Highly Sensitive Temperature Sensor Based on a UV Glue-Filled Fabry–Perot Interferometer Utilizing the Vernier Effect

Abstract

1. Introduction

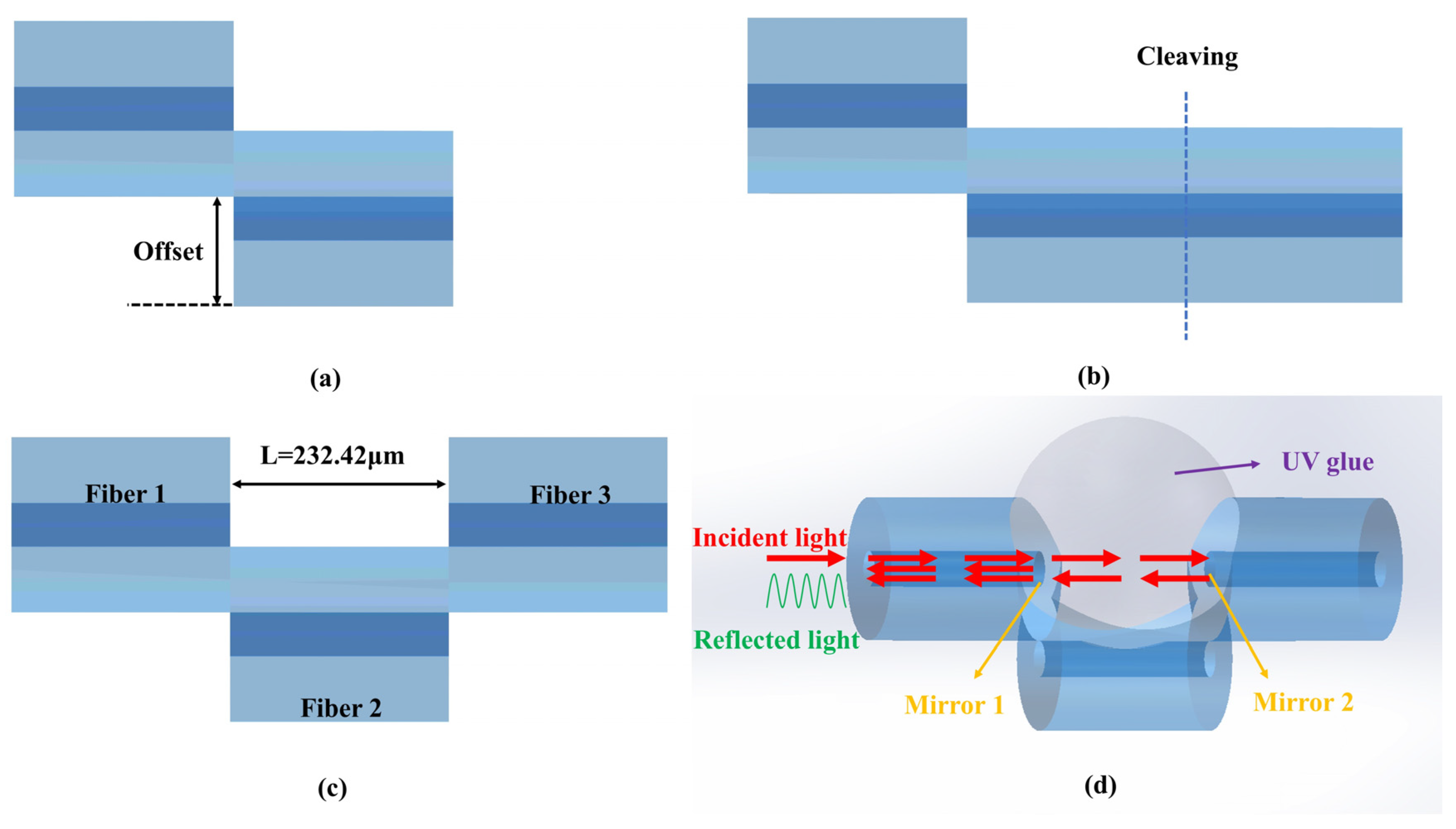

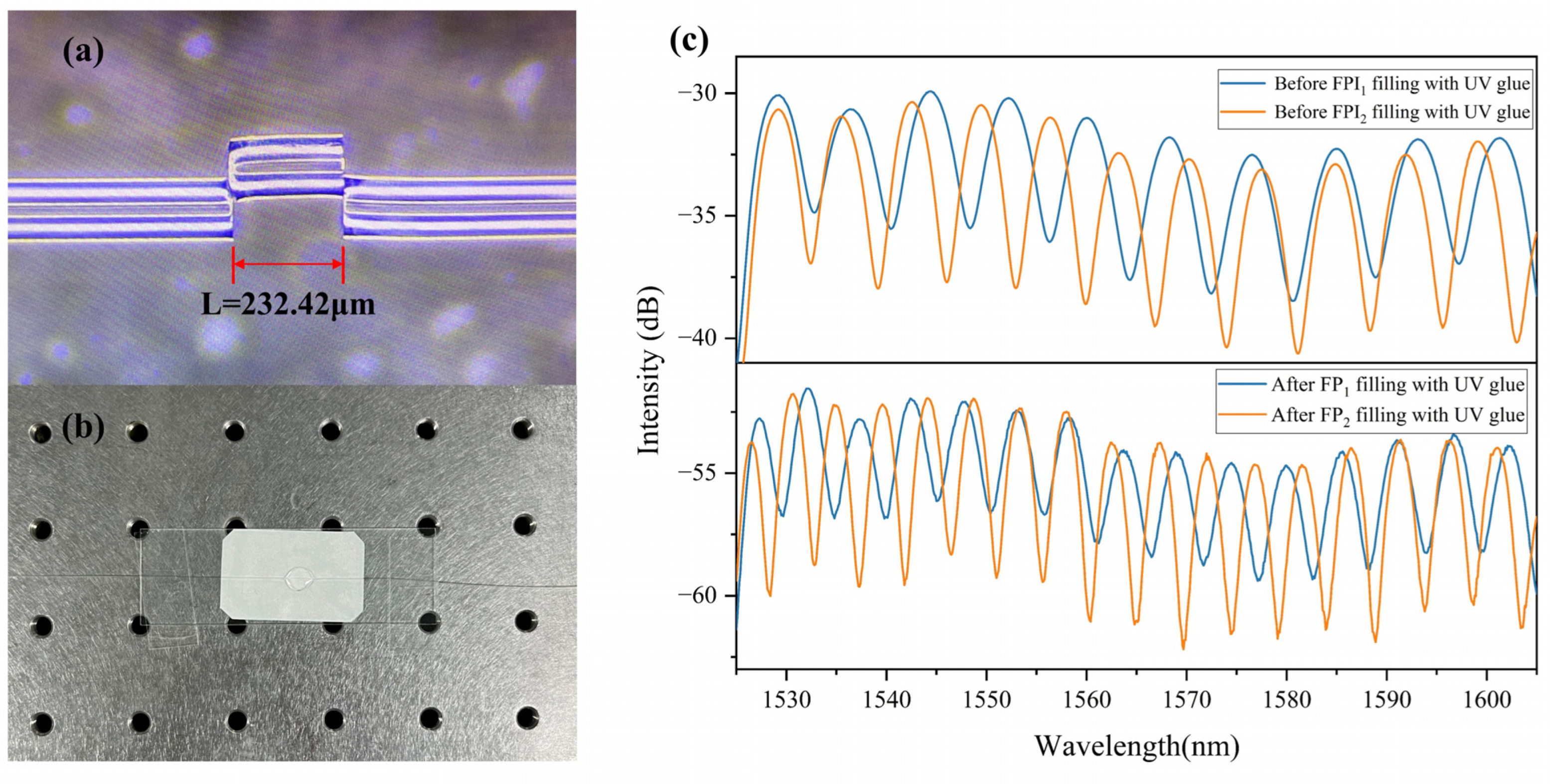

2. Preparation of FPI and Coating of UV Glue

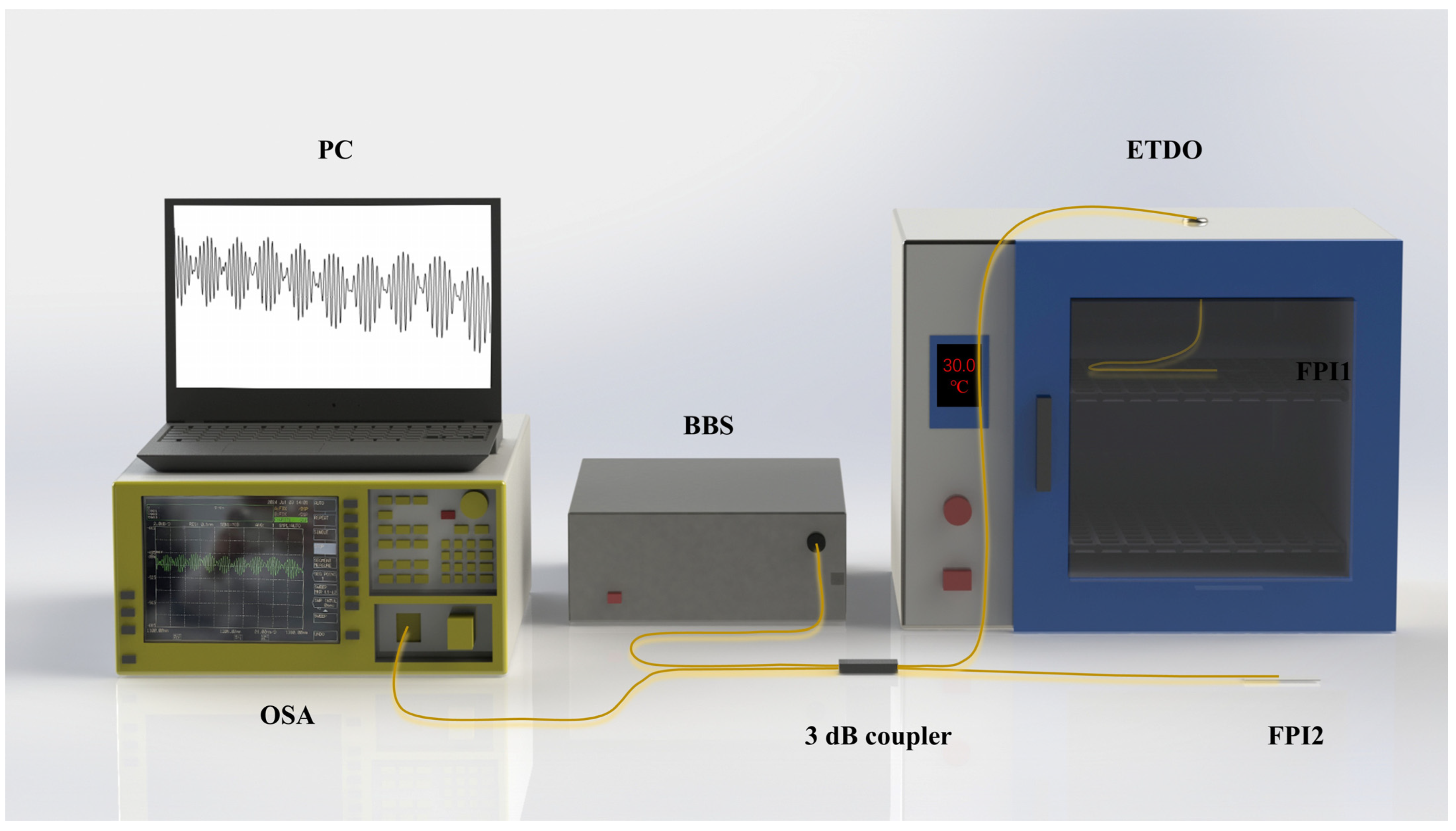

3. Experimental Setup and Working Principle

4. Results and Discussion

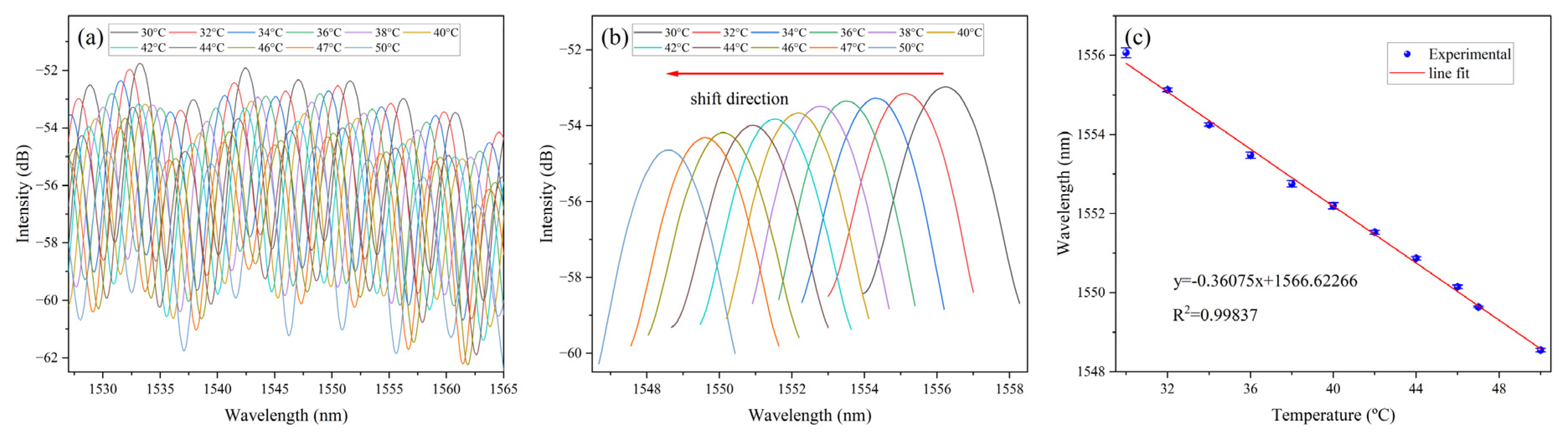

4.1. Temperature Response of the FPI Before Coating with UV Glue

