1. Introduction

In recent years, 6G communication based on terahertz waves has attracted widespread attention [

1]. The frequency of terahertz waves is higher than that of existing microwave communication. Therefore, terahertz waves have faster data transmission rates and larger data capacity. Space electromagnetic wave filters are one of the key functional devices in the field of wireless communication. With the development of 6G communication, the demand for space terahertz wave filters is obviously increasing. A terahertz filter with small size, easy integration, and rich functionality is expected.

A metasurface is a powerful special device [

2,

3,

4,

5,

6,

7], and its basic unit is a subwavelength artificial microstructure, which periodically expands in space to form a metasurface. Metasurfaces have been proven to have powerful electromagnetic wave manipulation capabilities. The physical characteristics of electromagnetic waves, such as frequency, phase, amplitude, polarization, orbital angular momentum, and spin angular momentum [

8,

9,

10,

11,

12,

13], can be manipulated by metasurfaces, enabling a variety of functions, including electromagnetic polarization transformation, wavefront manipulation [

14], imaging [

15], sensing [

16,

17], filtering [

18,

19,

20], and so on. Among them, the filtering characteristics of the metasurface are controlled by the resonance between electromagnetic waves and the metasurface. By adjusting the shape and size of the metasurface microstructure, we can control the resonance between spatial electromagnetic waves and the metasurface. This resonance effect will trigger the reflection, transmission, and absorption of waves at specific frequencies. For instance, Zhao et al. [

18] proposed a multi-layer metal structure consisting of a cross-shaped and open ring based on bandpass filtering theory. This structure achieves reflective C-band bandpass filtering with a polarization conversion function. Also, Ali Lalbakhsh et al. [

19] proposed a simpler metal structure that uses two identical pinwheel structures to achieve polarization independent transmission bandpass filtering capability. The device was successfully demonstrated in the X-band. Amirashkan Darvish et al. [

20] simultaneously proposed a flexible metasurface filter in which a unit cell consisting of two conductive rings and a flexible substrate is designed to achieve X-band filtering in a bent state. Generally, compared to traditional filters, metasurface filters have significant advantages, including small size, customizability, and rich functionality. The current development of metasurface filters is toward functional diversity, which is not only beneficial for further reducing the volume of communication systems but may also generate more novel applications.

