Abstract

A continuous-wave (CW), high-power, quasi-three-level Nd:YAG laser operating at 946 nm is reported. The beam quality of the laser is greatly improved. The laser consists of a composite Nd:YAG rod end pumped by a fiber-coupled diode laser inside a simple concave-plane cavity. At an incident pump power of 31 W, a maximum CW output of 9.98 W was obtained at 946 nm, with a beam quality factor of M2~5. The corresponding optical-to-optical efficiency was 32.2% with respect to the incident pump power. To the best of our knowledge, this is the highest output power at 946 nm with such a beam quality ever generated by diode-pumped Nd:YAG laser with bulk crystals.

1. Introduction

The quasi-three-level transition of a Nd:YAG crystal can be utilized to generate laser radiation at 946 nm. Compact bulk lasers are one of the simplest implementations of a solid-state laser consisting of a laser gain medium with dielectric mirrors placed very close to two ends of the gain medium [1,2]. Some advantageous characteristics of compact lasers are their small size, robust operation, and cost-effectiveness. There are various applications of these lasers due to their attractive properties. Compact, continuous-wave (CW) and pulsed lasers have been used in areas including efficient blue light generation, Raman spectroscopy, ultraviolet fluorescence spectroscopy, laser-induced breakdown spectroscopy, bio-fluorescence, and trace gas detection [2]. The benefits of pumping compact lasers using low-cost semiconductor laser diodes along with alignment-free monolithic solid-state structures differentiate them from the other laser systems that typically use free-space optics and sometimes require high-brightness pumping.

Isotropic Nd:YAG laser crystal has some great optical and thermal properties compared to the other Nd-doped crystals. It has very high thermal conductivity (14 Wm−1K−1) and relatively low thermo-optic coefficient (7.3 × 10−6 K−1) [3]. These characteristics make it very attractive for use in compact high-power, CW, solid-state lasers [4,5]. Nd:YAG has different laser transitions. The strongest laser transition is at 1064 nm. The laser transition at 946 nm, which we are interested in, is generally much more difficult to obtain with a high power and high beam quality than that at 1064 nm. This quasi-three-level laser transition (946 nm) is characterized by a high threshold pump power since its stimulated emission cross-section is about an order of magnitude lower compared to the 1064 nm transition. Moreover, one needs to suppress 1064 nm laser transition by choosing appropriate mirrors. Since the 946 nm wavelength falls within the absorption bands of different Yb-doped laser gain media, such as Yb:KYW, Yb:KGW, etc. [6,7,8,9], it can be used for their high-brightness pumping.

The high-power operation of compact 946 nm Nd:YAG lasers with a good beam quality is very desirable for the aforementioned applications. However, such operation presents contradictory requirements for the pump spot size due to the compact nature of the laser cavity. A smaller pump spot size for matching the laser mode in a compact laser cavity will lead to much stronger thermal effects during high-power operation, which will negatively affect the beam quality. On the other hand, a bigger pump spot size for reducing the thermal effects during high-power operation leads to a big mismatch between the pump and laser modes in the laser crystal, and hence also creates a poor-quality beam. Previous research on Nd:YAG laser operation at 946 nm has also been reported [10,11,12,13,14,15]. Cryogenically cooled Nd:YAG lasers operating at 946 nm produced tens of watts (>30 W) of output power owing to conducting the experiments at an extremely cold temperature [14,15], which adds to the complexity of the setup. Some works produced a very high beam quality (M2~1.5), although with a lower output power due to the conventional design of laser cavity (instead of a compact design) and good mode-matching between the pump and laser beam [11,12]. Other works used a compact laser cavity design and were able to reach high-power operation (>10 W) at the expense of the laser beam quality (M2 > 10) [10,13]. The choice of a bigger pump spot size to mitigate the thermal effects led to a poor laser beam quality at the output. In contrast, we designed a compact laser cavity where a good mode-matching between the pump and laser modes at a high pump power was implemented. In addition, the thermal effects were minimized by focusing the pump beam at the center of the crystal [16]. As a result, in this work, we demonstrated 9.98 W CW laser operation at 946 nm of a compact bulk Nd:YAG laser with a greatly improved beam quality of M2~5.

