; Petrakis, P.; Moustaizis, S.; Adamopoulos, S.; Karastergiou, S.; Passialis, C. An Application of a Laser Drilling Technique to Fir and Spruce Wood Specimens to Improve Their Permeability. In Proceedings of the 7th International Scientific and Technical Conference, Innovations in Forest Industry and Engineering Design, Yokohama, Japan, 3–8 November 2014. [Google Scholar]

- Fukuta, S.; Nomura, M.; Ikeda, T.; Yoshizawa, M.; Yamasaki, M.; Sasaki, Y. Wavelength Dependence of Machining Performance in UV-, VIS- and NIR-Laser Cutting of Wood. J. Wood Sci. 2016, 62, 316–323. [Google Scholar] [CrossRef]

- Azaman, M.I.H.; Mahdi, M.A.; Ahmad, M.R.; Shuib, A.R.; Khalid, M.R.; Bakri, M.A.; Md Radzi, M.K.F.; Ramli, A.S. Optimisation of Parameters Laser Cutting of Oil Palm Fronds Using Fibre Pulsed Laser of 1064 Nm Wavelength System. Adv. Agric. Food Res. J. 2020, 1. [Google Scholar] [CrossRef]

- Mathiassen, S.K.; Bak, T.; Christensen, S.; Kudsk, P. The Effect of Laser Treatment as a Weed Control Method. Biosyst. Eng. 2006, 95, 497–505. [Google Scholar] [CrossRef]

- Heisel, T.; Schou, J.; Christensen, S.; Andreasen, C. Cutting Weeds with a CO2 Laser. Weed Res. 2001, 41, 19–29. [Google Scholar] [CrossRef]

- Wang, M.; Leal-Naranjo, J.-A.; Ceccarelli, M.; Blackmore, S. A Novel Two-Degree-of-Freedom Gimbal for Dynamic Laser Weeding: Design, Analysis, and Experimentation. IEEE/ASME Trans. Mechatron. 2022, 27, 5016–5026. [Google Scholar] [CrossRef]

- Liu, J.; Hu, Y.; Xu, X.; Li, P. Feasibility and Influencing Factors of Laser Cutting of Tomato Peduncles for Robotic Harvesting. Afr. J. Biotechnol. 2011, 10, 15552–15563. [Google Scholar] [CrossRef]

- Ferraz, A.C.O.; Mittal, G.S.; Bilanski, W.K.; Abdullah, H.A. Mathematical Modeling of Laser Based Potato Cutting and Peeling. Biosystems 2007, 90, 602–613. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Duan, H.; Cai, X.; Yang, R.; Yao, F.; Tan, B.; Liu, F. Cutting Efficiency of a Newly Developed Incubator-Based Laser Cutting Method and Its Effects on Potato Tissue Culture Plantlet Growth. Potato Res. 2023, 66, 889–903. [Google Scholar] [CrossRef]

- Badoniya, P. CO2 Laser Cutting of Different Materials—A Review. Int. Res. J. Eng. Technol. 2018, 5, 1–12. [Google Scholar]

- Gapontsev, V. Ultra High Power Ytterbium Fiber Lasers. In Proceedings of the Pacific International Conference on Applications of Lasers and Optics; Laser Institute of America: Melbourne, Australia, 2004; p. 901. [Google Scholar]

- Verhaeghe, G. The Fiber Laser A Newcomer for Material Welding and Cutting/A new type of laser is attracting interest from the materials processing industry. Weld. J. 2005, 84, 56–60. [Google Scholar]

- Gitelson, A.A.; Buschmann, C.; Lichtenthaler, H.K. Leaf Chlorophyll Fluorescence Corrected for Re-Absorption by Means of Absorption and Reflectance Measurements. J. Plant Physiol. 1998, 152, 283–296. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).