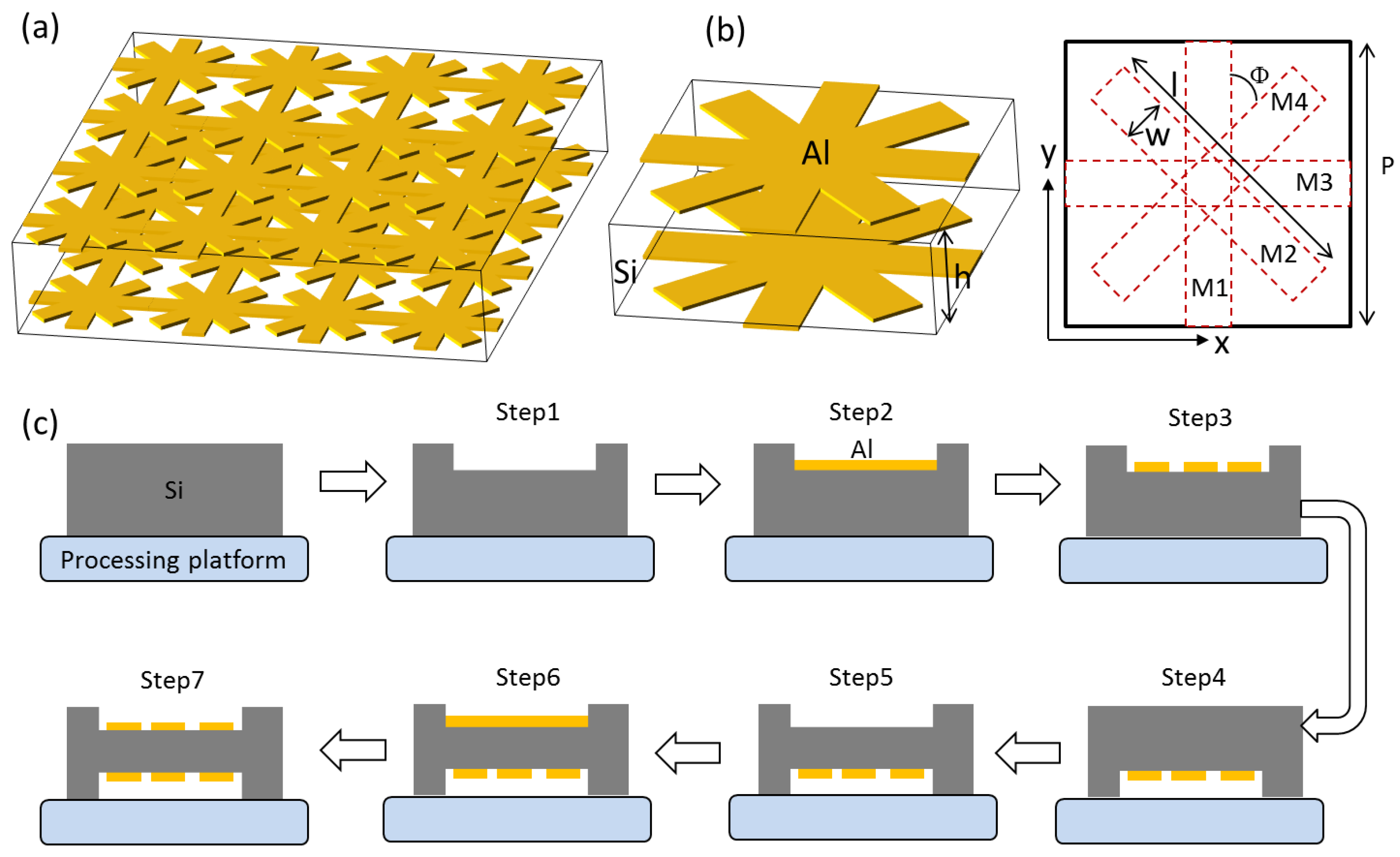

In this work, a bandpass-filtered metasurface device with the interaction between two adjacent resonances is designed based on a double-layer pinwheel-shaped metal cell and a substrate with high resistance silicon. The effective filtering range of this device is 167–203 GHz. When the transmission amplitude decreases by 3 dB, it has a filtering bandwidth of 36 GHz and a maximum transmission amplitude of 0.9. These characteristics are effective within a wave incidence angle of 20°. This work uses an equivalent RC resonance circuit to explain the formation of bandpass filtering. Furthermore, compared to previous reports [

18,

19,

20], this work achieves a bandpass filter with a dynamic on/off tuning function, where the photosensitive characteristics of silicon are used to modify the carrier concentration of silicon, thereby affecting the resonance intensity and enhancing the controllability of the bandpass filtering function. Ultimately, the device has filtering and switching characteristics under light excitation.

3. Results and Discussion

The operating frequency of the device is located in the terahertz band that can serve 6G communication. The incident wave is TE mode, and the transmission and reflection spectra in the vertical incidence are shown in

Figure 2. In this work, when a terahertz wave is incident vertically, the TE mode corresponds to y-polarization. The transmission characteristics of the device in the range of 100–300 GHz (0.1–0.3 THz) are shown in

Figure 2a,b. It is easy to know from the symmetry of the device that the same results as

Figure 2 can be obtained when an x-polarized terahertz wave is incident vertically on the device. It is usually defined that the filtering function is effective when the attenuation of the transmission amplitude of the filter does not exceed 3 dB. From

Figure 2a, it can be observed that the bandwidth of the transmission attenuation with 3 dB is 36 GHz, and the effective operating range of the filter is 167–203 GHz. The linear transmission amplitude spectrum corresponds to

Figure 2b, and a maximum transmission amplitude of 0.9 can be found. The bandpass filtering is formed by the interaction of two resonances located in close proximity. By detecting the reflection spectrum, the central frequencies of the two resonances can be clearly seen, as shown in

Figure 2c. The two resonances are

f1 = 175 GHz and

f2 = 200 GHz, respectively. In actual manufacture, the structural parameters may not be accurate, so the robustness of the device needs to be considered. The scattering performances may be changed with the disturbances in substrate thickness, metal size, and pattern offset on the opposite sides of the substrate. The variation in substrate thickness and metal size can be controlled very precisely during the manufacturing process (the effects of substrate thickness and metal size will be presented in subsequent discussions.). In contrast, the pattern offset on the opposite sides of the substrate is almost unavoidable and hard to control. Hence, we mainly discuss the pattern offset effect here. Due to the fact that the mask used in the actual manufacturing process is the same for patterns on the opposite sides of the substrate, the patterns can only undergo overall deviation. The offsets along the x and y directions are analyzed, as shown in