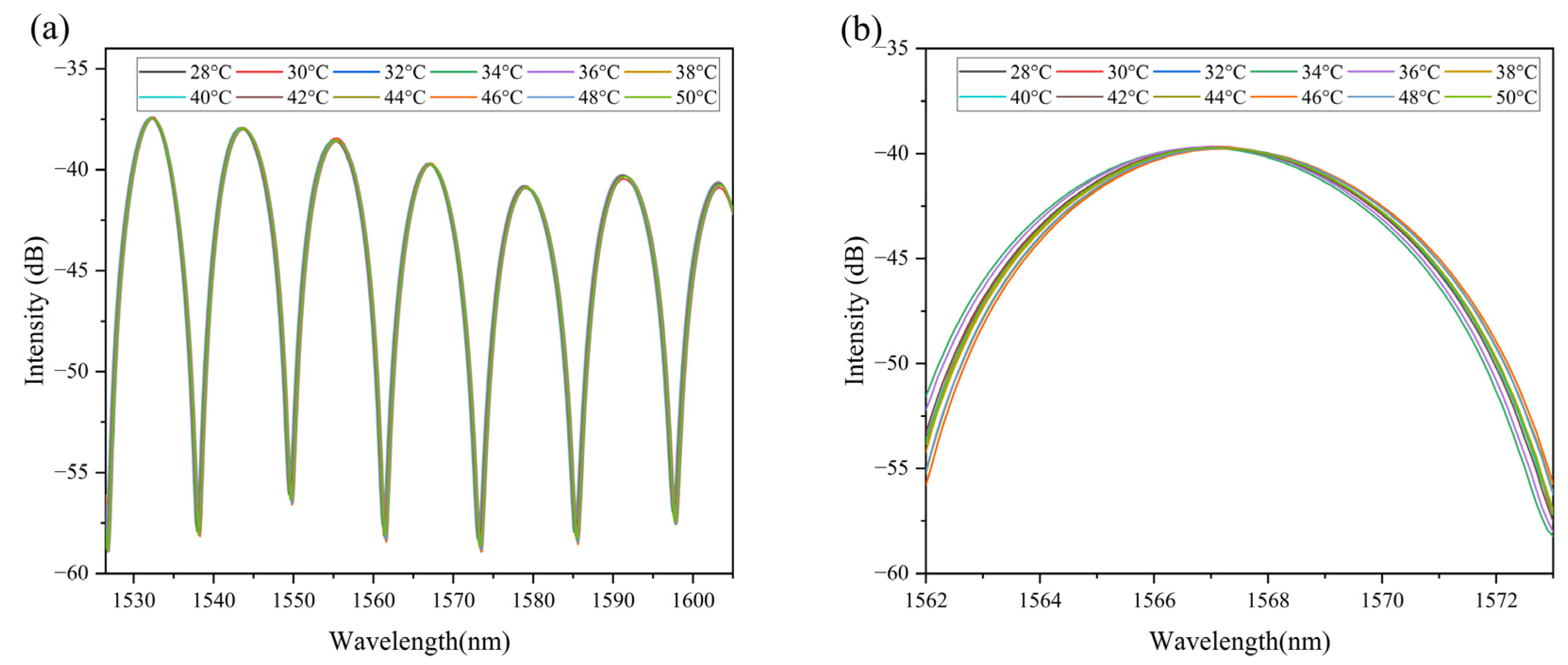

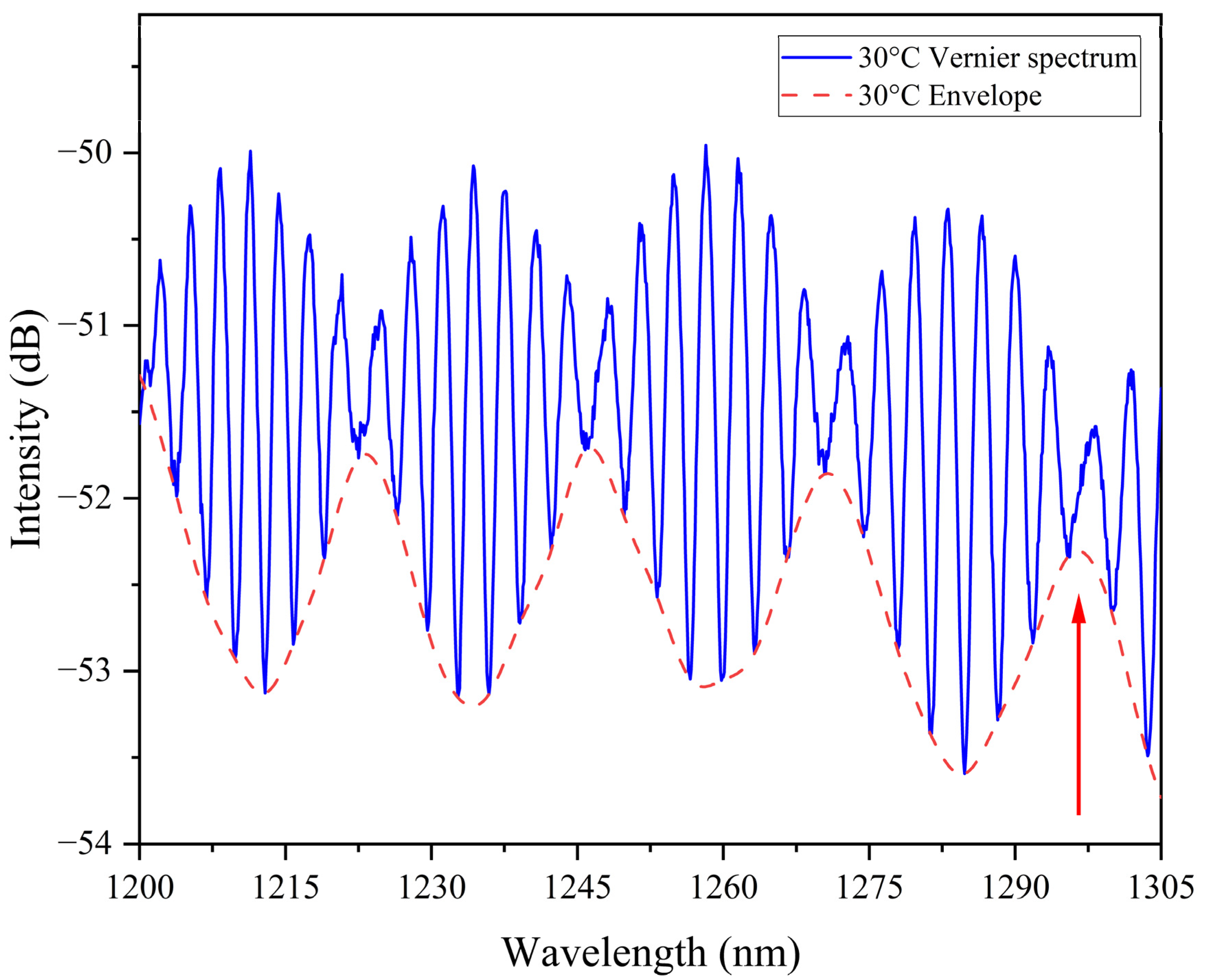

4.2. Temperature Response of a Single FPI Coated with UV Glue

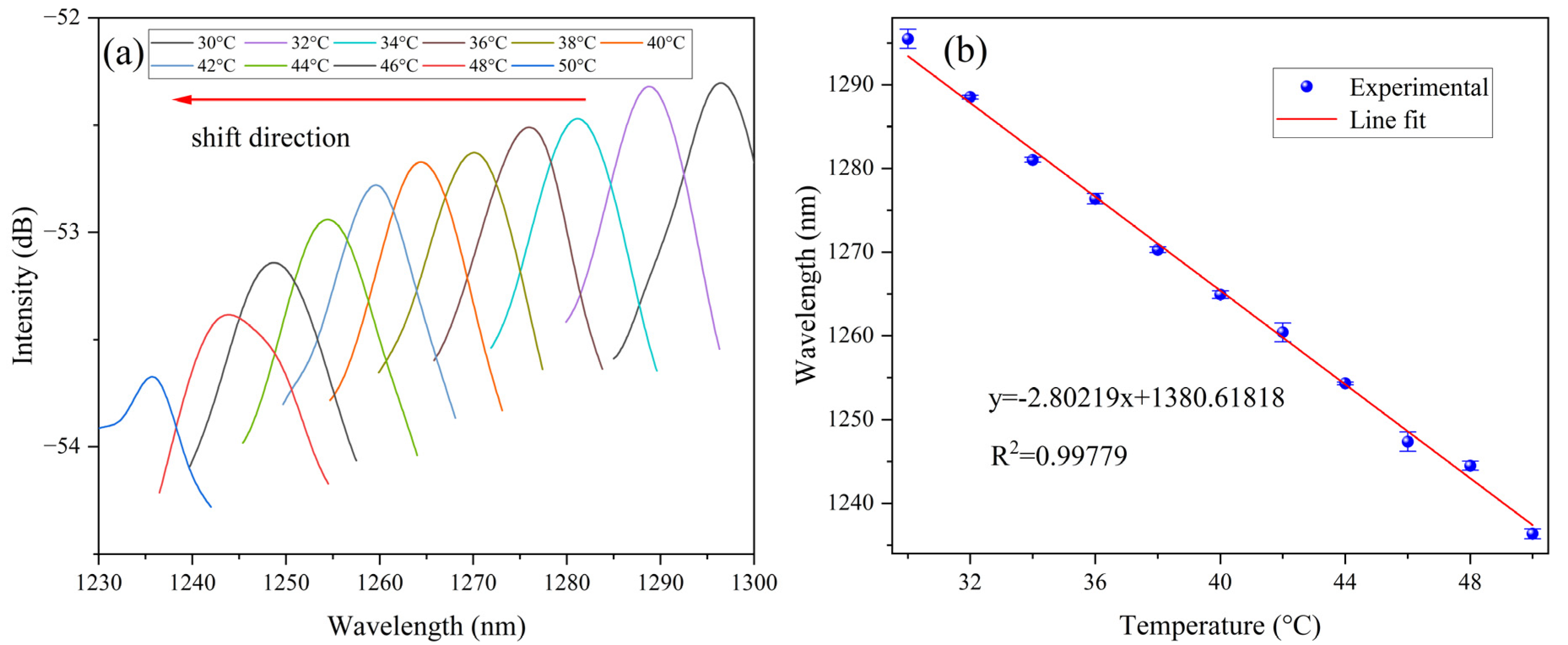

4.3. Temperature Response of the Vernier Effect in Parallel-Connected FPIs Coated with UV Glue

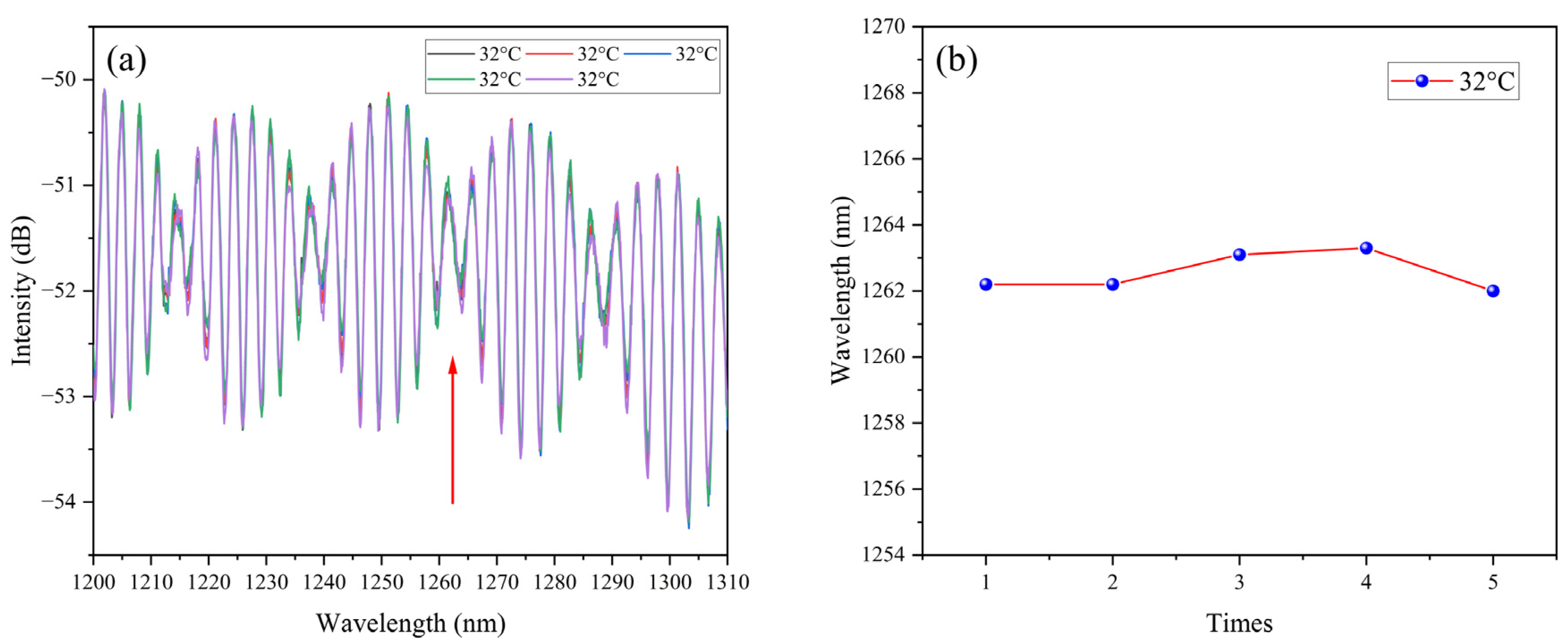

4.4. Characterization of Reproducibility

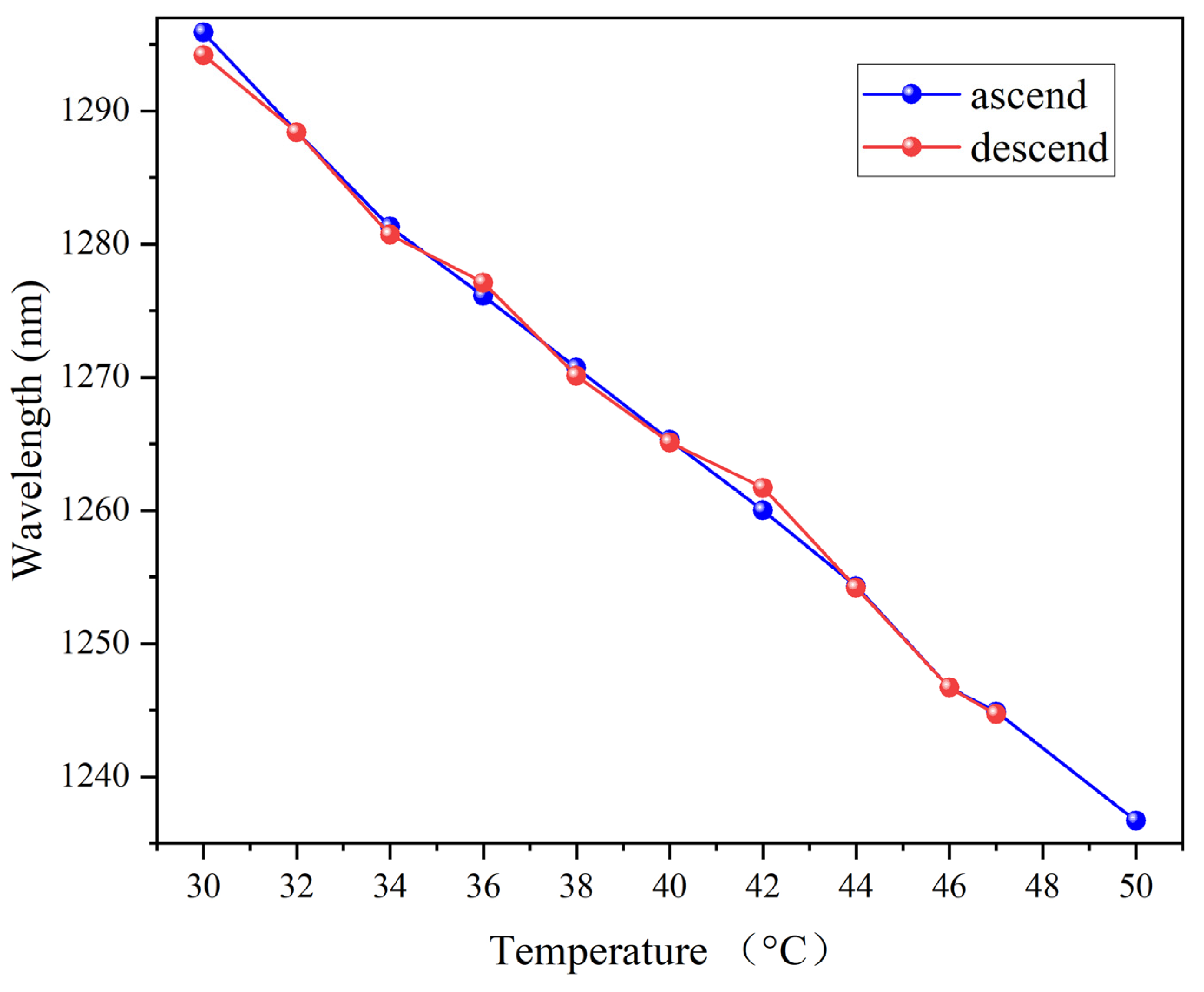

4.5. Characterization of Reversibility

