Numerical Simulation and Microstructure Examination of a Low-Alloy Structural Steel for Laser Transformation Hardening Treatment

Abstract

1. Introduction

2. Materials and Methods

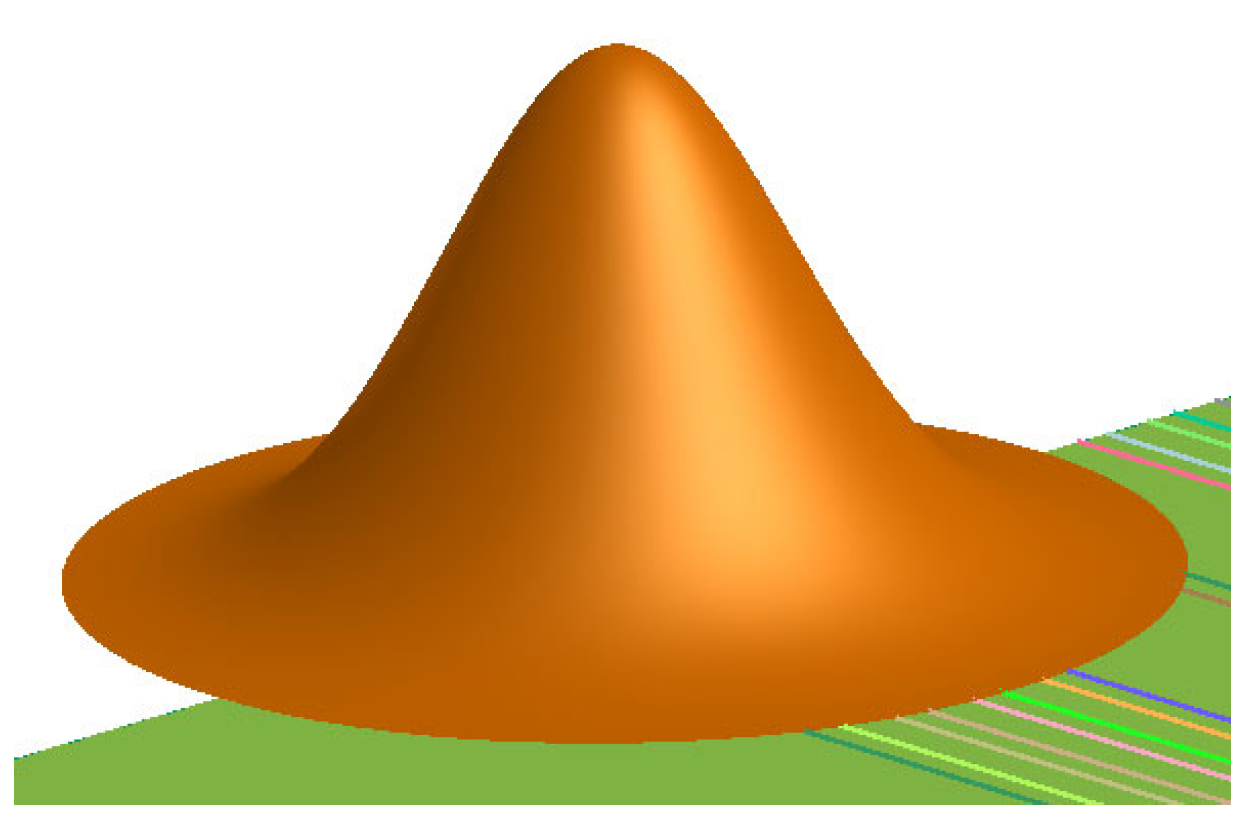