Figure 2d–f. It can be seen that when the patterns on the opposite sides of the substrate produce a relative dislocation with dx = 6 μm along the x direction (

Figure 2d), as well as a relative dislocation with dy = 6 μm along the y direction (

Figure 2e), the transmission spectra remain generally unchanged in the range of 100–250 GHz, even if these offsets are as high as 6 μm in both the x and y directions (

Figure 2f), which proves the great robustness of the structure.

The reflection amplitude of the second resonance

f2 is stronger than that of the first resonance

f1, and the reason for this result can be identified through the distribution of electric field and surface current. As shown in

Figure 3a, the surface current motion modes of the two resonances are the same, with the current flowing back and forth along the metal strip, which is a characteristic of dipole resonance. The surface current intensity and electric field distribution intensity both indicate that the resonance radiation of

f2 is stronger than that of

f1, so the reflection amplitude at

f2 in the reflection spectrum is higher than that at

f1. From the distribution of electric field amplitude at the cross-section of the device shown in

Figure 3b, it can be seen that the transmitted electric field at the output port for

f1 resonance is stronger than that at the output port for

f2 resonance, which is consistent with the transmission and reflection intensity trends of the two resonances shown in

Figure 2.

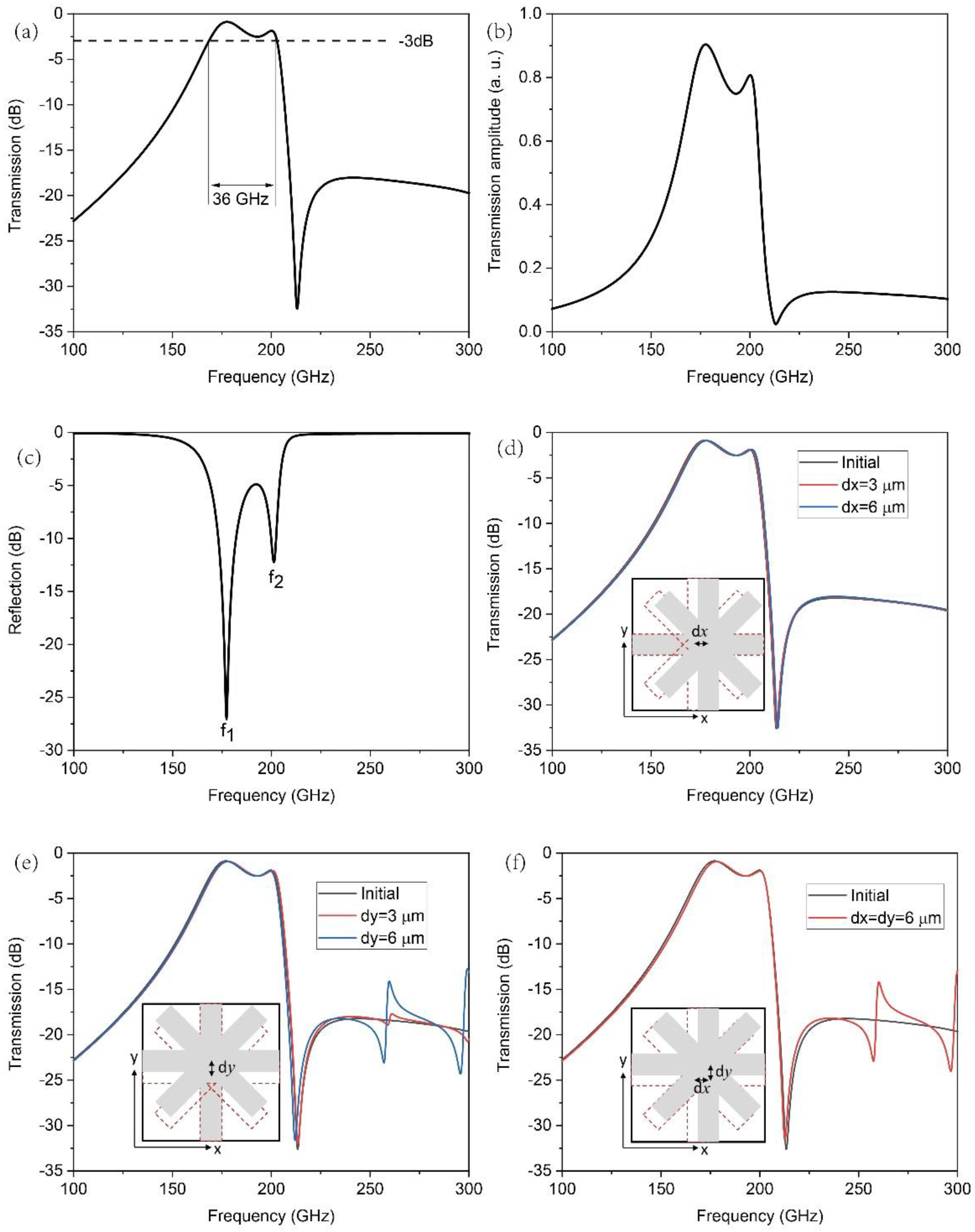

Next, we need to consider an issue as to why the designed metasurface can generate two resonances

f1 and

f2; in other words, how to explain the formation of these two resonances. To clarify the formation mechanism of two resonances, we use an equivalent circuit model, as shown in

Figure 4. The interaction between the incident alternating electric field and the metasurface generates various parasitic electrical effects. The metal strip itself has weak inductance (negligible self-resistance), and under the excitation of an external electric field, non-metallic media will also produce resistance and capacitive effects. The metal strips M1 and M3 on the surface of the unit cell can be equivalent to a weak inductance L

0, and the metal strips M2 and M4 can be equivalent to a weak inductance L

1. There are gaps between M2 and M2 (as well as M4 and M4) of adjacent unit cells, which will generate equivalent capacitance C

1 and resistance R

1 with a parallel connection. The metal structure on the bottom surface of the silicon substrate is identical to that on the top surface. The metal strips M1 and M3 on the bottom surface are equivalent to L