2. Experimental Setup and Results

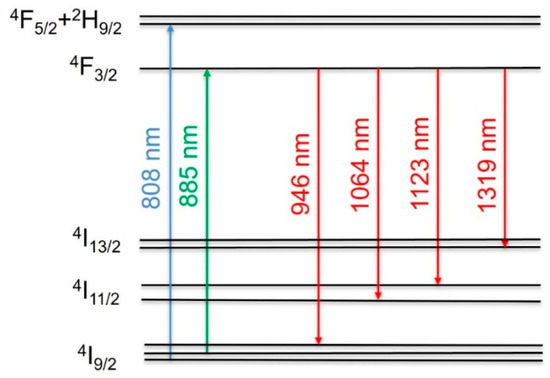

The energy diagram of Nd:YAG crystal [17] is shown in Figure 1. The most intense four-level laser transition is at 1064 nm. However, there are other laser transitions at longer and shorter wavelengths, as shown in Figure 1. Unfortunately, the laser transition at 946 nm is a quasi-three-level one (the lower laser level is near the ground state and is thermally populated) and requires careful cavity design to optimize the laser operation.

Figure 1.

Schematic energy level diagram of Nd:YAG crystal.

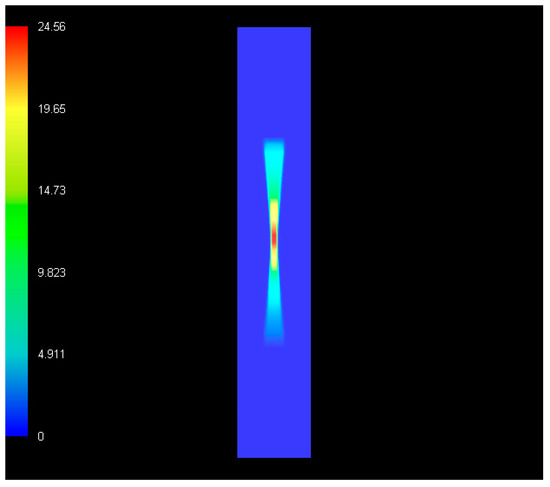

The high-power operation of lasers is strongly affected by thermal lensing. Without knowledge of the strength of thermal lensing, a certain cavity configuration might not generate the maximum amount of possible output power. It is even more critical in compact lasers because their operation relies on the stabilization of the laser cavity by the induced thermal lens. Moreover, pump and cavity mode overlap strongly depends on the thermal lensing value since this is the only degree of freedom in the monolithic design of compact lasers. By choosing the laser wavelength as 946 nm, rather than the typical strong 1064 nm transition, we reduced the quantum defect [18], and as a result, lowered the relative heat load inside the crystal. The influence of thermal lensing was simulated with commercially available LASCAD software. We explored a range of different pump spot sizes as well as pump power levels to determine their effect on thermal lensing. An example of LASCAD simulation is shown in Figure 2 for a 100 µm pump spot radius focused at the center of the crystal. This produced a thermal lens of ~66 mm. Using this approach, we found that the strength of the thermal lens for 75 µm pump spot radius at 37.5 W of pump power (maximum available pump power from a 40 W laser diode) was 60.4 mm in both the horizontal and vertical directions. In this case, the corresponding laser mode radius was found to be 76.3 µm, showing a good mode-matching condition between the pump and laser modes. A detailed discussion of these simulations can be found in [16].

Figure 2.

Heat load (in W/mm3) profile of 100 µm pump spot radius focused at 5.5 mm from the front surface (top of the image) of the crystal and 37.5 W of incident pump power. The crystal had two 3 mm long undoped endcaps (top and bottom of the image) and 5 mm long active medium between them.

