High-Precision Beam Deflection and Diagnostics System for EUV Synchrotron Radiation Illumination

Abstract

1. Introduction

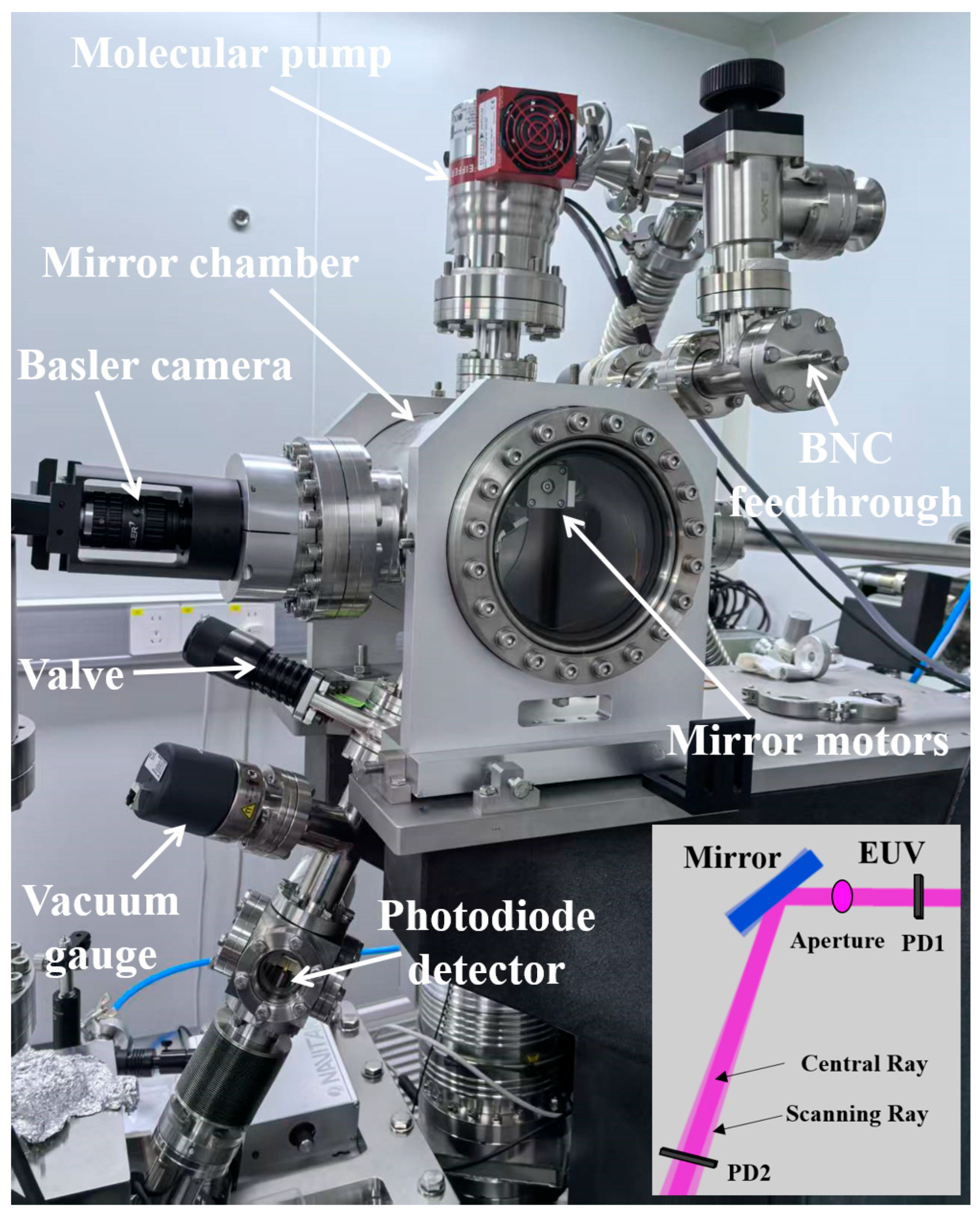

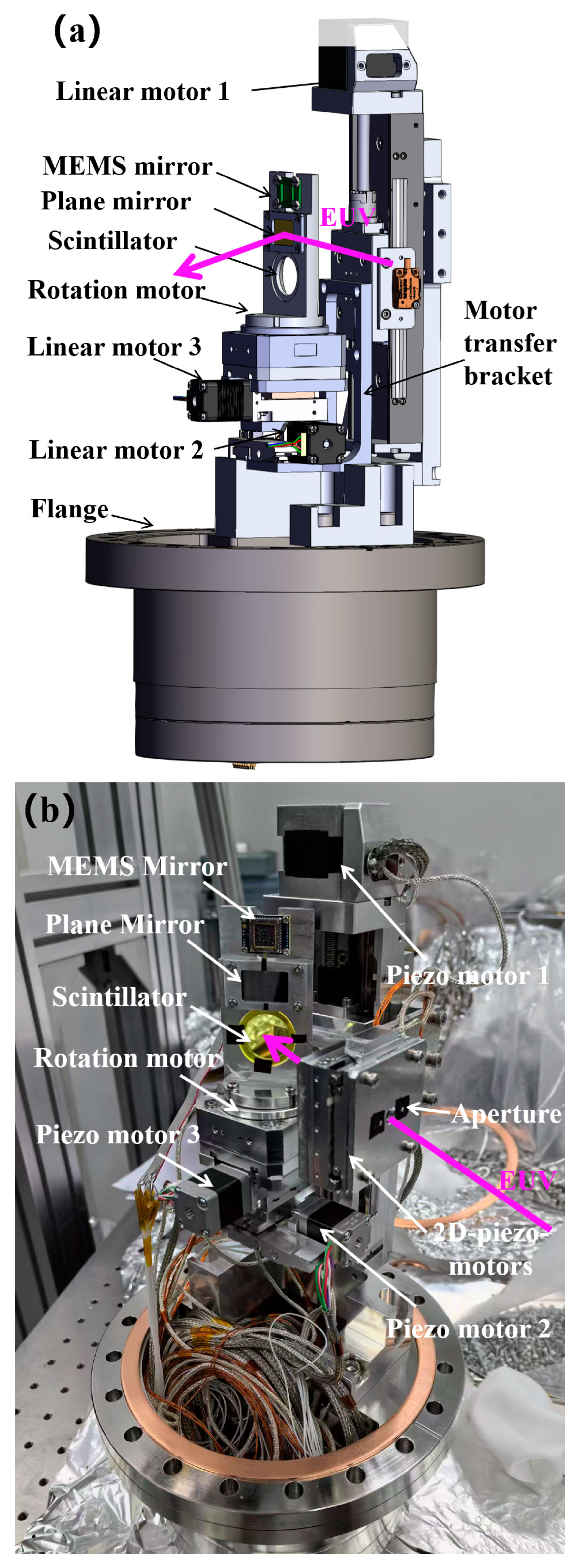

2. EUV Beam Deflection System

2.1. Deflection Planar Mirrors and Moving Stages

