Hybrid Growth of Clad Crystalline Sapphire Fibers for Ultra-High-Temperature (>1500 °C) Fiber Optic Sensors

Abstract

1. Introduction

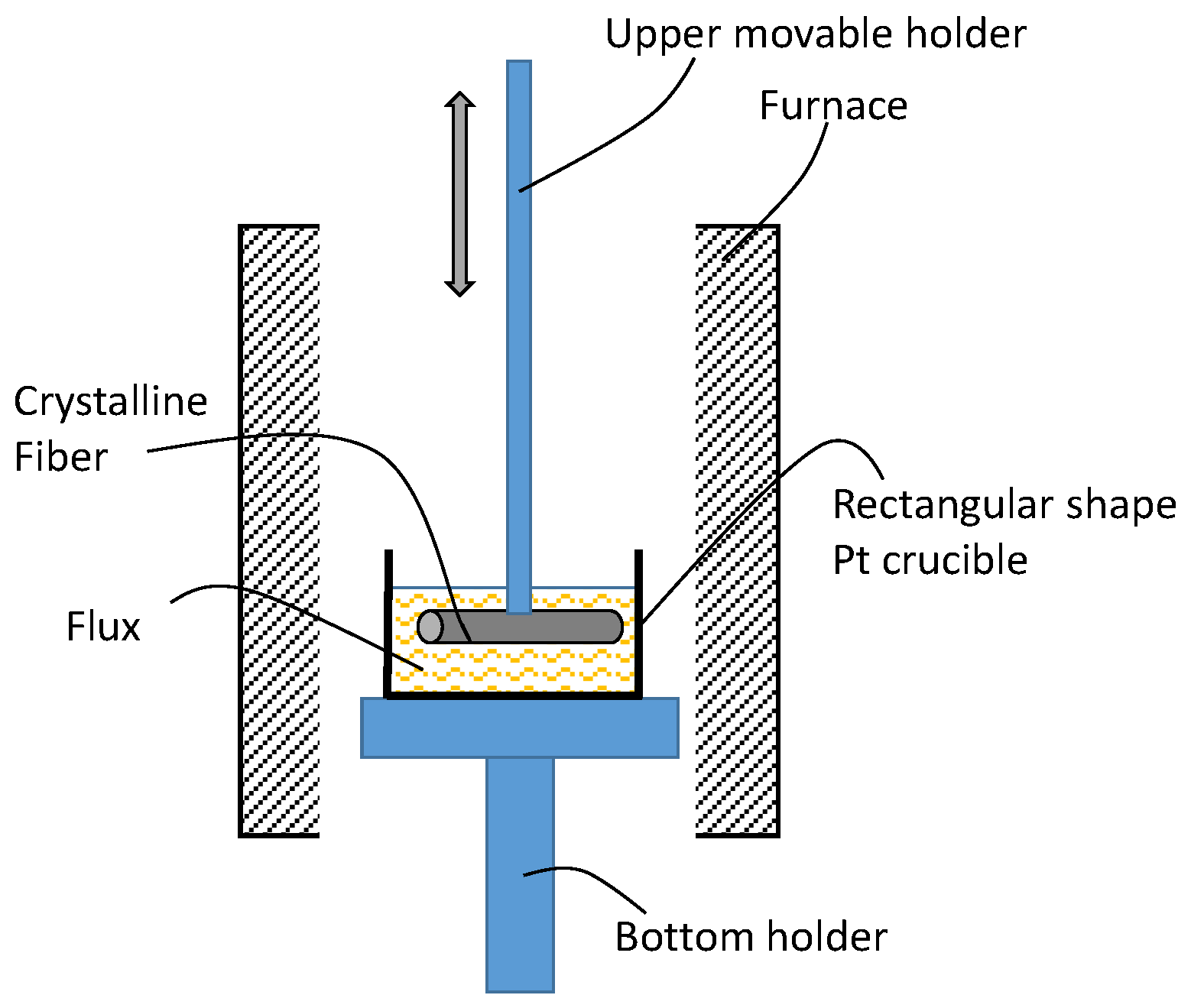

2. Materials and Methods

3. Results

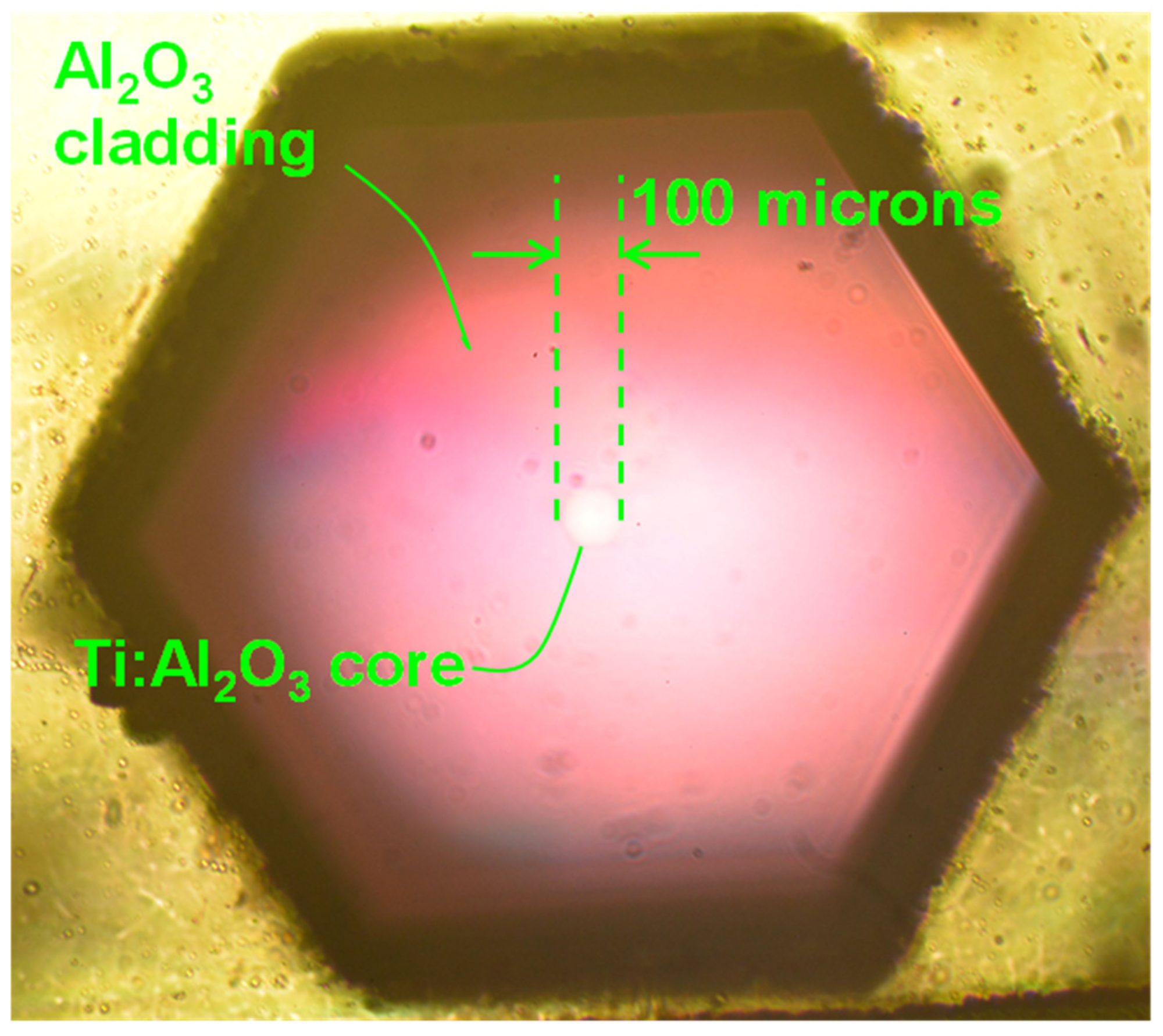

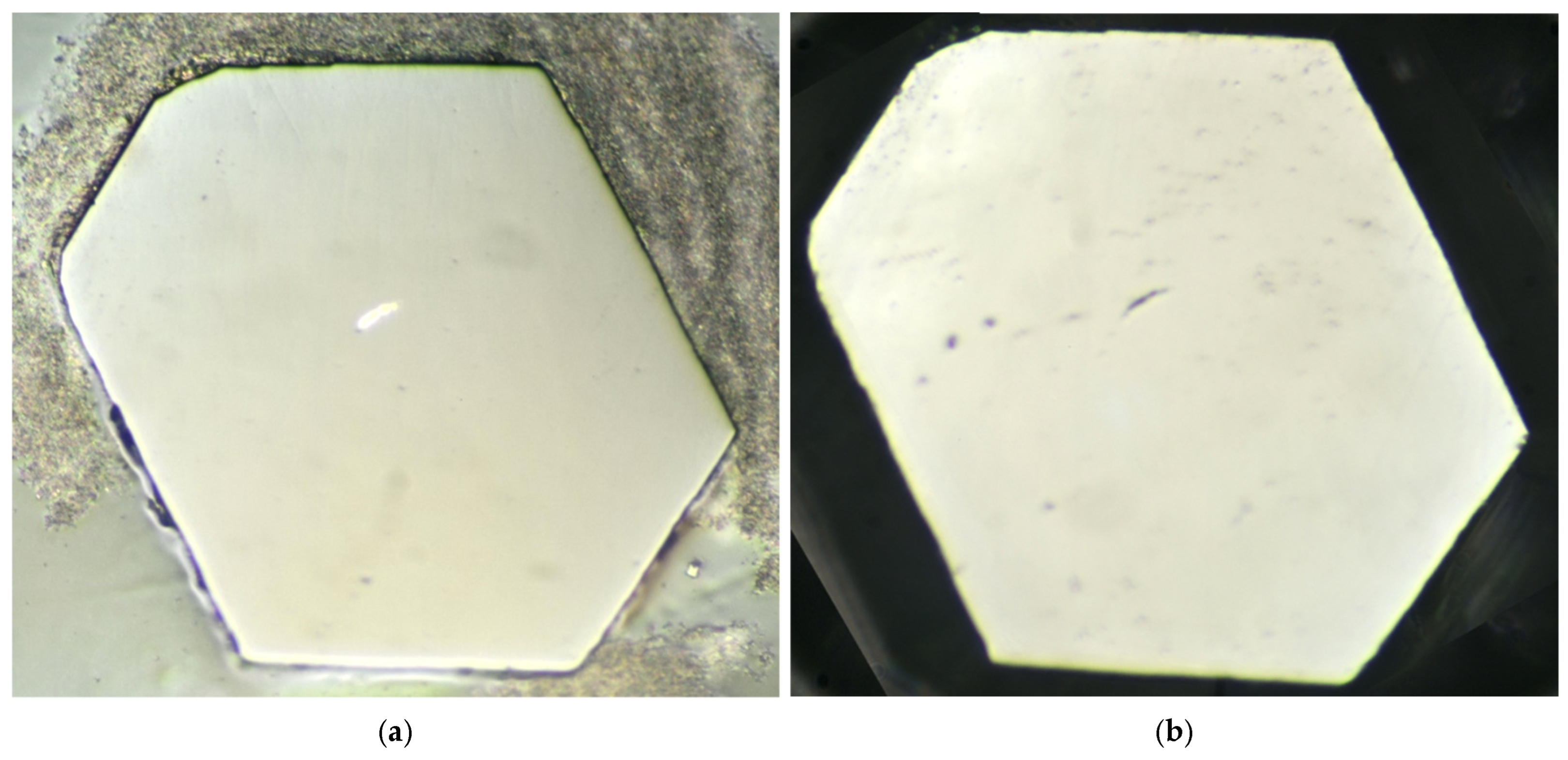

