Compact Six-Degree-of-Freedom Displacement Sensing Based on Laser Reflection and Position-Sensitive Detectors

Abstract

1. Introduction

2. Detection Methods and Theoretical Modeling

2.1. Operating Principle of the CCR

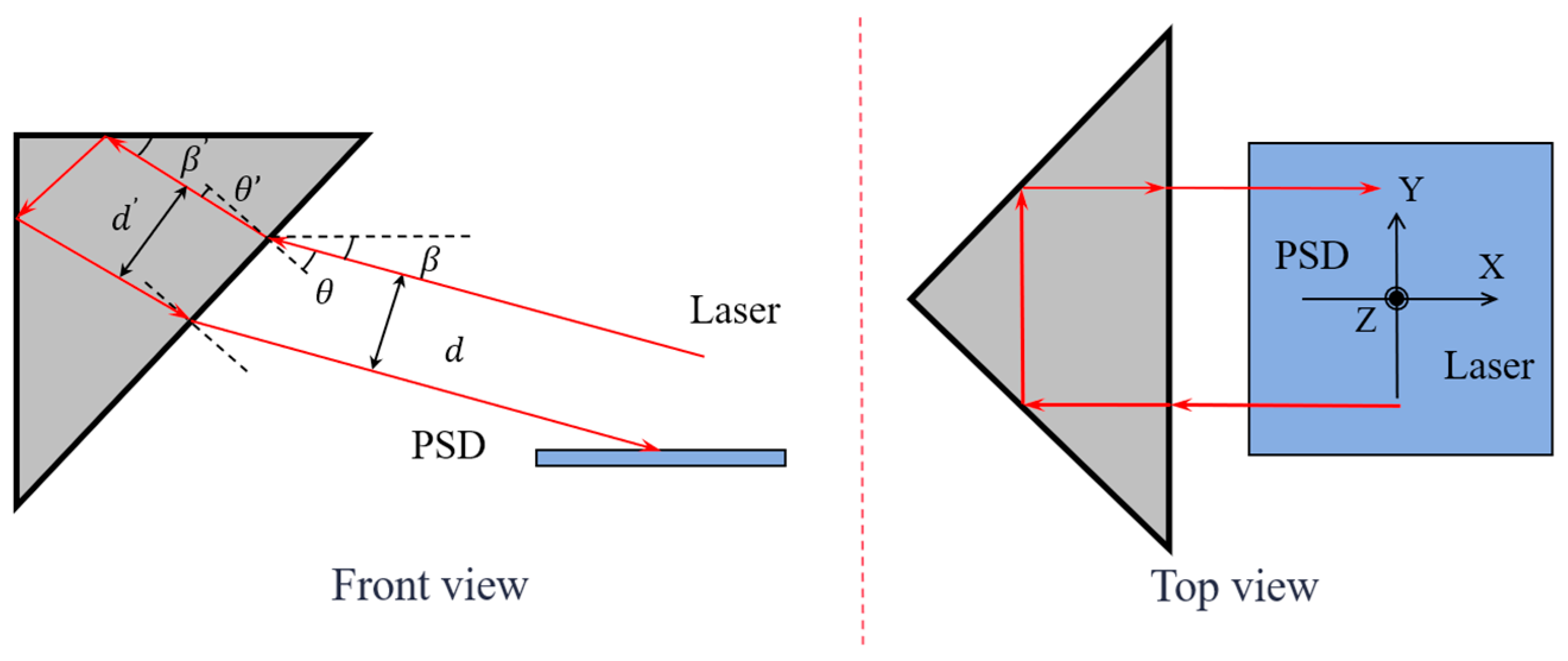

2.2. Theoretical Model for the Single PSD–CCR

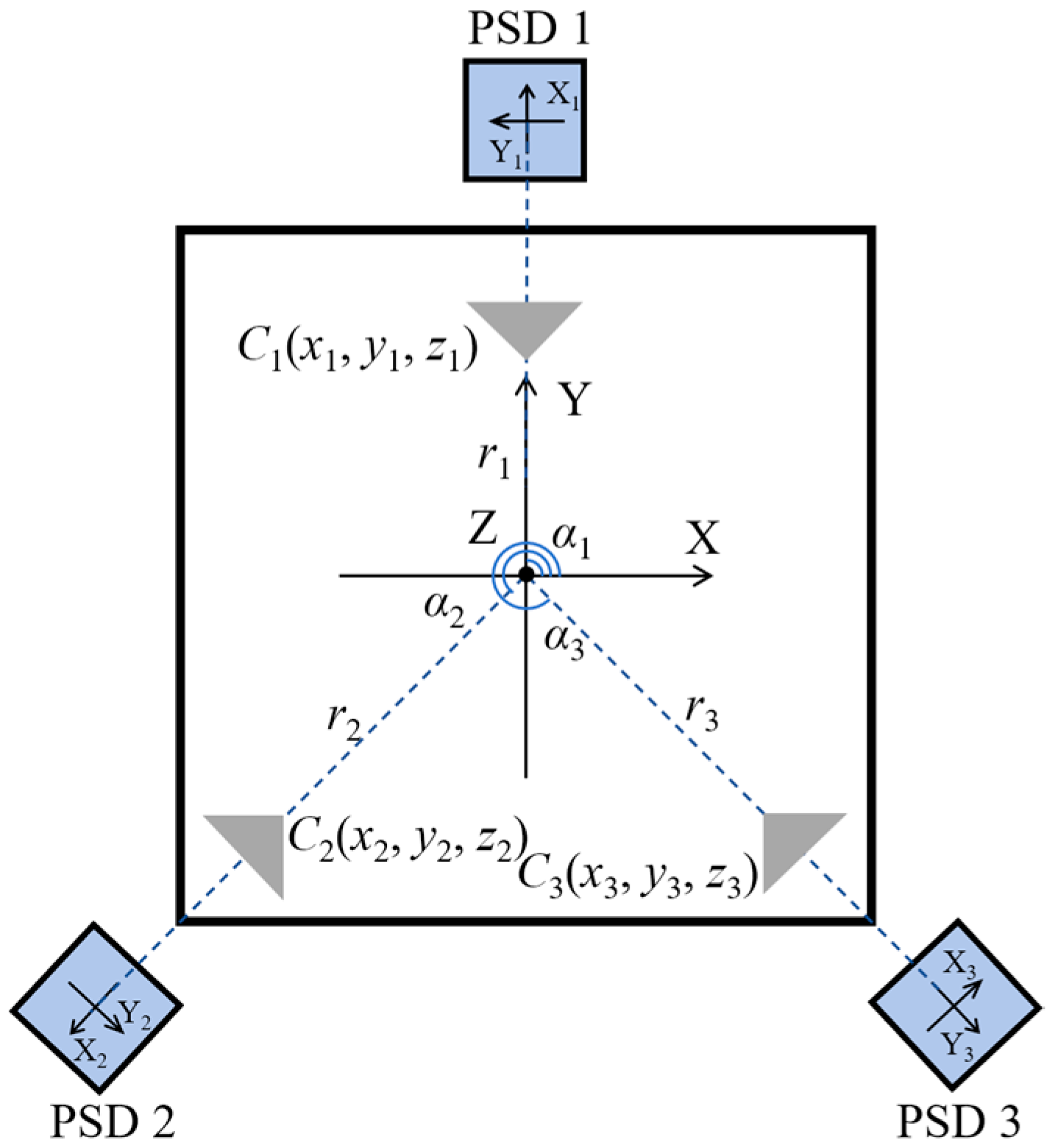

2.3. Overall Theoretical Model

3. Results

3.1. Single PSD–CCR Experiment

3.2. Overall Experiment

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, J.; Yang, Y.; Li, Y.; Cao, D. A 6-DOF micro-vibration isolation platform based on the quasi-zero-stiffness isolator. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 6019–6035. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhou, Z.; Huang, H. A multi-frequency MIMO control method for the 6DOF micro-vibration exciting system. Acta Astronaut. 2020, 170, 552–569. [Google Scholar] [CrossRef]