2.1. Heat Source Model

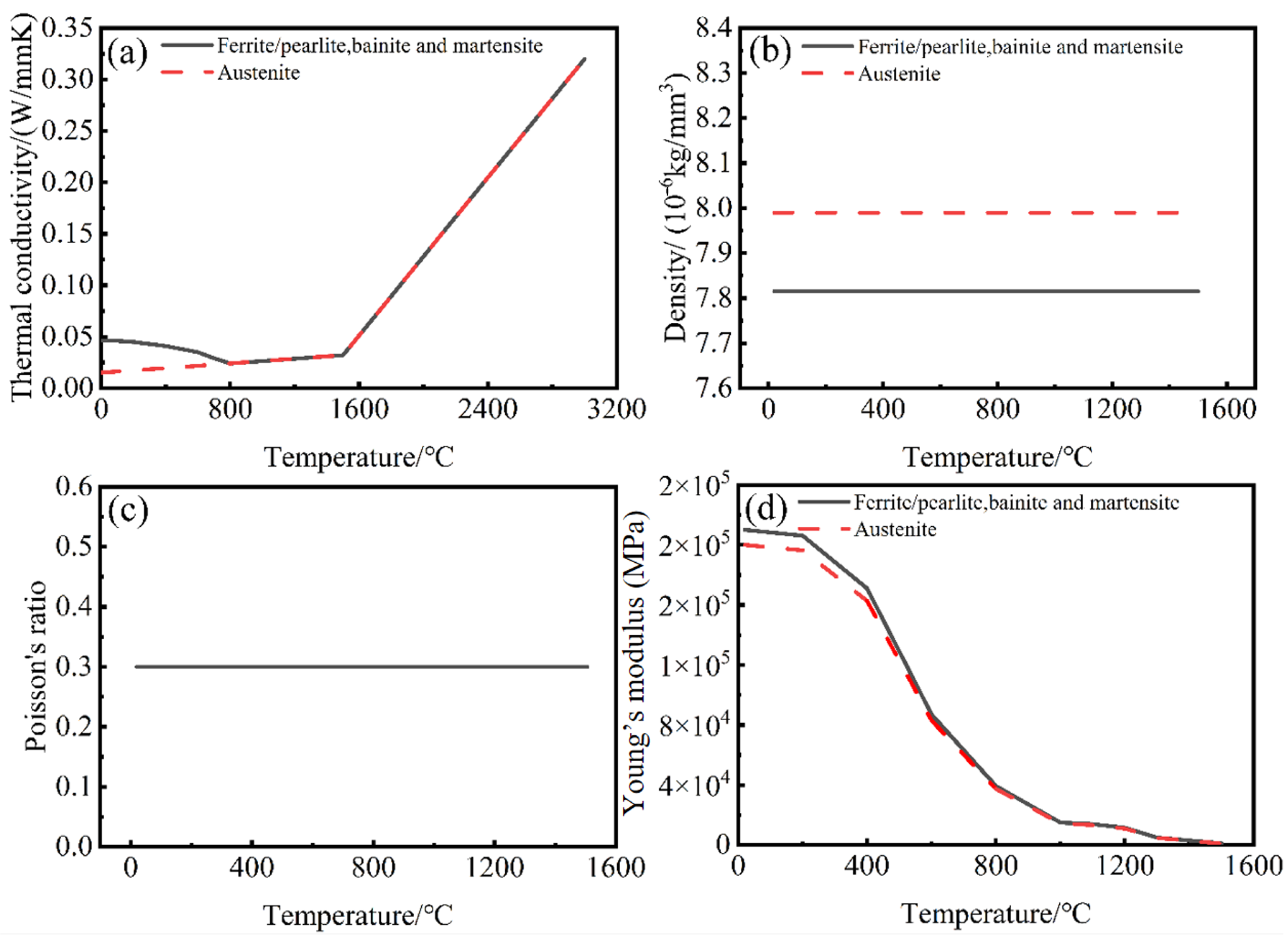

2.2. Establishment of the Numerical Model

3. Results and Discussion

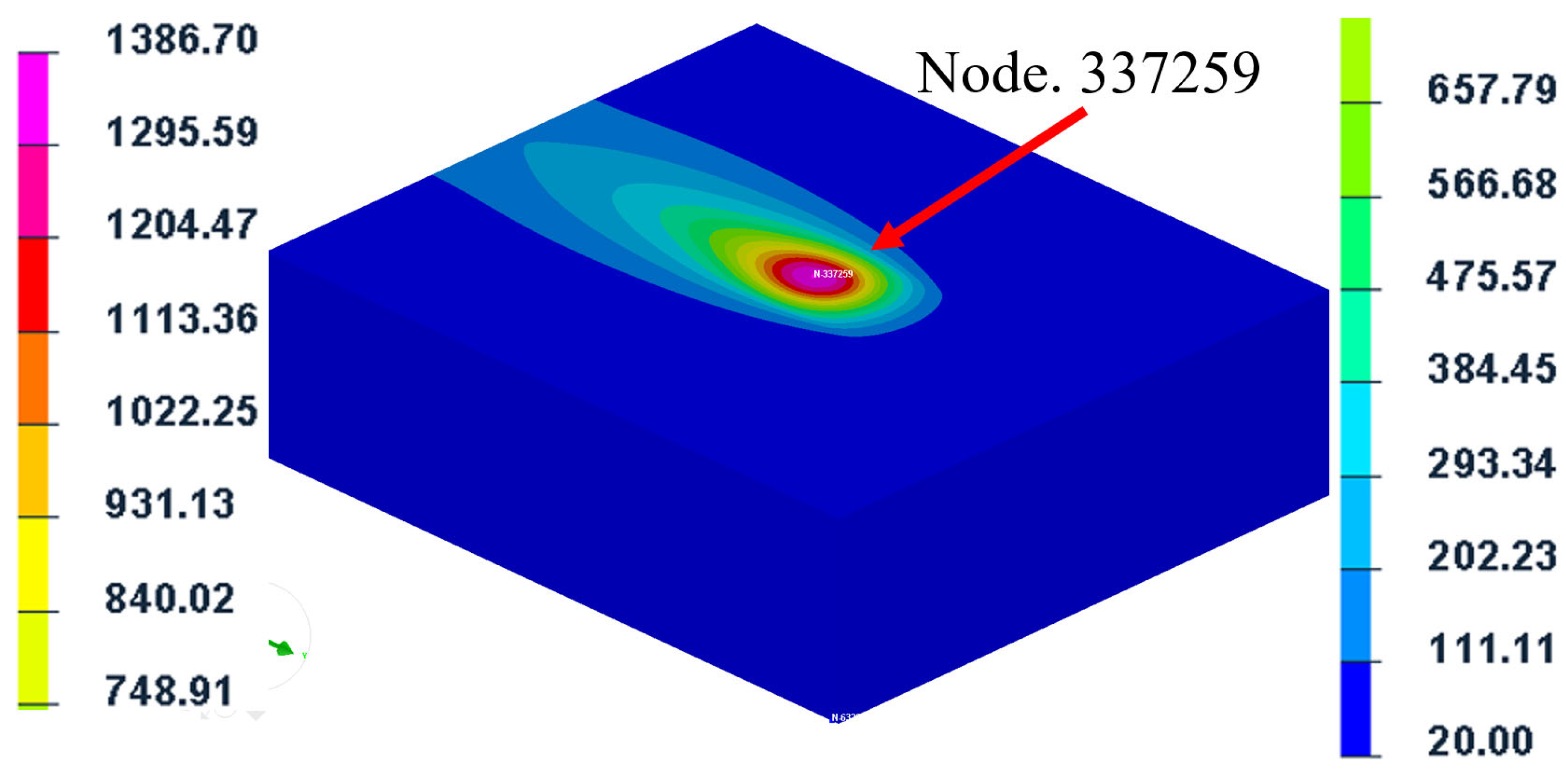

3.1. Temperature Field Simulation Analysis of Laser Phase Transformation Hardening Process