2.2. Micro Aperture

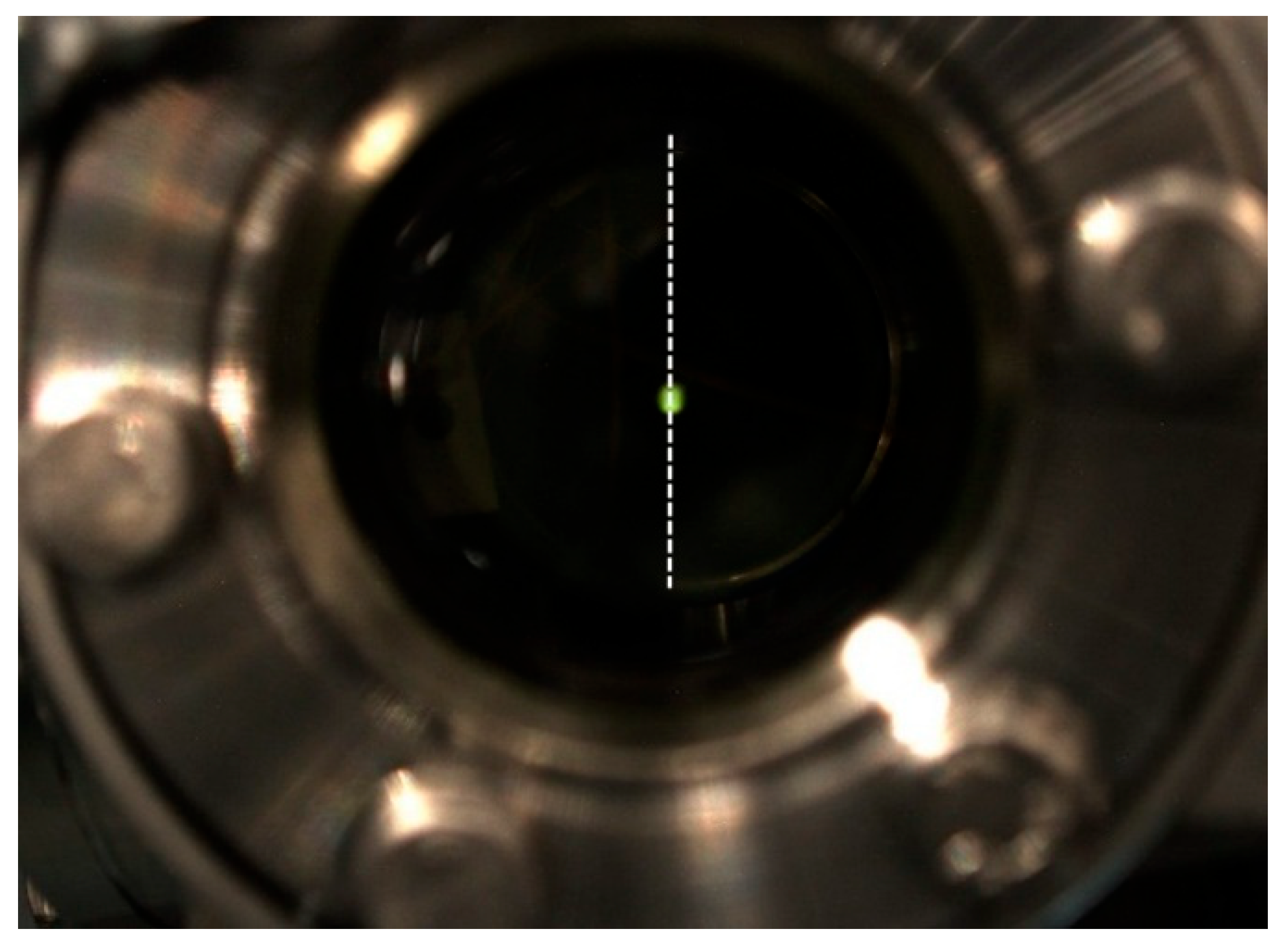

2.3. YAG Scintillator and Imaging Camera

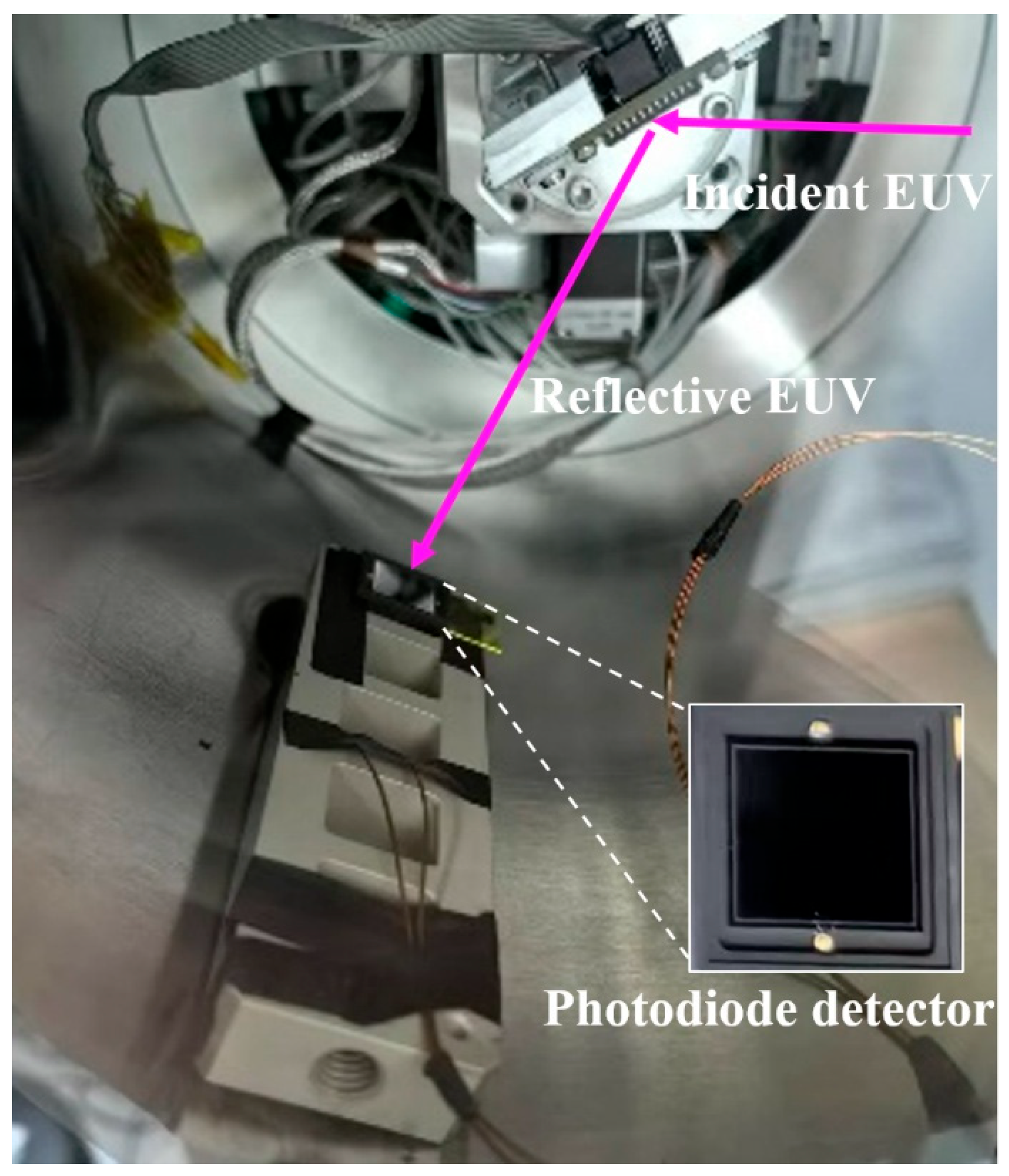

2.4. Photodiode Detector

3. Experimental Results

3.1. Incident EUV Spot Imaging