- Ayres, R.; Underwood, M.A.; Keller, T. Controlling 6-DOF systems with multiple exciters. Sound Vib. 2013, 47, 6–11. [Google Scholar]

- Gao, W.; Haitjema, H.; Fang, F.Z.; Leach, R.K.; Cheung, C.F.; Savio, E.; Linares, J.M. On-machine and in-process surface metrology for precision manufacturing. CIRP Ann. 2019, 68, 843–866. [Google Scholar] [CrossRef]

- Gao, W. Precision Nanometrology: Sensors and Measuring Systems for Nanomanufacturing; Springer: London, UK, 2010. [Google Scholar]

- Farago, F.T.; Curtis, M.A. Handbook of Dimensional Measurement; Industrial Press: New York, NY, USA, 1994. [Google Scholar]

- Lin, J.; Xin, R.; Shi, S.; Huang, Z.; Zhu, J. An accurate 6-DOF dynamic measurement system with laser tracker for large-scale metrology. Measurement 2022, 204, 112052. [Google Scholar] [CrossRef]

- Kumar, A.A.; George, B.; Mukhopadhyay, S.C. Technologies and applications of angle sensors: A review. IEEE Sens. J. 2020, 21, 7195–7206. [Google Scholar] [CrossRef]

- Gao, W.; Kim, S.W.; Bosse, H.; Haitjema, H.; Chen, Y.L.; Lu, X.D.; Knapp, W.; Weckenmann, A.; Estler, W.T.; Kunzmann, H. Measurement technologies for precision positioning. CIRP Ann. 2015, 64, 773–796. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, F.; Liu, T.; Li, J.; Qu, X. Absolute distance measurement with correction of air refractive index by using two-color dispersive interferometry. Opt. Express 2016, 24, 24361–24376. [Google Scholar] [CrossRef]

- Liang, X.; Lin, J.; Yang, L.; Wu, T.; Liu, Y.; Zhu, J. Simultaneous measurement of absolute distance and angle based on dispersive interferometry. IEEE Photon. Technol. Lett. 2020, 32, 449–452. [Google Scholar] [CrossRef]

- Straube, G.; Fischer Calderón, J.S.; Ortlepp, I.; Füßl, R.; Manske, E. A heterodyne interferometer with separated beam paths for high-precision displacement and angular measurements. Nanomanuf. Metrol. 2021, 4, 200–207. [Google Scholar] [CrossRef]

- Steinmetz, C.R. Sub-micron position measurement and control on precision machine tools with laser interferometry. Precis. Eng. 1990, 12, 12–24. [Google Scholar] [CrossRef]

- Ortlepp, I.; Zöllner, J.P.; Rangelow, I.W.; Manske, E. Heterodyne standing-wave interferometer with improved phase stability. Nanomanuf. Metrol. 2021, 4, 190–199. [Google Scholar] [CrossRef]

- Aasi, J.; Abbott, B.P.; Abbott, R.; Abbott, T.; Abernathy, M.R.; Ackley, K. Advanced LIGO. Class. Quantum Gravity 2015, 32, 074001. [Google Scholar]

- Bryan, J.B. The Abbe principle revisited: An updated interpretation. Precis. Eng. 1979, 1, 129–132. [Google Scholar] [CrossRef]

- Ruijl, T.A.M. Ultra Precision Coordinate Measuring Machine: Design, Calibration and Error Compensation. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2001. [Google Scholar]