3.1. Graphic Illustration of a Grown Clad Crystalline Sapphire Fiber

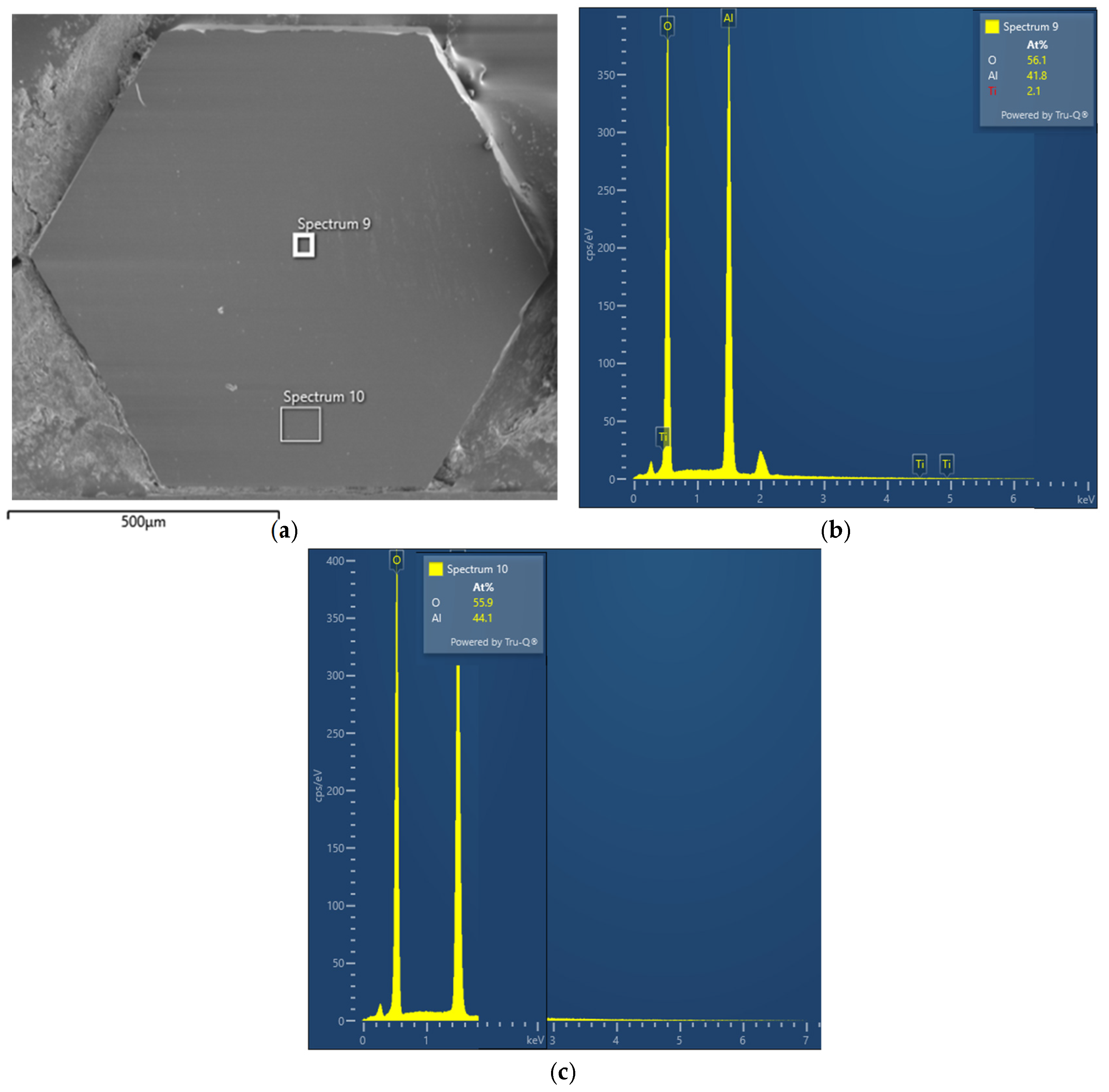

3.2. Characterizing the Composition of the Grown Clad Crystalline Sapphire Fiber

3.3. Confirmation of the Ultra-High-Temperature Sensing Capability of Grown Clad Crystalline Sapphire Fibers

