Refractive Index and Dispersion Measurement Principle with Polarization Change in Total Internal Reflection

Abstract

1. Introduction

2. Theory and Numerical Results

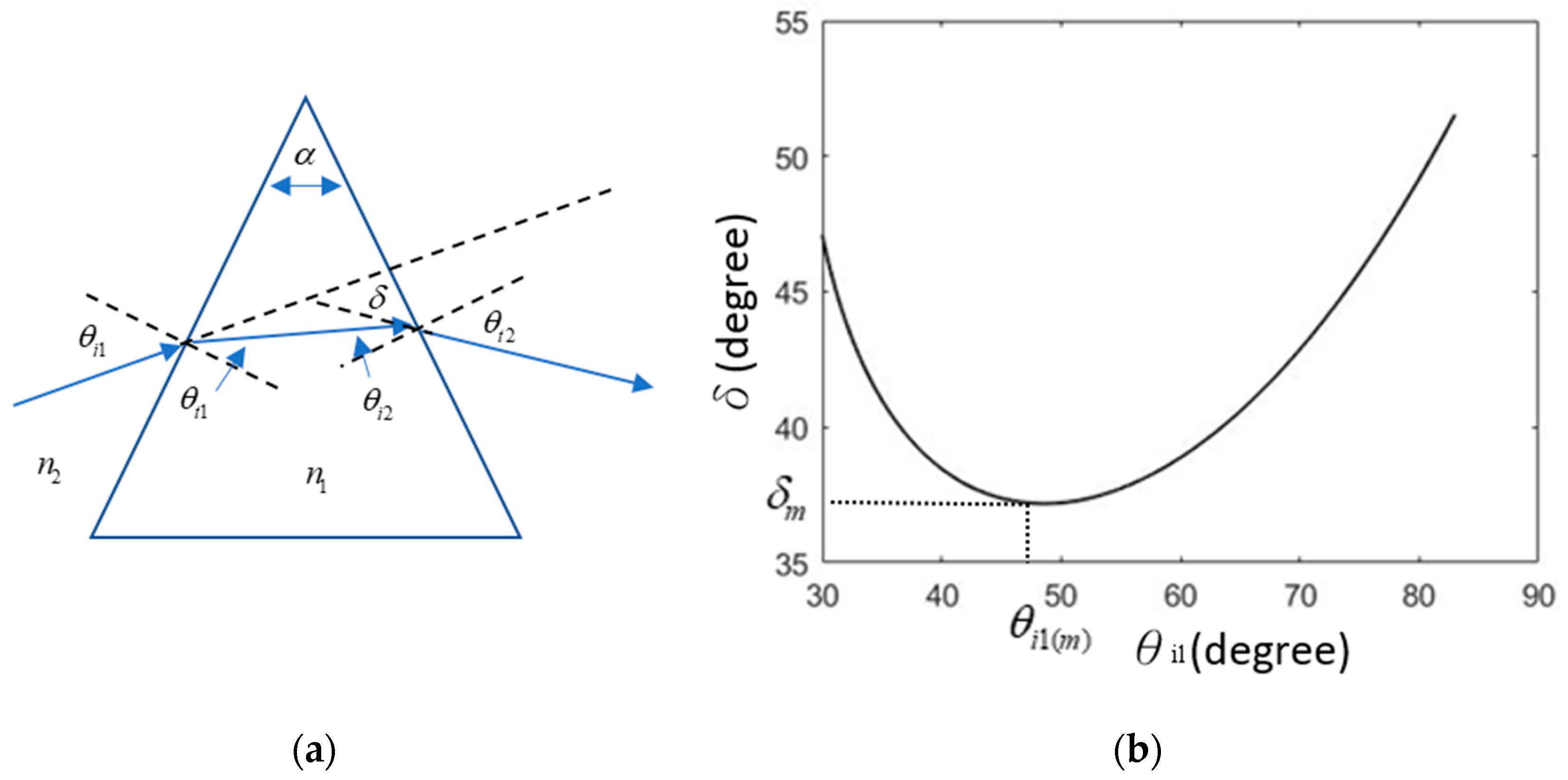

2.1. Method of Measuring Minimum Angular Deviation of a Prism

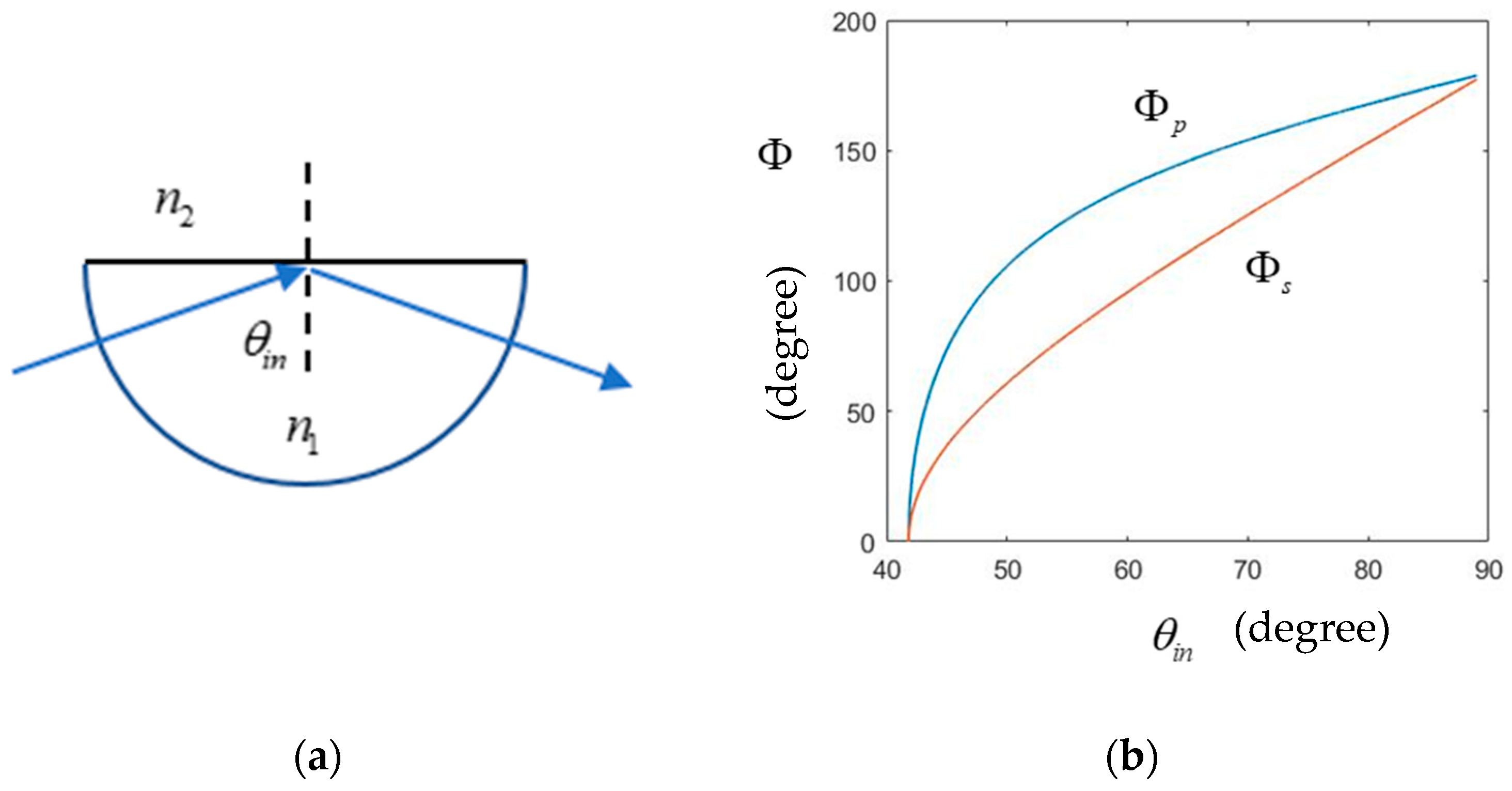

2.2. Method Measuring the Maximum Phase Change in TIR

2.3. Method for Measuring Ellipticity of TIR (without Scanning the Incident Angle)

2.4. Dispersion Measurement with Polychromatic Light

3. Conclusions and Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, S. Refractive index measurement and its applications. Phys. Scr. 2002, 65, 167–180. [Google Scholar] [CrossRef]

- Cardin, J.; Leduc, D. Determination of refractive index, thickness, and the optical losses of thin films from prism-film coupling measurements. Appl. Opt. 2008, 47, 894–900. [Google Scholar] [CrossRef] [PubMed]

- Choi, H.J.; Lim, H.H.; Moon, H.S.; Eom, T.B.; Ju, J.J.; Cha, M. Measurement of refractive index and thickness of transparent plate by dual-wavelength interference. Opt. Express 2010, 18, 9429–9434. [Google Scholar] [CrossRef] [PubMed]