3, while the metal strips M

2 and M

4 on the bottom surface are equivalent to L

2. The gaps between M2 and M2 (as well as M4 and M4) of adjacent unit cells on the bottom surface are equivalent to a parallel connection of C

2 and R

2. Due to the same size of all metal strips, where L

0 = L

1 = L

2 = L

3, R

1 = R

2, and C

1 = C

2. The metal structure between the top and bottom of the unit cell is a silicon substrate, which has parasitic capacitance and parasitic resistance. Therefore, it can be equivalent to a capacitor C

s and a resistor R

s in parallel. It can be understood that the RC circuit in

Figure 4 carries two resonance frequencies, namely 1/(2πR

1C

1) and 1/(2πR

sC

s), respectively.

By analyzing the changes in resonance positions under different structural parameters, we can determine the corresponding relationship between the two resonance frequencies (1/(2πR

1C

1) and 1/(2πR

sC

s)) in the RC equivalent circuit of

Figure 4 and the two resonance frequencies (

f1 and

f2) in the reflection spectrum of

Figure 2. Firstly, by keeping the structural parameters of the metal strip unchanged and changing the thickness of the silicon substrate, the reflection and transmission spectra of the device are obtained as shown in

Figure 5. Due to the constant size of the metal strip structure, both L

0–L

3, R

1–R

2, and C

1–C

2 in

Figure 4 remain unchanged, which means that 1/(2πR

1C

1) remains unchanged. In

Figure 5, the resonance located at 200 GHz (corresponding to

f2 in

Figure 2) does not vary with the thickness of the silicon substrate, indicating that the resonance

f2 originates from the metal structure. The values of R

1 and C

1 are easily estimated: the resistance value R

1 ≈ 1 × 10

6 Ω, which can be calculated by the distance between two tilted metal strips, the thickness of silicon

h, and the electrical resistivity

ρ; and the capacitance value C

1 ≈ 8 × 10

−18 F, which can be obtained by the metal strip width

w, metal thickness, gap distance, and vacuum permittivity

ε0. Thus,

f2 = 1/(2πR

1C

1) ≈ 200 GHz. The other resonance,

f1, is controlled by R

s and C

s. As the thickness of the silicon substrate increases, the equivalent capacitance C

s decreases while the equivalent resistance R

s significantly increases, ultimately causing 1/(2πR

sC

s) to decrease so that

f1 shifts toward low frequencies in the spectrum. Unlike

f2, the resonance associated with

f1 mainly occurs at the top of the tilted metal strip (as can be observed from the localized position of the electric field in