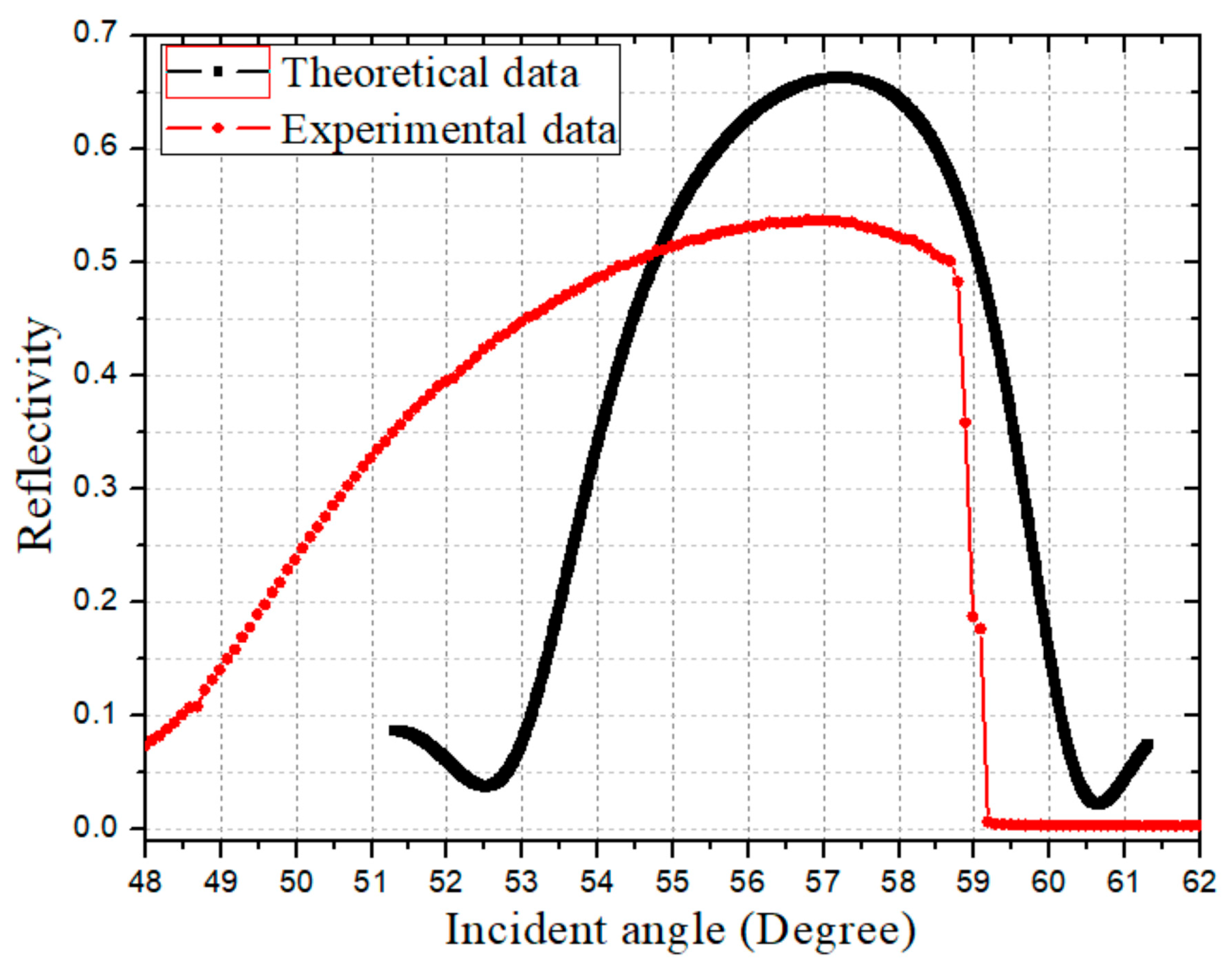

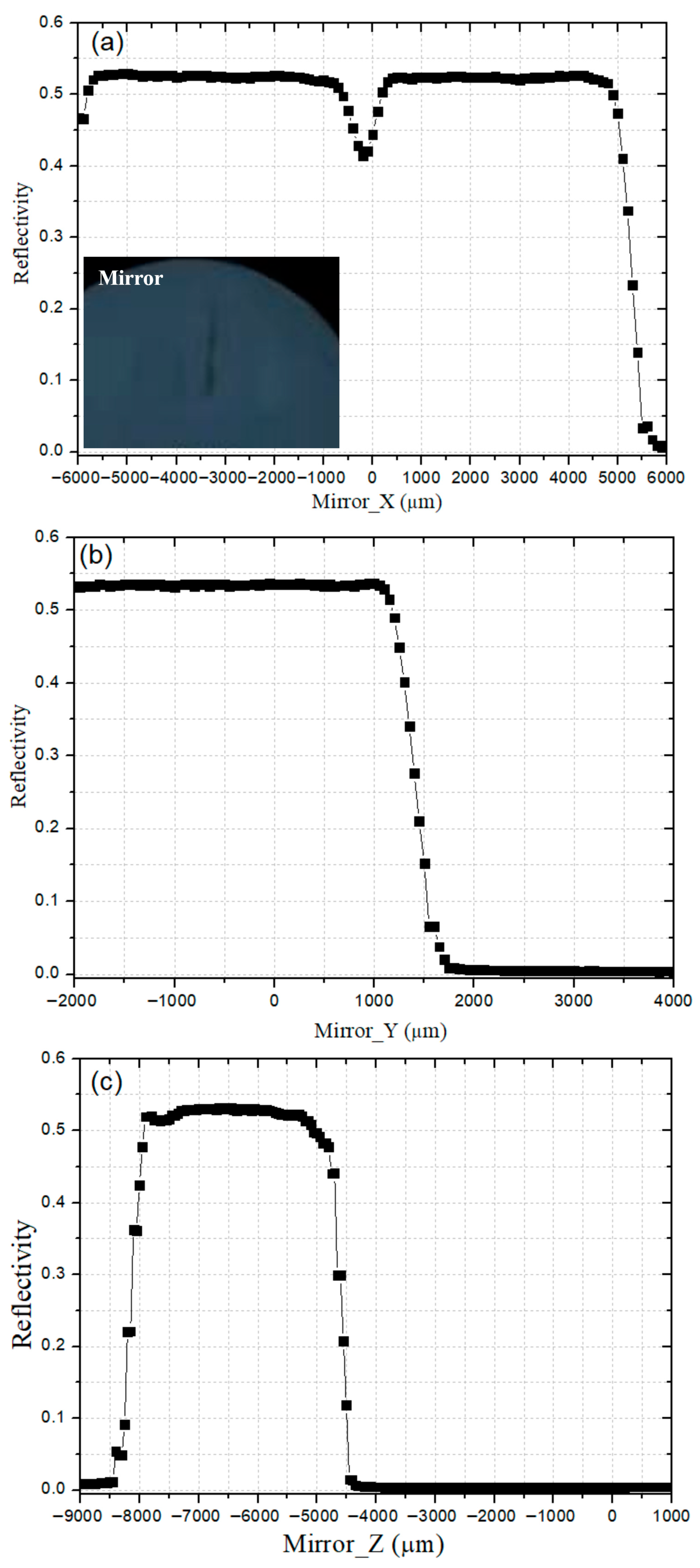

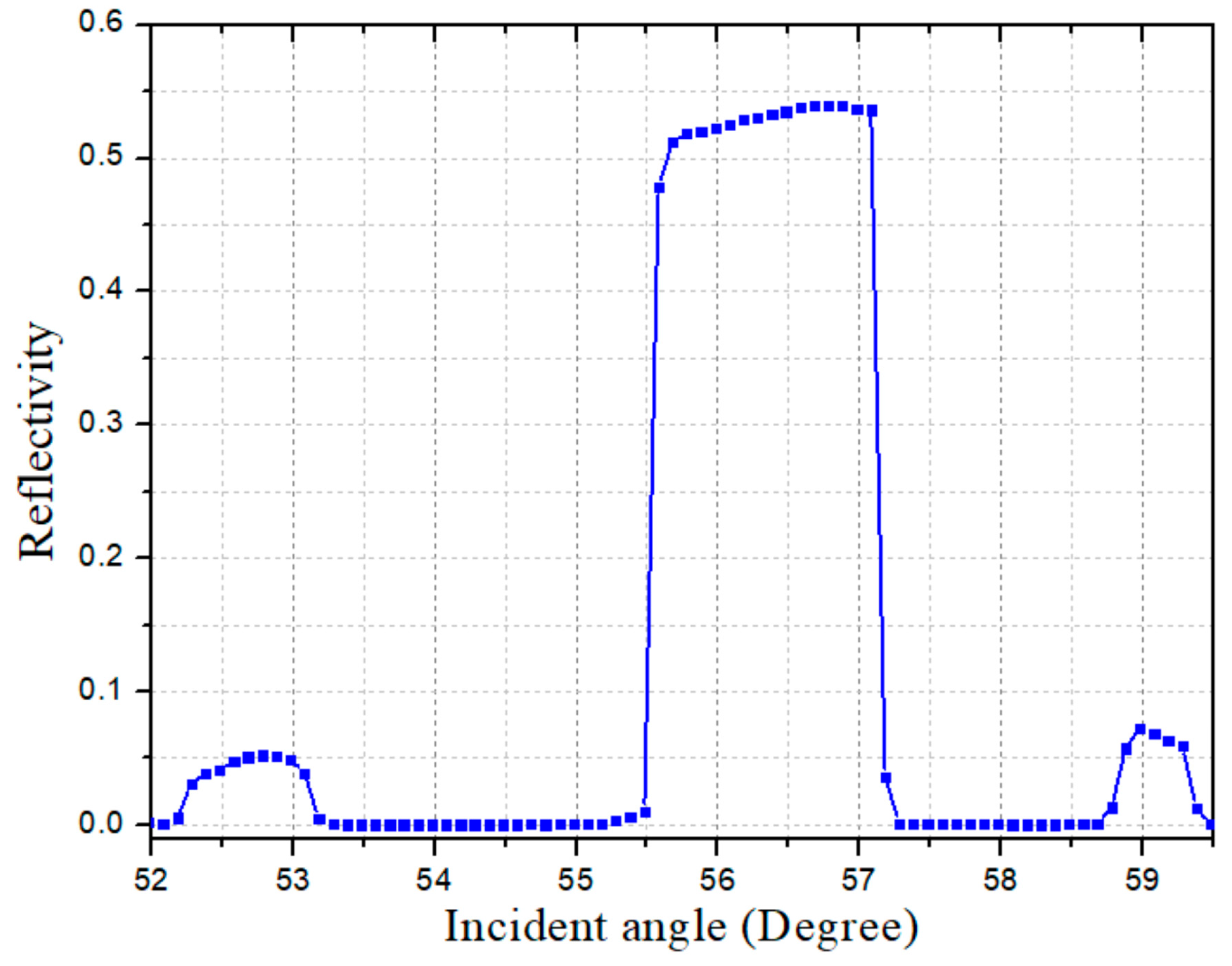

3.2. Mirror Reflection Efficiency

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SSRF | Shanghai Synchrotron Radiation Facility |

| EUV | Extreme Ultraviolet |

| LPP | Laser-Produced Plasma |

| DPP | Discharge-Produced Plasma |

| HHG | High-Harmonic Generation |

| FEL | Free-Electron Laser |

| NA | Numerical Apertures |

| MET | Micro-field Exposure Tool |

| PAL | Pohang Accelerator Laboratory |

| PSI | Paul Scherrer Institute |

References

- Yang, D.-K.; Wang, D.; Huang, Q.-S.; Song, Y.; Wu, J.; Li, W.-X.; Wang, Z.-S.; Tang, X.-H.; Xu, H.-X.; Liu, S.; et al. The development of laser-produced plasma EUV light source. Chip 2022, 1, 100019. [Google Scholar] [CrossRef]

- Borisov, V.; Eltzov, A.; Ivanov, A.; Khristoforov, O.; Kirykhin, Y.; Vinokhodov, A.; Vodchits, V.; Mishhenko, V.; Prokofiev, A. Discharge produced plasma source for EUV lithography. Proc. SPIE Int. Soc. Opt. Eng. 2007, 6611, 79–86. [Google Scholar] [CrossRef]