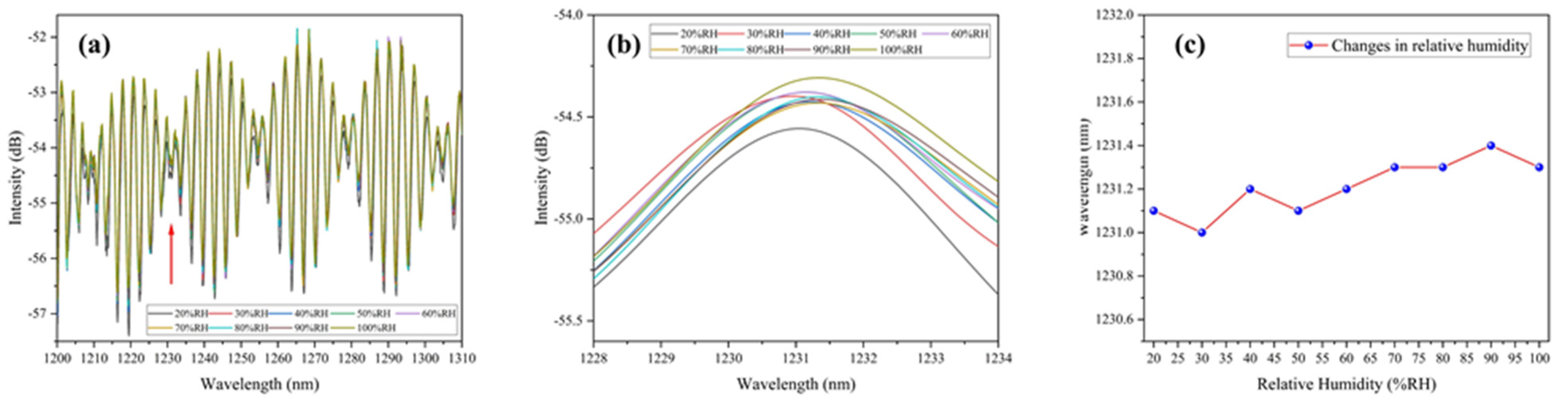

4.6. Humidity Response of the Vernier Effect in Parallel-Connected FPIs Coated with UV Glue

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Yang, J.; Ma, J. Highly sensitive temperature sensing performance of a microfiber Fabry-Perot interferometer with sealed micro-spherical reflector. Micromachines 2019, 10, 773. [Google Scholar] [CrossRef]

- Wei, R.; Bao, X. A low power energy-efficient precision CMOS temperature sensor. Micromachines 2018, 9, 257. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, R.; Paixao, T.; Lopes, G.; Domingues, M.F.; Oliveira, R.; Antunes, P. Vernier effect-based optical fiber sensor for humidity and temperature monitoring. IEEE Photonic Tech. L. 2021, 33, 1061–1064. [Google Scholar] [CrossRef]

- Maldonado-Hurtado, D.G.; Llera, M.; Flahaut, F.; Benoit, J.; Barrera, D. Weight measurement and vibration detection sensor based on a thermoplastic polyurethane optical fiber. J. Light. Technol. 2023, 42, 1740–1747. [Google Scholar] [CrossRef]

- Yuan, Y.; Tong, R.; Xing, B.; Wu, S.; Zheng, H.; Zhao, Y. Cascaded vernier effect optic fiber temperature sensor with DSHF-Based MZI and FPI. Measurement 2024, 231, 114625. [Google Scholar] [CrossRef]

- Ghaffar, A.; Ru, F.; Liu, J.; Chen, G.Y.; Ni, J.; Liu, J.; Hussian, S.; Yu, J.; Das, B.; Mehdi, M. High pressure sensor based on intensity-variation using polymer optical fiber. Sci. Rep. 2024, 14, 18604. [Google Scholar] [CrossRef]

- Wang, X.; Xiao, Y.; Rans, C.; Benedictus, R.; Groves, R.M. Enhanced strain measurement sensitivity with gold nanoparticle-doped distributed optical fiber sensing. Struct. Control. Health Monit. 2024, 2024, 2716156. [Google Scholar] [CrossRef]

- Rao, X.; Zhao, L.; Xu, L.; Wang, Y.; Liu, K.; Wang, Y.; Chen, G.Y.; Liu, T.; Wang, Y. Review of optical humidity sensors. Sensors 2021, 21, 8049. [Google Scholar] [CrossRef]