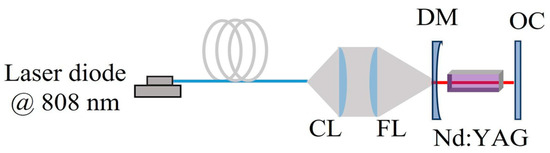

The experimental setup of the CW Nd:YAG laser is presented in Figure 3. A 40 W laser diode module coupled with a 106.5 μm core diameter (0.22 NA) optical fiber was employed for optical pumping. The wavelength and temperature of the laser diode module were stabilized with a temperature-controlled water-cooling system. The output of the laser diode was imaged with two antireflection (AR)-coated spherical lenses (50 and 75 mm focal lengths) on the gain medium. The composite gain medium was a 5 mm long Nd:YAG crystal with 1.1% Nd-doped part in the middle and two 3 mm long undoped end caps on both ends. The total crystal length was 11 mm, and it had antireflection coatings on the end surfaces for both the pump and laser wavelengths to minimize the losses at those wavelengths. The pump beam passed through a dichroic mirror coated for high transmission (>95%) at the pump wavelength and high reflection (>99.9%) at the laser wavelength (946 nm). The pump spot inside the crystal was ~80 μm in radius (the closest achievable pump radius to 75 μm with the imaging lenses and for the given fiber core diameter), corresponding to a confocal parameter of ~1 mm. The crystal was wrapped with indium foil, placed between copper mounts, and water-cooled from four sides at a temperature of 18 °C. A compact and simple 13 mm long laser cavity was formed by a concave dichroic mirror (radius of curvature r = 1000 mm) and a plane output coupler (OC) with transmission in the range between 5 and 23%. The cavity was configured to provide a mode size radius of about 80 μm inside the crystal.

Figure 3.

Schematic of the CW Nd:YAG laser cavity. DM: dichroic mirror; OC: output coupler. The distance between the DM and crystal was 1 mm, and the distance between the crystal and OC was 1 mm.

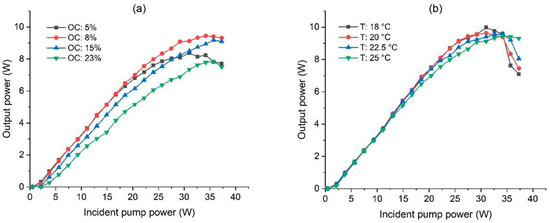

The performance of the laser in the CW regime is shown in Figure 4. The pump absorption in the crystal was measured to be 70–87% under lasing conditions depending on the pump power level. The pump absorption level is higher at a lower pump power and lower at higher pump power levels. The decreasing absorption of the pump power can be attributed to the fine shifting of the pump spectrum to a longer wavelength despite the fixed temperature of the laser diode. We have studied the performance of the laser with different output couplers in order to obtain the optimum result. The best performance was obtained with the 8% output coupler. The results are shown in Figure 4a. We have also explored the output power at various temperatures for the optimum output coupler (8%) as shown in Figure 4b. The highest output power was 9.98 W for 31 W of incident pump power using the 8% output coupler at 18 °C. The corresponding optical-to-optical efficiency was 32.2% with respect to the incident pump power. The laser delivered unpolarized radiation at 946 nm due to the isotropic nature of the Nd:YAG crystal. The roll-off of the output power at higher incident power can be attributed to strong thermal lensing, leading to degraded laser cavity stability.

Figure 4.

(a) Output power vs. incident pump power for various output couplers at 25 °C. (b) Output power vs. incident pump power at different diode temperatures for 8% output coupler.

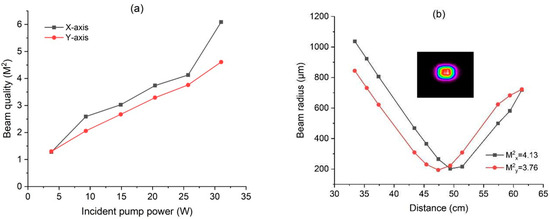

The beam quality factor (M2) was measured at different pump power levels by focusing the output beam with a 150 mm lens. The M2 varied from 1.3 at the incident pump power of 3.77 W to 5.4 at the incident power of 31 W, as shown in Figure 5a. Figure 5b shows the measurement of the beam quality factor at the incident power of 25.7 W with a transverse beam intensity profile.