- Bartels, R.A.; Paul, A.; Green, H.; Kapteyn, H.C.; Murnane, M.M.; Backus, S.; Christov, I.P.; Liu, Y.; Attwood, D.; Jacobsen, C. Generation of Spatially Coherent Light at Extreme Ultraviolet Wavelengths. Science 2002, 297, 376–378. [Google Scholar] [CrossRef] [PubMed]

- Ren-Zhong, T.; Yan-Qing, W.; Shu-Min, Y.; Lian-Sheng, W.; Jun, Z.; Chao-Fan, X.; Hai-Gang, L.; Zi-Jian, X. Developments at SSRF in soft X-ray interference lithography. Nucl. Sci. Tech. 2015, 26, 010101. [Google Scholar] [CrossRef]

- Kawata, H.; Nakamura, N.; Sakai, H.; Kato, R.; Hajima, R. High power light source for future extreme ultraviolet lithography based on energy-recovery linac free-electron laser. J. Micro/Nanopatterning Mater. Metrol. 2022, 21, 021210. [Google Scholar] [CrossRef]

- Abhari, R.; Rollinger, B.; Giovannini, A.; Morris, O.; Henderson, I.; Ellwi, S. Laser-produced plasma light source for extreme-ultraviolet lithography applications. J. Micro/Nanolithogr. MEMS MOEMS 2012, 11, 021114. [Google Scholar] [CrossRef]

- Kohyama, T.; Miyai, H.; Todoroki, T. Actinic Patterned Mask Inspection for EUV Lithography; SPIE: Bellingham, WA, USA, 2022; Volume 12325. [Google Scholar]

- Capelli, R.; Kersteen, G.; Krannich, S.; Koch, M.; Fischer, L.; Roesch, M.; Gwosch, K. Optical and EUV Nanolithography XXXV; SPIE: Bellingham, WA, USA, 2022; pp. 1205101–1205102. [Google Scholar]

- Rice, B.J.; Jindal, V.; Lin, C.C.; Harris-Jones, J.; Kwon, H.J.; Ma, H.C.; Goldstein, M.; Chan, Y.W.; Goodwin, F. Overview of Mask Metrology. AIP Conf. Proc. 2011, 1395, 281–289. [Google Scholar] [CrossRef]

- Xue, C.; Wu, Y.; Zhu, F.; Yang, S.; Liu, H.; Zhao, J.; Wang, L.; Tai, R. Development of broadband X-ray interference lithography large area exposure system. Rev. Sci. Instrum. 2016, 87, 043303. [Google Scholar] [CrossRef] [PubMed]

- Shiotani, H.; Suzuki, S.; Lee, D.G.; Naulleau, P.; Watanabe, T.; Fukushima, Y.; Ohnishi, R.; Kinoshita, H. Dual grating interferometric lithography for 22-nm node. In Proceedings of the 2007 Digest of Papers Microprocesses and Nanotechnology, Kyoto, Japan, 5–8 November 2007; pp. 46–47. [Google Scholar]

- Ekinci, Y.; Vockenhuber, M.; Hojeij, M.; Wang, L.; Mojarad, N. Evaluation of EUV resist performance with interference lithography towards 11 nm half-pitch and beyond. In Extreme Ultraviolet (EUV) Lithography IV; SPIE: Bellingham, WA, USA, 2013; Volume 8679, p. 867910. [Google Scholar]

- Goldberg, K.; Mochi, I.; Benk, M.; Allezy, A.; Dickinson, M.; Cork, C.; Zehm, D.; Macdougall, J.; Anderson, E.; Salmassi, F.; et al. Commissioning an EUV mask microscope for lithography generations reaching 8 nm. In Extreme Ultraviolet (EUV) Lithography IV; SPIE: Bellingham, WA, USA, 2013; Volume 8679. [Google Scholar]

- Anderson, C.; Allezy, A.; Chao, W.; Cork, C.; Cork, W.; Delano, R.; DePonte, J.; Dickinson, M.; Gaines, G.; Gamsby, J.; et al. Overview and Status of the 0.5-NA Micro-field Exposure Tool at Berkeley Lab. In Extreme Ultraviolet (EUV) Lithography X; SPIE: Bellingham, WA, USA, 2019; p. 1095708. [Google Scholar]

- Tanaka, Y.; Harada, T.; Amano, T.; Usui, Y.; Watanabe, T.; Kinoshita, H. Characterization of small phase defects using a micro-coherent extreme ultraviolet scatterometry microscope. Jpn. J. Appl. Phys. 2014, 53, 06JC03. [Google Scholar] [CrossRef]