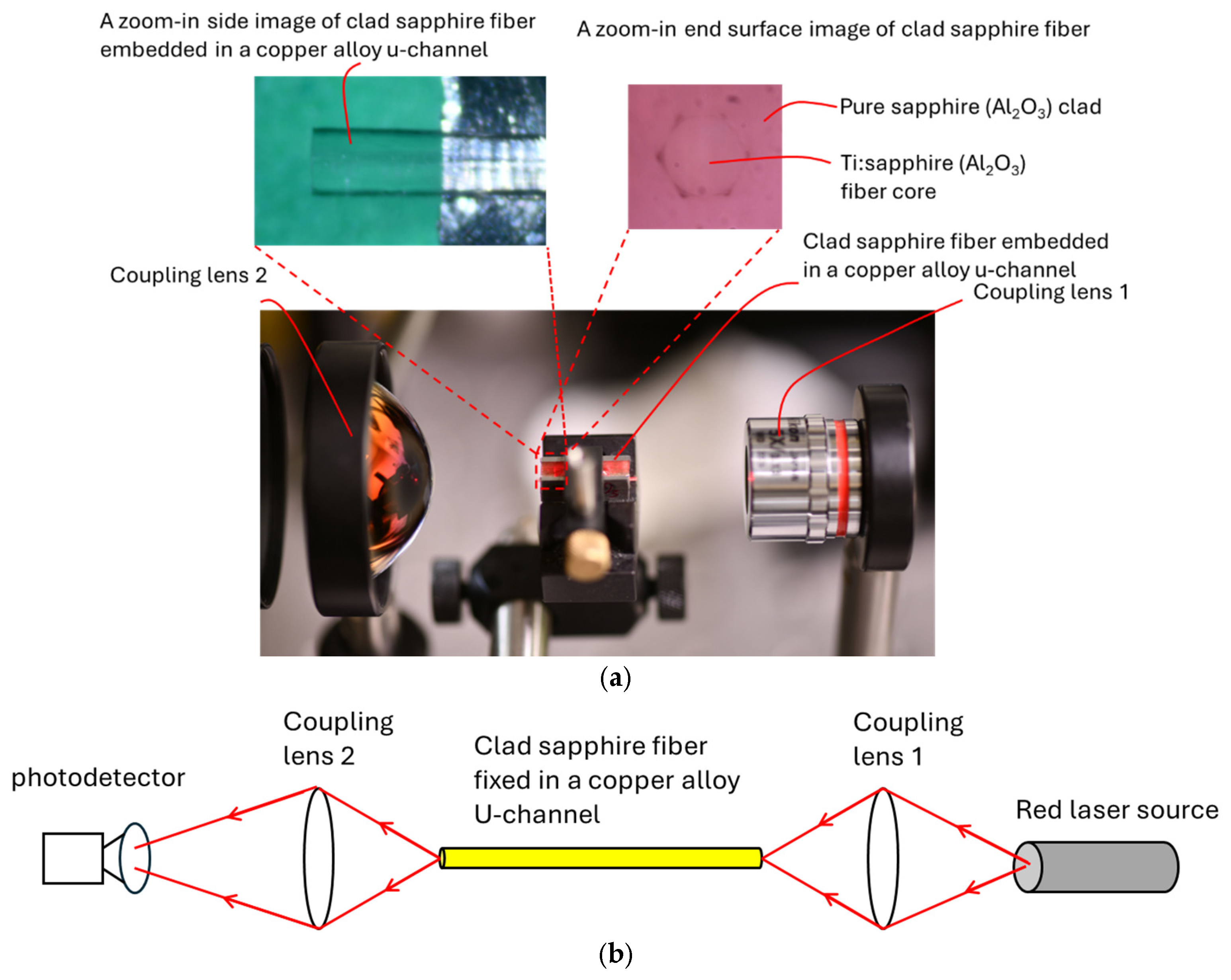

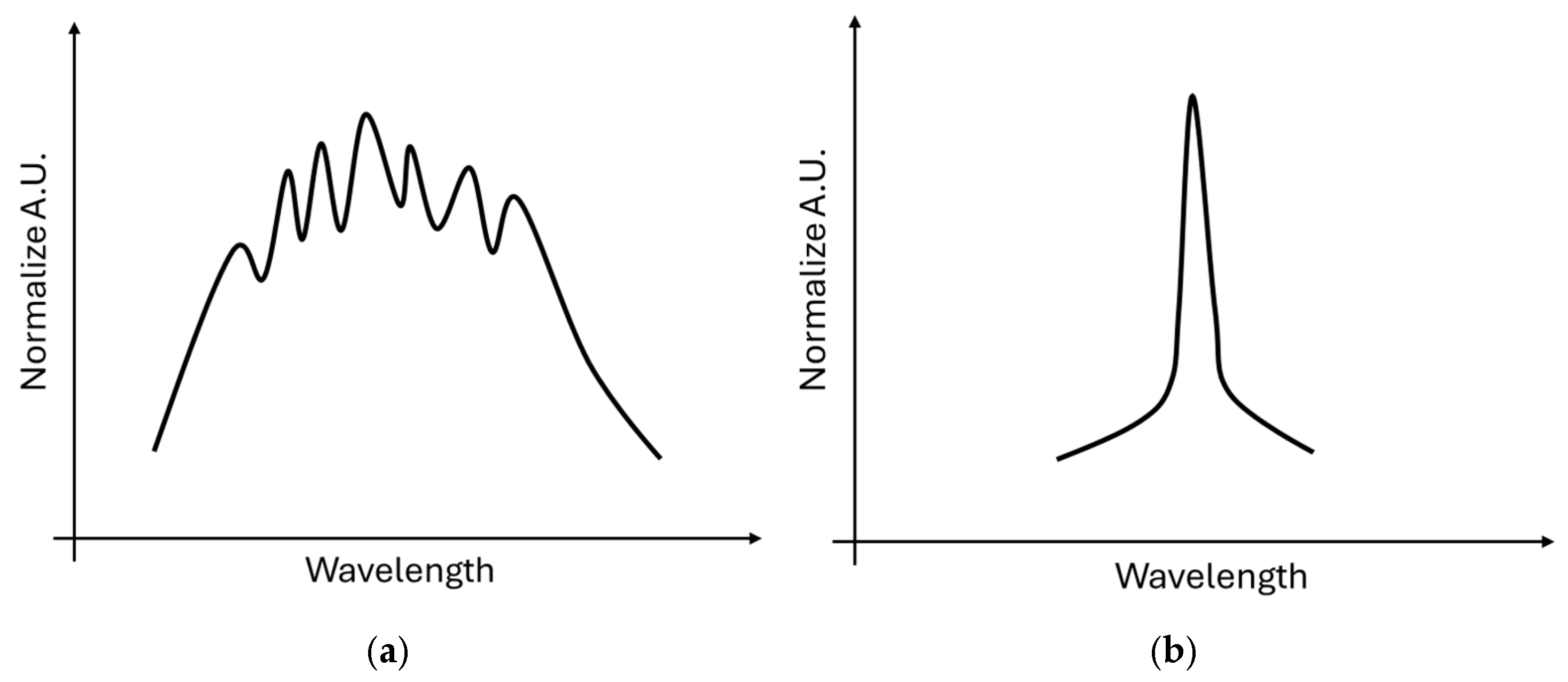

3.4. Measurement of the Transmission Capacity of the Grown Clad Sapphire Fiber

4. Discussion

4.1. Analysis of the Linearity of Clad Crystalline Sapphire Fiber at Elevated Temperature

4.2. Modelling the Accuracy of the Temperature Measurements

4.3. Analyzing the Requirements of the Fiber Core Diameter to Achieve Single-Transverse-Mode Operation

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Chen, L.; Wang, L.; Ma, J. Monitoring the Safety Status of a Blast Furnace Hearth Using Cooling Stave Heat Flux. AIP Adv. 2020, 10, 025308. [Google Scholar]

- Hashemian, H.M. On-Line Monitoring Applications in Nuclear Power Plants. Prog. Nucl. Energy 2011, 53, 167–181. [Google Scholar]

- Lei, J.-F.; Will, H.A. Thin-Film Thermocouples and Strain-Gauge Technologies for Engine Applications. Sens. Actuators A Phys. 1998, 65, 187–193. [Google Scholar]

- Liu, T.; Sullivan, J.P. Pressure and Temperature Sensitive Paints; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared Thermography for Condition Monitoring—A Review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar]