- Leach, R. Abbe error/offset. In CIRP Encyclopedia of Production Engineering; Chatti, S., Laperrière, L., Reinhart, G., Tolio, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Manske, E.; Jäger, G.; Hausotte, T.; Füßl, R. Recent developments and challenges of nanopositioning and nanomeasuring technology. Meas. Sci. Technol. 2012, 23, 074001. [Google Scholar] [CrossRef]

- Teimel, A. Technology and applications of grating interferometers in high-precision measurement. Precis. Eng. 1992, 14, 147–154. [Google Scholar] [CrossRef]

- Rieger, G.; Ludwig, K.; Hauch, J.; Clemens, W. GMR sensors for contactless position detection. Sens. Actuators A Phys. 2001, 91, 7–11. [Google Scholar] [CrossRef]

- Chen, Z.; Pu, H.; Liu, X.; Peng, D.; Yu, Z. A time-grating sensor for displacement measurement with long range and nanometer accuracy. IEEE Trans. Instrum. Meas. 2015, 64, 3105–3115. [Google Scholar] [CrossRef]

- Shimizu, Y.; Ishida, A.; Matsuno, Y.; Matsukuma, H.; Gao, W. A design study of a heat flow-type reading head for a linear encoder based on a micro thermal sensor. Nanomanuf. Metrol. 2019, 2, 100–110. [Google Scholar] [CrossRef]

- Yu, K.; Zhu, J.; Yuan, W.; Zhou, Q.; Xue, G.; Wu, G.; Wang, X.; Li, X. Two-channel six degrees of freedom grating-encoder for precision-positioning of sub-components in synthetic-aperture optics. Opt. Express 2021, 29, 21113–21128. [Google Scholar] [CrossRef]

- Gao, W.; Saito, Y.; Muto, H.; Arai, Y.; Shimizu, Y. A three-axis autocollimator for detection of angular error motions of a precision stage. CIRP Ann. 2011, 60, 515–518. [Google Scholar] [CrossRef]

- Krupa, A.; Lackowski, M.; Jaworek, A. Capacitance sensor for measuring void fraction in small channels. Measurement 2021, 175, 109046. [Google Scholar] [CrossRef]

- Beverte, I.; Cabulis, U.; Gaidukovs, S. Polytetrafluoroethylene films in rigid polyurethane foams’ dielectric permittivity measurements with a one-side access capacitive sensor. Polymers 2021, 13, 1173. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, R.; Du, H.; Lu, Y. Three-dimensional micro-displacement measurement method based on capacitance-grating sensor. Measurement 2022, 187, 110179. [Google Scholar] [CrossRef]

- Peng, Y.; Ito, S.; Shimizu, Y.; Azuma, T.; Gao, W.; Niwa, E. A Cr–N thin film displacement sensor for precision positioning of a micro-stage. Sens. Actuators A Phys. 2014, 211, 89–97. [Google Scholar] [CrossRef]

- Adachi, K.; Matsukuma, H.; Sugawara, T.; Shimizu, Y.; Gao, W.; Niwa, E.; Sasaki, Y. Integration of a Cr–N thin-film displacement sensor into an XY micro-stage for closed-loop nano-positioning. Nanomanuf. Metrol. 2019, 2, 131–139. [Google Scholar] [CrossRef]

- Mehta, A.; Mohammed, W.; Johnson, E.G. Multimode interference-based fiber-optic displacement sensor. IEEE Photon. Technol. Lett. 2003, 15, 1129–1131. [Google Scholar] [CrossRef]

- Xue, R.; Hooshmand, H.; Isa, M.; Piano, S.; Leach, R. Applying machine learning to optical metrology: A review. Meas. Sci. Technol. 2024, 36, 012002. [Google Scholar] [CrossRef]

- Zuo, C.; Qian, J.; Feng, S.; Yin, W.; Li, Y.; Fan, P.; Han, J.; Qian, K.; Chen, Q. Deep learning in optical metrology: A review. Light Sci. Appl. 2022, 11, 39. [Google Scholar] [CrossRef]