Figure 5.

(a) Beam quality vs. incident pump power for 8% output coupler. (b) Measurement of beam quality at 25.7 W of incident pump power. Inset: transverse intensity profile of the laser beam.

The experimental results of our work favorably compare with those of the other Nd:YAG lasers operating at 946 nm, as shown in Table 1. It is obvious from the table that when the output power of the laser increases, the beam quality decreases. Our work, on the other hand, produces similar levels of output power at a much lower M2 value. Better beam quality values compared to our work have also been produced, albeit at the expense of a substantially lower output power and lower optical-to-optical efficiency with respect to the incident pump power [11,12]. Higher optical-to-optical efficiency compared to this work was also reported at the expense of a substantially worse beam quality (M2 = 13.1) [10].

Table 1.

Comparison of beam quality for compact 946 nm Nd:YAG lasers with similar output powers.

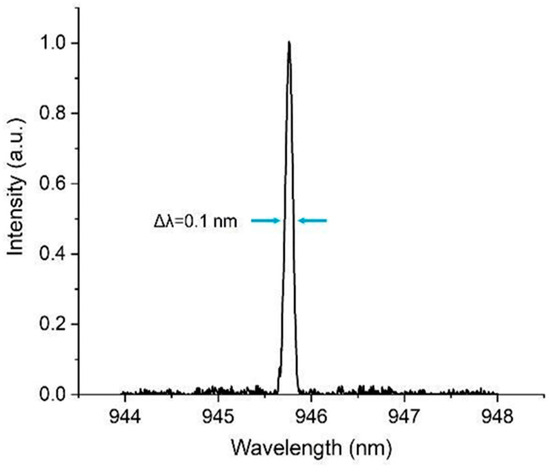

The spectrum of this compact laser was measured to have a FWHM of 0.1 nm and is shown in Figure 6. The measurement was taken with an Anritsu MS2687B spectrometer (resolution 0.07 nm).

Figure 6.

Spectrum of the compact Nd:YAG laser.

3. Conclusions

In conclusion, we demonstrated a compact, CW, high-power Nd:YAG laser operating at 946 nm with a greatly improved beam quality factor (M2~5). The laser provided the maximum output power of 9.98 W at 31 W of incident pump power, with an optical-to-optical efficiency of 32.2%. This optimum performance in terms of output power was obtained by using an 8% output coupler. The output power, in our case, was limited by a strong thermal lensing effect inside the crystal. The beam quality in our work is twice as high when compared to those of the other 946 nm Nd:YAG lasers (with bulk crystals) at similar power levels. We believe that this is a result of the good mode-matching condition between the pump and laser modes that was realized in the laser.

Author Contributions

Conceptualization, A.M.; methodology and investigation, R.C.T.; software, R.C.T.; validation, R.C.T. and A.M.; formal analysis and data curation, R.C.T. and A.M.; resources, A.M.; writing—original draft preparation, R.C.T.; writing—review and editing, A.M. and R.C.T.; supervision, A.M.; project administration, A.M.; funding acquisition, A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science and Engineering Research Council of Canada through the Discovery grant to A.M. We thank University of Manitoba, the Canada Foundation for Innovation and Western Economic Diversification Canada for funding to build research infrastructure.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All relevant data used in this manuscript can be accessed through the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zayhowski, J.J. Microchip lasers. Opt. Mater. 1999, 11, 255–267. [Google Scholar] [CrossRef]

- Zayhowski, J.J. Passively Q-switched Nd:YAG microchip lasers and applications. J. Alloys Compd. 2000, 303–304, 393–400. [Google Scholar] [CrossRef]

- Krennrich, D.; Knappe, R.; Henrich, B.; Wallenstein, R.; L’huillier, J.A. A comprehensive study of Nd:YAG, Nd:YAlO3, Nd:YVO4 and Nd:YGdVO4 lasers operating at wavelengths of 0.9 and 1.3 μm. Part 1: Cw-operation. Appl. Phys. B 2008, 92, 165. [Google Scholar] [CrossRef]