- Yin, S.; Ruffin, P.; Yu, F. Fiber Optic Sensors; CRC Press: New York, NY, USA, 2008. [Google Scholar]

- Wang, B.; Niu, Y.; Qin, X.; Yin, Y.; Ding, M. Review of high temperature measurement technology based on sapphire optical fiber. Measurement 2021, 184, 109868. [Google Scholar]

- Grobnic, D.; Mihailov, S.; Selser, C.; Ding, H. Sapphire fiber Bragg grating sensor made using femtosecond laser radiation for ultrahigh temperature applications. IEEE Photonics Technol. Lett. 2004, 16, 774–776. [Google Scholar]

- Zhan, C.; Kim, J.; Lee, J.; Yin, S.; Ruffin, P.; Luo, C. High temperature sensing using higher-order mode rejected sapphire-crystal fiber gratings. Opt. Mem. Neural Netw. 2007, 16, 204–210. [Google Scholar] [CrossRef]

- Yang, S.; Feng, Z.; Jia, X.; Pickrell, G.; Ng, W.; Wang, A.; Zhu, Y. All-sapphire miniature optical fiber tip sensor for high temperature measurement. J. Light. Technol. 2020, 38, 1988–1997. [Google Scholar]

- He, J.; Xu, X.; Du, B.; Xu, B.; Chen, R.; Wang, Y.; Liao, C.; Guo, J.; Wang, Y.; He, J. Stabilized ultra-high temperature sensors based on inert gas sealed sapphire fiber Bragg gratings. ACS Appl. Mater. Interfaces 2022, 14, 12359–12366. [Google Scholar]

- Yang, Y.; Liu, H.; Wang, S.; Chuang, K.; Chou, T.; Huang, S. Formation of ceramic and crystal cladding for a Ti: Sapphire crystalline fiber core. Opt. Mater. Express 2020, 10, 1215–1223. [Google Scholar]

- Janney, M.; Nunn, S.; May, R. Sapphire Fiber Optics Sensors for Engine Test Instrumentation; CRADA Final Report; Oak Ridge National Lab (ORNL): Oak Ridge, TN, USA, 2003; p. 00-0586. [Google Scholar]

- Wang, M.; Salter, P.; Payne, F.; Shiply, A.; Dyson, I.; Liu, T.; Wang, T.; Zhang, K.; Zhang, J.; Jia, Z.; et al. Single-mode sapphire fiber temperature sensor. J. Light. Technol. 2024, 42, 6409–6416. [Google Scholar]

- Nejad, J.; Soroosh, M.; Al-Shammri, F.; Alkhayer, A. High-sensitive and linear temperature sensor based on liquid-filled photonic crystal fiber. Opt. Quant. Electron. 2025, 57, 32. [Google Scholar]

- Kumar, V.; Raghuwanshi, S.; Kumar, S. Advances in SPR-based fiber optic sensors for voltage/electric field measurement—A review. IEEE Sens. J. 2024, 24, 11986–11997. [Google Scholar]

- Yin, Z.; Jing, X.; Li, K.; Zhang, Z.; Hu, L. Cascaded dual-channel broadband SPR fiber optic sensor based on Ag and Ag/ZnO/PDMS film structure. Opt. Express 2024, 32, 6190–6203. [Google Scholar]

- Mao, B.; Zhou, K.; Xiang, Y.; Zhang, Y.; Yuan, Q.; Hao, H.; Chen, Y.; Liu, H.; Wang, X.; Wang, X.; et al. A bioinspired robotic finger for multimodel tactile sensing powered by fiber optic sensors. Adv. Intell. Syst. 2024, 6, 2400175. [Google Scholar]

- Dubinskii, M.; Zhang, J.; Fromzel, V.; Chen, Y.; Yin, S.; Luo, C. Low-loss ‘crystalline-core/crystalline-clad’ (C4) fibers for highly power scalable high efficiency fiber lasers. Opt. Express 2018, 26, 5092–5101. [Google Scholar] [PubMed]

- Gryvnak, D.; Burch, D. Optical and infrared properties of Al2O3 at elevated temperatures. J. Opt. Soc. Am. 1965, 55, 625–629. [Google Scholar]