Figure 3a), and its resonance area is difficult to accurately calculate, resulting in the high resistance silicon capacitance value covered by the resonance area being difficult to calculate. But the order of magnitude of C

2 can still be estimated because the thickness of high resistance silicon is of the same order of magnitude as the gap between tilted metal strips (both in the order of hundreds of micrometers), and the dielectric parameter of silicon relative to vacuum is of the order of 10, so the capacitance value of C

2 is about 10

−17 F level. In addition, high resistance silicon is sandwiched between the upper and lower metal, with a resistance of about 10

5 Ω level, which is easily calculated based on the area, thickness, and resistivity of silicon. Therefore, the order of magnitude of

f1 = 1/(2πR

sC

s) is also at the 10

2 GHz level.

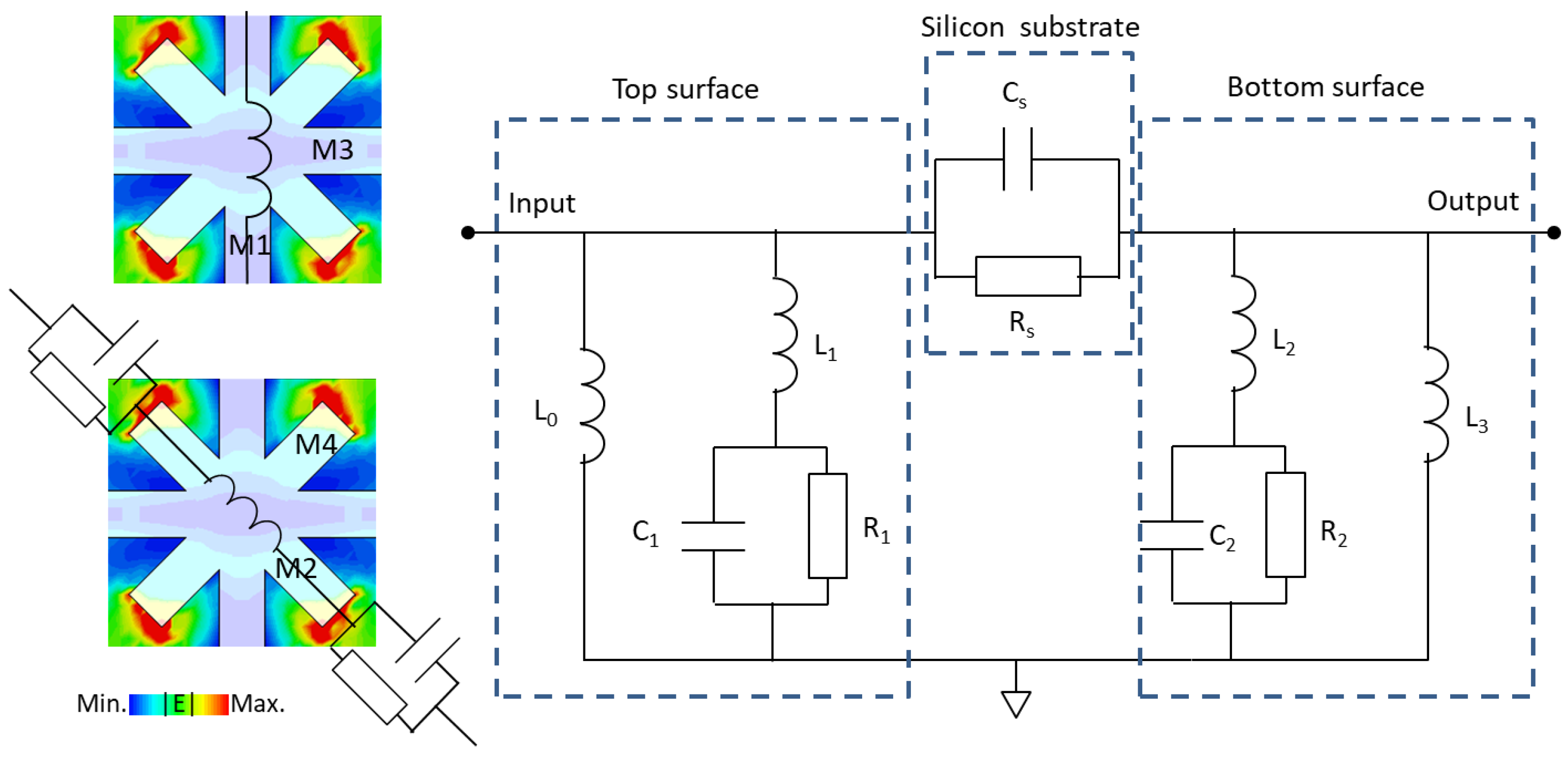

The analysis in

Figure 5 shows that resonance

f1 is correlated with R

s.