- Cheng, M.; Jiang, W.; Guo, L.; Li, J.; Forbes, A. Metrology with a twist: Probing and sensing with vortex light. Light Sci. Appl. 2025, 14, 4. [Google Scholar] [CrossRef]

- Shin, M.K.; Yoon, H.S.; Park, K.H. Study on comparing the signal processing of a linear CCD with a PSD for displacement measurement. In Proceedings of the 2004 International Symposium on Intelligent Signal Processing and Communication Systems, Seoul, Republic of Korea, 18–19 November 2004; pp. 762–766. [Google Scholar]

- Zefeng, S.; Jiehu, K.; Zhen, Z.; Luyuan, F.; Bin, W. High-accuracy and efficient method for calibrating spatial laser beam based on optimized PSD. Opt. Commun. 2023, 527, 128946. [Google Scholar]

- Dwik, S.; Sasikala, G.; Natarajan, S. Advancements and applications of position-sensitive detector (PSD): A review. Optoelectron. Lett. 2024, 20, 330–338. [Google Scholar] [CrossRef]

- Das, S.; Saha, A. Laser beam position-dependent PSD-based calibrated self-vibration compensated noncontact vibration measurement system. IEEE Trans. Instrum. Meas. 2018, 68, 3308–3320. [Google Scholar] [CrossRef]

- Hu, L.; Sun, D.; Duan, H.; Shu, A.; Zhou, S.; Pei, H. Non-cooperative spacecraft pose measurement with binocular camera and TOF camera collaboration. Appl. Sci. 2023, 13, 1420. [Google Scholar] [CrossRef]

- Hu, L.; Duan, H.; Pei, H.; Sun, D.Q.; Shu, A. Binocular vision position and attitude measurement for key features of non-cooperative spacecraft. Chin. J. Lasers 2022, 49, 1704003–1704009. [Google Scholar]

- Li, L.; Yong, L.; Hao, M.; Jiaxing, H. New method for measuring 6-DOF micro-displacement based on multi-collimated beams. Infrared Laser Eng. 2019, 48, 0617002. [Google Scholar]

- Gao, Y.; Liu, W.; Lv, S.; Zhang, Y.; Dong, W. Six-degree-of-freedom displacement and angle measurement system based on two-dimensional position-sensitive detector. Opt. Precis. Eng. 2018, 26, 2930–2939. [Google Scholar]

- Huang, X.; Yu, W.; Tan, J. Study on real-time compensation method for laser drift in 2D displacement measurement. J. Optoelectron. Laser 2014, 25, 299–304. [Google Scholar]

- Chen, Y.; Lin, W.; Liu, C. Design and experimental verification of novel six-degree-of freedom geometric error measurement system for linear stage. Opt. Lasers Eng. 2017, 92, 94–104. [Google Scholar]

- Liu, C.; Pu, Y.; Chen, Y.; Luo, Y. Design of a measurement system for simultaneously measuring six-degree-of-freedom geometric errors of a long linear stage. Sensors 2018, 18, 3875. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Sun, S.; Yan, X.; Liu, F.; Cao, L.; Wang, Q.; Sun, Y. Six-degree-of-freedom posture measurement technologies using position sensitive detectors (PSDs): State of the art. Micromachines 2022, 13, 1903. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, L.D.; Ross, M.; Tipton, G.; Cross, K.; Hunter, N., Jr.; Harvie, J.; Nelson, G. Experimental execution of 6DOF tests derived from field tests. In Shock & Vibration, Aircraft/Aerospace, Energy Harvesting, Acoustics & Optics, Volume 9, Proceedings of the 35th International Modal Analysis Conference, A Conference and Exposition on Structural Dynamics 2017, Garden Grove, CA, USA, 30 January–2 February 2016; Springer International Publishing: Cham, Switzerland, 2017; pp. 125–132. [Google Scholar]