- Wilson, B.; Petrie, C.; Blue, T. High temperature effects on the light transmission through sapphire optical fiber. J. Am. Ceram. Soc. 2018, 101, 3452–3459. [Google Scholar]

- Cui, Y.; Jiang, Y.; Xie, S.; Feng, X.; Zhang, Y.; Hu, J.; Jiang, L. Measurement of sapphire wafer thermos-optic coefficient using high-temperature optical fiber sensors. IEEE Sens. J. 2022, 22, 2244–2249. [Google Scholar]

- Xu, X.; Tan, Q.; Li, Z.; Wu, J.; Li, H.; He, J.; He, Z.; Qin, Y.; Xu, T.; Ran, Z.; et al. Sapphire fiber Bragg gratings demodulated with cross correlation algorithm for long-term high-temperature measurement. IEEE Sens. J. 2024, 24, 7905–7911. [Google Scholar]

- Ghatak, A.; Thyagarajan, K. Introduction to Fiber Optics; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Pollnau, M.; Grivas, C.; Laversenne, L.; Wilkinson, J.; Eason, R.; Shepherd, D. Ti: Sapphire waveguide lasers. Laser Phys. Lett. 2007, 4, 560. [Google Scholar] [CrossRef]

- Gui, X.; Li, Z.; Fu, X.; Guo, H.; Wang, Y.; Wang, C.; Wang, J.; Jiang, D. Distributed optical fiber sensing and applications based on large-scale fiber Bragg grating array: Review. J. Light. Technol. 2023, 41, 4187–4200. [Google Scholar]

- Resisi, S.; Popoff, S.; Bromberg, Y. Image transmission with a dynamically perturbed multimode fiber by deep learning. Laser Photonics Rev. 2021, 15, 2000553. [Google Scholar] [CrossRef]

- Bagley, N.; Kremp, T.; Lamb, E.; Westbrook, P. Transfer learning and generalization of a neural-network-based multimode position and imaging sensor under thermal perturbations. Opt. Fiber Technol. 2022, 70, 102855. [Google Scholar] [CrossRef]

- Yin, S.; Luo, F. Method and Apparatus for Producing Crystalline Cladding and Crystalline Core Optical Fibers. U.S. Patent No. 10,274,673, 30 April 2019. [Google Scholar]

- Yin, S.; Luo, F. Method and Apparatus for Producing Crystalline Cladding and Crystalline Core Optical Fibers. U.S. Patent No. 10,054,735, 21 August 2018. [Google Scholar]

- Yin, S.; Luo, F. Method and Apparatus for Producing Crystalline Cladding and Crystalline Core Optical Fibers. U.S. Patent No. 9,995,875, 12 June 2018. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kabir, M.A.; Wu, K.-C.; Chou, K.-T.; Luo, F.; Yin, S. Hybrid Growth of Clad Crystalline Sapphire Fibers for Ultra-High-Temperature (>1500 °C) Fiber Optic Sensors. Photonics 2025, 12, 299. https://doi.org/10.3390/photonics12040299

Kabir MA, Wu K-C, Chou K-T, Luo F, Yin S. Hybrid Growth of Clad Crystalline Sapphire Fibers for Ultra-High-Temperature (>1500 °C) Fiber Optic Sensors. Photonics. 2025; 12(4):299. https://doi.org/10.3390/photonics12040299

Chicago/Turabian StyleKabir, Mohammad Ahsanul, Kai-Cheng Wu, Kai-Ting Chou, Fang Luo, and Shizhuo Yin. 2025. "Hybrid Growth of Clad Crystalline Sapphire Fibers for Ultra-High-Temperature (>1500 °C) Fiber Optic Sensors" Photonics 12, no. 4: 299. https://doi.org/10.3390/photonics12040299

APA StyleKabir, M. A., Wu, K.-C., Chou, K.-T., Luo, F., & Yin, S. (2025). Hybrid Growth of Clad Crystalline Sapphire Fibers for Ultra-High-Temperature (>1500 °C) Fiber Optic Sensors. Photonics, 12(4), 299. https://doi.org/10.3390/photonics12040299