- Sampath, U.; Kim, D.; Song, M. Hydrous ethanol detection using a graphene oxide-coated Fresnel reflection sensor. IEEE Sens. J. 2019, 19, 4069–4073. [Google Scholar] [CrossRef]

- Li, A.; Wen, X.; Ma, H.; Yang, X.; Jiang, H.; Teng, P.; Zhang, B.; Li, K.; Sivanathan, S.; Roula, M.A. Smartphone-based selective and sensitive detection of vitamin B1 in synthetic urine using U-bend SPR optical fiber probe. Opt. Fiber Technol. 2024, 84, 103769. [Google Scholar] [CrossRef]

- Fu, R.; Chen, X.; Yan, X.; Li, H.; Hu, T.; Wei, L.; Qu, Y.; Cheng, T. Optical fiber sensors for heavy metal ion sensing. J. Mater. Sci. Technol. 2024, 189, 110–131. [Google Scholar] [CrossRef]

- Xu, F.; Ma, J.; Hu, K.; Zhang, Z.; Ma, C.; Guan, B.; Chen, K. Ultrahigh sensitivity of hydrogen detection with a perforated Pd film on a miniature fiber tip. Sens. Actuat. B Chem. 2024, 400, 134875. [Google Scholar] [CrossRef]

- Fan, Z.; Zhong, S.; Zhao, K.; Wang, Q.; Li, Y.; Zhang, G.; Ma, G.; Zhao, J.; Yan, H.; Huang, Z.; et al. A Hermetic Package Technique for Multi-Functional Fiber Sensors through Pressure Boundary of Energy Systems Based on Glass Sealants. Photonics 2024, 11, 792. [Google Scholar] [CrossRef]

- Ding, Y.; Chen, Y.; Luo, S.; Ling, Q.; Zhang, Y.; Yu, Z.; Guan, Z.; Chen, D. All-fiber MZI hydrostatic pressure sensor. Opt. Laser Technol. 2024, 171, 110414. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Mu, X.; Sun, L.; Wang, J.; Li, Y. Fiber optic temperature sensor based on the harmonic Vernier effect generated by two Sagnac interferometers. IEEE Sens. J. 2024, 24, 12419–12425. [Google Scholar] [CrossRef]

- Shao, M.; Yuan, Y.; Liu, Y.; Fu, H.; Qiao, X. All-fiber Michelson interferometer for heart rate and breath monitoring. IEEE Sens. J. 2024, 24, 23909–23917. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, D.; Qian, Y.; Yin, X.; Wang, L.; Zhang, S.; Wang, Y. Research on fiber optic surface plasmon resonance biosensors: A review. Photonic Sens. 2024, 14, 240201. [Google Scholar] [CrossRef]

- Hu, X.; Xu, Y.; Zhang, H.; Xie, J.; Niu, D.; Zhao, Z. The fiber bragg grating (FBG) sensing glove: A review. IEEE Sens. J. 2023, 23, 11374–11382. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, K.; Zhao, J.; Wang, Q.; Zhong, S.; Lalam, N.; Wright, R.; Zhou, P.; Chen, K.P. FiberFlex: Real-time FPGA-based Intelligent and Distributed Fiber Sensor System for Pedestrian Recognition. ACM Trans. Reconfigurable Technol. Syst. 2024, 17, 1–30. [Google Scholar] [CrossRef]

- Zhao, S.; Du, C.; Wang, Q.; Jia, B.; Zhang, L.; Cui, L.; Deng, X.; Chen, S. A long period fiber grating seawater salinity sensor based on bend insensitive single mode fiber. Opt. Fiber Technol. 2023, 77, 103269. [Google Scholar] [CrossRef]

- Liu, B.; Ruan, Y.; Yu, Y. All-fiber laser-self-mixing sensor for acoustic emission measurement. J. Light. Technol. 2021, 39, 4062–4068. [Google Scholar] [CrossRef]

- Li, R.; Hu, Z.; Li, H.; Zhao, Y.; Liu, K.; Tu, Y. All-fiber laser-self-mixing interferometer with adjustable injection intensity for remote sensing of 40 km. J. Light. Technol. 2022, 40, 4863–4870. [Google Scholar] [CrossRef]

- Ma, C.; Peng, D.; Bai, X.; Liu, S.; Luo, L. A review of optical fiber sensing technology based on thin film and Fabry–Perot cavity. Coatings 2023, 13, 1277. [Google Scholar] [CrossRef]

- Li, C.; Yang, W.; Wang, M.; Yu, X.; Fan, J.; Xiong, Y.; Yang, Y.; Li, L. A review of coating materials used to improve the performance of optical fiber sensors. Sensors 2020, 20, 4215. [Google Scholar] [CrossRef]

- Liao, Y.; Liu, Y.; Li, Y.; Lang, C.; Cao, K.; Qu, S. Large-range, highly-sensitive, and fast-responsive optical fiber temperature sensor based on the sealed ethanol in liquid state up to its supercritical temperature. IEEE Photonics J. 2019, 11, 1–12. [Google Scholar] [CrossRef]

- Cao, K.; Liu, Y.; Qu, S. Compact fiber biocompatible temperature sensor based on a hermetically-sealed liquid-filling structure. Opt. Express 2017, 25, 29597–29604. [Google Scholar] [CrossRef]

- Liao, Y.; Liu, Y.; Lang, C.; Li, Y.; Qu, S. Highly sensitive optical fiber temperature sensor based on the thermal shift of the liquid–air interface. Opt. Eng. 2019, 58, 117105. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, D.; Wang, C.; Gao, H.; Cheng, F. Ultrasensitive temperature sensor based on optic fiber Fabry–Pérot interferometer with Vernier effect. Opt. Commun. 2023, 541, 129567. [Google Scholar] [CrossRef]

- Ahmed, I.; Ali, M.; Elsherif, M.; Butt, H. UV polymerization fabrication method for polymer composite based optical fiber sensors. Sci. Rep. 2023, 13, 10823. [Google Scholar] [CrossRef]

- Ramírez-Hernández, M.Á.; Alonso-Murias, M.; Monzón-Hernández, D. Highly sensitive temperature sensor based on vernier effect using a sturdy double-cavity fiber Fabry-Perot interferometer. Polymers 2023, 15, 4567. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, L.; Hao, S.; Tang, J. Advanced fiber sensors based on the Vernier effect. Sensors 2022, 22, 2694. [Google Scholar] [CrossRef] [PubMed]