- Nabors, C.D.; Sanchez, A.; Mooradian, A. High-power, continuous-wave, Nd:YAG microchip laser array. Opt. Lett. 1992, 17, 1587–1589. [Google Scholar] [CrossRef] [PubMed]

- Zayhowski, J.J.; Mooradian, A. Frequency-modulated Nd:YAG microchip lasers. Opt. Lett. 1989, 14, 618–620. [Google Scholar] [CrossRef] [PubMed]

- Manjooran, S.; Major, A. Efficient operation of a diode-pumped multi-watt continuous wave Yb:KYW laser with excellent beam quality. Laser Phys. Lett. 2017, 14, 035805. [Google Scholar] [CrossRef]

- Zhao, H.; Major, A. A continuous wave Yb:KGW laser with polarization-independent pump absorption. Laser Phys. 2013, 23, 095001. [Google Scholar] [CrossRef]

- Major, A.; Langford, N.; Lee, S.T.; Ferguson, A.I. Additive-pulse mode locking of a thin-disk Yb:YAG laser. Appl. Phys. B 2003, 76, 505–508. [Google Scholar] [CrossRef]

- Major, A.; Cisek, R.; Tuer, A.; Prent, N.; Barzda, V. Ultrafast Yb:KGd(WO4)2 laser for multimodal biomedical imaging with reduced photodamage. Proc. SPIE 2008, 6881, 688108. [Google Scholar] [CrossRef]

- Zhou, R.; Li, E.; Li, H.; Wang, P.; Yao, J. Continuous-wave, 15.2 W diode-end-pumped Nd:YAG laser operating at 946 nm. Opt. Lett. 2006, 31, 1869–1871. [Google Scholar] [CrossRef] [PubMed]

- Clarkson, W.A.; Koch, R.; Hanna, D.C. Room-temperature diode-bar-pumped Nd:YAG laser at 946 nm. Opt. Lett. 1996, 21, 737–739. [Google Scholar] [CrossRef] [PubMed]

- Abraham, M.; Bar-Lev, A.; Epshtein, H.; Goldring, A.; Zimmerman, Y.; Lebiush, E.; Lavy, R. 7.4W CW output power of Nd:YAG laser radiation at 946nm and 500mW of 473nm laser by extra cavity doubling using periodically poled KTP. In Proceedings of the Advanced Solid-State Lasers, Seattle, WA, USA, 28–31 January 2001; p. WB8. [Google Scholar]

- Zhou, R.; Zhang, T.; Li, E.; Ding, X.; Cai, Z.; Zhang, B.; Wen, W.; Wang, P.; Yao, J. 8.3 W diode-end-pumped continuous-wave Nd:YAG laser operating at 946-nm. Opt. Express 2005, 13, 10115–10119. [Google Scholar] [CrossRef] [PubMed]

- Cho, C.; Huang, T.; Cheng, H.; Huang, K.; Chen, Y. Exploring the power scaling of the cryogenic 946 nm monolithic laser. Laser Phys. Lett. 2018, 15, 085801. [Google Scholar] [CrossRef]

- Cante, S.; Valle, S.; Yoon, S.J.; Meckenzie, J.I. 60-W 946-nm cryogenically-cooled Nd:YAG laser. Appl. Phys. B 2019, 125, 135. [Google Scholar] [CrossRef]

- Talukder, R.C.; Major, A. Modeling of thermal lensing in a microchip Nd:YAG laser for high power operation. Proc. SPIE 2021, 11664, 1166415. [Google Scholar] [CrossRef]

- RP-Photonics. Available online: https://www.rp-photonics.com/neodymium_doped_laser_gain_media.html (accessed on 14 December 2023).

- Talukder, R.C.; Eibna Halim, M.Z.; Waritanant, T.; Major, A. Multiwatt continuous wave Nd:KGW laser with hot-band diode pumping. Opt. Lett. 2016, 41, 3810–3812. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).