Figure 6 shows the reflection and transmission spectra after changing the metal width of the device with constant silicon thickness (

h = 100 um). The increasing width of the metal leads to an increase in the metal pattern area, which directly increases the covered silicon area. Therefore, the equivalent resistance R

s of the silicon substrate decreases, resulting in 1/(2πR

sC

s) increasing; thus,

f1 moves toward high frequencies. At the same time, increasing the width of the metal will also lead to a decrease in R

1, resulting in 1/(2πR

1C

1) increasing; thus,

f2 also moves toward high frequencies.

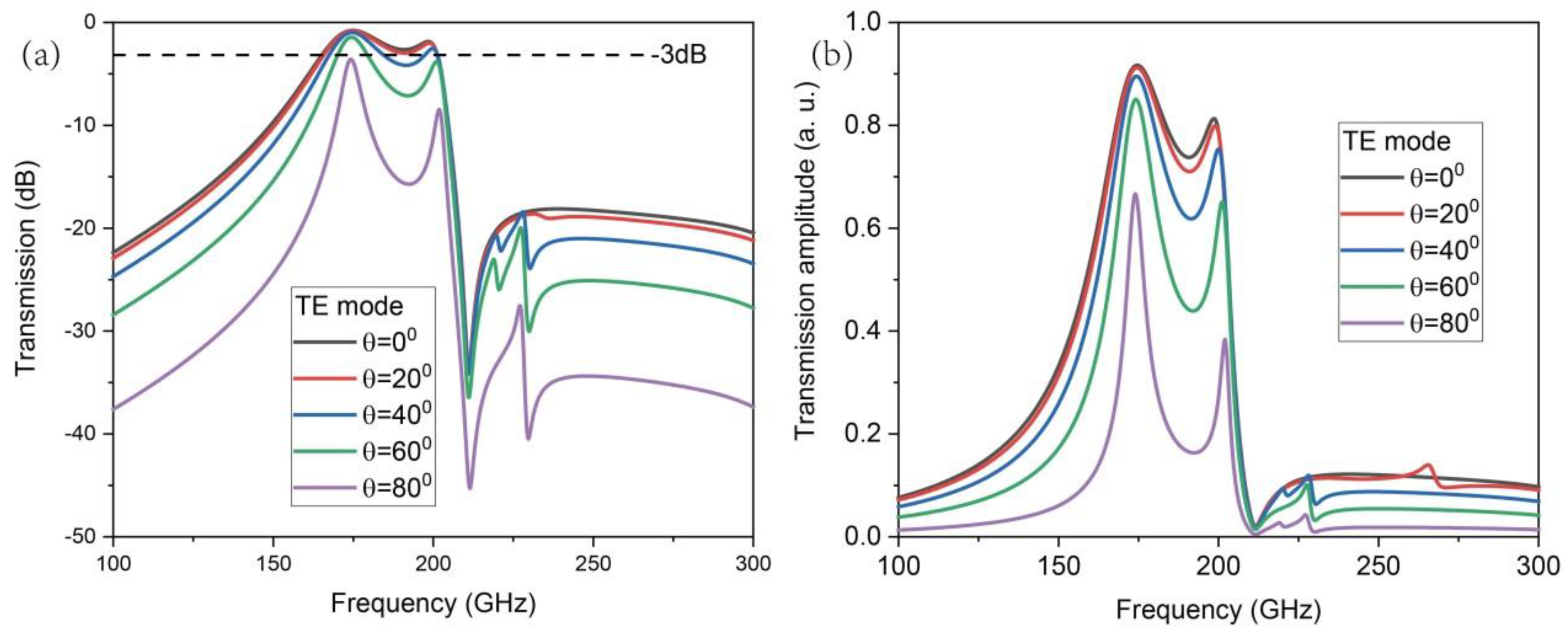

Considering that in practical applications, electromagnetic beams are not completely perpendicular to the device surface, it is necessary to consider the impact of beam incidence angle on the filtering characteristics of the device. The transmission spectra at different incident angles are shown in