- Pedinoff, M.E.; Braunstein, M.; Stafsudd, O.M. Refractive indices of ir materials: 10.6-μm ellipsometer measurements. Appl. Opt. 1977, 16, 2849–2856. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Lv, J.; Hao, Q. Refractive Index Measurement of Glass with Arbitrary Shape Based on Brewster’s Law and a Focusing Probe Beam. Sensors 2021, 21, 2421. [Google Scholar] [CrossRef] [PubMed]

- Song, W.; Yang, F.; Min, C.; Zhu, S.; Yuan, X. Toward Ultrasensitive, Broadband, Reflection-Mode In Vivo Photoacoustic Microscopy Using a Bare Glass. Laser Photonics Rev. 2022, 17, 2200030. [Google Scholar] [CrossRef]

- Yuan, H.; Yang, F.; Song, W.; Yuan, X. Optical Microscopic Evanescent Sensing of Ultrasound with Ultrabroad Bandwidth. IEEE Sens. J. 2024, 24, 7663–7670. [Google Scholar] [CrossRef]

- Ash, W.M.; Kim, M.K. Digital holography of total internal reflection. Opt. Express 2008, 16, 9811–9820. [Google Scholar] [CrossRef] [PubMed]

- Keuren, E.R.V. Refractive index measurement using total internal reflection. Am. J. Phys. 2005, 73, 611–614. [Google Scholar] [CrossRef]

- Calhoun, W.R.; Maeta, H.; Roy, S.; Bali, L.M.; Bali, S. Sensitive real-time measurement of the refractive index and attenuation coefficient of milk and milk-cream mixtures. J. Dairy Sci. 2010, 93, 3497–3504. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Xie, S. Measurement method of the refractive index of biotissue by total internal reflection. Appl. Opt. 1996, 35, 1793–1795. [Google Scholar] [CrossRef] [PubMed]

- Iizuka, K. Elements of Photonics; Wiley: Hoboken, NJ, USA, 2002; Volume 1, pp. 164, 137, 138. [Google Scholar]

- Chiu, M.H.; Lee, J.Y.; Su, D.C. Refractive-index measurement based on the effects of total internal reflection and the uses of heterodyne interferometry. Appl. Opt. 1997, 36, 2936–2939. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Zou, H.; Zhong, L.; Li, J.; Li, B.; Tian, J.; Lu, X. Dynamic refractive index distribution measurement of dynamic process by combining dual-channel simultaneous phaseshifting interferometry and total internal reflection. Sci. Rep. 2018, 8, 15231. [Google Scholar] [CrossRef] [PubMed]

- Hecht, E. Optics, 4th ed.; Addison Wesley: Boston, MA, USA, 2002; p. 188. [Google Scholar]

- Teich, M.; Saleh, B. Fundamentals of Photonics, 2nd ed.; Wiley: Hoboken, NJ, USA, 2007; p. 203. [Google Scholar]

- Lee, J.Y.; Chiang, C.Y.; Sung, W.Y.; Weng, T.Y.; Chen, J.H.; Hsu, C.C. Measurement of the refractive index of lenses from the maximum phase difference of the total internal reflection with a polarization camera. Appl. Opt. 2021, 60, B106–B112. [Google Scholar] [CrossRef] [PubMed]

- Han, P. Spatial–Spectral Correspondence Relationship for Mono—Poly chromatic Light Diffraction. In Progress in Optics; Visser, T.D., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; Volume 63, pp. 33–87. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, J.-P.; Tsai, C.-M.; Weng, J.-H.; Han, P. Refractive Index and Dispersion Measurement Principle with Polarization Change in Total Internal Reflection. Photonics 2024, 11, 505. https://doi.org/10.3390/photonics11060505

Chang J-P, Tsai C-M, Weng J-H, Han P. Refractive Index and Dispersion Measurement Principle with Polarization Change in Total Internal Reflection. Photonics. 2024; 11(6):505. https://doi.org/10.3390/photonics11060505

Chicago/Turabian StyleChang, Jyun-Ping, Cheng-Mu Tsai, Jun-Hong Weng, and Pin Han. 2024. "Refractive Index and Dispersion Measurement Principle with Polarization Change in Total Internal Reflection" Photonics 11, no. 6: 505. https://doi.org/10.3390/photonics11060505

APA StyleChang, J.-P., Tsai, C.-M., Weng, J.-H., & Han, P. (2024). Refractive Index and Dispersion Measurement Principle with Polarization Change in Total Internal Reflection. Photonics, 11(6), 505. https://doi.org/10.3390/photonics11060505