3.1.1. Single-Pass Laser Phase Transformation Hardening Simulation Analysis

3.1.2. Two-Pass Overlaying Laser Phase Transformation Hardening Simulation Analysis

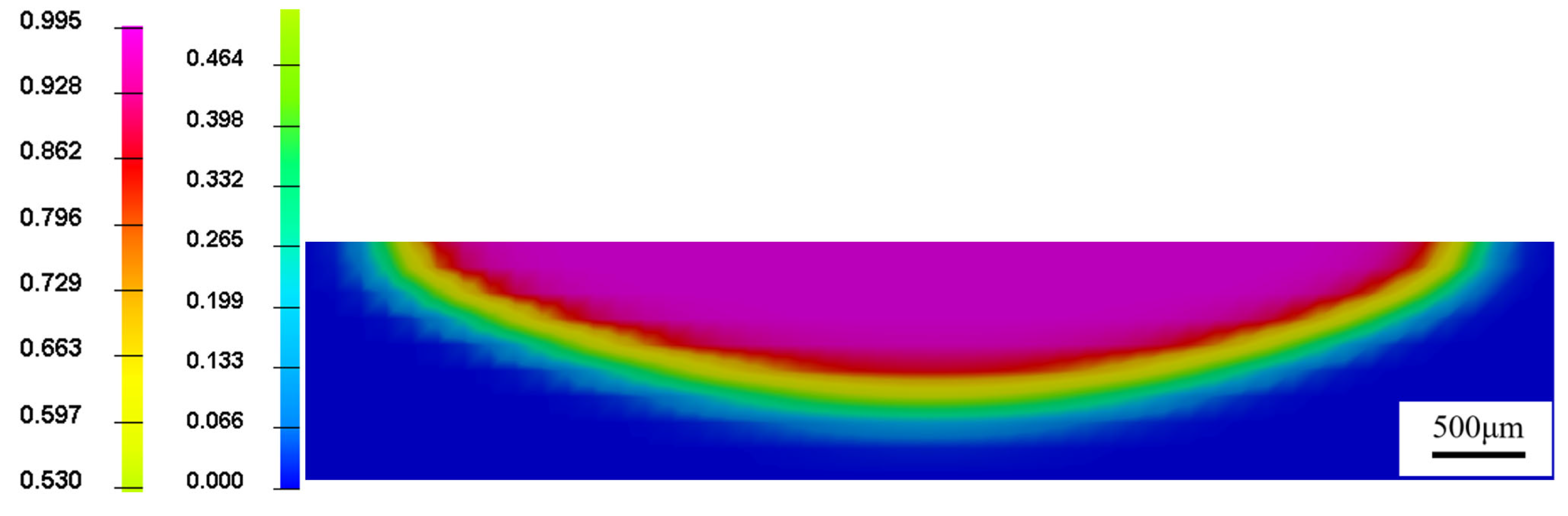