- Mochi, I.; Helfenstein, P.; Mohacsi, I.; Rajendran, R.; Kazazis, D.; Yoshitake, S.; Ekinci, Y. RESCAN: An actinic lensless microscope for defect inspection of EUV reticles. J. Micro/Nanolithogr. MEMS MOEMS 2017, 16, 041003. [Google Scholar] [CrossRef]

- Bergmann, R.M.; Bieri, T.; Craievich, P.; Ekinci, Y.; Garvey, T.; Gough, C.; Negrazus, M.; Rivkin, L.; Rosenberg, C.; Schulz, L.; et al. A Compact Storage Ring for the Production of EUV Radiation. In Proceedings of the International Topical Meeting on Nuclear Applications of Particle Accelerators, Quebec City, QC, Canada, 31 July–4 August 2017. [Google Scholar]

- Ko, J.H.; Kim, M.W.; Lee, S.; Han, J.-H.; Hong, J. Strip-line injection kicker for PAL-EUV booster synchrotron. J. Korean Phys. Soc. 2024, 84, 189–197. [Google Scholar] [CrossRef]

- Schafers, F.; Bischoff, P.; Eggenstein, F.; Erko, A.; Gaupp, A.; Kunstner, S.; Mast, M.; Schmidt, J.-S.; Senf, F.; Siewert, F.; et al. The at-wavelength metrology facility for UV- and XUV-reflection and diffraction optics at BESSY-II. J. Synchrotron Radiat. 2016, 23, 67–77. [Google Scholar] [CrossRef] [PubMed]

- Miyakawa, R.; Naulleau, P. Preparing for the Next Generation of EUV Lithography at the Center for X-ray Optics. Synchrotron Radiat. News 2019, 32, 15–21. [Google Scholar] [CrossRef][Green Version]

- Li, Z.; Fan, Y.; Xue, L.; Zhang, Z.; Wang, J. The design of the test beamline at SSRF. AIP Conf. Proc. 2019, 2054, 060040. [Google Scholar] [CrossRef]

- Xue, L.; Li, Z.; Liu, J.; Chen, H.; Zhao, G.; Wang, Y.; Zhu, W. Optical design and commissioning results of a constant-imaging-distance fixed-included-angle grating monochromator at SSRF. J. Synchrotron Radiat. 2025, 32, 605–608. [Google Scholar] [CrossRef] [PubMed]

- Milanović, V.; Kasturi, A.; Siu, N.; Radojičić, M.; Su, Y. “MEMSEYE” for optical 3D tracking and imaging applications. In Proceedings of the Transducers 2011 Conference, Beijing, China, 5–9 June 2011. [Google Scholar]

- Naulleau, P.P.; Goldberg, K.A.; Batson, P.; Bokor, J.; Denham, P.; Rekawa, S. Fourier-synthesis custom-coherence illuminator for extreme ultraviolet microfield lithography. Appl. Opt. 2003, 42, 820–826. [Google Scholar] [CrossRef] [PubMed]

- Montcalm, C.; Bajt, S.; Mirkarimi, P.B.; Spiller, E.A.; Weber, F.J.; Folta, J.A. Proceedings of SPIE; SPIE: Bellingham, WA, USA, 1998; pp. 42–51. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Zhao, B.; Meng, X.; Zhao, J.; Guo, Z.; Zhang, X.; Wang, Y.; Huang, Q.; Zhang, Z.; Wang, Z.; et al. High-Precision Beam Deflection and Diagnostics System for EUV Synchrotron Radiation Illumination. Photonics 2025, 12, 970. https://doi.org/10.3390/photonics12100970

Liu H, Zhao B, Meng X, Zhao J, Guo Z, Zhang X, Wang Y, Huang Q, Zhang Z, Wang Z, et al. High-Precision Beam Deflection and Diagnostics System for EUV Synchrotron Radiation Illumination. Photonics. 2025; 12(10):970. https://doi.org/10.3390/photonics12100970

Chicago/Turabian StyleLiu, Haigang, Bo Zhao, Xiangyu Meng, Jun Zhao, Zhi Guo, Xiangzhi Zhang, Yong Wang, Qiushi Huang, Zhe Zhang, Zhanshan Wang, and et al. 2025. "High-Precision Beam Deflection and Diagnostics System for EUV Synchrotron Radiation Illumination" Photonics 12, no. 10: 970. https://doi.org/10.3390/photonics12100970

APA StyleLiu, H., Zhao, B., Meng, X., Zhao, J., Guo, Z., Zhang, X., Wang, Y., Huang, Q., Zhang, Z., Wang, Z., & Tai, R. (2025). High-Precision Beam Deflection and Diagnostics System for EUV Synchrotron Radiation Illumination. Photonics, 12(10), 970. https://doi.org/10.3390/photonics12100970