- Gomes, A.D.; Bartelt, H.; Frazão, O. Optical Vernier effect: Recent advances and developments. Laser Photonics Rev. 2021, 15, 2000588. [Google Scholar] [CrossRef]

- Naku, W.; Huang, J.; Zhu, C. Optical fiber sensors based on advanced Vernier Effect-A Review. IEEE Sens. J. 2024. [Google Scholar] [CrossRef]

- Chen, S.; Pan, P.; Xie, T.; Fu, H. Sensitivity enhanced fiber optic temperature sensor based on optical carrier microwave photonic interferometry with harmonic Vernier effect. Opt. Laser Technol. 2023, 160, 109029. [Google Scholar] [CrossRef]

- Xiao, J.; Zhou, T.; Yao, N.; Ma, S.; Pan, C.; Wang, P.; Fu, H.; Liu, H.; Pan, J.; Yu, L.; et al. Optical fibre taper-enabled waveguide photoactuators. Nat. Commun. 2022, 13, 363. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Y.; Liu, Q.; Lou, K.; Wang, S.; Zhang, N.; Jiang, N.; Yetisen, A.K. Multiplexed optical fiber sensors for dynamic brain monitoring. Matter 2022, 5, 3947–3976. [Google Scholar] [CrossRef]

- Ran, Y.; Xu, Z.; Chen, M.; Wang, W.; Wu, Y.; Cai, J.; Long, J.; Chen, Z.; Zhang, D.; Guan, B. Fiber-optic theranostics (FOT): Interstitial fiber-optic needles for cancer sensing and therapy. Adv. Sci. 2022, 9, 2200456. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, J.; Jin, F.; Xiao, J.; Lan, N.; Xu, Z.; Yue, X.; Li, Z.; Li, C.; Cao, D.; et al. Fiber-optic drug delivery strategy for synergistic cancer photothermal-chemotherapy. Light Sci. Appl. 2024, 13, 228. [Google Scholar] [CrossRef]

- Oliveira, R.; Bilro, L.; Nogueira, R. Fabry-Pérot cavities based on photopolymerizable resins for sensing applications. Opt. Mater. Express 2018, 8, 2208–2221. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, C.; Xu, B.; Wang, D.; Yang, M. Optical cascaded Fabry–Perot interferometer hydrogen sensor based on vernier effect. Opt. Commun. 2018, 414, 166–171. [Google Scholar] [CrossRef]

- Zhang, T.; Han, Q.; Liang, Z.; Jiang, J.; Cheng, Z. A Fabry–Pérot sensor with cascaded polymer films based on Vernier effect for simultaneous measurement of relative humidity and temperature. Sensors 2023, 23, 2800. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.H.; Li, D.; Liu, Z.G.; Wang, Q.; Tang, J.R. Polymer-coated fiber-optic Fabry-Perot interferometer-based temperature sensor with high sensitivity. Opt. Fiber Technol. 2023, 81, 103471. [Google Scholar] [CrossRef]

- Yin, J.; Liu, T.; Jiang, J.; Liu, K.; Wang, S.; Qin, Z. Batch-producible fiber-optic Fabry–Pérot sensor for simultaneous pressure and temperature sensing. IEEE Photonics Technol. Lett. 2014, 26, 2070–2073. [Google Scholar]

- Zeng, Y.; Zhang, P.; Li, Z.; Shen, J.; Li, C. Fabry-Perot interferometers with resin scaffolders for high sensitivity temperature sensing. Front. Phys. 2024, 12, 1366488. [Google Scholar] [CrossRef]

| Reference | Configuration | Temperature Range | Temperature Sensitivity |

|---|---|---|---|

| [41] | Two cascaded FPIs | 15 °C to 40 °C | −0.4825 nm/°C |

| [42] | PDMS-coated FPI | −30 °C to 85 °C | 0.698 nm/°C |

| [43] | Silicon–glass–silicon-sandwich bonding structure | −20 °C to 70 °C | 142.02 nm/°C |

| [44] | Optical fibers within a 3D-printed resin scaffold | 34.9 °C to 38.5 °C | 14.330 nm/°C |

| This work | Two parallel FPIs | 30 °C to 50 °C | −2.80219 nm/°C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiang, C.; Chu, C.; Wang, Y.; Yang, X.; Yang, X.; Hou, Y.; Wen, X.; Teng, P.; Zhang, B.; Sivanathan, S.; et al. Highly Sensitive Temperature Sensor Based on a UV Glue-Filled Fabry–Perot Interferometer Utilizing the Vernier Effect. Photonics 2025, 12, 256. https://doi.org/10.3390/photonics12030256

Qiang C, Chu C, Wang Y, Yang X, Yang X, Hou Y, Wen X, Teng P, Zhang B, Sivanathan S, et al. Highly Sensitive Temperature Sensor Based on a UV Glue-Filled Fabry–Perot Interferometer Utilizing the Vernier Effect. Photonics. 2025; 12(3):256. https://doi.org/10.3390/photonics12030256

Chicago/Turabian StyleQiang, Chengwen, Chu Chu, Yuhan Wang, Xinghua Yang, Xinyu Yang, Yuting Hou, Xingyue Wen, Pingping Teng, Bo Zhang, Sivagunalan Sivanathan, and et al. 2025. "Highly Sensitive Temperature Sensor Based on a UV Glue-Filled Fabry–Perot Interferometer Utilizing the Vernier Effect" Photonics 12, no. 3: 256. https://doi.org/10.3390/photonics12030256

APA StyleQiang, C., Chu, C., Wang, Y., Yang, X., Yang, X., Hou, Y., Wen, X., Teng, P., Zhang, B., Sivanathan, S., Jones, A., & Li, K. (2025). Highly Sensitive Temperature Sensor Based on a UV Glue-Filled Fabry–Perot Interferometer Utilizing the Vernier Effect. Photonics, 12(3), 256. https://doi.org/10.3390/photonics12030256