3.2. Laser Phase Transformation Hardening Experimental Verification

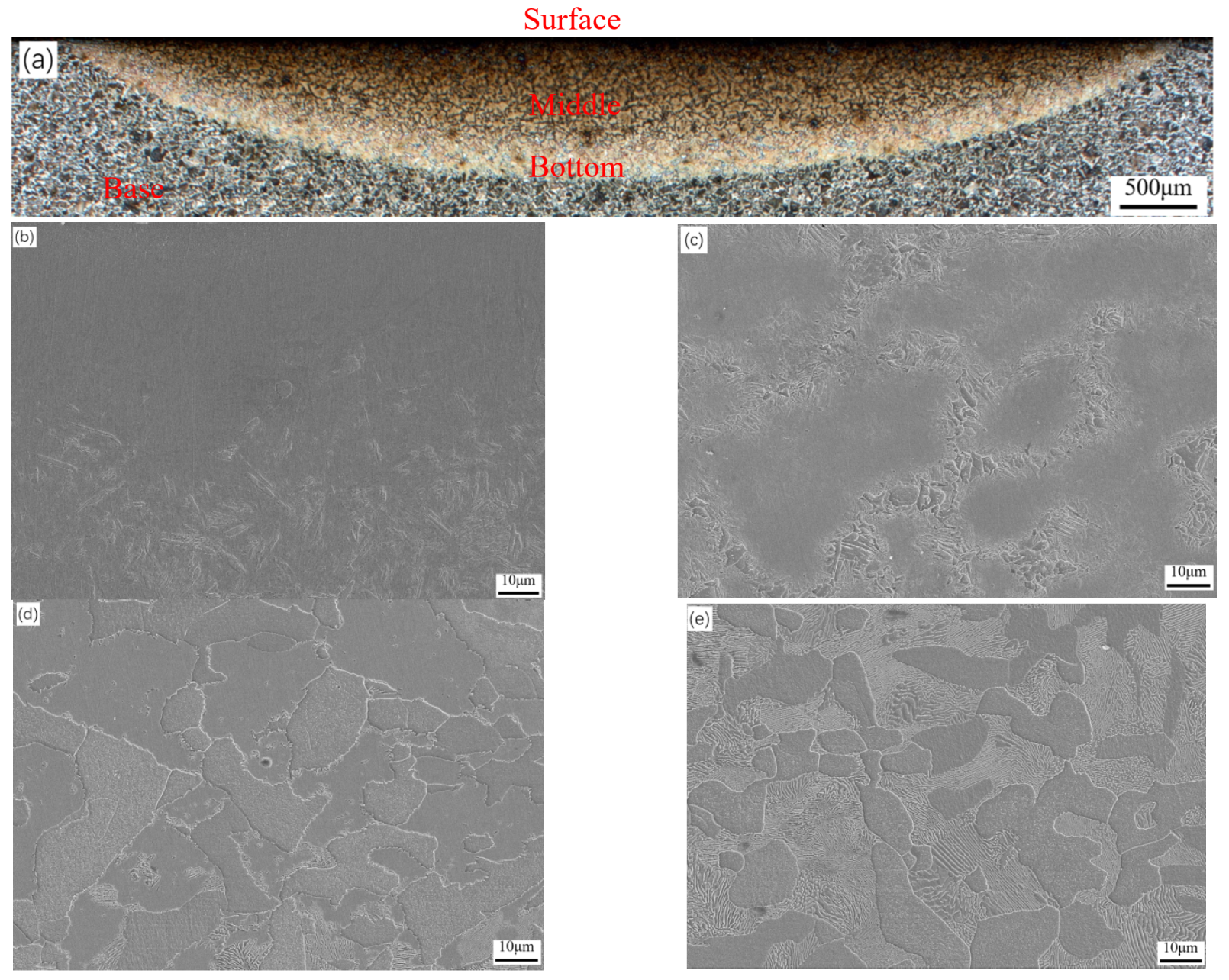

3.2.1. Single-Pass Laser Phase Transformation Hardening Metallographic Structure

3.2.2. Analysis of Two-Pass Laser