- Kim, Y.H.; Kapoor, A.; Mansi, T.; Kamen, A. A wide-area, low-latency, and power-efficient 6-DoF pose tracking system for rigid objects. IEEE Sens. J. 2022, 22, 4558–4568. [Google Scholar] [CrossRef]

- Lin, S.; Wang, W.; Wang, H.; Song, Y.; Pan, Y.; Qiao, J.; Xue, Y.; Chen, Q.; Liu, M.; Shen, Y. A high-precision dynamic six degree-of-freedom pose measurement of the subreflectors of large antennas based on a position sensitive detector and laser array. Adv. Astron. 2022, 2022, 3255088. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Z.; Cheng, S.; Yang, H.; Huang, B.; Liu, J. Study on the effect of spot size and non-linearity on PSD positioning accuracy. Wuhan Univ. J. Nat. Sci. 2025, 30, 213–221. [Google Scholar] [CrossRef]

- Fu, W.; Lu, Z.; Wu, X.; Huang, Y.; Gao, B.; Chen, X. Research on decoupling method for six-degree-of-freedom displacement measurement based on PSD. Infrared Laser Eng. 2024, 53, 113–124. [Google Scholar]

- Chang, Y.; Hao, G.; Liu, C. Design and characterisation of a compact 4-degree-of-freedom fast steering mirror system based on double Porro prisms for laser beam stabilization. Sens. Actuators A Phys. 2021, 322, 112639. [Google Scholar] [CrossRef]

- Wang, Y.; Qin, C.; Xu, Z. Non-contact large-stroke position and attitude measurement system for parallel robots. Electr. Meas. Technol. 2025, 48, 1–8. [Google Scholar]

- Zhao, Y.; Zhang, B.; Feng, Q. Measurement system and model for simultaneously measuring 6DOF geometric errors. Opt. Express 2017, 25, 20993–21007. [Google Scholar] [CrossRef]

| Configuration Type | Unit Position Accuracy (×10−3) | Unit Angular Accuracy (×10−3) | |

|---|---|---|---|

| Fu et al. [51] | Normal incidence | 3.02 | 5.67 |

| Chang et al. [52] | Normal incidence | 30.00 | 5.00 |

| Wang et al. [53] | Normal incidence | 4.15 | 14.25 |

| Kim et al. [48] | Normal incidence | 10.00 | 22.22 |

| Zhao et al. [54] | Normal incidence | 7.73 | 4.45 |

| Ours | Refraction | 3.93 | 5.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Li, J.; Diao, Y.; Wang, K.; Dong, W.; Yu, M.; Li, Z. Compact Six-Degree-of-Freedom Displacement Sensing Based on Laser Reflection and Position-Sensitive Detectors. Photonics 2025, 12, 1072. https://doi.org/10.3390/photonics12111072

Chen J, Li J, Diao Y, Wang K, Dong W, Yu M, Li Z. Compact Six-Degree-of-Freedom Displacement Sensing Based on Laser Reflection and Position-Sensitive Detectors. Photonics. 2025; 12(11):1072. https://doi.org/10.3390/photonics12111072

Chicago/Turabian StyleChen, Jingyu, Junjie Li, Yuan Diao, Ke Wang, Wenbo Dong, Mengxi Yu, and Zongfeng Li. 2025. "Compact Six-Degree-of-Freedom Displacement Sensing Based on Laser Reflection and Position-Sensitive Detectors" Photonics 12, no. 11: 1072. https://doi.org/10.3390/photonics12111072

APA StyleChen, J., Li, J., Diao, Y., Wang, K., Dong, W., Yu, M., & Li, Z. (2025). Compact Six-Degree-of-Freedom Displacement Sensing Based on Laser Reflection and Position-Sensitive Detectors. Photonics, 12(11), 1072. https://doi.org/10.3390/photonics12111072