Figure 7, with the incident wave vector located in the

yz plane and the angle between the incident wave and the

z-axis normal in the

yz plane being

θ. It can be seen that the two resonance centers located at 175 GHz and 200 GHz do not change with the change in incident angle, while the resonance amplitude depends on the incident angle. When the incident angle

θ does not exceed 20°, the device can maintain a similar operating bandwidth and transmission amplitude as in the case of vertical incidence.

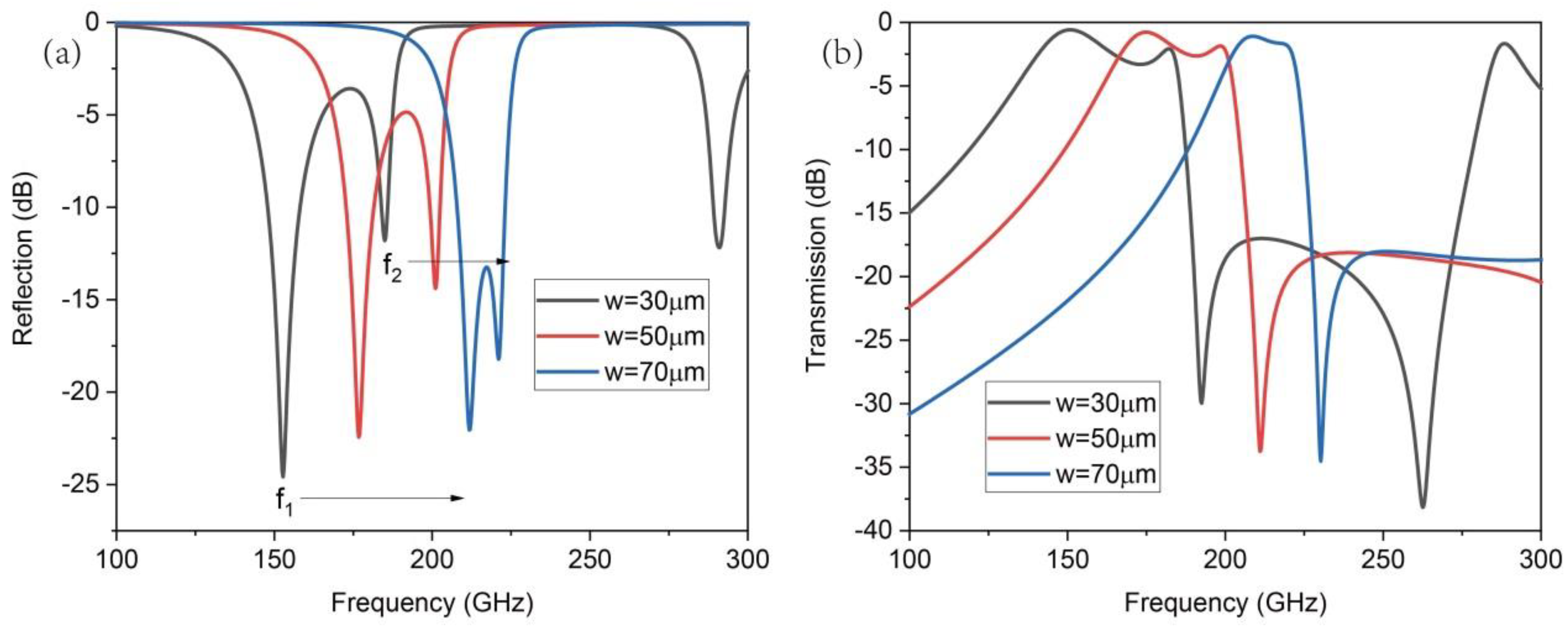

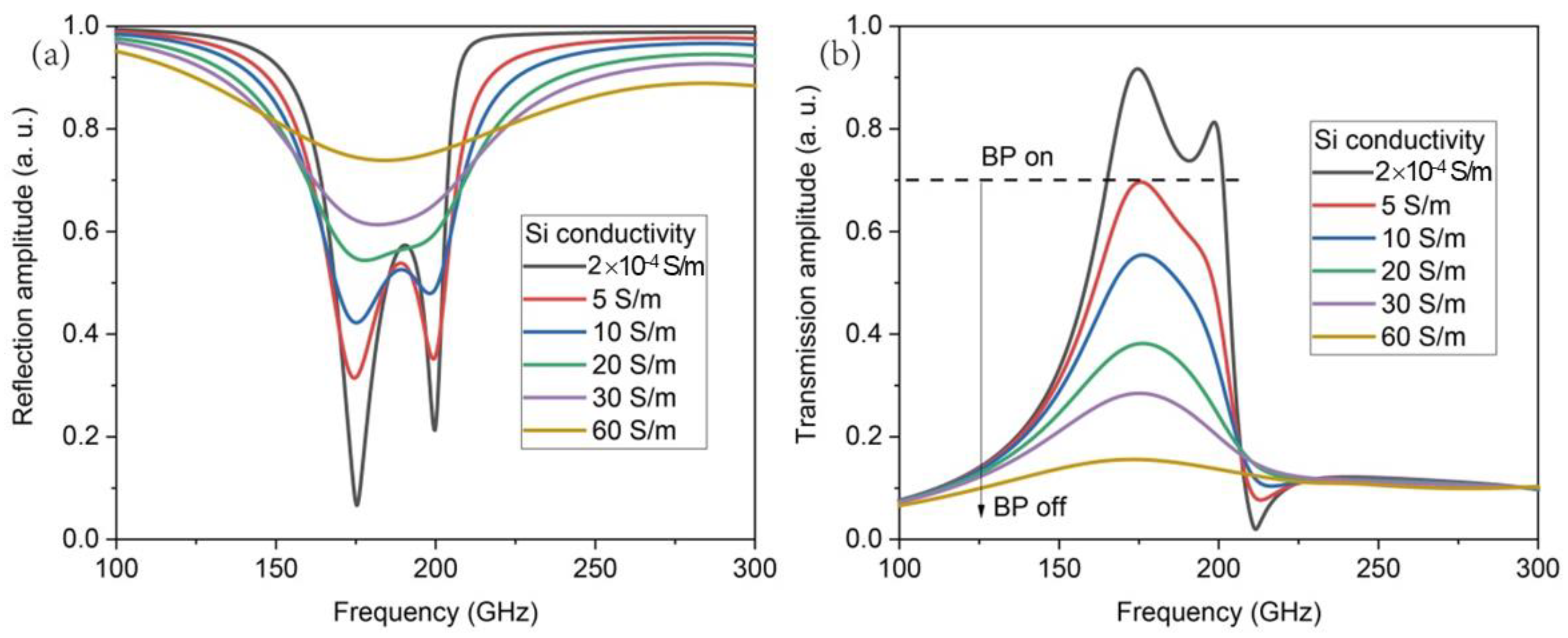

The carrier concentration of silicon medium can be changed under external light excitation (it is necessary that the photon energy of excitation light is greater than the energy gap of silicon), resulting in variable resonance intensity [

21]. This property enables this device to have filtering and switching characteristics. Exciting light can be achieved by selecting a continuous wave with a wavelength of 1064 nm. Previous studies have shown that high resistance silicon can absorb light with a wavelength of 1064 nm, and 1064 nm light can penetrate a high resistance silicon with at least 500 μm thickness [

21]. The silicon thickness used in this work is only 100 μm, which means that carriers in the entire silicon can be excited by 1064 nm light. Experiments have shown that when the power of a 1064 nm continuous wave reaches several mW, the conductivity of high resistance silicon can reach tens of S/m [

21]. Therefore, it is reasonable for this work to simulate the influence of light excitation on the performance of the device by changing the silicon conductivity. The results of the reflection and transmission spectra of the device, accompanied by changes in silicon conductivity, are shown in

Figure 8. When the conductivity of silicon transitions from a high resistance state to a low resistance state, terahertz resonance weakens, and the reflection of terahertz waves by silicon is significantly enhanced, mainly due to an increase in carriers on the silicon surface. Correspondingly, the transmission amplitude of the device is significantly reduced. When the conductivity of silicon increases from 2 × 10

−4 S/m to 60 S/m, the maximum transmission amplitude decreases from 0.9 to 0.1, meaning that the bandpass filtering characteristics of the device are turned off.