Phase Transformation Hardened Area Structure

3.2.3. Laser Phase Transformation Hardening Hardness Test

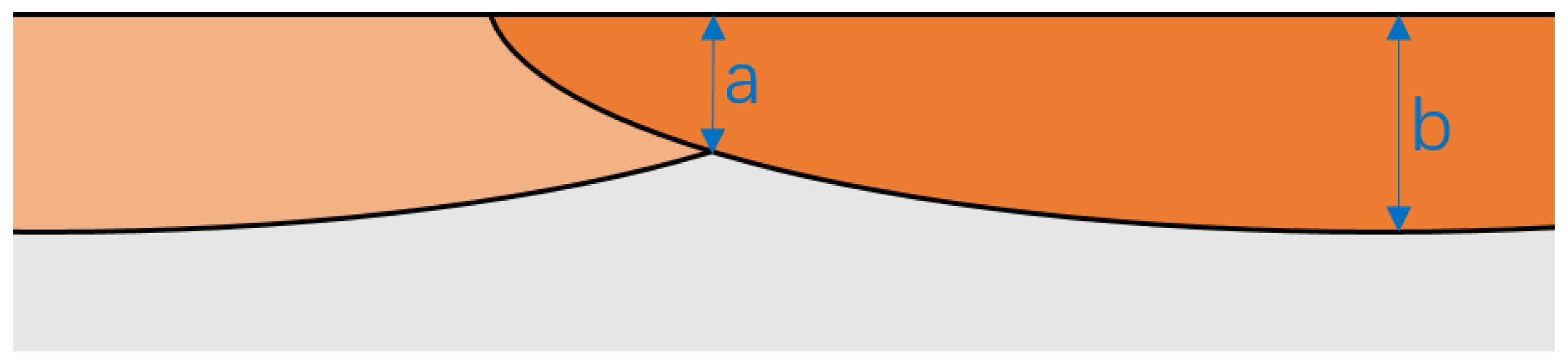

3.3. Study on Laser Phase Transformation Hardening Overlap Rate

4. Conclusions

- (1)

- The error between the width of the hardened layer obtained from single-pass laser phase transformation hardening simulations and experimental results is 10.7%, while the error in depth is 1.2%, both within an acceptable range. The results of two-pass overlapping laser phase transformation hardening experiments are generally consistent with the simulation results in terms of morphology. The error between the simulated and measured softened zone widths on the surface is approximately 6.5%, while at a depth of 250 μm, the error in softened zone width is about 9.1%.

- (2)

- A comparison between simulations and experiments of two-pass overlapping laser phase transformation hardening revealed that the depth of the second laser pass is slightly greater than that of the first. This is attributed to heat accumulation from the initial laser processing, resulting in a higher starting temperature during the second pass, which increases the overall temperature during the second phase transformation hardening. Optimizing laser phase transformation hardening parameters and overlap rates is essential for mitigating the effects of the tempered softened zones and achieving more uniform hardening results. The choice of the degree of overlapping will vary depending on the conditions of the laser exposure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Z.-X.; Tong, B.-Q.; Zhang, Q.-L.; Yao, J.-H.; Kovalenko, V. Microstructure refinement and properties of 1.0C-1.5Cr steel in a duplex treatment combining double quenching and laser surface quenching. Mater. Sci. Eng. A 2020, 776, 138994. [Google Scholar] [CrossRef]

- Wang, G.; Wang, J.; Cheng, K.; Yang, K.; Zhang, W. Nano hierarchical hill-like structure with TA1 surface manufactured by LIPSS for anti-corrosion and anti-icing. J. Mater. Res. Technol. 2025, 35, 562. [Google Scholar] [CrossRef]

- Makarov, A.V.; Korshunov, L.G.; Malygina, I.Y.; Osintseva, A.L. Effect of laser quenching and subsequent heat treatment on the structure and wear resistance of a cemented steel 20KhN3A. Phys. Met. Met. 2007, 103, 507–518. [Google Scholar] [CrossRef]

- Chen, Z.; Zhu, Q.; Wang, J.; Yun, X.; He, B.; Luo, J. Behaviors of 40Cr steel treated by laser quenching on impact abrasive wear. Opt. Laser Technol. 2018, 103, 118–125. [Google Scholar] [CrossRef]

- Zhang, T.; Fan, Q.; Ma, X.; Wang, W.; Wang, K.; Shen, P.; Yang, J. Microstructure and Mechanical Properties of Ti-35Nb-2Ta-3Zr Alloy by Laser Quenching. Front. Mater. 2019, 6, 318. [Google Scholar] [CrossRef]

- Adel, K. Enhancement of Dry Sliding Wear Characteristics of CK45 Steel Alloy by Laser Surface Hardening Processing. Procedia Mater. Sci. 2014, 6, 1639–1643. [Google Scholar] [CrossRef]

- Babu, P.D.; Marimuthu, P. Status of laser transformation hardening of steel and its alloys: A review. Emerg. Mater. Res. 2019, 8, 188–205. [Google Scholar] [CrossRef]

- Karamimoghadam, M.; Moradi, M.; Azami, M. A comparative investigation of different overlaps of the diode laser hardening in low-carbon steel and stainless steel. Optik 2022, 251, 168093. [Google Scholar] [CrossRef]

- Li, C.; Gao, H.; Chen, X.; Liu, Z.; Han, X. Study on Multi-Field Coupled Evolution Mechanism of Laser Irradiated 40Cr Steel Quenching Process Based on Phase Change Induced Plasticity. Met. Mater. Int. 2021, 28, 1919–1937. [Google Scholar] [CrossRef]

- Muthukumaran, G.; Babu, P.D. Laser transformation hardening of various steel grades using different laser types. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 1–29. [Google Scholar] [CrossRef]

- Wang, S.; Yan, S.; Lin, J.; Batako, A.D. Study on the effects of laser quenching power and scanning speed on the property of cast iron. J. Phys. Conf. Ser. 2022, 2198, 012050. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, M.; Ji, S.; Zhang, J.; Fan, H. Numerical simulation and experimental study on laser hardening process of the 42CrMo4 steel. Adv. Mech. Eng. 2021, 13, 1–9. [Google Scholar] [CrossRef]

- Aberbache, H.; Mathieu, A.; Bolot, R.; Bleurvacq, L.; Corolleur, A.; Laurent, F. Experimental analysis and numerical simulation of Laser welding of thin austenitic stainless-steel sheets using two models: Bilinear isotropic strain hardening model and Johnson–Cook model. J. Adv. Join. Process. 2024, 9, 100198. [Google Scholar] [CrossRef]

- Li, Z.-X.; Wang, X.-N.; Chen, J.; Zhang, Z.-Y.; Hu, Z.-R.; Chu, Y.-J.; Chen, J.-S.; Han, Y.-J. Influence of laser surface treatment on the microstructure distribution, bearing capacity and impact property of 1.0C-1.5Cr steel. Mater. Today Commun. 2023, 35, 106216. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, M.; Ji, S.; Dou, Y. Combining the Finite Element Analysis and Kriging Model for Study on Laser Surface Hardening Parameters of Pitch Bearing Raceway. Materials 2022, 15, 2681. [Google Scholar] [CrossRef] [PubMed]

- Xu, X. Research on Numerical Simulation and Temperature Control Technology of Laser Transformation Hardening; Shandong University: Jinan, China, 2022. [Google Scholar] [CrossRef]

- Schüßler, P.; Damon, J.; Mühl, F.; Dietrich, S.; Schulze, V. Laser surface hardening: A simulative study of tempering mechanisms on hardness and residual stress. Comput. Mater. Sci. 2023, 221, 112079. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhang, B.; Zheng, M.; Zhao, X.; Xu, J. Corrosion Behaviors of S355 Steel under Simulated Tropical Marine Atmosphere Conditions. J. Mater. Eng. Perform. 2022, 31, 10054–10062. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | S | P | Fe |

|---|---|---|---|---|---|---|

| Concentration | 0.18 | 0.45 | 1.35 | 0.032 | 0.036 | Bal. |

| Laser Irradiation Power (W) | Scanning Speed (mm/s) | Spot Diameter Φ (mm) | Overlapping Ratio |

|---|---|---|---|

| 1000 | 20 | 6 | / |

| Lap Width (mm) | Least Depth (mm) | Maximum Depth (mm) | Flatness (Y) |

|---|---|---|---|

| 0 | 0 | 0.798 | 0 |

| 1 | 0 | 0.797 | 0 |

| 2 | 0.318 | 0.801 | 0.397 |

| 3 | 0.481 | 0.813 | 0.592 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, P.; Qian, L.; Ren, J.; Wang, Y. Numerical Simulation and Microstructure Examination of a Low-Alloy Structural Steel for Laser Transformation Hardening Treatment. Photonics 2025, 12, 992. https://doi.org/10.3390/photonics12100992

He P, Qian L, Ren J, Wang Y. Numerical Simulation and Microstructure Examination of a Low-Alloy Structural Steel for Laser Transformation Hardening Treatment. Photonics. 2025; 12(10):992. https://doi.org/10.3390/photonics12100992

Chicago/Turabian StyleHe, Peiyu, Liming Qian, Junnan Ren, and Yun Wang. 2025. "Numerical Simulation and Microstructure Examination of a Low-Alloy Structural Steel for Laser Transformation Hardening Treatment" Photonics 12, no. 10: 992. https://doi.org/10.3390/photonics12100992

APA StyleHe, P., Qian, L., Ren, J., & Wang, Y. (2025). Numerical Simulation and Microstructure Examination of a Low-Alloy Structural Steel for Laser Transformation Hardening Treatment. Photonics, 12(10), 992. https://doi.org/10.3390/photonics12100992